Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

183 results about "Impact angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

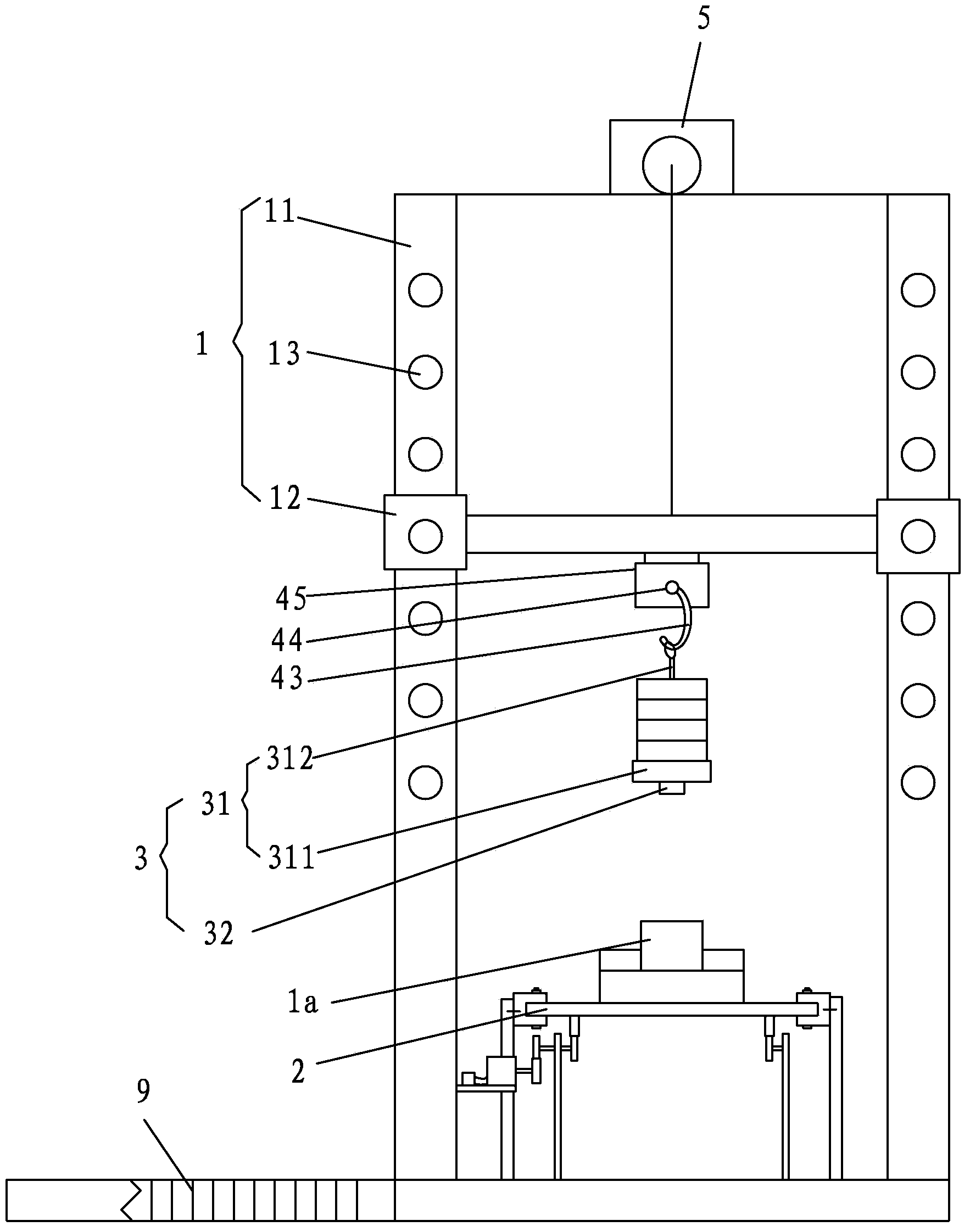

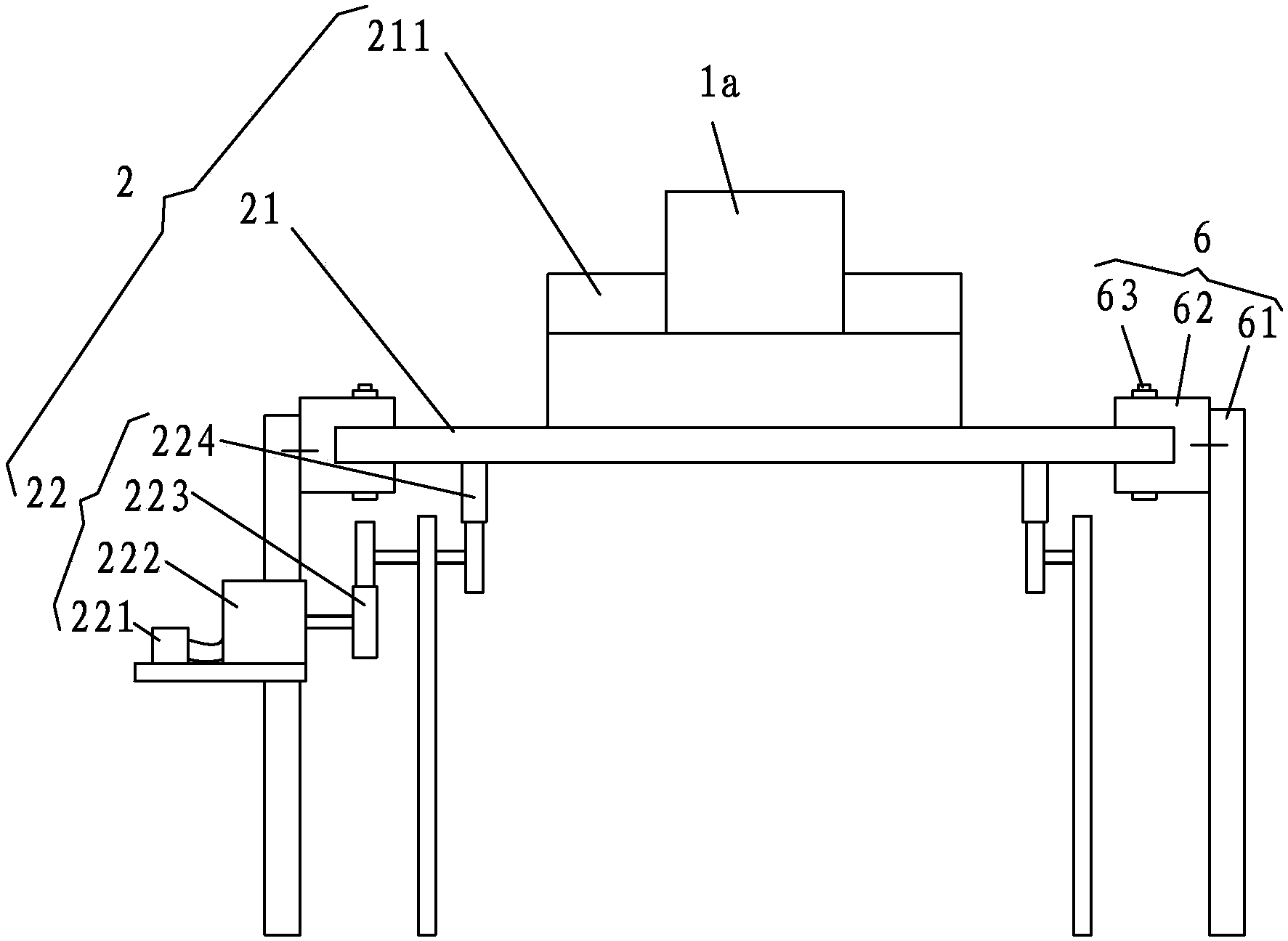

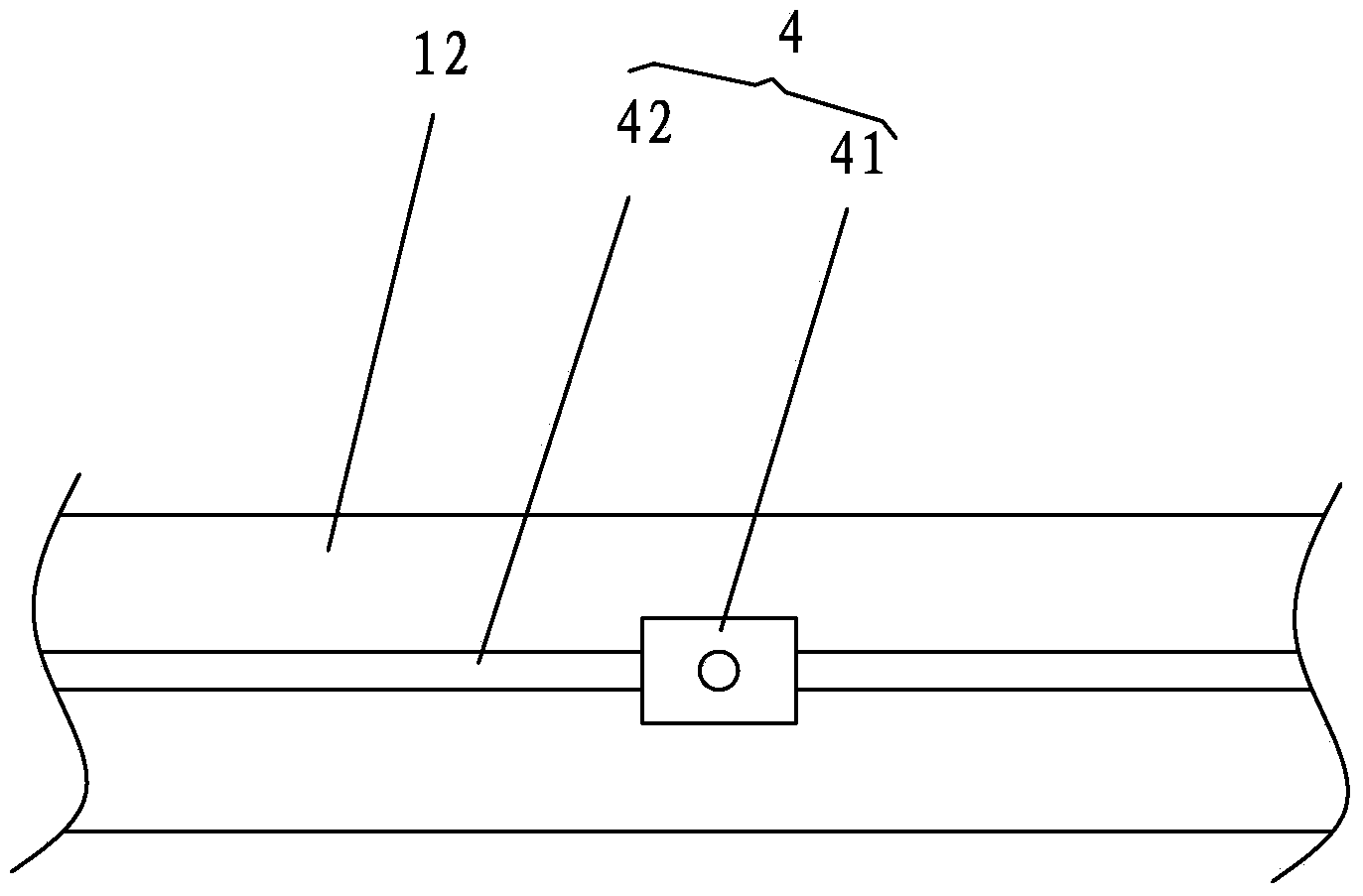

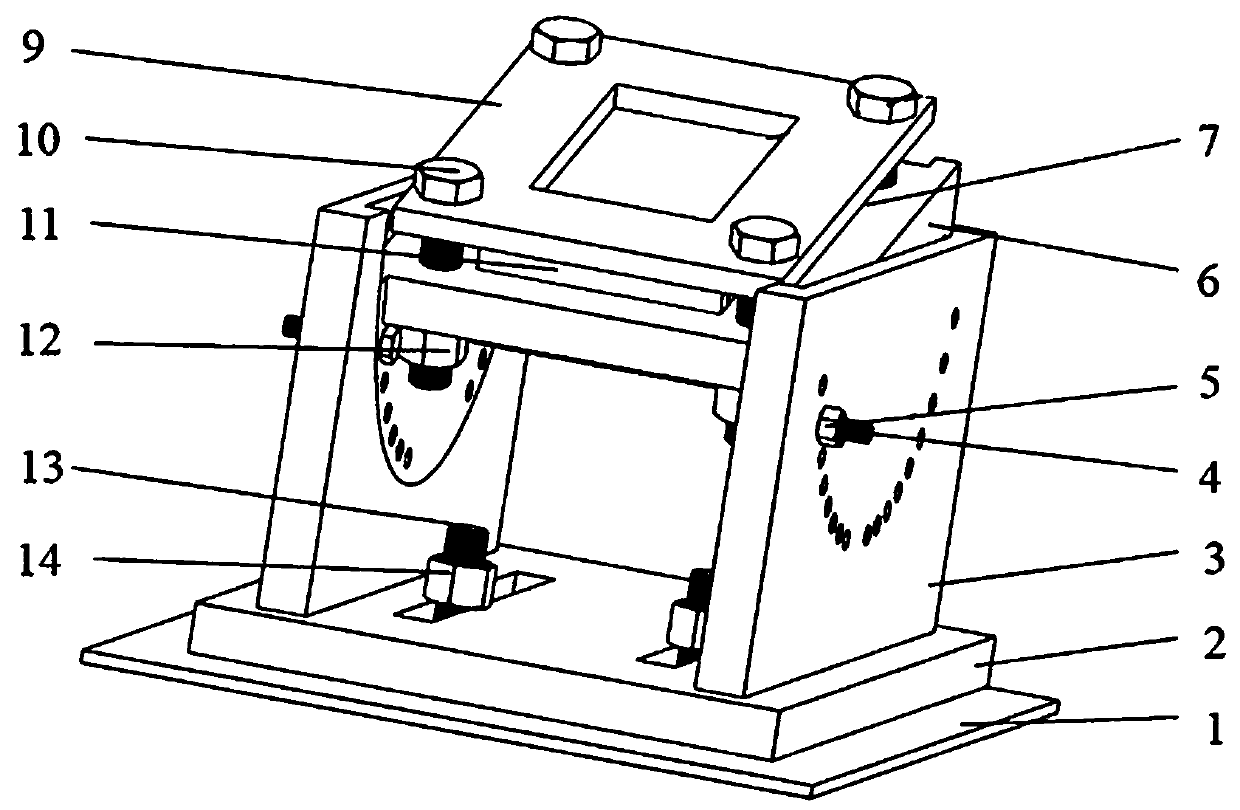

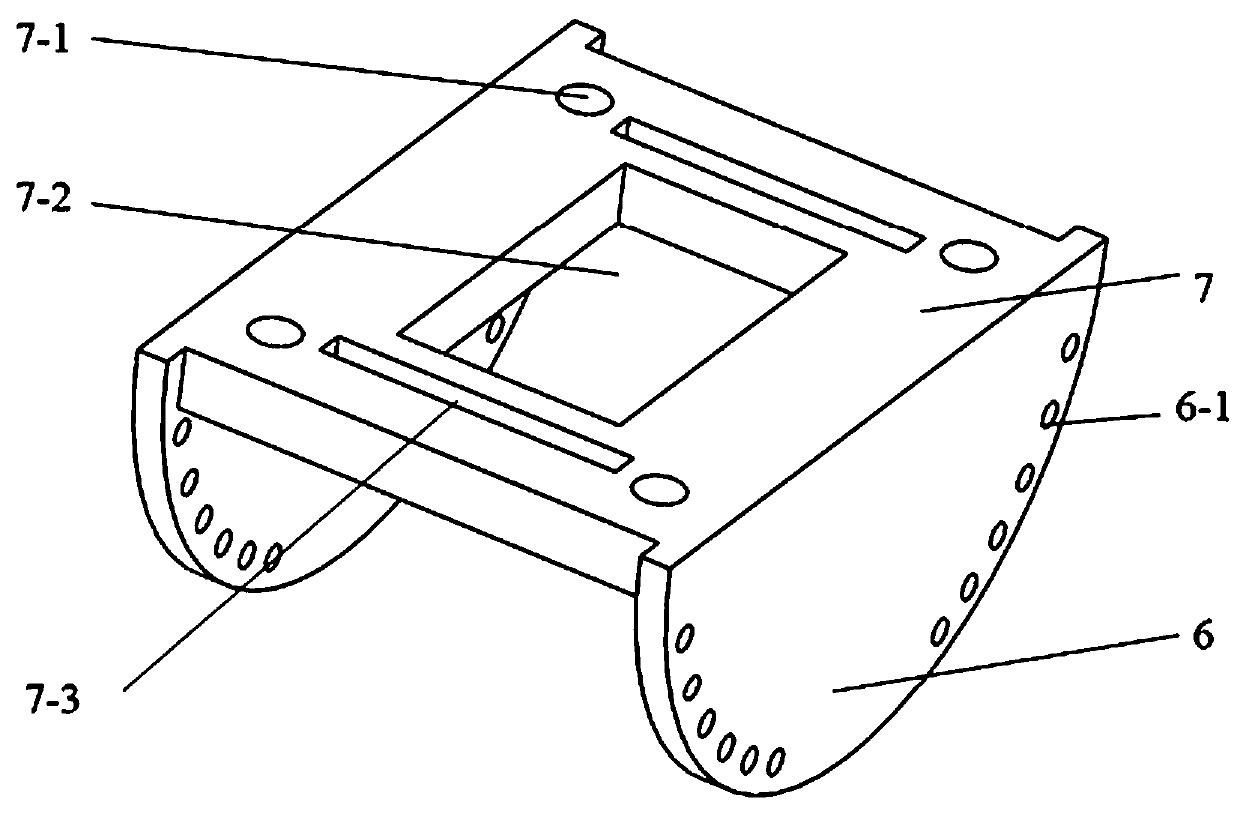

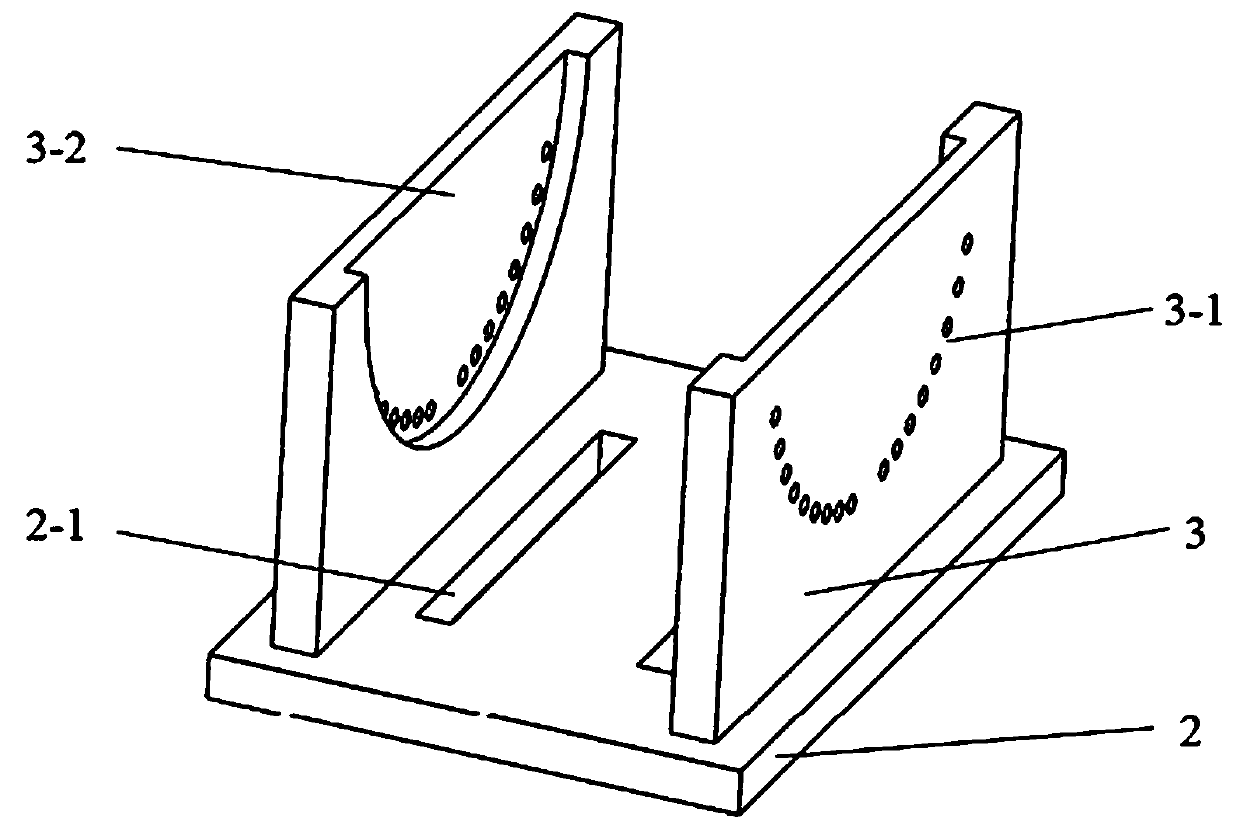

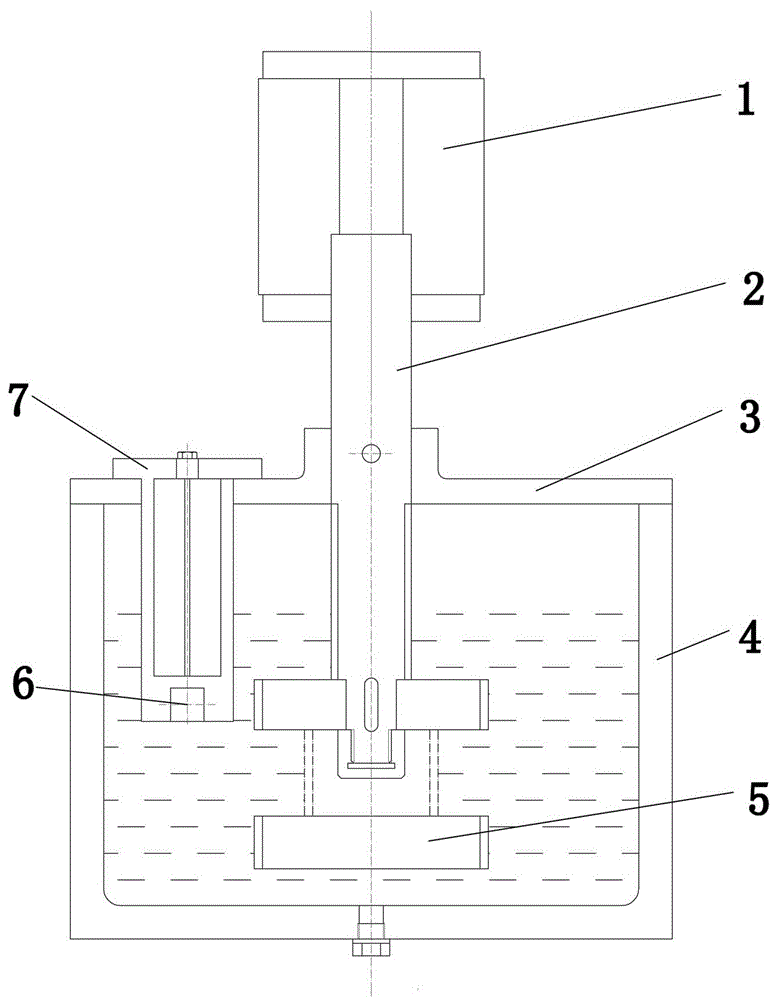

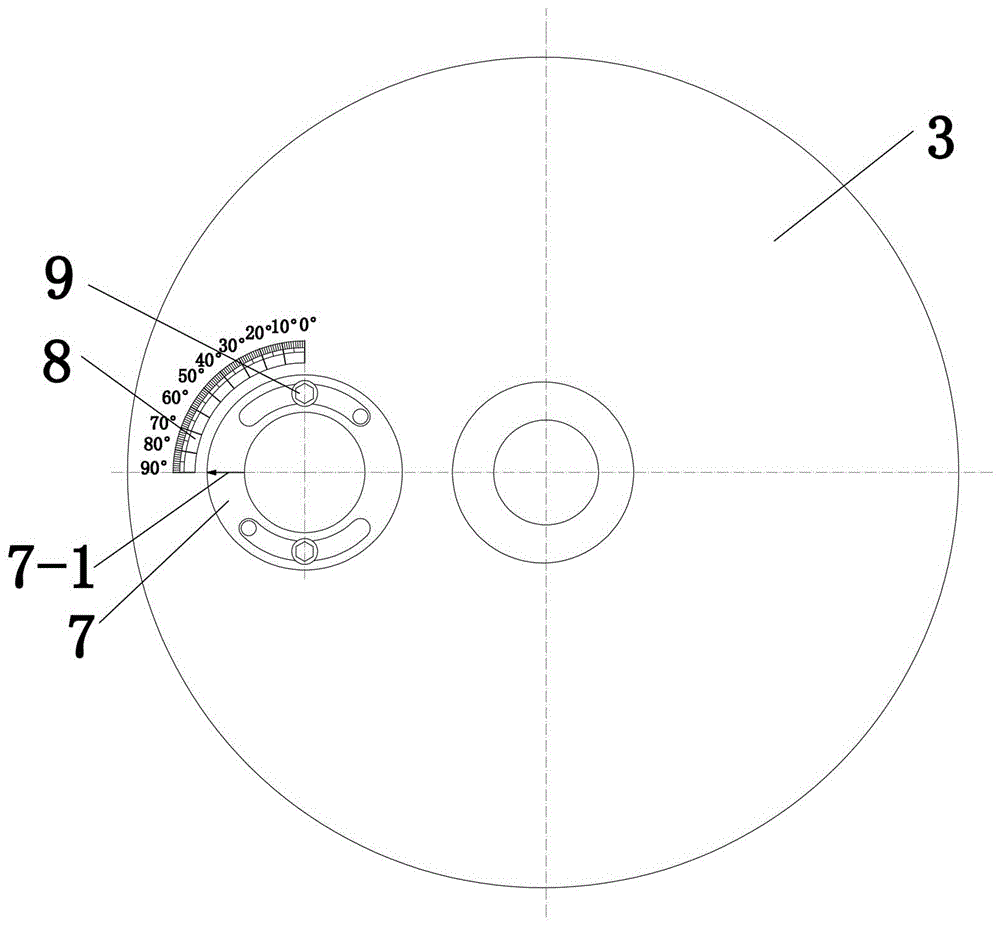

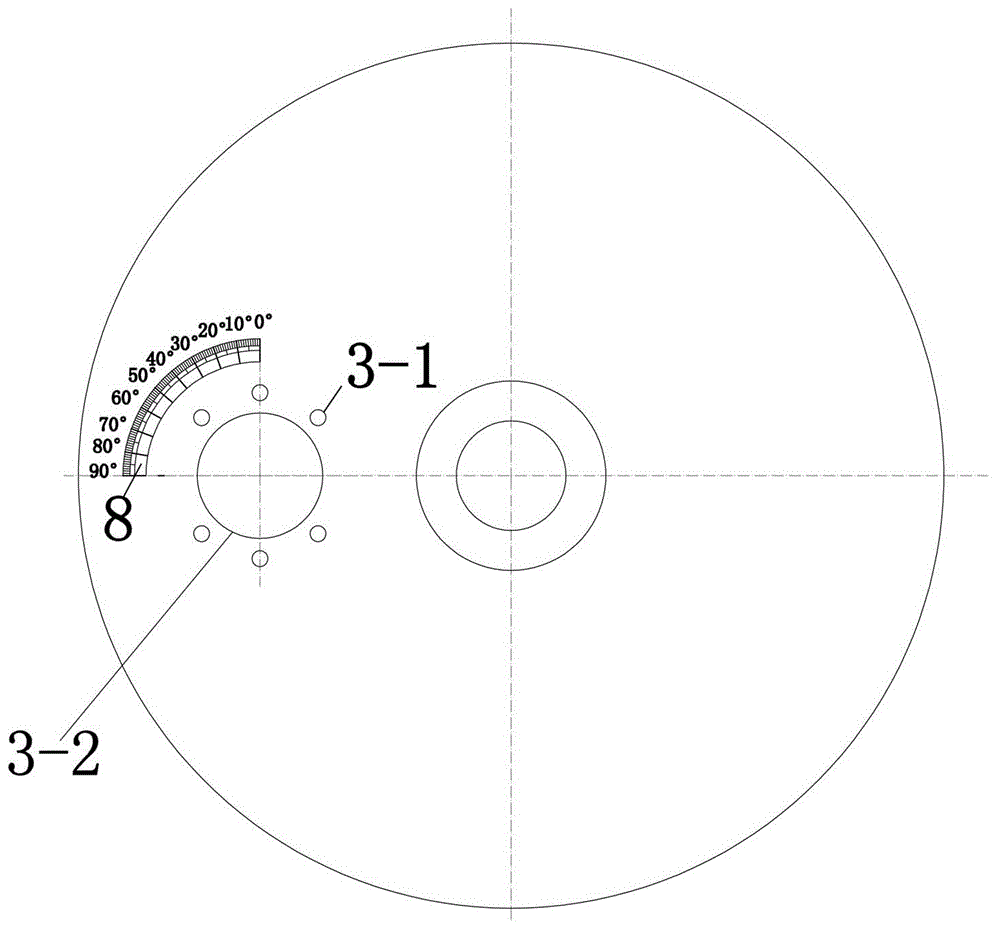

Multi-angle drop-hammer impact testing device and test bench thereof

ActiveCN103728190AIncrease flexibilityIncrease breadthStrength propertiesSoftware engineeringImpact testing

The invention discloses a multi-angle drop-hammer impact testing device. The multi-angle drop-hammer impact testing device comprises a test bench for fixing a test specimen, a drop-hammer assembly and a lifting mechanism, wherein the drop-hammer assembly is correspondingly arranged above the test bench by the lifting mechanism; the test bench comprises a test bench main body and an angle adjustment mechanism for adjusting the rotation of the test bench main body, and the drop-hammer assembly is kept to correspond to the test specimen on the test bench main body by a hammer adjustment mechanism. The invention also discloses the test bench of the multi-angle drop-hammer impact testing device using the structure. The test bench main body rotates by a preset angle by the angle adjustment mechanism, so as to simulate the impacts from different angles; the drop-hammer assembly is allowed to impact the test specimen from different angles, and the impacts comprise front-surface impact, the offset impact and the lateral impact, so that the material mechanical properties of the test specimen can be analyzed from different impact angles, and the flexibility and universality of the drop-hammer impact test are greatly improved.

Owner:HUAQIAO UNIVERSITY

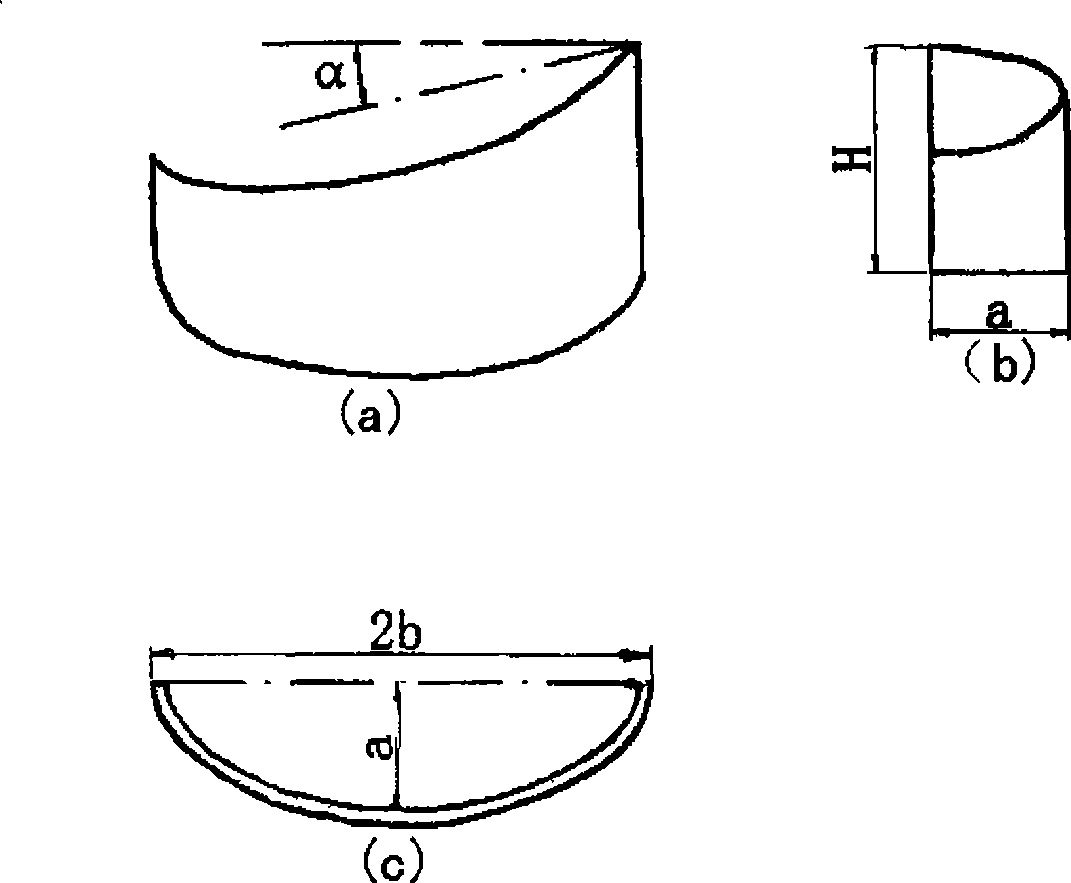

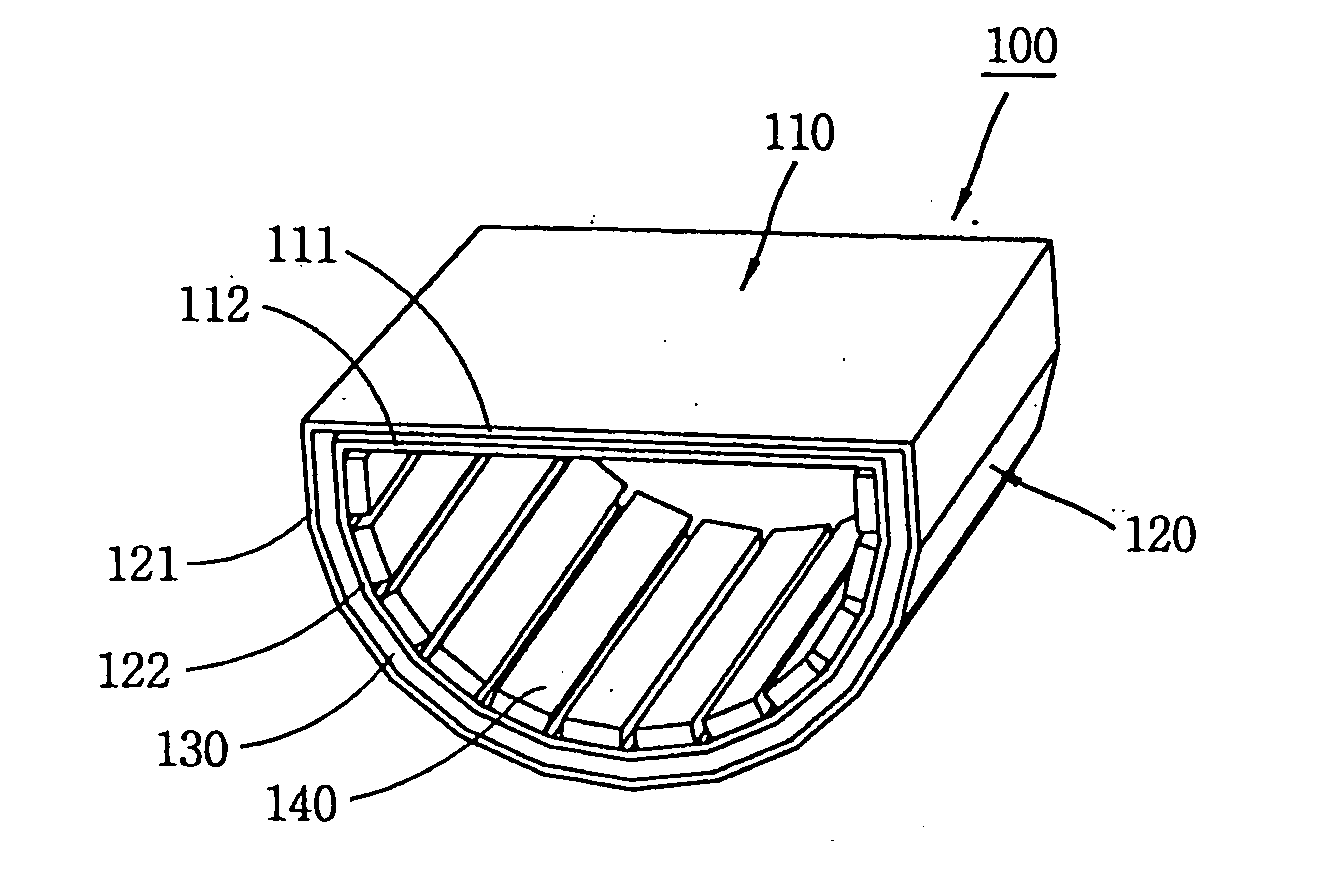

Reinforced heat transfer element of truncated cylindrical surface wing type vortex generator

InactiveCN101532798AReduce transportation energy consumptionEnhanced convective heat transferHeat transfer modificationTransportation energyEngineering

The invention discloses a reinforced heat transfer element of a truncated cylindrical surface wing type vortex generator, belonging to the field of heat transfer parts of heat exchanger. The vertical surface of a wing type vortex generator is bent into a semi cylindrical surface or a semi elliptic cylindrical surface to be arranged on a fin tube or a fin tube of a plate-fin heat exchanger or other passage flow heat exchanger plate surface in a certain incident flow impact angle and a certain array manner so as to induce the end longitudinal vortex and the root part horse shoe vortexes to couple to be thinned or destruct the boundary layer clinging to the wall face or reinforce the turbulence intensity to realize the passive reinforced heat exchange and improve the efficiency of the heat exchanger. In addition, due to the streamline surface, the shape resistance is reduced, thus lowering the flowing pressure loss and the fluid transportation energy consumption. The vortex generator can be manufactured by metal or other bendable molding materials, has the characteristics of simple manufacturing and convenient installation, and has extensive application prospect and promotion value in gas-liquid or gas-gas heat exchangers.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

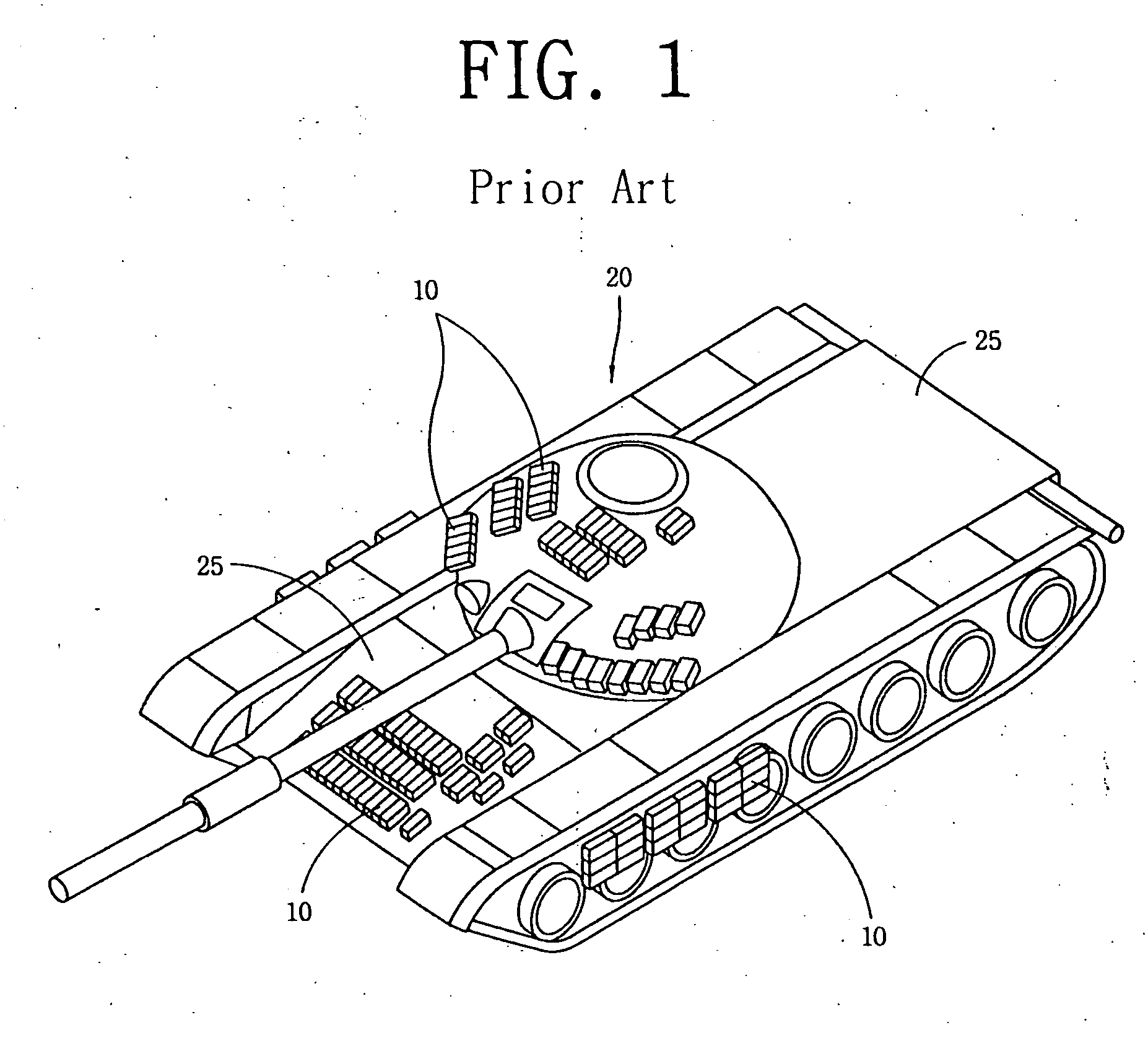

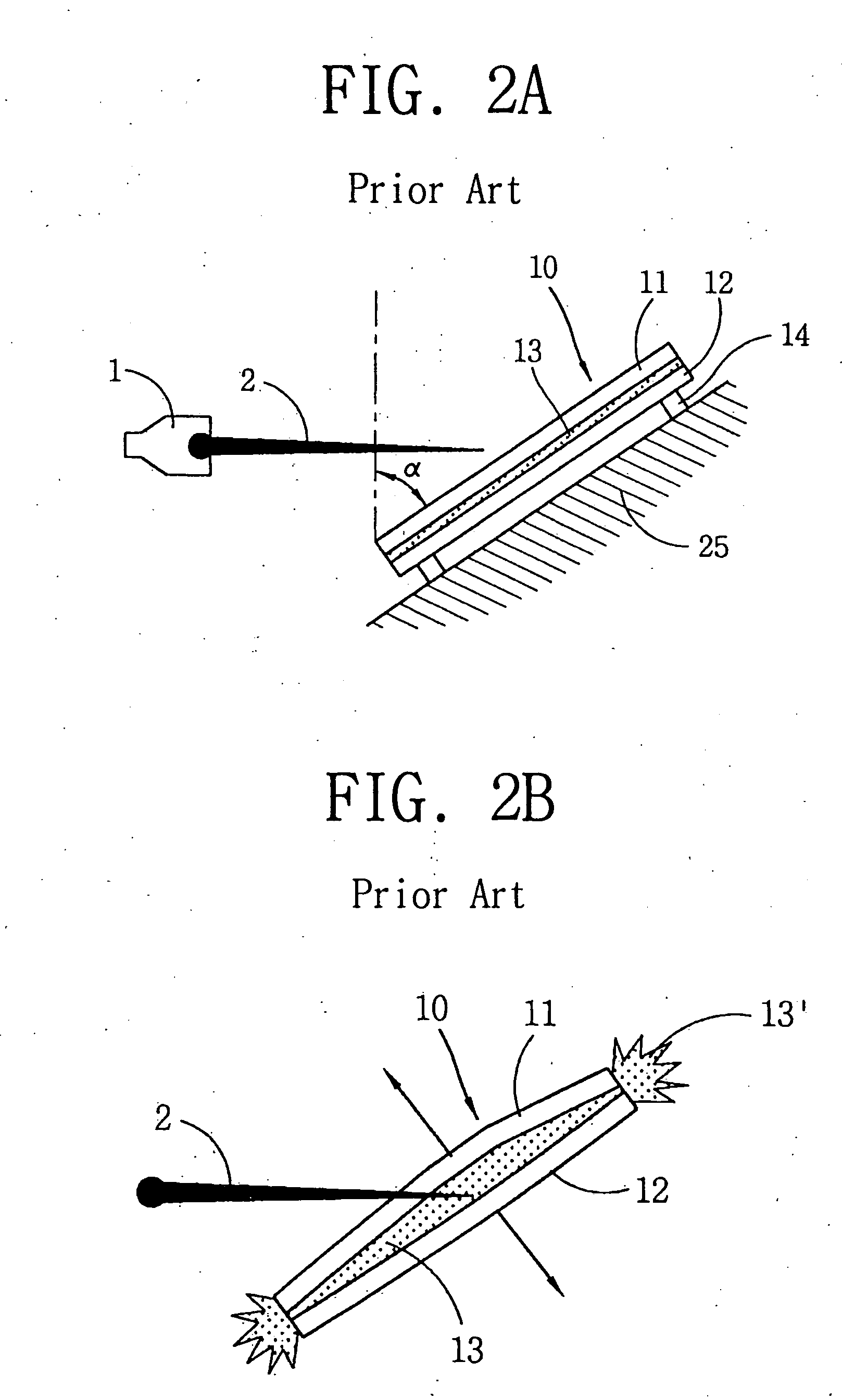

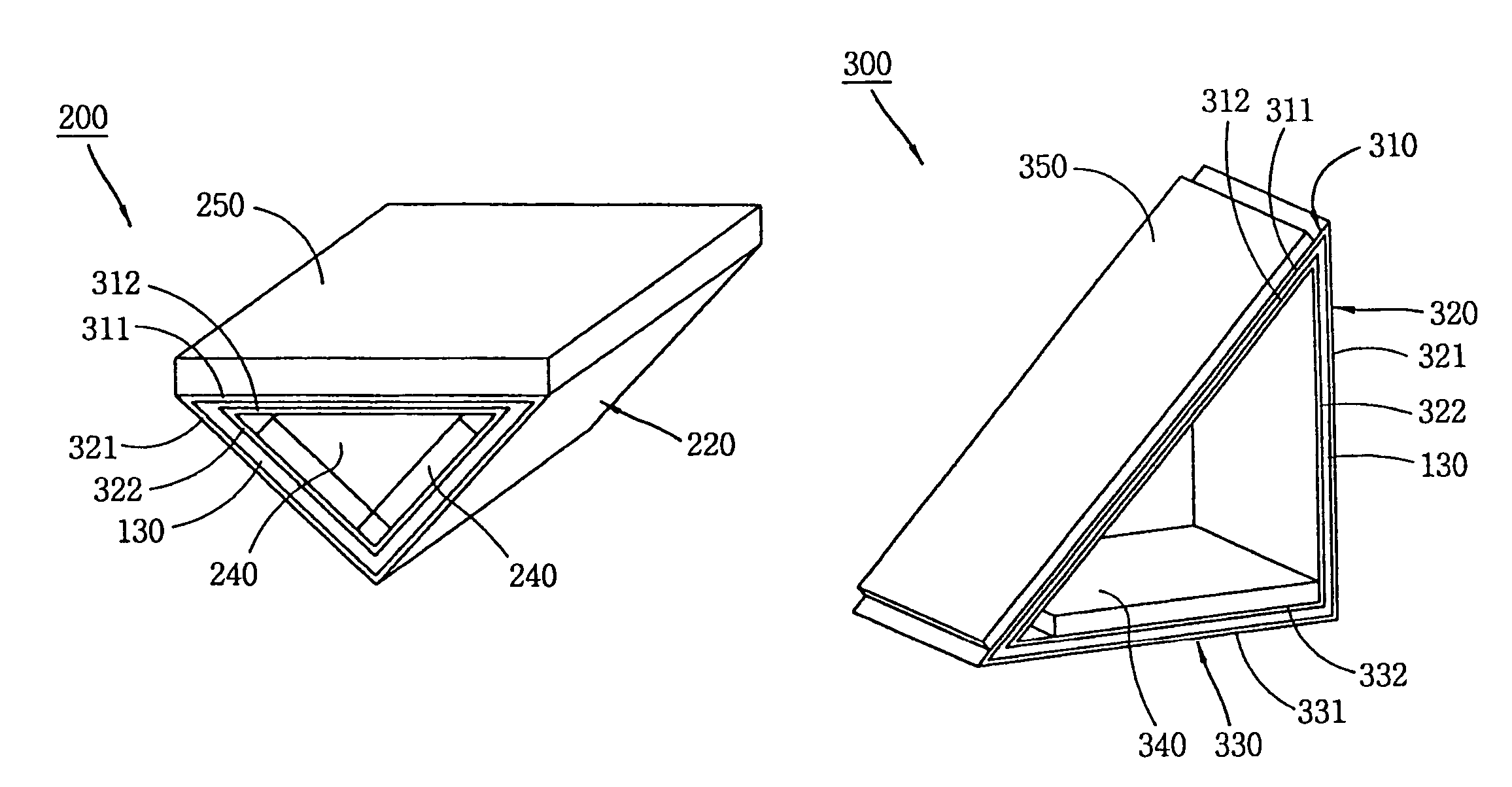

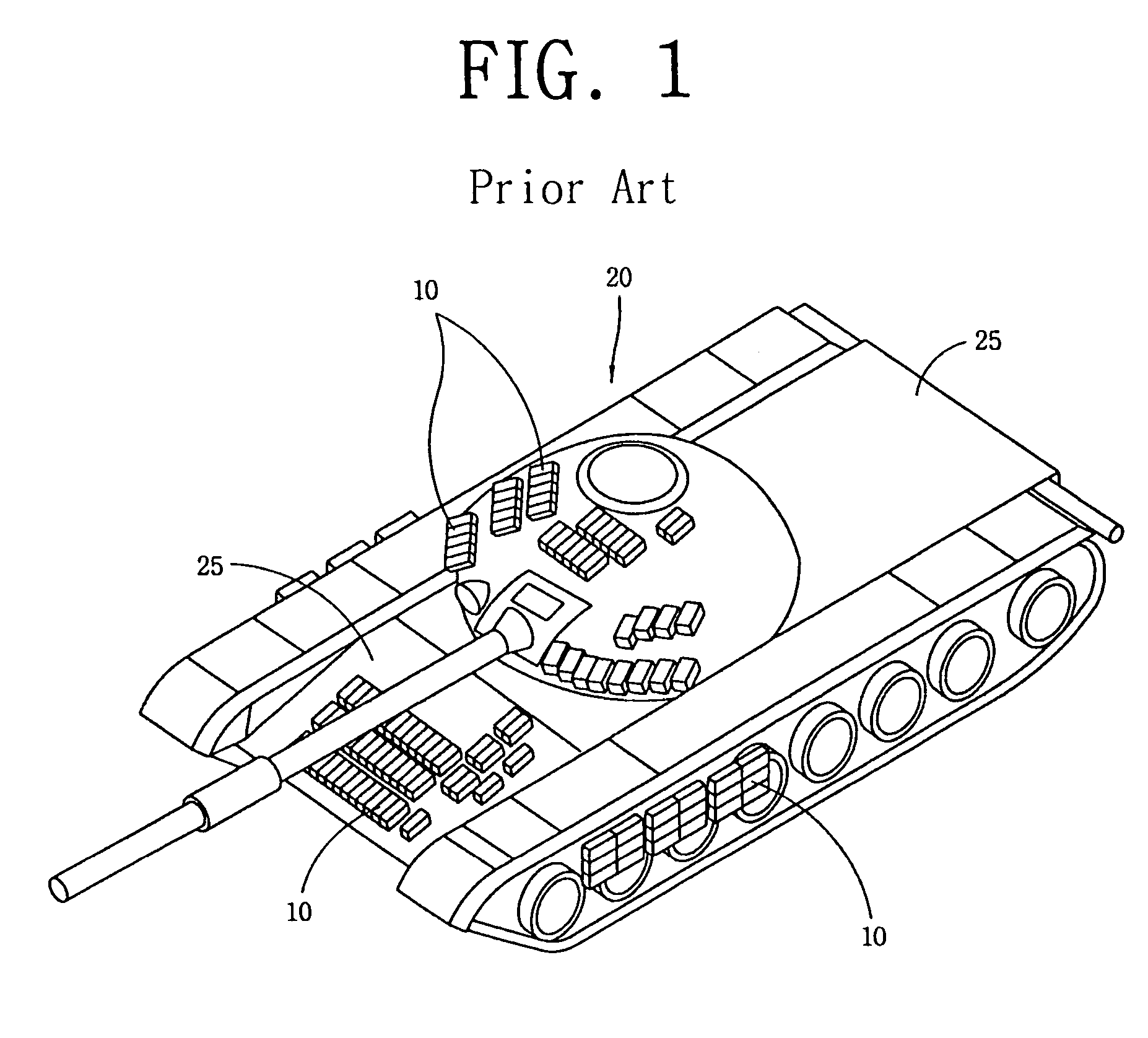

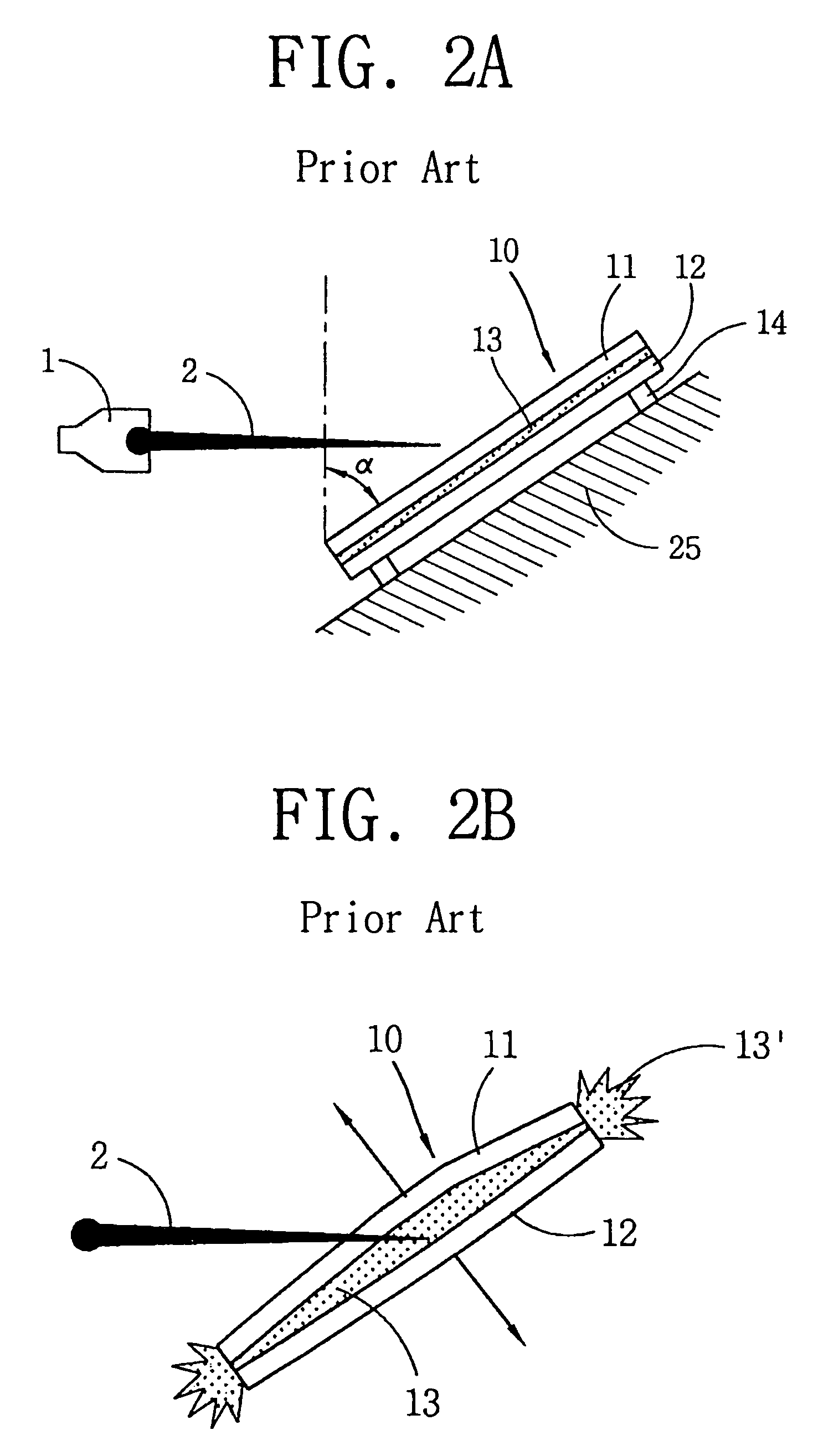

Explosive reactive armor with momentum transfer mechanism

ActiveUS20060086243A1Enhanced interactionImprove protectionDefence devicesArmoured vehiclesDetonationSlant angle

Disclosed is an explosive reactive armor with a momentum transfer mechanism by developing a new protection mechanism in which a momentum transfer mechanism by detonation of a reactive material is integrated with a thickness increase mechanism. In this explosive reactive armor with the momentum transfer mechanism, a flying element always travels with a vertical angle or a slant angle with respect to an ongoing direction of the threat such that a momentum of the flying element is transferred to the threat effectively. As a result of this, shear force is induced over an entire length of the threat and thus the threat can be destroyed. Therefore, a protection effect can always be achieved regardless of an impact angle of the threat. Also, a protection capability can be achieved even in case of a vertical impact which is the most vulnerable case for the existing explosive reactive armor.

Owner:AGENCY FOR DEFENSE DEV

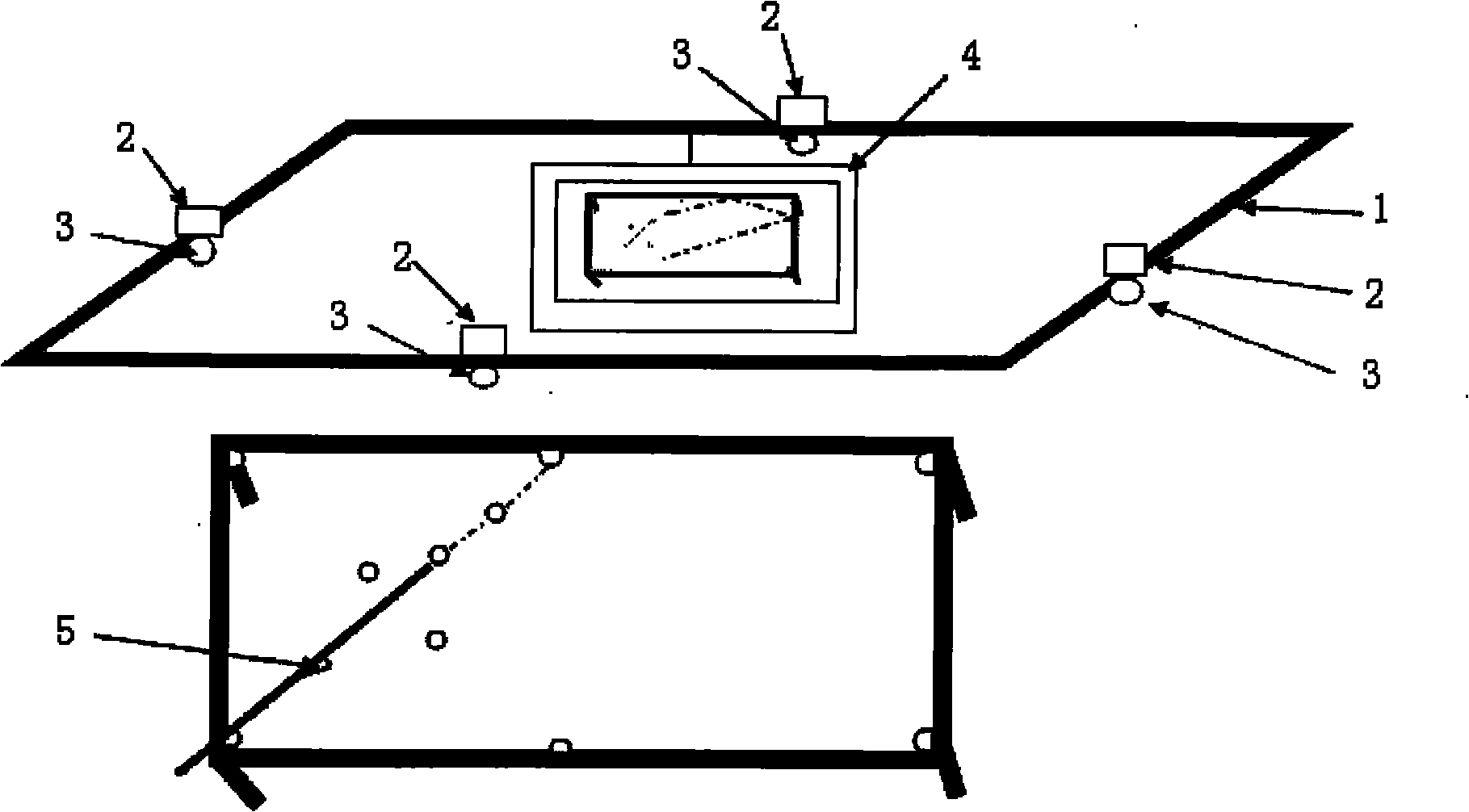

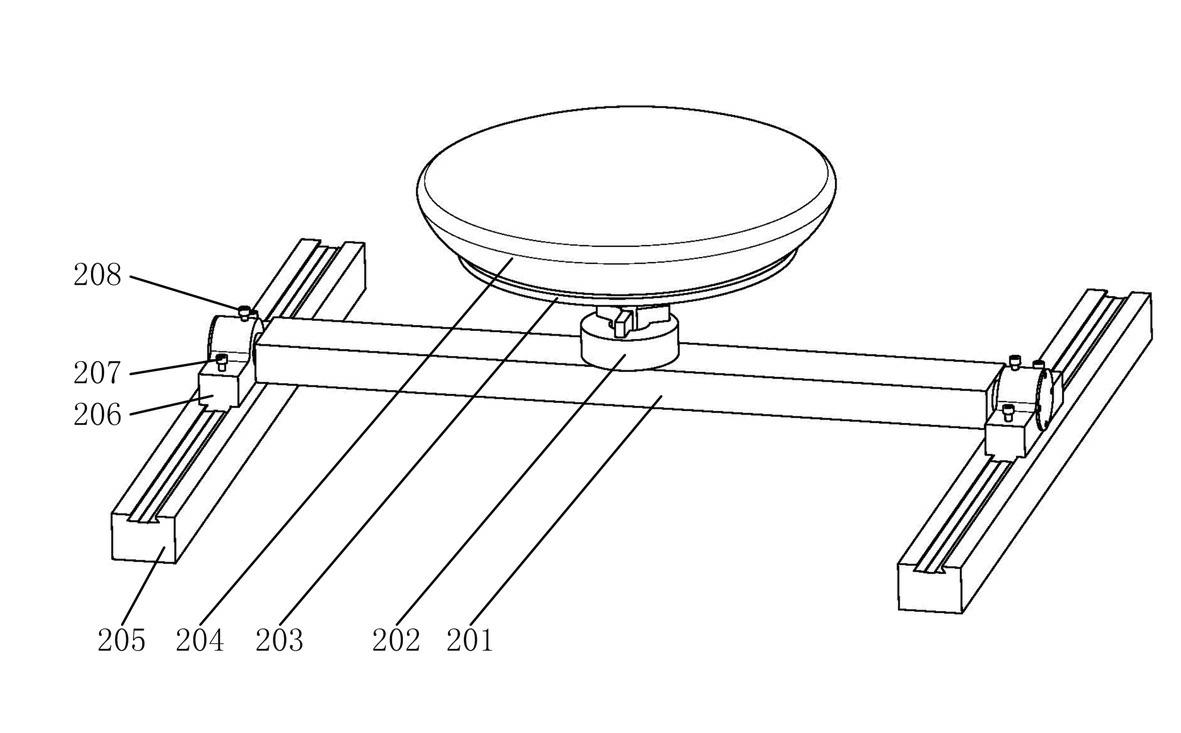

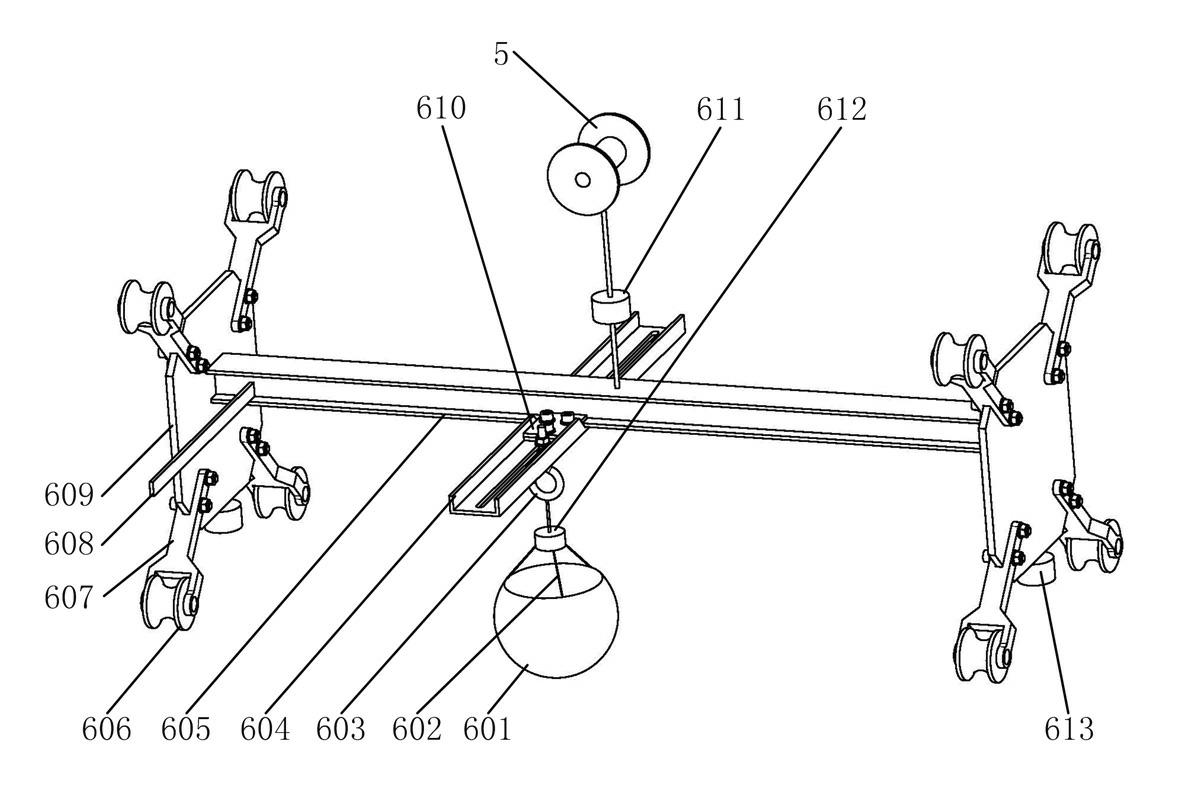

Television system for analyzing displacement of billiards

InactiveCN101848376AEffective comprehensionEffectively help comprehendTelevision system detailsColor television detailsTelevision systemComputer module

The invention relates to a television system for analyzing displacement of billiards, which consists of a slide rail system, an image sensor, a television functional module, a communication module, a remote controller and related software and is concretely characterized in that a slide rail is hung on a ceiling, and the image sensor and the communication module are arranged on the slide rail; a television display is hung on the slide rail and can slide along the slide rail, the condition corresponding to the field billiards in the display can be observed easily when people play billiards by moving the position of the display, and simultaneously, advance routes, rotation ways, impact angles and other key information of a cue ball and an object ball can be simulated and displayed on the display; corresponding simulative routes and the rotation angles of the billiards can be changed correspondingly by freely changing the impacting way and the impacting position; and simultaneously, after the object ball is impacted by the cue ball, a microprocessor can compare and analyze the actual displacement routes and the simulative routes of the billiards to continuously correct the simulative routes, so that a billiard practicer can learn about the displacement changes of billiards caused by the change of impacting, thereby quickly helping the practicer to improve the billiard technic.

Owner:朱万政

Explosive reactive armor with momentum transfer mechanism

ActiveUS7540229B2Enhanced interactionImprove protectionDefence devicesArmoured vehiclesDetonationSlant angle

Disclosed is an explosive reactive armor with a momentum transfer mechanism by developing a new protection mechanism in which a momentum transfer mechanism by detonation of a reactive material is integrated with a thickness increase mechanism. In this explosive reactive armor with the momentum transfer mechanism, a flying element always travels with a vertical angle or a slant angle with respect to an ongoing direction of the threat such that a momentum of the flying element is transferred to the threat effectively. As a result of this, shear force is induced over an entire length of the threat and thus the threat can be destroyed. Therefore, a protection effect can always be achieved regardless of an impact angle of the threat. Also, a protection capability can be achieved even in case of a vertical impact which is the most vulnerable case for the existing explosive reactive armor.

Owner:AGENCY FOR DEFENSE DEV

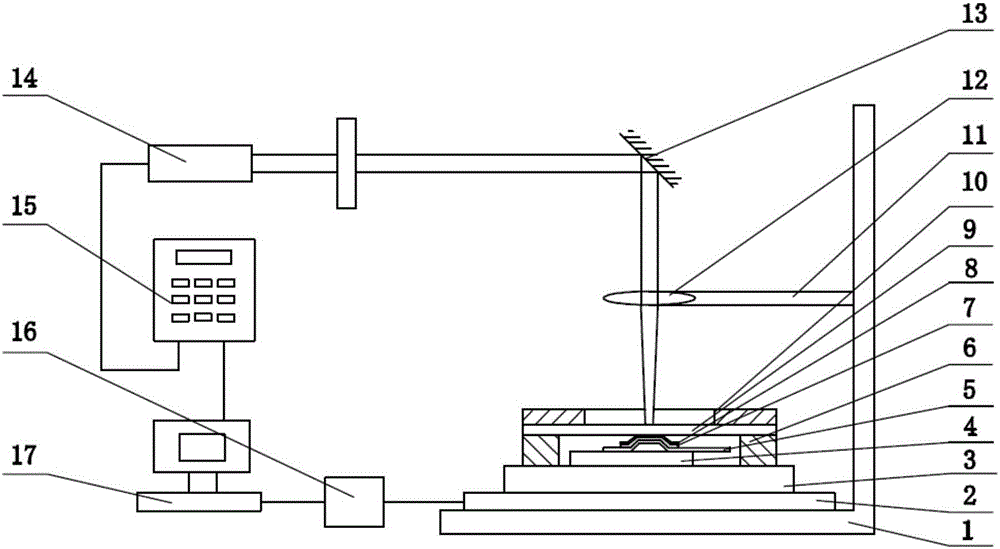

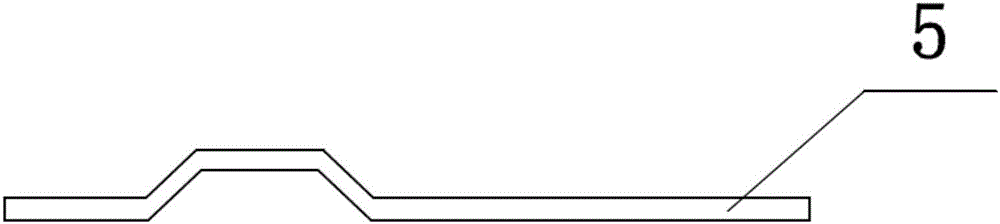

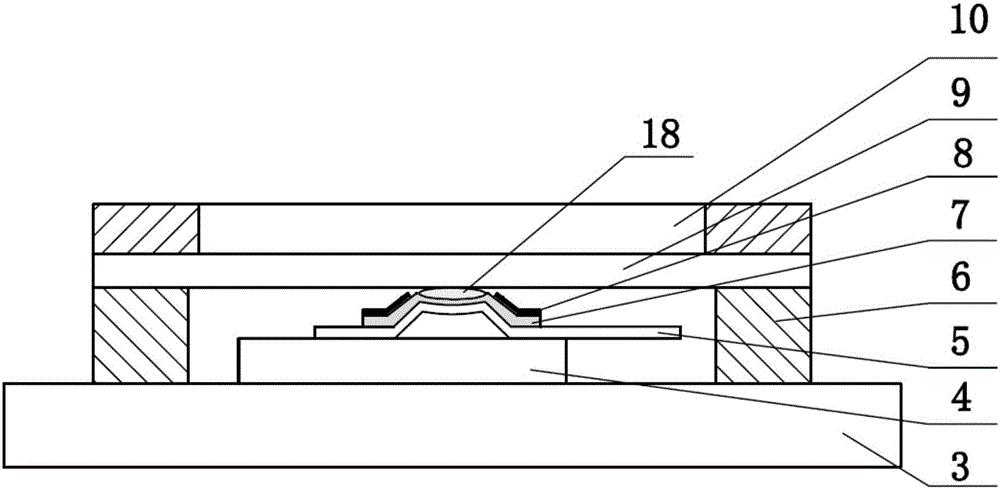

Laser impact welding device and laser impact welding method

InactiveCN106238912AEfficient connectionFirmly connectedLaser beam welding apparatusMicro devicesEngineering

The invention discloses a laser impact welding device and a laser impact welding method, relating to the field of high speed impact welding. The laser impact welding device comprises a laser generating device, a welding device, a three-coordinate moving platform device and a control device, wherein an inverted trapezoidal step is machined at an upper-layer plate in the welding device, thus being convenient for forming an impact angle and an impact speed required by impact welding. According to the laser impact welding device and the laser impact welding method, the limitation of a conventional laser impact welding method that a certain flying distance is required to be given between an upper-layer plate and a lower-layer plate can be overcome, and the problem that the dimension of the upper-layer plate is limited by the dimension of a laser spot can be solved. In addition, the welding device is simple, the welding efficiency is high, the surface quality of a joint is high, and the welding device and the welding method are applicable to efficient and reliable connection of micro devices.

Owner:JIANGSU UNIV

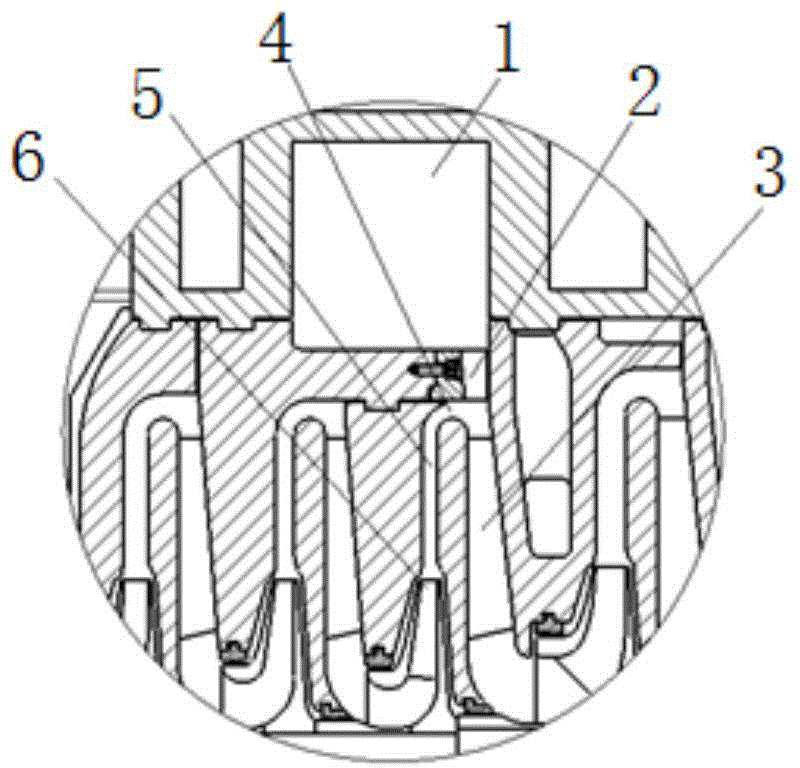

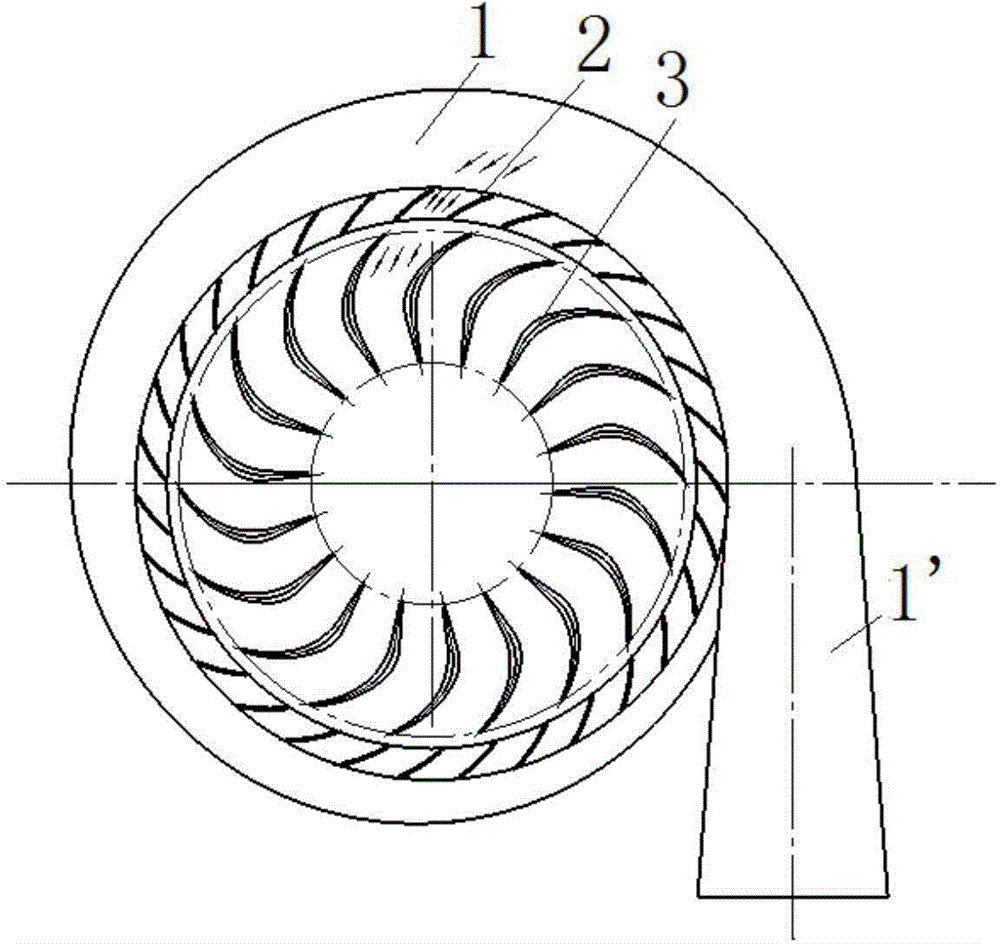

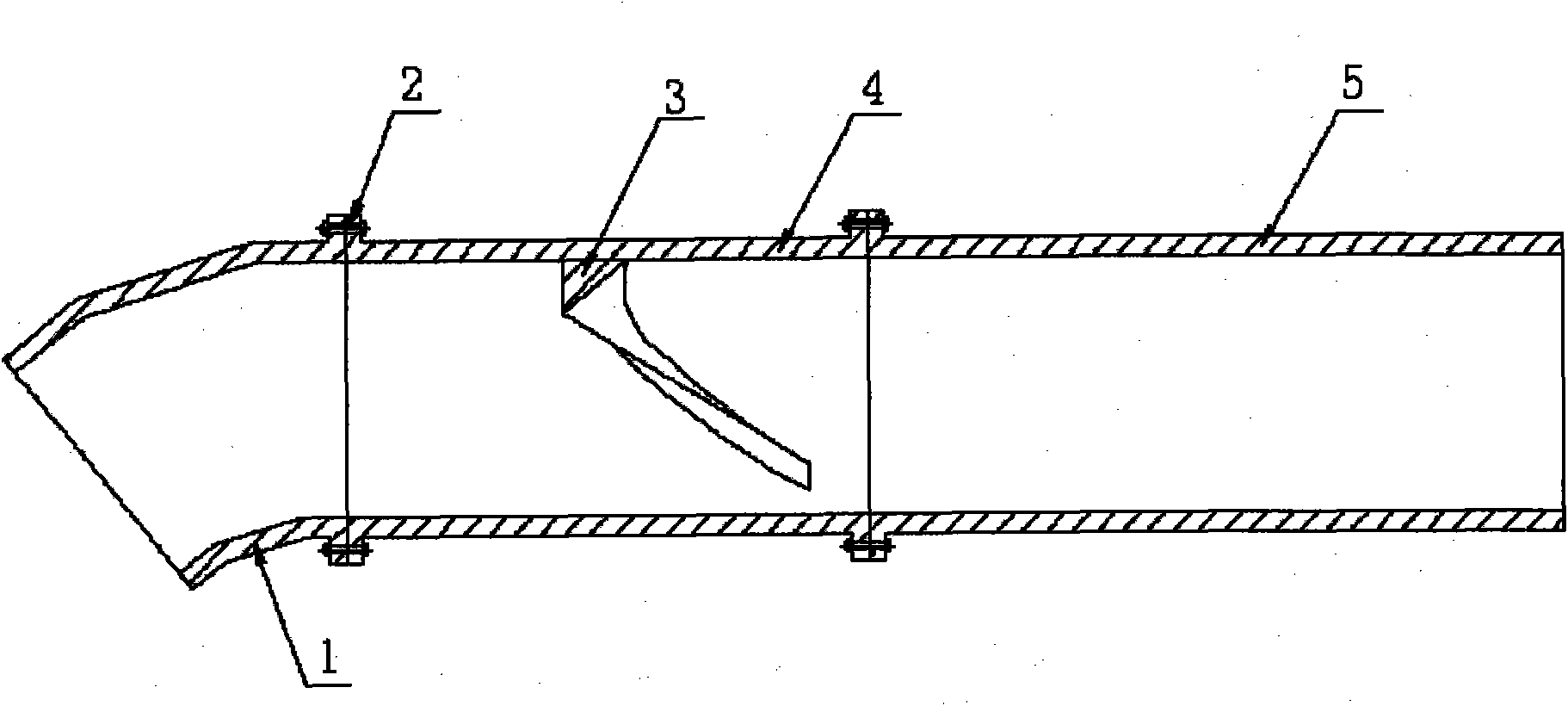

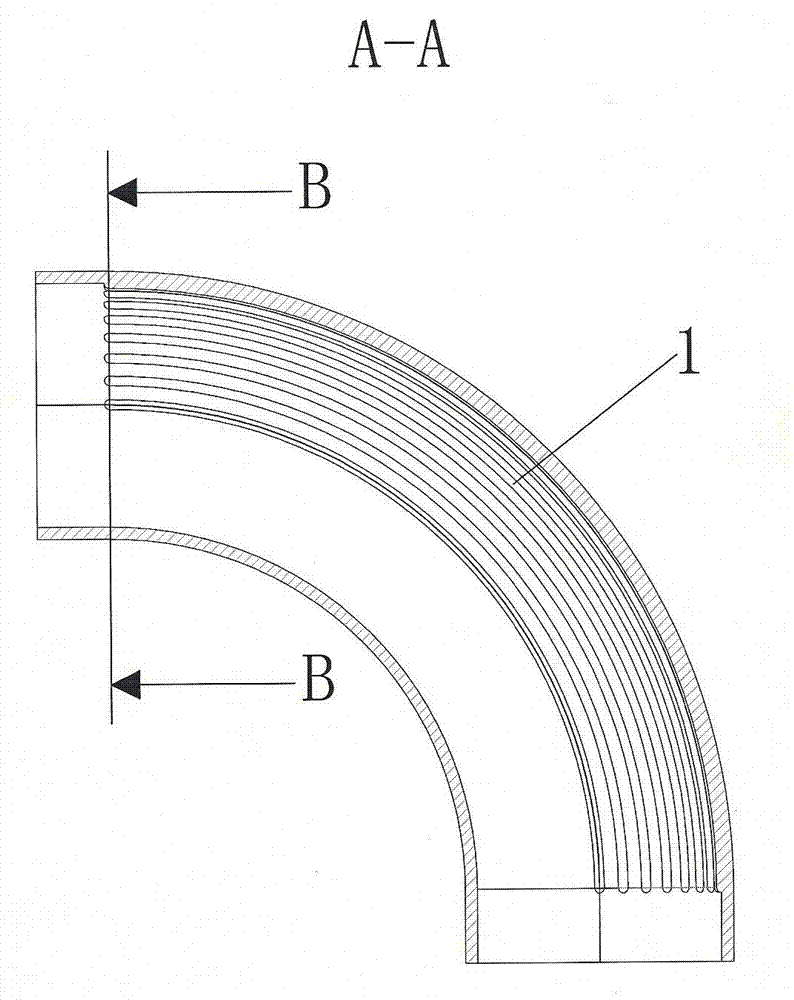

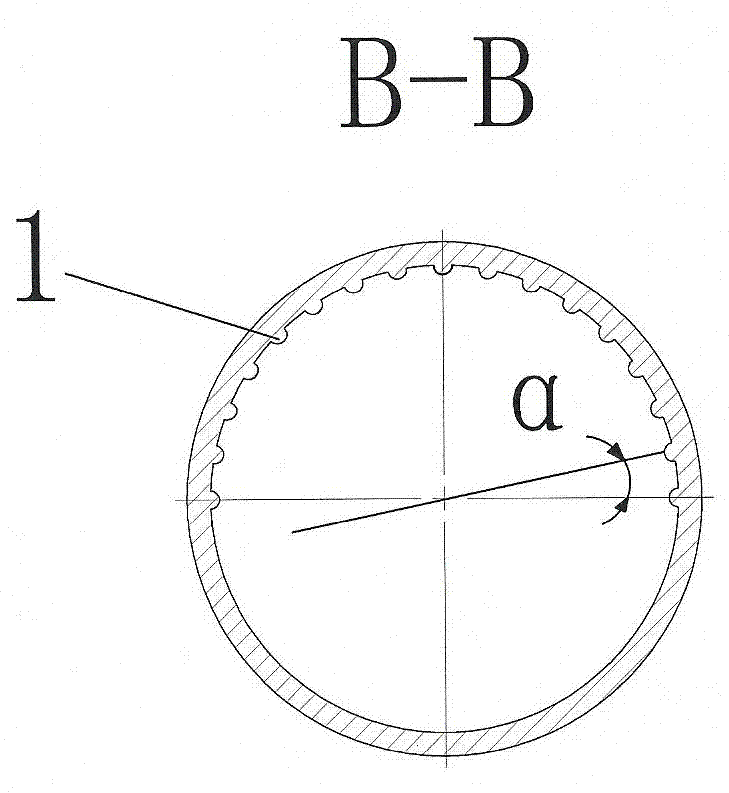

Inter-stage air feeding structure of centrifugal compressor and design method thereof

ActiveCN104533836AImprove circumferential uniformityChanging the gas flow anglePump componentsSpecial data processing applicationsCentrifugal compressorDesign methods

The invention provides an inter-stage air feeding structure of a centrifugal compressor. An air feeding port is formed in the bend of at least one stage of the centrifugal compressor, and the air feeding structure is additionally arranged at the air feeding port, so that fed airflow is led in for main airflow. The air feeding structure comprises an air feeding volute chamber and air feeding guide vanes. The air feeding vanes are circumferentially and uniformly distributed on a volute of the volute chamber in the same vane profile, so that the circumferential uniformity of the airflow is improved, the angle of the fed airflow is changed, and it is guaranteed that the fed airflow and the main airflow do not generate any large impact angle when flowing to a next-stage backflow device after being mixed. The invention further provides a design method of the inter-stage air feeding structure of the centrifugal compressor. By adopting the inter-stage air feeding structure of the centrifugal compressor and the design method of the inter-stage air feeding structure of the centrifugal compressor, when the number of the vanes is large, the axial span of the compressor can be reduced, and the requirement of the critical rotation speed of a set can be met more easily.

Owner:SHENYANG BLOWER WORKS GRP INSTALLATION MAINTENANCE FITTINGS

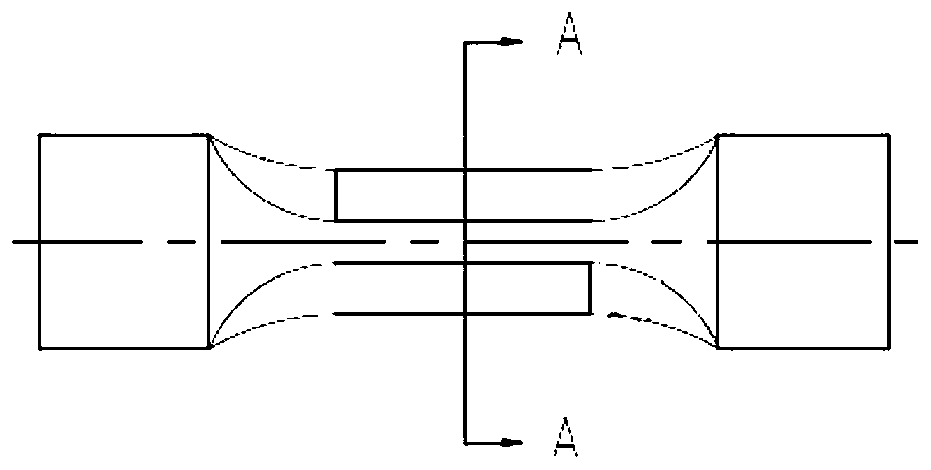

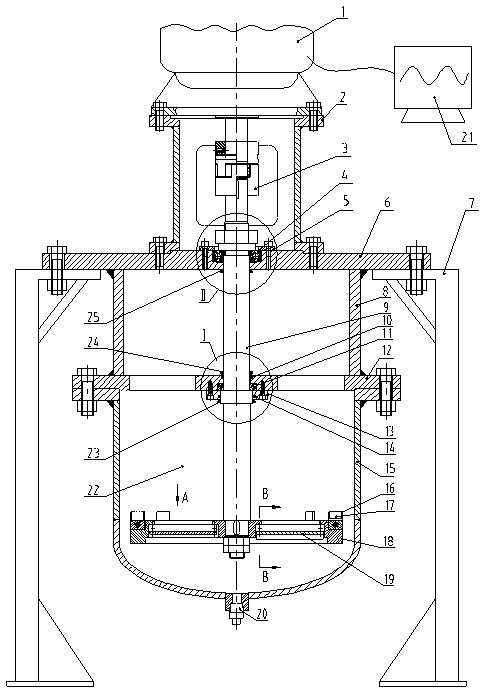

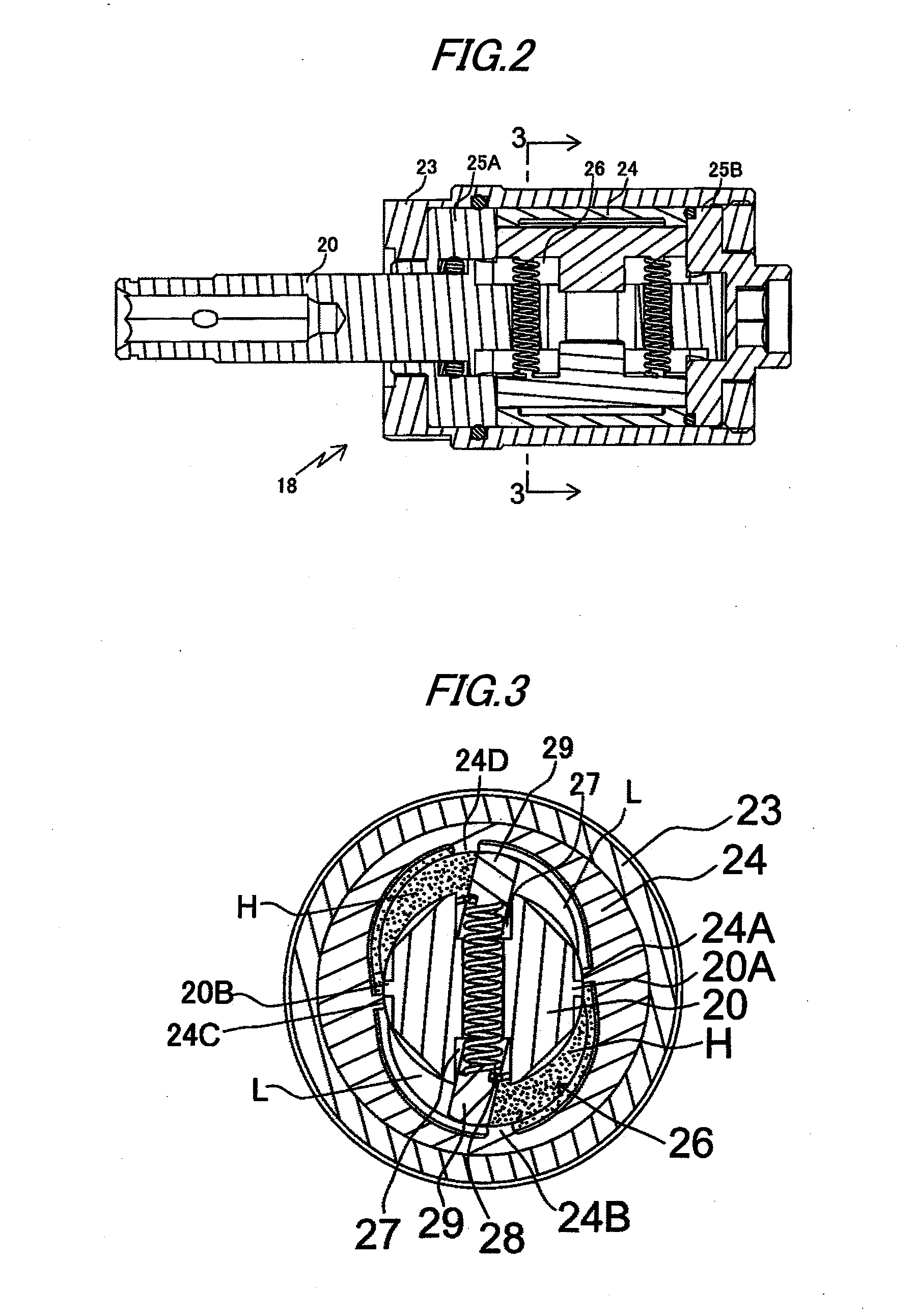

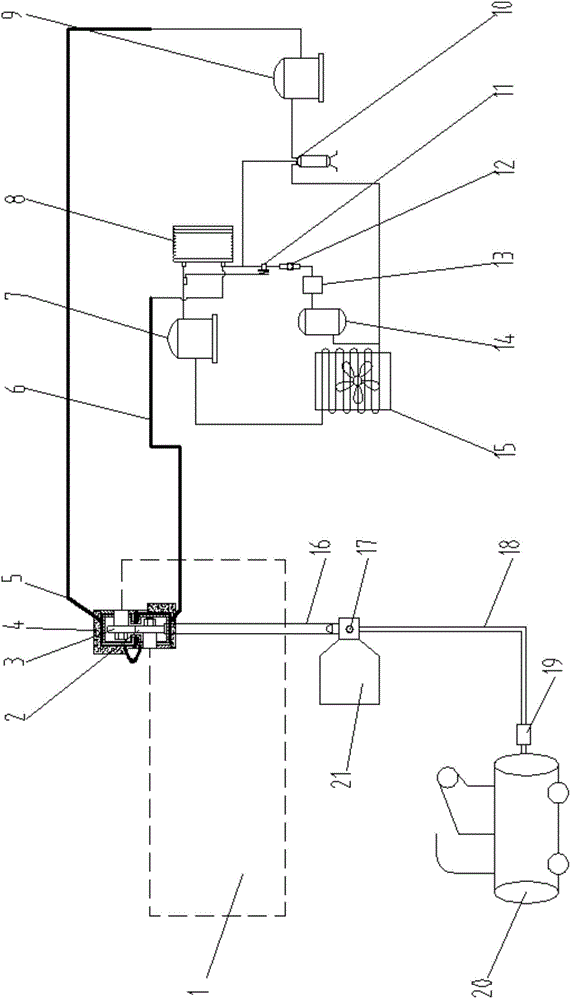

Jet type gas/solid erosion test device

InactiveCN102288538AFlow field stabilityPrecise control of impact angleWeather/light/corrosion resistanceSpray nozzleEngineering

The invention discloses a jet type gas / solid erosion test device, which is composed of an air compressor, a pressure gauge, a pressure control valve, a control box, a dust collector, a spray gun, a nozzle, a sample turntable, a sand storage room, a frequency conversion motor, The air compressor is connected with the spray gun through the gas delivery pipe, the sand delivery pipe and the body. The air compressor is connected with the spray gun. The gas delivery pipe is equipped with a pressure gauge and a pressure control valve. There is a nozzle at the lower end of the spray gun. The sample turntable is located under the nozzle. Driven by a frequency conversion motor, the sand storage chamber is connected to the spray gun through the sand delivery pipe. The spray gun and the sample turntable are located in the closed body, and the sand storage chamber is located at the bottom of the body. Air compressor, pressure gauge, pressure control valve, control box , The dust collector and the frequency conversion motor are located outside the body, and the dust collector is used for dust removal inside the body; the spraying angle of the spray gun is 10° to 90°; the invention makes the sample be eroded by the gas / solid two-phase flow at the same time; the invention is in the working process The medium flow field is stable, and the impact angle can be precisely controlled.

Owner:JILIN UNIV

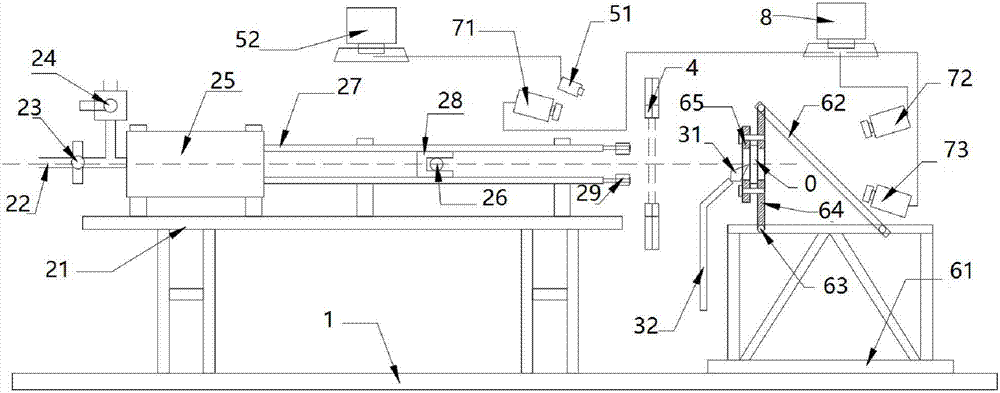

Dynamic ablation measurement apparatus and dynamic ablation measurement method for online applying of impact load

ActiveCN106950128ARealize quantitative measurement of temperatureRealize dynamic deformation measurementStrength propertiesMeasurement deviceEngineering

The present invention discloses a dynamic ablation measurement apparatus and a dynamic ablation measurement method for online applying of impact load. The measurement apparatus comprises a dynamic ablation platform, an impact load applying device, a flame heating device, a laser velometer, a temperature measurement system, a sample clamping device, a first camera, a second camera, a third camera, and an image treatment system. According to the present invention, the impact load applying device is used, the impact load is loaded during the abstraction process of the sample, the size and the material of the suitable impact material can be selected according to the actual working condition, and the impact mode and the impact angle can be selected, such that the actual impact condition of the sample during the work can be simulated, and the sample simulation effect close to the actual use environment can be provided; and by combining the temperature measurement system and the image treatment system, the quantitative temperature measurement of the material oxidation ablation process, the dynamic ablation process image capture and the dynamic deformation measurement of the sample can be achieved.

Owner:TSINGHUA UNIV +1

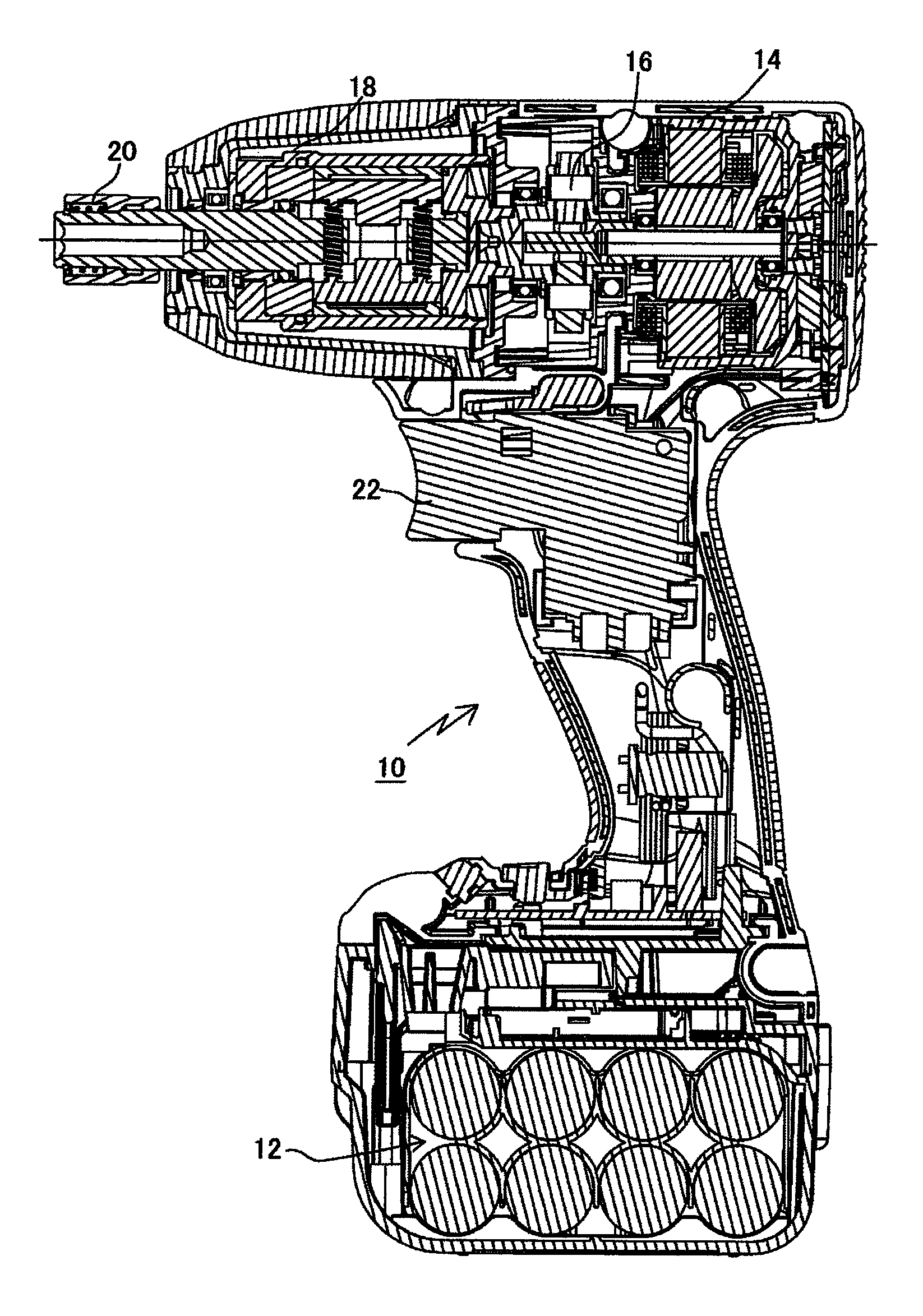

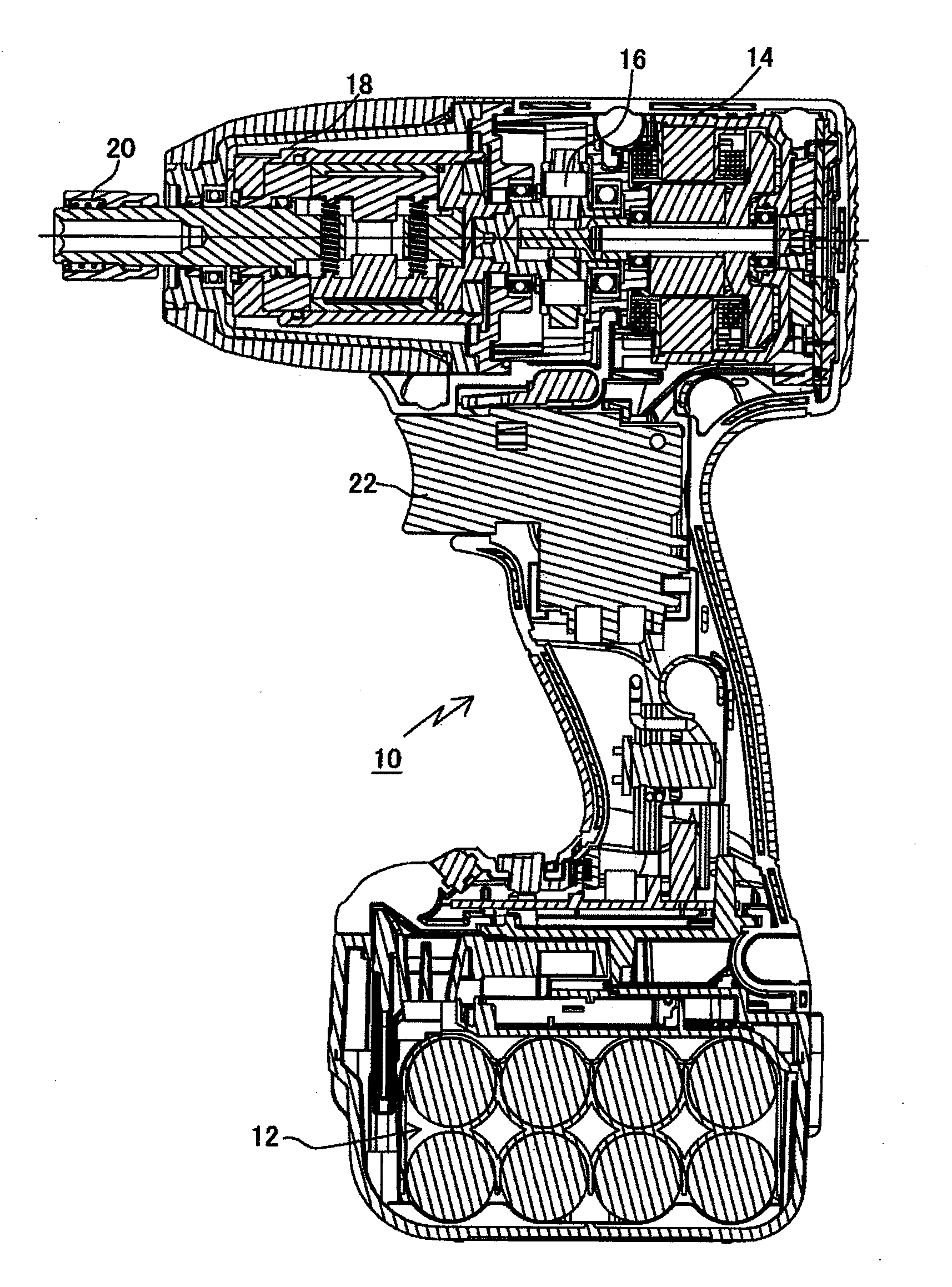

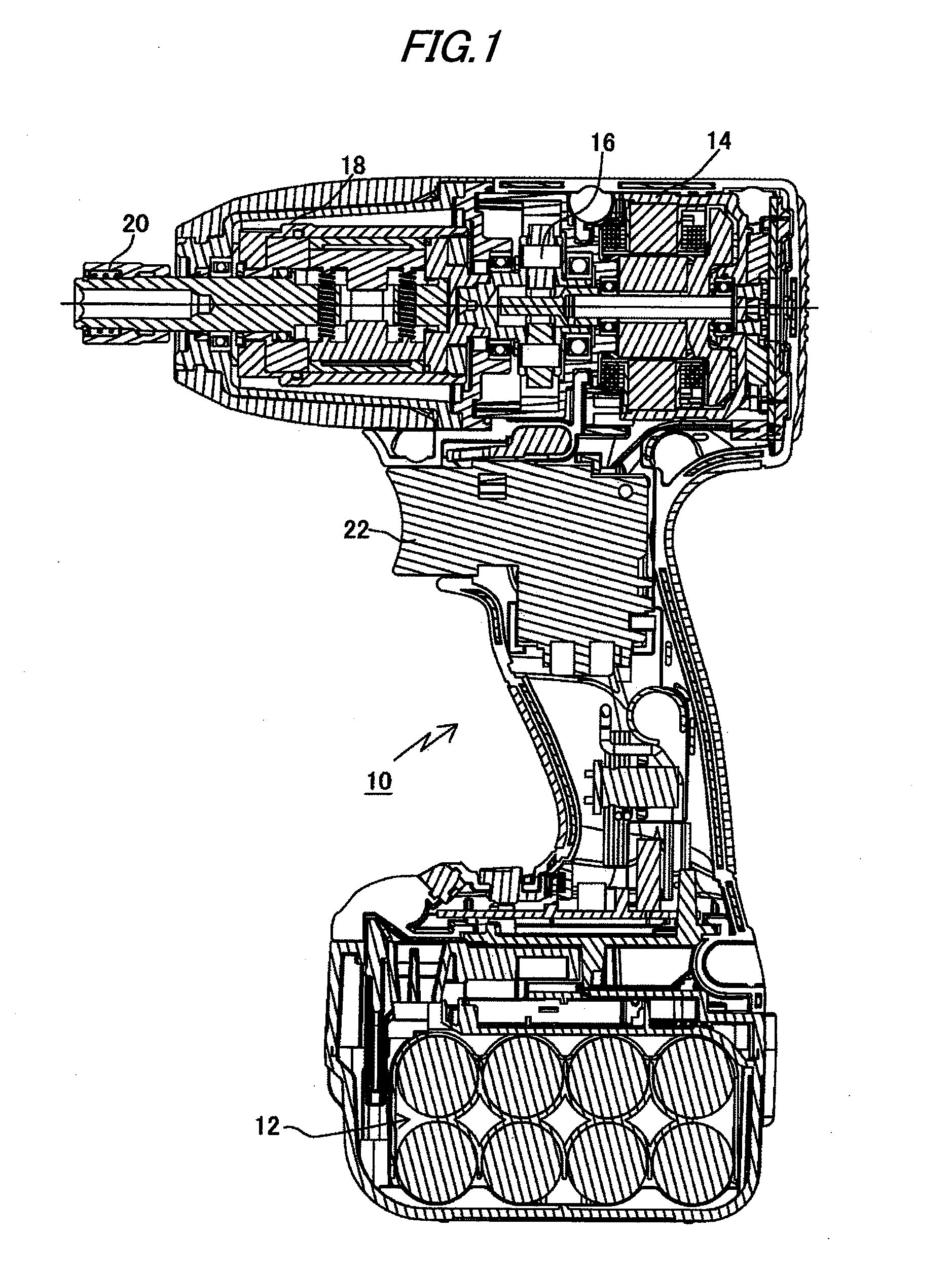

Electric power tool and motor control method thereof

ActiveUS8302701B2Reduce speedContinuation of failure is suppressedPortable percussive toolsSpannersElectric power systemMotor control

Owner:MAX CO LTD

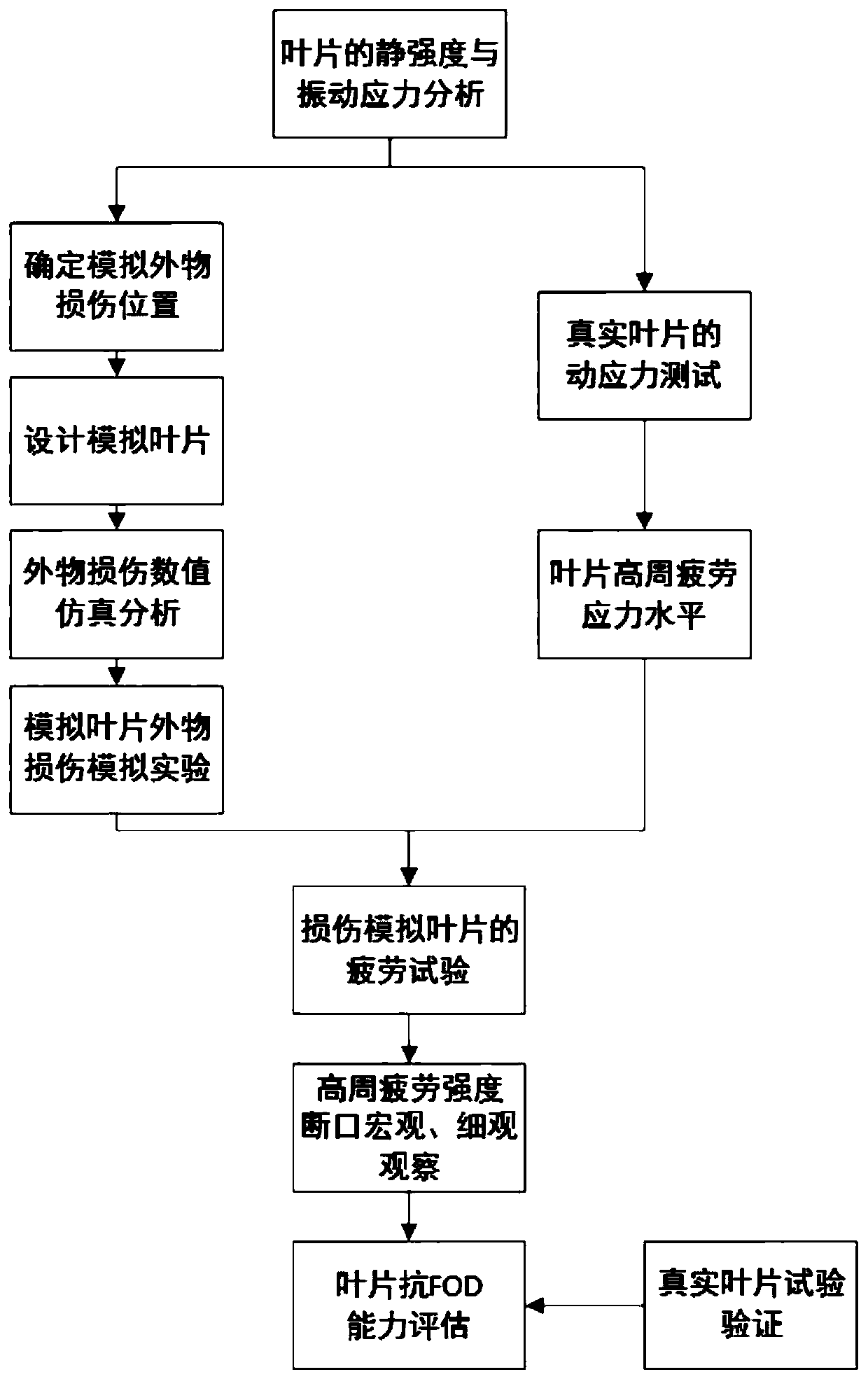

A method for evaluating the FOD resistance of an aero-engine blade

ActiveCN109815521AHigh cycle fatigue strengthAssessing the ability to resist FODSpecial data processing applicationsForeign object damageForeign object

The invention relates to a method for evaluating the FOD resistance of an aero-engine blade. The method comprises steps of carrying out impact dynamics simulation of foreign object damage on a simulated blade numerical model; obtaining the relation between the macroscopic characteristics of the notch and the foreign object type, the impact speed and the impact angle, determining foreign object damage test conditions on the basis of the relation, carrying out an external simulated object damage test on the simulated blade by using an air cannon, and observing the macroscopic characteristics ofthe impact notch; Taking the static stress and the dynamic stress under the working load at the dangerous position of the front edge of the blade as the initial static load and the dynamic load of thehigh-cycle fatigue test, carrying out the high-cycle fatigue test on the damaged simulated blade, obtaining the high-cycle fatigue strength of the blade through a stepping method, and evaluating theFOD resistance of the blade according to the result of the high-cycle fatigue test; And carrying out foreign object damage simulation and high-cycle fatigue test on a small number of real blades to obtain the high-cycle fatigue strength of the real blades so as to verify the conformity of the simulated blades and the real blade test result.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

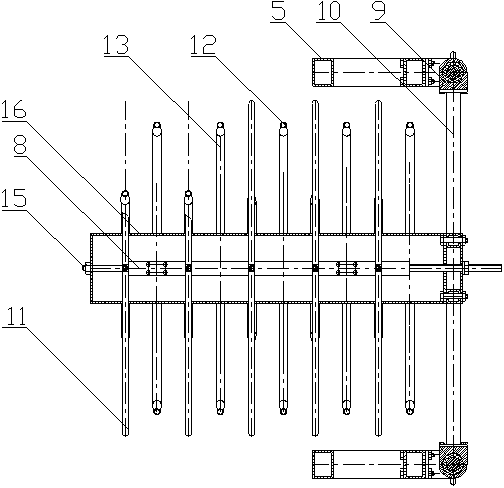

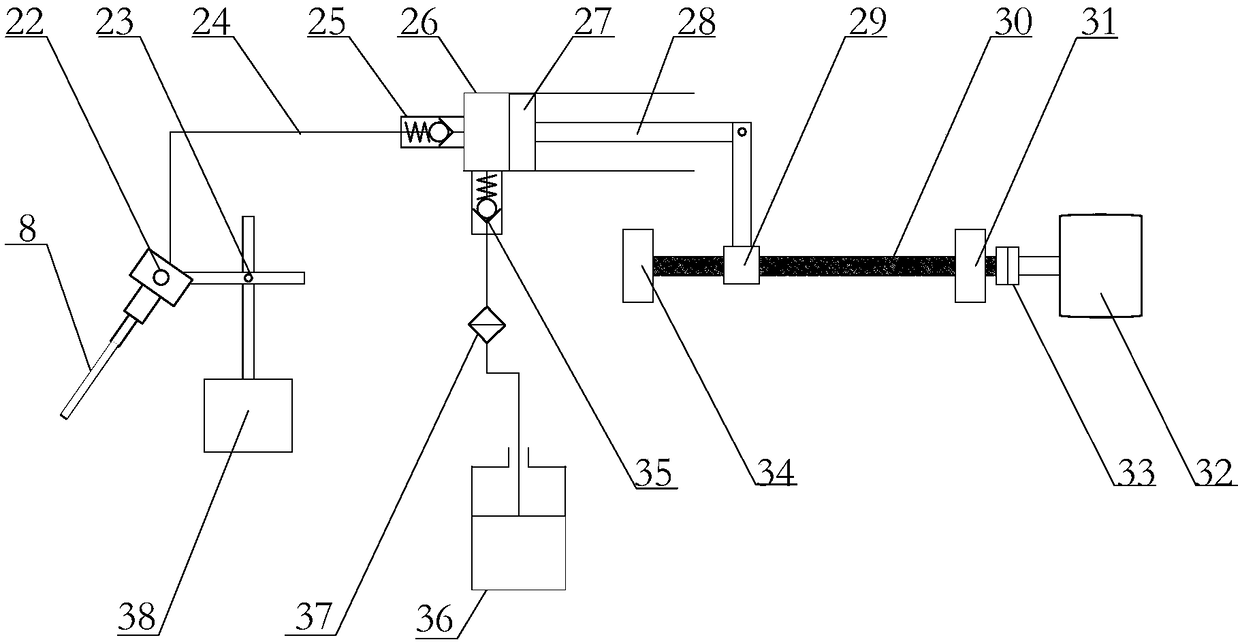

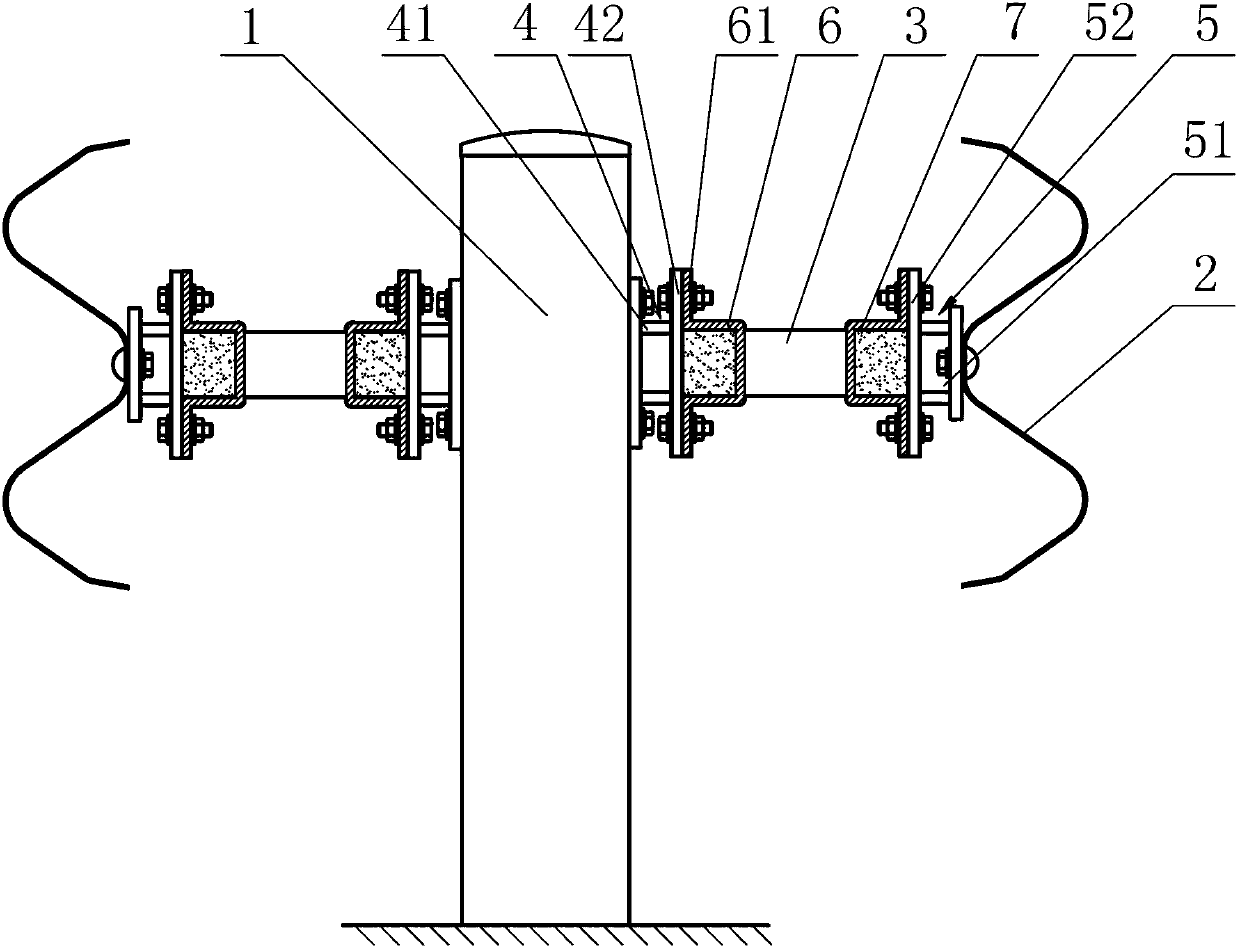

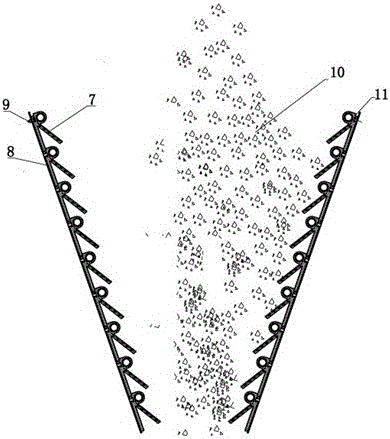

Impacted-pneumatic hybrid rice seed production pollination machine and method thereof

The invention discloses an impacted-pneumatic hybrid rice seed production pollination machine and a method thereof. The machine comprises a power chassis, a spike impact assembly and a blowing assembly, and the spike impact assembly and the blowing assembly are installed on the power chassis. The spike impact assembly is composed of a pull bar, a support, spike impact bars, a spike impact rack and the like, the pull bar is installed in the spike impact rack, the spike impact bars have a hinged joint with the pull bar and can slide in holes at two sides of the spike impact rack, and the spike impact angles of the spike impact bars can be adjusted by moving the pull bar; and the blowing nozzle of the blowing assembly is fixed below the spike impact assembly, and when pollens are slightly impacted by the spike impact bars and shed, the pollens transmit and diffuse with airflow blown by the blowing nozzle, and then settle to female parent stigmas to realize pollination. The machine which allows the impact to be adjusted through adjusting the angles of the spike impact bars and the pollens shredding after the slight impaction to be conveyed to the female parent through the airflow has the advantages of stable and uniform pollination, good pollination effect, small damages of the pollination process to plants, comfortable and convenient operation, high work efficiency, and suitableness for the large-scale hybrid rice seed production pollination.

Owner:ZHEJIANG UNIV

Laser electrochemical compound micromachining method and device for semiconductor material

ActiveCN108526627AImprove processing efficiencyReduce heat damageLaser beam welding apparatusElectrolysisSemiconductor materials

The invention discloses a laser electrochemical compound micromachining method and device for a semiconductor material, and belongs to the field of special machining. The method comprises the steps that the semiconductor material is heated with laser beams through the characteristic that the electric conductivity of the semiconductor material such as monocrystalline silicon is significantly increased along with increasing of the temperature, the electric conduction property of the material near a machining area is locally enhanced, an electric conduction channel that currents pass preferentially is formed, on this basis, electrolytic machining is introduced in a bias electro-hydraulic beam mode, laser electrochemical self-coupling combined machining near the machining area is achieved, tool setting is not needed, therefore, it is guaranteed that no surface residue adhesion occurs in the laser machining process, the cooling effect can be strengthened, and the purposes of reducing heat damage and residual stress and improving the machining surface quality are achieved. The device comprises a laser, an external light path, an electrolytic power supply and a stable jet flow generatingdevice. The device can generate stable low-voltage electrolytic solution jet flow and achieve impact angle and position adjustment, and it is guaranteed that precise adjustment of the relative positions between the laser beams and the impact jet flow is achieved.

Owner:JIANGSU UNIV

Airbag head hammer falling static testing device

InactiveCN102680200AAdjustable positionAdjustable impact angleVehicle testingShock testingAutomatic controlEngineering

The invention relates to an automobile testing device, in particular relates to an airbag head hammer falling static testing device. The head hammer is oriented by rolling a roller wheel on a guide track so as to control the impact point of the head hammer; the elevating height of the head hammer is controlled automatically so as to ensure the speed of impacting the airbag; the explosion of the airbag and the separation of the head hammer from a suspension frame mechanism are controlled automatically, so that the influence of the suspension frame mechanism to the collision response is eliminated; the suspension frame mechanism can adjust the position of the head hammer at the front, the back, the left and the right; and the airbag adjusting mechanism can adjust the inclination angle and the front and the back positions of the airbag. The impact angle and the position of the head hammer to the airbag are adjustable; and the quality of an impact object can be controlled; the collision position, the angle and the mass of the object are ensured to accord with a corresponding automobile model; and the test is good in repeatability effect.

Owner:HUNAN UNIV

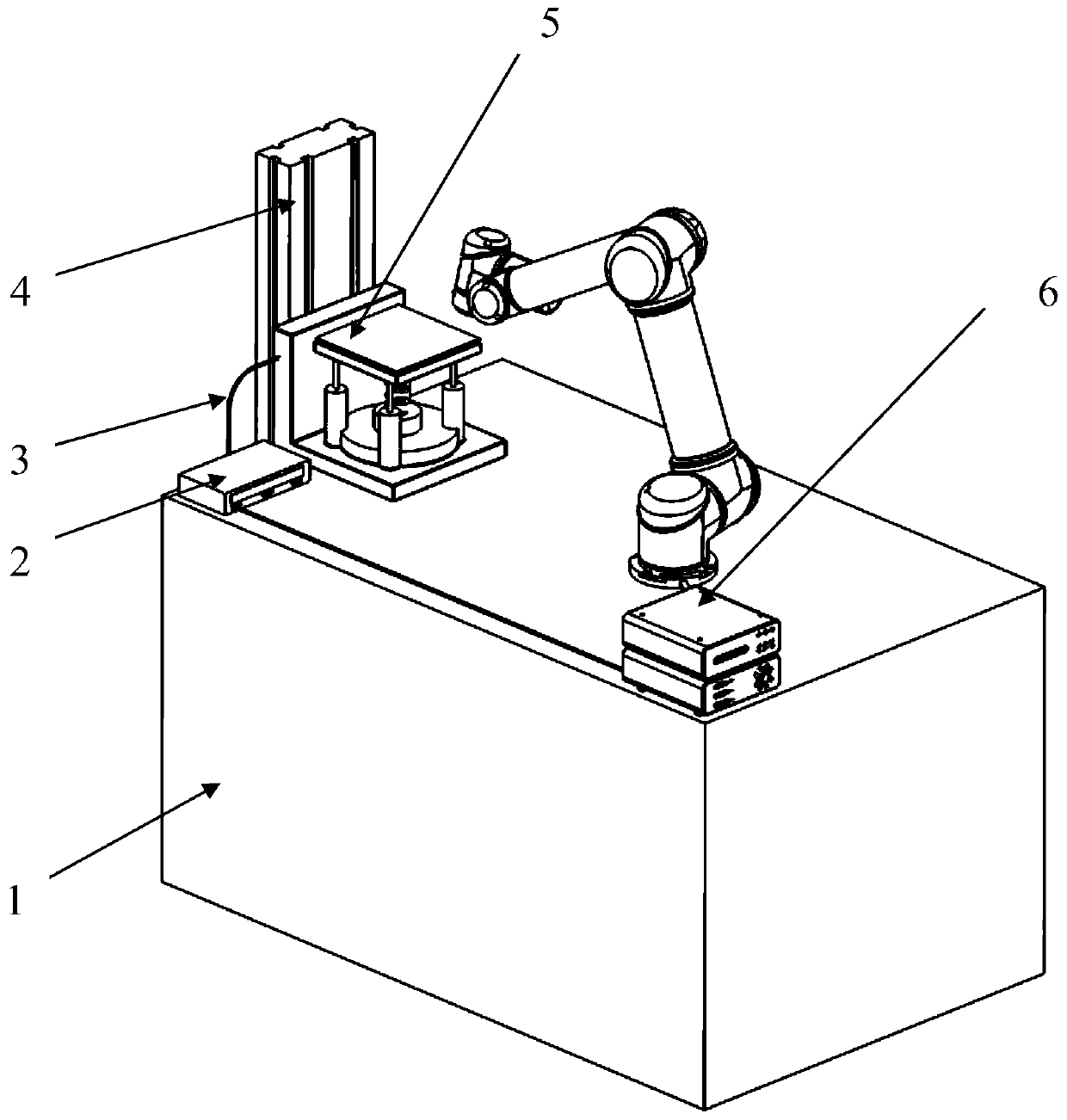

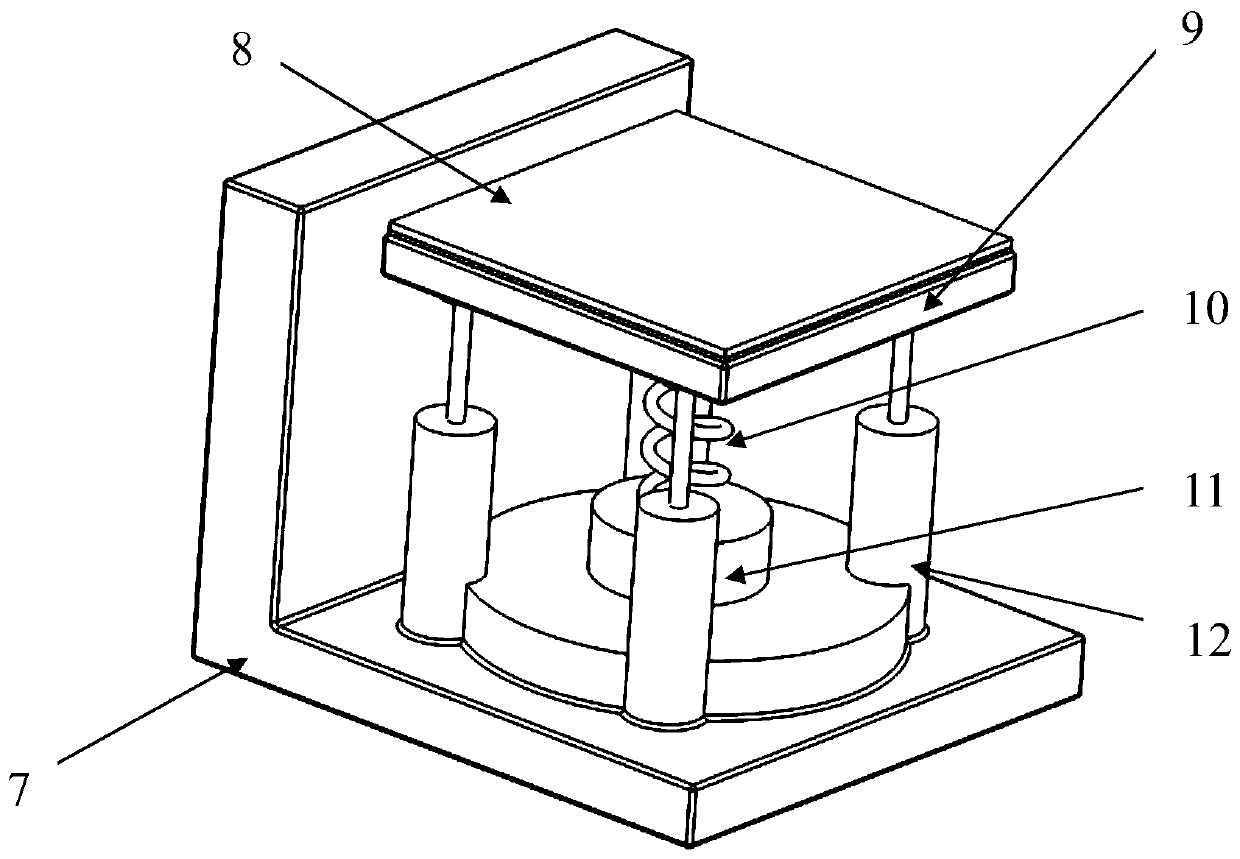

Collaborative robot collision safety test system and test method

InactiveCN110154087ARealize real-time pressure distributionEasy to useManipulatorSynchronous motorSynchronous control

The invention discloses a collaborative robot collision safety test system and test method, and belongs to the technical field of collaborative robots. The test system comprises an experiment table, an angle adjusting base, a force sense system, a synchronous control system and a test instrument; the angle adjusting base is fixed to the side face of the experiment table, according to different robot impact angles, a fixed base of the force sense system is fixed to the upper surface of the experiment table or the angle adjusting base, the synchronous control system and the test instrument are fixed to the upper surface of the experiment table, the force sense system is connected with the input end of the synchronous control system through a communication cable, and the output end of the synchronous control system is connected with the test instrument. The test system and method are specially used for testing the contact force of the collaborative robot, use is convenient, and the measuring work efficiency is high.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

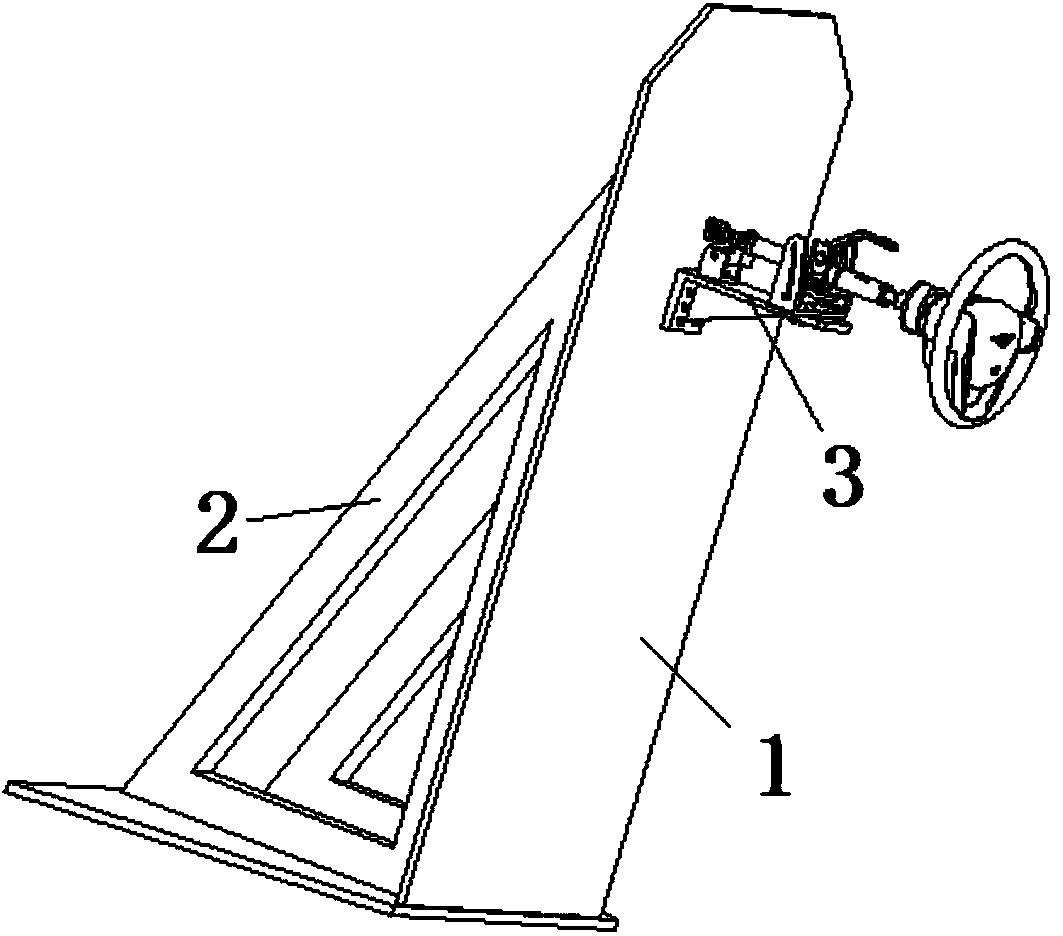

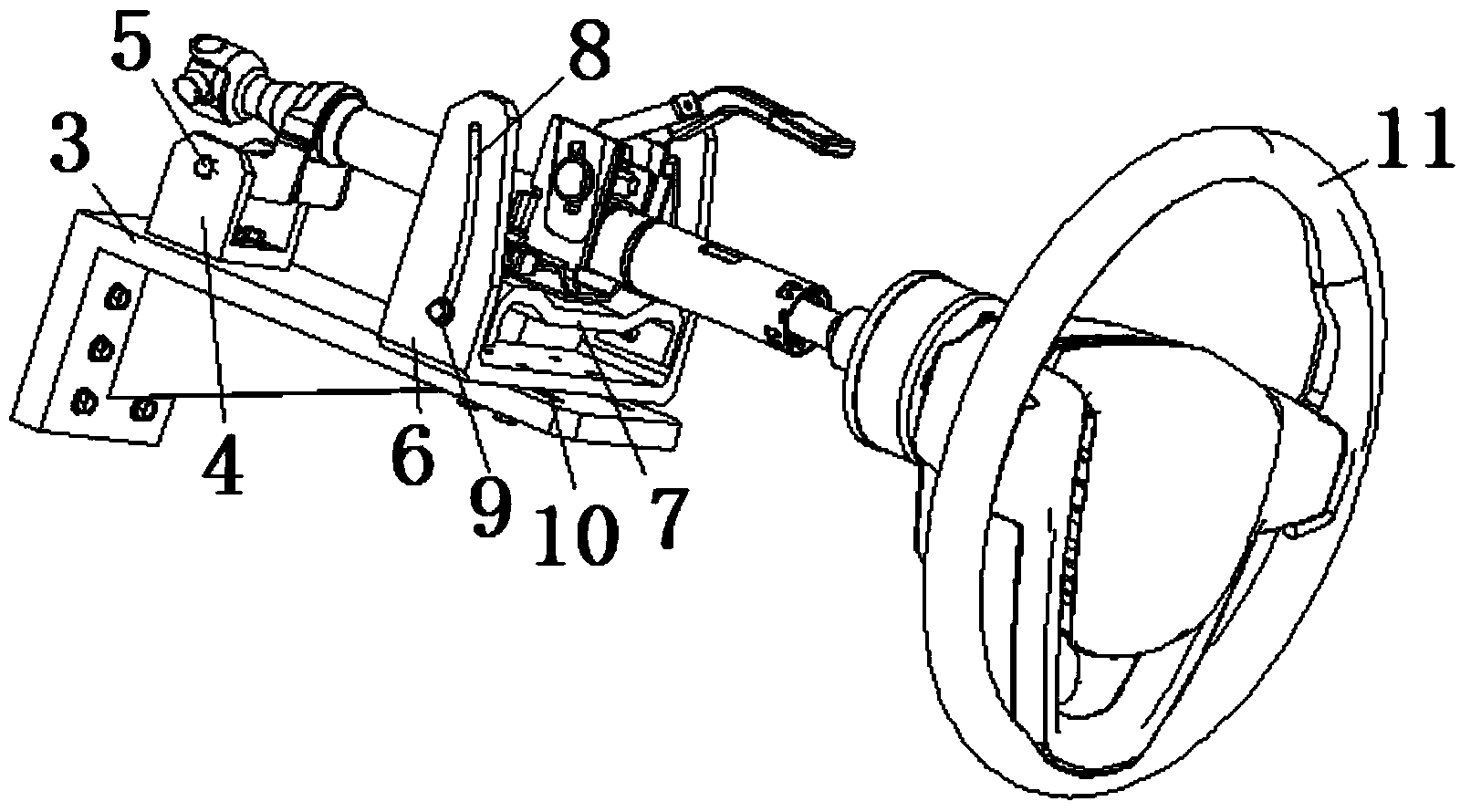

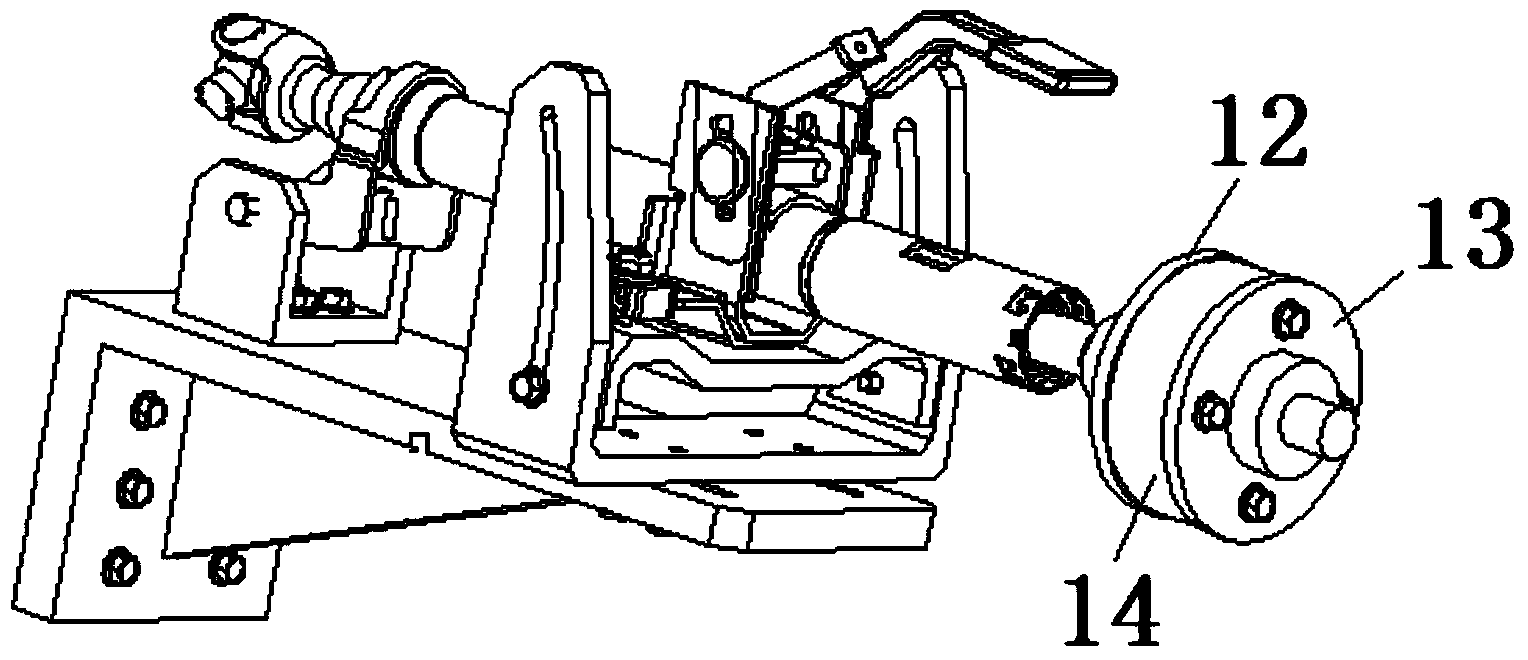

Dynamic impact test bed for automobile steering column

ActiveCN104019953ATruly reflect the crushing situationSimple structureShock testingSteering columnEngineering

The invention discloses a dynamic impact test bed for an automobile steering column. The dynamic impact test bed comprises a fixing base. The fixing base is provided with a U-shaped support and a U-shaped plate, wherein the U-shaped support is used for being hinged to a lower fixed point of the steering column, and the U-shaped plate is used for fixing an upper fixed point of the steering column. A fixing plate connected with the upper fixed point of the steering column is arranged in the U-shaped plate. The fixing plate is arranged in the U-shaped plate in a movable and adjustable mode relative to the fixing base. The U-shaped plate is arranged on the fixing base in a movable and adjustable mode relative to the U-shaped support. By the adoption of the dynamic impact test bed, the angle and the distance between the fixed points of the steering column can be adjusted; the dynamic impact test bed can be applied to dynamic impact tests of the automobile steering columns with different vehicle types and different impact angles and can truly reflect the crushing conditions of the steering column in the actual impact process.

Owner:CHERY AUTOMOBILE CO LTD

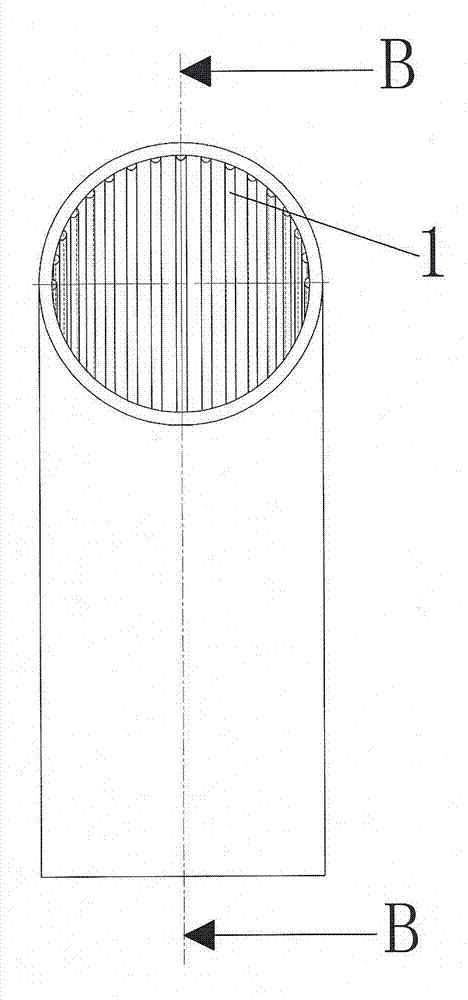

Rotary type liquid-solid two-phase flow erosive wear test device

InactiveCN102564934ASimple designSimple structureWeighing by removing componentWeather/light/corrosion resistancePipe fittingCoupling

The invention discloses a rotary type liquid-solid two-phase flow erosive wear test device. A variable frequency motor is arranged at the upper end of a bell-shaped cover; a stirring shaft passes through an upper installation plate and a lower installation plate from bottom to top and is connected with a shaft head of the variable frequency motor through a coupler; the tail end of the stirring shaft passes through a rotary table; eight test pieces are uniformly arranged in eight opened grooves which are arranged at the edge of the rotary table at intervals; the upper installation plate and the lower installation plate are welded by a coupling sleeve; a slurry tank filled with a fluid medium is connected and fixed with the lower installation plate; and stirring blades are uniformly distributed and fixed inside the rotary table in a manner of forming a 15-degree angle with the horizontal plane. The test device can realize testing to the erosive wear characteristic of different materialsby utilizing the characteristic that the variable frequency motor generates different rotation speeds so as to obtain the functional relations between the erosive wear rate and the variables such as material characteristics, rotation speeds and impact angles, therefore the test device can provide important data support for erosive wear prediction of engineering actual pipelines and is applicable to research on safety guarantee technologies such as erosive wear predication and optimal design of pipe fittings such as multiple-phase flow pipelines and valves in the fields of petrochemical industry and coal chemical industry.

Owner:HANGZHOU FURUDE TECH

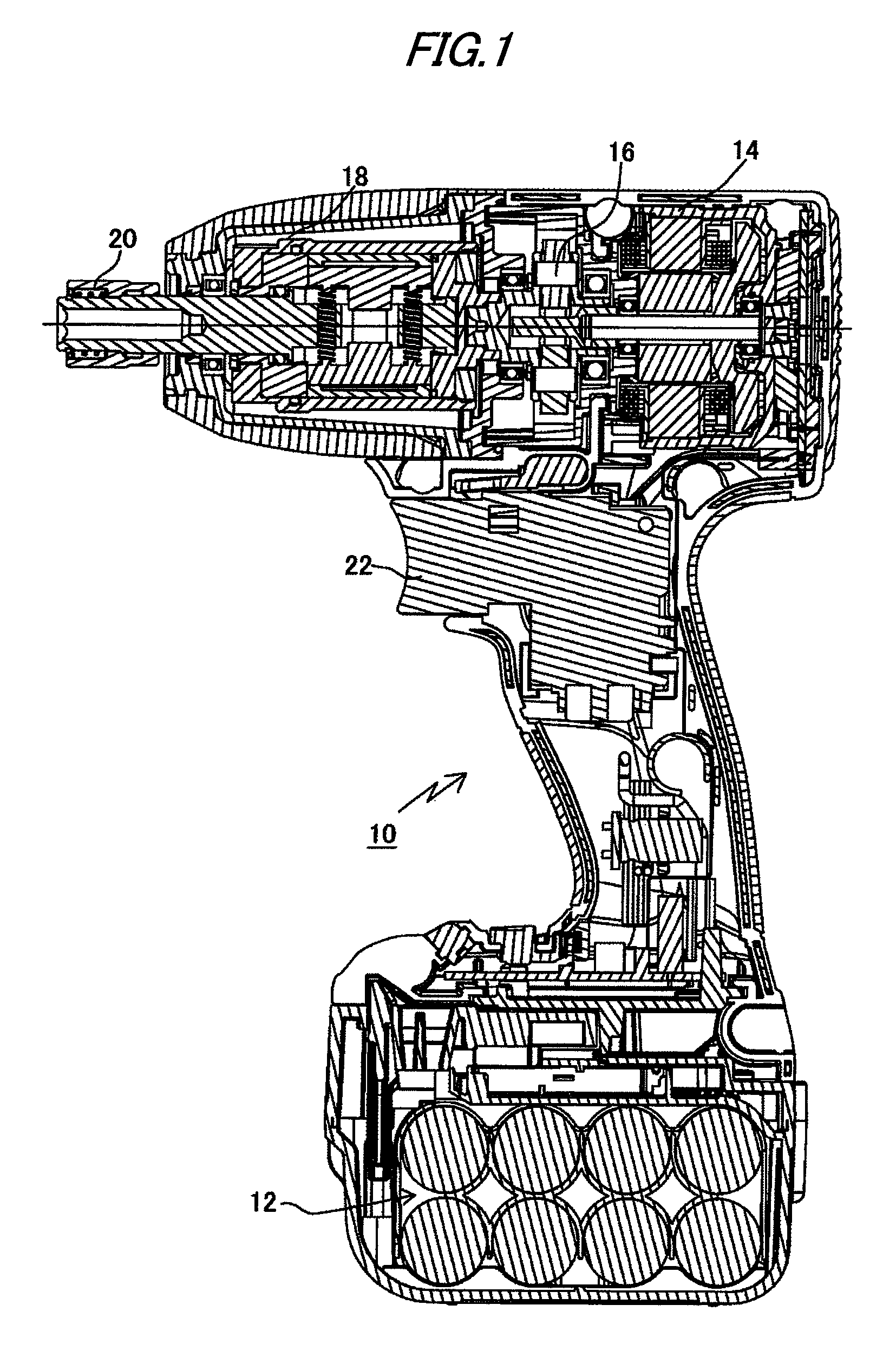

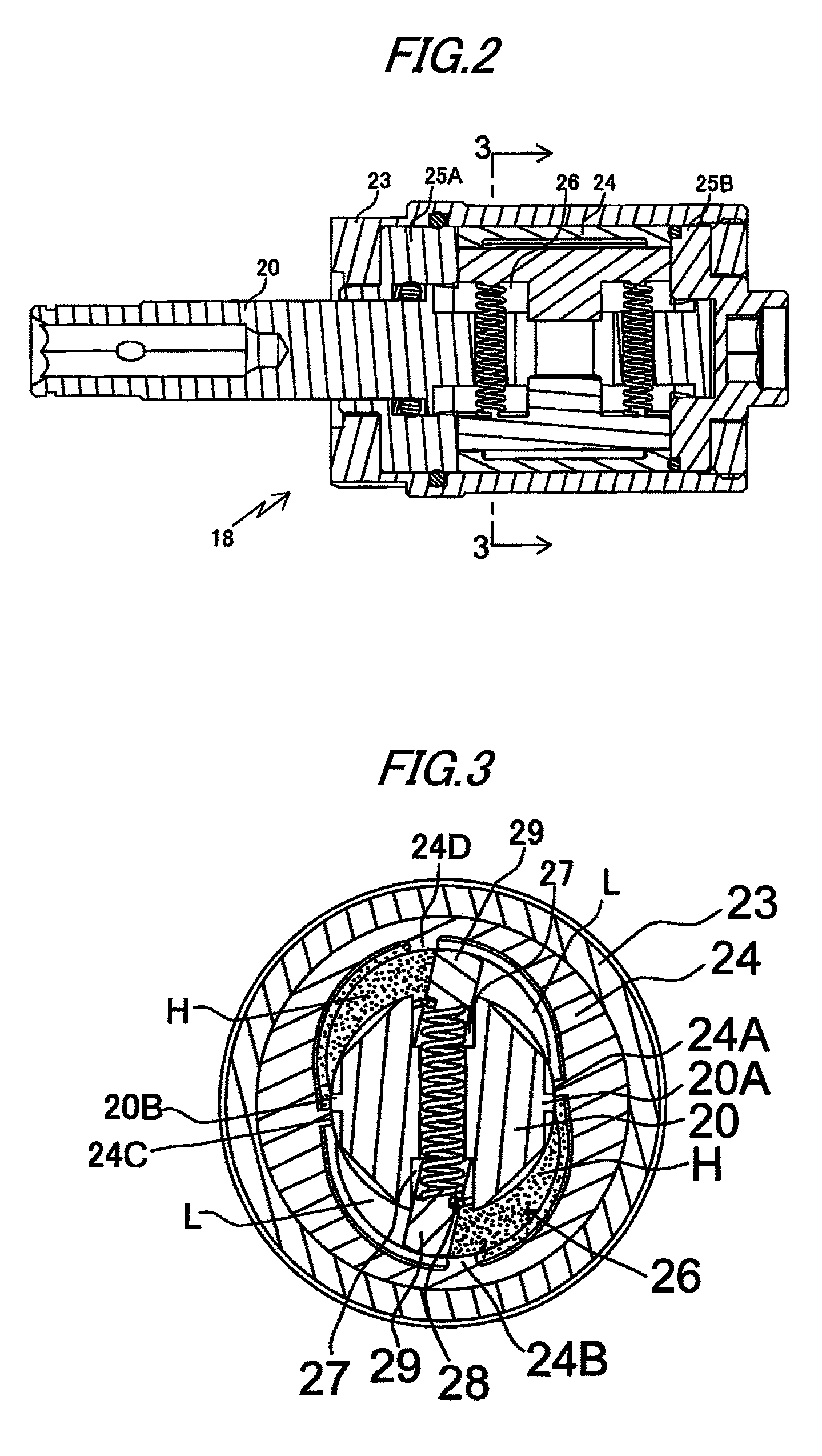

Electric power tool and motor control method thereof

ActiveUS20100252287A1Smooth fastening operationReduce speedPortable percussive toolsSpannersRotation velocityMotor control

An electric power tool is provided with: a motor; a hydraulic pressure generator driven by the motor and configured to generate a plurality of impacts in one revolution thereof; an impact angle detector configured to detect an impact angle in one impact of the hydraulic pressure generator; an electric current detector configured to detect an electric current applied to the motor; a determination unit configured to determine an impact failure based on the impact angle and the electric current detected by the impact angle detector and the electric current detector; and a rotation controller configured to decrease a rotation speed of the motor when the determination unit determines the impact failure.

Owner:MAX CO LTD

High-cold wind-sand environment wheel rail abrasion simulation experimental device

ActiveCN104634685AFacilitate conductionReduce the temperatureInvestigating abrasion/wear resistanceFriction torqueEngineering

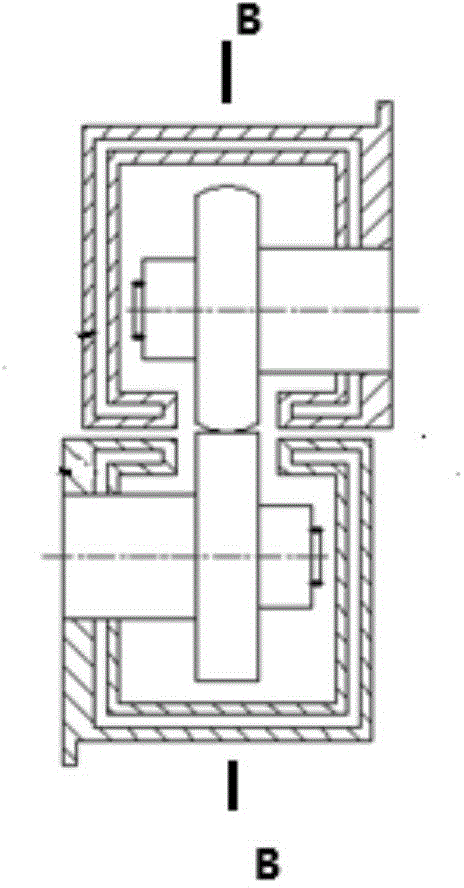

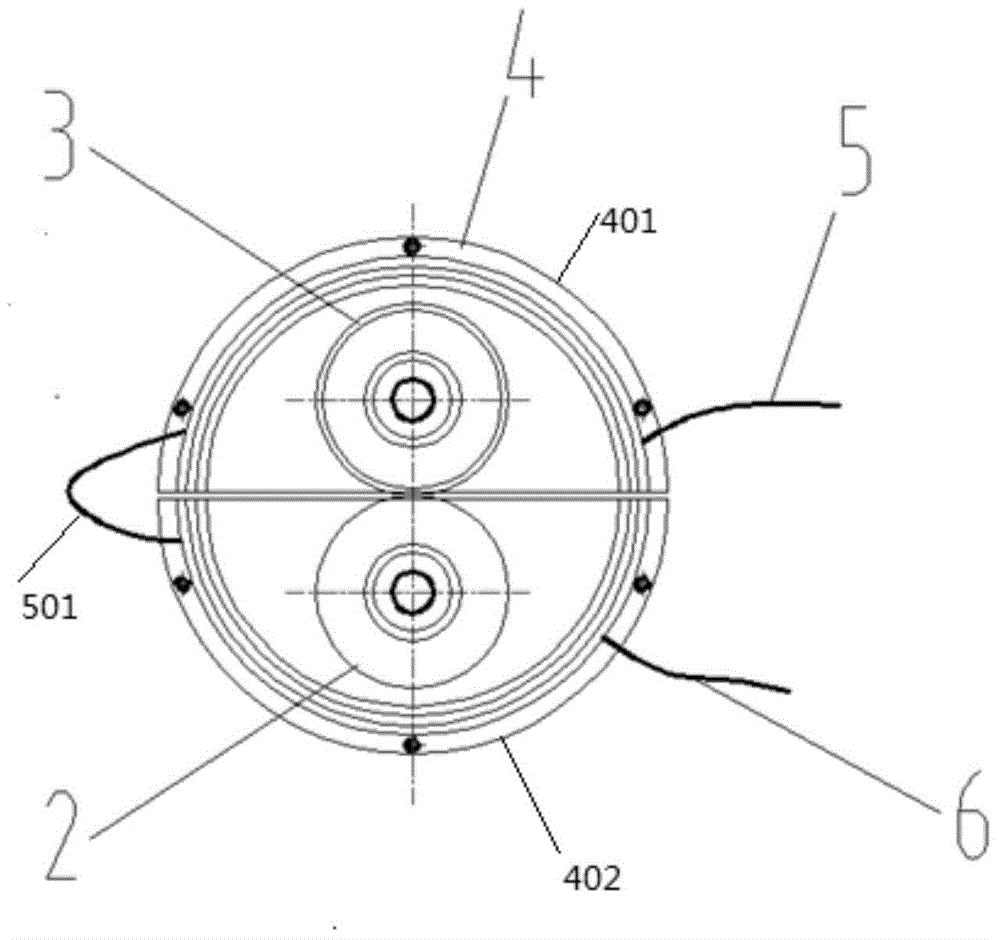

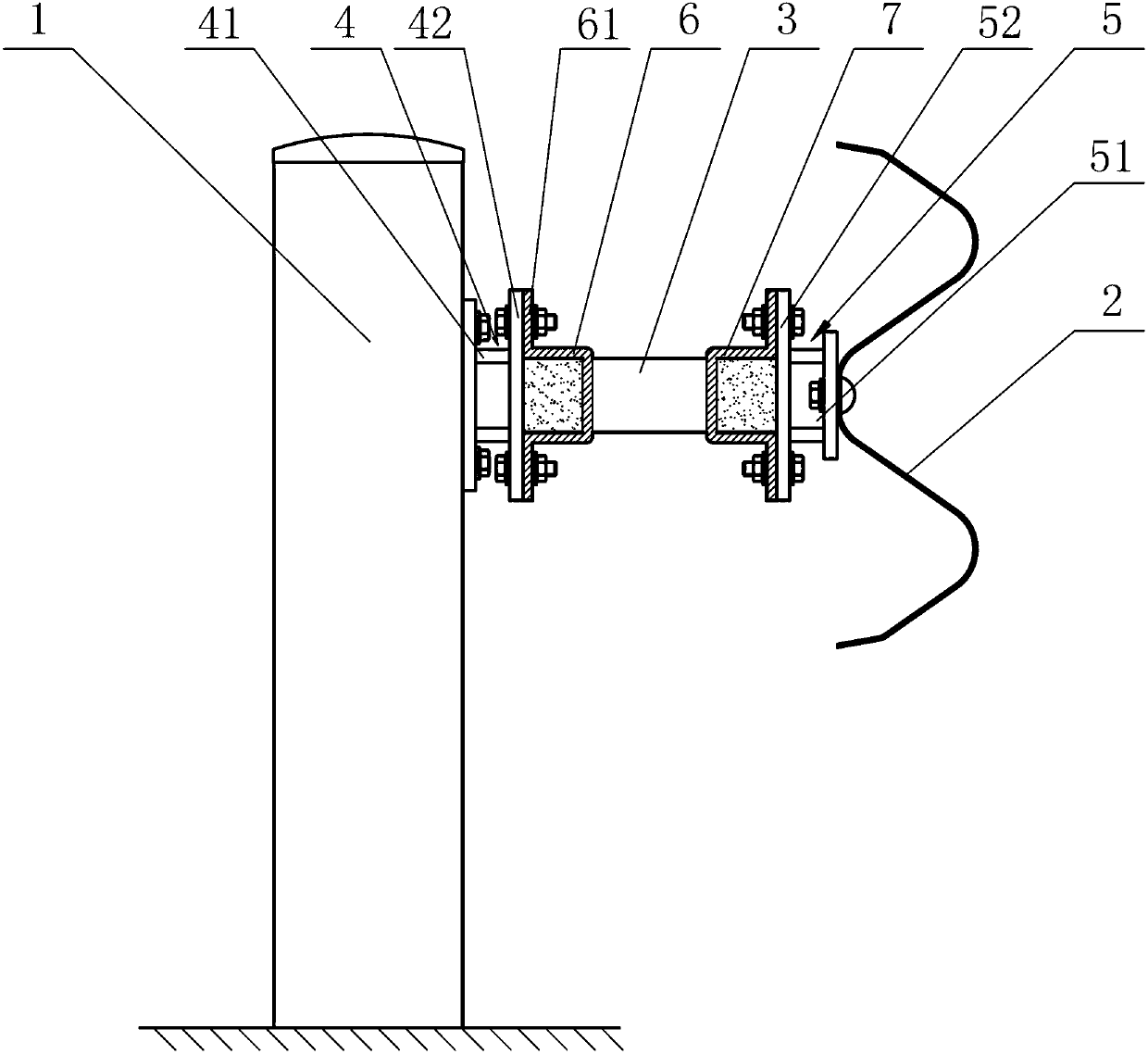

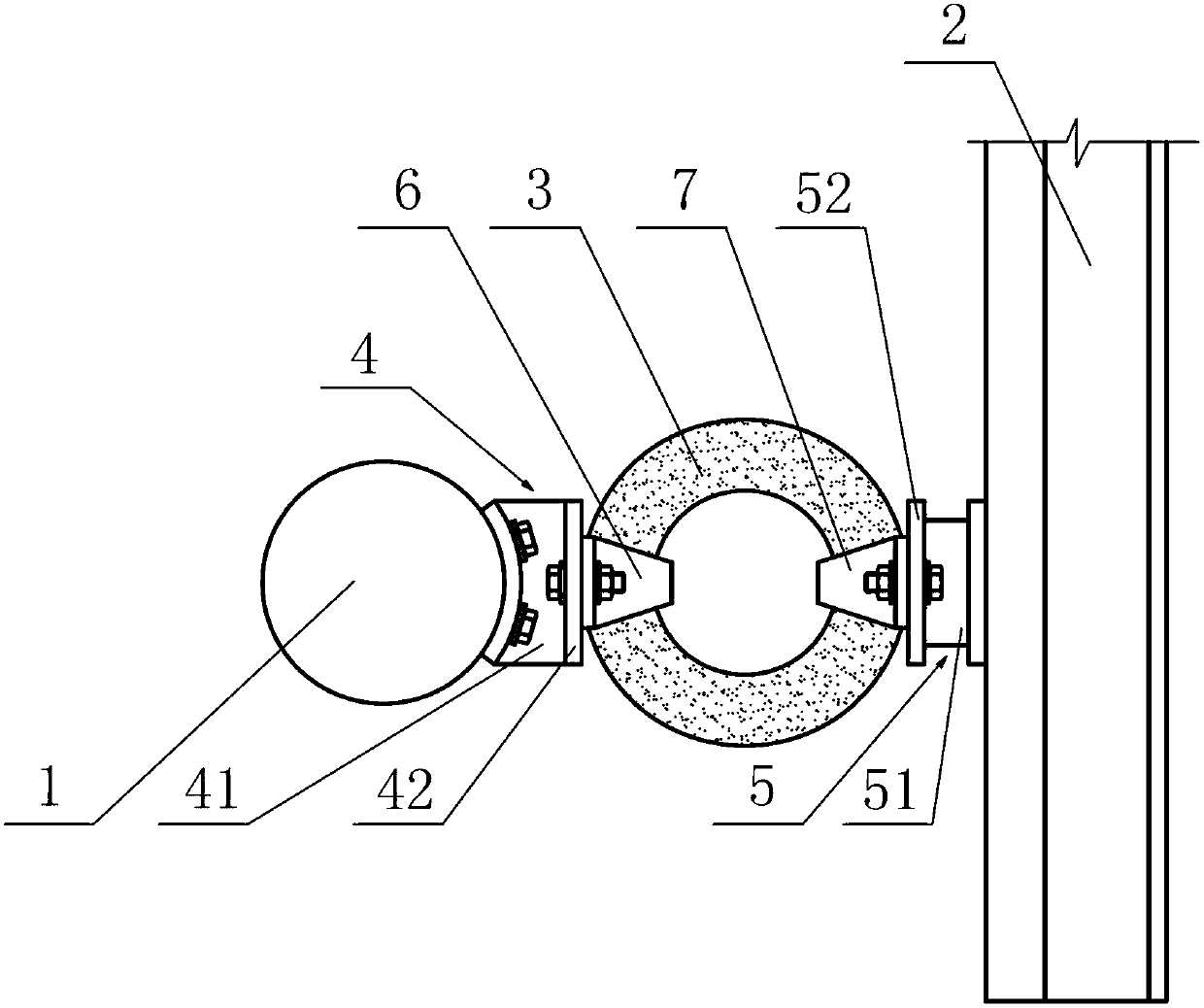

The invention discloses a high cold wind sand environment wheel rail abrasion simulation experimental device. The high cold wind sand environment wheel rail abrasion simulation experimental device consists of a wheel rail rolling abrasion test rack and a wheel rail rolling abrasion simulation auxiliary system. A low-temperature cavity wind-sand environmental cavity (4) is communicated with a wind-sand simulation control unit by virtue of a sand conveying pipe (16); the low-temperature cavity wind-sand environmental cavity (4) is a double-layer cavity which is made of a copper alloy and is provided with an upper part and a lower part, namely an upper cavity (401) and a lower cavity (402); a refrigerant connecting pipe (501) is connected to the upper cavity (401) and the lower cavity (402); an upper refrigerant pipe (5) is used for inputting refrigerant prepared by a low-temperature cavity unit into the upper cavity (401), and a lower refrigerant pipe (6) is used for conveying the refrigerant of the lower cavity (402) back to the low-temperature cavity unit. By adopting the high-cold wind-sand environment wheel rail abrasion simulation experimental device, a high-cold wind-sand environment can be simulated, the interactive relationship of factors such as temperature, wind-sand conditions, applied load, rotation speed of a test piece, slide difference, an impact angle, friction torque, experiment time, post experiment forms and the like can be accurately and reliably analyzed, and reliable experimental data can be provided for researching a wheel rail abrasion mechanism and building a measure for alleviating the abrasion.

Owner:SOUTHWEST JIAOTONG UNIV

Highway guardrail with good energy absorption capacity

InactiveCN103015347AImprove flexibilityImprove featuresRoadway safety arrangementsRubber ringEnergy absorption

The invention discloses a highway guardrail with good energy absorption capacity, which comprises an upright column and a guardrail plate arranged on at least one side of the upright column, and is characterized in that a rubber ring obstruction block is fixedly arranged between the upright column and the guardrail plate, a first connecting block is fixedly arranged on the upright column, a second connecting block is fixedly arranged on the guardrail plate, a first lantern ring and a second lantern ring are arranged on the rubber ring obstruction block and symmetrically arranged along the central line of the rubber ring obstruction block, and the rubber ring obstruction block is fixed with the first connecting block through the first lantern ring, and fixed with the second connecting block through the second lantern ring. The highway guardrail has the advantages that the rubber ring obstruction block is arranged between the upright column and the guardrail plate, as rubber has good flexibility and viscoelasticity, and when a vehicle with a certain mass bumps onto the highway guardrail at a certain impact angle at a certain speed, the rubber ring obstruction block can absorb the impact kinetic energy of the vehicle greatly to protect the double corrugated steel sheet from greater deformation, so that the vehicle is guided to the right lane at a smaller angle.

Owner:NINGBO UNIV

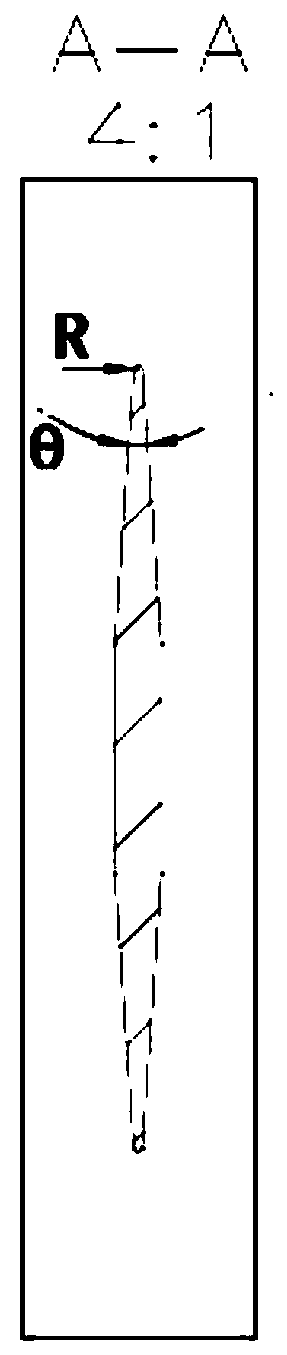

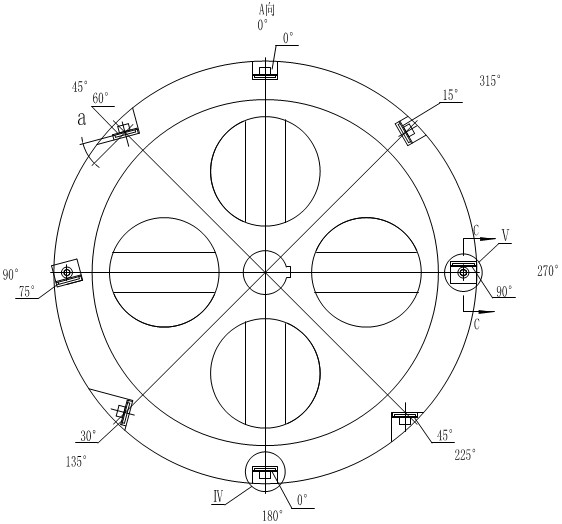

Testing component of rotary liquid-solid two-phase flow erosive wear testing device

InactiveCN102830056AReduce calculation errorsSimple structureWeather/light/corrosion resistanceWear testingVertical plane

The invention discloses a testing component of a rotary liquid-solid two-phase flow erosive wear testing device. Eight test pieces to be tested are arranged in rectangular grooves of respective test piece fastening plates respectively; the test piece fastening plates are attached and fixedly connected with rectangular tangential planes of respective test piece racks by using screws; eight equal grooves are formed in a circular ring fixing frame; oblong tables at the bottoms of the test piece racks are embedded into the corresponding grooves of the circular ring fixing frame to be fixedly connected by using screws; and the circular ring fixing frame is welded with the inner wall of a slurry tank. The eight test piece racks all consist of upper semi-cylinders and lower oblong tables, and are arranged at angles of 0 degree, 15 degrees, 30 degrees, 45 degrees, 0 degree, 60 degrees, 75 degrees and 90 degrees with a central vertical plane in length direction of the oblong tables. According to the testing component, test pieces at different impact angles can be simultaneously tested, and the calculation errors of the actual impact speed and the impact angle are reduced; and the testing component is suitable for test of wear resistant properties of different materials and research of an erosive wear rule under various influencing factors.

Owner:HANGZHOU FURUDE TECH

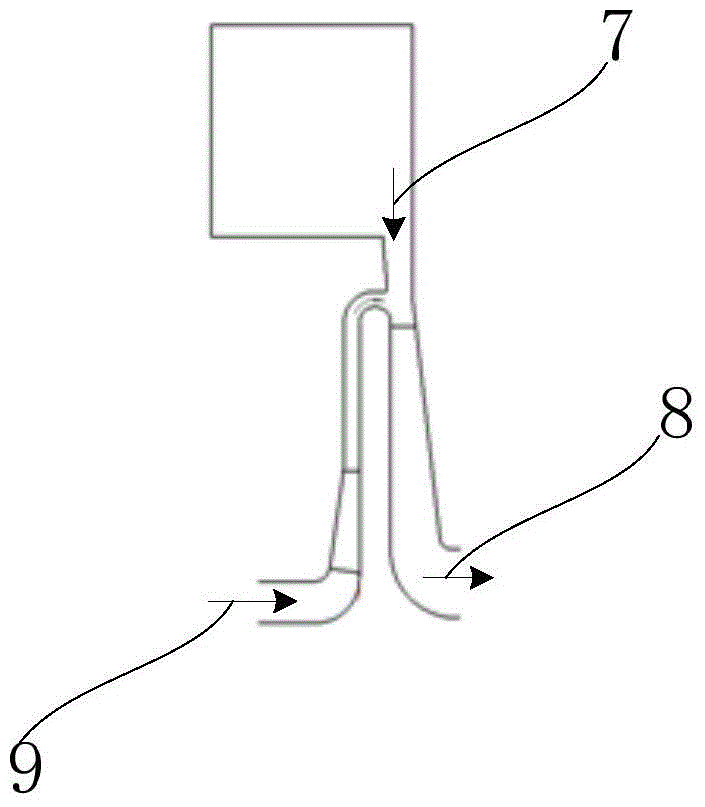

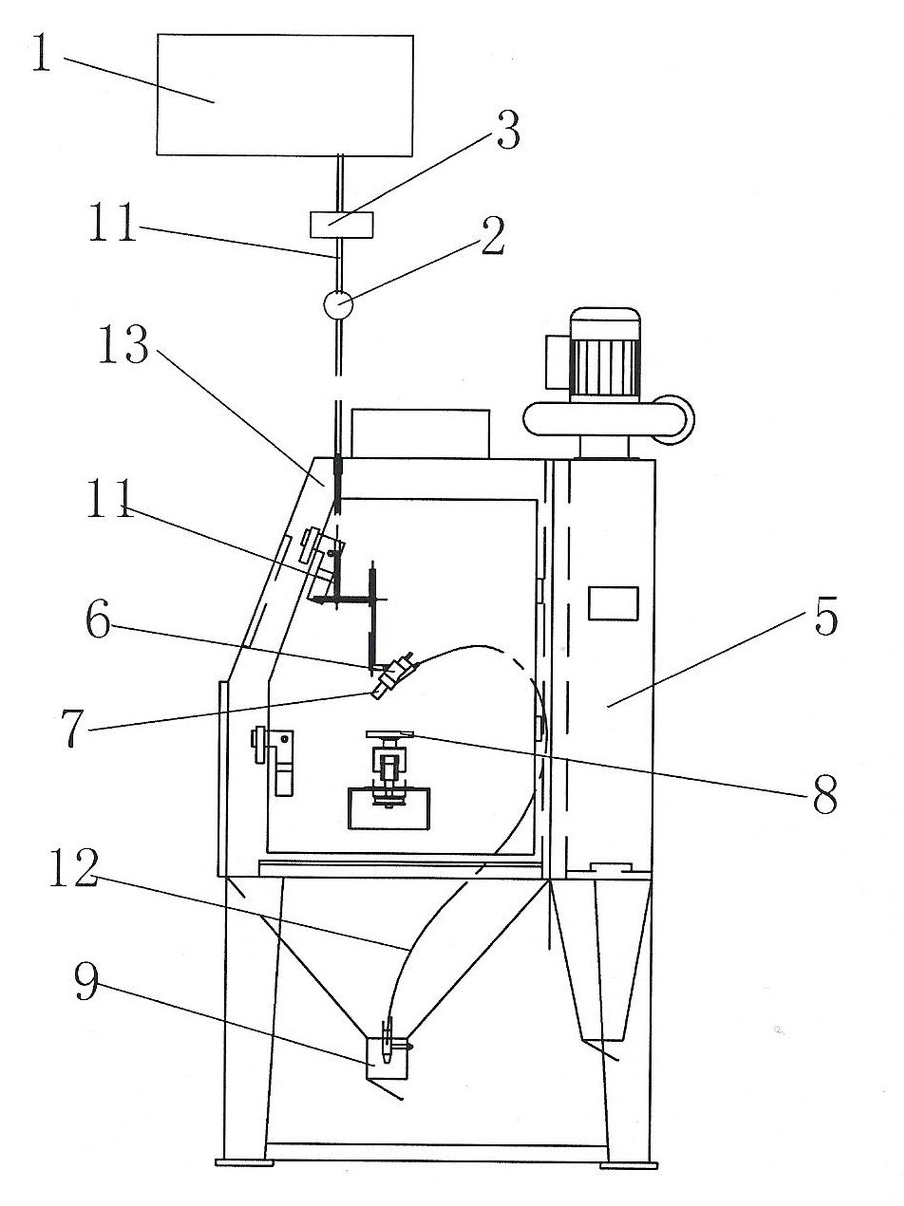

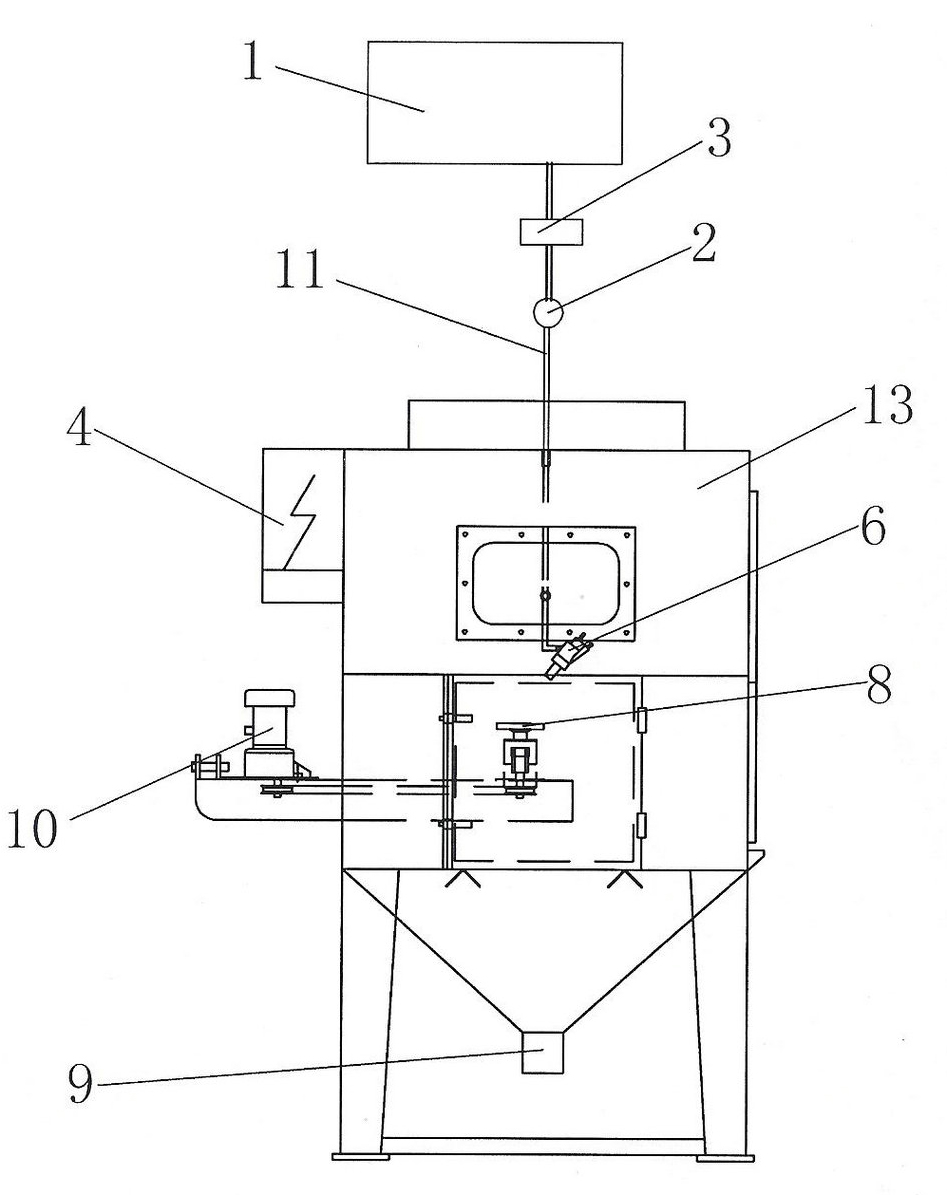

Testing device for detecting impact friction abrasion of workpiece

ActiveCN103528908ATest the anti-friction abilityExtend your lifeInvestigating abrasion/wear resistanceEngineeringDust collector

A testing device for detecting impact friction abrasion of a workpiece comprises a rack and a work chamber on the rack. A sand leaking plate used for recycling abrasives is arranged on the bottom face of a box body of the work chamber. A conical transition cavity is formed below the sand leaking plate. The conical transition cavity is communicated with an abrasive storage cavity, and discharged materials of the abrasive storage cavity are driven to be conveyed to a material conveying pipe through compressed air. An abrasive output opening and a clamp and a sample clamp of the abrasive output opening are arranged in the box body. The sample clamp is mounted on a nonflexible adjusting device, and the angle of a sample can be adjusted through the nonflexible adjusting device. The testing device further comprises a dust collector used for dedusting the inside of the work chamber. The testing device for detecting the impact friction abrasion of the workpiece is simple and reliable in sample operation, compact in structure, suitable for samples of different specifications, and capable of enabling the positions of the samples to be adjusted so that various working conditions can be simulated. An abrasive nozzle can also be firmly clamped, and the impacting angle to the samples can be adjusted. In addition, the abrasives can be used in a recycling mode, and the abrasives are saved.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

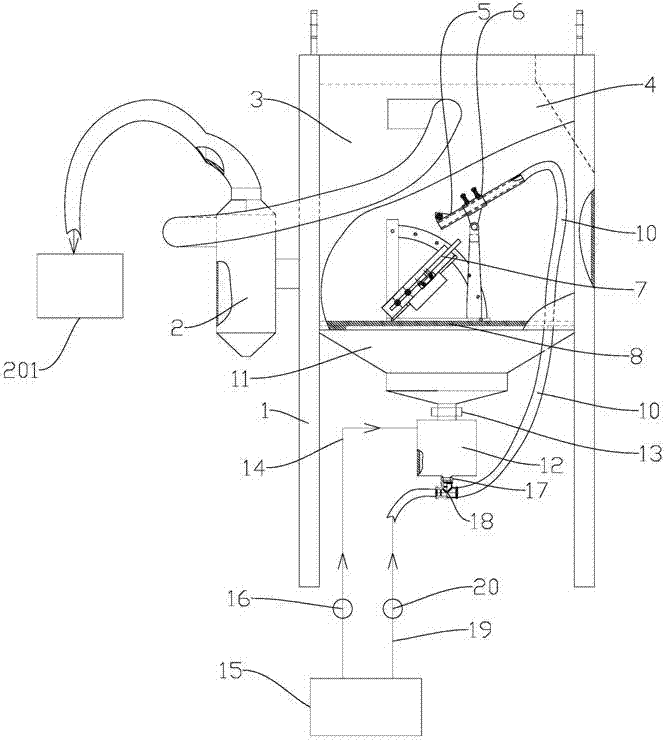

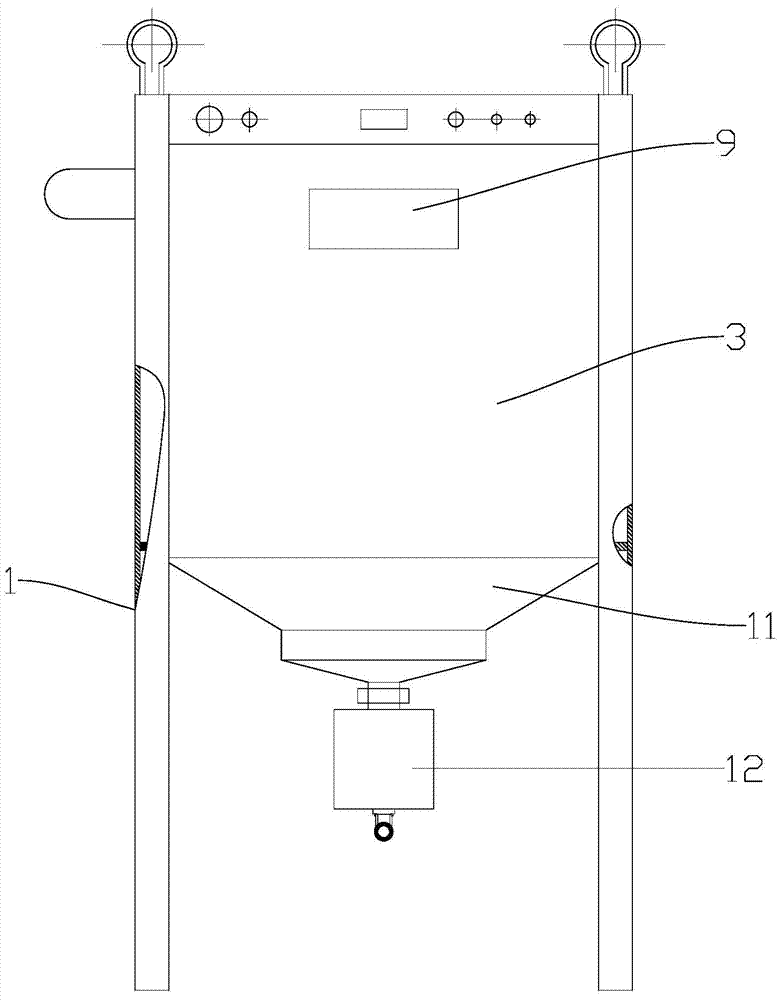

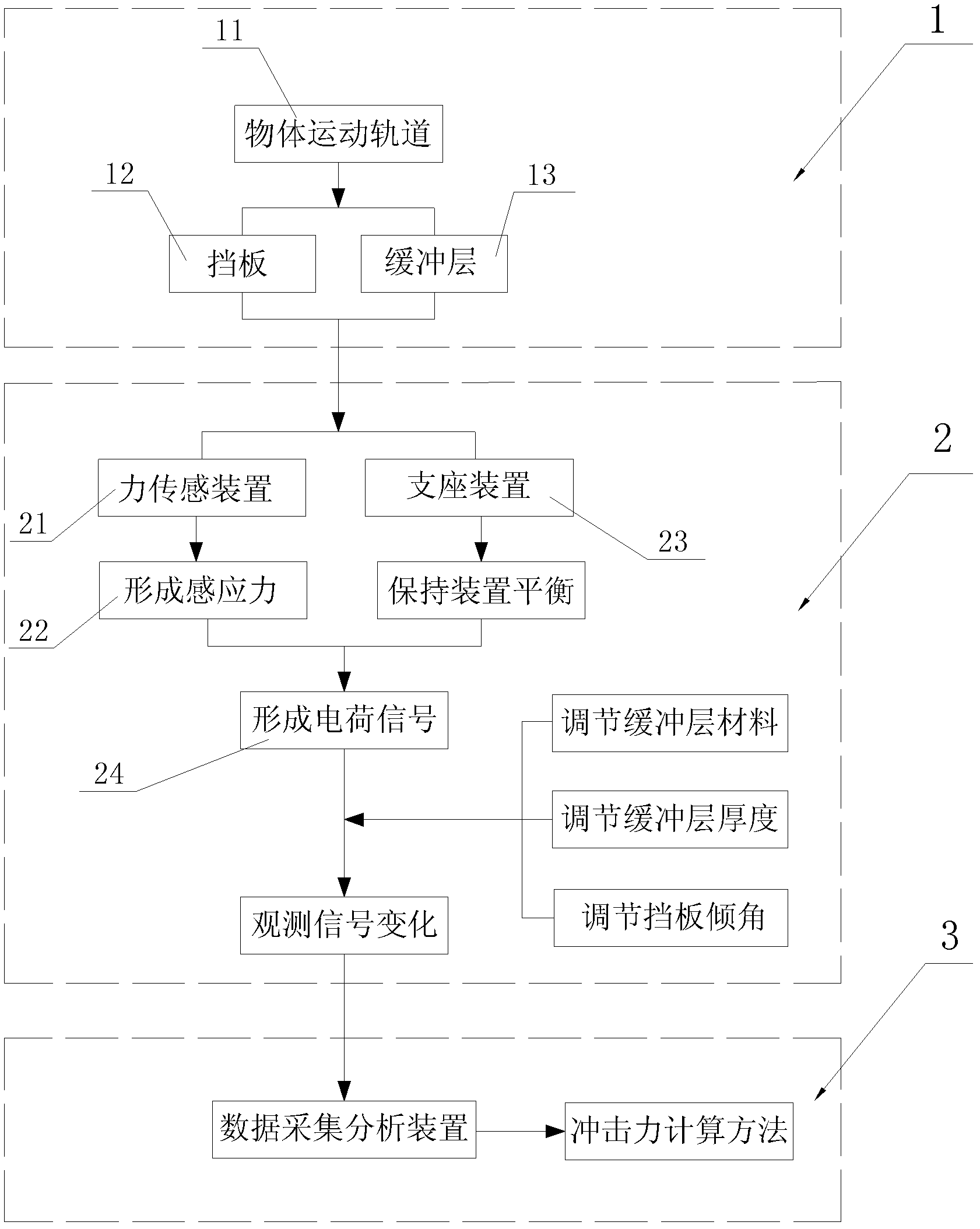

Rolling stone impact force testing device

The invention relates to a rolling stone impact force testing device, and relates to the measurement technology of geological engineering. The rolling stone impact force testing device comprises a bottom support, an upper baffle and a lower baffle, wherein the upper baffle and the lower baffle are overlappedly arranged and are connected by a connecting part, and a force sensor is arranged at the connecting part; and a buffer layer made of an elastic material is arranged on the upper surface of the upper baffle, and the bottom support comprises an angle adjustment device and is connected with the lower baffle. The rolling stone impact force testing device has the beneficial effects that: different impact angles and different impact speeds of impact objects can be simulated, different buffer materials are selected, different buffer thicknesses are set, and thereby the magnitude of the impact force of the impact objects can be tested.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

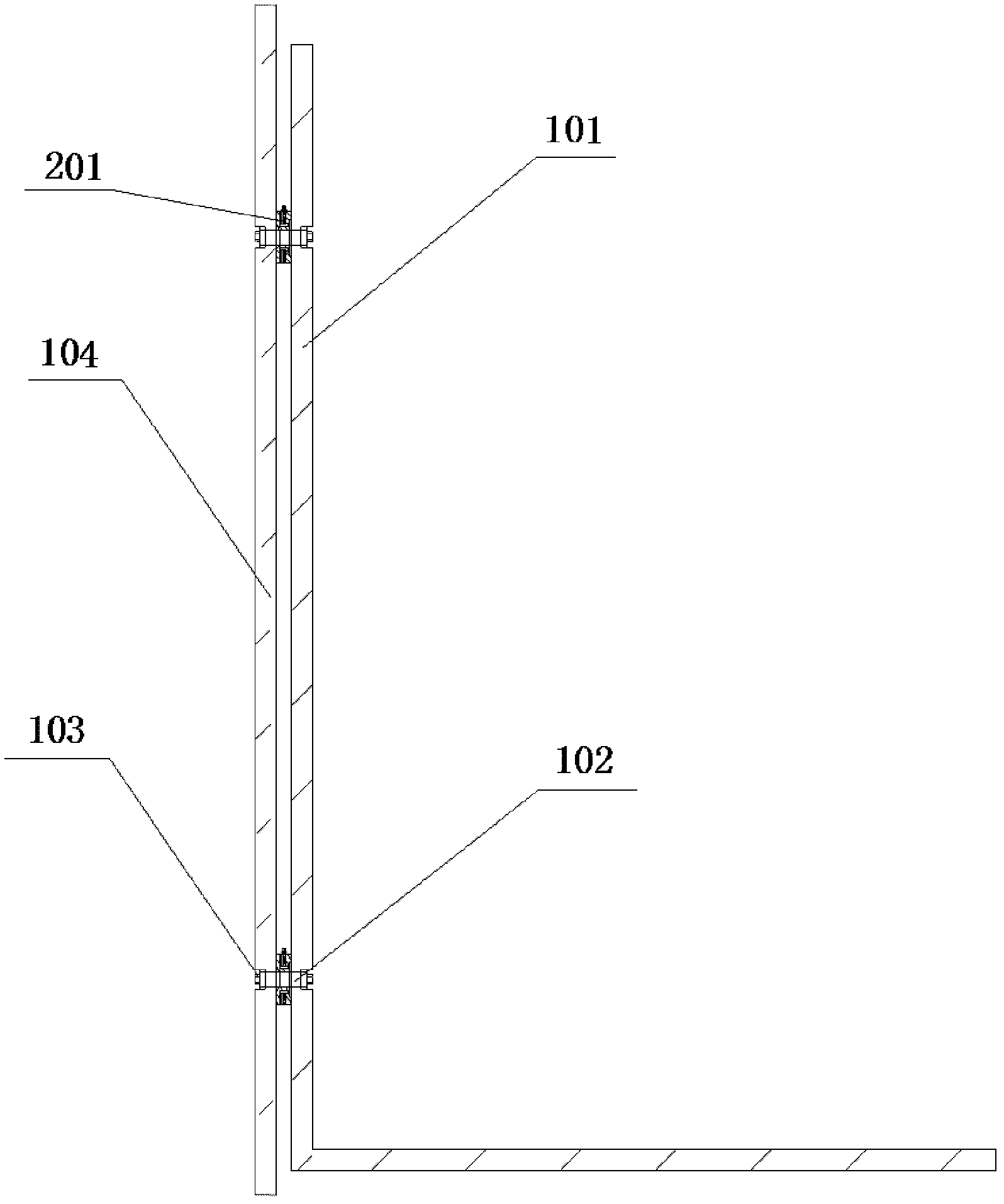

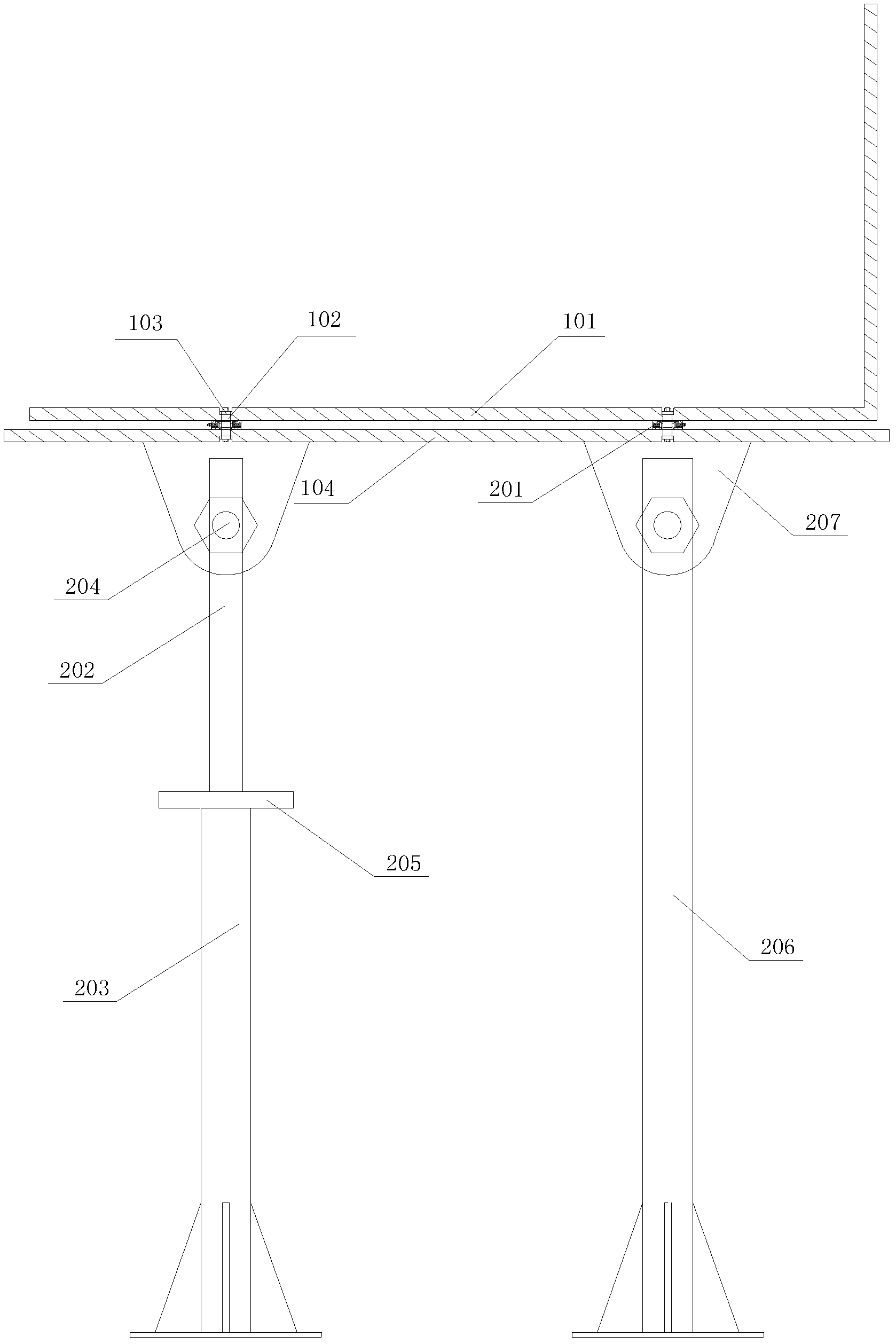

Impact resistance test device for overhead rail glass

InactiveCN101825539AHanging height adjustableAdjustable hanging angleStrength propertiesLocking mechanismEngineering

The invention relates to the technical field of quality detection device of building engineering, in particular to an impact resistance test device for overhead rail glass, which solves the problems of the prior art such as high detection cost, inconvenient transportation and the like. The impact resistance test device for overhead rail glass comprises a frame, a rope and an impact hammer, wherein one end of the rope is fixedly connected with the frame, and the other end is fixedly connected with the impact hammer; the frame is provided with an angle indication mechanism for displaying the impact angle; the angle indication mechanism is connected with the frame through a detachable structure; a locking mechanism is arranged between the rope and the frame; and the locking mechanism and the frame are connected through a detachable structure. The invention has the following advantages: 1, the split detachable structure is convenient to assemble, disassemble, transport and load and flexible and convenient to use, and is particularly applicable to the construction site; 2, spot check of the installation quality is available anytime so as to discover and correct the construction deviation, thus improving the security of glass rail and effectively lowering the detection cost; and 3, the hanging height and hanging angle of the impact hammer can be adjusted, thus ensuring wide application range.

Owner:常州华厦建设工程质量检测有限公司 +1

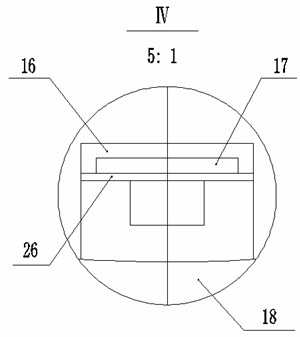

Test piece gripper and spin multiphase flow erosive wear test machine

InactiveCN106872265AImprove accuracyGuaranteed safe operationWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceSoftware engineeringSpins

The invention discloses a test piece gripper, used for a spin multiphase flow erosive wear test machine, and comprising a base and two clamp splices; each clamp splice is a half-cylinder; one end of each clamp splice is provided with a nip, the other end is provided with a half flange plate, and the central part is provided with a mounting hole; a test piece is gripped by the nips of the two clamp splices, the two clamp splices are connected and fixed through the mounting hole, and are connected with the base through the flange plate; the base is arranged on a turntable of the erosive wear test machine and can adjust angle installation of the test piece. The test piece gripper is capable of distributing a plurality of identical test pieces at different mounting angles, so that every test piece is different in impact angle in a test process, and the relationship between the impact angles and erosive wear speed can be obtained, thus improving accuracy of erosive wear test, providing important data for the actual engineering pipeline erosive wear prediction, and providing reference for ensuring the safe operation of a pipeline. The invention also discloses a spin multiphase flow erosive wear test machine.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

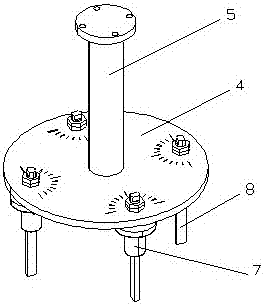

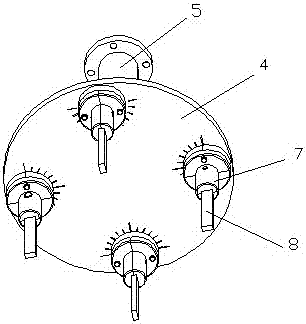

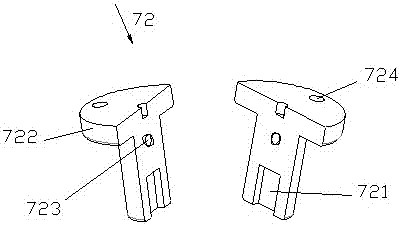

Drop hammer type multi-angle impact clamp with stable impact position

ActiveCN110658059AAvoid damagePrevent slippingNuclear energy generationMaterial strength using repeated/pulsating forcesCircular discImpact

The invention provides a drop hammer type multi-angle impact clamp with a stable impact position. Two side plates of a rotating frame are of semi-disc shapes respectively, each side plate is providedwith first fixing holes which are evenly distributed in the circumferential direction, wall plates are vertically arranged in the outer sides of the two side plates respectively, the upper inner sideof each wall plate is provided with a rotating groove adapted to the corresponding side plate, each rotating groove is provided with second fixing holes cooperated with the first fixing holes at the same circumferential positions as the side plate, each side plate is embedded into the corresponding rotating groove and can rotate freely in the rotating groove, and when the rotating frame is rotatedto a required impact angle, at least two communicated first and second fixing hole groups are selected from the outer side of the wall plate, and fastening pieces are inserted into the selected fixing holes to fix the rotating frame. The multi-angle impact clamp can realize multi-angle adjustment, ensure the stability of the impact angle, and avoid damage of clamping on a test piece.

Owner:ZHENGZHOU UNIV

Specimen impacting angle adjusting component and method of rotary erosion wear test device

PendingCN106198192AEasy to controlHigh precisionInvestigating abrasion/wear resistanceSlurryEngineering

The invention provides a specimen impacting angle adjusting component and method of a rotary erosion wear test device. The specimen impacting angle adjusting component comprises a specimen and a cylindrical specimen protection device, a flange plate is arranged at the cylindrical upper end of the specimen protection device, a rectangular groove is formed in the bottom of the specimen protection device, an adjusting hole and a threaded hole are formed in a slurry tank cover plate, the specimen protection device penetrates the adjusting hole and is mounted on one side of the slurry tank cover plate by a fastening screw, an angular scale is arranged on the slurry tank cover plate, and an angular pointer is arranged on the flange plate. The specimen impacting angle adjusting component has the advantages that an impacting angle is easy to control and high in precision, and the component is simple in structure and convenient to operate. The component can conveniently change specimen impacting angles of the rotary erosion wear test device to study erosion wear resistance of a material under different impacting angles, the specimen impacting angle adjusting component determines specimen impacting angles according to the corresponding relation among the angular pointer and scale lines on the angular scale, and other angular measuring tools are omitted.

Owner:HENAN POLYTECHNIC UNIV

Impact-resistant and high-abrasion-resistant rubber stock bin lining plate with ultrastrong self-cleaning performance

The invention discloses an impact-resistant and high-abrasion-resistant rubber stock bin lining plate with ultrastrong self-cleaning performance. The problem that an existing device is prone to bursting apart and being damaged severely is solved. The rubber stock bin lining plate is characterized in that a chute lining plate is composed of a plurality rubber lining plate bodies in a combined mode and fixed in a chute cylinder steel plate through T-shaped square-head bolts; each rubber lining plate body is formed integrally and made from high-performance rubber and a reinforced fabric framework in a composite mode through vulcanization; and each rubber lining plate body is in an R shape and comprises a semicircular stop table, a round through hole, a flat lining plate provided with a T-shaped square-head bolt mounting hole and a self-cleaning fin. The rubber stock bin lining plate can achieve continuous bearing, can bear large impact loads, is suitable for various severe working conditions, can change the impact angle of a material, better absorbs or reduces the impulse of the material, has the characteristics of impact resistance, high abrasion resistance, low friction, self-cleaning and the like, effectively reduces the impact loads, improves the buffer capacity, is fast to install, is convenient to maintain, and is long in service life.

Owner:ANHUI ZHONGYI RUBBER BELTS

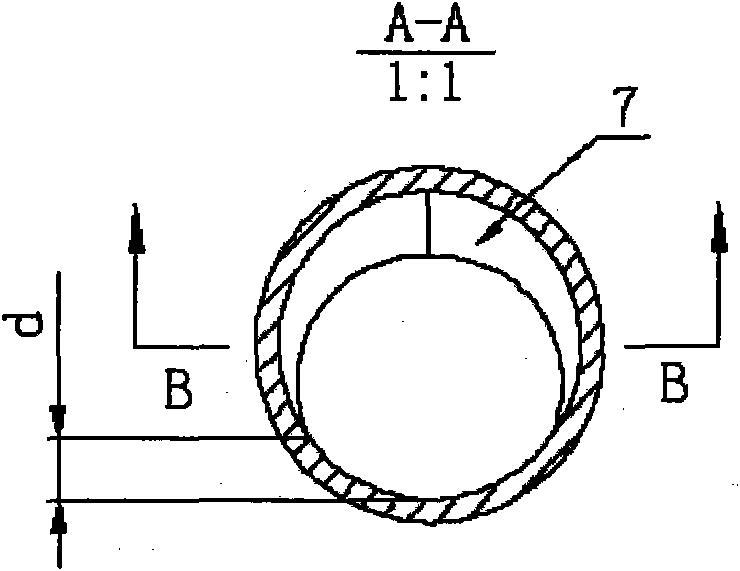

Anti-bias DC burner

InactiveCN101865460ASpray evenlyReduce the maximum concentrationPulverulent fuel combustion burnersSiphonEngineering

The invention discloses an anti-bias DC burner which comprises a siphon, a diversion rudder pipeline section and a nozzle section sequentially connected. A diversion rudder is arranged in the diversion rudder pipeline section and integrated with the diversion rudder pipeline section which is connected with the siphon and nozzle section through flanges. The burner can effectively realize that even-concentration coal powder is sprayed in a furnace hearth, and can increase or reduce the maximum concentration at an outlet by replacing the diversion rudder pipeline section; and the value of an impact angle beta is an important parameter for adjusting the concentration of the coal powder at the outlet.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com