Drop hammer type multi-angle impact clamp with stable impact position

A technology of impact position and drop hammer type, which is applied in the direction of measuring device, strength characteristics, and test material strength by applying repeated force/pulsation force, can solve the problems of inability to guarantee the stability of impact angle, damage, etc., to avoid slippage, The effect of preventing the angle from changing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

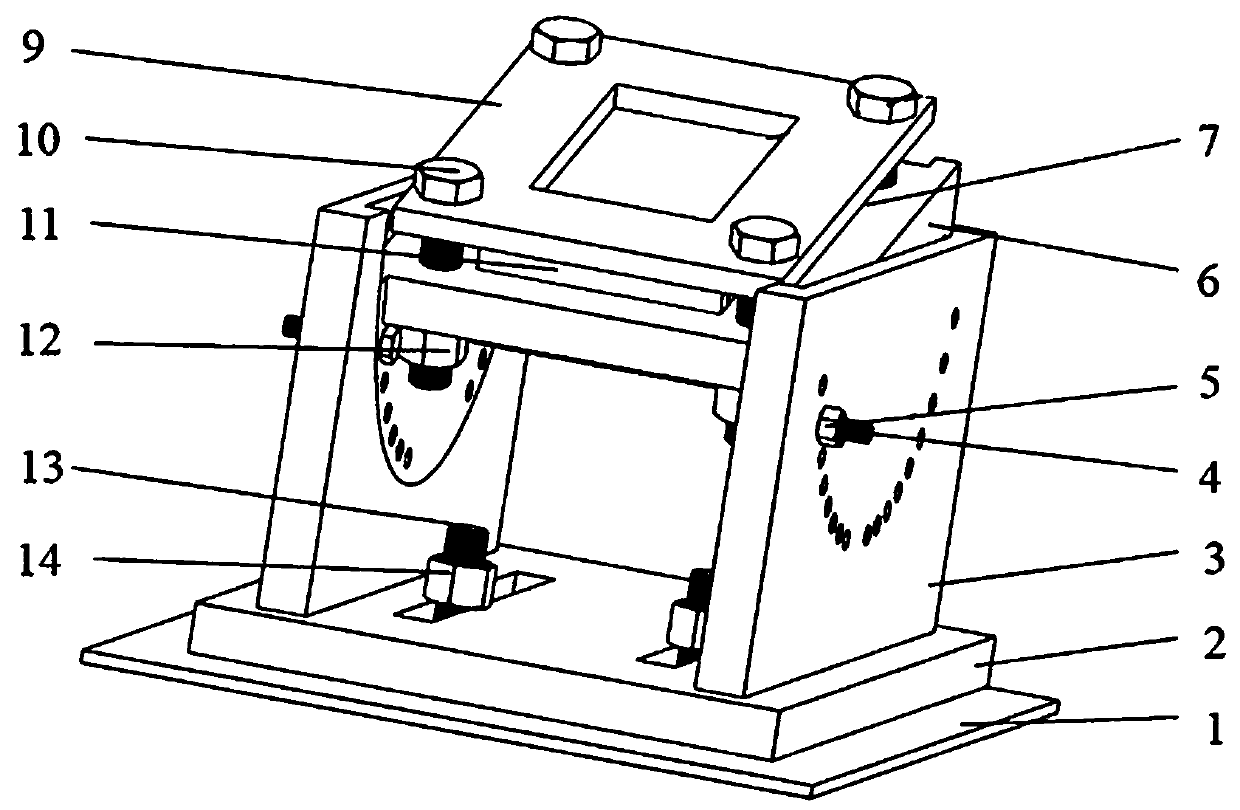

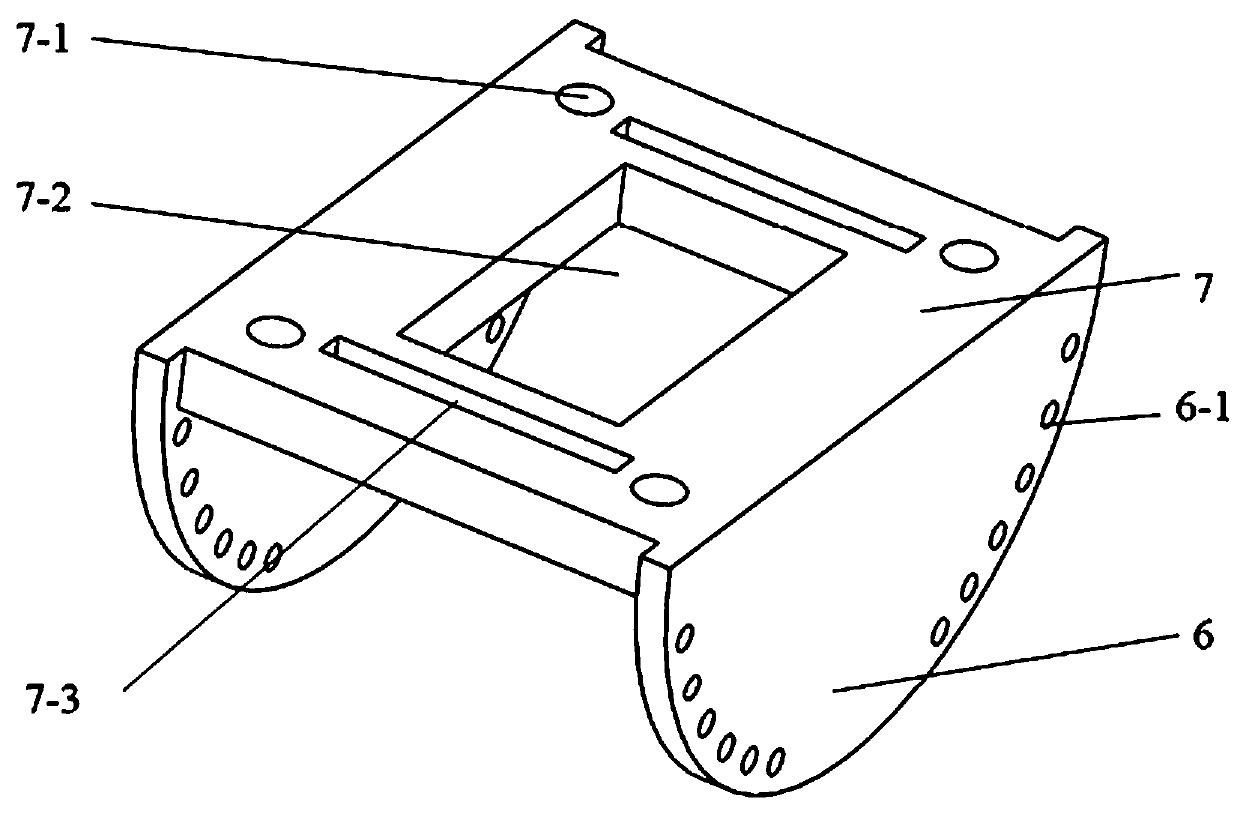

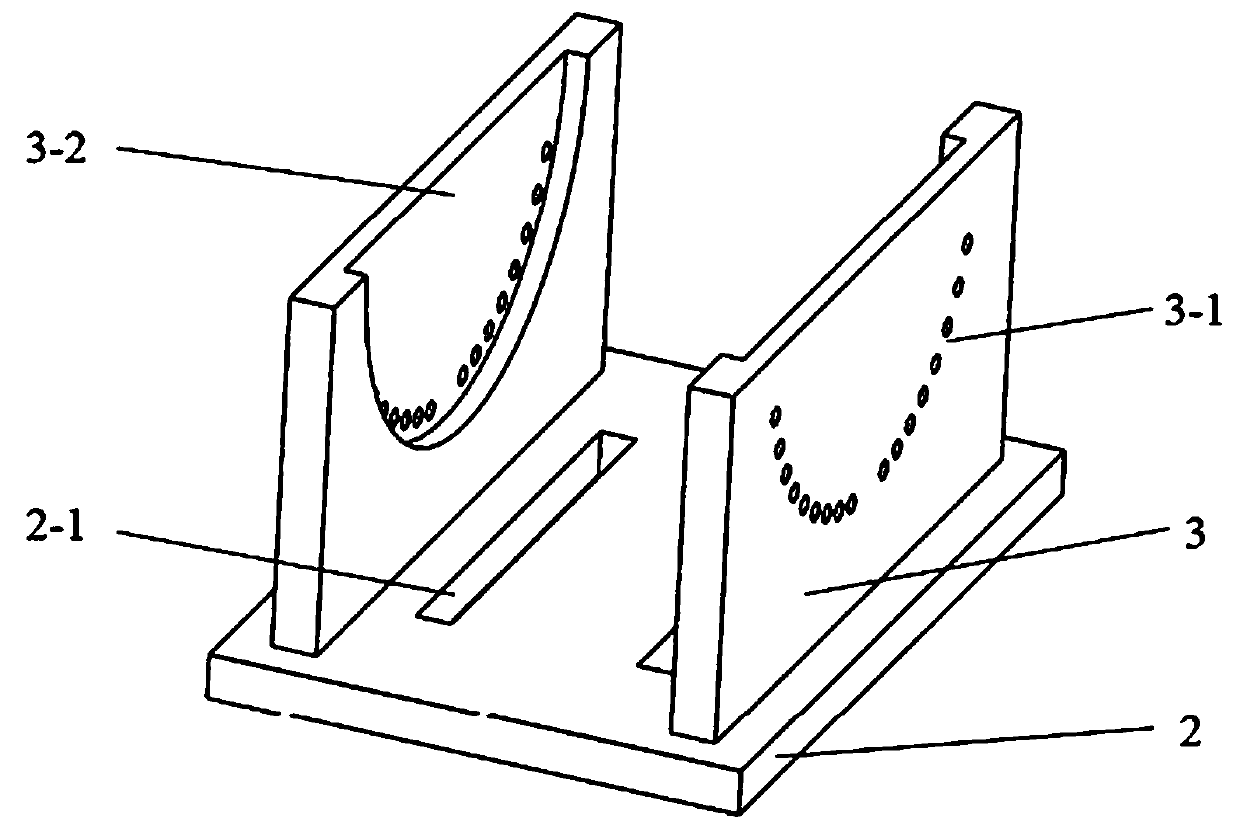

[0026] like Figures 1 to 5 As shown, a drop hammer type multi-angle impact fixture with a stable impact position includes a turret, the turret includes a cuboid top plate 7 and two side plates 6 that are left-right symmetrical and vertically arranged with respect to the top plate 7, A pressure plate 9 is parallelly arranged above the top plate 7, and the top plate 7 and the pressure plate 9 are connected by several height-adjustable first connectors, and a height-adjustable and used for clamping is formed between the top plate 7 and the pressure plate 9. space for holding the test piece. In this embodiment, the first connecting piece is a bolt and nut piece, and the pressure plate 7 and the top plate 9 are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com