Rolling stone impact force testing device

A testing device and impact force technology, applied in measuring devices, force/torque/power measuring instruments, instruments, etc., can solve the problems of lack of systematic research on impact force changes, insufficient research on impact resistance of cushioning materials, and large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

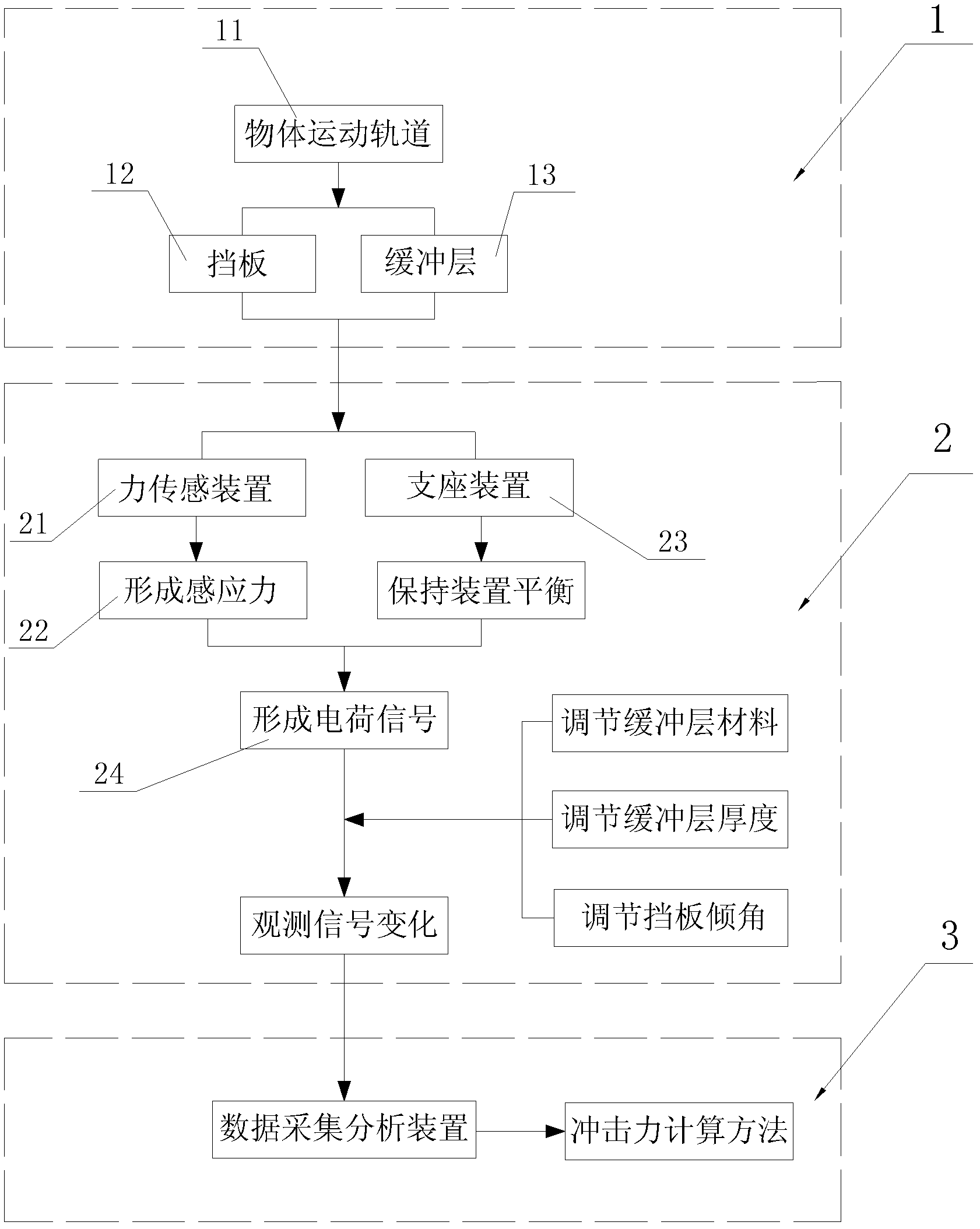

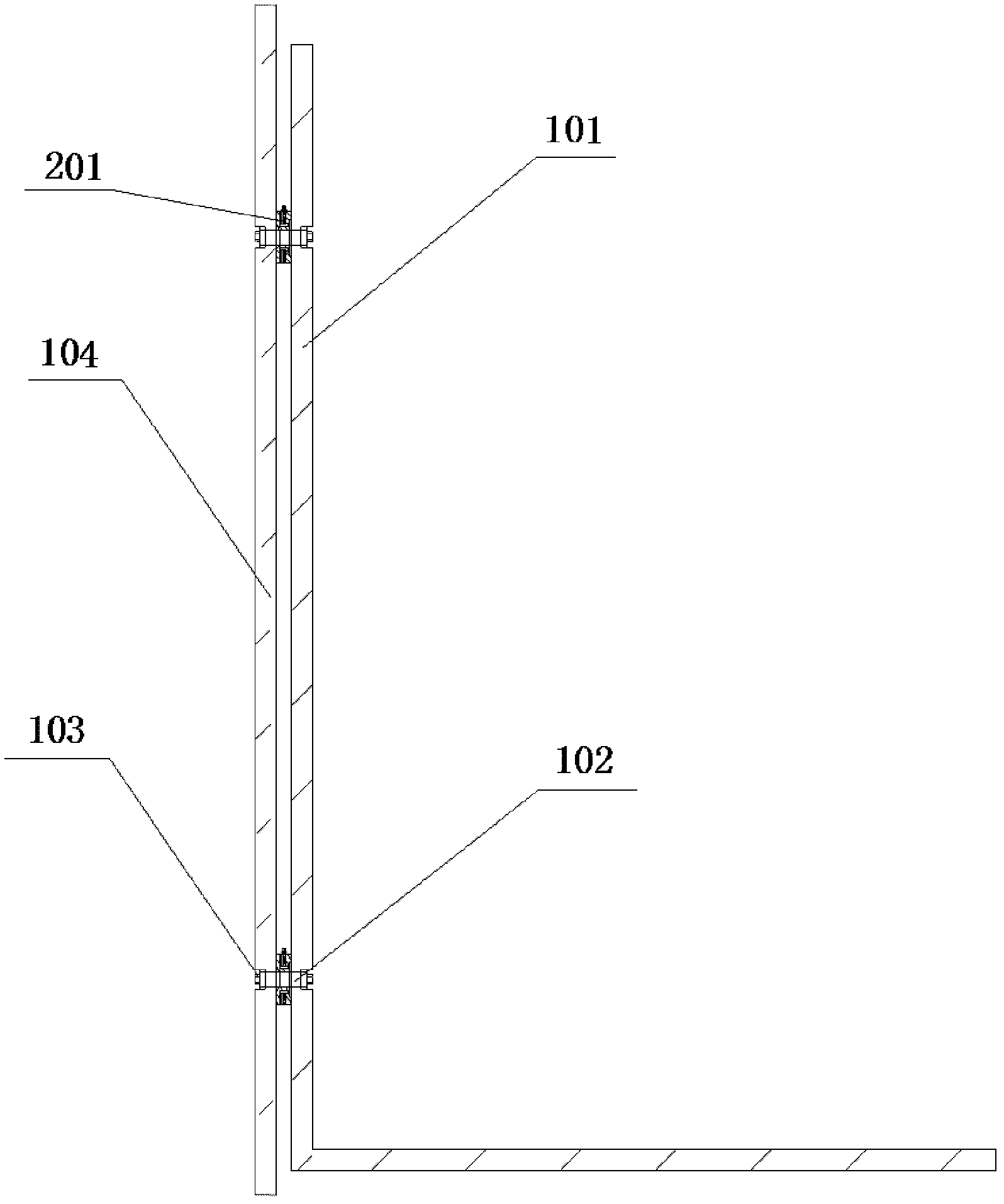

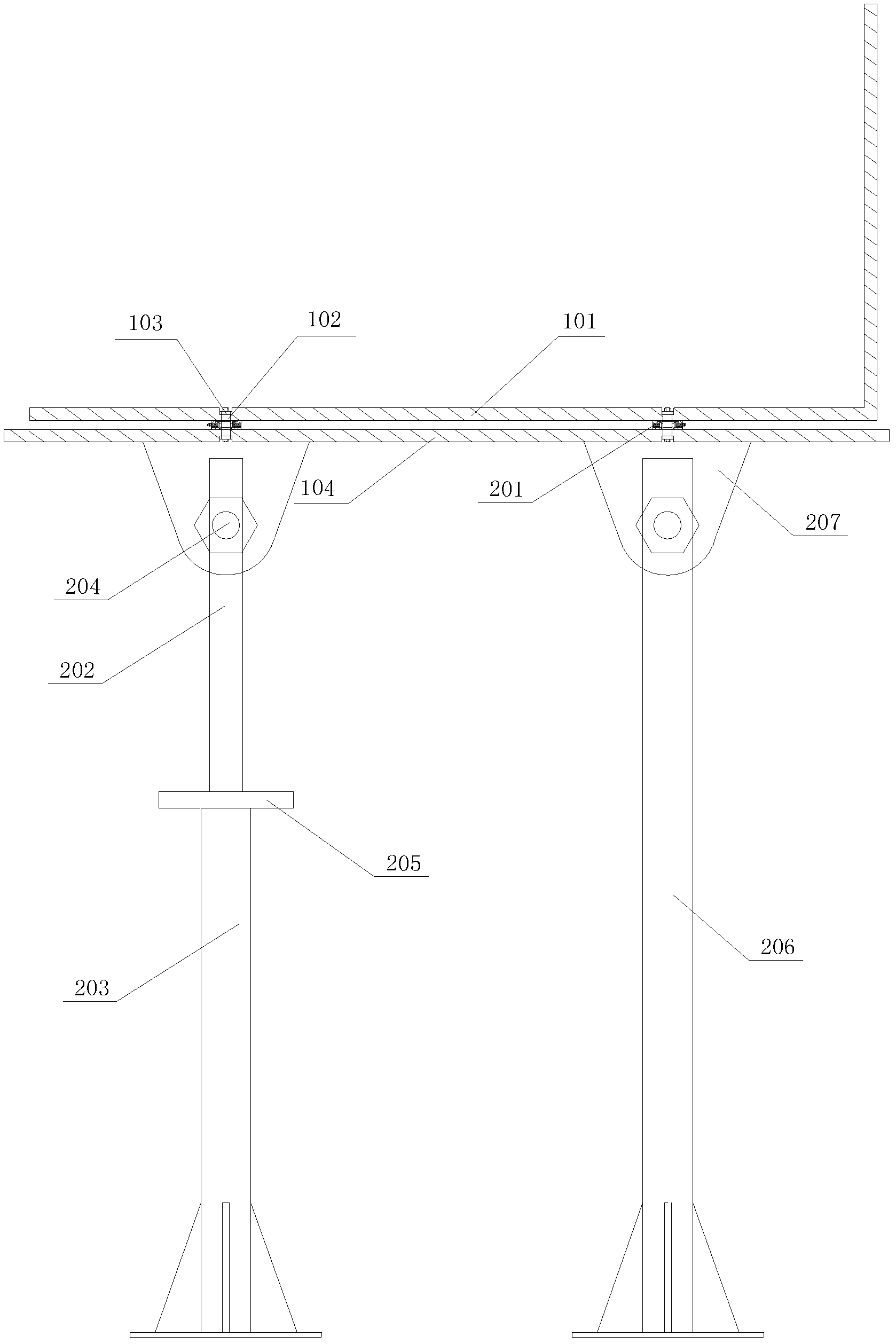

[0017] figure 1 It is a working principle diagram of a specific embodiment of the impact force testing device of the present invention. In the figure, the impact testing device includes an impact blocking device 1, a force sensing testing device 2 and a data acquisition and analysis device. The impact blocking device 1 includes an object moving track 11 , a baffle plate 12 and a buffer layer 13 . The object moves downward from the moving track according to the designed height and size, and hits the baffle plate 12 carrying the cushioning material 13 to generate an impact effect. This impact force provides an impact signal to the force-sensing testing device 2 through the baffle plate 12 . Wherein the inclination angle of the baffle can be adjusted by the device 2.

[0018] The impact action forms an induced force 22 through the force sensor device 21 in the force sensor test device 2 . In order to maintain the balance of the test device during operation and reduce test err...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com