Collaborative robot collision safety test system and test method

A technology of safety testing and testing systems, applied in the direction of manipulators, manufacturing tools, etc., to achieve the effect of high measurement work efficiency and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

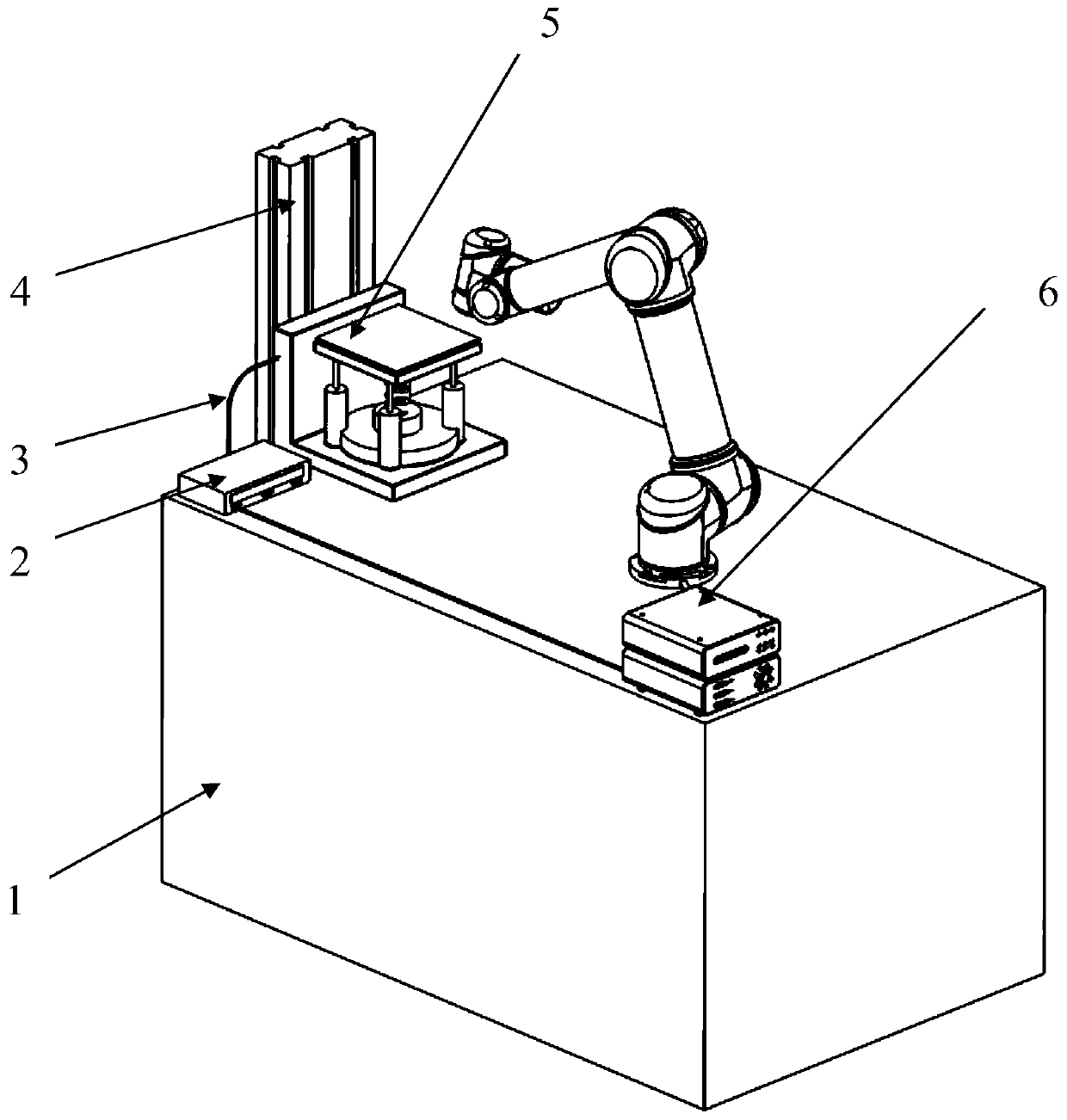

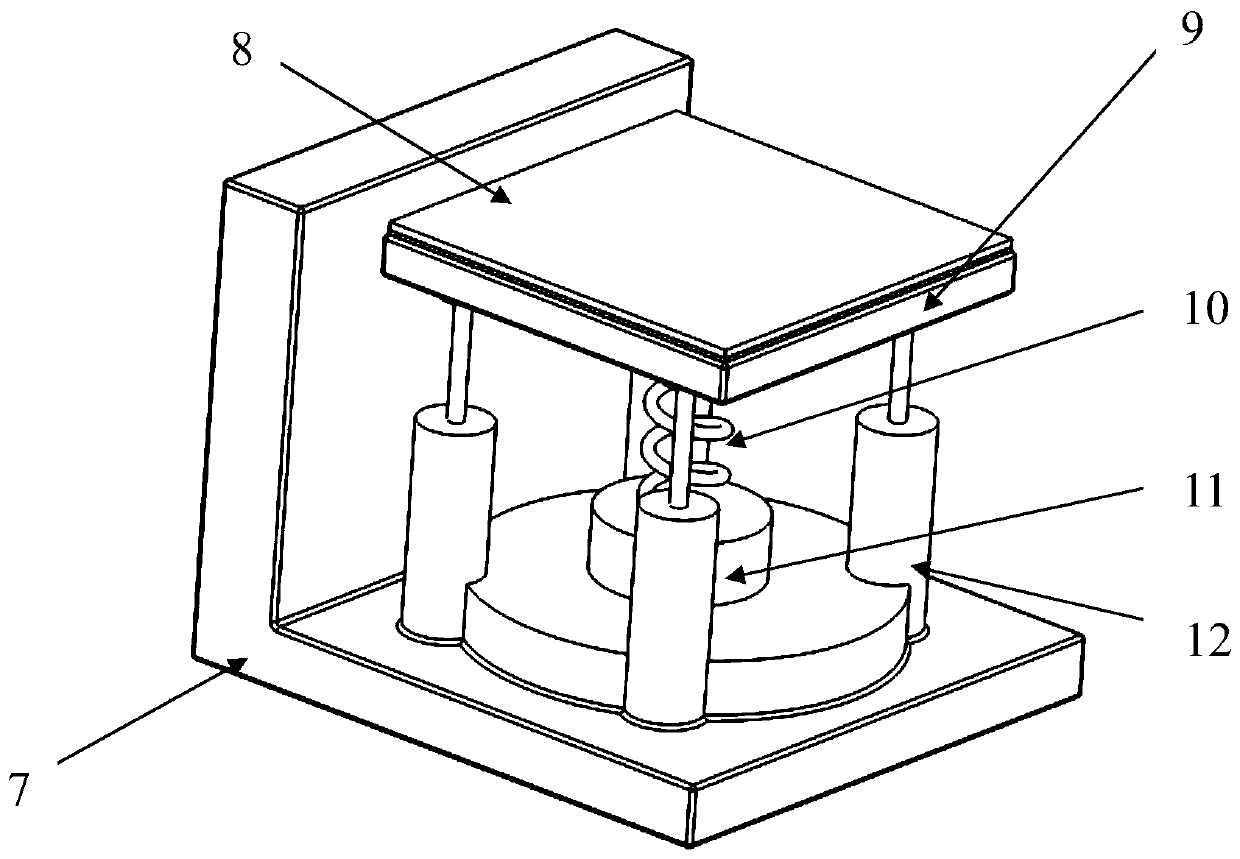

[0026] The invention provides a collaborative robot collision safety testing system and testing method, such as Figure 1-2 shown. The testing system comprises a test bench 1, an angle adjustment seat 4, a force sense system 5, a synchronous control system 2 and a tester 6; wherein: the angle adjustment seat is fixed on the side of the test bench; the force sense system Including the fixed base 7, the fixed base is composed of a bottom plate and a side plate connected vertically. According to the different impact angles of the robot, the fixed base fixes the bottom plate on the upper surface of the test bench through screws or fixes the side plates on the angle adjustment seat through screws. above; the fixed base of the force sense system is installed on the angle adjustment seat; the synchronous control system 2 and the tester 6 are fixed on the upper surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com