Rotary type liquid-solid two-phase flow erosive wear test device

A wear test, rotary technology, used in measuring devices, chemical industry, weighing by removing certain components, etc., can solve problems such as failure area and damage degree of wear that cannot be accurately predicted and scientifically evaluated, and achieve Easy-to-promote, simple-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

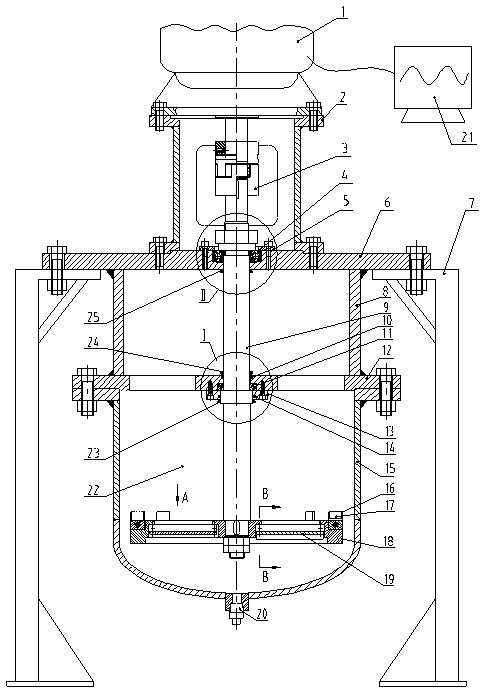

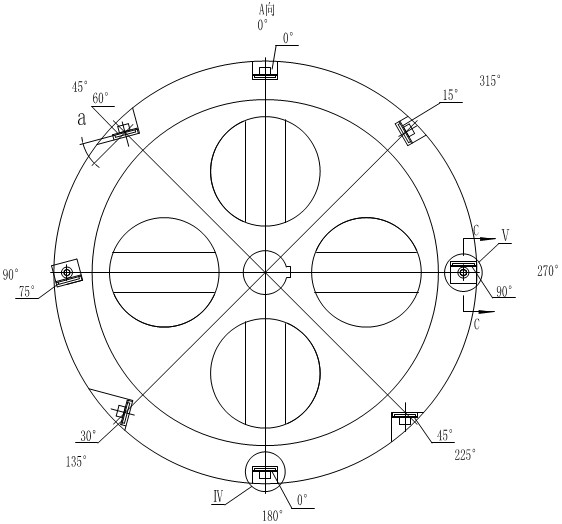

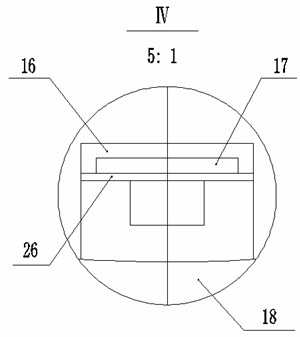

[0025] Such as figure 1 As shown, the present invention includes a slurry tank 15, a lower mounting plate 12, an upper mounting plate 6, a deep groove ball bearing 4, a turntable 18, a test piece mounting plate 16, eight test pieces 17, a stirring blade 19, and a connecting sleeve 8 , stirring shaft 9, the first high-speed dust-proof ring 10, the second high-speed dust-proof ring 14, angular contact ball bearing 11, angular contact ball bearing cover plate 13, bell housing 2, frequency conversion motor 1, plum-shaped elastic coupling 3. Plug 20, frequency converter 21, fluid medium 22, first water seal 23, second water seal 25, third water seal 24; frequency converter 21 and frequency conversion motor 1 are connected by cables, and frequency conversion motor 1 is connected through four The evenly distributed bolt connection is fixed vertically on the upper end of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com