Airbag head hammer falling static testing device

An airbag and static test technology, applied in measuring devices, impact tests, vehicle tests, etc., can solve the problems of incompatibility, inability to reflect the performance of the airbag well, and is not conducive to reflect the performance of the airbag, and achieve repeatable results Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

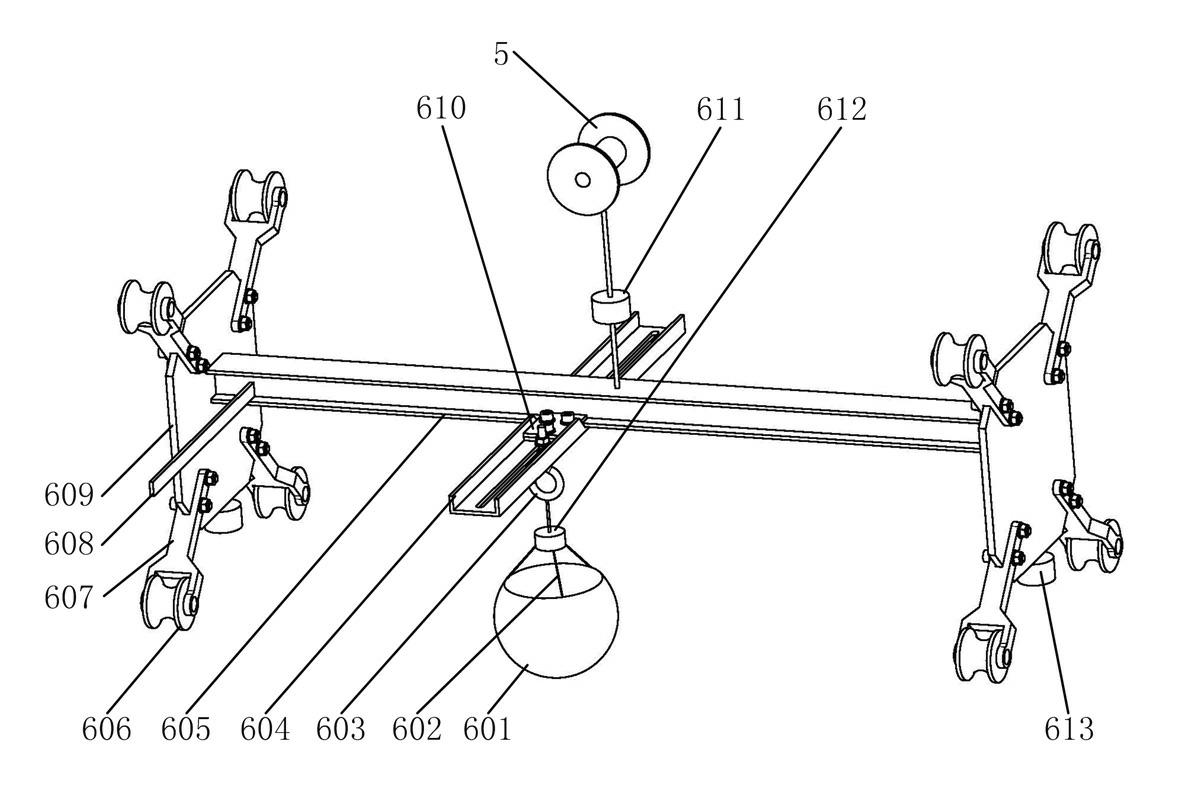

[0024] Such as Figure 1-Figure 3 As shown, an airbag head hammer drop static test device includes a frame bracket 1 and a steering wheel 203 with an airbag 204. The inner bottom of the bracket 1 is provided with an airbag adjustment mechanism 2 for adjusting the position of the steering wheel 203, and the bracket 1 is equipped with There is a hanger mechanism 6 for lifting the head hammer 601, and a lifting mechanism 5 for controlling the vertical movement of the hanger mechanism 6 is installed on the top of the bracket 1, and the head hammer 601 is connected to the hanger mechanism 6 through the head hammer hook 603;

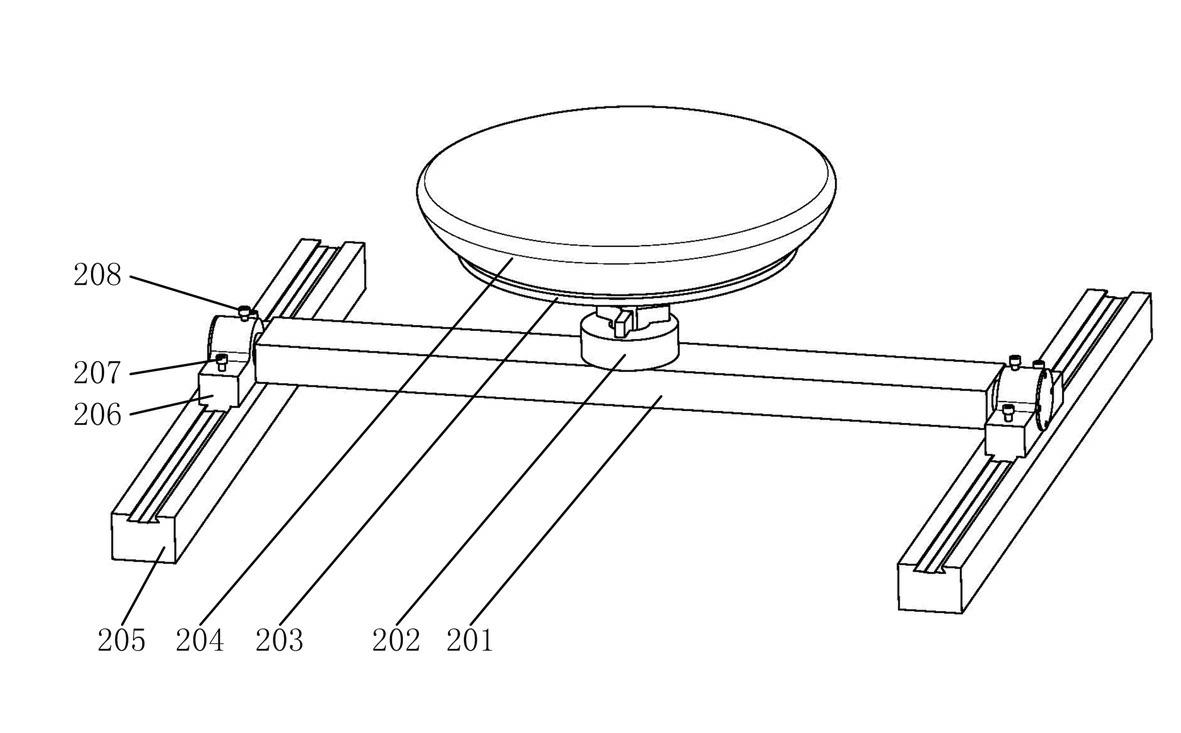

[0025] The airbag adjustment mechanism includes two parallel airbag adjustment guide rails 205 fixed on the left and right sides of the bottom of the bracket 1 with dovetail grooves, and the airbag adjustment guide rails 205 are equipped with an airbag adjustment slider 206 that can slide along the dovetail grooves, and set An airbag rotating beam 201 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com