Specimen impacting angle adjusting component and method of rotary erosion wear test device

An angle adjustment component and wear test technology, applied in the direction of measuring devices, strength characteristics, test wear resistance, etc., can solve the problems of high processing requirements for sample grooves, fastening plates cannot be used normally, and the erosion angle is difficult to adjust. , to achieve the effect of clear scale lines, light weight and easy identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings.

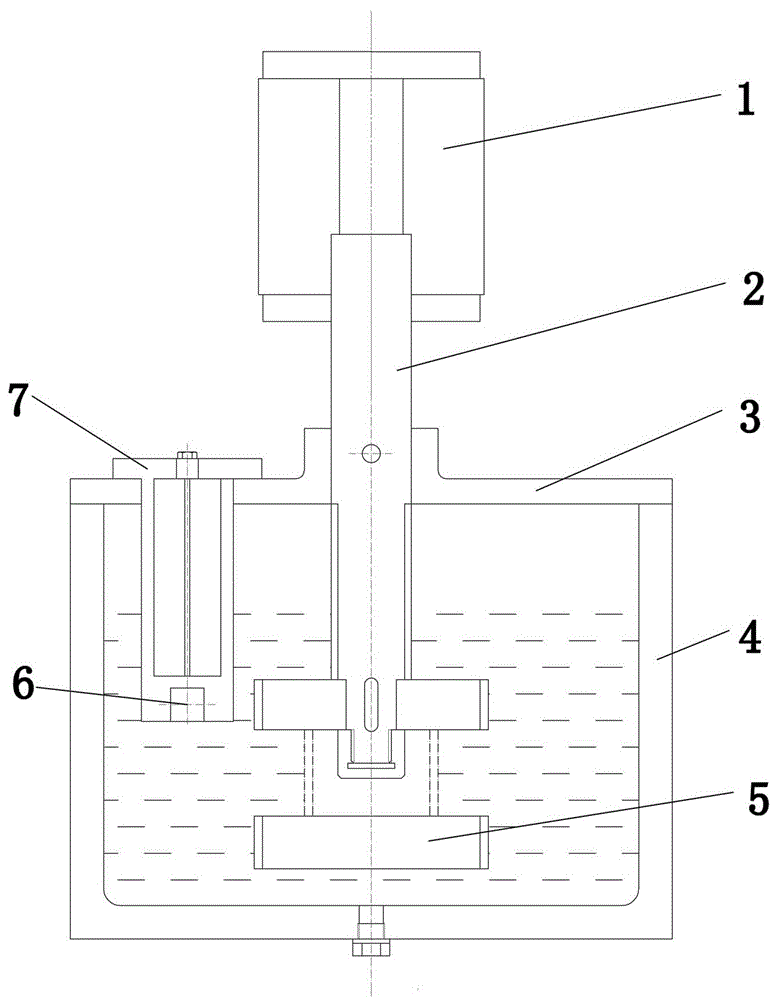

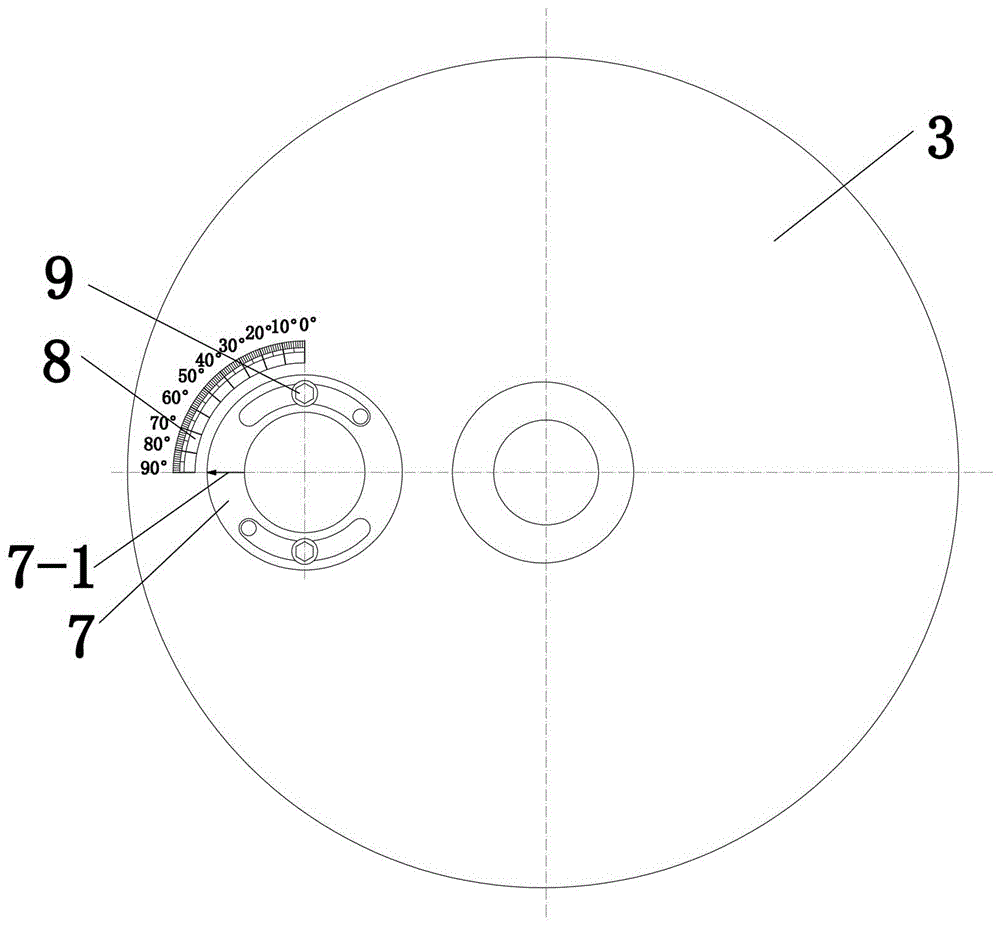

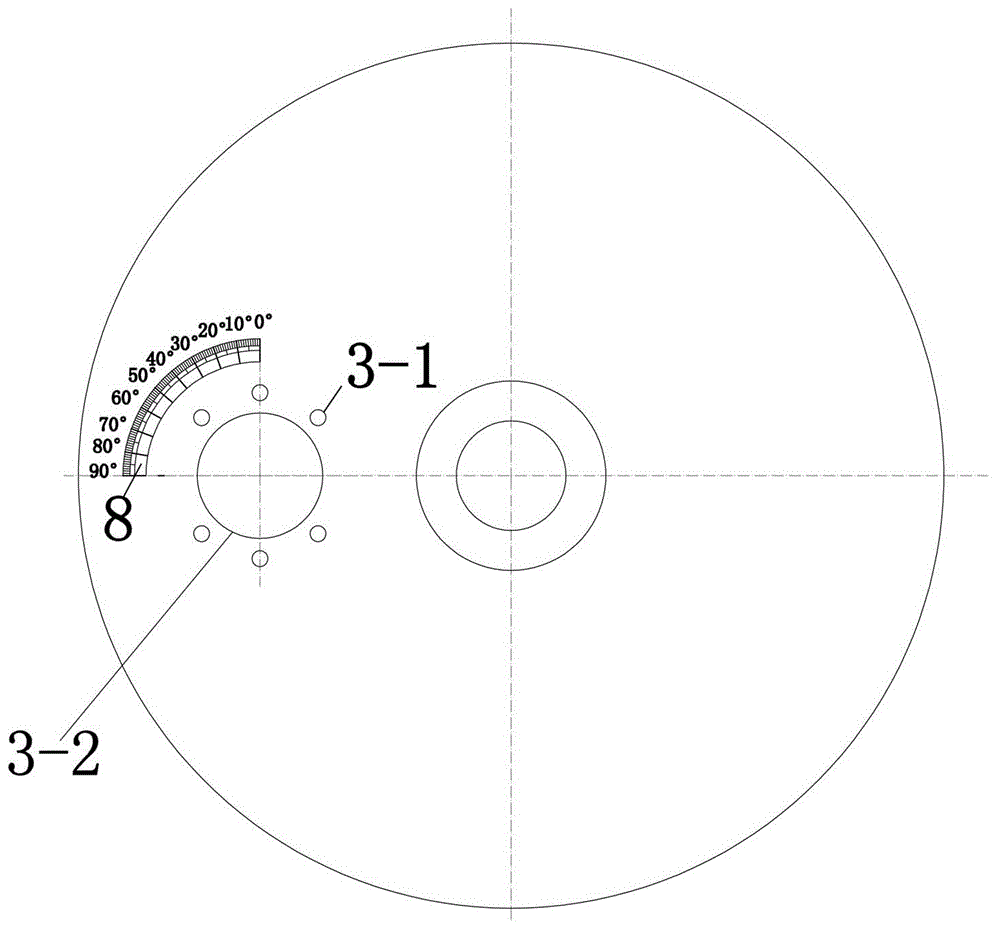

[0036] like figure 1 As shown, the servo motor 1 drives the stirring impeller 5 through the main shaft 2 to stir the liquid-solid two-phase or multi-phase fluid in the slurry tank 4 to form a high-speed moving fluid. The sample 6 is installed in the rectangular groove at the bottom of the sample protection device 7 , and the sample protection device 7 is fixed on the cover plate 3 of the slurry tank. like figure 1 , 2, 5, the sample protection device 7 is provided with an angle pointer 7-1 and an annular groove 7-2, and the required angle is adjusted to the corresponding angle of the angle scale 8 by rotating the sample protection device 7. , after the adjustment is completed, tighten the fastening screw 9. The high-speed moving fluid erodes and wears the sample 6. By adjusting the angle pointer 7-1 on the sample protection device 7 to correspond to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com