Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Glow Discharge Mass Spectrometry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mass spectrometry technique in which a solid sample is atomized and ionized by sputtering in low-pressure direct-current plasma prior to the separation and detection of the ions in a mass analyzer. This technique is utilized to analyze trace and ultra-trace elemental constituents of inorganic materials.

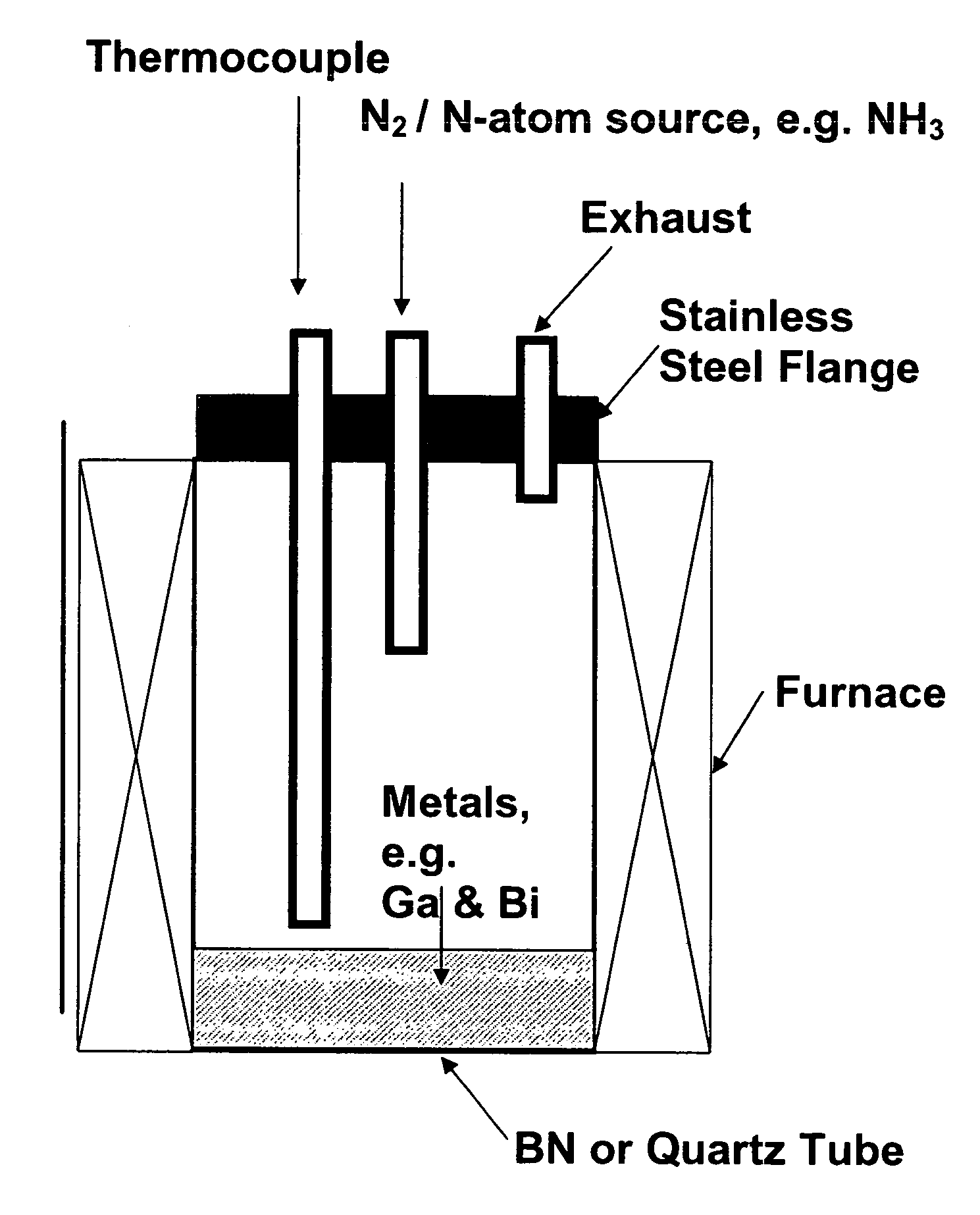

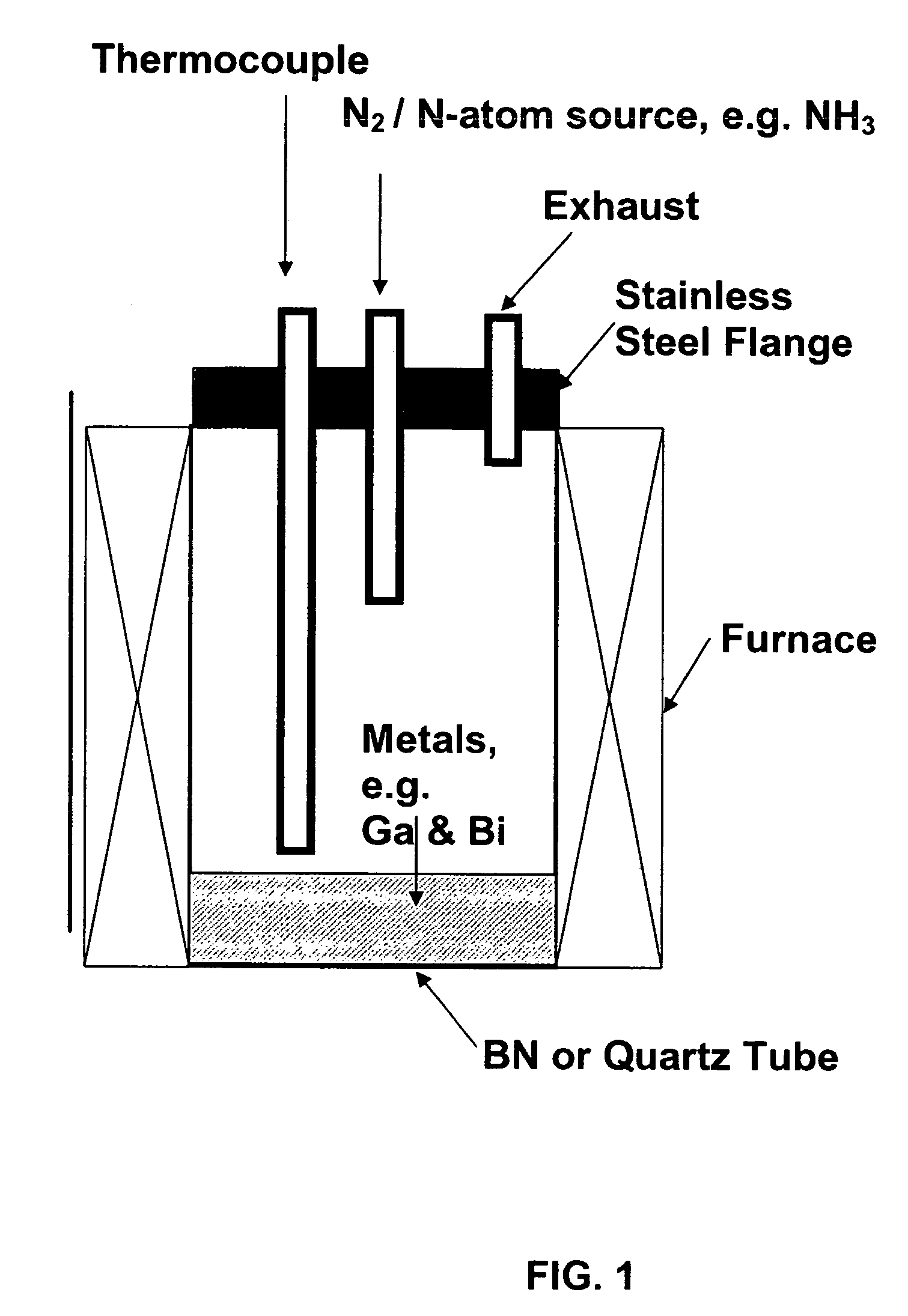

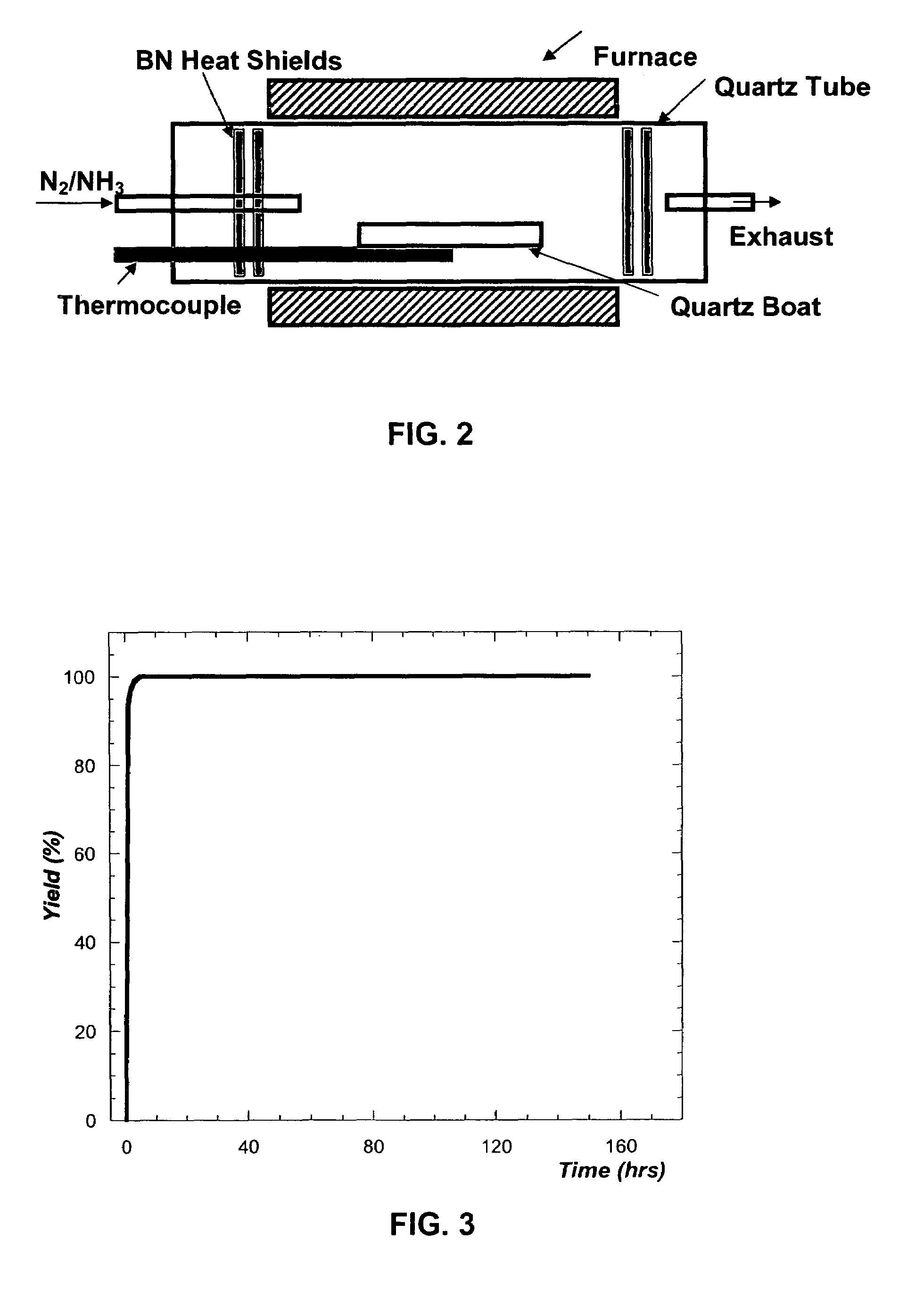

Method of making Group III nitrides

InactiveUS7381391B2High purityShort reaction timePolycrystalline material growthNitrogen-metal/silicon/boron binary compoundsOptical propertyGlow Discharge Mass Spectrometry

The present invention provides compositions and a novel high-yielding process for preparing high purity Group III nitrides. The process involves heating a Group III metal and a catalytic amount of a metal wetting agent in the presence of a nitrogen source. Group III metals can be stoichiometrically converted into high purity Group III nitride powders in a short period of time. The process can provide multi-gram quantities of high purity Group III nitrides in relatively short reaction times. Detailed characterizations of GaN powder were preformed and are reported herein, including morphology and structure by SEM and XRD, optical properties by cathodoluminescence (CL), and Raman spectra to determine the quality of the GaN particles. The purity of GaN powder was found to be greater than 99.9% pure, as analyzed by Glow Discharge Mass Spectrometry (GDMS). Green, yellow, and red light emission can be obtained from doped GaN powders.

Owner:CORNELL RES FOUNDATION INC

Determination of trace impurity elements in high purity indium through glow discharge mass spectrometry method

InactiveCN103884772AReduce distractionsShort processMaterial analysis by electric/magnetic meansIndiumInfrared lamp

The invention relates to a determination method for trace impurities in a rare metal, particularly to a determination method for trace impurities in high purity indium. The determination method comprises: (1) cutting a sample into a sheet, washing oil stain on the sample surface with toluene, washing with ultrapure water, etching for 8 min with 50% (volume concentration) nitric acid, repeatedly rinsing with ultrapure water, storing in methanol, and taking and drying under an infrared lamp before analysis; (2) placing the sample in a sample clamper, pushing into an ion source chamber, respectively adjusting the discharge voltage and the discharge current to 0.9-1.2 kV and 40-45 mA when the vacuum degree achieves 2.2-2.4 mbar, and sputtering for about 30-40 min, wherein generally stabilization of signals of Na, Fe and Ca easily introducing contamination is adopted as the reference so as to eliminate possibly-produced contamination during the sample preparation process; and (3) respectively adjusting the discharge voltage and the discharge current to 0.9-1.2 kV and 40-45 mA, carrying out high voltage discharge, collecting the ion signals of the elements to be detected, and calculating the concentration of the impurity elements to be detected according to the quantitative analysis principle of the glow discharge mass spectrometer. The method has characteristics of simple operation, less interference and short process, and can well meet requirements of determination of trace impurities in high purity indium.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Method for detecting content of trace impurity content in metal by glow-discharge mass spectrometry

InactiveCN106198712AAvoid pollutionReduce pollutionMaterial analysis by electric/magnetic meansMass spectrometryHigh pressure

The invention provides a method for detecting content of trace impurity content in metal by a glow-discharge mass spectrometry. The method comprises the following steps: 1) processing a metal sample to a sheet shape or a needle shape, putting the metal sample in a nitric acid solution for performing ultrasonic cleaning, and drying the material; 2)performing vacuum-pumping on a sample warehouse of a glow-discharge mass spectrometer, opening a ball valve, pushing the metal sample into an ion source chamber, opening high pressure and glow, introducing work gas, adjusting discharge voltage and discharge current, adjusting resolution to 3000-4800 through ion source tuning, wherein the matrix peak intensity is 0.05-0.25 V, and pre-sputtering for 30-80 min; and 3) selecting a metal matrix and the impurity element required to be determined, and performing a direct current glow discharge mass spectrometry to obtain the concentration of metal trace impurity. According to the invention, grinding and polishing are not required for a cut sample according to the specification, the sample is only required for being cleaned, pollution can be effectively avoided; sampling is directly carried out, operation is simple and easy; effective tuning is carried out on the ion source, sensitivity is high, detection limit is low, resolution is high, and one-time analysis of the main content elements to ppt-grade element can be carried out.

Owner:锦州市国家光伏材料质量监督检验中心

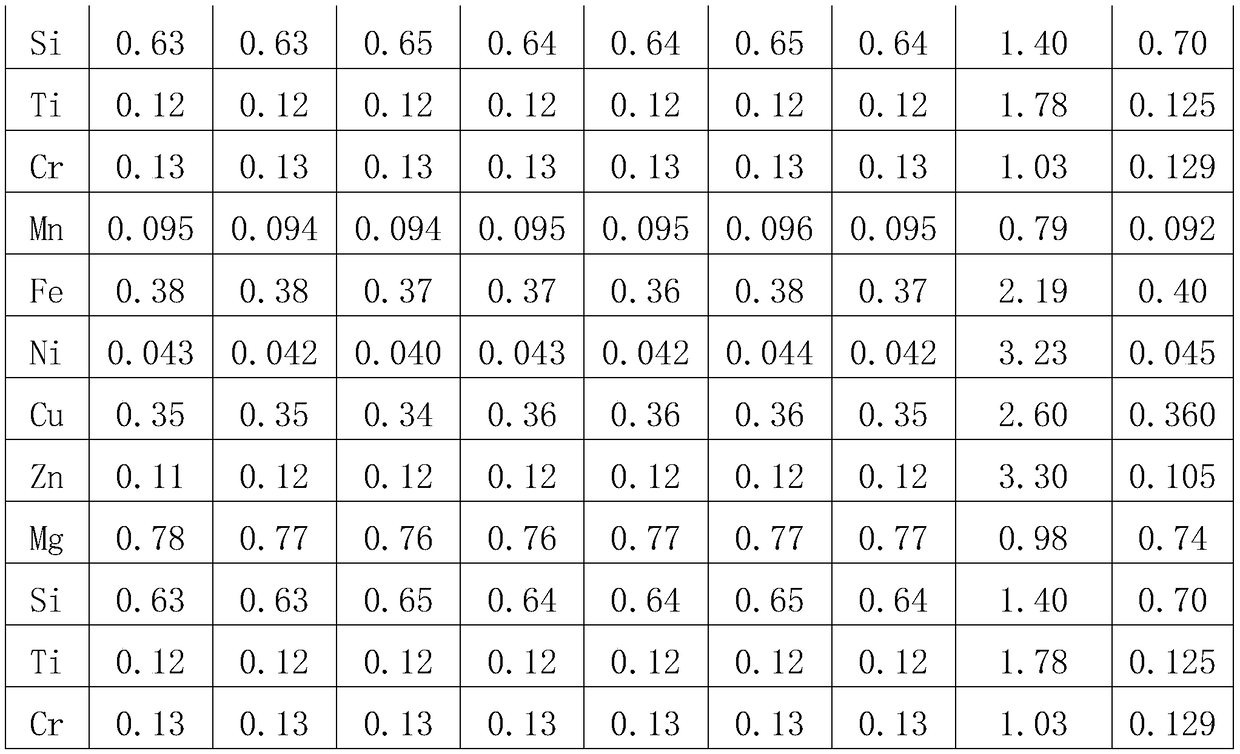

High-purity aluminium grain material and method for producing the same

InactiveUS20160289801A1High purityGood physical propertiesDetergent mixture composition preparationPackaging under vacuum/special atmosphereManganeseMetallic Nickel

An object of the present invention is to provide an aluminium grain material having significantly high purity, and a method for producing the same. Disclosed is an aluminium grain material having an average mass per grain of 0.01 to 10 g, wherein the total content of twelve elements of silicon (Si), iron (Fe), copper (Cu), magnesium (Mg), titanium (Ti), vanadium (V), chromium (Cr), manganese (Mn), nickel (Ni), zinc (Zn), gallium (Ga), and zirconium (Zr) in the aluminium grain material, measured by glow discharge mass spectrometry, is 5 ppm by mass or less.

Owner:SUMITOMO CHEM CO LTD

Method for detecting content of impurity elements in aluminum alloy powder

InactiveCN109298065ASolve the problem of not being able to directly compress tabletsThe content of impurity elements does not changePreparing sample for investigationMaterial analysis by electric/magnetic meansMass spectrometrySpectrometer

The invention provides a method for detecting the content of impurity elements in aluminum alloy powder. The method for detecting the content of the impurity elements in the aluminum alloy powder comprises the following steps of (1) heating a to-be-detected aluminum alloy powder sample to be molten; (2) cooling molten aluminum alloy to obtain an aluminum alloy blocky sample; (3) compressing the aluminum alloy blocky sample to obtain an aluminum alloy sample wafer; (4) cleaning the aluminum alloy sample wafer; (5) placing the cleaned aluminum alloy sample wafer into a GD-MS sample clamp, and ina direct-current mode, setting a discharge current to be 60-90 mA and discharge gas flow to be 350-490 mL / min; and (6) performing pulse glow discharge mass spectrometer analysis under the set condition in the step (5), collecting the signal intensity of the to-be-detected elements, and calculating out the mass fraction of the trace impurity elements by applying a relative sensitivity factor. Themethod for detecting the content of the impurity elements in the aluminum alloy powder is simple and easy to operate and high in detection speed; and the glow discharge mass spectrometry analysis method for simultaneous detection of multiple elements in the aluminum alloy powder can be carried out.

Owner:XINJIANG JOINWORLD CO LTD

Metal powder sample preparation method for glow discharge mass spectrometry

PendingCN111551422AInlaid firmlyNot easy to fall offPreparing sample for investigationMaterial analysis by electric/magnetic meansGlow Discharge Mass SpectrometryMetal powder

The invention provides a metal powder sample preparation method for glow discharge mass spectrometry, which comprises the following steps: putting metal powder to be detected on a conductive substrate, putting the metal powder to be detected and the conductive substrate into a mold together, performing heating and pressurizing, and embedding the metal powder into the conductive substrate to finishsample preparation. According to the method, the metal powder is embedded into the conductive substrate through heating and pressurizing, the metal powder is embedded stably and is not prone to falling off, a high-quality sample for GDMS detection can be prepared, and the success rate can reach 98% or above; by means of acid pickling before sample preparation and use of the mold, impurities on the surfaces of the conductive substrate and the mold can be effectively removed, pollution possibly caused by the sample is reduced, and the accuracy of detection data is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Direct current glow discharge mass-spectrography method for determination of impurity elements in high purity alpha-Al2O3

InactiveCN104297333ASimplify preprocessing stepsMeet the requirements of rapid analysisMaterial analysis by electric/magnetic meansMass spectrographyImpurity

A direct current glow discharge mass-spectrography method for determination of impurity elements in high purity alpha-Al2O3 comprises the following steps: (1) evenly mixing Al2O3 powder and copper powder according to the proportion, then tabletting the mixed powder, blowing away the powder on the surface of the sample with N2, and filling the sample into a sample pool; (2) setting the flow of discharge gas at 500 mL / min, discharge current of 30 mA and ion source cooling temperature at 5-25 DEG C, and pre-sputtering for 15 min; (3) acquiring the signal intensity of the element to be measured under the experimental conditions set in step (2), defining the total sum of signal intensity generated by Al, O and Cu as 100%, and calculating the element content to be measured in the mixed powder according to the ratio of the signal intensity of the element to be measured to the total signal intensity of the three elements Al, O and Cu; and deducting the content of the element to be measured in the copper powder to obtain the content of the element to be measured in Al2O3. The invention realizes the determination of the content of impurity elements in non-conductive alpha-Al2O3 powder by the direct current glow discharge mass-spectrometry method, and the determination results are basically consistent with those of the DC arc emission spectroscopy method.

Owner:GUOBIAO BEIJING TESTING & CERTIFICATION CO LTD

Method of manufacturing analysis specimen

InactiveCN101046433AWill not pollutePrevent oxidationPreparing sample for investigationMetallurgyRuthenium

A method for preparing a sample for analyzing high-purity ruthenium powder by glow discharge mass spectrometry (GDMS) is provided. In this method, in the process of analyzing the grade of ruthenium powder using a glow discharge mass spectrometer, the material is yttrium-stabilized zirconia. The analysis sample of ruthenium powder.

Owner:JX NIPPON MINING & METALS CO LTD

Cleaning method for ceramic chip for glow discharge mass spectrometry equipment

InactiveCN108212912AAvoid detection impactImprove detection accuracyDrying solid materials with heatDrying solid materials without heatMetal impuritiesMegasonic cleaning

The invention provides a cleaning method for a ceramic chip for glow discharge mass spectrometry equipment. The cleaning method comprises the following steps: providing the ceramic chip for the glow discharge mass spectrometry equipment; carrying out a first cleaning process on the ceramic chip; and carrying out a second cleaning process on the ceramic chip after the first cleaning process, wherein the second cleaning process comprises an ultrasonic cleaning process; and carrying out a drying process on the ceramic chip at a preset temperature after the second cleaning process. The first cleaning process is mainly used for removing metal impurities on the surface of the ceramic chip, the ceramic chip is provided with many micropores, and the impurities (such as metal dissolved matters after the first cleaning process) are easily adsorbed in the micropores, therefore, the residual impurities in the micropores after the first cleaning process can be effectively removed through the ultrasonic cleaning process; and moreover, during the drying process at the preset temperature, the residual impurities with low melting points in the micropores can be further evaporated, so that the impurity removal effect on the ceramic chip is improved, the impurity residue of the ceramic chip is reduced, and then the detection accuracy for glow discharge mass spectrometry is improved, and the detection efficiency for the glow discharge mass spectrometry is increased.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

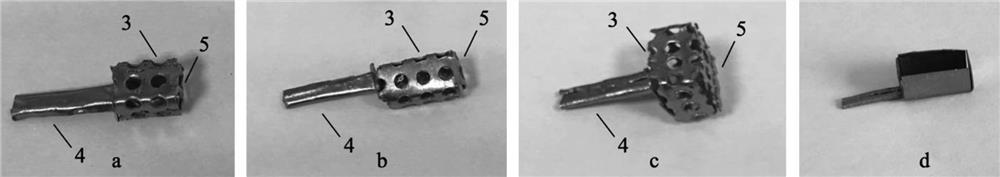

Cage-like sampling device for glow discharge mass spectrometry and sample test method

ActiveCN110749645AIncrease signal strengthQuick analysisMaterial analysis by electric/magnetic meansElectrical batteryPhysical chemistry

The invention provides a cage-like sampling device for glow discharge mass spectrometry and a sample test method, and aims at solving the difficulty of the glow discharge mass spectrometry (GD-MS) foranalyzing different types of samples with different sizes. The cage-like sampling device comprises a cage-like metal groove and a metal handle which is arranged at one end of the cage-like metal groove; the metal handle is used for fixing the cage-like sampling device relative to a glow discharge mass spectrometer; a sample loading port is formed in the other end of the cage-like metal groove toload and unload samples; the cage-like metal groove is prepared by carrying out punching and machining on a metal sheet with the purity greater than 99.995%; the size of the cage-like metal groove issmaller than the size of a glow discharge battery of the glow discharge mass spectrometer and the cage-like metal groove can be put in the glow discharge battery; and the volume of the cage-like metalgroove is smaller than the volume of the glow discharge battery.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Sample preparation method for detecting high-purity silver sample through glow discharge mass spectrometry

PendingCN111964997ARealize Glow Discharge Mass Spectrometry DetectionAvoid introducingPreparing sample for investigationMaterial analysis by electric/magnetic meansGlow Discharge Mass SpectrometryMass spectrometry

The invention relates to a sample preparation method for detecting a high-purity silver sample through glow discharge mass spectrometry. The length of the high-purity silver sample is 6-8 mm, and thewidth of the high-purity silver sample is 3-5 mm. The sample preparation method comprises the steps that the high-purity silver sample is sequentially subjected to acid pickling, first rinsing, secondrinsing, drying and sample pressing treatment, and a to-be-detected silver sample is obtained. By designing acid pickling in the sample preparation process, glow discharge mass spectrometry detectionof a fine silver sample is realized, introduction of impurities is avoided, the detection efficiency is high, and the detection time is short.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Method for purifying iron solution by adopting extraction chromatography

InactiveCN102382981AImprove purification effectReduce consumptionPhotography auxillary processesProcess efficiency improvementGlow Discharge Mass SpectrometryIngot

The invention relates to a method for purifying an iron solution by adopting extraction chromatography. The method comprises the following steps of: (1) extracting the iron solution by using a chromatographic column, namely adsorbing a P204 extracting agent to macroporous absorption resin in a saponification adsorption mode, obtaining P204 extracted resin, performing wet column filling, adding the iron solution, and leaching the P204 extracted resin chromatographic column; (2) leaching with a leaching solution, namely leaching the iron-carrying P204 extracted resin chromatographic column by using an acid solution as the leaching solution; and (3) leaching with a back extraction solution and concentrating, namely leaching with the acid back extraction solution, back extracting the iron in the P204 extracted resin chromatographic column to the aqueous phase, obtaining a high-purity iron salt solution, concentrating the high-purity iron salt solution, performing electrolytic deposition, and performing vacuum smelting on the electrolytic deposition iron obtained at the cathode to obtain a high-purity iron ingot, wherein the purity of the iron is over 4N by glow discharge mass spectrometry. The method is simple in process flow, easy in operation, high in equipment capacity, low in investment and low in consumption of chemical materials.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Gallium electrolytic refining method

InactiveCN102011142AAvoid direct contactAvoid pollutionPhotography auxillary processesProcess efficiency improvementPlatinumElectrolysis

The invention discloses a gallium electrolytic refining method, which relates to a gallium electrolytic refining process, in particular to a method for improving electrode materials in a refining process. The method is characterized in that: in the electrolytic refining process, a metal gallium sheet is used in places of a foil sheet as a cathode; and a platinum wire serving as a cathode lead wire is provided with a clean FEP tube protective layer. In the method, when the measures are carried out, the electrochemical corrosion problem of the foil is solved, the cathode foil sheet is replaced completely, the foil content in the electrolytic product is reduced from 0.08 to 0.2ppm before improvement to 0.01 ppm which is lower than a detection limit of glow discharge mass spectrometry, the product quality is improved, and operation flow is simplified.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Glow discharge mass spectrometry high-purity gallium testing method

PendingCN113533493AGuaranteed cooling effectPreparing sample for investigationMaterial analysis by electric/magnetic meansIndiumMass spectrometry

One or more embodiments of the invention provide a glow discharge mass spectrometry high-purity gallium testing method, which comprises the following steps: heating solid gallium to obtain liquid gallium, cleaning a polytetrafluoroethylene mold, air-drying, putting the polytetrafluoroethylene mold on a cooling device, pouring the liquid gallium into the polytetrafluoroethylene mold placed on the cooling device, transferring the polytetrafluoroethylene mold into an ultra-clean bench within a set time, standing until a formed sample is obtained, fixing the formed sample, charging the sample into a GDMS sample chamber, vacuumizing, cooling the sample in a semiconductor refrigeration mode, discharging within the set time, and removing surface pollution through discharge sputtering; after the signal is stable, collecting and analyzing data are through the GDMS, and after the analysis is finished, recording and storing the data, so that the purpose that the plane to be measured can be obtained through a form conversion mode for low-melting-point metal such as gallium and indium for measurement is achieved.

Owner:宣城开盛新能源科技有限公司 +1

Method for preparing high-pure-cobalt solution through stirring and extraction

ActiveCN105154673AImprove purification effectHigh strengthProcess efficiency improvementElectrolysisKerosene

The invention relates to a method for preparing a high-pure-cobalt solution through stirring and extraction, and belongs to the technical field of preparing a metal material. The method comprises: preparing a cobalt solution in a high-level extraction tank; adding sulfonated kerosene, a P507 extractant, and sodium hydroxide in a low-level extraction tank, performing stirring for saponification, and pumping the obtained product into the high-level extraction tank for stirring and extraction to enable cobalt in the cobalt solution extracted into an organic phase; adding hydrochloric acid to wash the loading organic phase while performing stirring, and performing back extraction to prepared a cobalt-rich liquid; adding a macroporous adsorption resin for deep purification, and performing condensation and electrolytic deposition; and performing vacuum melting of electrolytic deposited cobalt to obtain a high-pure cobalt ingot. The purity of the high-pure cobalt ingot is analyzed by glow discharge mass spectrometry, and the purity of more than 70 kinds of elements in the cobalt ingot is more than 99.999%. According to the invention, high selectivity of liquid-liquid extraction and properties, such as turbulence and shear force, of stirring are combined to enhance the reaction process and to improve the purification capability of the cobalt solution. The method is simple, and is easy to operate and low in cost. Processes in the method are relatively independent, so that the method is high in flexibility. Chemical materials are less in consumption, and the equipment is high in productivity, so that the method benefits scale production.

Owner:有研资源环境技术研究院(北京)有限公司

A pre-measurement method for high-purity indium samples used for glow discharge mass spectrometry detection

ActiveCN110542604BCreate pollutionNo importPreparing sample for investigationMaterial analysis by electric/magnetic meansIndiumTest sample

The invention discloses a pre-test treatment method of a high-purity indium sample for glow discharge mass spectrometric detection. According to the method, firstly, the to-be-tested high-purity indium sample is subjected to ultrasonic corrosion, then the corroded sample is subjected to ultrasonic cleaning and blow-drying sequentially, and the blow-dried sample is placed between two non-metallic hard plates; an external force is applied to the upper non-metallic hard plate, so that a plane is generated at the bottom of the sample after the sample is extruded; the external force continues to beapplied to the upper hard plate till the plane at the bottom of the sample is gradually enlarged to a size required by a glow discharge mass spectrometric test, and then application of the external force is stopped; and the flaky sample between the two non-metallic hard plate is taken out, cleaned and blow-dried, and then a to-be-tested sample sheet meeting the test demand is obtained. Compared with a traditional pre-test treatment method, the method is simple, easy to implement, free of impurity introduction and pollution to the sample and low in cost; and through the method, the time of theglow discharge mass spectrometric detection is shortened, the detection speed is increased, and the practical value is high.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of tungsten block sample for glow discharge mass spectrometry detection

InactiveCN110864949ASolve the problem that the size is not suitable for the detection and analysis of glow discharge mass spectrometrySolve the problem that it is not suitable for the detection and analysis of glow discharge mass spectrometryPreparing sample for investigationMaterial analysis by electric/magnetic meansPhysical chemistryGlow Discharge Mass Spectrometry

The invention relates to a preparation method of a tungsten block sample for glow discharge mass spectrometry detection. The method comprises the following steps of cutting a tungsten bar column, polishing, cleaning the tungsten bar column by an organic reagent, embedding the tungsten bar column, roughly grinding the tungsten block, finely grinding the tungsten bar column, soaking and washing by acid liquor, washing by deionized water, cleaning by the organic reagent and drying by blowing. The problem that the size of the slender tungsten bar is unsuitable for glow discharge mass spectrometrydetection and analysis is solved, and the common metallographic mosaic powder replaces the conductive metallographic mosaic powder with relatively higher price, thereby reducing the detection cost.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

Method for removing impurity bismuth in metal gallium

The invention discloses a method for removing impurity bismuth in metal gallium, which adopts a partial crystallization purification technique to implement the operation for four times. The technical condition is set as: a temperature gradient is 1.1 to 1.4 DEG C / cm, an average crystallization speed is 3.2 to 4.2g / min, and the solid-liquid ratio is 75 to 85 percent. Compared with the prior art, the method can effectively lower the bismuth content in the gallium metal to the limit (5ppb) or less detected by a glow discharge mass spectrometry (GDMS), so that a good condition can be created for preparing high-purity gallium with the purity of 99.9999 percent.

Owner:朝阳金美镓业有限公司

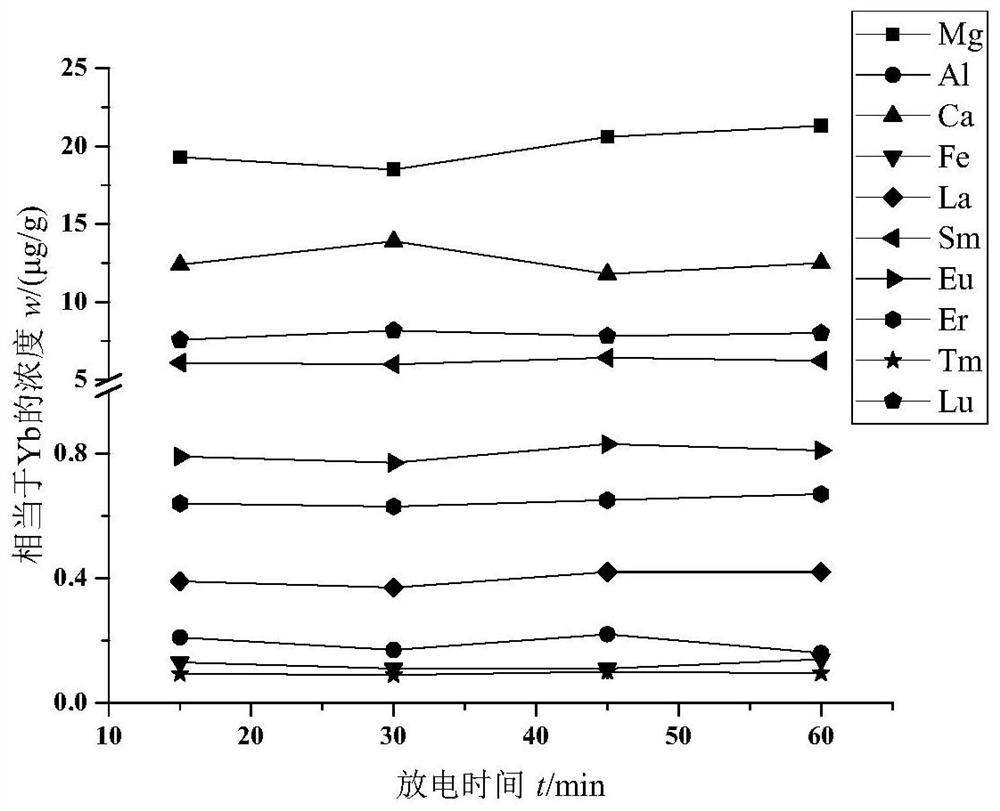

Method of measuring thickness of Nd-Fe-B alloy coating

InactiveCN106895801AAccurate measurementSimple methodMaterial analysis by electric/magnetic meansUsing wave/particle radiation meansSputteringPower flow

The invention relates to a method of measuring the thickness of an Nd-Fe-B alloy coating, which belongs to the technical field of coating detection. Absolute ethanol is used for cleaning the surface of the Nd-Fe-B alloy coating, and a nitrogen gas is used for drying; glow discharge mass spectrometry (GD-MS) is adopted to carry out all-element qualitative measurement on the alloy coating, and the coating type is judged; the discharge current of a GD-MS instrument is adjusted to be 20 mA, the discharge gas Ar flow is 400 mL / min, and corresponding lens parameters are adopted for each coating; uninterrupted sputtering is carried out on the alloy coating, data are collected for one time at each 15 seconds until a Fe element content rises straightly, and sputtering is stopped; the obtained data are used for drawing an element mass fraction-sputtering time distribution map, a boundary point in each layer is found out on the map, and the sputtering time in each coating layer is obtained; and according to the sputtering rate and the sputtering time of each layer, the thickness of each coating is calculated, the method is simple and easy to operate, and the accuracy is high.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Preparation method and application of needle-shaped sample for glow discharge mass spectrometry detection

PendingCN112557496AImprove cooling effectAvoid meltingMaterial analysis by electric/magnetic meansElectrical conductorCooling effect

The invention provides a preparation method and application of a needle-shaped sample for glow discharge mass spectrometry detection, and belongs to the technical field of analysis and detection. Theliquid gallium is injected into a needle-shaped sample holder, a sample to be detected is inserted into the liquid gallium, then the sample holder is inserted into the liquid nitrogen to be cooled, and after the liquid gallium is solidified, the sample holder is taken out to obtain the needle-shaped sample, so that when the obtained needle-shaped sample is used for glow discharge mass spectrometrydetection, a good cooling effect is achieved; the sample can be prevented from melting when the low-melting-point sample is detected, meanwhile, the size range of the sample capable of being detectedby glow discharge mass spectrometry is widened, and a conductor and a semiconductor with the size of 0-3 mm*0-3 mm*8-22 mm can be directly measured.

Owner:安徽中飞科技有限公司

Method for detecting gallium in glow discharge mass spectrometry

PendingCN111638267AAvoid introducingGuaranteed accuracyPreparing sample for investigationMaterial analysis by electric/magnetic meansPhysical chemistryGlow Discharge Mass Spectrometry

The invention relates to a method for detecting gallium in glow discharge mass spectrometry. The method comprises the following steps of sequentially refrigerating and sputtering a gallium sample to be detected, which is subjected to sample preparation treatment, and then testing. According to the detection method provided by the invention, introduction of impurities can be avoided, the analysis time is shortened, accuracy of data is ensured, meanwhile, a relatively strong signal can be obtained through the detection method provided by the invention, and detection sensitivity is high.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Method for detecting impurity elements and content thereof in graphene oxide

ActiveCN111351833ASolve the problem of large detection errorEasy to operateMaterial analysis by electric/magnetic meansPhysical chemistryGlow Discharge Mass Spectrometry

The invention relates to a method for detecting impurity elements and content thereof in graphene oxide. The method comprises the following steps: S10, detecting each element and contents thereof in high-purity aluminum powder by adopting glow discharge mass spectrometry; S20, carrying out drying pretreatment on the graphene oxide, grinding, adding high-purity aluminum powder, grinding, and uniformly mixing to obtain a sample; and S30, detecting the sample by adopting the glow discharge mass spectrometry in the step S10 to obtain detection data, and carrying out quantitative analysis to obtainimpurity elements in the graphene oxide and the content of the impurity elements. By using a doping method, graphene oxide is doped into high-purity aluminum powder for GDMS detection, and a to-be-detected sample is pretreated, so that the to-be-detected sample is sputtered and diffused into plasma more easily, and the problem of relatively large detection error caused by relatively poor C / O element detection limit of GDMS is solved.

Owner:新疆烯金石墨烯科技有限公司

Sample preparation method of molybdenum scraps in glow discharge mass spectrometry

PendingCN113030237AAvoid introducingGuaranteed accuracyPreparing sample for investigationMaterial analysis by electric/magnetic meansPhysical chemistryGlow Discharge Mass Spectrometry

The invention provides a sample preparation method of molybdenum scraps in glow discharge mass spectrometry, which comprises the following steps of: placing molybdenum scraps to be detected in a blind hole of a conductive substrate, and then tabletting to complete sample preparation of the molybdenum scraps. According to the invention, a blind hole is formed in a conductive substrate, and molybdenum chips are subjected to sample preparation by using the blind hole of the conductive substrate, so that the pollution possibly caused by the sample is reduced, and the accuracy of detection data is improved; and the sample preparation success rate of the sample preparation method can reach 95% or above.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Sample preparation method and test method of glow discharge mass spectrometry ammonium paratungstate powder

PendingCN113358442AAvoid introducingImprove accuracyPreparing sample for investigationMaterial analysis by electric/magnetic meansIndiumAmmonium paratungstate

The invention provides a sample preparation method and a test method of glow discharge mass spectrometry ammonium paratungstate powder. The method comprises the steps: forming a groove in the surface of a high-purity indium sheet, cleaning the indium sheet, transferring the ammonium paratungstate powder into the groove by using a cleaned medicine spoon, and compacting by using a press machine to obtain a sample to be tested. According to the sample preparation method, introduction of impurities can be fully avoided, the analysis time is shortened, and the accuracy of a test result is improved; and the test signal obtained by the test method is strong, and the sensitivity is high.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Method for analyzing small-size conductive and non-conductive materials by applying glow discharge mass spectrometry

PendingCN113514534ANo need to grindNo sinteringPreparing sample for investigationMaterial analysis by electric/magnetic meansConductive materialsMaterials science

The invention relates to a method for analyzing small-size conductive and non-conductive materials by applying glow discharge mass spectrometry, and belongs to the field of material analysis. The method comprises the following steps: placing graphite powder in an aluminum cup, and slightly vibrating the aluminum cup to flatten the surface of the graphite powder; placing a small-size conductive material or a non-conductive material on the graphite powder; covering with a plurality of layers of parchment paper; pressing by using a tablet press to prepare a test sample; and carrying out direct current glow discharge mass spectrometry. According to the analysis method, grinding, sintering and heating are not needed, the pretreatment is simple, and the pollution is avoided; the problem that the metal element cannot be measured when the metal is used as a conducting medium and the mass spectrum interference formed by the metal element are avoided; the analysis time is shortened, and the analysis efficiency is improved; the method can be suitable for analysis of small-size conductive materials such as crumb-shaped, granular and powdery conductive materials and fine-granular and powdery non-conductive materials, and is high in universality and wide in application range; the method has good discharge stability, analysis repeatability and analysis accuracy.

Owner:国合通用测试评价认证股份公司 +1

Sample preparation method and test method of trititanium pentoxide crystal particles in glow discharge mass spectrum

PendingCN113109121AGuaranteed accuracyImprove washabilityPreparing sample for investigationMaterial analysis by electric/magnetic meansIndiumPhysical chemistry

The invention provides a sample preparation method and a test method of trititanium pentoxide crystal particles in glow discharge mass spectrometry, and the sample preparation method comprises the following steps: (1) sequentially carrying out acid pickling, first water washing, first ethanol washing and first drying on an indium sheet to obtain a treated indium sheet; (2) sequentially carrying out second ethanol washing, second water washing, third ethanol washing and second drying on the trititanium pentoxide crystal particles to obtain treated trititanium pentoxide crystal particles; (3) placing the trititanium pentoxide crystal particles in the step (2) on the surface of the indium sheet, and tabletting to obtain a sample to be detected. The step (1) and the step (2) do not have a sequence; according to the sample preparation method, introduction of impurities is avoided as much as possible, so that the analysis time is shortened, and the data accuracy is ensured; according to the test method, strong signals can be obtained through specific test parameters, and the sensitivity is high.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

A kind of stirring extraction prepares the method for high-purity cobalt solution

ActiveCN105154673BImprove purification effectHigh strengthProcess efficiency improvementElectrolysisKerosene

The invention relates to a method for preparing a high-pure-cobalt solution through stirring and extraction, and belongs to the technical field of preparing a metal material. The method comprises: preparing a cobalt solution in a high-level extraction tank; adding sulfonated kerosene, a P507 extractant, and sodium hydroxide in a low-level extraction tank, performing stirring for saponification, and pumping the obtained product into the high-level extraction tank for stirring and extraction to enable cobalt in the cobalt solution extracted into an organic phase; adding hydrochloric acid to wash the loading organic phase while performing stirring, and performing back extraction to prepared a cobalt-rich liquid; adding a macroporous adsorption resin for deep purification, and performing condensation and electrolytic deposition; and performing vacuum melting of electrolytic deposited cobalt to obtain a high-pure cobalt ingot. The purity of the high-pure cobalt ingot is analyzed by glow discharge mass spectrometry, and the purity of more than 70 kinds of elements in the cobalt ingot is more than 99.999%. According to the invention, high selectivity of liquid-liquid extraction and properties, such as turbulence and shear force, of stirring are combined to enhance the reaction process and to improve the purification capability of the cobalt solution. The method is simple, and is easy to operate and low in cost. Processes in the method are relatively independent, so that the method is high in flexibility. Chemical materials are less in consumption, and the equipment is high in productivity, so that the method benefits scale production.

Owner:有研资源环境技术研究院(北京)有限公司

Testing method for detecting low-melting-point material by glow discharge mass spectrometry

PendingCN114034762ALow detection limitImprove matrix strengthMaterial analysis by electric/magnetic meansLiquid stateGlow Discharge Mass Spectrometry

The invention discloses a testing method for detecting a low-melting-point material by glow discharge mass spectrometry. The testing method comprises the following steps of 1, manufacturing a metal carrier; 2, obtaining a treated metal carrier; 3, a liquid low-melting-point material being obtained, and then a proper amount of the liquid low-melting-point material being taken and poured into the circular groove; 4, sequentially rinsing the surface of the solidified to-be-detected sample with deionized water ethanol for three times, and then naturally airing and putting into a sample cup; and 5, cooling the ion source chamber, connecting the sample cup with an electrode, pushing the sample cup into the ion source chamber, and detecting impurity components. According to the method, complex pretreatment is avoided, so analysis efficiency is improved, impurity interference caused by pretreatment is avoided for component analysis of the high-purity low-melting-point material, accuracy of an analysis result is ensured, and the method can be used for simultaneously analyzing multiple elements, has advantages of high analysis speed, small matrix effect, good environmental friendliness and the like, and has wide application prospects.

Owner:江西省钨与稀土产品质量监督检验中心(江西省钨与稀土研究院)

Method for measuring content of major elements in multi-component alloy by proportionality coefficient correction glow mass spectrometry

The invention relates to a method for determining the content of major elements in a multi-component alloy through proportionality coefficient correction glow mass spectrometry, and belongs to the technical field of analytical testing. The method comprises the following steps: determining a group of multi-component alloys with different major elements and different contents by adopting a glow discharge mass spectrometer to obtain mass counts of the major elements; establishing a proportion coefficient f of the major element content to mass counting; and finally, rapidly obtaining the mass count of the major elements in the to-be-detected multi-element alloy sample by using glow discharge mass spectrometry, correcting by using a proportionality coefficient f, and quantitatively obtaining the content of the major elements. According to the method, the constant-value multicomponent alloy is used, the mass counting proportionality coefficient relation with the glow discharge mass spectrometry is established, so that the content of the major elements in the multicomponent alloy is quantitatively determined, and the method has the advantages of rapidness, accuracy, reliability and the like, and is an effective content analysis method for the major elements in binary and ternary alloy materials.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

A cage-shaped sampling device and sample testing method for glow discharge mass spectrometry analysis

ActiveCN110749645BEasy to handleLarge sputtering areaMaterial analysis by electric/magnetic meansPhysical chemistryMass Spectrometry-Mass Spectrometry

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com