Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

153 results about "Fluid milk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluid milk. "Fluid milk" means milk and any other product made by the addition of a substance to milk or to a liquid form of milk product if the milk or other product is produced, processed, distributed, sold or offered or exposed for sale for human consumption.

Liquid state milk suitable for baby from newborn to six months old

ActiveCN101233873AGuaranteed stabilityEnsure safetyMilk preparationFood preparationVegetable oilGalactooligosaccharide

The invention relates to milk and a method for preparing thereof, in particular to fluid milk applicable for infants below six months old, which belongs to a milk technical field. The milk comprises 18.5-33 percent of fresh milk or reconstituted milk, 0.8-1.6 percent of concentrated lactoalbumin, 3.1-8.5 percent of sugar, 0.35-2.5 percent of vegetable oil, 0.01-0.6 percent of emulsifier (0.1-0.4 percent is preferable), 3-10 mg / 100g of ethylamine sulfonic acid, 1-7mg / 100 g of nucleotide, 20-30mg / 100 g of casein phospho peptides, 1-21mg / 100 g of DHA, 4-30mg / 100 g of ARA, 4-15mg / 100 g of lactoferrin, 50-70mg / 100g of GOS, 40-60mg / 100 g of FOS, 5-28mg / 100 g of choline, 5-28mg / 100 g of phaseomannite, 0.007-0.03 percent of Vitamin B complex, 0.00005-0.08 percent of complex mineral element (by elements) and soft water for the rest percentage.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Liquid state milk suitable for baby from 12 to 36 months old

ActiveCN101233874AGuaranteed stabilityEnsure safetyMilk preparationFood preparationVegetable oilGalactooligosaccharide

The invention relates to milk and a method for preparing thereof, in particular to fluid milk applicable for infants of 12-36 months old, which belongs to a milk technical field. The milk comprises 5.5-16 percent of full-cream milk powder, 0.12-3.3 percent of dried skimmed milk, 0.065-7.26 percent of sugar, 0.35-2.5 percent of vegetable oil, 0.01-0.6 percent of emulsifier, 3-10mg / 100 g of ethylamine sulfonic acid, 1-12mg / 100 g of nucleotide, 20-30mg / 100 g of casein phospho peptides, 0.3-10mg / 100g of DHA, 0.6-22mg / 100g of ARA, 4-15mg / 100g of lactoferrin, 20-130mg / 100g of GOS, 30-500mg / 100g of FOS, 5-35mg / 100g of choline, 3-28mg / 100g of phaseomannite, 0.007-0.08 percent of Vitamin B complex, 0.00005-0.08 percent of complex mineral element (by elements) and water for the rest percentage.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

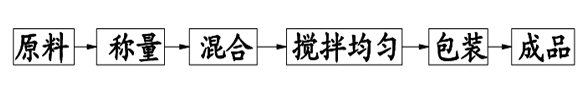

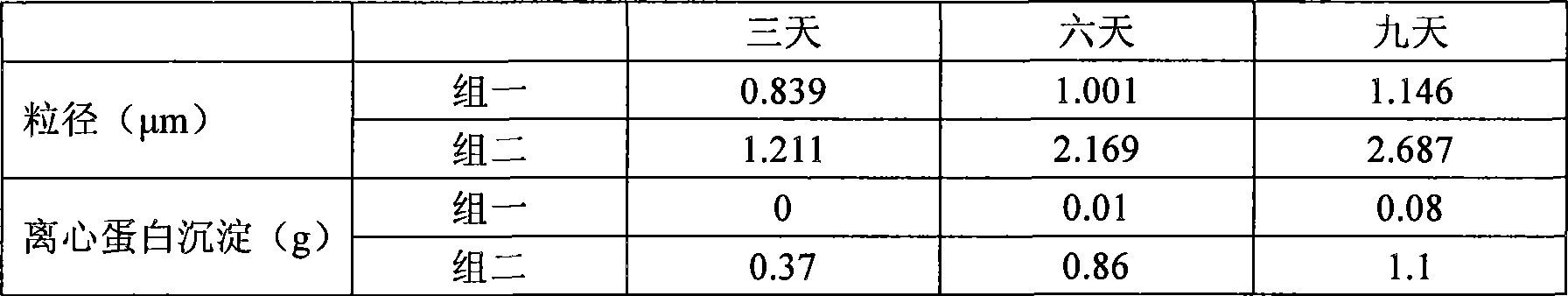

Production process of solidified brown yogurt, and product of process

ActiveCN103141572AEnhances gel strength and water holding capacityThick and smoothMilk preparationFlavorChemistry

The invention relates to a production process of solidified brown yogurt and a product of the process, which belong to the technical field of liquid milk processing. The production process comprises the following steps of: uniformly mixing 87.5%-90.5% of raw milk, 7.5%-8.5% of edible sugar, 1.5%-2.5% of whey protein and 0.5%-1.5% of milk protein concentrate in percentage by weight, and performing homogenization, sterilization for browning, cooling, inoculation, bottling, fermentation and cold storage on the mixture to obtain the yogurt. The process can be used for producing the solidified brown yogurt having the characteristics that the curd is firm, no whey is separated out, the color is brown, the mouthfeel is thick and smooth, and the yogurt has a pleasant Maillard flavor. By virtue of the process, under the condition that no additive needs to be used, the jelly strength and the water retention property of the yogurt can be improved, so that the solidified brown yogurt is thick and smooth in mouthfeel and has the pleasant Maillard flavor; and in logistic and sale links, the mechanical disruption resistance of the yogurt is high, and no whey is separated out in the shelf life of the yogurt.

Owner:HANGZHOU NEW HOPE BIMODAL DAIRY CO LTD

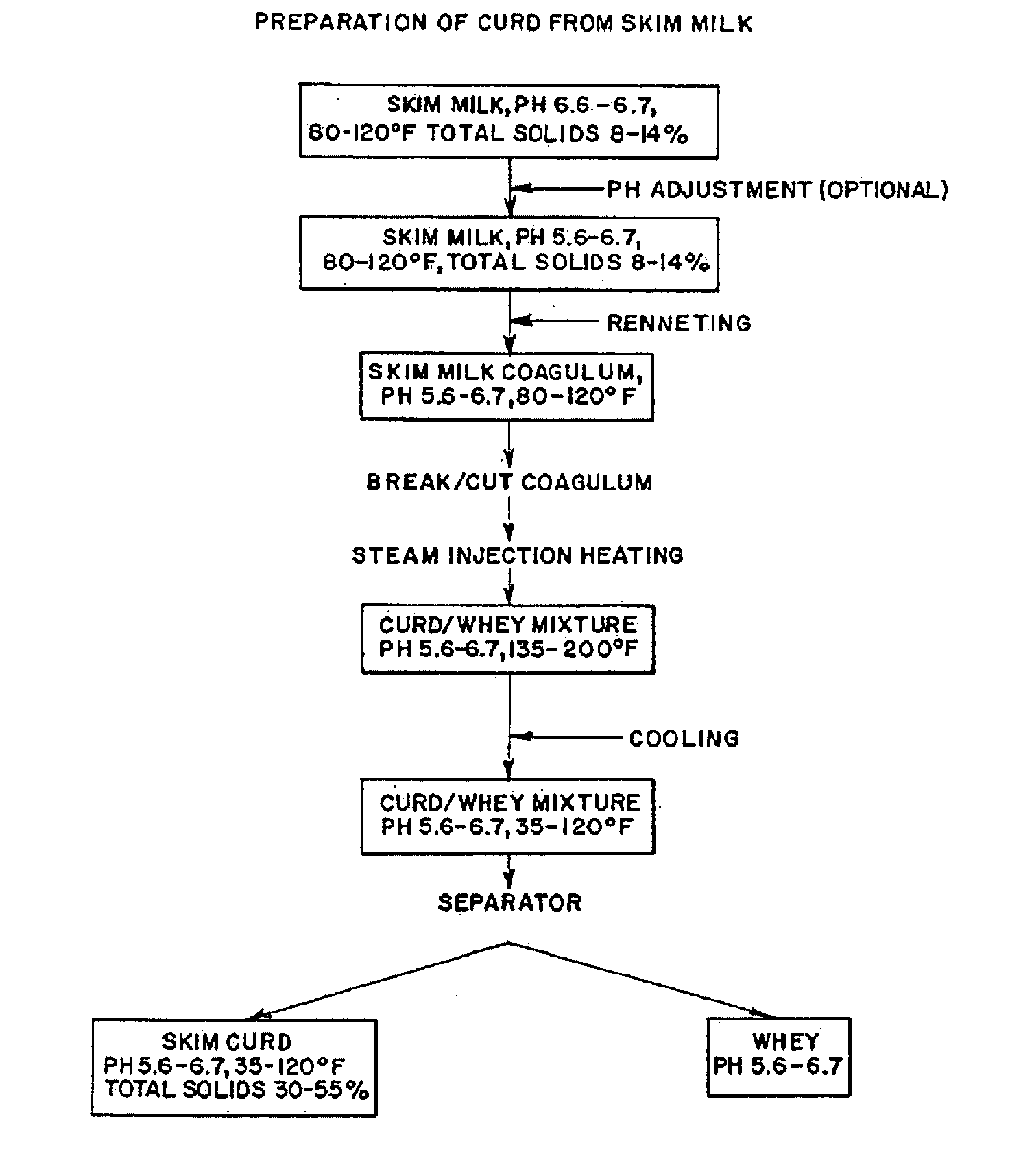

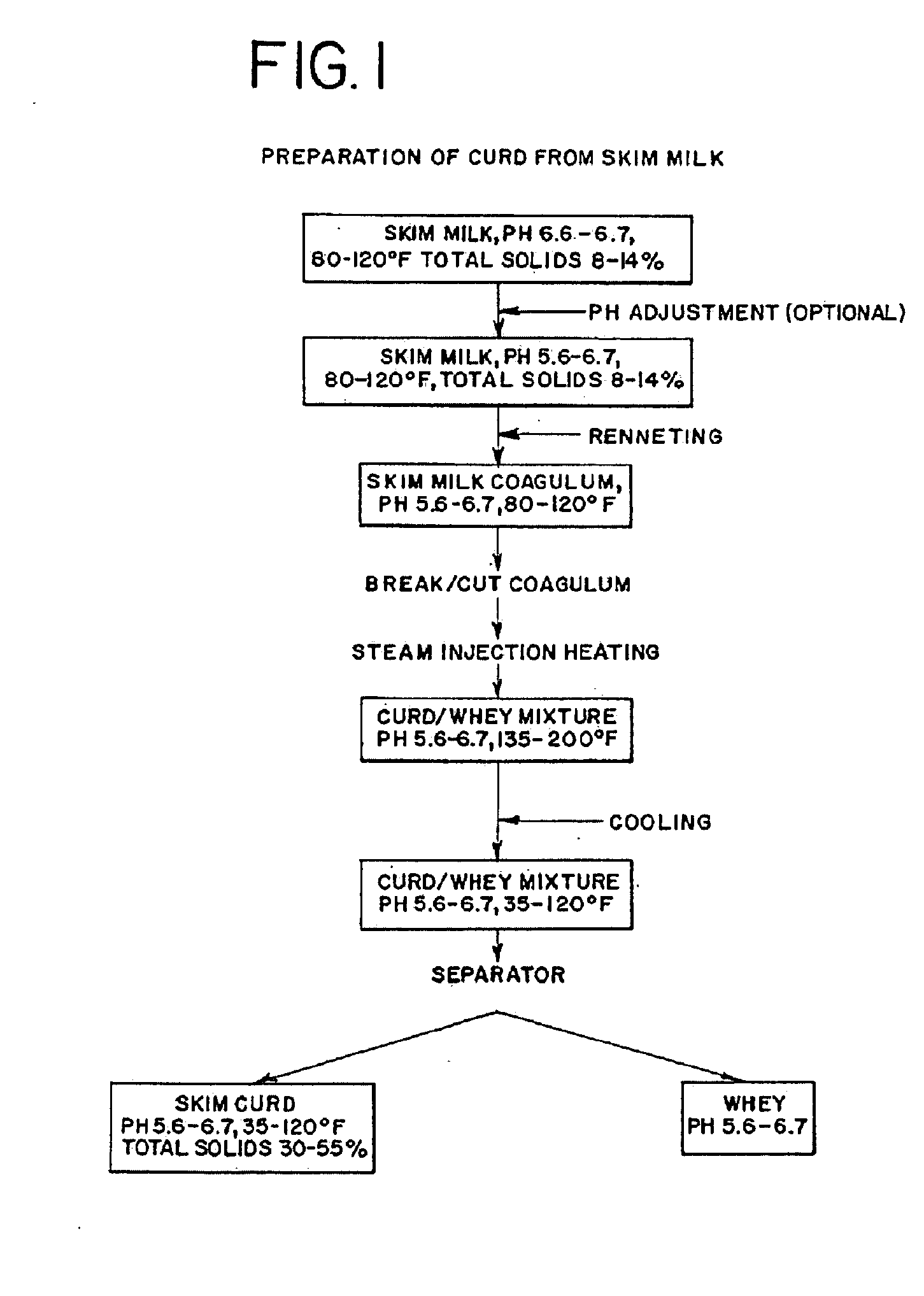

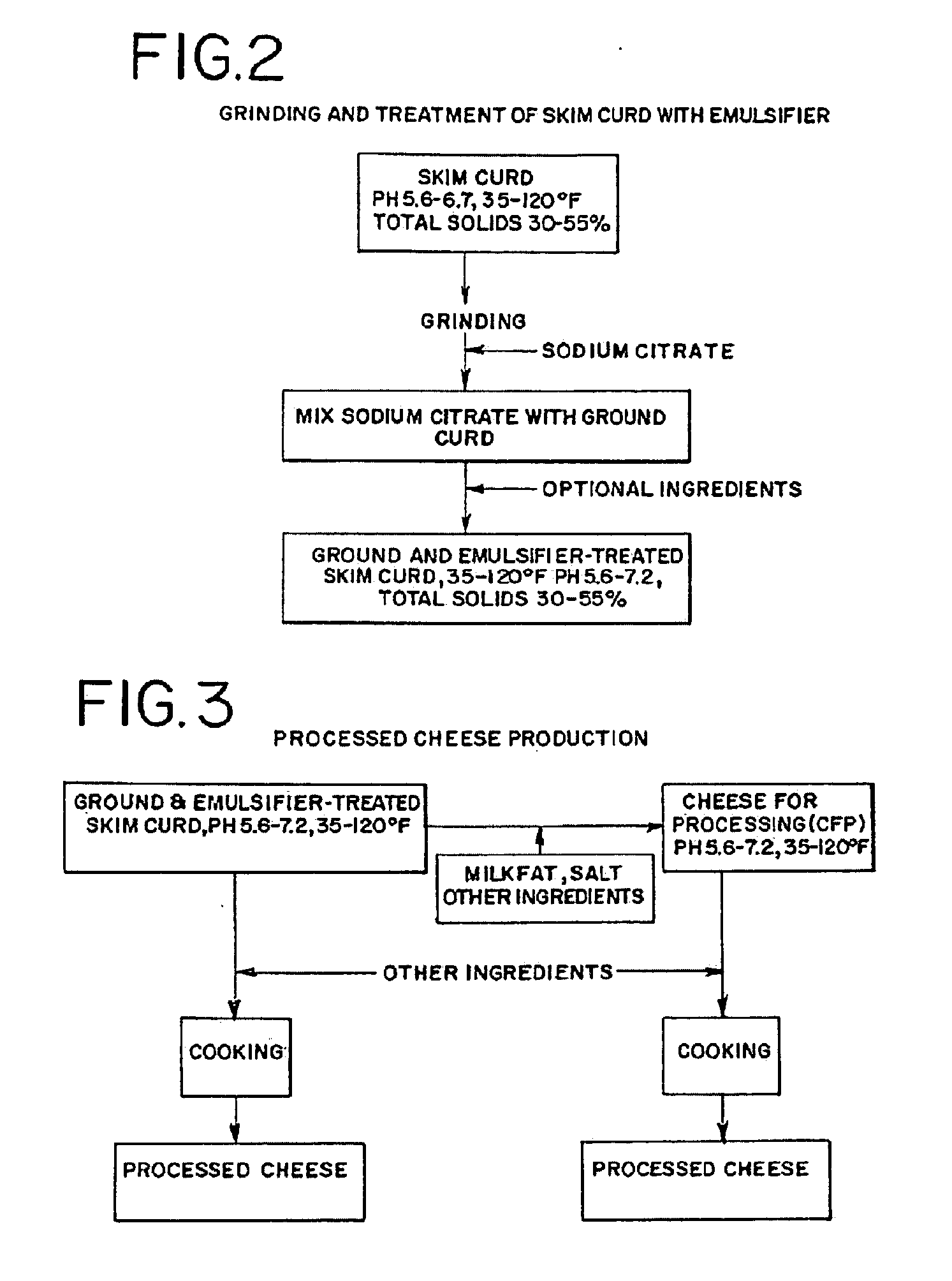

Curds for processed and imitation cheese, cheese products produced therefrom, novel intermediate products and methods of making same

InactiveUS20060062873A1High activityRapid and economical productionMilk preparationCheese manufactureAdditive ingredientEnzyme

Methods of making novel cheese curds and cheese products comprise the steps of providing a fluid milk protein source containing casein; mixing a milk coagulating enzyme into the fluid milk protein source; allowing the milk coagulating enzyme to react with the casein for a time sufficient for the fluid milk protein source to form coagulum while at a pH of 5.6 or above; heating the coagulum containing the enzyme treated casein to a temperature of at least 135° F., more preferably at least 150° F., while the fluid milk protein source is at a pH of 5.6 or above, for a time sufficient to cause syneresis of the coagulum and to form curds; and separating the curds from liquid remaining from the curd formation. In another embodiment, the milk coagulating enzyme is allowed to react with the casein for at least three hours while at a temperature at which a coagulum does not form; after which the fluid milk protein source containing the enzyme treated casein is heated to at least 135° F., for a time sufficient to cause the casein to form curds. The curds from either embodiment may be mixed with additional ingredients to make the cheese products, including processed and imitation cheese. A composition consisting essentially of a fluid milk protein source containing casein and milk coagulating enzyme in the form of a coagulum at a temperature of at least about 160° F., as well as ground curds having a weight average particle size of about 1.5 mm or less, are novel.

Owner:SCHREIBER FOODS

Liquid milk added with active polysaccharide

ActiveCN101356940AIncrease varietyRealize the combinationMilk preparationFood preparationChemistryFlavor

The invention discloses liquid milk added with active polysaccharide, and the components per 1000 weight portions contain: 600 to 900 portions of milk, 1 to 3 portions of active polysaccharide, 40 to 60 portions of sugar, 1 to 5 portions of honey, 0.1 to 1.5 portions of stabilizer, 0.5 to 1.5 portions of emulsifier and residual purified water. As the immune active polysaccharide is added, the liquid milk is a novel, functional and prepared milk, and after super-high temperature sterilization according to the manufacturing process of liquid milk, the product can keep the immune activity and good taste and flavor. Combined with nutritional components of milk, the liquid milk achieves the effect of homology of medicine and food in daily drink.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Fermented milk beverage containing peanut, lotus root and pawpaw and production method thereof

The invention relates to the field of liquid milk, in particular relating to a fermented milk beverage containing peanut, lotus root and pawpaw and a production method thereof. On the basis of 100 parts of fermented milk beverage by weight, the fermented milk beverage containing peanut, lotus root and pawpaw comprises: 30-80 parts of liquid milk by weight, 0.004-0.007 part of leaven by weight, 3.5-8.0 parts of sweet substance by weight, 0.2-0.7 part of acidity regulator by weight, 0.1-1.5 parts of stabilizing agent by weight, 1-30 parts of peanut paste by weight, 1-10 parts of lotus root powder by weight, 1-5 parts of pawpaw primary paste by weight and the balance water, wherein the stabilizing agent is composed of thickening agent and / or emulsifier, and the thickening agent contains 0.1-0.25 part of high acyl pectin and propylene glycol alginate. The product of the invention has refreshing and smooth taste when being drunk and contains special fragrance of peanut, lotus root and pawpaw products. Tests prove that the product has no layering phenomenon or severe fat flotation in the storage and placement process within the 6-month quality guarantee period. Thus, the product of theinvention has favorable stability.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

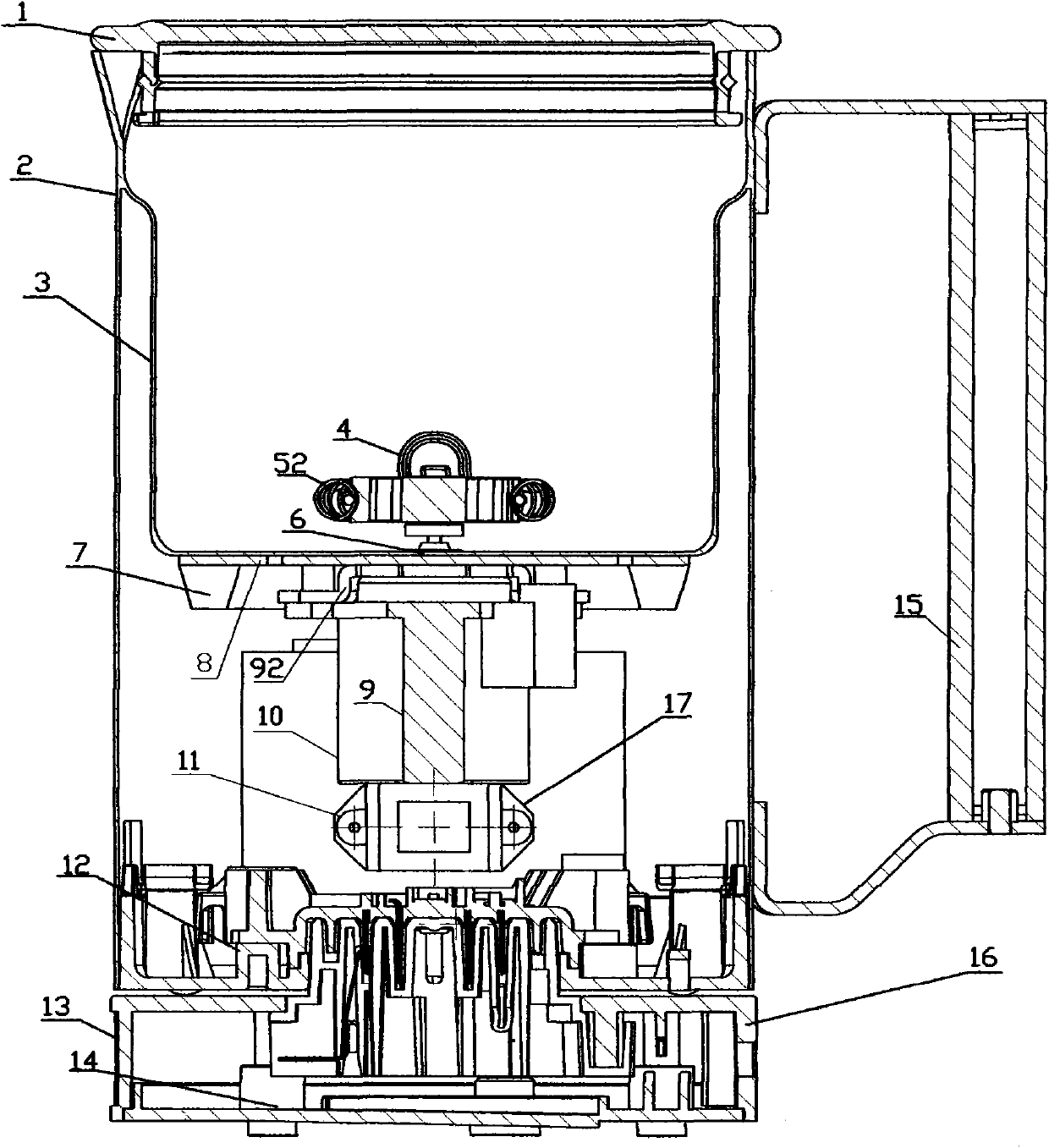

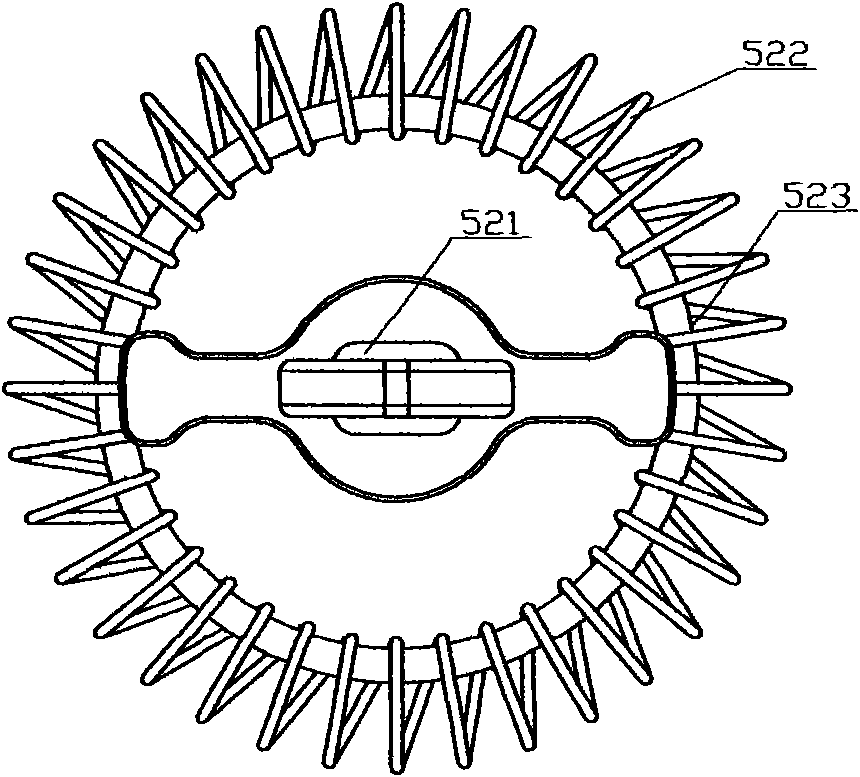

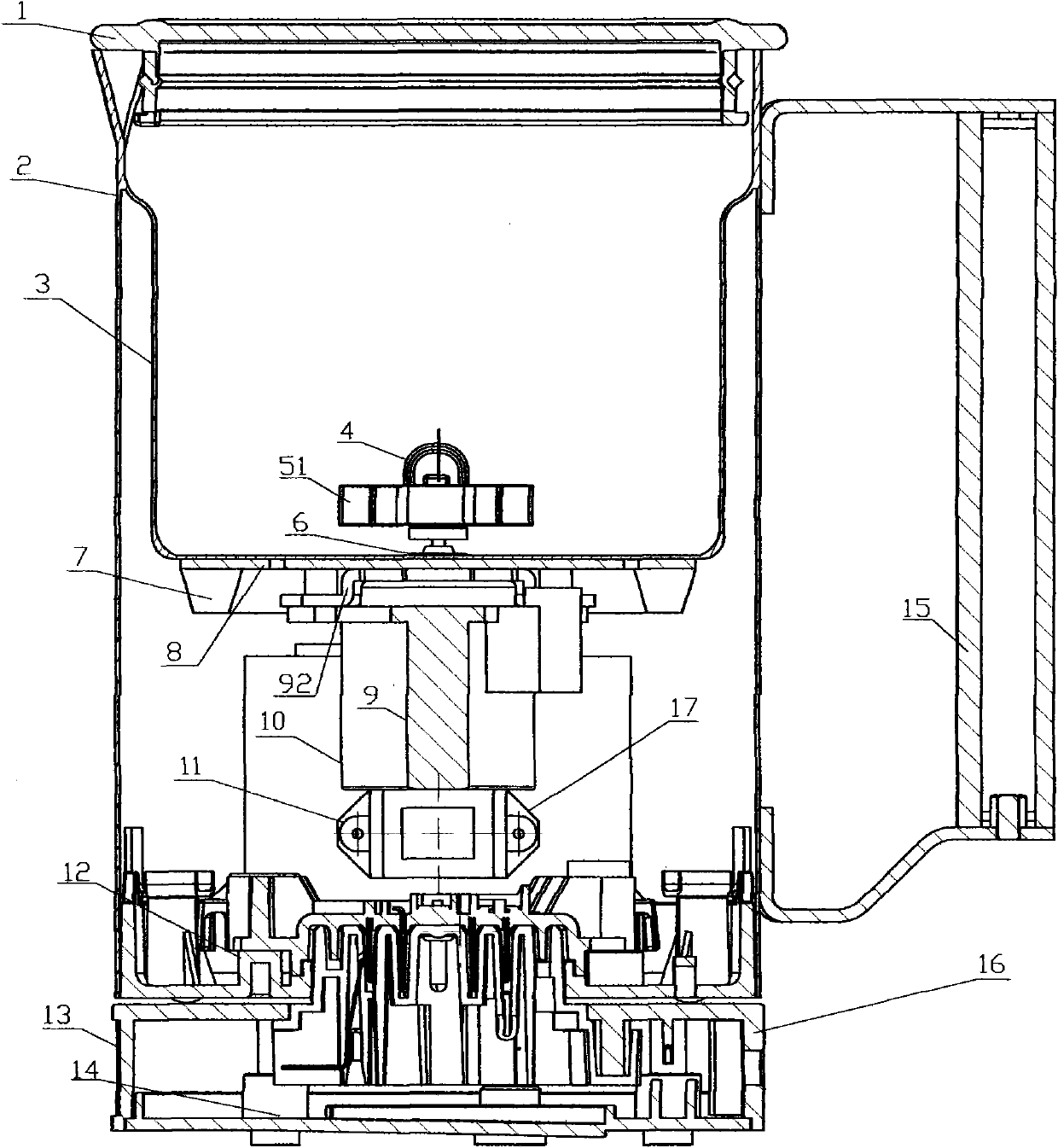

Milk foam machine directly driven by motor

ActiveCN101904700ASimple structureGood shaft seal performanceKitchen equipmentElectric machineLiquid state

Owner:GUANGDONG MASTER ELECTRICAL APPLIANCE CO LTD

Lactose-reduced dairy compositions and related methods

Compositions for ameliorating the symptoms associated with lactase deficiency, the composition including a lactose reduced dairy product, and an effective amount of a probiotic, a prebiotic, or a mixture thereof. The lactose reduced dairy product is selected from a fluid milk, a smoothie, a liquado, ice cream, yogurt, and a yogurt drink. Methods for treating lactose intolerance in a patient in need thereof, the method includes providing a composition having a lactose reduced dairy product, and an effective amount of a probiotic, a prebiotic, or a mixture thereof. The lactose reduced dairy product is selected from a fluid milk, a smoothie, a liquado, ice cream, yogurt, and a yogurt drink.

Owner:MCNEIL NUTRITIONALS

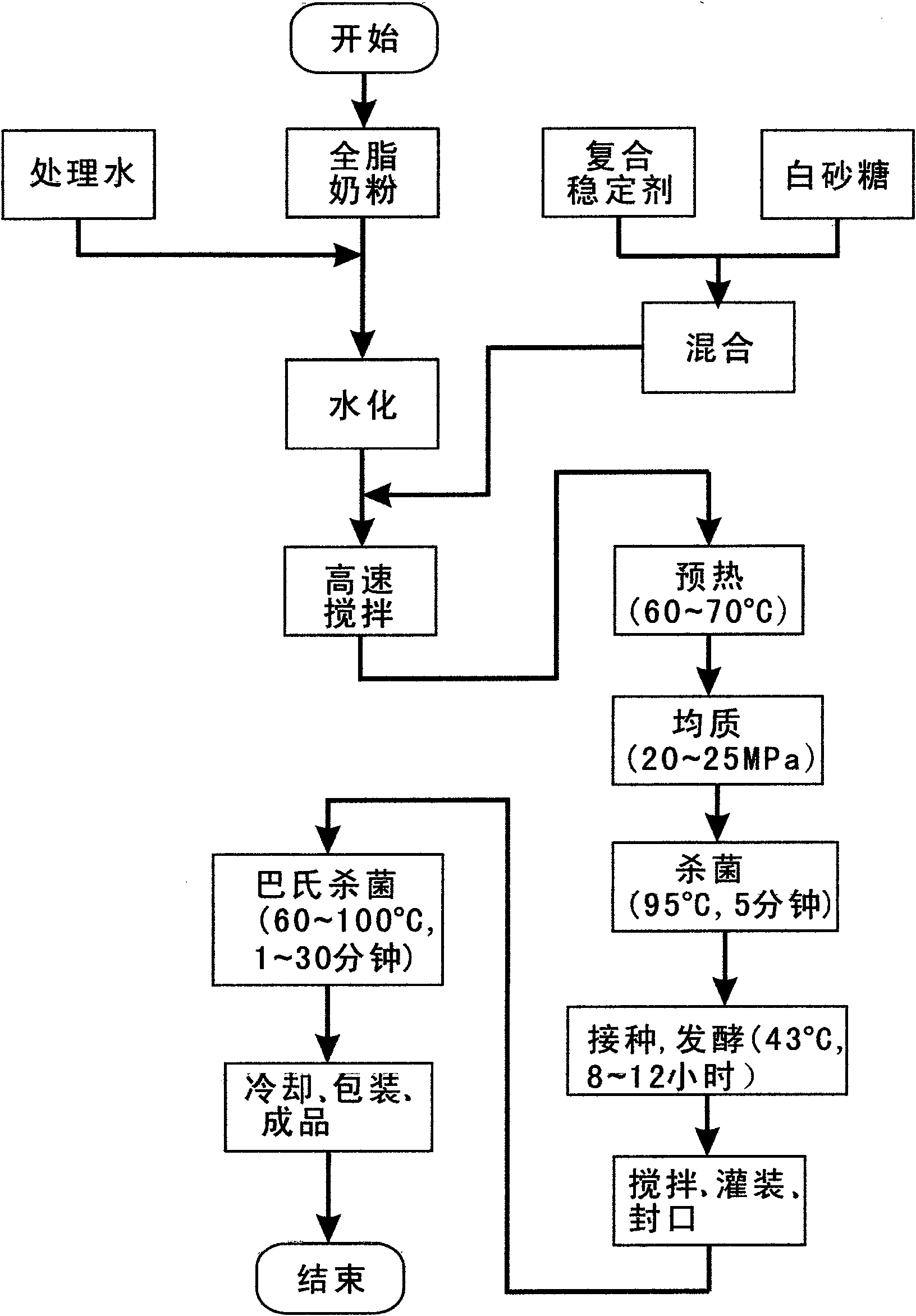

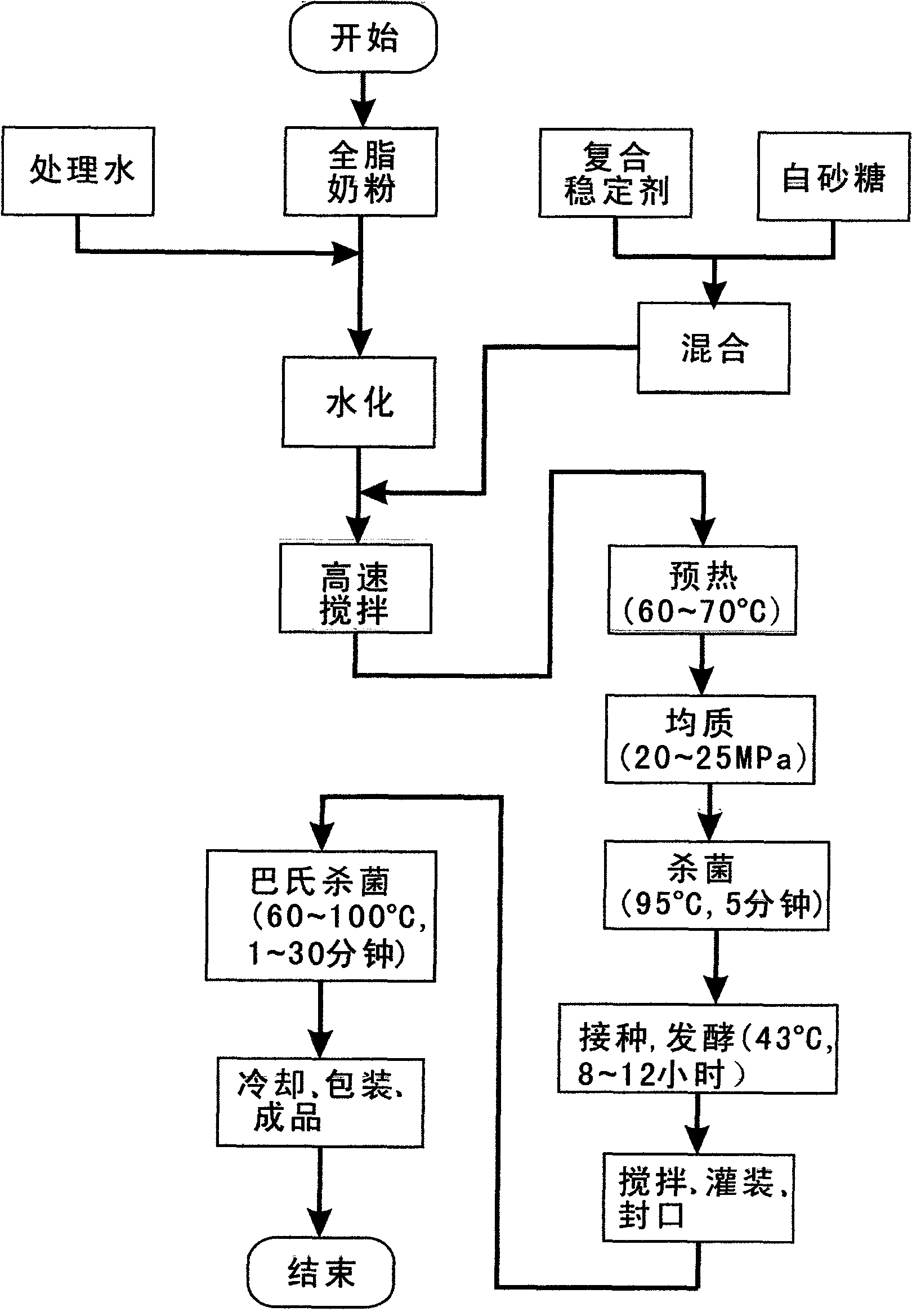

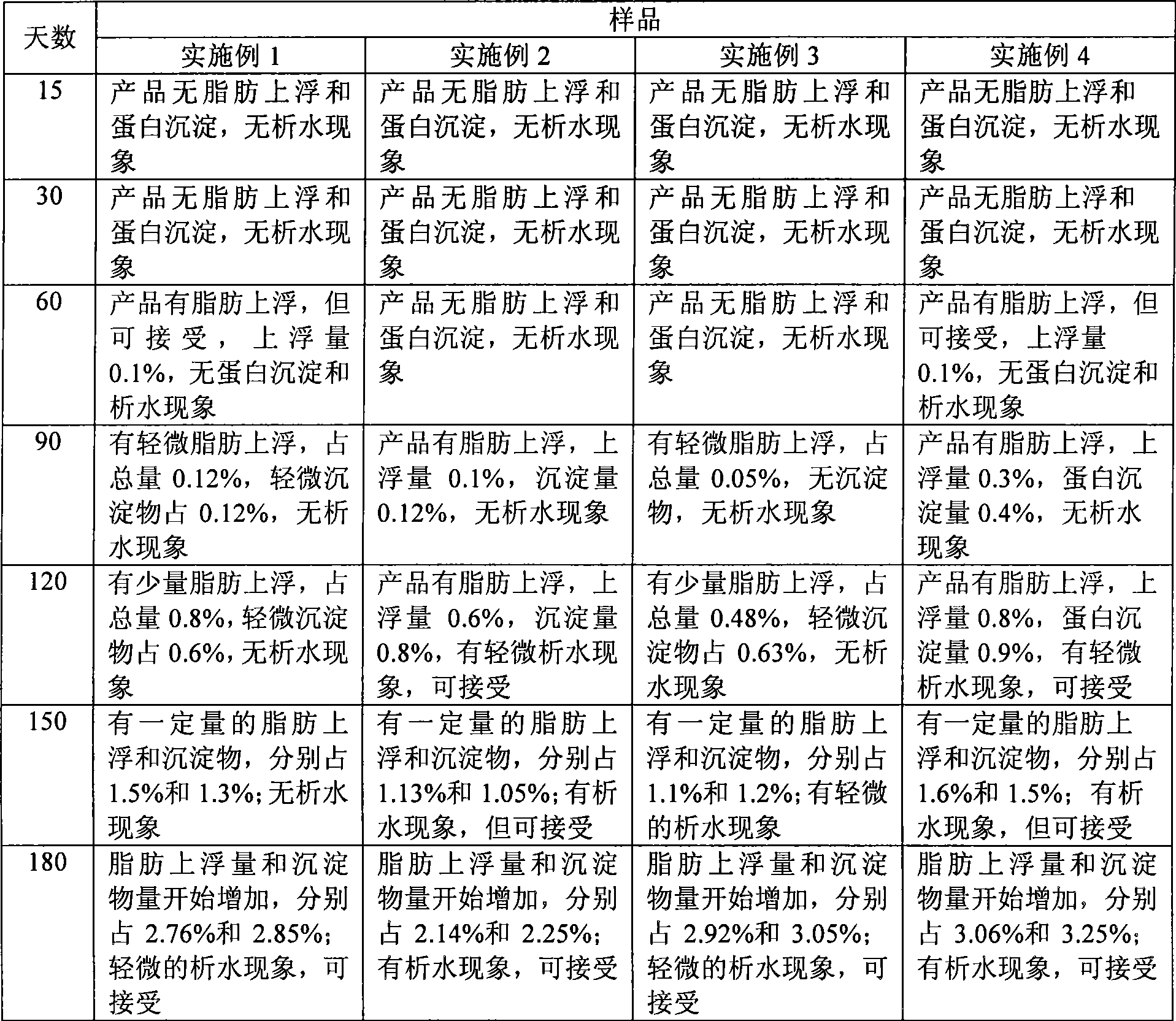

Preparation method and special yoghourt stabilizer of yoghourt with long shelf life

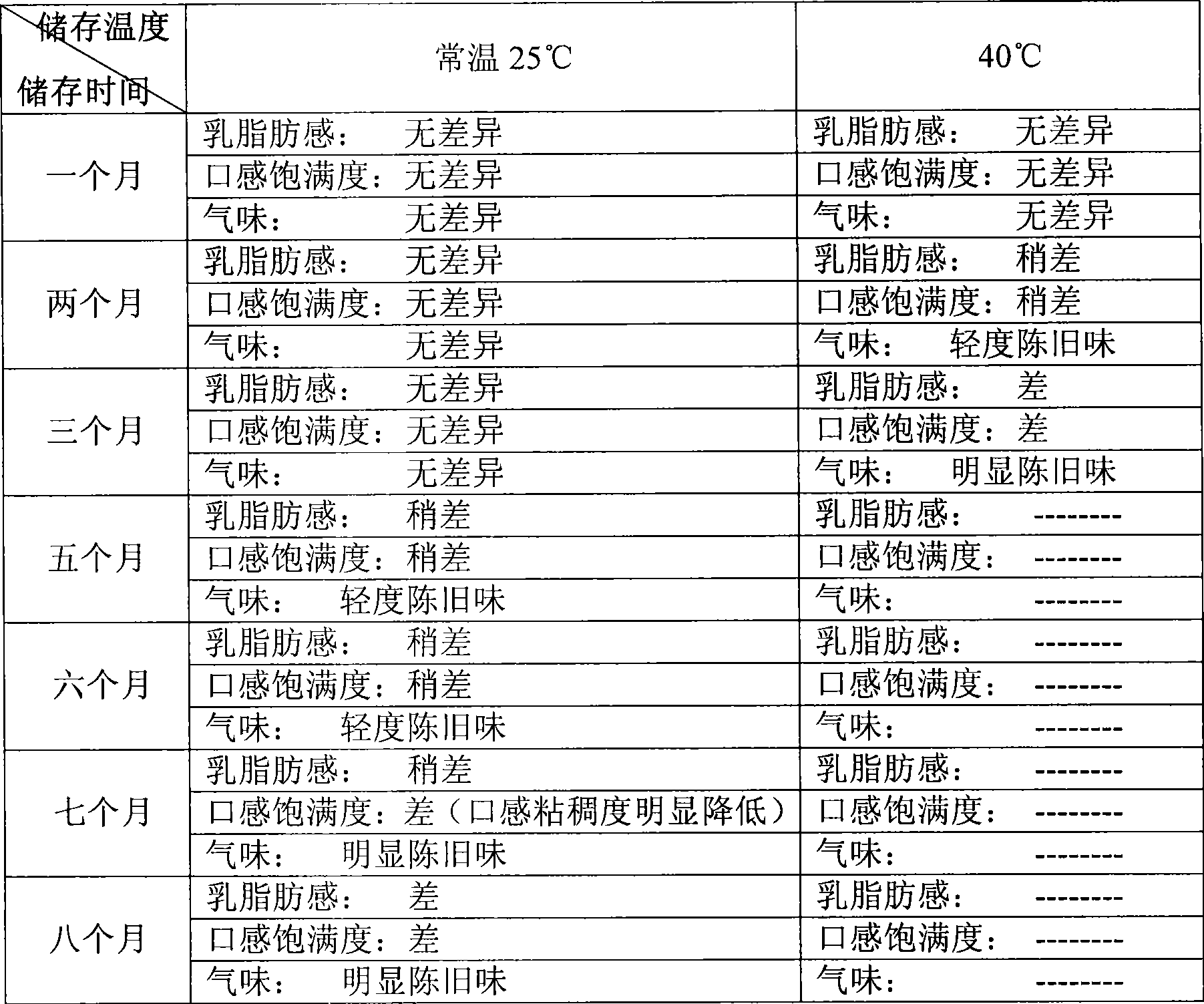

The invention discloses a preparation method and special yoghourt stabilizer of yoghourt with long shelf life. The method of the invention comprises the following steps: dissolving whole milk powder, stabilizer and sucrose; 2) preheating and homogenizing the materials; 3) sterilizing fluid milk at 90-95 DEG C for 5min, cooling; 4) inoculating, fermenting, breaking emulsion; 5) filling, sealing; 6) pasteuring; 7) cooling, packaging, and 8) inspecting and warehousing. In the method of the invention, the mixed yoghourt is creatively pasteurized, the flora in the yoghourt can be killed and the syneresis of protein resulting in precipitating large amount of whey can not be caused under the protection of the stabilizer; and after either stirred yoghurt or set yoghurt is pasteurized, the yoghourt stabilizer can realize the aims of preventing the precipitation of whey, improving mouthfeel and product quality and increasing product stability. The special yoghourt stabilizer of the invention can effectively prolong the shelf life of yoghourt without controlling the cold chain, and the product shelf life is up to six months under the room temperature.

Owner:DONG GUAN SHI LONG JIN WEI BEVERAGE & FOOD

Liquid Milk Beverage For Toddlers

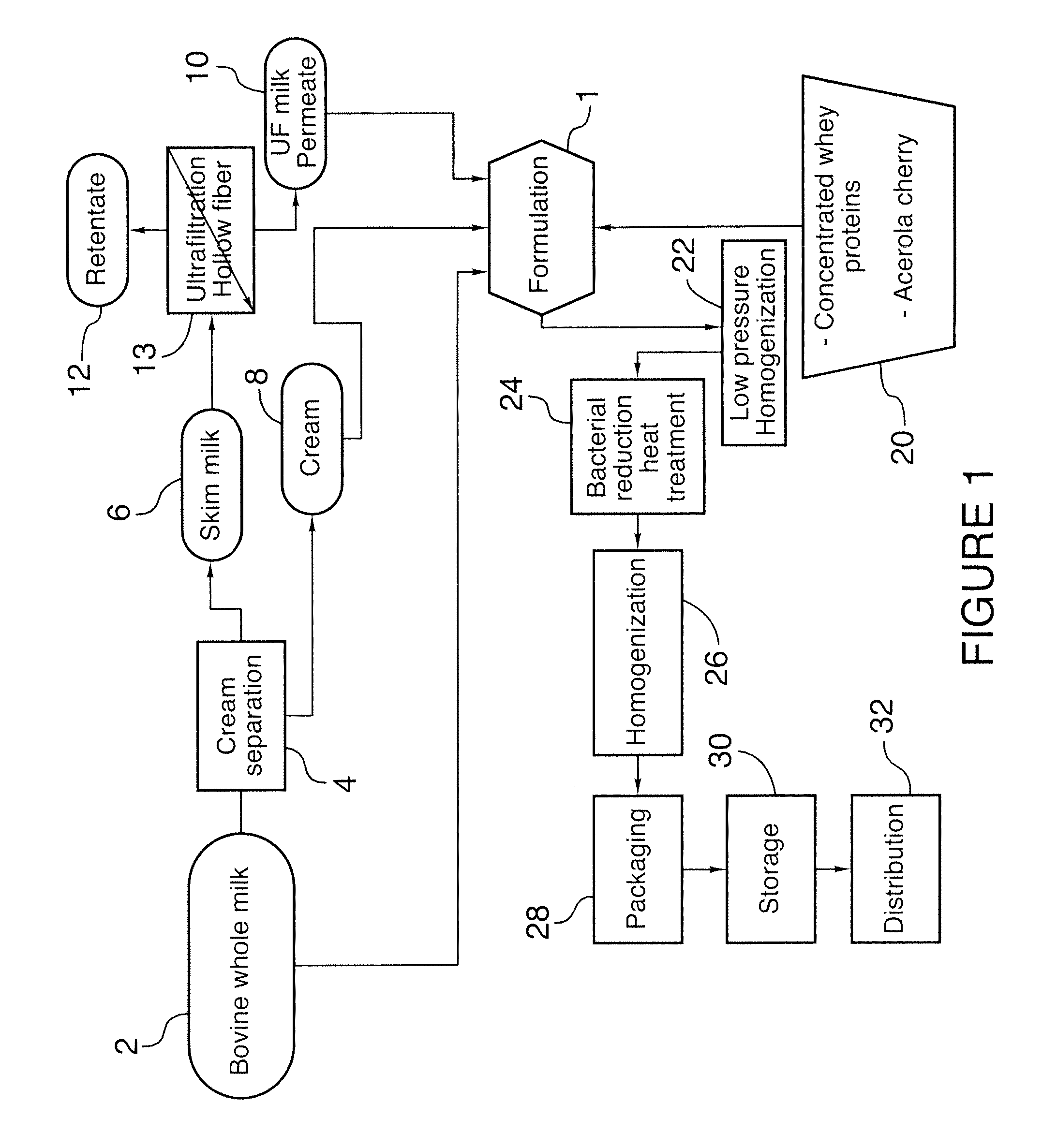

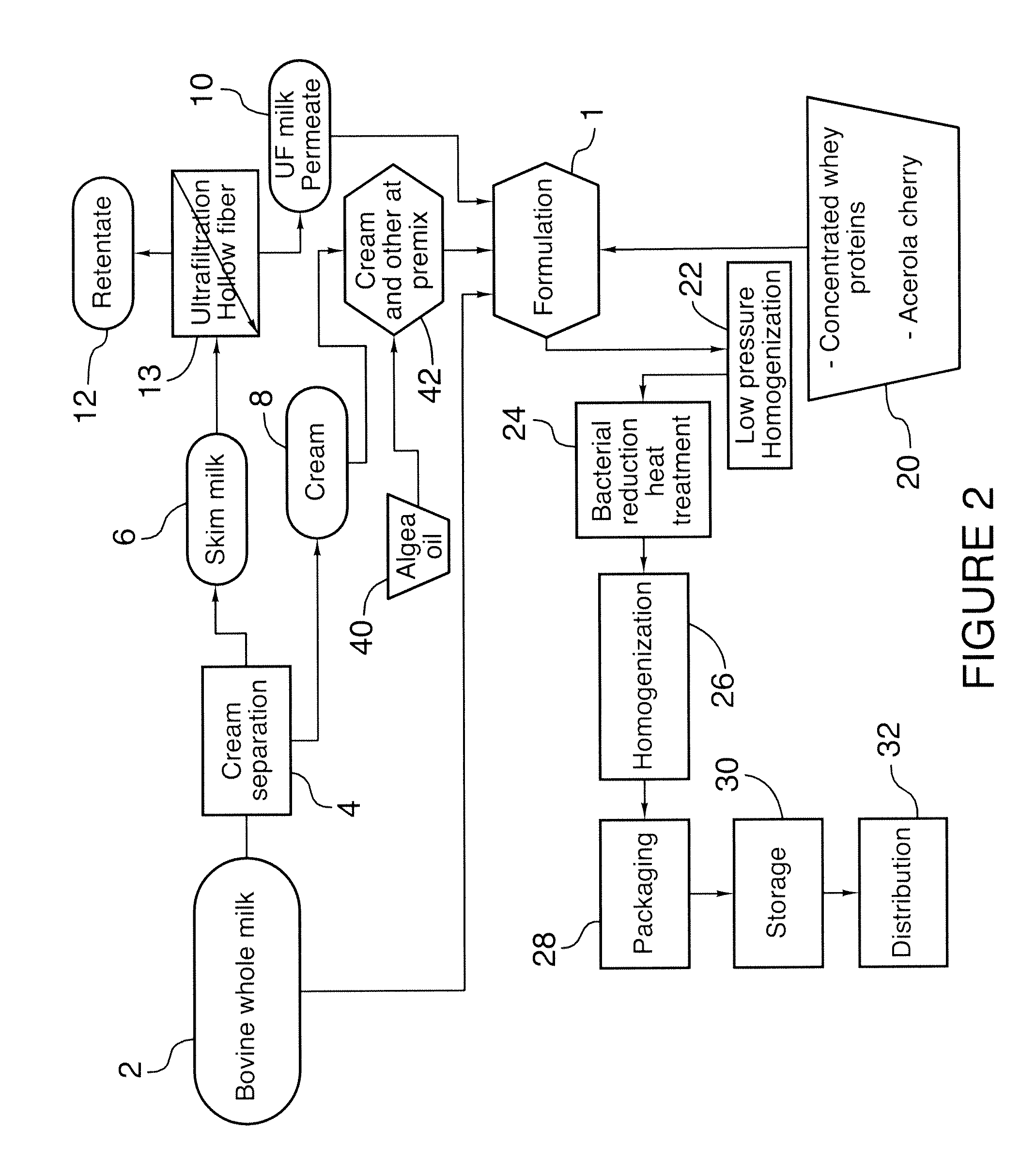

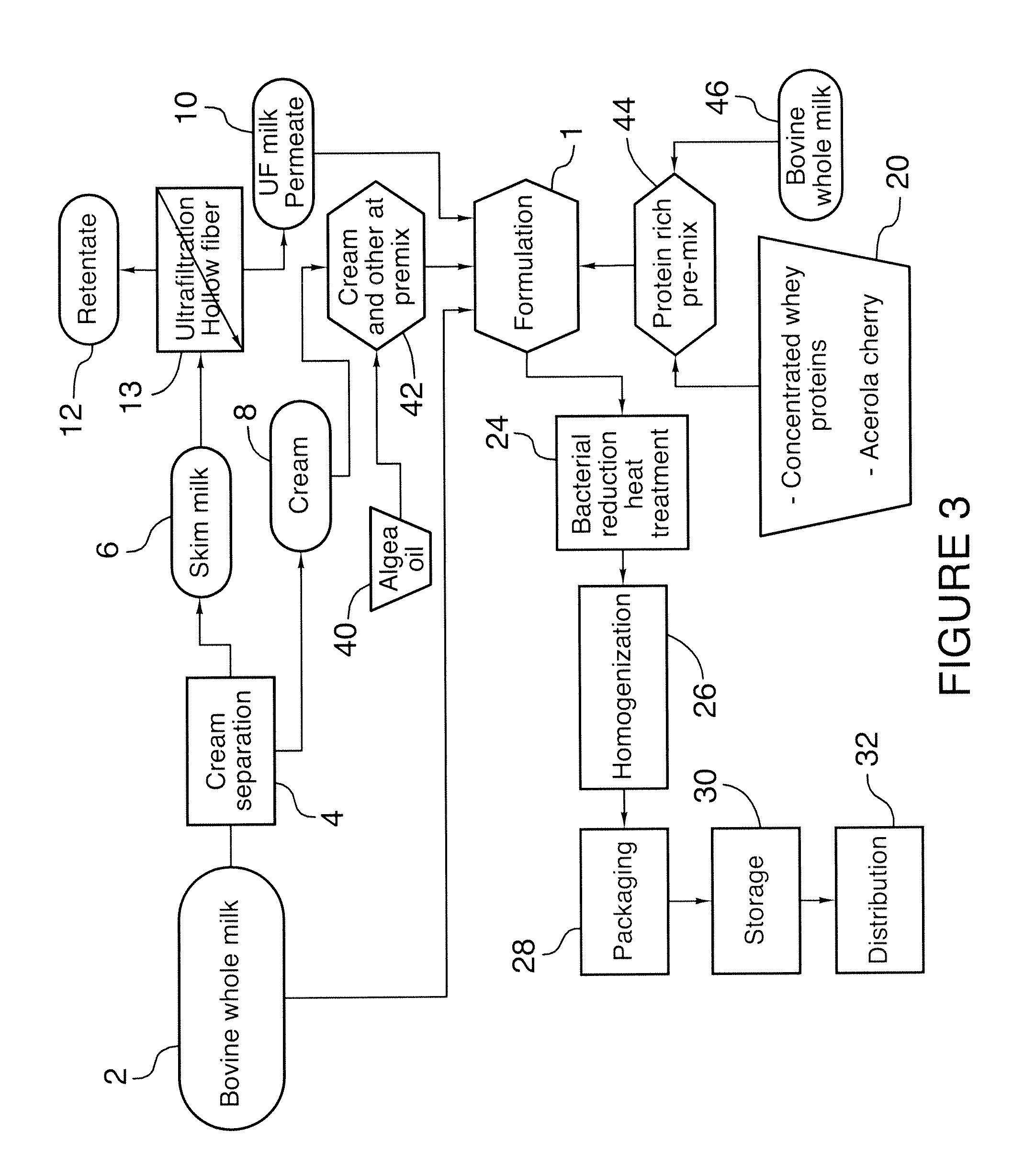

InactiveUS20130064923A1Less-expensive to manufacturePromote digestionMilk preparationVitamin food ingredientsFormula feedingWhey protein

Described herein are a liquid milk beverage for toddlers comprising non-hydrolyzed, non-fermented and protein-rebalanced cow's milk, processes for making same and methods of uses. The non-hydrolyzed, non-fermented rebalanced cow's milk comprises a reduced weight / weight proportion of casein:whey proteins when compared to untreated cow's milk. The non-hydrolyzed, non-fermented rebalanced cow's milk may further comprises a reduced total protein concentration when compared to untreated cow's milk. The reduced proportion and / or reduced total concentration of proteins facilitate digestion of the liquid milk beverage by infant and toddlers. Also described are methods for providing nutrition to a toddler, methods for facilitating transition from breast feeding and / or artificial formula feeding of a child towards drinking of cow's homogenized milk, and methods for increasing digestion of cow's milk in an individual.

Owner:AGROPUR COOP

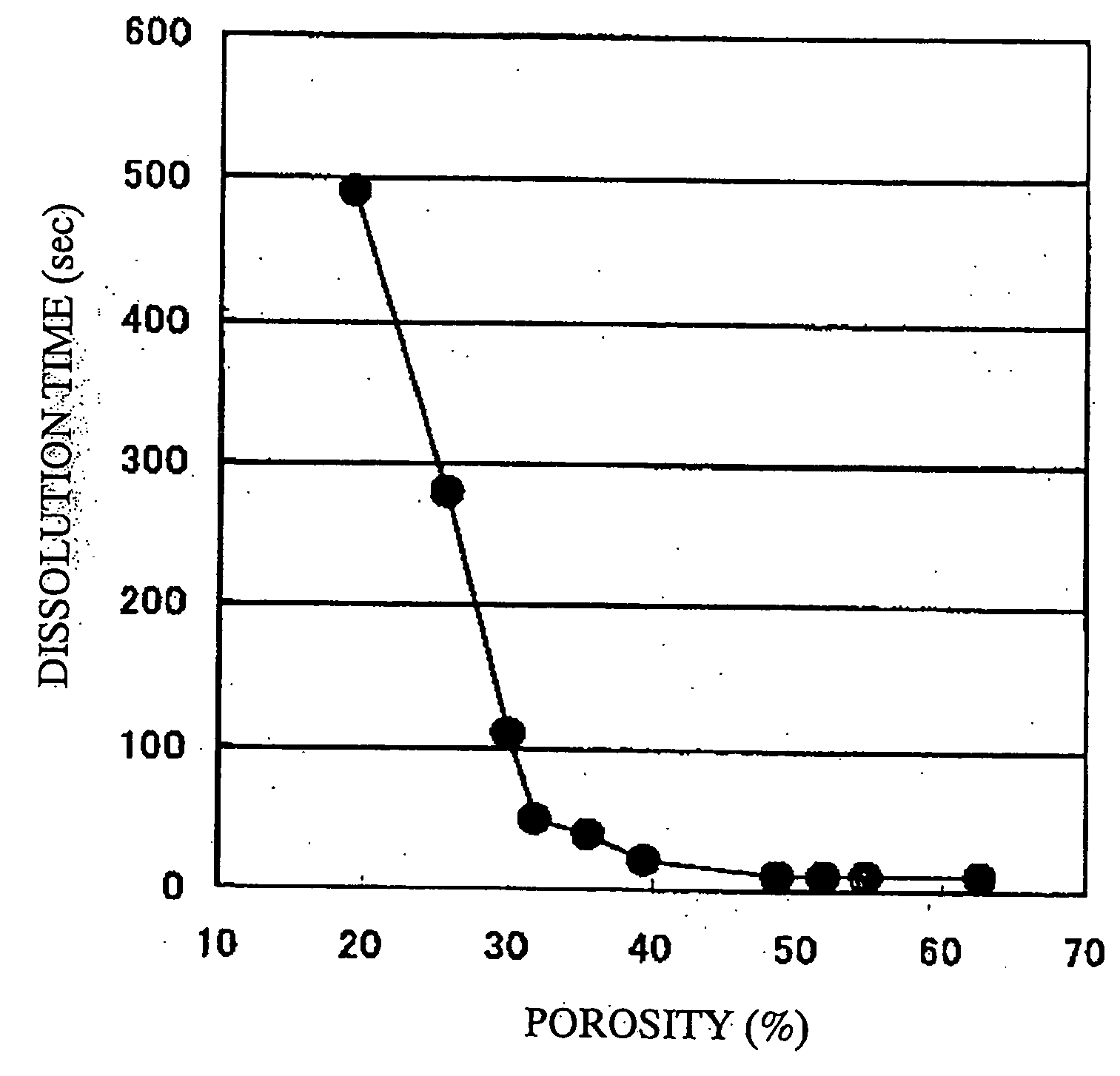

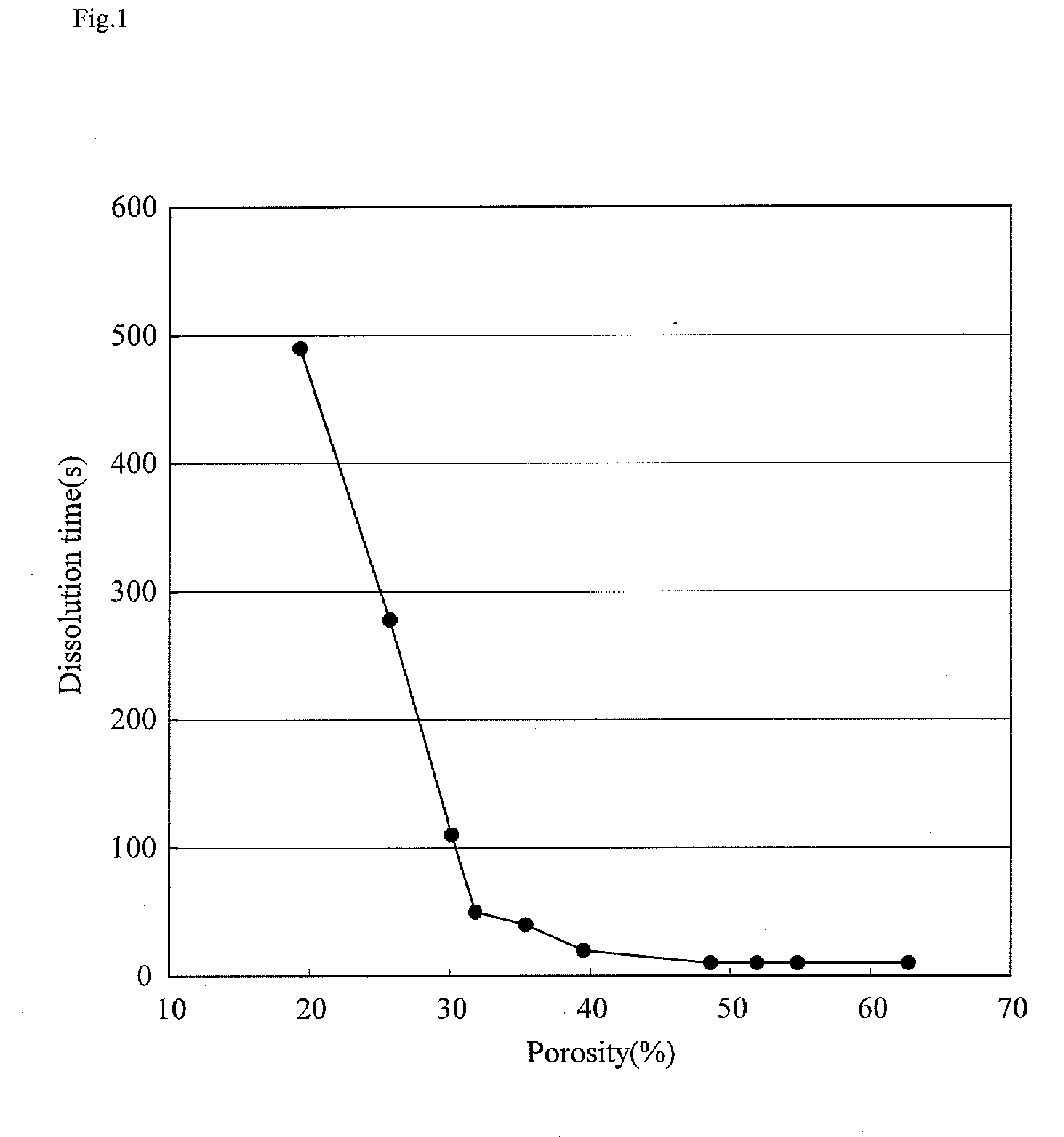

Solid Milk and Method for Manufacturing Thereof

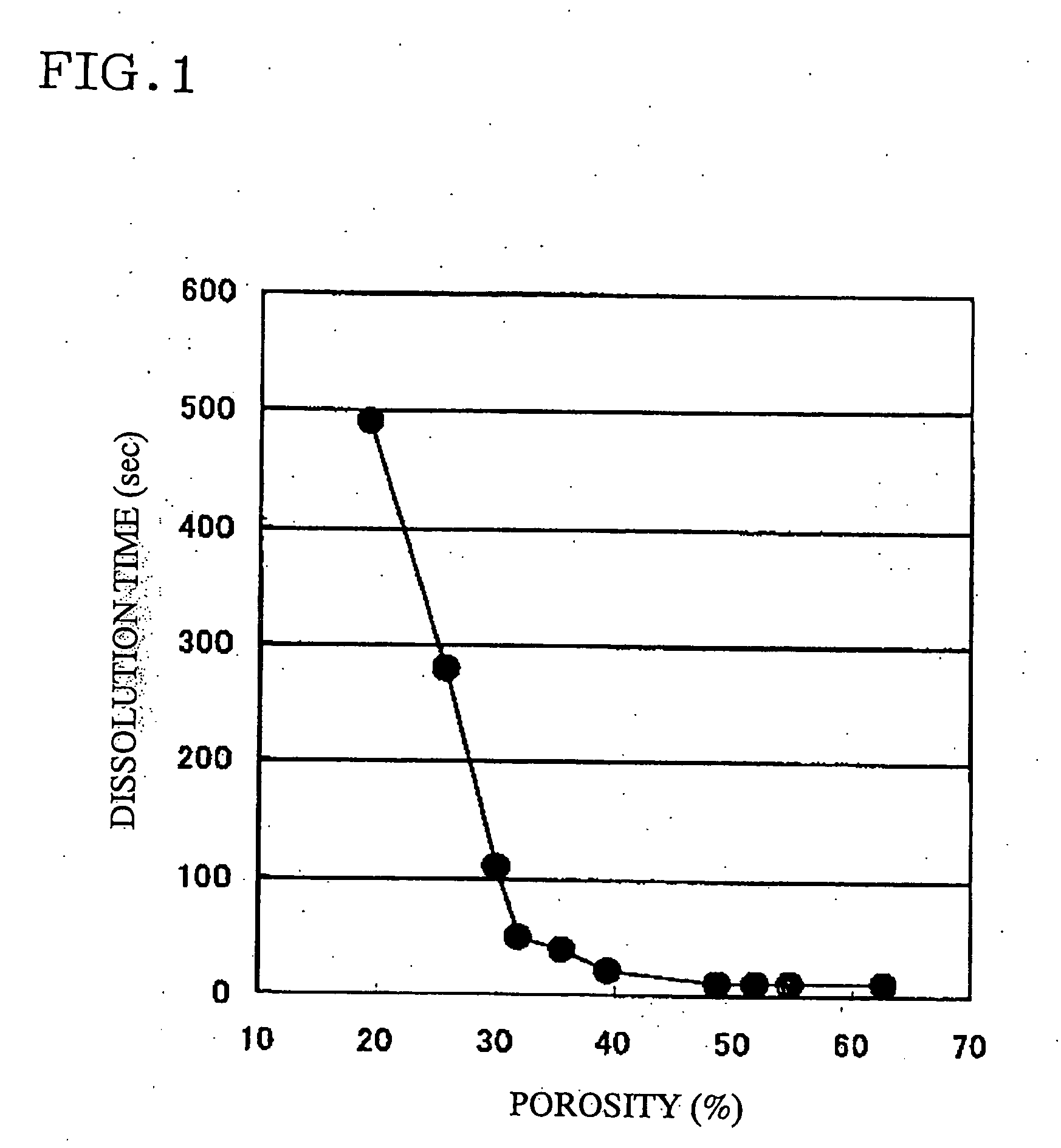

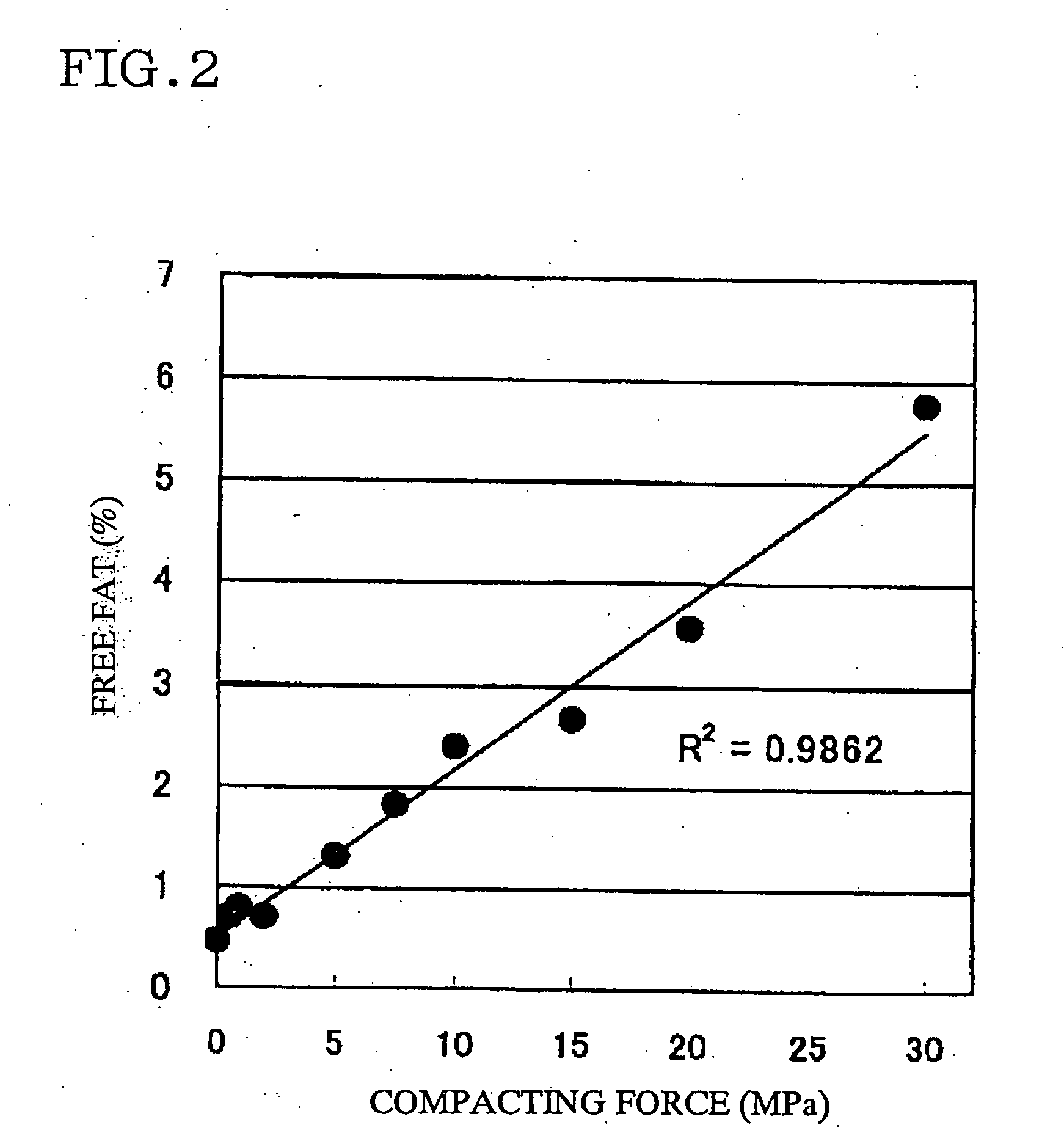

The object of the present invention is to provide solid milk having suitable solubility and strength and a method for manufacturing such solid milk.The present invention is based on the knowledge that solid milk combining sufficient strength with sufficient solubility can be obtained basically by compacting and molding only powdered milk as an ingredient under a condition where porosity and free fat content thereof are controlled within fixed ranges and then humidifying and drying. The above-described object can be attained with solid milk with a porosity of 30% to 50% and a method for manufacturing solid milk, comprising a compacting process for compacting powdered milk and obtaining a solid compacted body of powdered milk, a humidifying process for wetting the compacted body of powdered milk obtained in the compacting process, and a drying process for drying the compacted body of powdered milk humidified in the humidification process.

Owner:MEIJI CO LTD

Method for modifying soybean protein

InactiveCN102150742AGood emulsifying effectImprove gel performanceVegetable proteins working-upBiotechnologyFreeze-drying

The invention provides a method for modifying soybean protein, which comprises the following steps of: inducing dissociation of soybean protein subunits through acid or ions; reaggregating the soybean protein by using technologies such as homogenization, restrictive enzymolysis and the like; and performing spray drying or freeze drying. The functional characteristics of the obtained soybean protein are obviously improved; when the modified soybean protein is applied to a liquid emulsion system, the average grain diameter of emulsion is obviously reduced, and an emulsion system is uniform and stable through microscopic observation; and the modified soybean protein can be applied to various foods such as liquid milk, ham sausage and the like.

Owner:SOUTH CHINA UNIV OF TECH

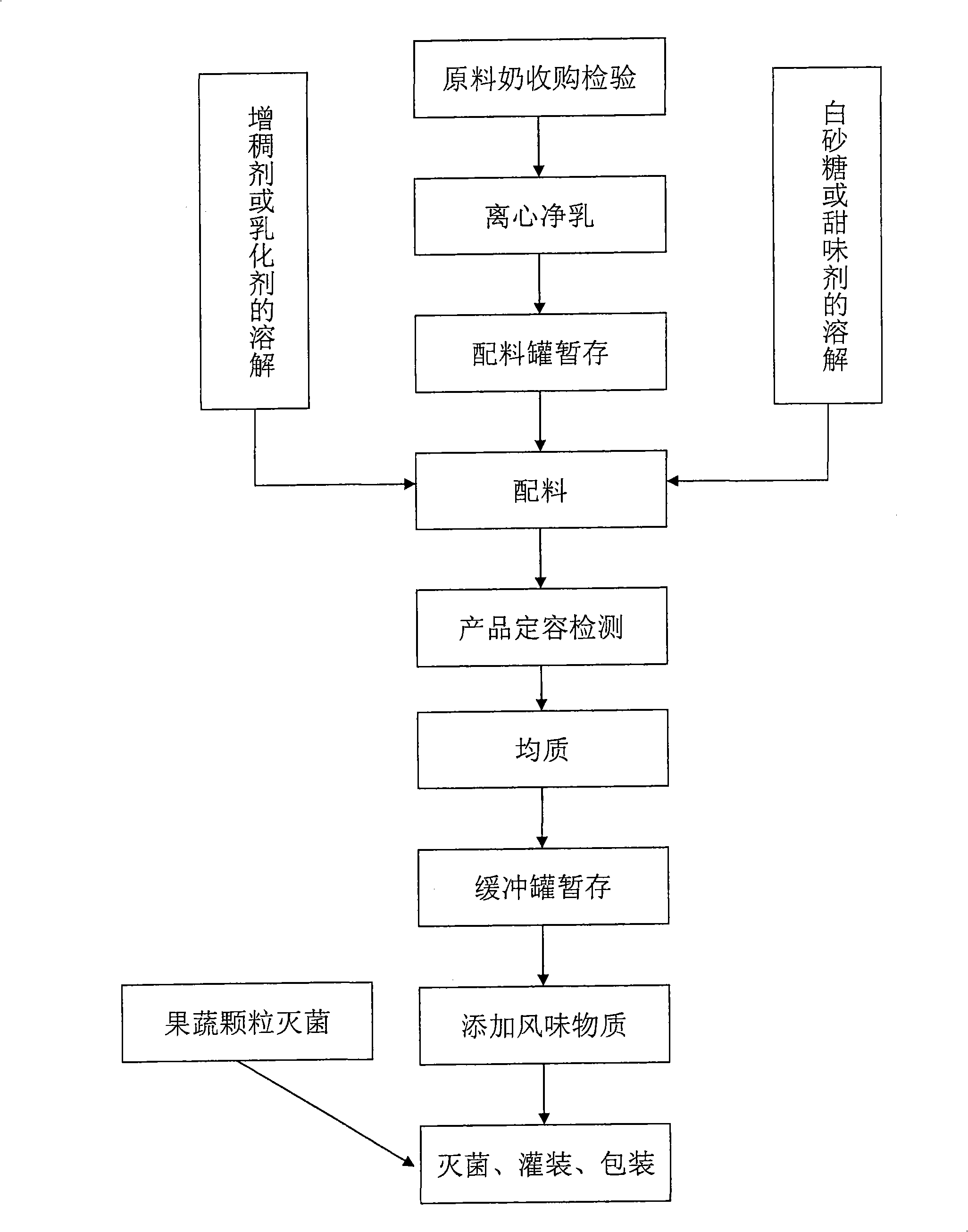

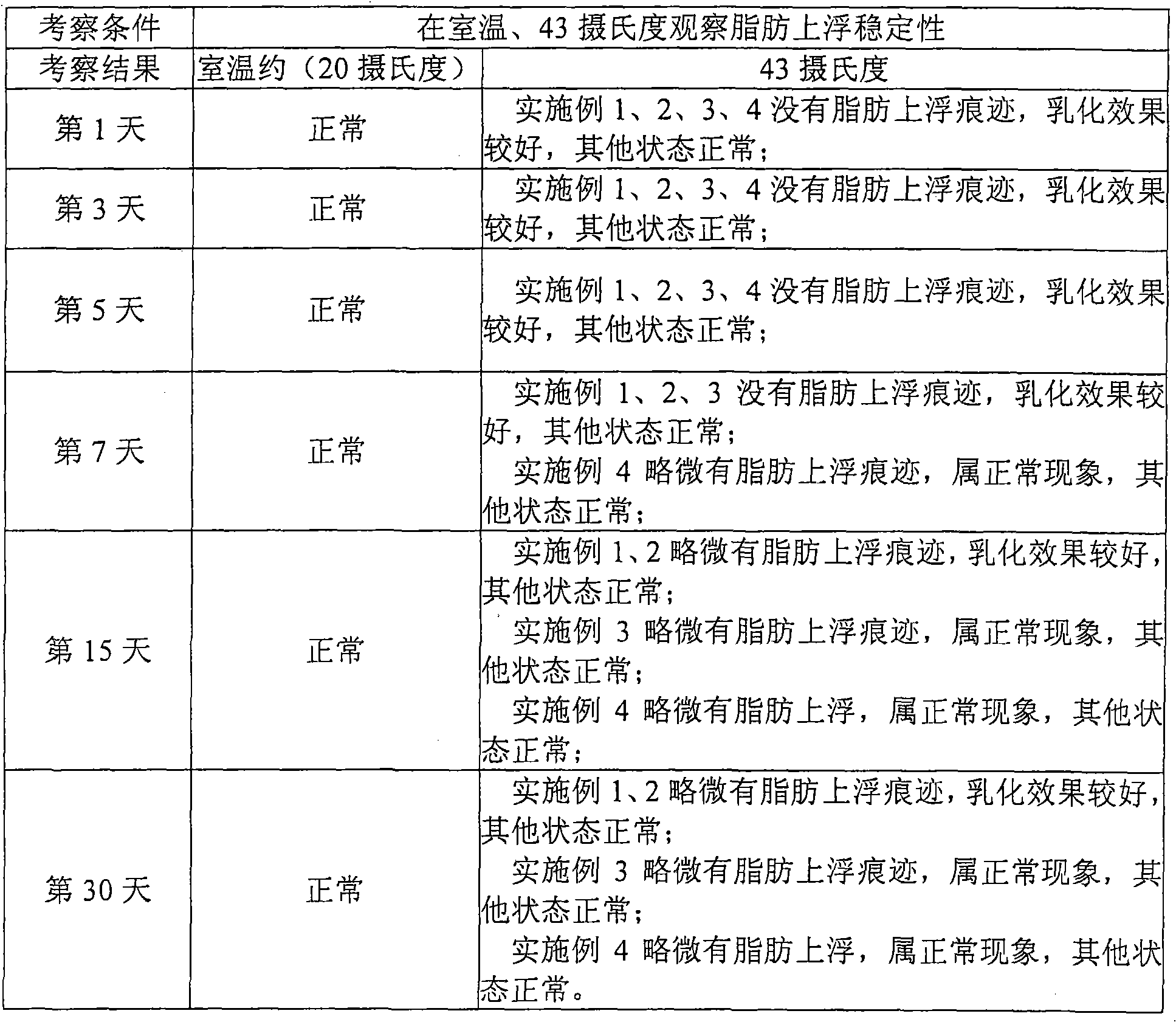

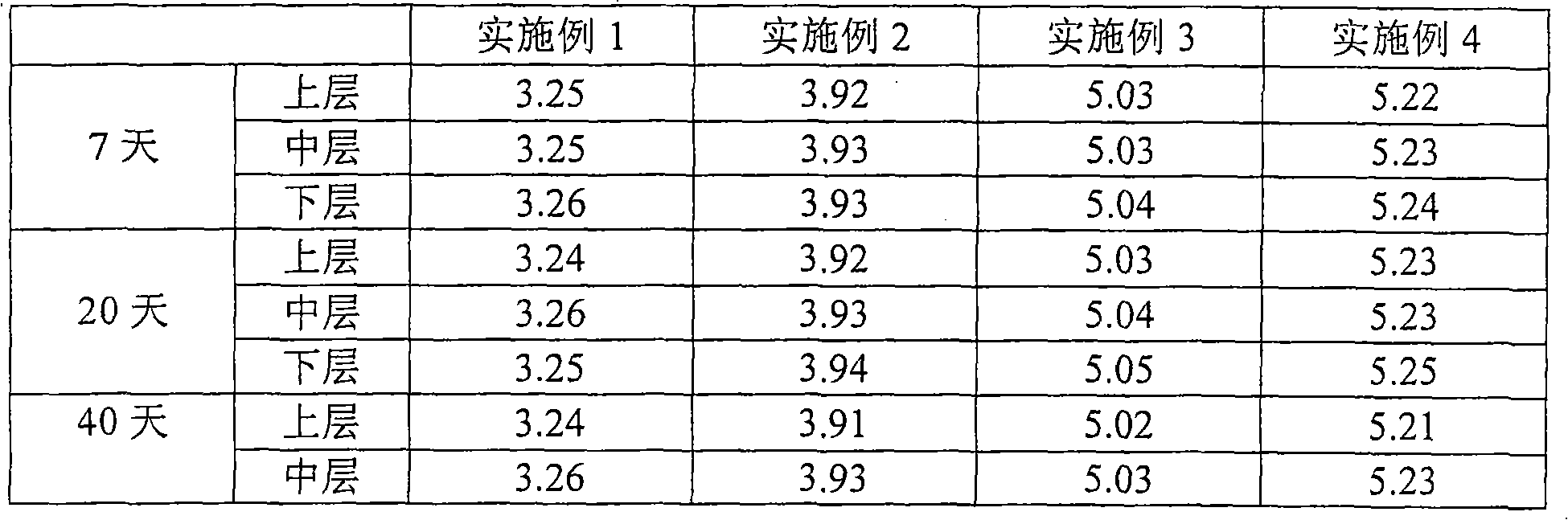

Liquid dairy product containing fruit-vegetable granules and method for producing same

ActiveCN101513213ARetain nutrientsReasonable nutritionMilk preparationFood preparationNutritive valuesLiquid product

The invention provides a liquid dairy product containing fruit-vegetable granules, which comprises the following components in percentage by weight in terms of the total weight of the liquid dairy product: 30 to 98.7 percent of milk, 0.1 to 5 percent of stabilizing agent, 1 to 20 percent of fruit-vegetable granules, 0 to 0.7 percent of acidity regulator, and water. The liquid dairy product combines components of vitamins, minerals, cellulose, and the like in fruits and vegetables with milk protein in effective proportion, thus the nutrition of the product is more reasonable and more uniform and improves the nutritive value; simultaneously, the addition of natural fruit-vegetable granules obviously improves the flavor and the mouthfeel of the product so that a consumer really feels the existences of the fruit-vegetable granules in mouthfeel and visual sense; besides, the liquid dairy product containing the fruit-vegetable granules achieves the even stable suspension of the fruit-vegetable granules in a milk solution more completely for a longer time, and achieves the stability of the product in a long shelf life.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Suspension stabilizer for fruit milk

The invention claims a suspension stabilizer for fruit milk, belonging to the technical field of food additive manufacturing. The suspension stabilizer for the fruit milk consists of the following components by weight percentage: 70% to 80% of sodium carboxymethylcellulose, 5% to 15% of polyglycerol monostearate, 5% to 10% of carrageenan, 1% to 3% of gellan gum and 5% to 10% of sodium citrate. The invention discloses the suspension stabilizer for fruit milk which is a food additive and adopts structure modifiers such as emulsifier, thickener, acidity regulator and the like which are mixed and prepared according to certain proportion. The suspension stabilizer for the fruit milk plays a role of suspension and stabilization in the fruit milk, effectively prevents the phenomena of obvious fruit sinking and protein flocculation during the retention period of fruit milk and keeps the fruit milk uniform and stable.

Owner:厦门欧凯科技有限公司

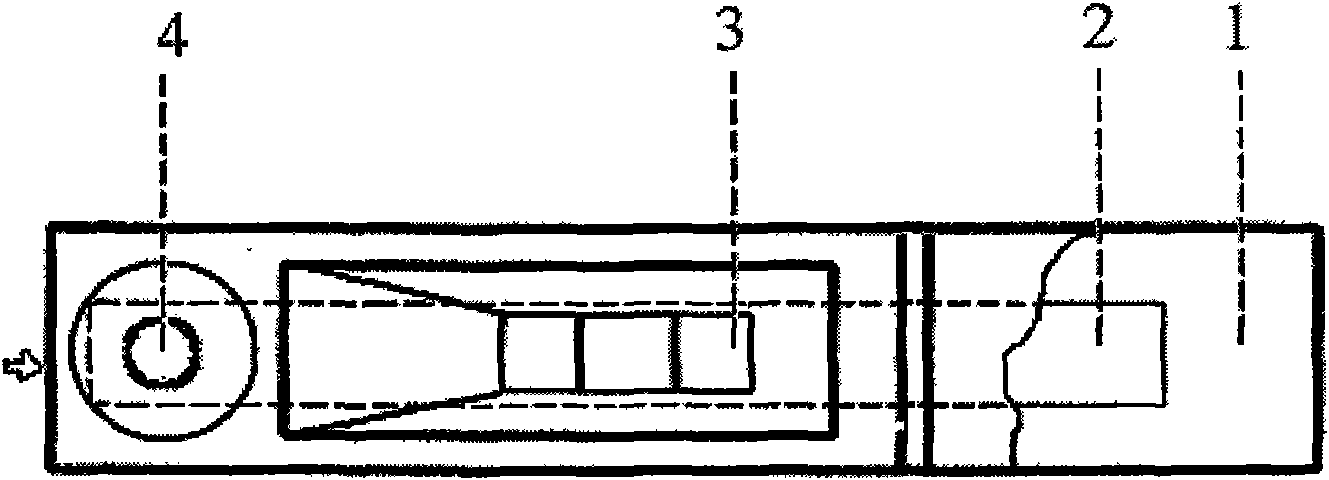

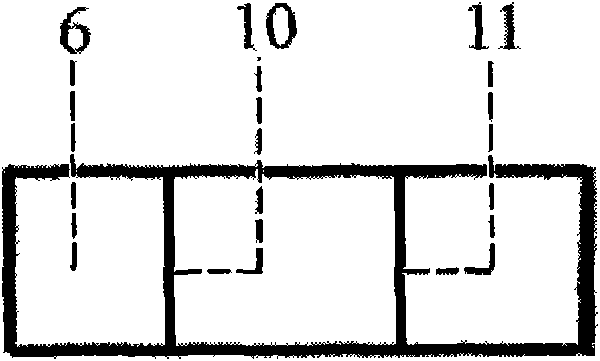

Casein rapid detection card and detection method thereof

InactiveCN101625368AEasy to manufactureLow detection costPreparing sample for investigationBiological testingGlass fiberBiology

The invention relates to a casein rapid detection card and a detection method thereof, belonging to the technical field of dairy detection. A testing strip is arranged in a shell of the casein rapid detection card; a sample pad, an aurosol membrane, a pyroxylin membrane and a water absorption membrane are adhered on a support back plate in sequence; the aurosol membrane is a glass fibre membrane containing a casein-resistant antibody aurosol label, two testing tapes are arranged on the pyroxylin membrane, wherein one detection tape is a detection tape containing casein, and the other detection tape is a quality-control tape containing a rabbit-resistant antibody or mouse-resistant antibody. The invention has the advantages that the casein content of fluid milk, milk powder and dairy products can be directly detected by applying an immunological method. The casein rapid detection card is easy to prepare, convenient and rapid to use and accurate in results.

Owner:长沙安迪生物科技有限公司

Liquid dairy product containing linoleic acid and linolenic acid and preparation method thereof

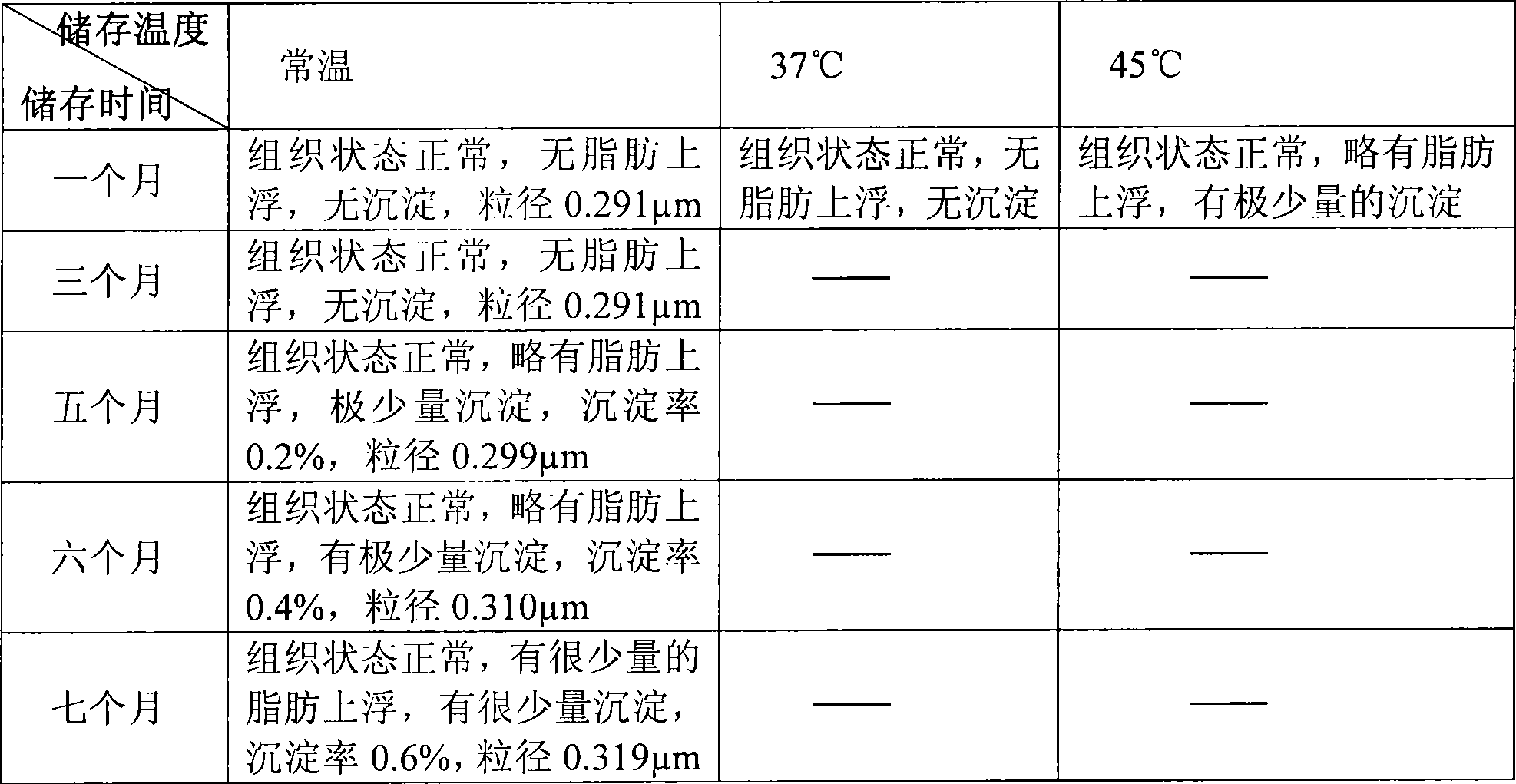

The invention provides a liquid dairy product containing linoleic acid and linolenic acid. The linoleic acid exists in the liquid dairy product in a plant oil form; and the liquid dairy product comprises the following components by weight: 400 to 900 portions of liquid milk, 30 to 50 portions of plant oil, 4 to 6 portions of linolenic acid, 1.0 to 3.5 portions of emulsifier and 0.5 to 1.5 portionsof thickening agent. The liquid dairy product is added with the linoleic acid and the linolenic acid, and is added with the emulsifier and the thickening agent in proper proportion to successively solve the problem that the quality of the components added is not stable in the ultra-temperature liquid milk, so that the product has normal flavor and mouthfeel and stable quality.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

New method for preparing rice gluten milk powder and rice gluten milk by using crushed rice

The invention relates to a new method for preparing rice gluten milk powder and rice gluten milk by using crushed rice and belongs to the technical field of natural protein separation and extraction as well as deep processing. According to the characteristic that starch grain in rice endosperm is combined with proteosome, physical high-pressure homogenized splitting method is adopted for splitting the thin cell wall of amyloplast, and the split starch and protein are centrifugalize according to the difference of specific weight, and the protein in light phase is concentrated, formulated and formed to prepare the milk powder and fluid milk. The method completely maintains the physicochemical property of natural rice protein, is high in extraction rate, concise in process and low in cost and avoids the three wastes.

Owner:铜陵峰元科技发展有限公司

DHA emulsion, preparation method thereof and applications thereof in UHT liquid milk

InactiveCN103416759AImprove thermal stabilityIncrease flexibilityMilk preparationFood preparationSucroseSodium Caseinate

The invention relates to a DHA emulsion, and particularly to a DHA emulsion with good thermal stability. Every 100 g of raw material for preparing the DHA emulsion comprises 10 to 20 g of algae oil or fish oil, 2 to 12 g of emulsifiers, 0.1 to 1 g of stabilizers, and 0.2 to 1.0 g of antioxidants, with the balance being water. The antioxidants comprise water-soluble antioxidants and fat-soluble antioxidants. The emulsifiers comprise one type or a combination of several types of emulsifiers selected from starch sodium octenyl succinate, soy lecithin, mono- and diglycerides, sorbitan esters, polyoxyethylene sorbitan esters, sucrose fatty acid ester, whey protein, and sodium caseinate. The DHA emulsion has good thermal stability, and thus when the DHA emulsion is added into a product, the DHA emulsion and the product can be sterilized together at a high temperature, so that the DHA emulsion is improved in flexibility and range of application in production. The invention also provides a preparation method of the DHA emulsion and applications of the DHA emulsion in UHT liquid milk.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Liquid milk containing soya peptide and production method thereof

ActiveCN101449707AHas health benefitsImprove actual functionsMilk preparationFood preparationCITRATE ESTERPhosphate

The invention provides a liquid milk product containing soy peptide and a method of producing the same. Raw materials of the liquid milk product comprise: milk 300-999.29 permillage, soy peptide power 0.1-10 permillage, emulsifying agent 0.5-2.0 permillage, thickening agent 0.1-5.0 permillage and protein protective agent 0.01-0.5 permillage, wherein the permillage and protein protective agent is phosphate and / or citrate. The invention provides a functional liquid beverage bonding soy peptide and milk nutrient contents through reasonable prescription and proper technology, realizes excellent stability and good mouth feel in a shelf period.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

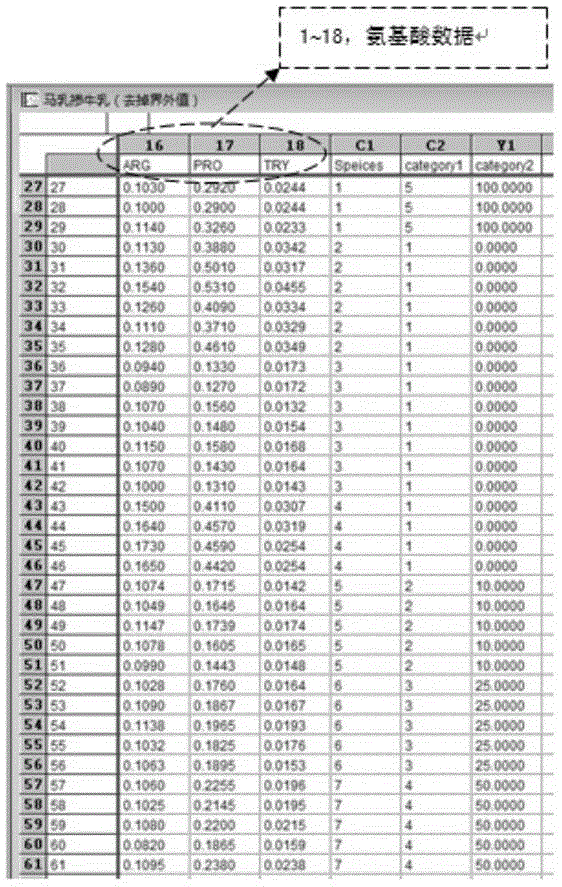

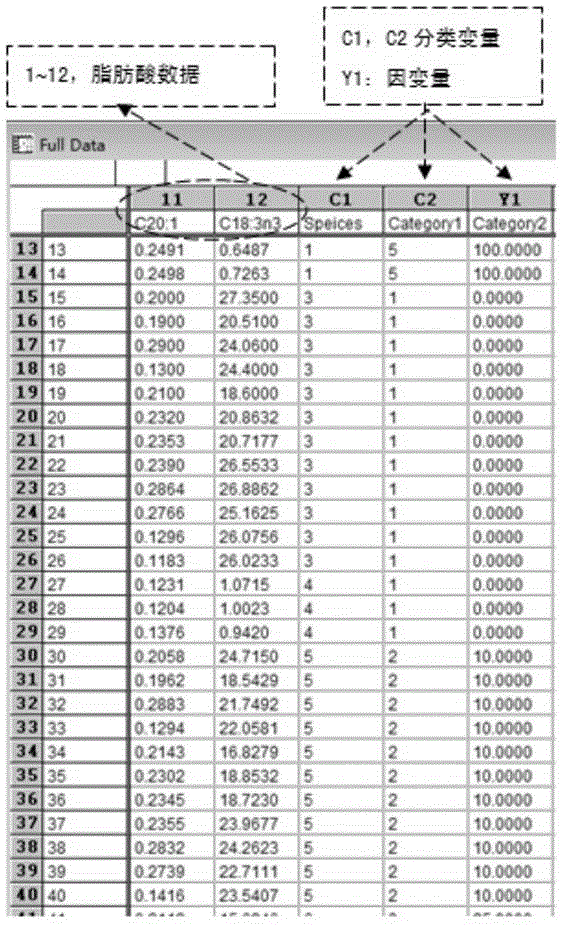

Authenticity identifying method and system for raw milk or liquid milk

The invention discloses an authenticity identifying method and an authenticity identifying system for raw milk or liquid milk. The method comprises the following steps: performing amino acid fingerprint, fatty acid fingerprint or fatty acid gas chromatography fingerprint collection on a collected training sample set of a raw milk or liquid milk sample, performing data structure analysis by chemical metrology software, and constructing a qualitative and quantitative identification model; meanwhile, performing amino acid fingerprint, fatty acid fingerprint or fatty acid gas chromatography fingerprint collection on a milk sample verification sample set, inputting the acquired data into the constructed qualitative and quantitative identification model to verify the accuracy and the stability of the model, and performing model optimization until the accuracy of the model meets the requirement; finally identifying the authenticity of the raw milk or the liquid milk by the optimized identification model. The method can be used for identifying the authenticity of the milk sample accurately and reliably.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY +1

Liquid dairy produce containing casein phosphoeptides and method for producing the same

ActiveCN101467560AAvoid lostImprove qualityMilk preparationFood preparationAfter treatmentAqueous solution

The invention provides a kind of liquid dairy product and its production method, specifically a liquid dairy product containing CPP and its production method. 0.01-0.16g of CPP is contained per 100g of the product; the CPP is added into the product after treatment in water-contained solution with temperature of 35-45 DEG C for 20-30 minutes. According to the reasonable formulation and proper process of the invention, the effective content of CPP is extremely remained, and the liquid dairy product has good stability and can be preserved for a long term.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Cheese liquid milk and preparation method thereof

The invention discloses cheese liquid milk and a preparation method thereof. The chess liquid milk comprises the following components: 30-90% of raw milk, 0.5-3% of cheese powder, 0.02-2% of yolk powder, 0.01-5% of dilute cream, 0.05-0.2% of emulsifier, 0.05-0.3% of stabilizer and the balance of water. The preparation method comprises the following steps: heating the raw milk to 70-90 DEG C, uniformly mixing with 70-90% of the emulsifier, the stabilizer, the dilute cream, the yolk powder and the water to obtain a feed liquid A; heating the cheese and the rest emulsifier to 65-80 DEG C, melting for 15-25 minutes, uniformly stirring and mixing to form an emulsion and obtain a feed liquid B; mixing the feed liquid A with the feed liquid B, standardizing protein and fat and carrying out second-level homogenizing; firstly carrying out pre-sterilization and then carrying out immersion type super-high temperature instant sterilization to obtain the cheese liquid milk. By means of the preparation method disclosed by the invention, the phenomenon of pipeline blockage or pipe wall serious coking is incapable of happening when the product is sterilized.

Owner:BRIGHT DAIRY & FOOD

Solid Milk and Method of Making the Same

ActiveUS20090175998A1Reduce porosityEasy to transportMilk preparationFood shapingSolubilityCompression molding

The present invention is based on knowledge that basically, solid milk provided with both of adequate strength and solubility can be obtained by using only powdered milk as ingredient to be provided with compression molding under state where the porosity and the free fat is controlled within predetermined ranges, and then humidified and dried. Namely, solid milk having porosity of 30%-60%, and method of making solid milk including: a compression step for compressing powdered milk to obtain a solid form of compressed powdered milk; a humidifying step for humidifying the compressed powdered milk obtained by the compression step; and a drying step for drying the compressed powdered milk humidified by the humidifying step achieves the object of providing solid milk having preferred solubility and strength, and method of making the same.

Owner:MEIJI CO LTD

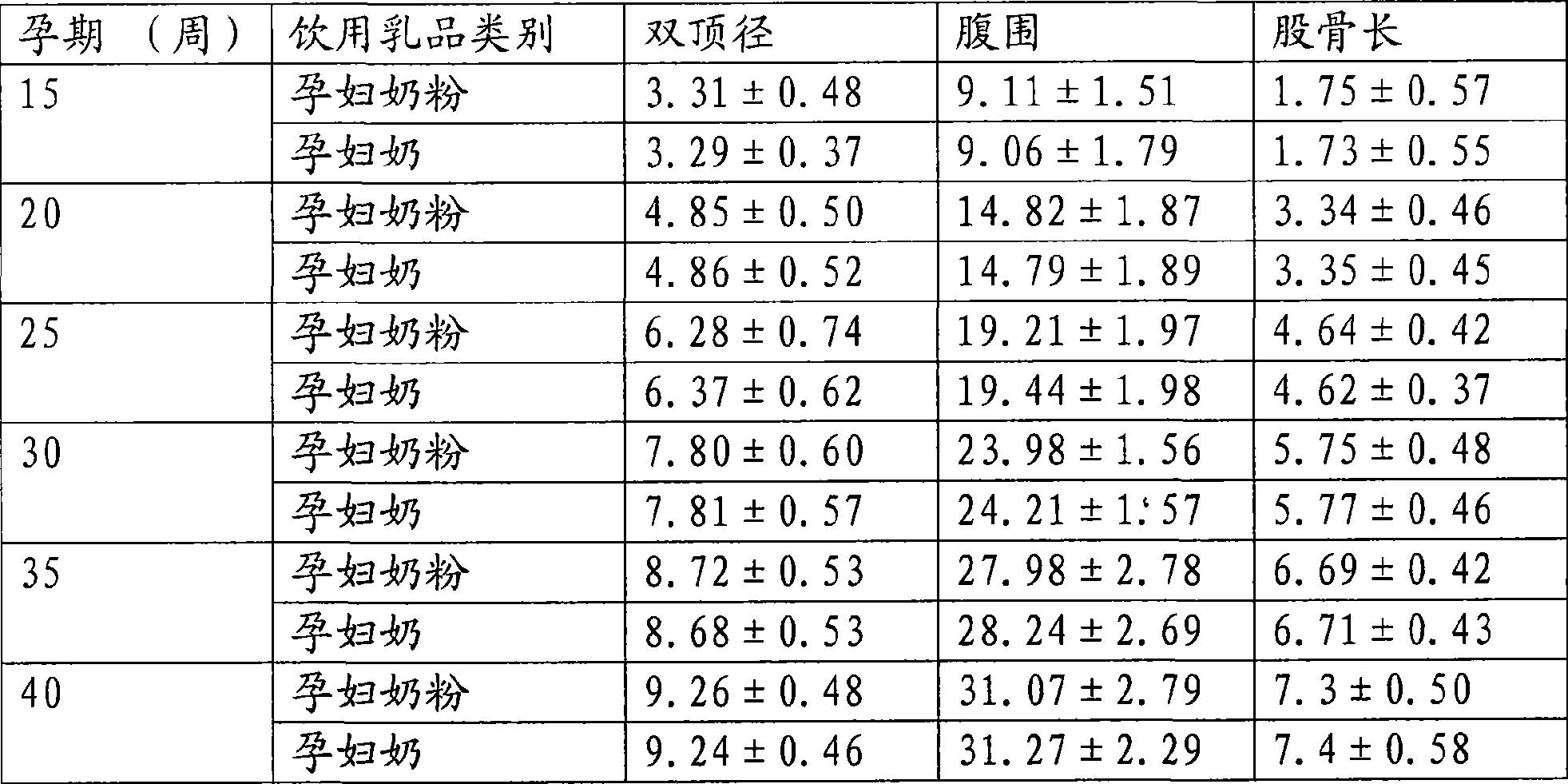

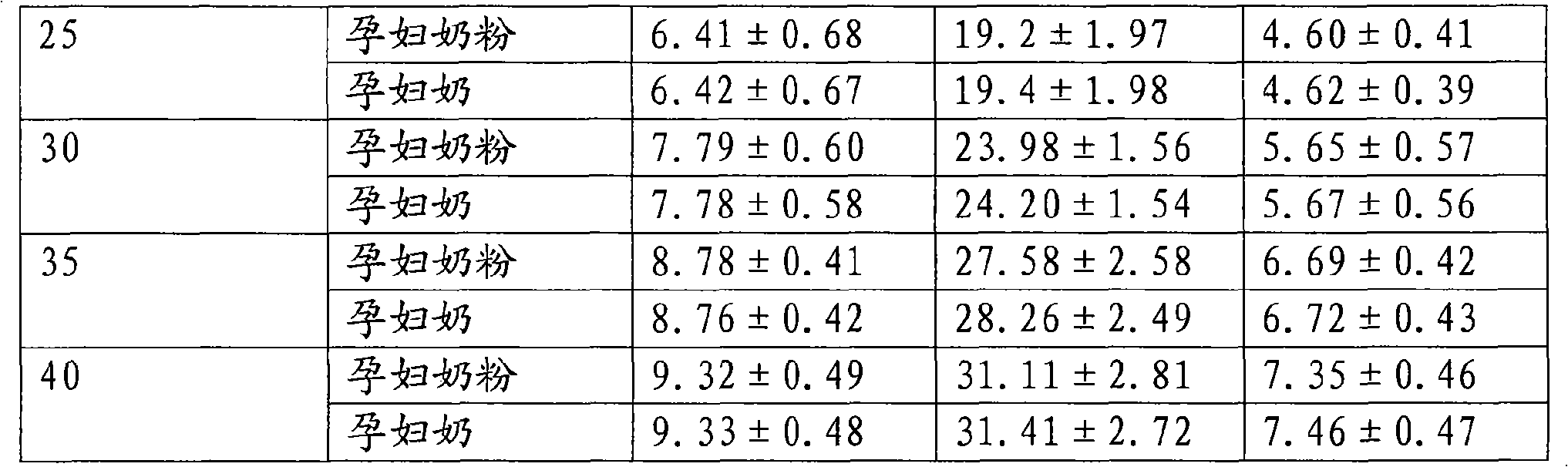

Liquid milk for pregnant and ylying-in woman with additive lecithin and method of producing the same

InactiveCN101427784ANutritional balanceMellow tasteMilk preparationFood preparationBiotechnologyAnimal science

The invention relates to liquid milk, in particular to liquid milk supplemented with lecithin suitable for pregnant and lying-in women, and a preparation method thereof, which belongs to the technical field of dairy products. The ingredients (by weight parts) of the liquid milk suitable for pregnant and lying-in women are as follows: 800Kg to 990Kg of cow milk or remade milk, 1.5Kg to 5Kg of emulsion stabilizers, 0.8g to 600g of vitamin complex, 120g to 340g of complex minerals, 5Kg to 15Kg of prebiotics, and 0.5Kg to 2Kg of lecithin. The liquid milk has reasonable ratio of nutrients and meets the needs for pregnant and lying-in women in special physiological periods. Compared with the prior fresh milk and the prior milk powder, the liquid milk has the advantages of scientific nutrient ratio, mellow flavor and convenience for eating.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Steamed cake and making method thereof

The invention provides steamed cakes and a making method thereof. The steamed cakes are prepared from the following raw materials in parts by weight: 400-600 parts of steamed cake premixed flour, 300-500 parts of eggs, 80-120 parts of milk, 80-120 parts of liquid cream, 10-30 parts of cake oil and 10-25 parts of composite emulsifier oil (also called emulsified oil). According to the improvement on the raw material formula and manufacturing process, the produced steamed cakes are long in storage time, sweet, soft and loose in taste, fine and smooth in texture, white as snow and bulky in taste and are steamed without causing internal heat. The steamed cake premixed flour is special flour, is premixed flour mixed according to the ratio and is convenient to use, rapid to weigh and standard in finished product.

Owner:DONGGUAN HECHUANG FOOD

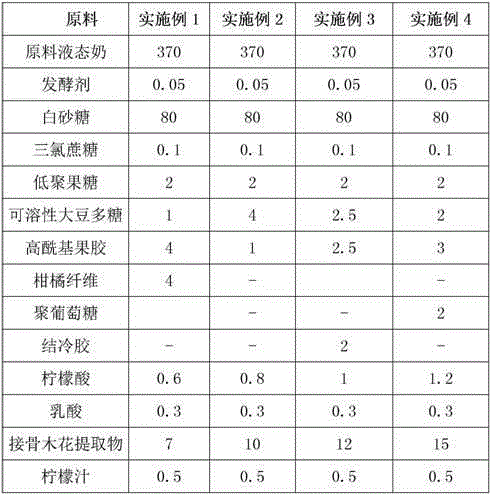

Active lactobacillus beverage and preparation method thereof

The invention particularly relates to an active lactobacillus beverage and a preparation method thereof. The active lactobacillus beverage is prepared by the following materials in percent by weight: 30-90% of liquid milk, 0.002-0.008% of fermenting agent, 8-12% of sweet substance, 0.5-1% of stabilizing agent, 0.2% of fructooligosaccharide, 0.5-1.5% of sambucus extract, 0.5-0.1% of lemon juice, 0.08-0.15% of acidity regulating agent and the balance of pure water. The preparation method comprises the following steps of preparing fermented milk, preparing base materials and filling and the like. The active lactobacillus beverage and the preparation method have the beneficial effects that the effective components of the sambucus extract, the lemon juice and the fermented milk are perfectly combined, so that the taste is fresh and pleasant, the stability of a lactobacillus beverage product can be maintained, and the nutrition and health-care effects of milk products are effectively improved.

Owner:河南花花牛乳业集团股份有限公司

Liquid milk with additive vitamin suitable for pregnant woman drink and preparation method thereof

InactiveCN101313717ANutritional balanceMellow tasteMilk preparationMilk preservationFlavorAdditive ingredient

The invention relates to liquid milk, in particular to the liquid milk which is added with vitamins and contributes to the health of pregnant women and a preparation method thereof, which belong to the milk product technical field. The liquid milk suitable for the pregnant women comprises the following compositions that: 790 to 950Kg of milk (or reconstituted milk), 1.8 to 5Kg of emulsifying stabilizer, and 0.9 to 600g of compound vitamin. The liquid mil has more reasonable nutrition compositions so as to meet the need of special physiological periods of the pregnant women. Compared with the fresh milk and the ordinary milk powder, the liquid milk has the advantages of scientific nutrition-allocated proportion, strong flavor, and convenient eating.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Process for producing high-moisture, smooth-textured shaped cereal foods

InactiveUS20050249859A1Improve freeze-thaw stabilityEvenly dispersedMilk preparationDough treatmentHand heldMoisture

The present invention provides a process for making hand-held shaped cereal and milk products having a smooth, homogenous-consistency texture and a moisture content higher than 35%, using about the same amount and ratio of cereal flour to fluid-milk as found in a traditional combination of (RTE) cereal pieces (made from cereal flour) and fluid-milk that have to be eaten from a bowl with a spoon. In the process of the present invention, each pound of cereal flour is cooked with 3 to 4 pounds of fluid-milk together with starch-complexing agents in a continuous cooker at temperatures above 175 F. It is then discharged as a hot, fluid-milk-hydrated, starch-complexed cereal flour which continues to absorb retained fluid-milk until it becomes fully-cooked, fully-hydrated and viscous enough to retain a shape. It is then formed into units, baked to firm their textures while retaining a higher than 35% moisture, and stored refrigerated or frozen.

Owner:ZUKERMAN HAROLD W +1

DHA (Docosahexaenoic Acid) emulsion, production method and application thereof

InactiveCN102132882AImprove absorption and utilizationSimple production processFood preparationBiotechnologyNutritive values

The invention discloses DHA (Docosahexaenoic Acid) emulsion, comprising the following components in the mass percentage: 22-27% of DHA algal oil, 27-32% of packaging material, 40-45% of water, 0.02-0.05% of antioxidant, 3.0-5.0% of stabilizing and thickening agent, 0.1-0.3% of emulsifying agent and 2.0-3.0% of adhesive. The DHA emulsion is prepared by the following steps: firstly preparing a water phase and an oil phase, then mixing the materials, emulsifying, homogenizing and finally sterilizing. In application of preparing DHA beverages, the DHA emulsion is used as a nutrition enhancer and added to liquid milk, acid milk, various milk beverages, juice beverages, nutritional and sports beverages and foods in the proportion of 40-180mg / 100g. The production process of the DHA emulsion is simple and feasible, the absorption and utilization ratio of DHA in a human body is high. When in use, the DHA emulsion has good dispersing performance, stable light resistance, oxygen resistance, acid and alkaline resistance and the like the functions of enhancing memory and thought and improving intelligence, high nutritional value, as well as extremely wide use range.

Owner:XIAMEN HUISON BIOTECH

Liquid milk for pregnant women using on-line adding technique and preparation thereof

ActiveCN101322509ANutritional balanceMellow tasteMilk preparationMilk preservationDairy foodsAdditive ingredient

The invention relates to liquid milk, in particular to the liquid milk which uses the online adding technology and is used for pregnant women and a preparation method thereof. The liquid milk belongs to the technical field of dairy food. Every 100g of the liquid milk which is provided by the invention and applicable to the pregnant women for drinking contains ingredients with the following weight: 900 to 1190Kg of milk (or reconstituted milk), 1 to 5Kg of emulsifying stabilizer, 0.9 to 600g of compound vitamin, 135 to 340g of compound mineral substance, 5 to 15Kg of probiotics and 0.2 to 1Kg of algae DHA oil. The nutrients of the liquid milk of the invention are more reasonable, thereby meeting the needs of the pregnant women during the special physiological period. Compared with fresh milk and ordinary milk powder, the product has the advantages of scientific nutrition-allocated proportion, thick aroma and convenient administration.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com