Preparation method and special yoghourt stabilizer of yoghourt with long shelf life

A production method and shelf-life technology, which is applied in the field of food processing, can solve problems such as inability to produce yogurt with a long shelf life, inability to produce yogurt with a long shelf life, and inability to effectively stabilize protein, so as to improve product quality, improve product stability, and prevent whey The effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

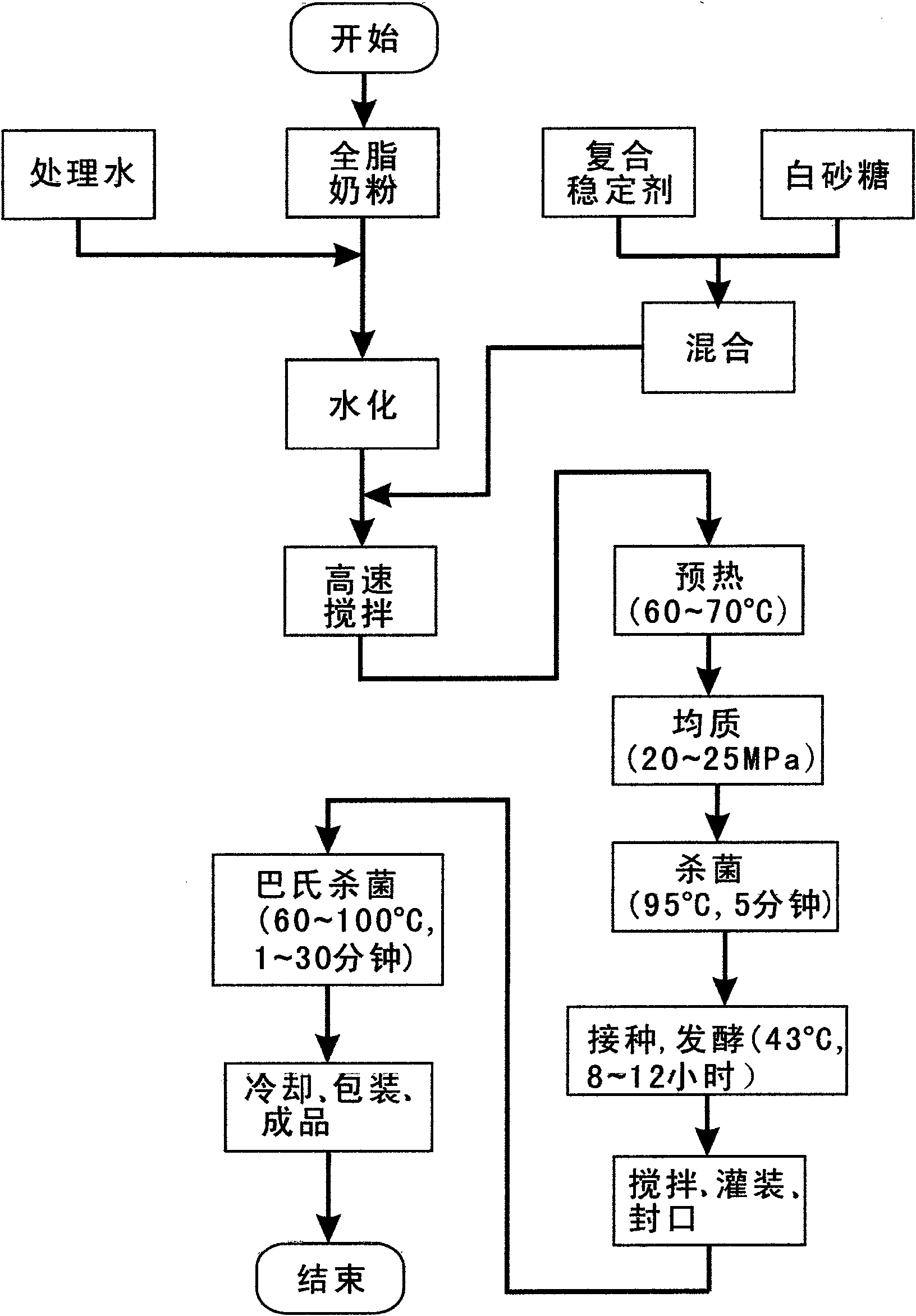

[0052] Embodiment 1, the production of coagulation type long shelf-life yoghurt.

[0053] Experimental raw materials: New Zealand whole milk powder, white granulated sugar, direct throw type lactic acid bacteria bacterial classification (Denmark Hansen), JO-748 yogurt stabilizer of L company, 8039 yogurt stabilizer of D company, and yogurt stabilizer of the present invention.

[0054] Wherein, the yoghurt stabilizer of the present invention consists of (mass content):

[0055] Acid-resistant CMC 12.4%

[0056] High Ester Pectin 5.0%

[0057] Modified Starch Purity 77 49.6%

[0058] Modified Starch Textra 33.0%

[0059]Method: add the yoghurt stabilizer of the present invention and do not add the yoghurt stabilizer of the present invention when investigating the production of long shelf-life coagulated yoghurt, before and after pasteurization, the influence of the product tissue state is divided into four groups: sample 1# (without adding Yogurt stabilizer, 10% whole milk p...

Embodiment 2

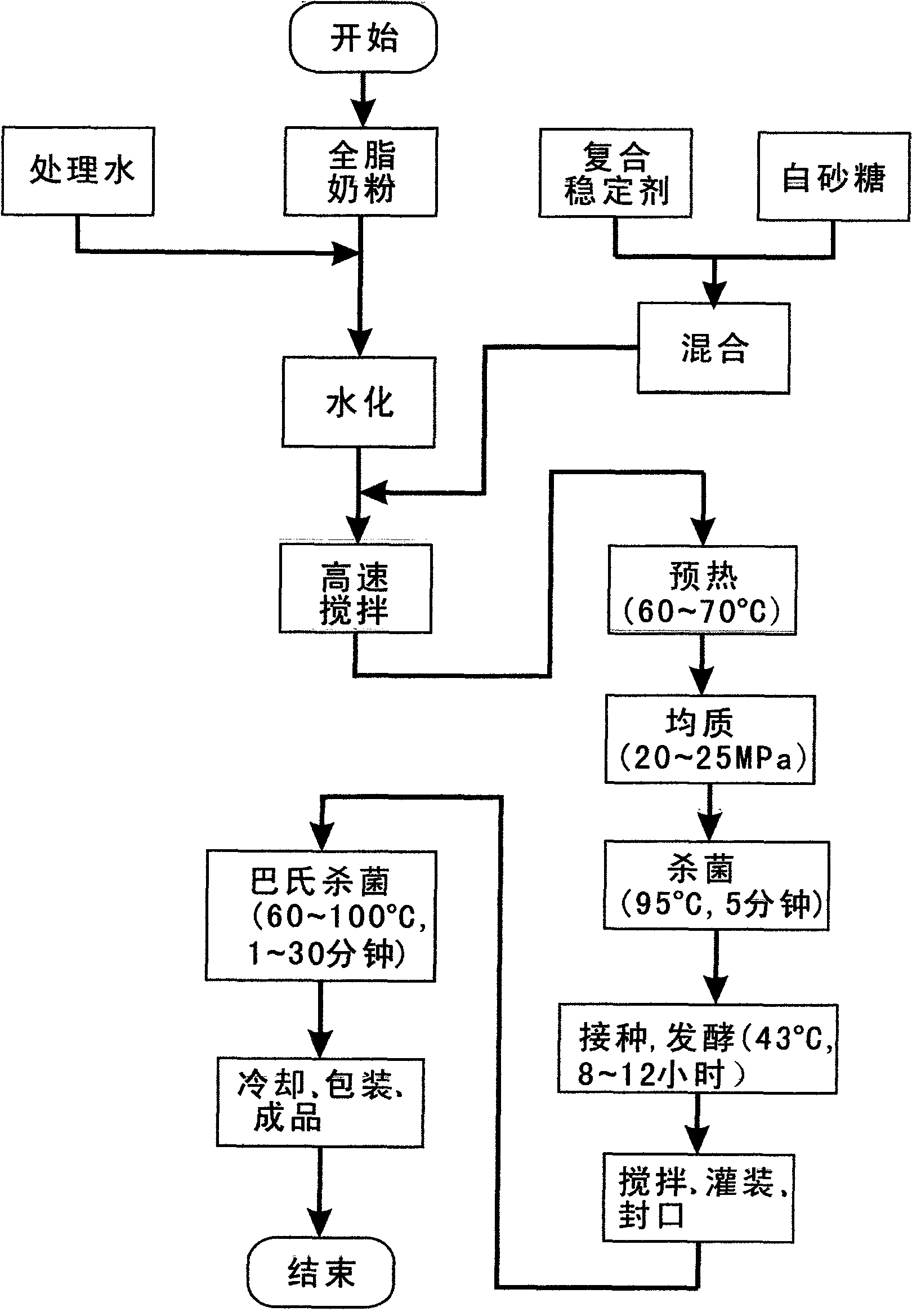

[0071] Embodiment 2, the production of stirring type long shelf-life yogurt

[0072] Experimental raw materials: New Zealand whole milk powder, white sugar, direct-injected lactic acid bacteria strains (Denmark Hansen), L company JO-749 yogurt stabilizer, L company JO-752 yogurt stabilizer, D company 258-C yogurt stabilizer Agent, yogurt stabilizer of the present invention.

[0073] Wherein, the composition of this yoghurt stabilizer is (mass percentage composition):

[0074] Acid-resistant CMC 14.6%

[0075] High Ester Pectin 7.3%

[0076] Modified Starch Purity 77 48.8%

[0077] Modified Starch Textra 29.3%

[0078] Method: add the yoghurt stabilizer of the present invention and do not add the yoghurt stabilizer of the present invention when investigating the production of long shelf-life stirring type yoghurt, before and after pasteurization, the influence of the product tissue state is divided into five groups: sample 1# (without adding Yogurt stabilizer, 10% whole mi...

Embodiment 3

[0090] Embodiment 3, the production of stirring type long shelf-life high-fiber coconut fruit yoghurt

[0091] The yoghurt stabilizer consists of (mass percentage):

[0092] Acid-resistant CMC 12.9%

[0093] High Ester Pectin 5.6%

[0094] Modified Starch Purity 77 42.9%

[0095] Modified Starch Textra 38.6%

[0096] Whole milk powder → hydration → preheating (60°C-70°C) plus stabilizer, sugar → stirring → sterilization (90-95°C, 5min) cooling down to 43°C → inoculation → fermentation to an acidity of about 85°T → demulsification → Add fruit pieces → Filling → Sealing → Pasteurization → Tasting the next day.

[0097] Incorporate the following processes at the sealing position:

[0098] High-fiber nata de coco → rinsing in hot water until neutral → dipping in syrup → saccharifying for 24 hours → draining → sealing.

[0099] The product was observed and tasted the next day. The structure was good, the texture was uniform, the taste was delicate, and the fruit particles wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com