Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Ferritic alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The ferritic stainless steels are sometimes called “non-hardenable” 400 series grades or alloys, and 409 and 430 are the most common. Alloys of chromium and iron with limited carbon contents that are generally below 0.12% (442, 446 are at 0.20).

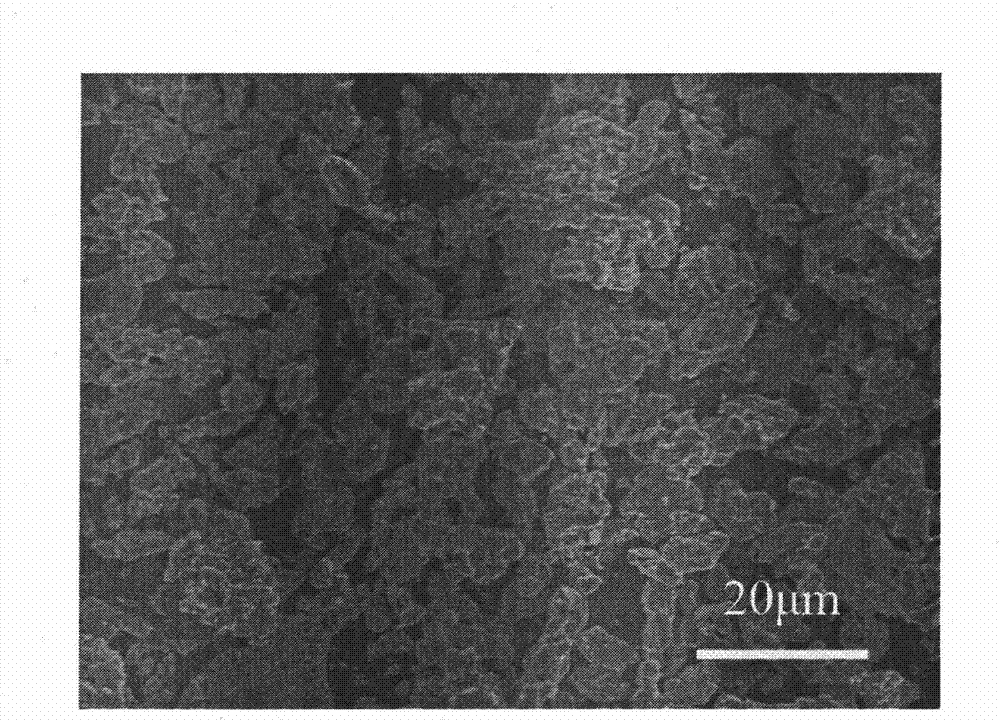

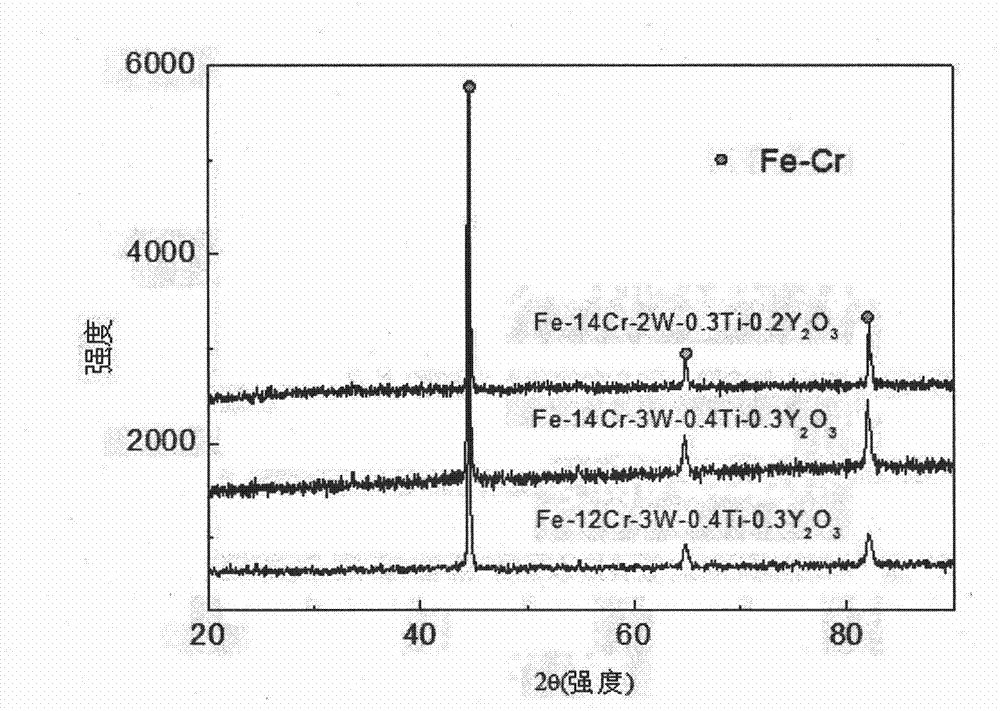

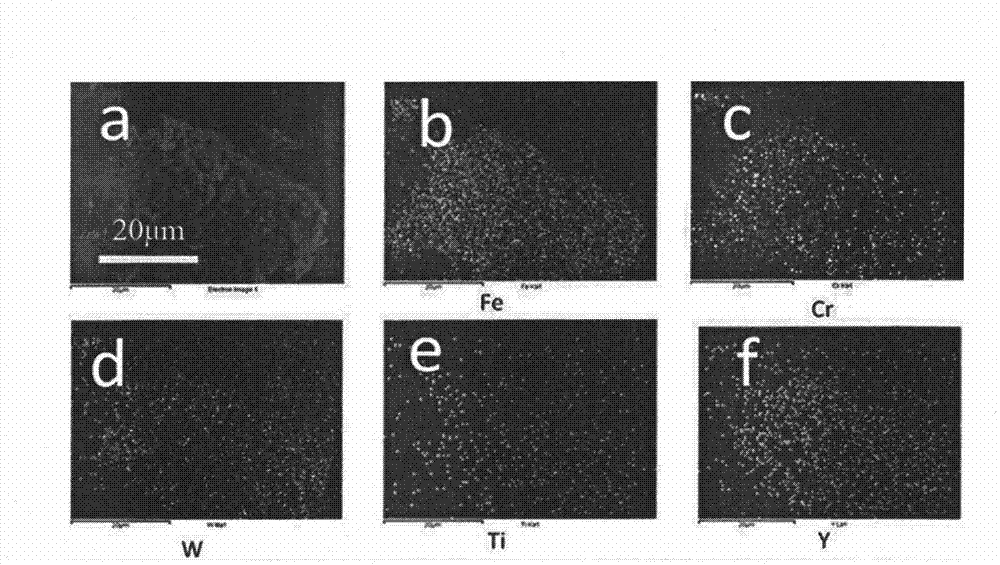

Method for preparing dispersion strengthening ferritic alloy steel powder of nanometer yttrium oxide particles

InactiveCN102814503AHigh purityEnergy-saving preparation methodMaterial nanotechnologyEthylenediamineAmmonium paratungstate

The invention discloses a method for preparing dispersion strengthening ferritic alloy steel powder of nanometer yttrium oxide particles. The method includes adding ethylene diamine tetraacetic acid and chromic nitrate into water, stirring the mixture at a temperature in a range from 50 DEG C to 60 DEG C for at least 12 hours, and obtaining a mixed liquid; adding citric acid, ferric nitrate, ammonium paratungstate, yttrium nitrate and tetrabutyl titanate into the mixed liquid, mixing the mixture at a temperature in a range in a range from 60 DEG C to 70 DEG C for at least 3 hours, and obtaining colloidal sol; adding polyethylene glycol into the colloidal sol, stirring the mixture at a temperature in a range in a range from 70 DEG C to 80 DEG C to form gel; and finally drying the gel at a temperature in a range from 100 DEG C to 120 DEG C for at least 12 hours and roasting the gel at a temperature in a range from 300 DEG C to 600 DEG C for 4 to 5 hours in sequence to obtain precursor oxide powder, placing the gel in a reducing atmosphere, roasting the gel at a temperature in a range from 1100 DEG C to 1300 DEG C for at least 3 hours to obtain object products which comprise, by weight, 12% to 14% of chromium, 2% to 3% of tungsten, 0.2% to 0.5% of titanium, 0.1% to 1% of yttrium oxide, and the balance iron. Yttrium oxide is evenly dispersed and distributed on matrixes composed of chromium, tungsten, titanium and iron, and the products can be used in fast breeder reactors and fusion reactors.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Ferritic Fe-Cr-Ni-Al alloy having exellent oxidation resistance and high strength and a plate made of the alloy

Disclosed is a ferritic Fe-Cr-Ni-Al alloy having excellent oxidation resistance and high strength, which consists essentially of, by mass, 0.003 to 0.08% C, 0.03 to 2.0% Si, not more than 2.0% Mn, from more than 1.0% to not more than 8.0% Ni, from not less than 10.0% to less than 19.0% Cr, 1.5 to 8.0% Al, 0.05 to 1.0% Zr, and the balance of Fe and incidental impurities, wherein an F value is not less than 12% and an S value is not more than 25%, where the F value is defined by the following equation (1) and the S value is defined by the following equation (2): (1) F=-34.3C+0.48Si-0.012Mn-1.4Ni+Cr+2.48Al, and (2) S=Ni+Cr+Al. The Fe-Cr-Ni-Al alloy, after an annealing heat treatment at 600 to 1050° C., has 0.2% yield strength of 550 to 1,000 MPa by a tensile test at room temperature.

Owner:HITACHI METALS LTD

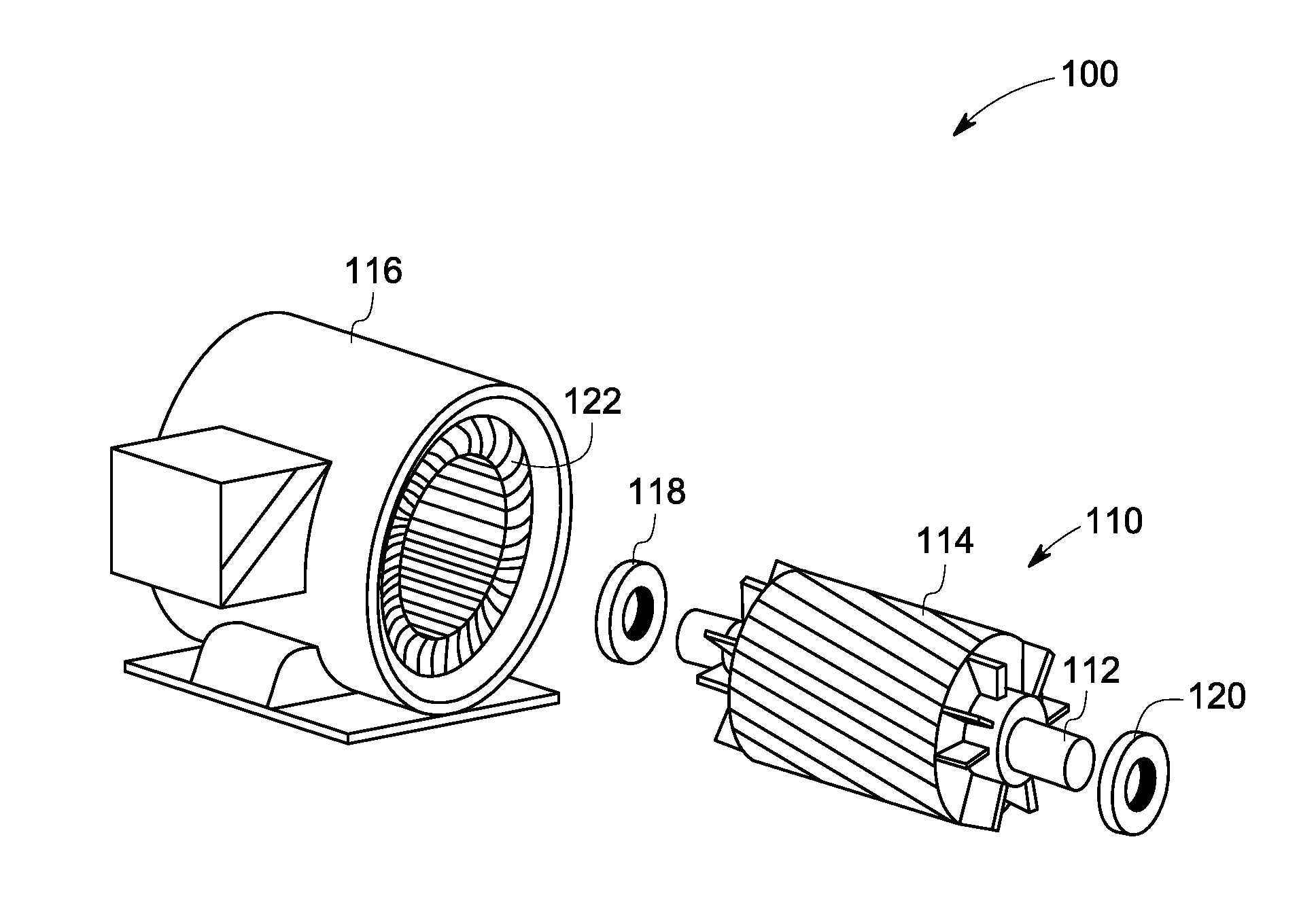

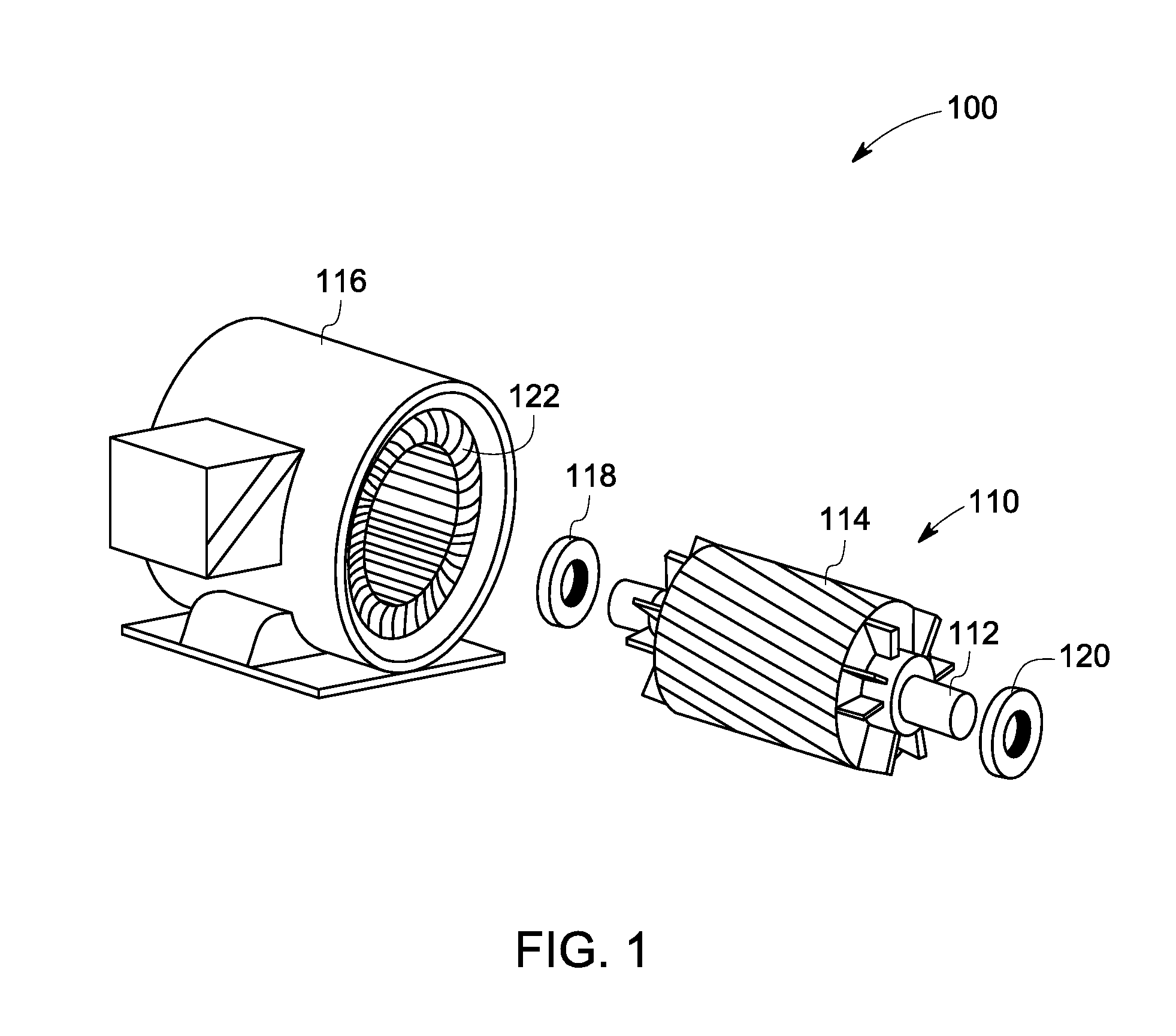

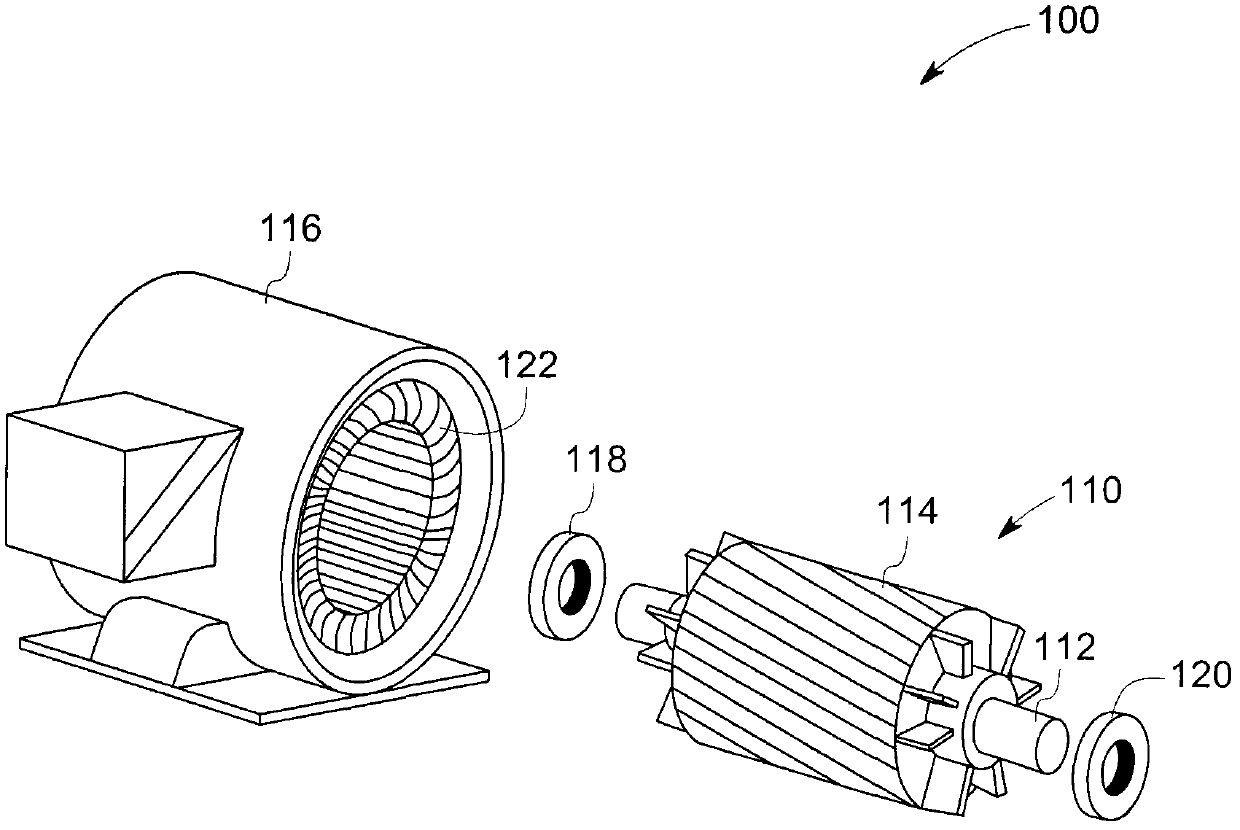

Article formed using nanostructured ferritic alloy

In one embodiment, an article is provided. The article comprises a soft magnetic component. The soft magnetic component includes a nanostructured ferritic alloy. The nanostructured ferritic alloy includes a plurality of nanofeatures disposed in an iron-containing alloy matrix, wherein the nanofeatures comprise an oxide.

Owner:GENERAL ELECTRIC CO

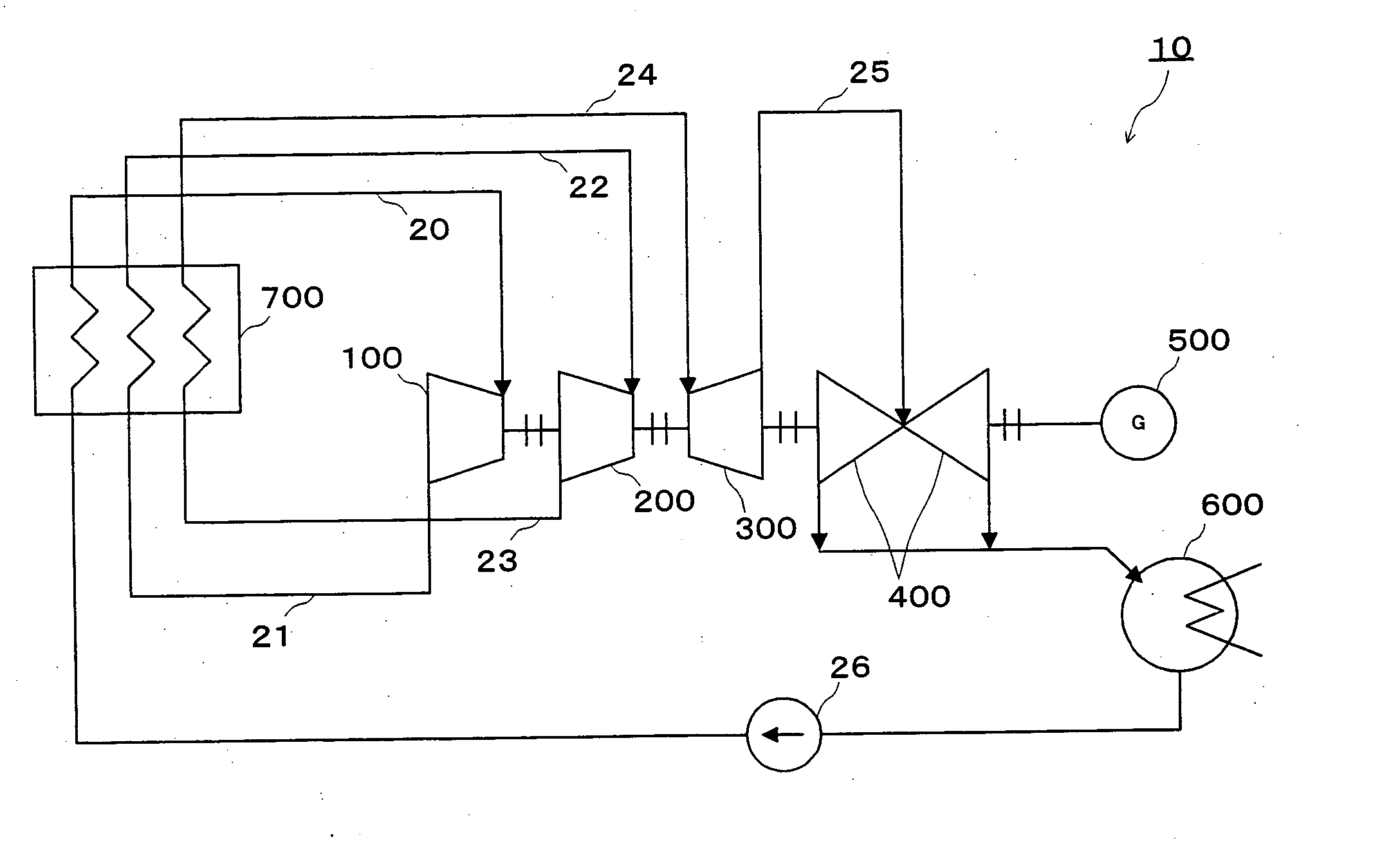

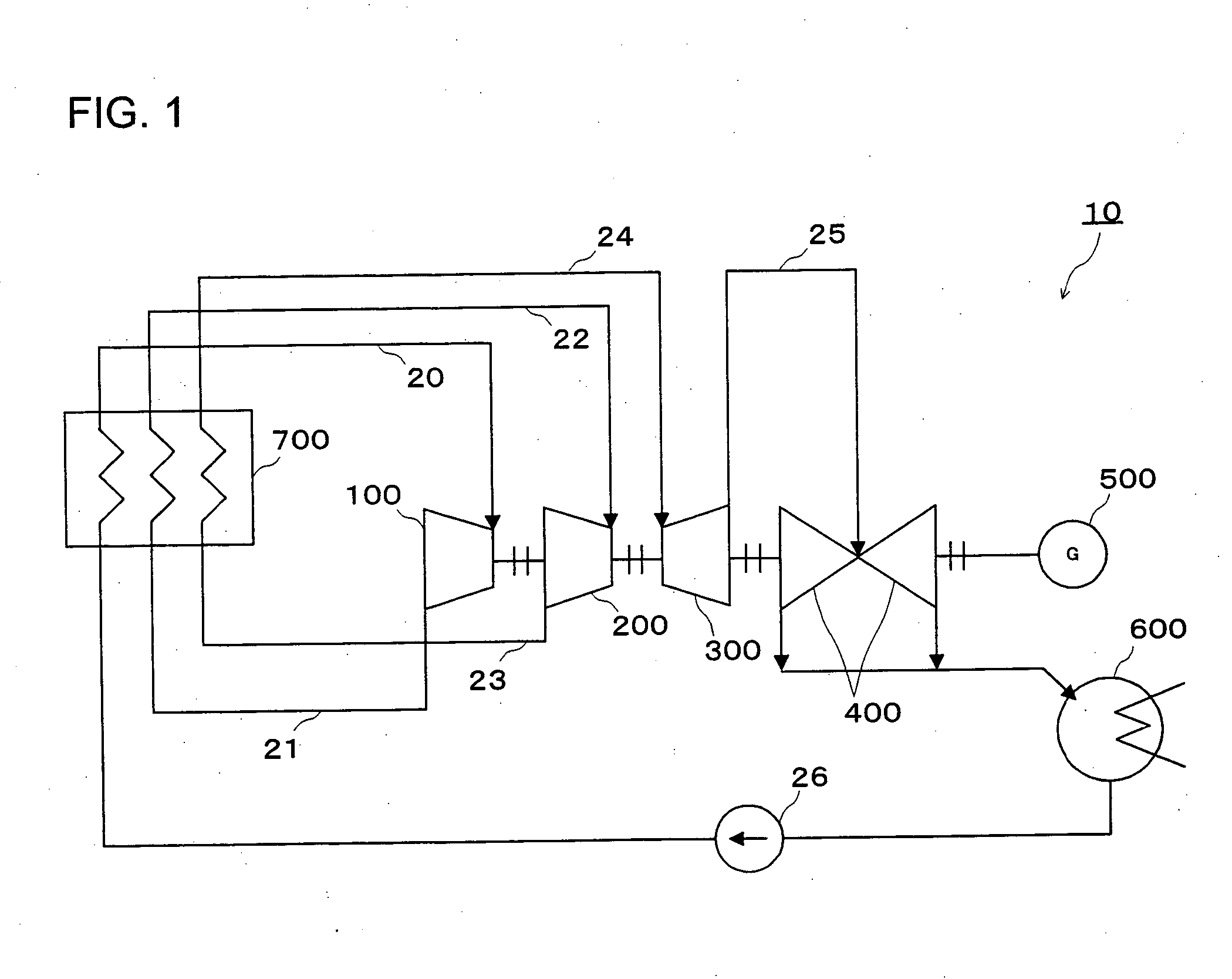

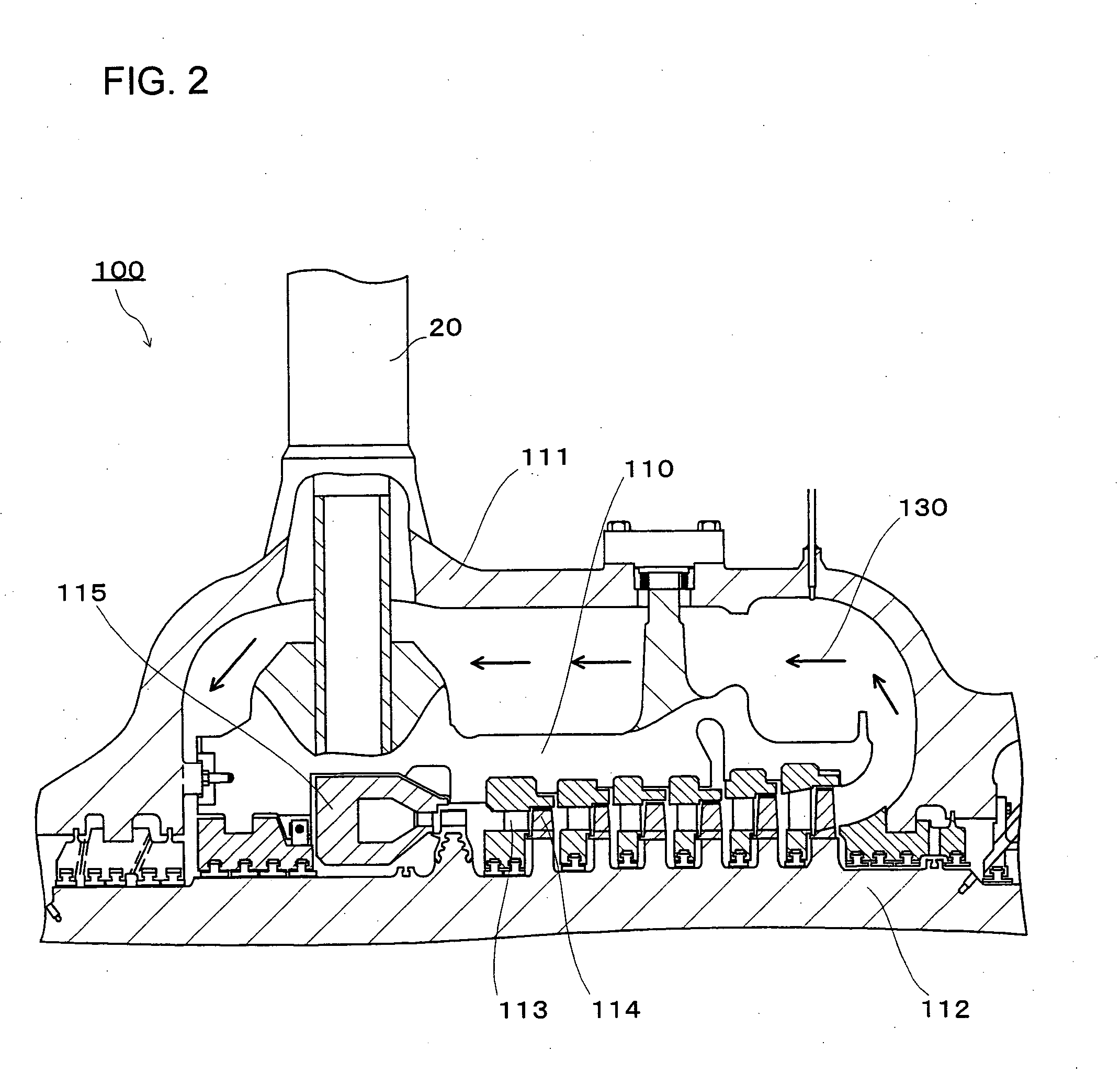

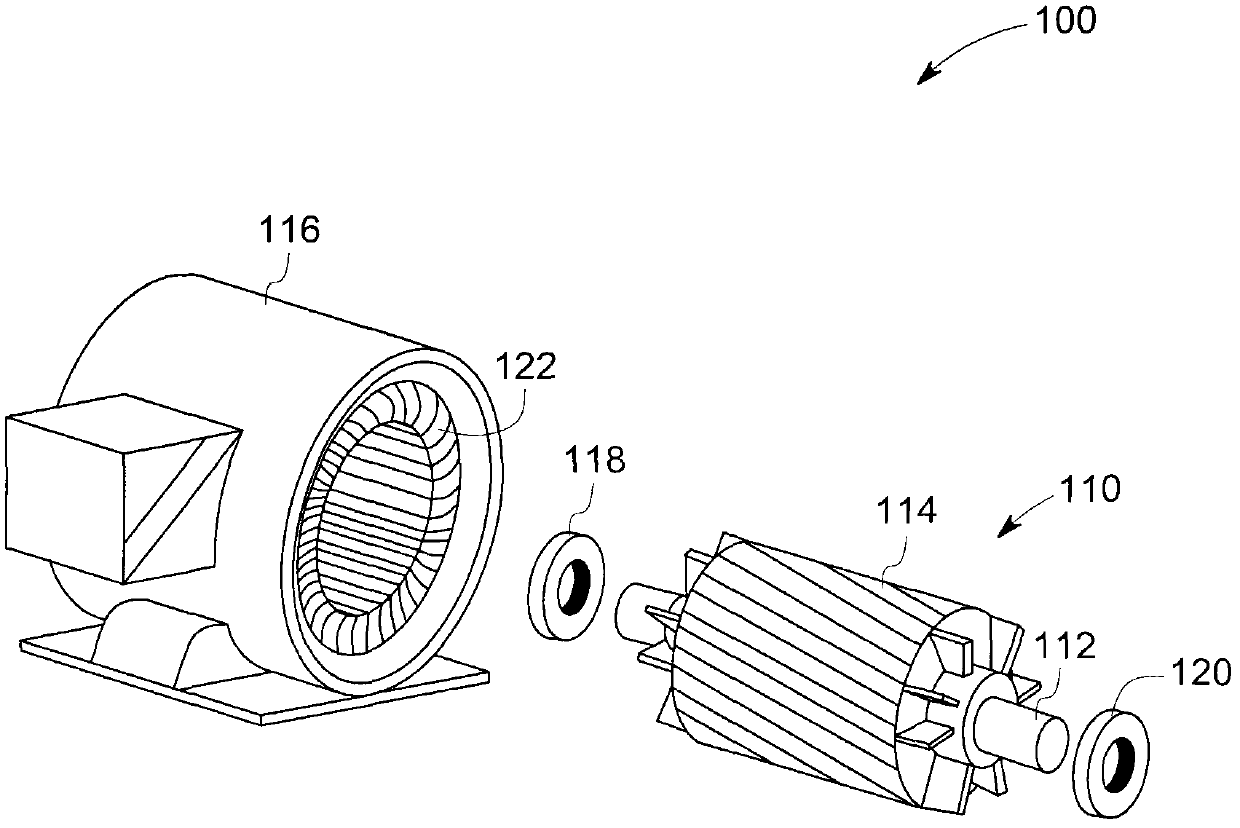

Steam turbine power plant

ActiveUS20060245911A1Improve thermal efficiencyEconomical efficiencyPump componentsStatorsPower stationFerritic alloy

A steam turbine power plant which is provided with an extra-high-pressure turbine 100, a high-pressure turbine 200, an intermediate-pressure turbine 300 and a low-pressure turbine 400, and has high-temperature steam of 650° C. or more introduced into the extra-high-pressure turbine 100, wherein the extra-high-pressure turbine 100 has an outer casing cooling unit which cools an outer casing 111, and a turbine rotor 112, an inner casing 110 and a nozzle box 115 of the extra-high-pressure turbine 100 are formed of an Ni base heat-resisting alloy, and the outer casing 111 is formed of a ferrite-based alloy.

Owner:KK TOSHIBA

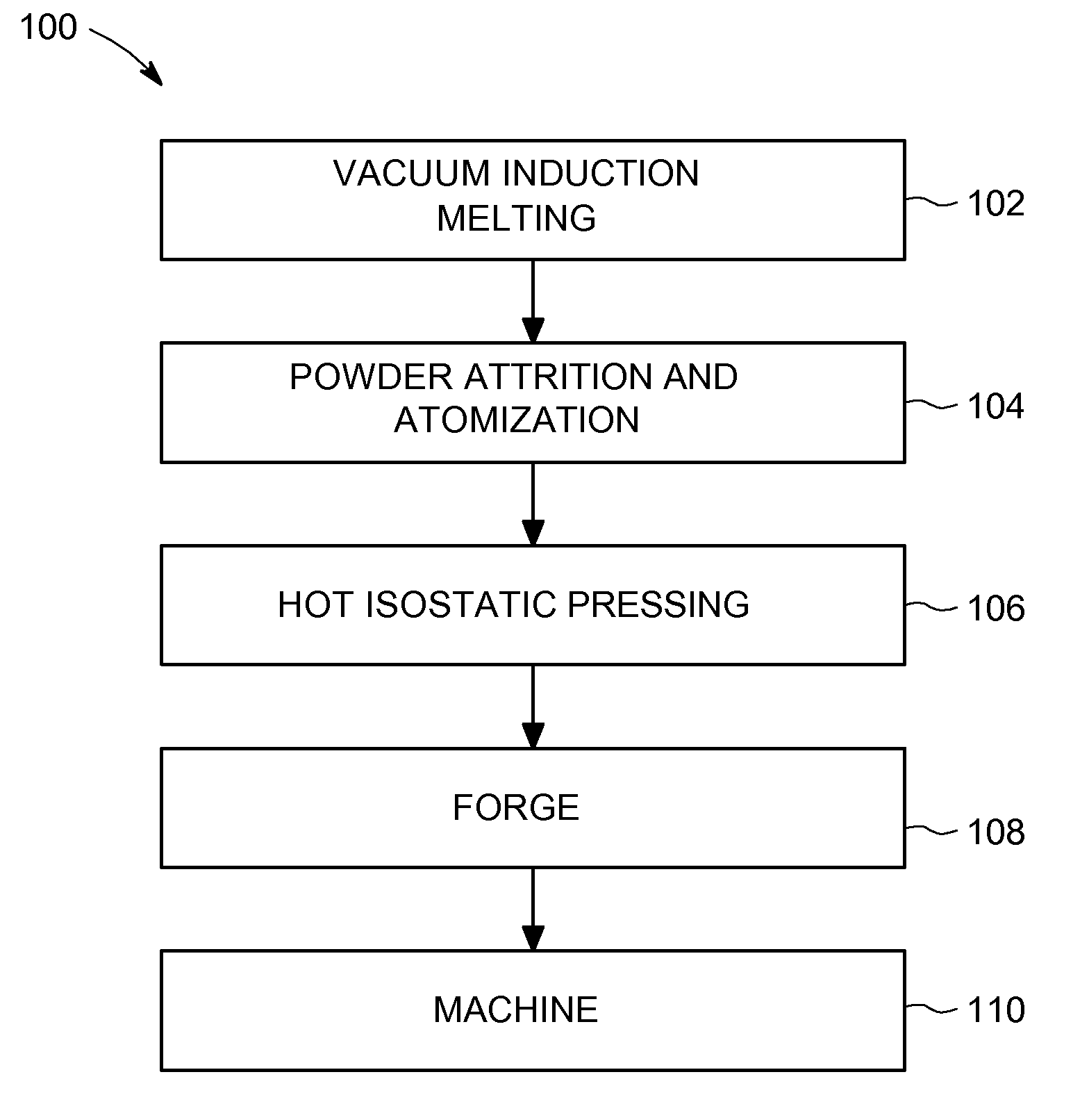

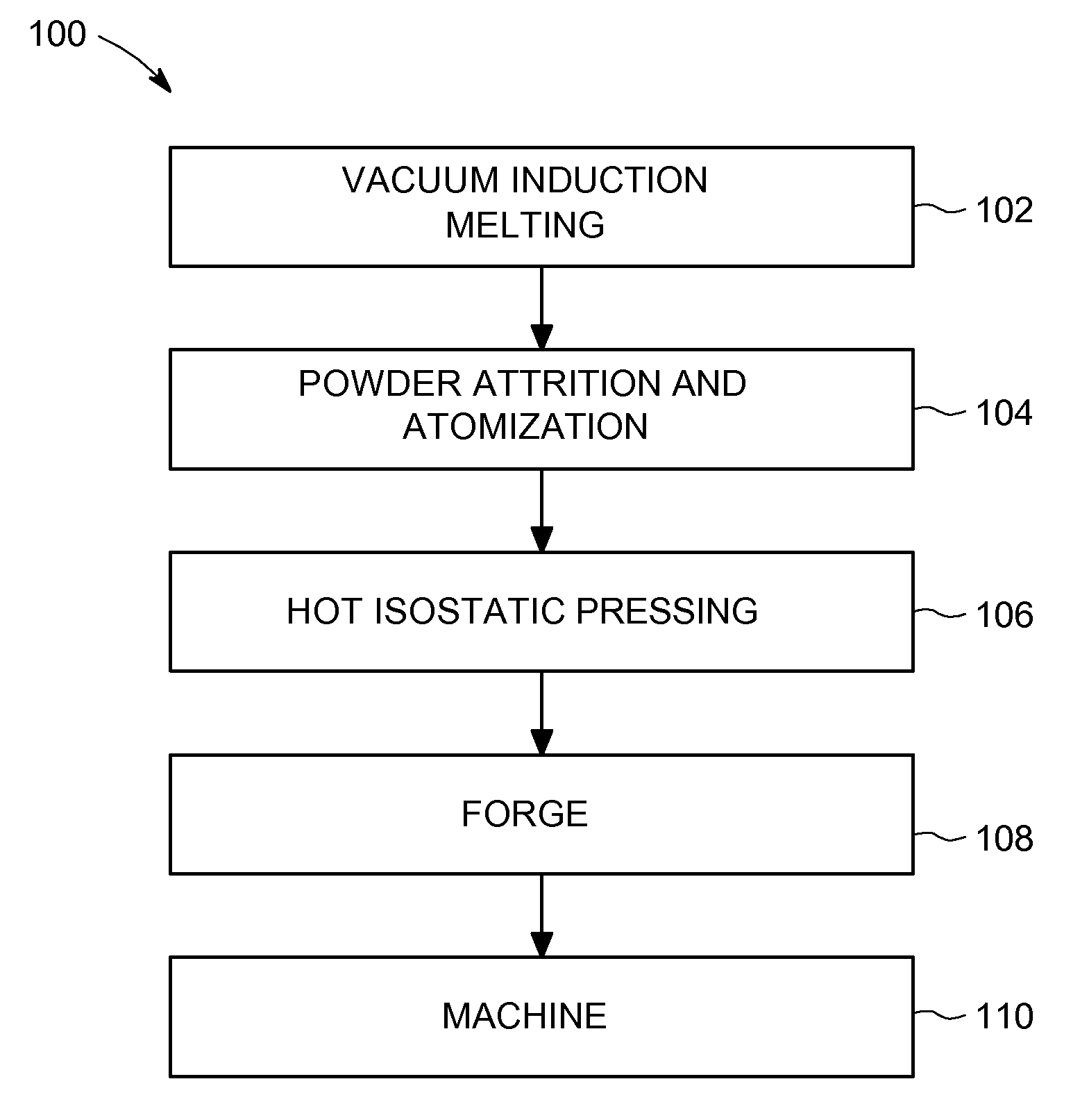

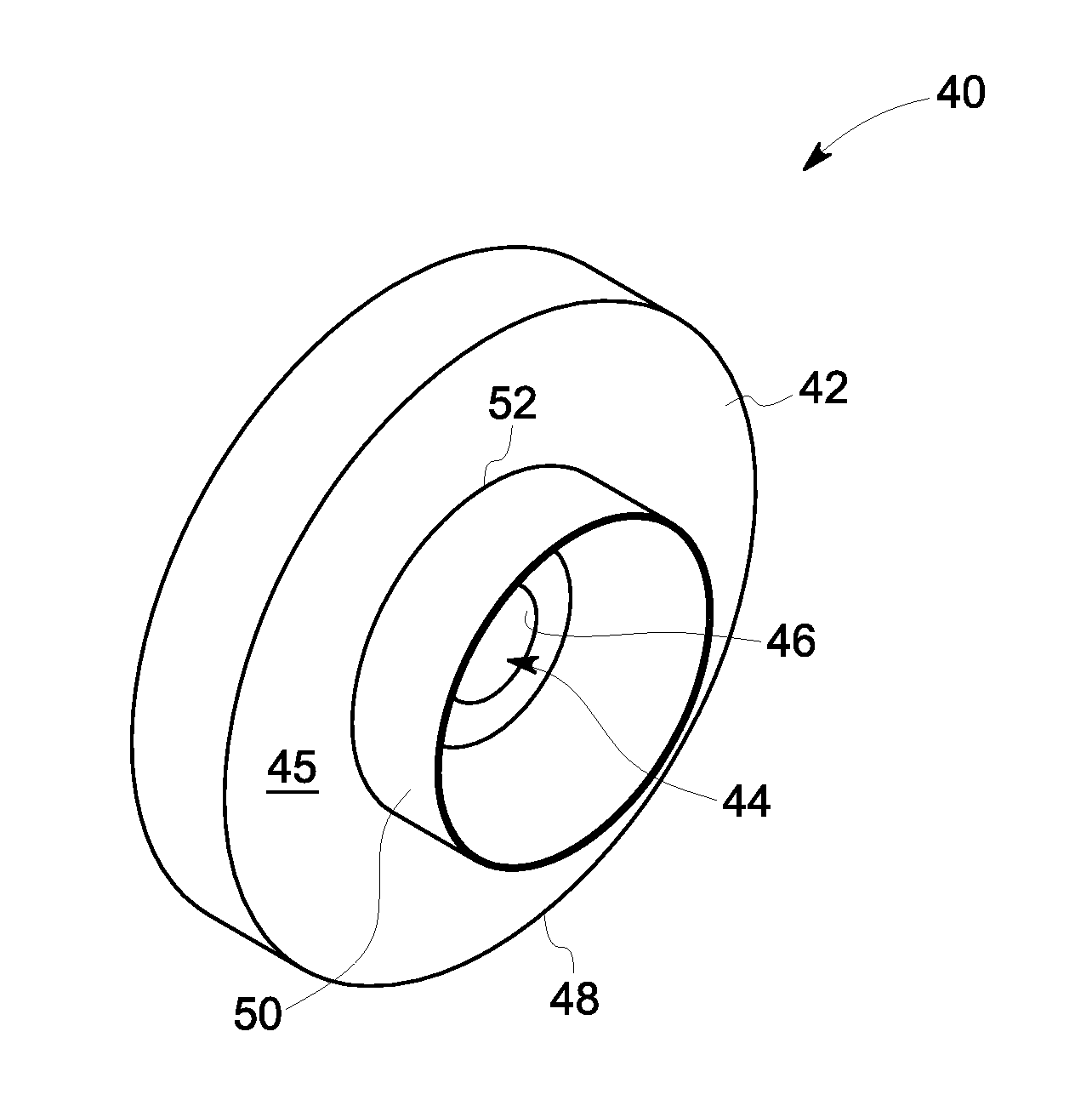

Methods for processing nanostructured ferritic alloys, and articles produced thereby

A formed article comprising a nanostructured ferritic alloy is provided. Advantageously, the article is not formed via extrusion, and thus, cost savings are provided. Methods are also provided for forming the article, and the articles so produced, exhibit sufficient continuous cycle fatigue crack growth resistance and hold time fatigue crack growth resistance to be utilized as turbomachinery components, and in particular, large, hot section components of a gas or steam turbine engines. In other embodiments, a turbomachinery component comprising an NFA is provided, and in some such embodiments, the turbomachinery component may be extruded.

Owner:GENERAL ELECTRIC CO

Ferritic Fe-Cr-Ni-Al alloy having exellent oxidation resistance and high strength and a plate made of the alloy

Disclosed is a ferritic Fe-Cr-Ni-Al alloy having excellent oxidation resistance and high strength, which consists essentially of, by mass, 0.003 to 0.08% C, 0.03 to 2.0% Si, not more than 2.0% Mn, from more than 1.0% to not more than 8.0% Ni, from not less than 10.0% to less than 19.0% Cr, 1.5 to 8.0% Al, 0.05 to 1.0% Zr, and the balance of Fe and incidental impurities, wherein an F value is not less than 12% and an S value is not more than 25%, where the F value is defined by the following equation (1) and the S value is defined by the following equation (2): (1) F=-34.3C+0.48Si-0.012Mn-1.4Ni+Cr+2.48Al, and (2) S=Ni+Cr+Al. The Fe-Cr-Ni-Al alloy, after an annealing heat treatment at 600 to 1050° C., has 0.2% yield strength of 550 to 1,000 MPa by a tensile test at room temperature.

Owner:HITACHI METALS LTD

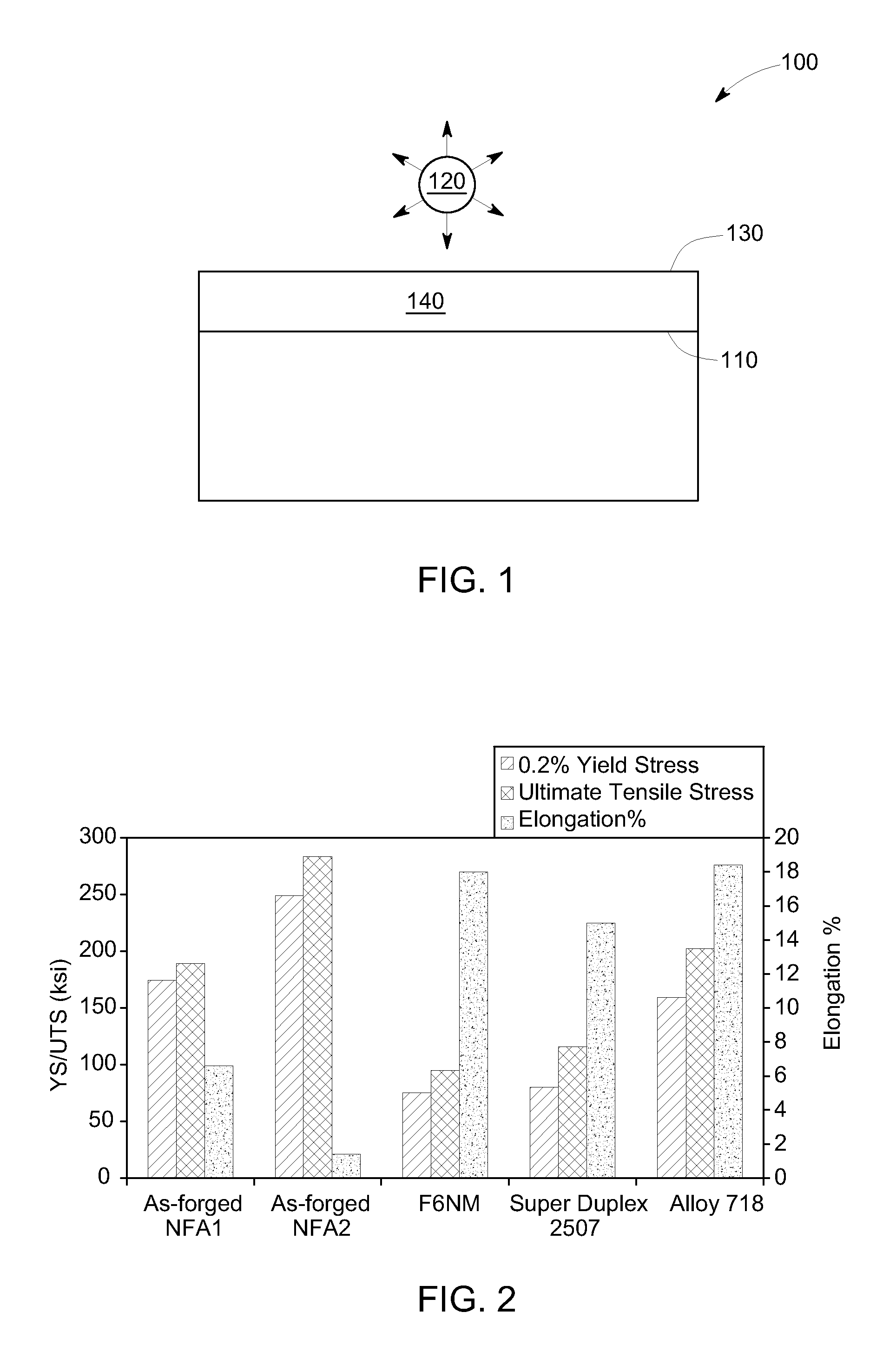

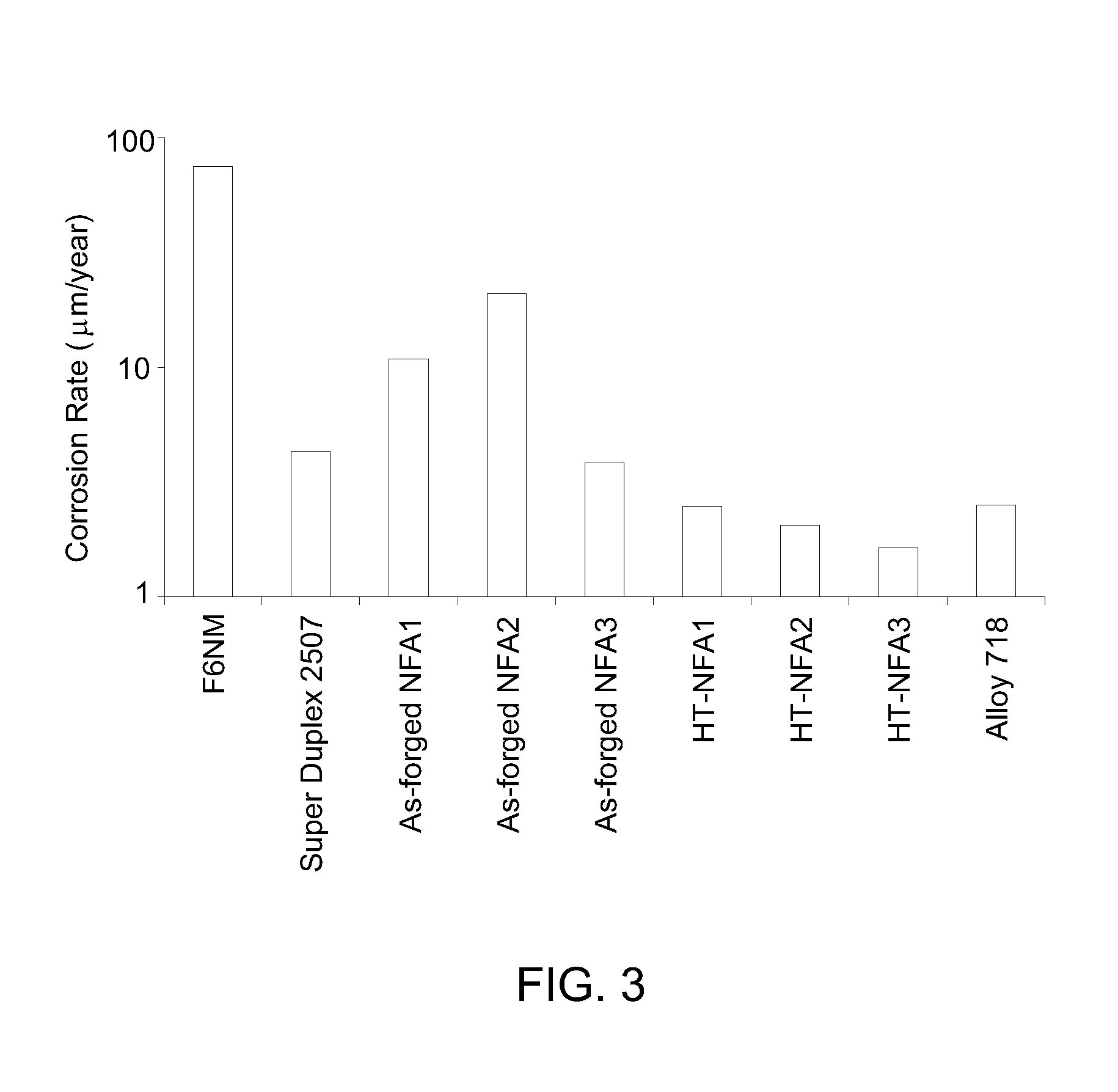

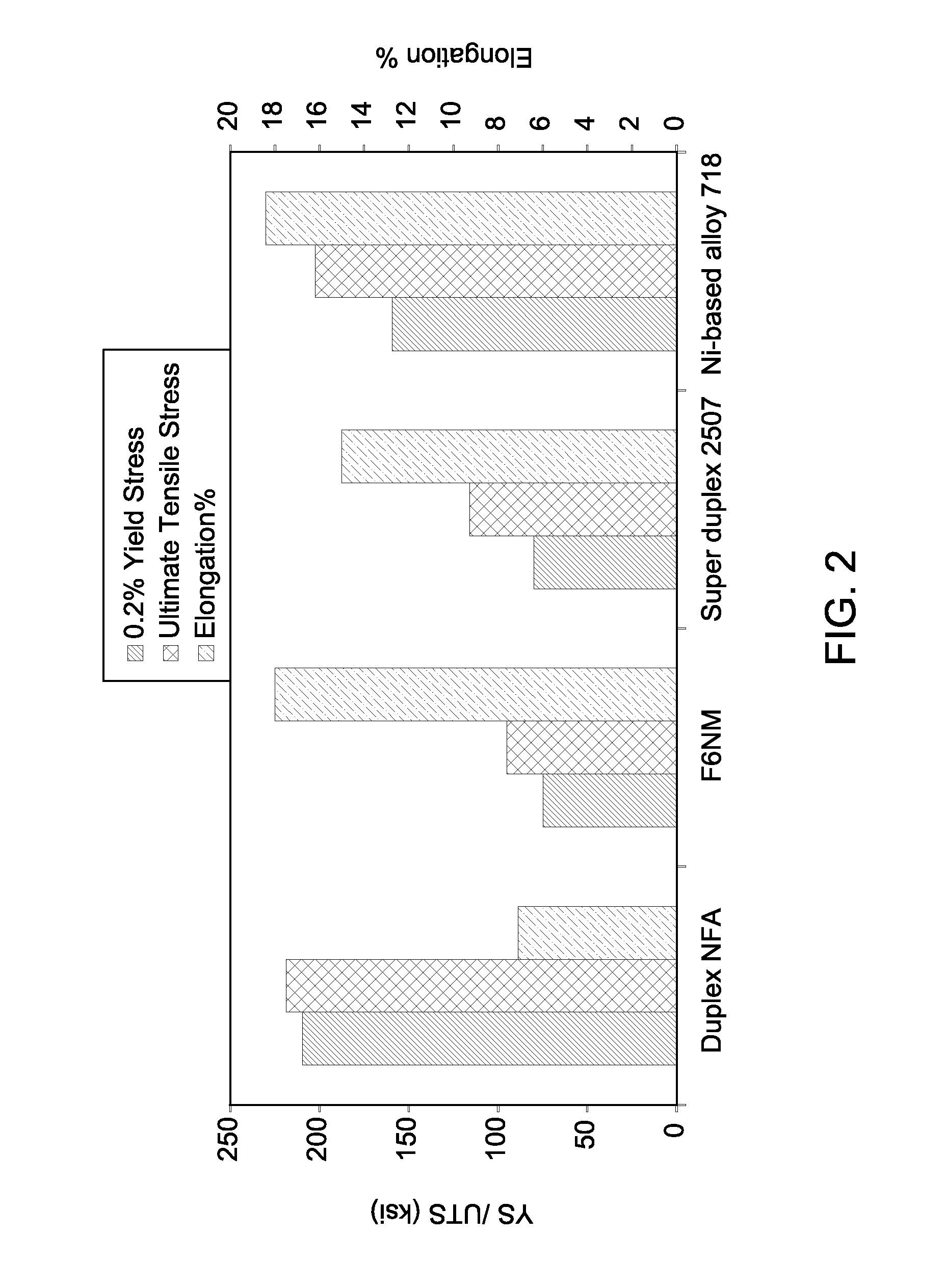

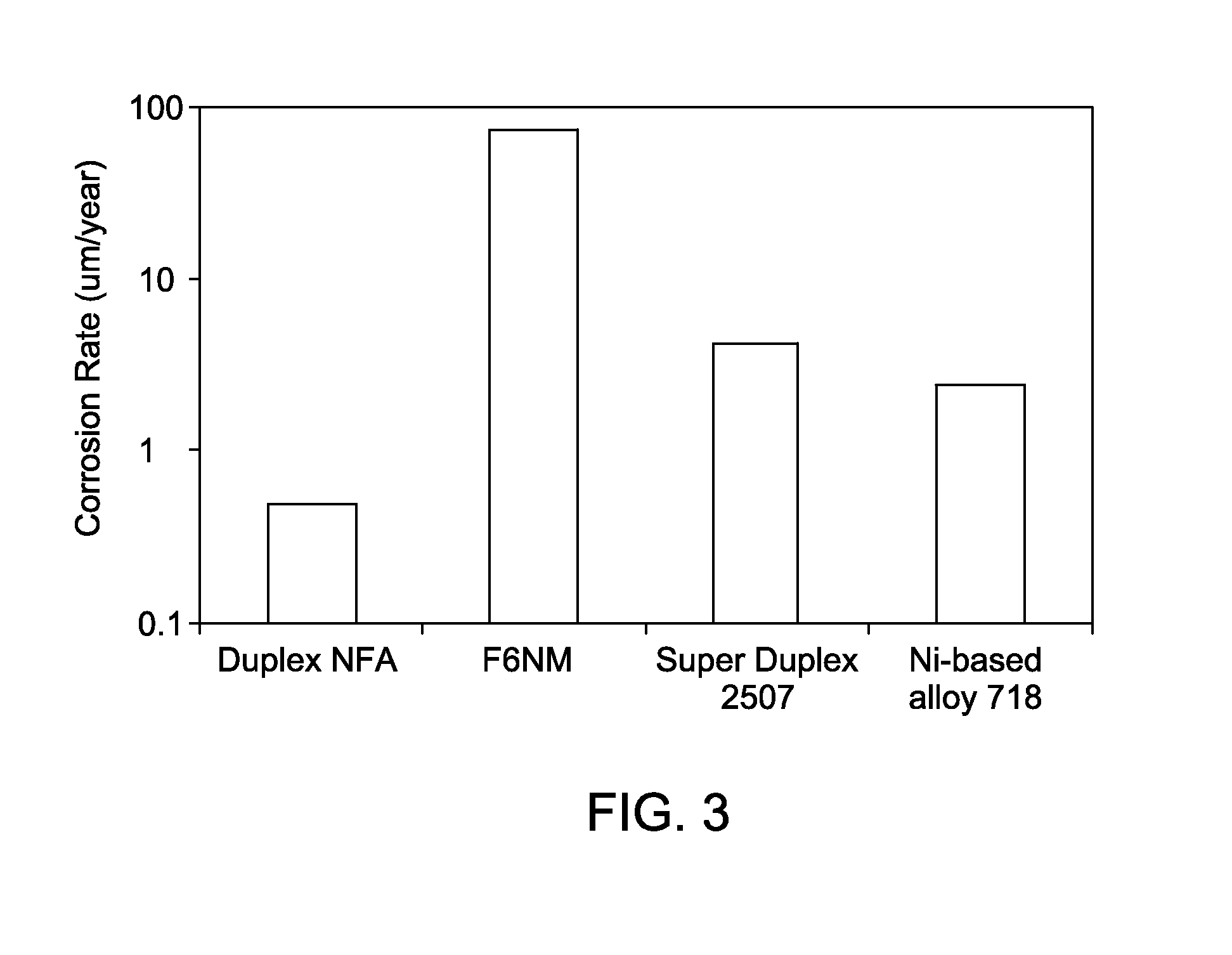

Corrosion resistant article and methods of making

An article and method of forming the article are disclosed. The article has a surface comprising a nanostructured ferritic alloy. The surface includes a plurality of nanofeatures that include complex oxides of yttrium and titanium disposed in an iron-bearing alloy matrix. The iron-bearing alloy matrix at the surface includes about 5 weight percent to about 30 weight percent of chromium, and about 0.1 weight percent to about 10 weight percent of molybdenum. Further, a concentration of a chi phase or a sigma phase in the nanostructured ferritic alloy at the surface is less than about 5 volume percent. The method generally includes the steps of milling, thermo-mechanically consolidating, annealing, and then cooling at a rate that hinders the formation of chi and sigma phases in the nanostructured ferritic alloy at the surface.

Owner:NUOVO PIGNONE TECH SRL

Fr-Cr-Al alloys for electric resistance wires

The present invention relates to Fe-Cr-Ar type alloys with additions to improve workability thereof, strength, and heat resistance. The present Fe-Cr-Al alloy for electric resistance wires comprises a basic alloy added with only Be of below 0.01 wt % or with both Be and misch metal composed of rare earth elements wherein the basic alloy consists of a balance element of Fe, a Cr element of 12~30 wt %, an Al element of 3~14 wt %, a Zr element of 0.01~1.5 wt %, and a Ti element of 0.001~0.1 wt %. The present Fe-Cr-Al type alloys remarkably improve physical properties of Fe-Cr-Al ferritic alloys, especially, workability and mechanical properties, and heating characteristic.

Owner:KOREA ELECTROTECH RES INST

Methods for processing nanostructured ferritic alloys, and articles produced thereby

Owner:GE INFRASTRUCTURE TECH INT LLC

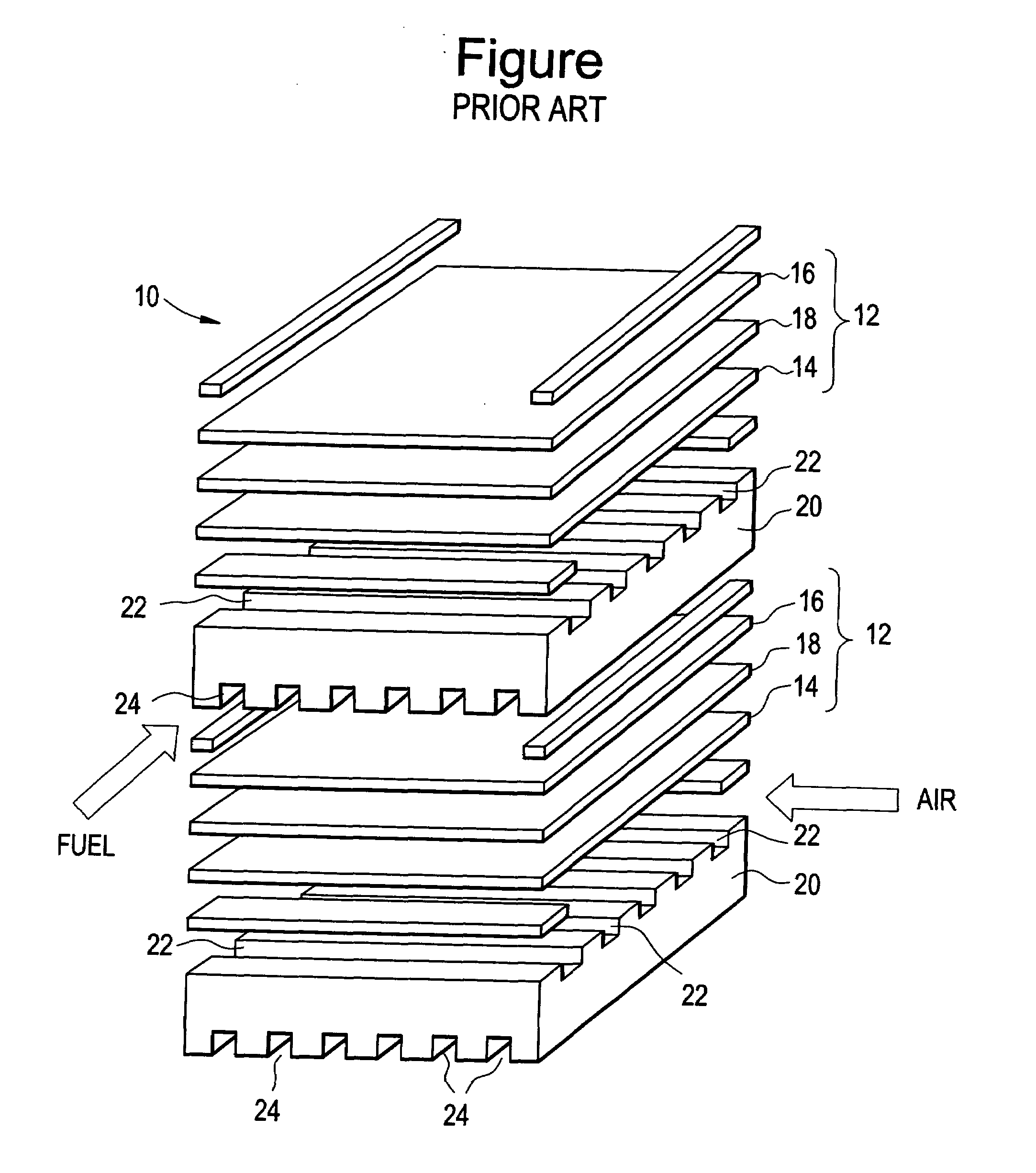

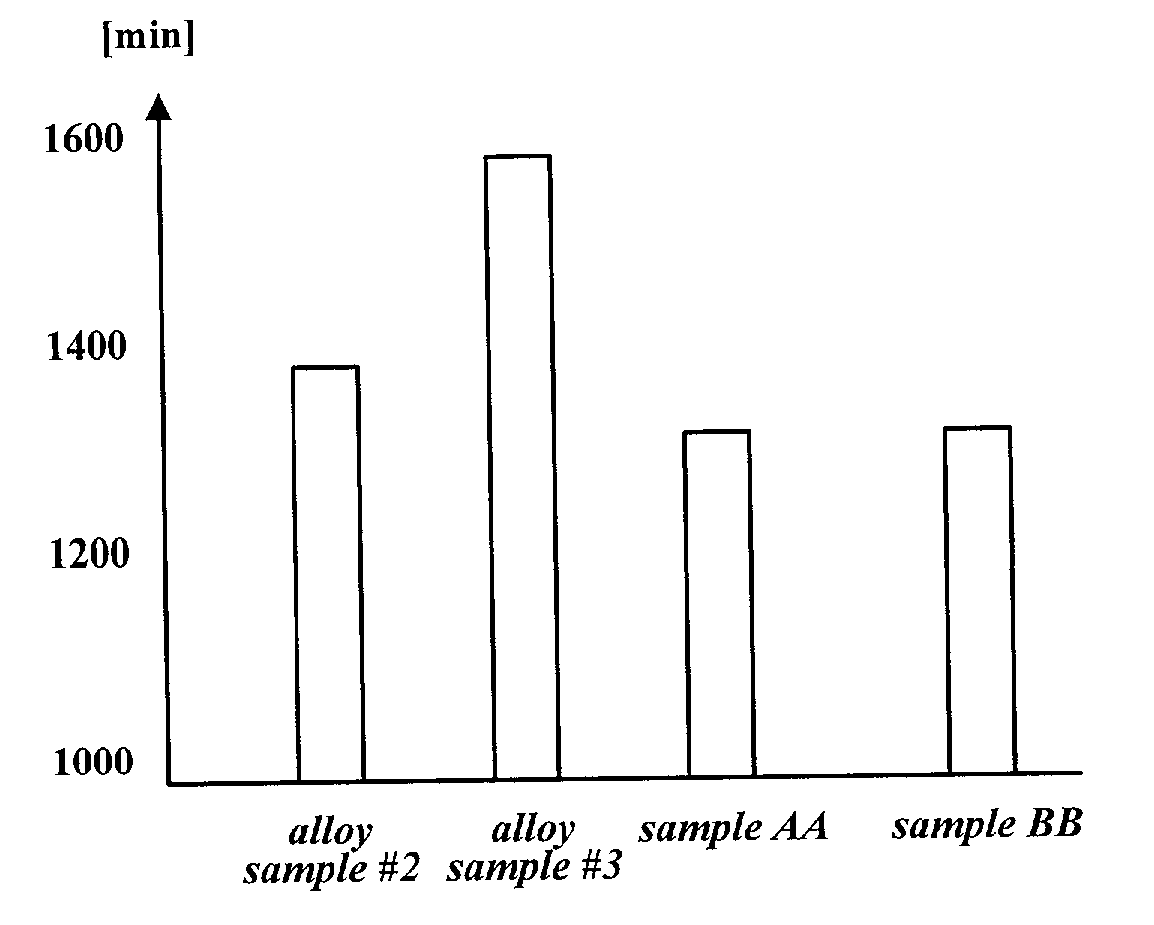

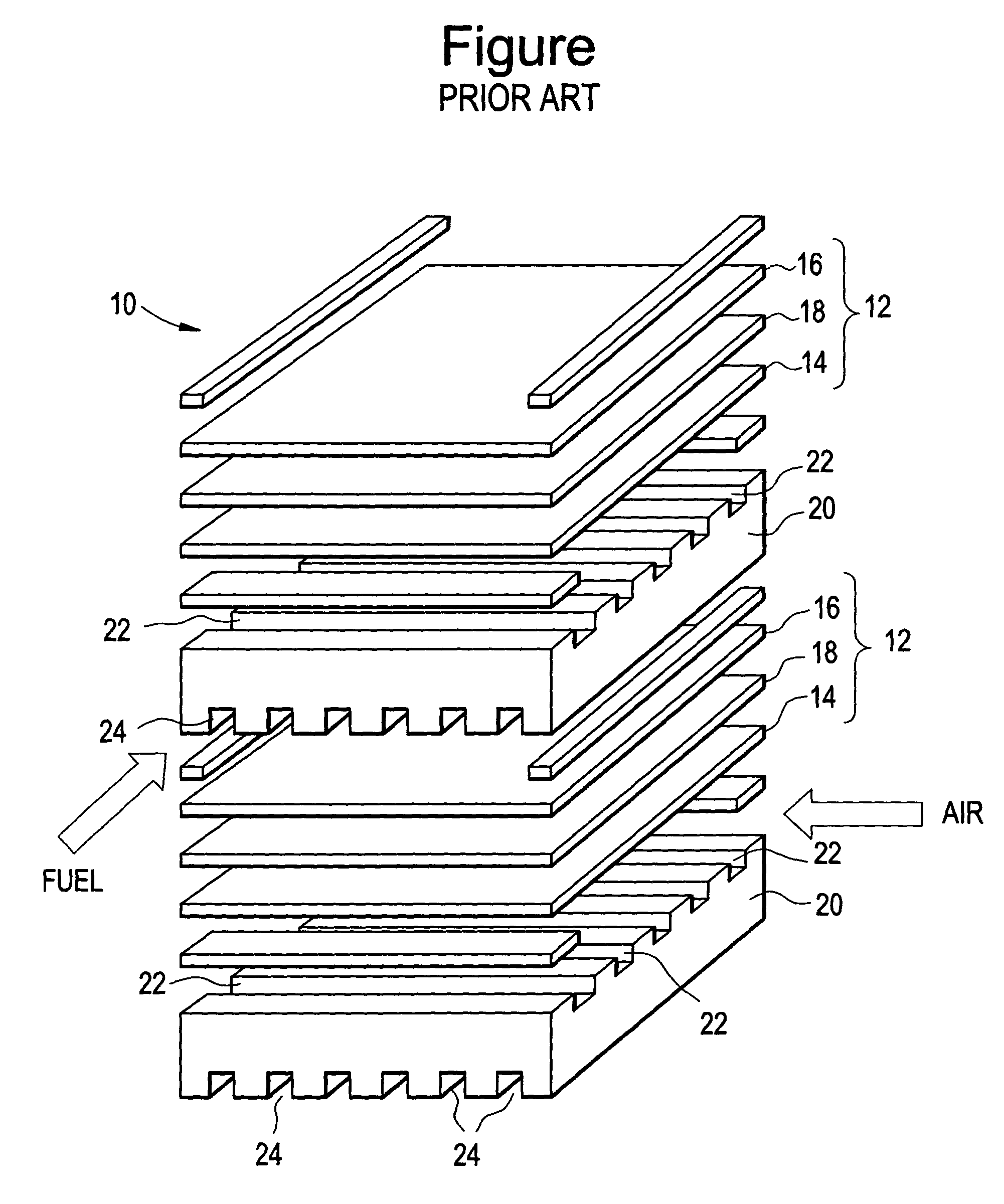

Ferritic steels for solid oxide fuel cells and other high temperature applications

Oxidation-resistant ferritic steel alloys for high temperature applications consist essentially of chromium (Cr) in an amount from about 18 to about 25 atom percent, tungsten (W) in an amount from about 0.5 to about 2 atom percent, manganese (Mn) in an amount less than about 0.8 atom percent, aluminum (Al) in an amount less than about 0.2 atom percent, silicon (Si) in an amount less than about 0.1 atom percent, and rare earth metals that includes neodymium (Nd) in an amount from about 0.002 to about 0.2 atom percent with the balance being iron (Fe). Also disclosed herein are solid oxide fuel cells that include separators formed for the oxidation resistant ferritic alloys.

Owner:CUMMINS ENTERPRISE LLC

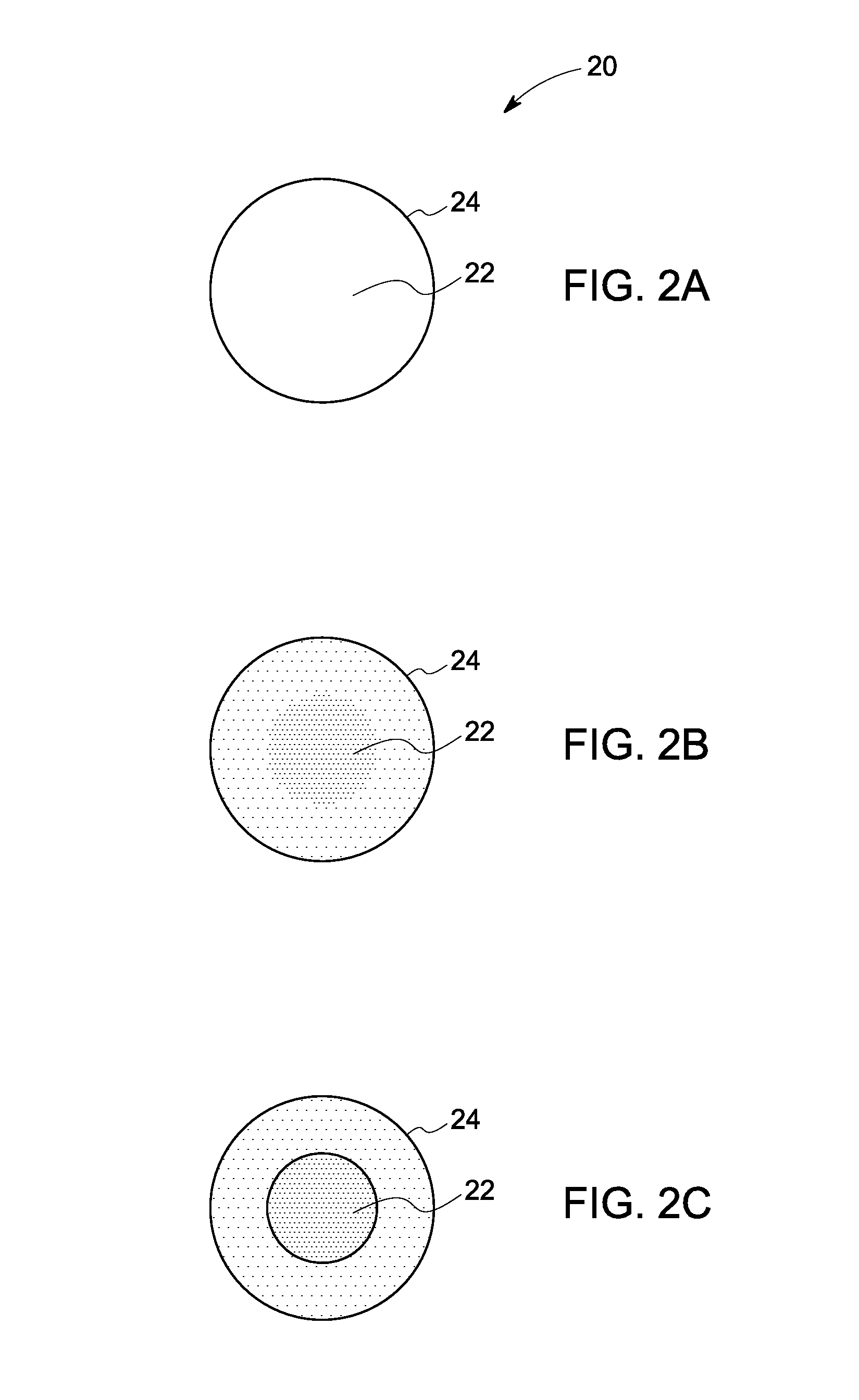

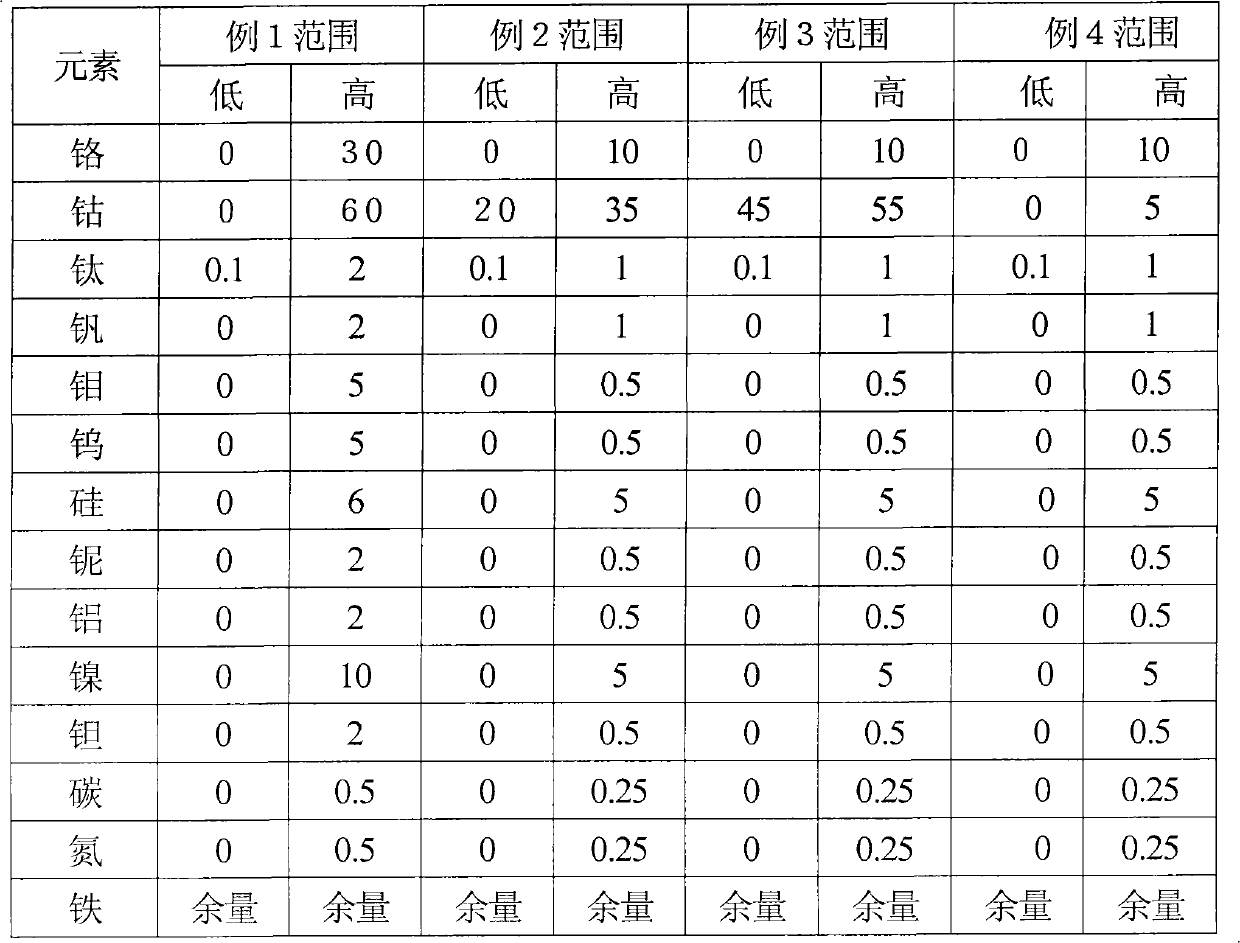

Precipitate strengthened nanostructured ferritic alloy and method of forming

An alloy and method of forming the alloy are provided. The alloy includes a matrix phase, and a population of particulate phases dispersed within the matrix. The matrix includes iron and chromium; and the population includes a first subpopulation of particulate phases and a second subpopulation of particulate phases. The first subpopulation of particulate phases include a complex oxide, having a median size less than about 20 nm, and present in the alloy in a concentration from about 0.1 volume percent to about 5 volume percent. The second subpopulation of particulate phases have a median size in a range from about 30 nm to about 10 microns, and present in the alloy in a concentration from about 1 volume percent to about 15 volume percent.

Owner:GENERAL ELECTRIC CO

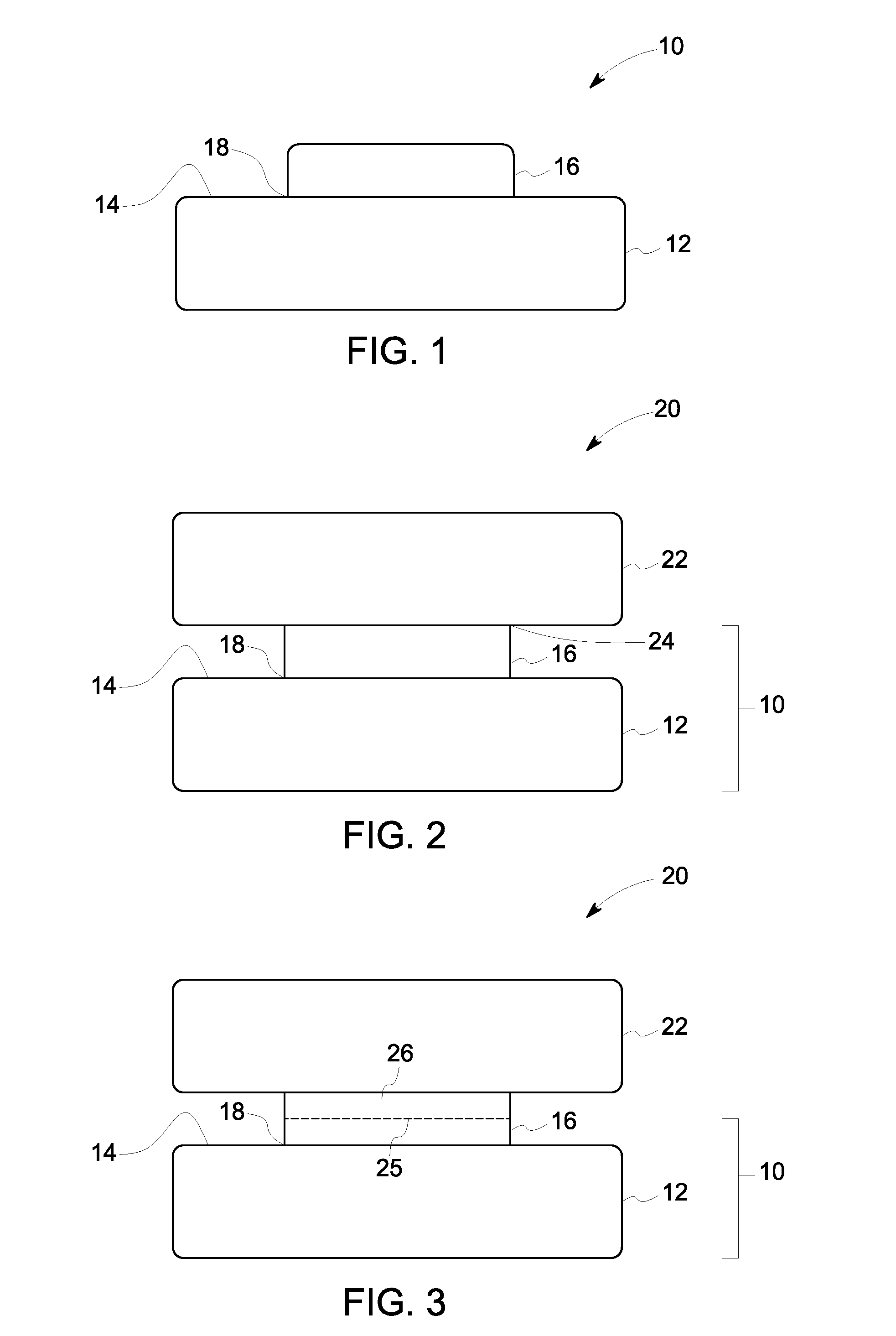

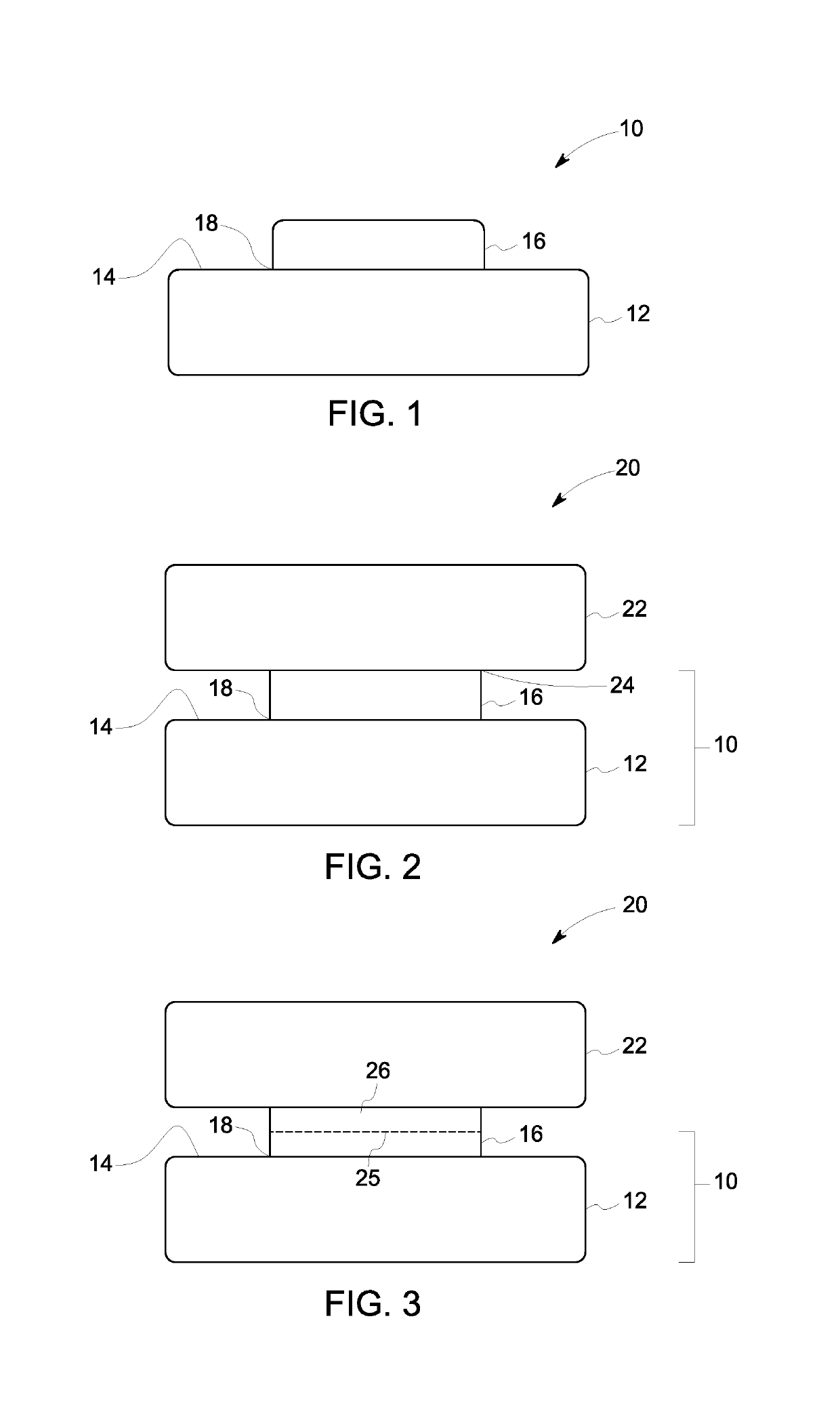

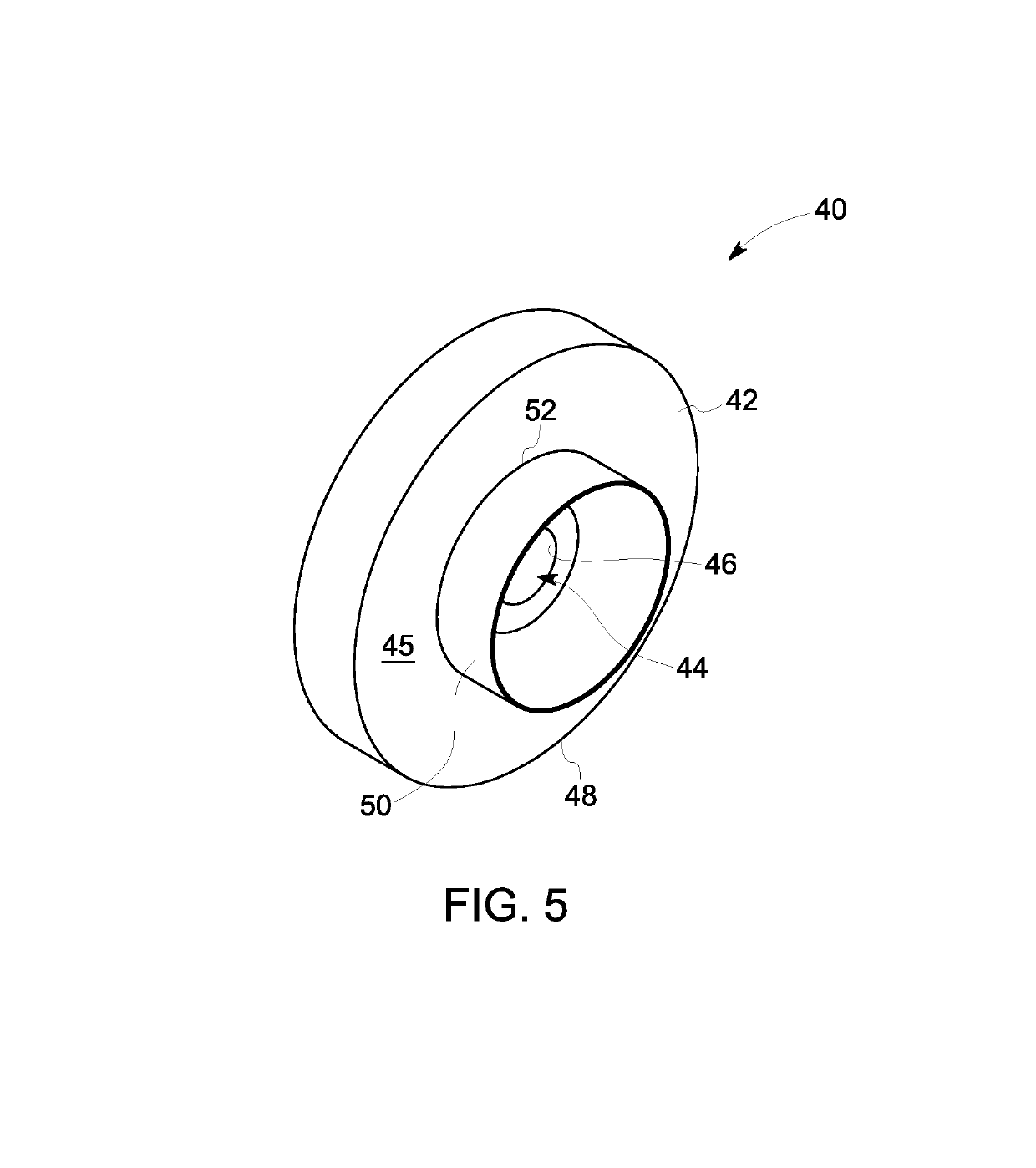

Nanostructured ferritic alloy components and related articles

An article, for example a turbomachinery article is presented. The article includes a weldable first component having a base portion and a flange portion. The flange portion is outwardly projecting normal to a surface of the base portion; and is joined with the base portion by a solid state joint. The base portion comprises a nanostructured ferritic alloy; and the flange portion comprises a steel substantially free of oxide nanofeatures. The first component is joined to a second component through the flange portion of the first component by a weld joint.

Owner:GENERAL ELECTRIC CO

Corrosion resistant article and methods of making

An article and method of forming the article are disclosed. The article has a surface comprising a duplex nanostructured ferritic alloy. The surface includes a plurality of nanofeatures that include complex oxides of yttrium and titanium disposed in an iron-bearing alloy matrix. The iron-bearing alloy matrix includes both a ferrite phase and an austenite phase. Further, a concentration of a chi phase or a sigma phase in the duplex nanostructured ferritic alloy at the surface is less than about 5 volume percent. The method generally includes the steps of milling, thermo-mechanically consolidating, annealing, and then cooling at a rate that hinders the formation of chi and sigma phases in the duplex nanostructured ferritic alloy at the surface.

Owner:GENERAL ELECTRIC CO

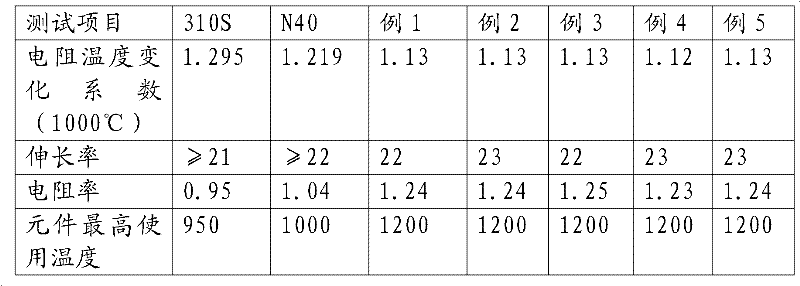

Locomotive braking resistance tape and preparation method thereof

ActiveCN102296237AImprove resistance uniformitySmall temperature coefficient of resistanceFurnace typesHeat treatment furnacesAcid washingRare earth

The invention relates to a locomotive braking resistance belt and a preparation method thereof. The resistance belt comprises the following main components in percentage by weight: 13.5-14.5 percent of chromium, 3.5-4.5 percent of aluminum, 0.25-0.35 percent of titanium, less than or equal to 0.04 percent of carbon, 0.05-0.10 percent of rare earth and the balance of iron. The preparation method of the resistance belt sequentially comprises the following steps of: performing vacuum melting, electroslag remelting, hammering, hot rolling, annealing heat treatment, acid washing, grinding and trimming, cold rolling, gas protected annealing, stripping and forming. The locomotive braking resistance belt disclosed by the invention is ferrite alloy, and metal nickel is not used, so that the production cost can be greatly reduced. The titanium element is adopted, so that the resistance uniformity of the resistance belt can be improved, meanwhile, the resistance temperature coefficient of the resistance belt can be reduced, and further, the product quality can be improved. The preparation method comprises a vacuum melting process, so that air content in the generated resistance belt can be less, and the purity of a product is guaranteed.

Owner:DANYANG HUALONG SUPERIOR STEEL

Ferritic alloy for adjusting content of dissolved oxygen in molten steel, and preparation and usage method thereof

ActiveCN103333991AIncrease profitStable and accurate oxygen controlProcess efficiency improvementLiquid stateMolten steel

The invention belongs to the technical field of smelting, and in particular relates to a ferritic alloy for adjusting content of dissolved oxygen in molten steel, and preparation and a usage method thereof. The preparation method comprises the steps of: heating a raw material of industrial pure iron, pig iron, scrap steel or low carbon steel to a liquid state; blowing in air or oxygen; when the dissolved oxygen reaches a saturated or supersaturated state, casting the liquid into balls or blocks; and cooling rapidly to obtain the ferritic alloy. A usage method is as below: when steel for high heat input welding is refined in a converter, determining mass fraction W (O) 0 of dissolved oxygen in molten steel with oxygen level to be adjusted; determining a target dissolved oxygen content w [O] T of the molten steel with oxygen level adjusted; calculating and determining the amount of ferritic alloy required to achieve the target value; and adding ferritic alloy in steel liquid and mixing. The method provided by the invention has the high utilization rate of ferritic alloy, stable and accurate oxygen control, and has the advantages of simpleness, fastness and accuracy.

Owner:江苏星爵实业有限公司

Liquid-Pb/Bi-corrosion-resistant high-strength Fe-Cr-Zr-W-Mo-B ferrite alloy and preparing method thereof

InactiveCN111549294AGuaranteed thermal stabilityImprove thermal stabilityChemical compositionFerritic matrix

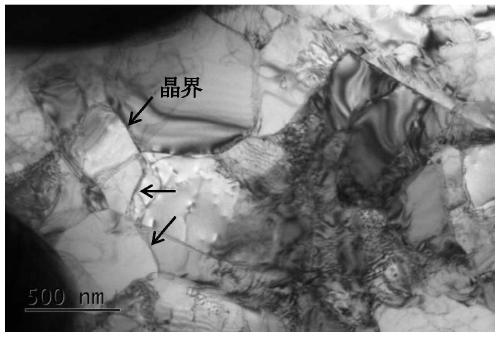

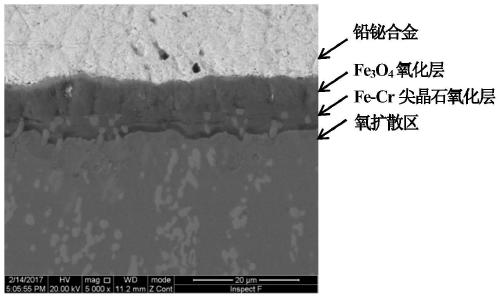

The invention discloses a liquid-Pb / Bi-corrosion-resistant high-strength Fe-Cr-Zr-W-Mo-B ferrite alloy and a preparing method thereof, and belongs to the technical field of heat-resistant alloy materials. Chemical components of the alloy include: smaller than or equal to 0.01% of C, 8.0-12.0% of Cr, 0-2.0% of Mo, 0-2.0% of W, 5.0-10.0% of Zr, 10-50 ppm of B and the balance Fe. On the basis of Fe-(9-12 wt%)Cr, Zr is added, so that an Fe-Zr intermetallic phase is separated out of a base body, and the high-temperature strength of the material is improved due to the diffusion reinforcing effect ofthe Fe-Zr intermetallic phase; and B is added, so that a grain size of the ferrite base body can be reduced to 1 [mu]m or below, and the liquid-Pb / Bi-corrosion-resistant performance of the alloy is improved due to the reduced grain size. The Fe-Cr-Zr-W-Mo-B ferrite alloy meets the requirements for high-temperature-resistant performance, Pb / Bi-corrosion-resistant performance and anti-radiation performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Ferritic alloy

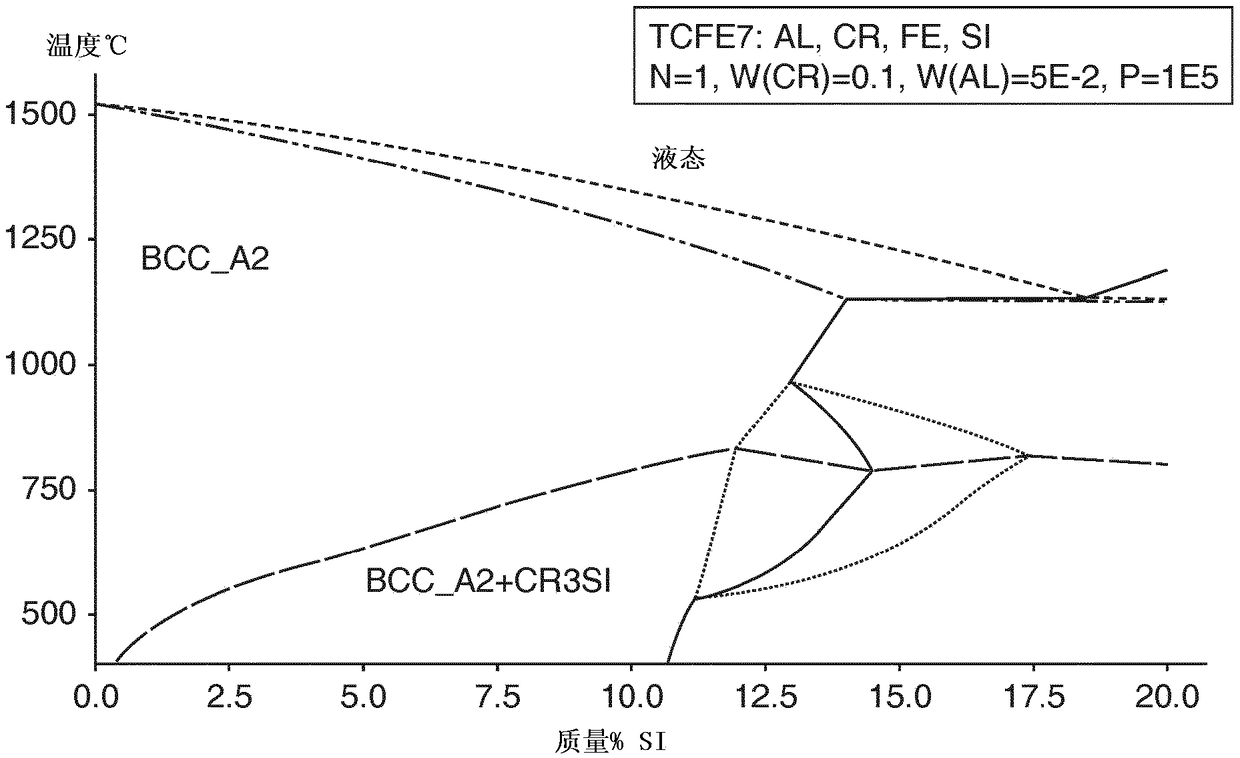

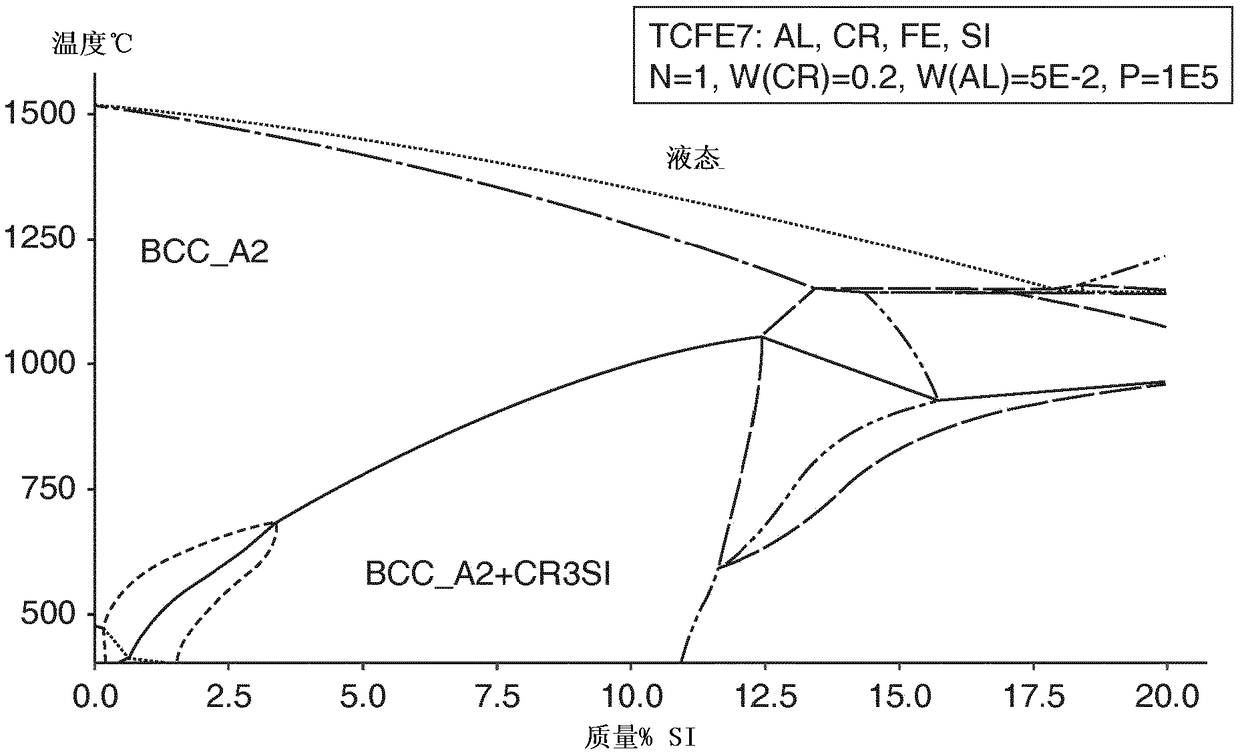

A ferritic alloy comprises the following elements in weight% [wt%]: C: 0.01 to 0.1; N: 0.001 to 0.1; O: smaller than or equal to 0.2; Cr: 4 to 15; Al: 2 to 6; Si: 0.5 to 3; Mn: smaller than or equal to 0.4; Mo+W: smaller than or equal to 4; Y: smaller than or equal to 1.0; Sc, Ce, and / or La: smaller than or equal to 0.2; Zr: smaller than or equal to 0.40; RE: smaller than or equal to 0.4; balancebeing Fe and normal occurring impurities. Moreover, the following equation has to be fulfilled: 0.014<=(Al+0.5SQ (Cr+10Si+0.1)<=0.022.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Ferritic alloy

The invention relates to a ferritic alloy. Specifically, a ferritic alloy comprising the following elements in wt% [wt%]: C 0.01 to 0.1wt%; 0.001 to 0.1wt% of N; O: < = 0.2wt%; 4 to 15 wt% of Cr; 2 to 6 wt% of Al; 0.5 to 3wt% of Si; Mn: < = 0.4wt%; Mo + W < = 4wt%; Y < = 1.0wt%; Sc, Ce and / or La < = 0.2wt%; Zr < = 0.40 wt%; RE <= 0.4 wt%; the balance is Fe and normally appearing impurities; and the ferrite alloy also needs to meet the following equation: 0.014 <=(Al+0.5SQ(Cr+10Si+0.1) <= 0.022.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

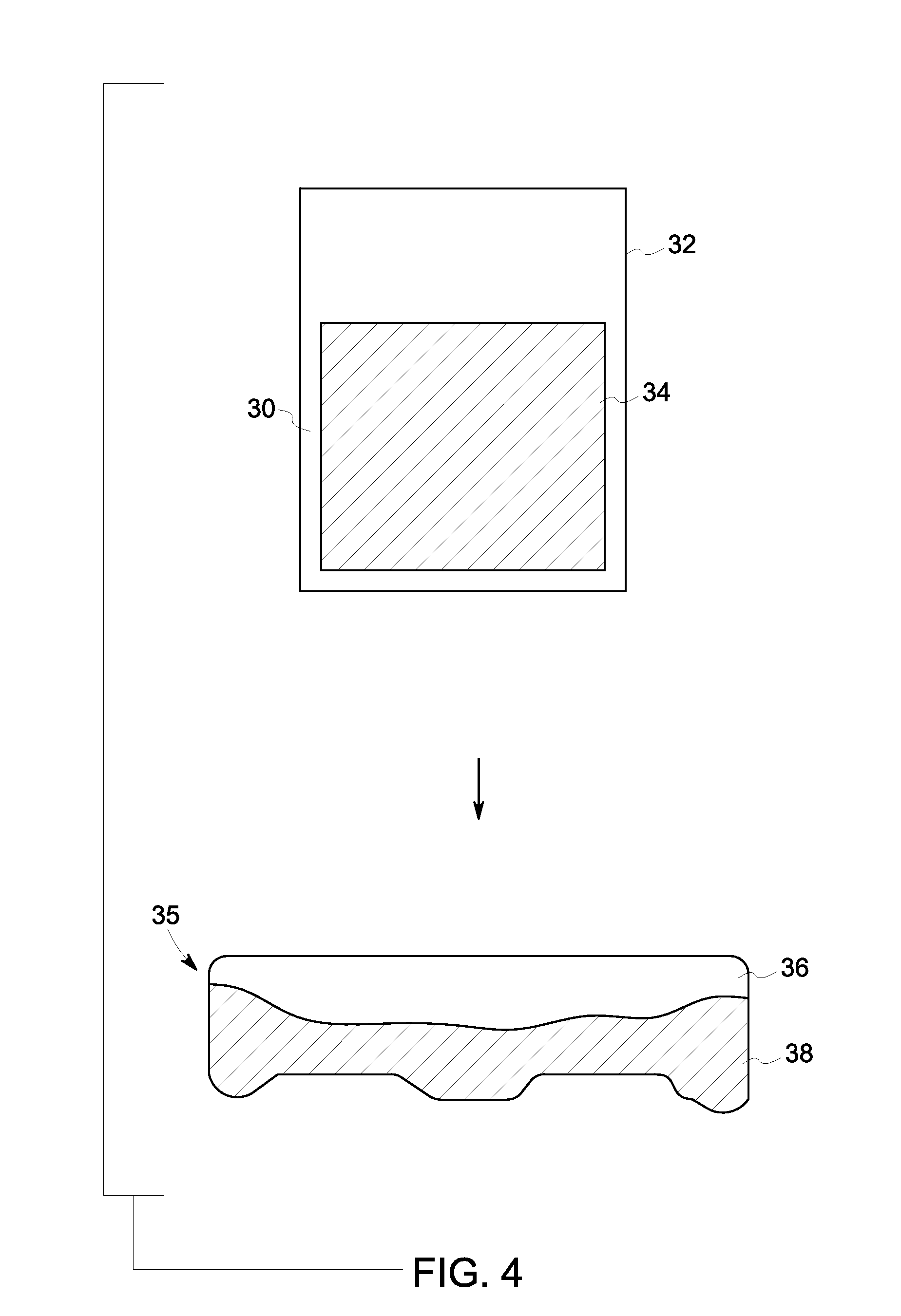

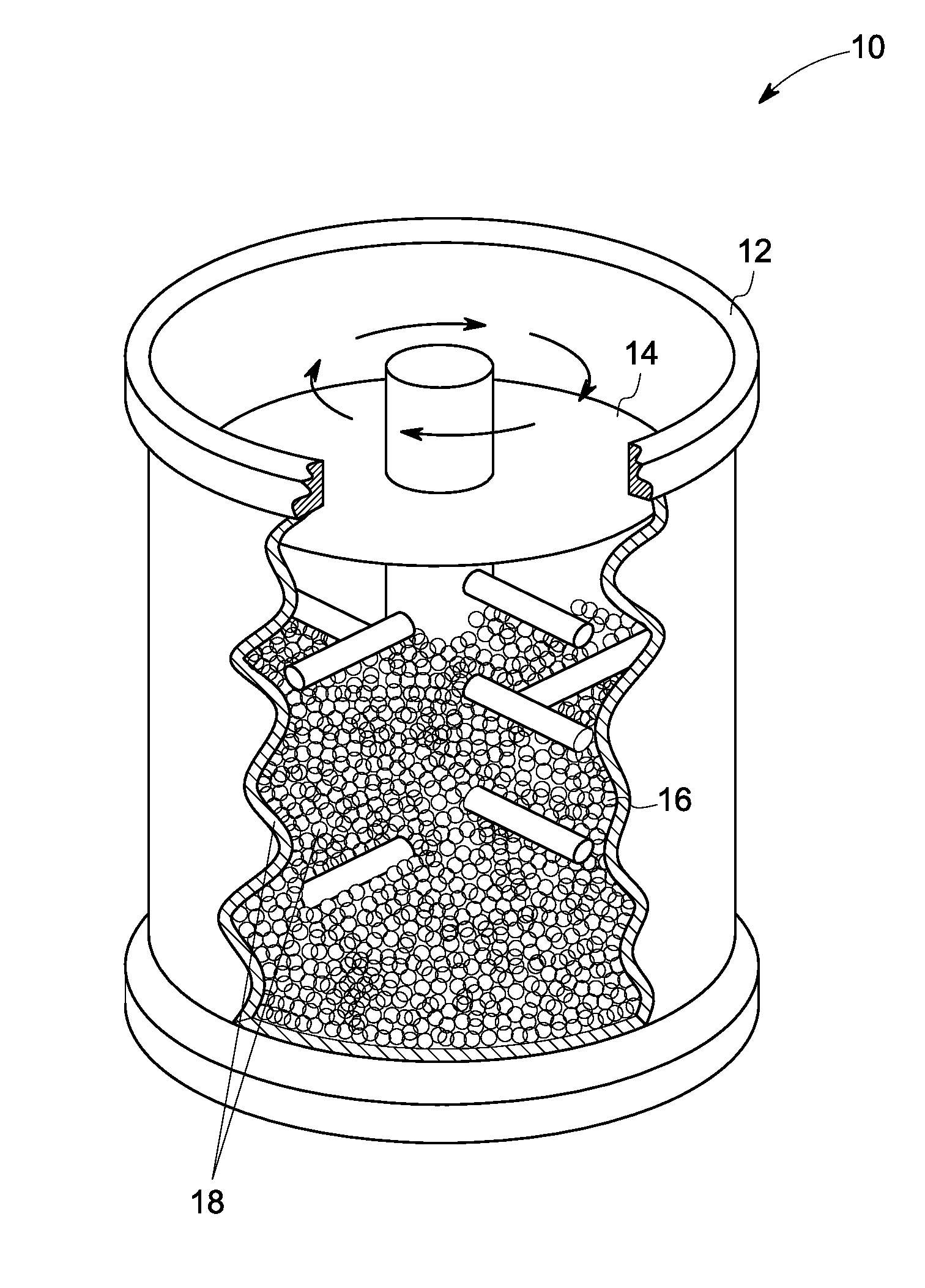

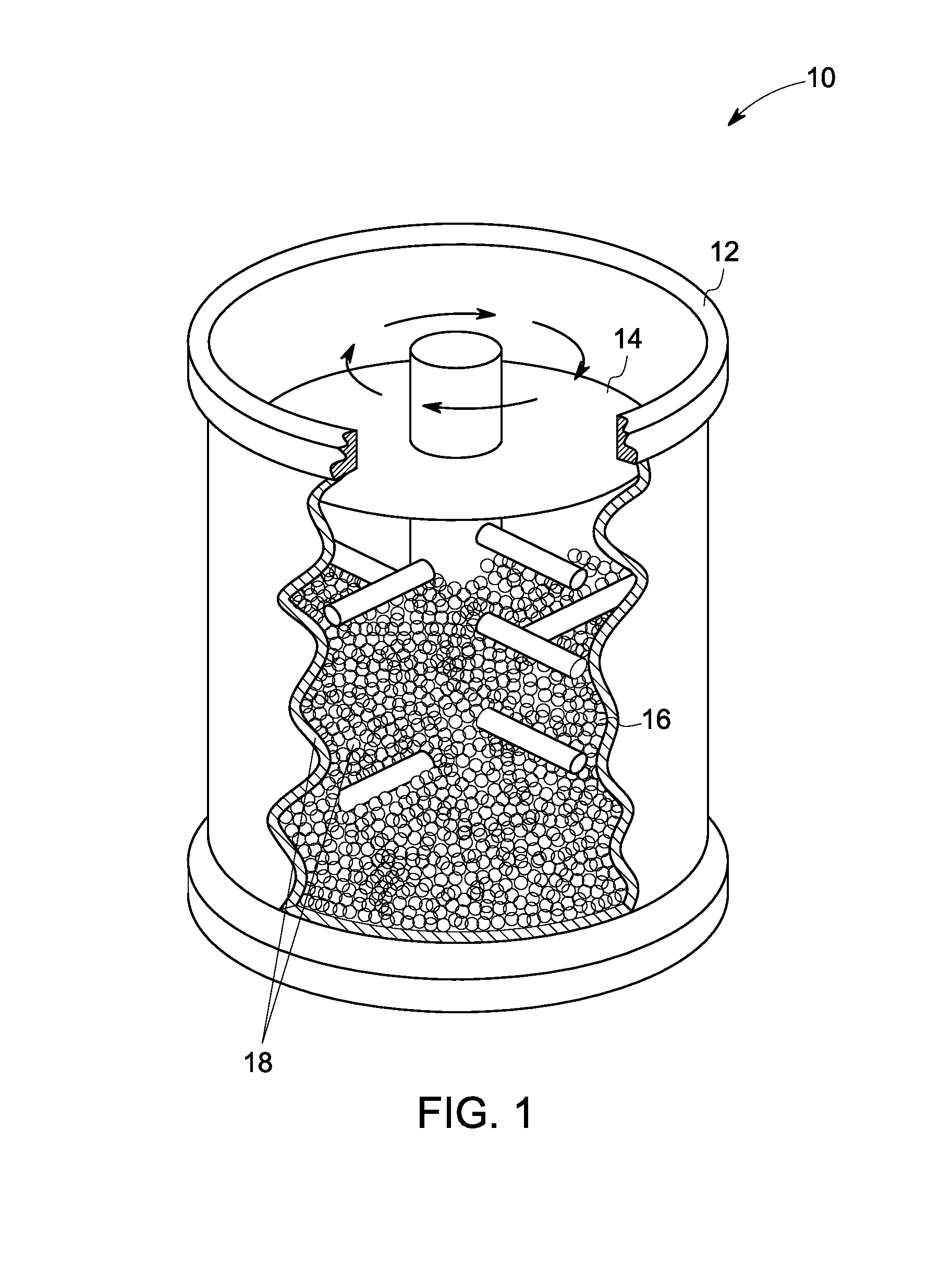

System and method of forming nanostructured ferritic alloy

A system for mechanical milling and a method of mechanical milling are disclosed. The system includes a container, a feedstock, and milling media. The container encloses a processing volume. The feedstock and the milling media are disposed in the processing volume of the container. The feedstock includes metal or alloy powder and a ceramic compound. The feedstock is mechanically milled in the processing volume using metallic milling media that includes a surface portion that has a carbon content less than about 0.4 weight percent.

Owner:GENERAL ELECTRIC CO

Method for producing tough high chromium ferritic alloy

InactiveCN101538640ASimple processShort smelting timeProcess efficiency improvementIngotLiquid steel

The invention discloses a method for producing tough high chromium ferritic alloy, which comprises the following steps: 1) raw material selection; 2) technological processes: a, vacuum melting; b, high-temperature vacuum refining; c, reductive slagging; d, temperature reduction and solidification; e, temperature rise and deoxidation; f, quenching and tempering and homogenization; and g, casting ingots. The method can reduce the end points C and N contents of liquid steel to below 100 ppm through the steps. The method has the advantages of simple process, short melting time, less short splash and less argon consumption. The product produced by the method not only has excellent corrosion resistance, but also has good toughness.

Owner:JIANGSU XIHU SPECIAL STEEL

High-temperature seamless ferritic alloyed steel and production method thereof

The invention relates to high-temperature seamless ferritic alloyed steel and a production method thereof. The steel is characterized by consisting of the following chemical components in percentage by mass: 0.05 to 0.09 percent of C, 0.20 to 0.50 percent of Si, 0.10 to 0.60 percent of Mn, 1.95 to 2.55 percent of Cr, 1.50 to 1.75 percent of W, 0.001 to 0.005 percent of B, 0.005 to 0.06 percent of Ti, 0.05 to 0.30 percent of Mo, 0.02 to 0.08 percent of Nb, 0.20 to 0.30 percent of V, less than or equal to 0.015 percent of N, less than or equal to 0.020 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.015 percent of total Al, less than or equal to 0.003 percent of O, and the balance of Fe and inevitable impurities. The ratio of Ti to N is more than or equal to 3.5. A normalizing and tempering technology is adopted in heat treatment, the normalizing temperature is 1,040 to 1,080 DEG C, the heat preservation time is not less than 1.5 minutes per 1 milliliter of wall thickness and is not less than 30 minutes, and cooling is performed at an austenitizing speed by accelerating air; and the tempering temperature is 730 to 800 DEG C, the heat preservation time is not less than 1 hour, and cooling is performed in still air. The method is high in production efficiency, high in economic benefits and suitable for large-scale production, and has high popularization value.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

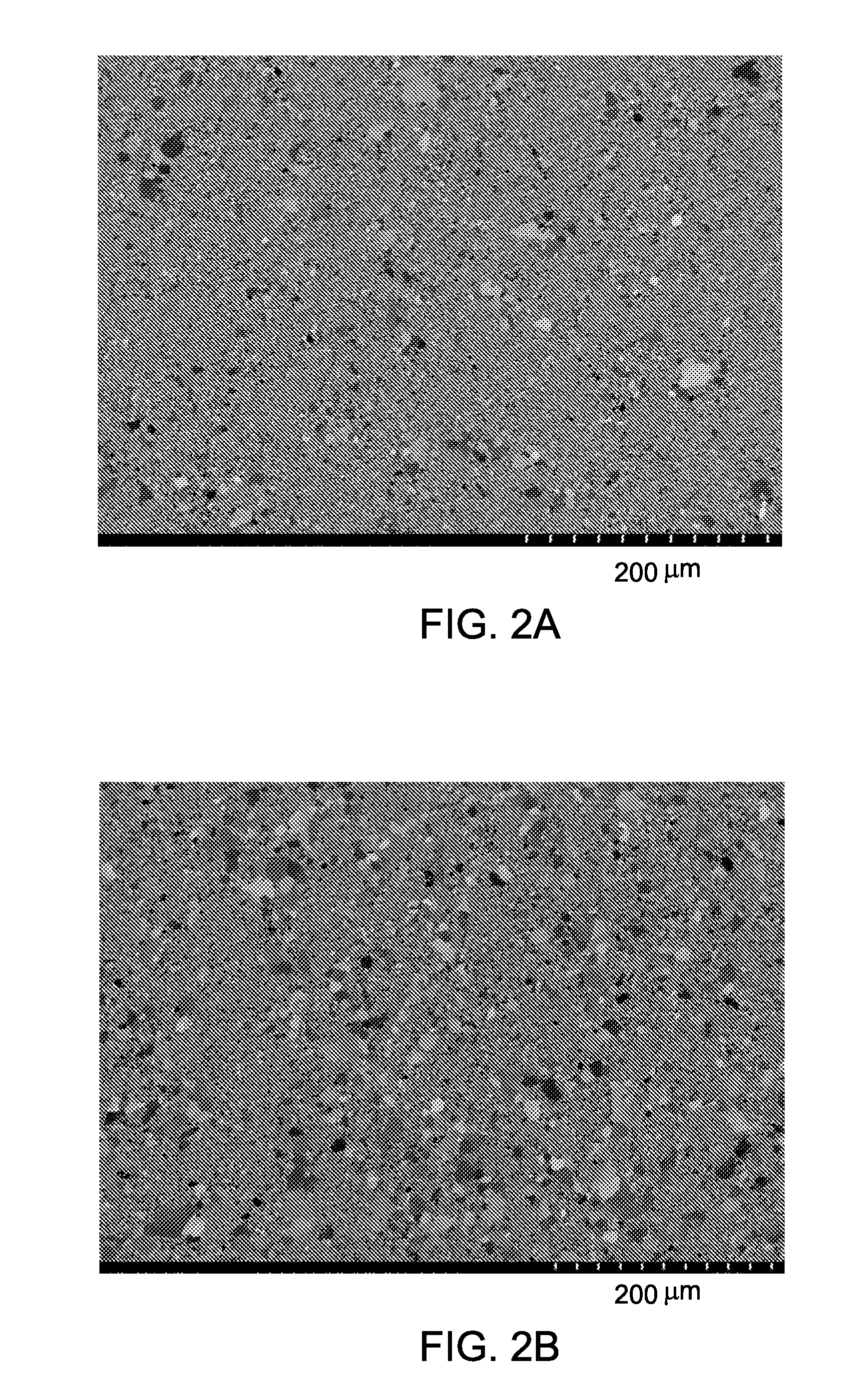

Article formed using nanostructured ferritic alloy

The invention relates to an article formed by using nanostructured ferritic alloy. In one embodiment, an article is provided. The article comprises a soft magnetic component. The soft magnetic component includes a nanostructured ferritic alloy. The nanostructured ferritic alloy includes a plurality of nanofeatures disposed in an iron-containing alloy matrix, wherein the nanofeatures comprise an oxide.

Owner:GENERAL ELECTRIC CO

Malleable high chromium ferritic alloy

The invention discloses a malleable high chromium ferritic alloy, which comprises the following chemical compositions according to weight percentage: less than or equal to 0.001 percent of C, less than or equal to 0.001 percent of N, less than or equal to 0.05 percent of Si, less than or equal to 0.05 percent of Mn, 29 to 31 percent of Cr, less than or equal to 0.12 percent of Mo, less than or equal to 0.014 percent of P, less than or equal to 0.003 percent of S, and the balance of Fe and inevitable impurities. The stability ratio of the Mo to (the C and the N) is 8 to 20. The malleable high chromium ferritic alloy has excellent corrosion resistance and toughness.

Owner:JIANGSU XIHU SPECIAL STEEL

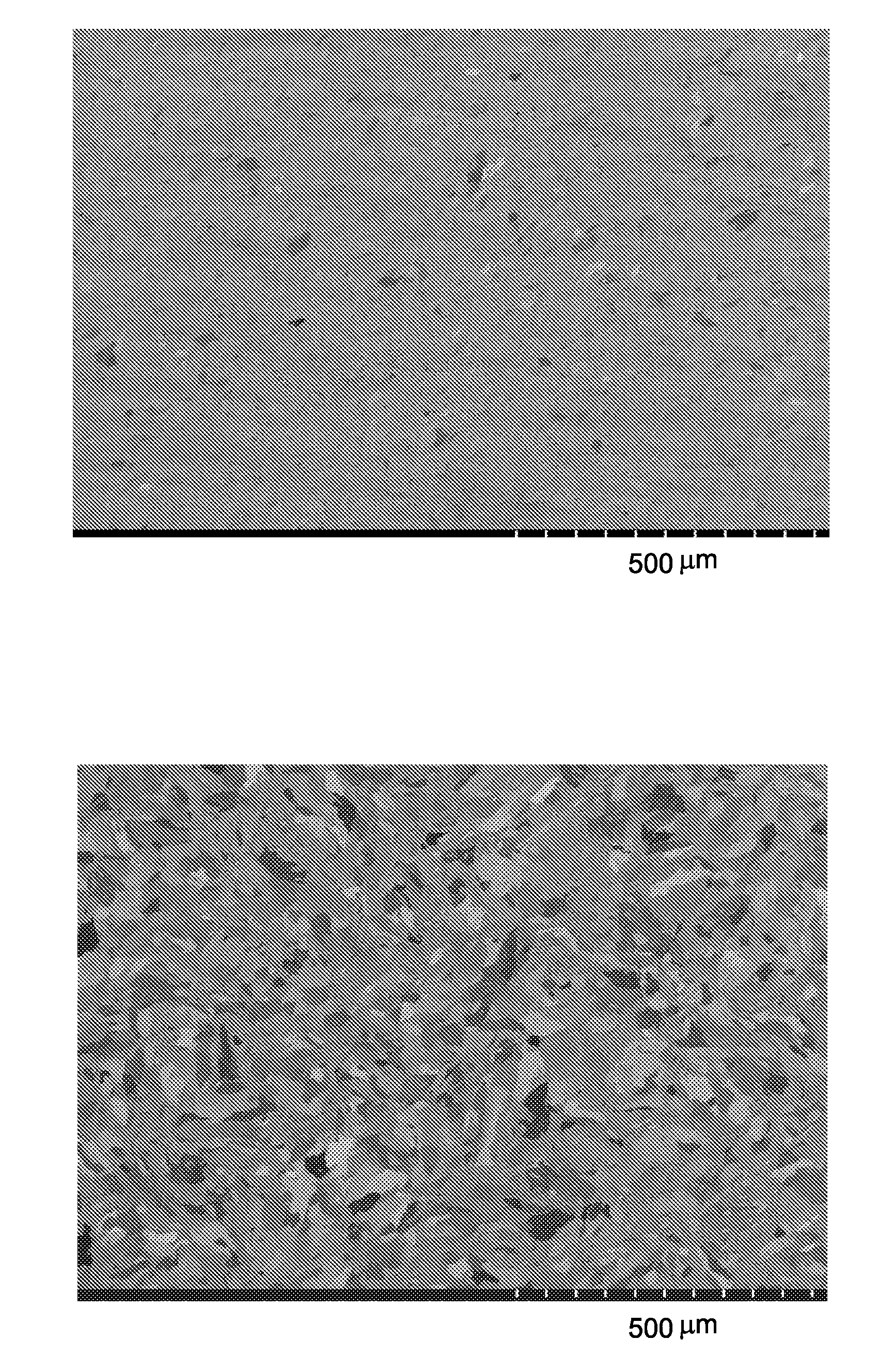

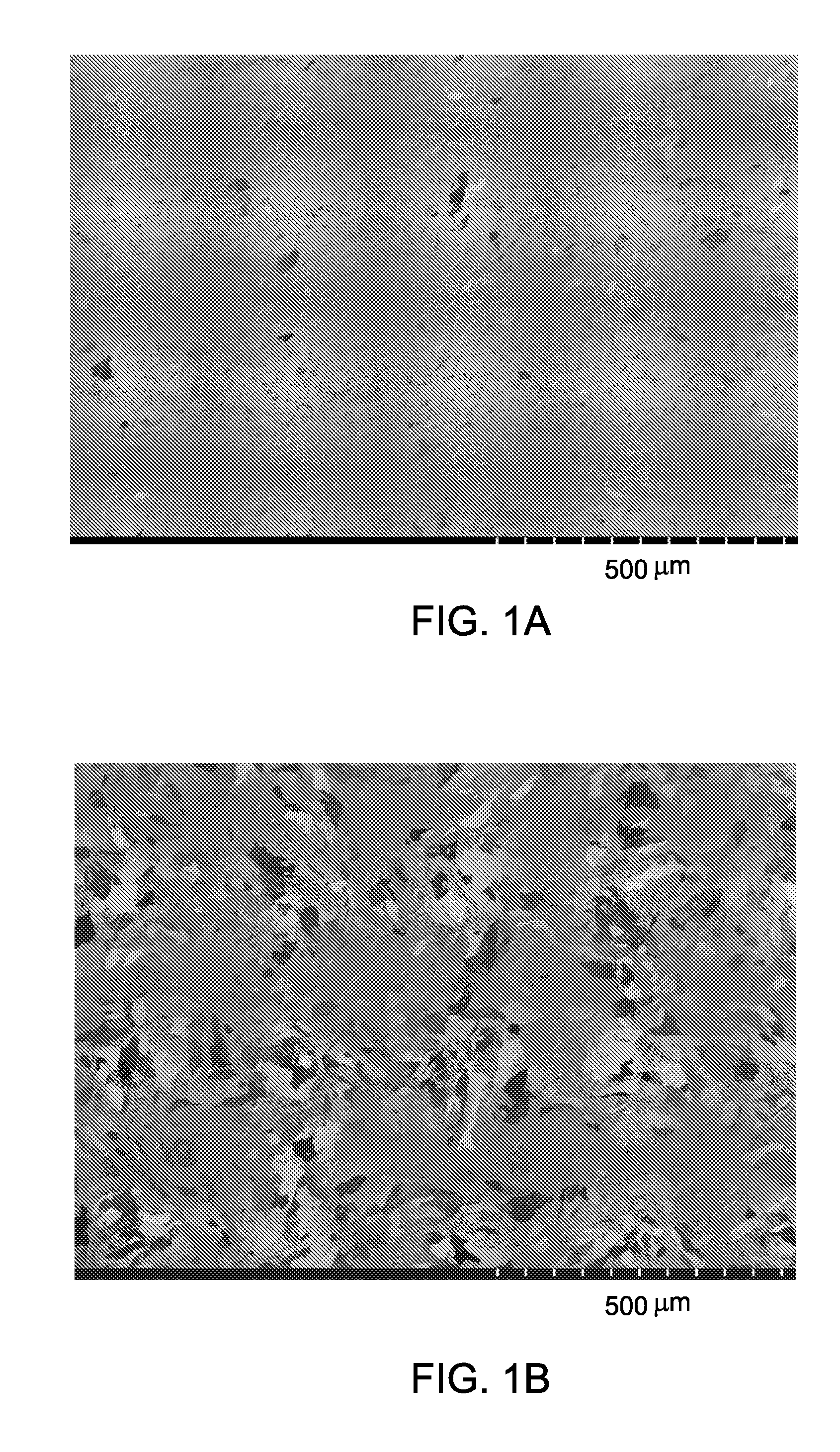

Nanostructured ferritic alloy and method of forming

An alloy and method of forming the alloy are provided. The alloy includes a matrix phase, and a multimodally distributed population of particulate phases dispersed within the matrix. The matrix includes iron and chromium, and the population includes a first subpopulation of particulate phases and a second subpopulation of particulate phases. The first subpopulation of particulate phases include a complex oxide, having a median size less than about 15 nm, and present in the alloy in a concentration from about 0.1 volume percent to about 5 volume percent. The second subpopulation of particulate phases have a median size in a range from about 25 nm to about 10 microns, and present in the alloy in a concentration from about 0.1 volume percent to about 15 volume percent. Further embodiments include articles, such as turbomachinery components and fasteners, for example, that include the above alloy, and methods for making the alloy.

Owner:GENERAL ELECTRIC CO

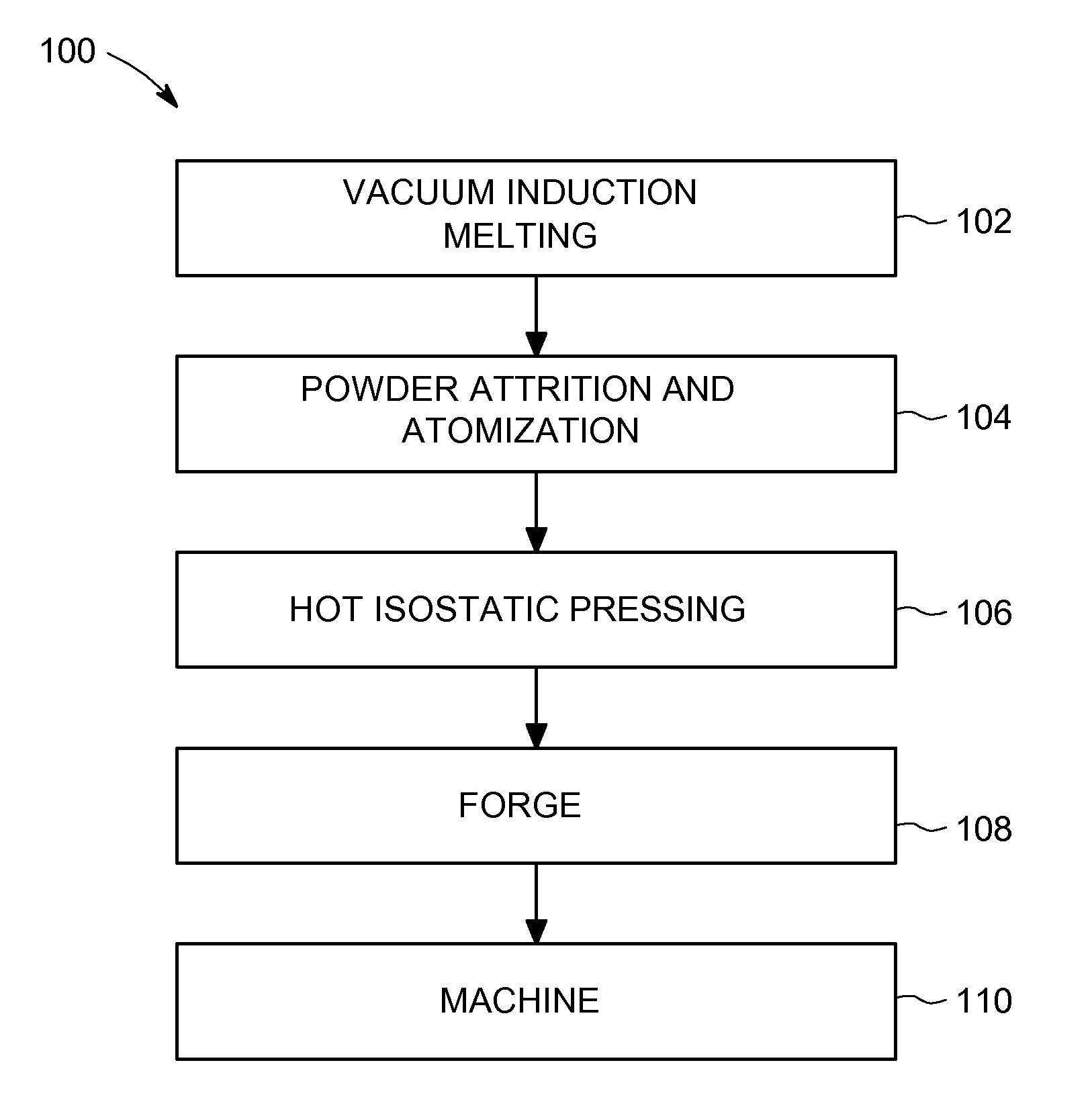

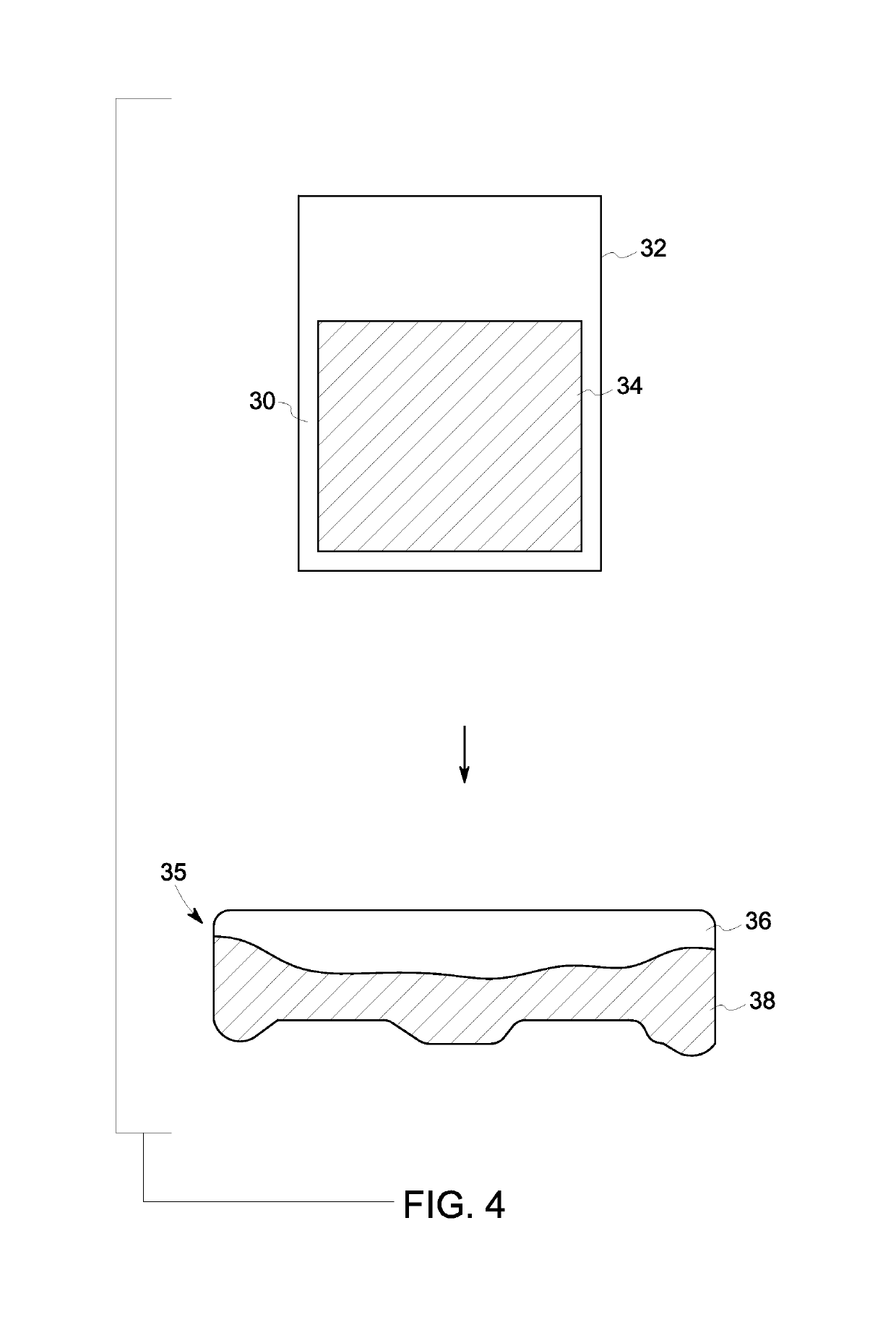

Methods for processing nanostructured ferritic alloys, and articles produced thereby

A method of forming an article including a nanostructured ferritic alloy is provided. The method provides steps for substantially inhibiting grain growth of a workpiece that includes nanostructured ferritic alloy, during heating and deforming at high temperatures and at high strain rates. Advantageously, the article is formed via conventional high strain rate techniques and thus, cost savings are provided. Articles are also provided which are formed by the method, and the articles so produced exhibit good mechanical properties at high operating temperatures, and thus are utilized as turbomachinery components, and in particular, component of a heavy duty gas turbine or steam turbine. A turbomachinery component comprising an NFA is provided.

Owner:GENERAL ELECTRIC CO

Nanostructured ferritic alloy components and related articles

An article, for example a turbomachinery article is presented. The article includes a weldable first component having a base portion and a flange portion. The flange portion is outwardly projecting normal to a surface of the base portion; and is joined with the base portion by a solid state joint. The base portion comprises a nanostructured ferritic alloy; and the flange portion comprises a steel substantially free of oxide nanofeatures. The first component is joined to a second component through the flange portion of the first component by a weld joint.

Owner:GENERAL ELECTRIC CO

Fe-Cr-Al alloys for electric resistance wires

InactiveUS7005105B2Increase heatHigh strengthConductive materialMetal/alloy conductorsRare-earth elementMisch metal

The present invention relates to Fe—Cr—Ar type alloys with additions to improve workability thereof, strength, and heat resistance. The present Fe—Cr—Al alloy for electric resistance wires comprises a basic alloy added with only Be of below 0.01 wt % or with both Be and misch metal composed of rare earth elements wherein the basic alloy consists of a balance element of Fe, a Cr element of 12˜30 wt %, an Al element of 3˜14 wt %, a Zr element of 0.01˜1.5 wt %, and a Ti element of 0.001˜0.1 wt %. The present Fe—Cr—Al type alloys remarkably improve physical properties of Fe—Cr—Al ferritic alloys, especially, workability and mechanical properties, and heating characteristic.

Owner:KOREA ELECTROTECH RES INST

Ferritic steels for solid oxide fuel cells and other high temperature applications

Oxidation-resistant ferritic steel alloys for high temperature applications consist essentially of chromium (Cr) in an amount from about 18 to about 25 atom percent, tungsten (W) in an amount from about 0.5 to about 2 atom percent, manganese (Mn) in an amount less than about 0.8 atom percent, aluminum (Al) in an amount less than about 0.2 atom percent, silicon (Si) in an amount less than about 0.1 atom percent, and rare earth metals that includes neodymium (Nd) in an amount from about 0.002 to about 0.2 atom percent with the balance being iron (Fe). Also disclosed herein are solid oxide fuel cells that include separators formed for the oxidation resistant ferritic alloys.

Owner:CUMMINS ENTERPRISE LLC

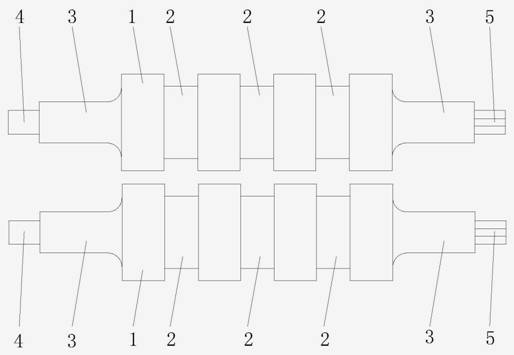

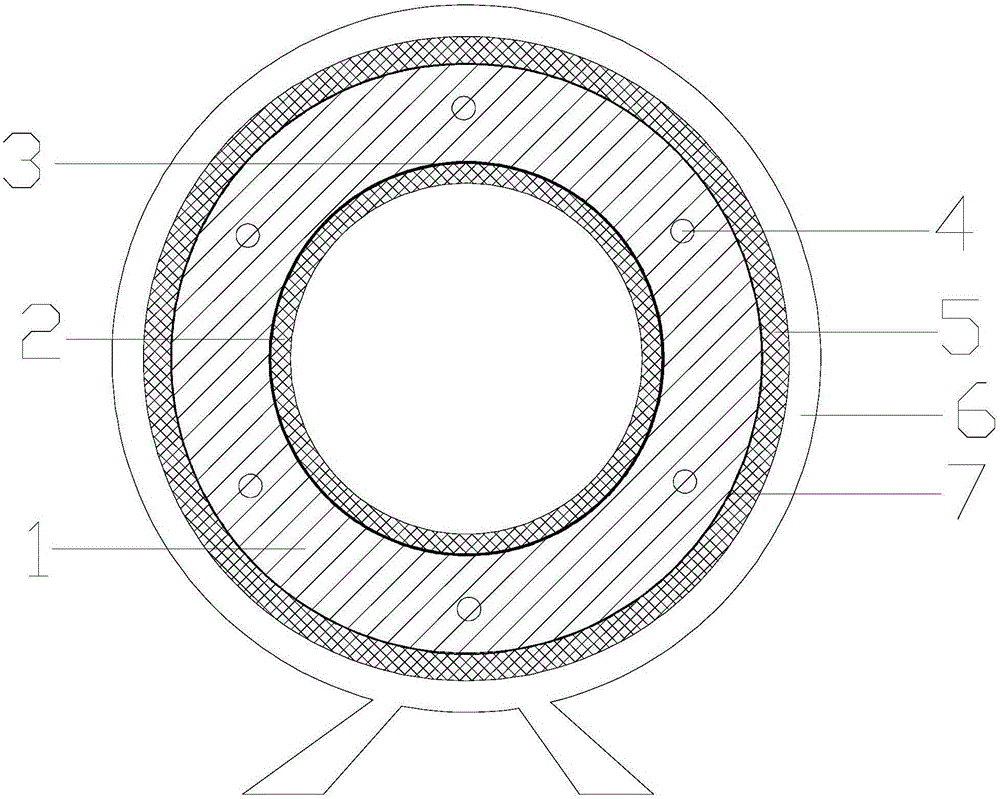

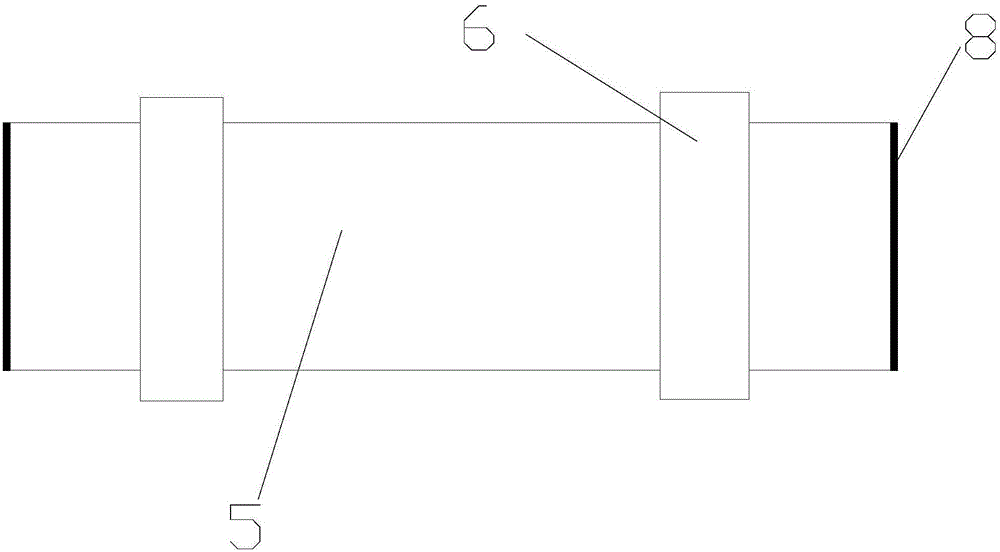

Improved ferritic square steel roughing roll and preparation method thereof

PendingCN111778449ATensile strength improvement and increaseImproved wear resistance and increasedFoundry mouldsFurnace typesCrack resistanceNiobium

The invention discloses an improved ferritic square steel roughing roll and a preparation method thereof. Two rolls symmetrically distributed up and down are provided, the rolls are provided with rollmain bodies made of a ferrite alloy, a plurality of rectangular roughing circular grooves are uniformly formed in the roll main bodies along a length direction, the two ends of the roll main bodies are respectively provided with bearing installation parts made of the ferrite alloy, a connecting part made of the ferrite alloy is arranged outside the bearing installation part at one side, and a transmission part made of the ferrite alloy is arranged outside the bearing installation part at the other side; the roughing roll comprises, by weight, 3.2-3.4% of carbon, 2-2.1% of silicon, 0 .5%-0.7%of manganese, 0.2-0.4% of chromium, 0.3-0.5% of molybdenum, 1.4-1.6% of nickel, 0.1-0.3% of niobium and 0 .05-0.15% of vanadium. The tensile strength, wear resistance, thermal crack resistance, impacttoughness and uniform hardness of the roll prepared by the method are improved and enhanced.

Owner:常州市瑞宏轧辊有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com