Ferritic alloy for adjusting content of dissolved oxygen in molten steel, and preparation and usage method thereof

A technology of dissolved oxygen content and dissolved oxygen, which is applied in the field of smelting, can solve the problems of poor applicability, poor oxygen control accuracy, and low oxygen control accuracy, and achieve the effect of high utilization rate and stable and accurate oxygen control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An iron-oxygen alloy for adjusting the dissolved oxygen content of molten steel. The oxygen content is 0.01% by mass percentage, and exists in the form of supersaturated solid solution, bubbles and FeO, and the balance is Fe and unavoidable impurities.

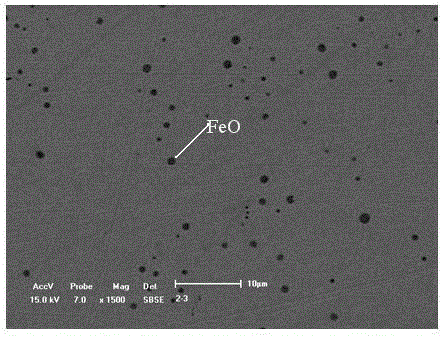

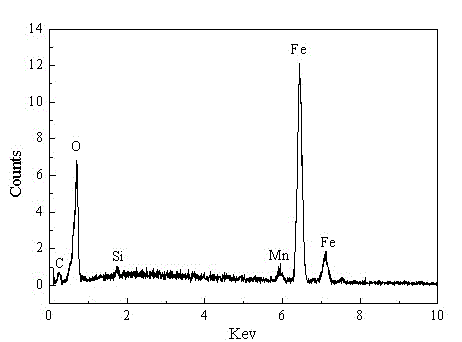

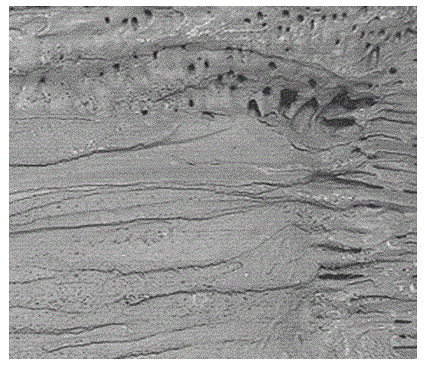

[0037] Its scanning electron microscope picture is as figure 1 shown, from figure 1 It can be seen that FeO is dispersed in the ferrite alloy; its XRD pattern is as follows figure 2 shown, from figure 2 It can be seen that there are obvious O peaks and Fe peaks; its macroscopic morphology is shown in image 3 shown, from image 3 Visible air bubbles can be seen in the

[0038] Put 10 kg of industrial pure iron into a 20 kg induction furnace, turn it on to heat and melt it, and continue heating to a constant temperature of 1600°C;

[0039] Air is blown into the molten iron, and the mass fraction of dissolved oxygen is measured in real time with a temperature and oxygen measuring instrument. When the blowing amount...

Embodiment 2

[0046] An iron-oxygen alloy for adjusting the dissolved oxygen content of molten steel. The oxygen content is 0.15% by mass percentage, and exists in the form of supersaturated solid solution, bubbles and FeO, and the balance is Fe and unavoidable impurities.

[0047] Put 2t of industrial pure iron into a 3t electric furnace, turn it on to heat and melt it, and continue heating to a constant temperature of 1600°C;

[0048] Oxygen is blown into the molten iron, and the mass fraction of dissolved oxygen is measured in real time with a temperature and oxygen measuring instrument. When the blowing amount reaches 100 standard cubic meters, the heating is stopped, and the molten iron is cast into small pieces and cooled rapidly.

[0049] Sampling was carried out to detect the prepared ferrite alloy pieces, and the mass fraction of oxygen in the prepared ferrite alloy was analyzed to be 0.15%.

[0050] In the production process of ship plate steel E36 for high-energy welding in steel...

Embodiment 3

[0055] An iron-oxygen alloy for adjusting the dissolved oxygen content of molten steel. The oxygen content is 0.37% by mass percentage, and exists in the form of supersaturated solid solution, bubbles and FeO, and the balance is Fe and unavoidable impurities.

[0056] Put 1 ton of industrial pure iron into a 2 ton induction furnace, turn it on to heat and melt it, and continue heating to a constant temperature of 1560°C;

[0057] Oxygen is blown into the molten iron, and the mass fraction of dissolved oxygen is measured in real time with a temperature and oxygen measuring instrument. When the blowing amount reaches 30 standard cubic meters, the heating is stopped, and the molten iron is cast into small pieces and cooled rapidly.

[0058] Sampling was carried out to detect the prepared ferrite alloy pieces, and the mass fraction of the prepared ferrite alloy oxygen was analyzed to be 0.37%.

[0059] In the production process of ship plate steel E36 for high-energy welding in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com