Ferritic alloy

A ferrite and alloy technology, applied in metal material coating process, coating, etc., can solve the problem that alloy cannot provide high temperature resistance

Pending Publication Date: 2018-12-21

SANDVIK INTELLECTUAL PROPERTY AB

View PDF24 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the resulting alloy does not provide high temperature resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

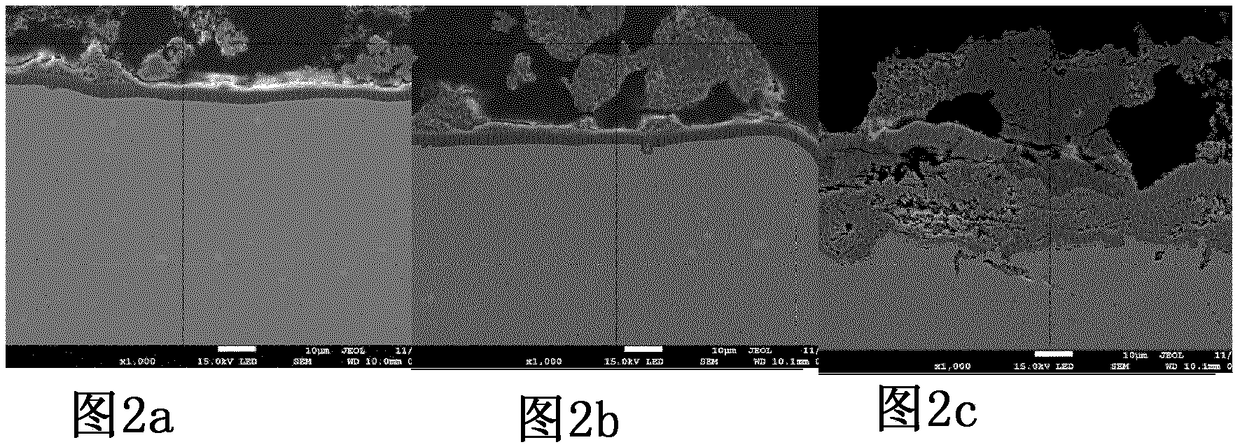

[0083] Test melts were produced in vacuum furnaces. The composition of the test melt is shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

A ferritic alloy comprises the following elements in weight% [wt%]: C: 0.01 to 0.1; N: 0.001 to 0.1; O: smaller than or equal to 0.2; Cr: 4 to 15; Al: 2 to 6; Si: 0.5 to 3; Mn: smaller than or equal to 0.4; Mo+W: smaller than or equal to 4; Y: smaller than or equal to 1.0; Sc, Ce, and / or La: smaller than or equal to 0.2; Zr: smaller than or equal to 0.40; RE: smaller than or equal to 0.4; balancebeing Fe and normal occurring impurities. Moreover, the following equation has to be fulfilled: 0.014<=(Al+0.5SQ (Cr+10Si+0.1)<=0.022.

Description

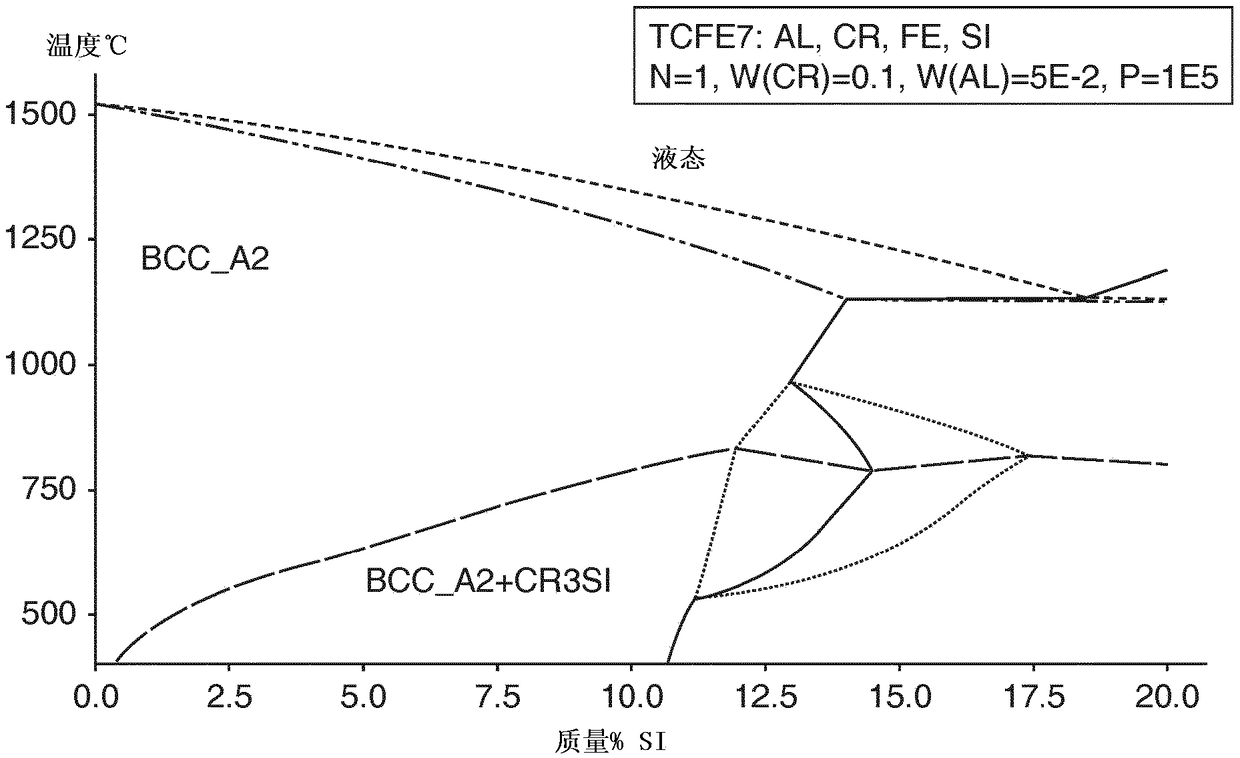

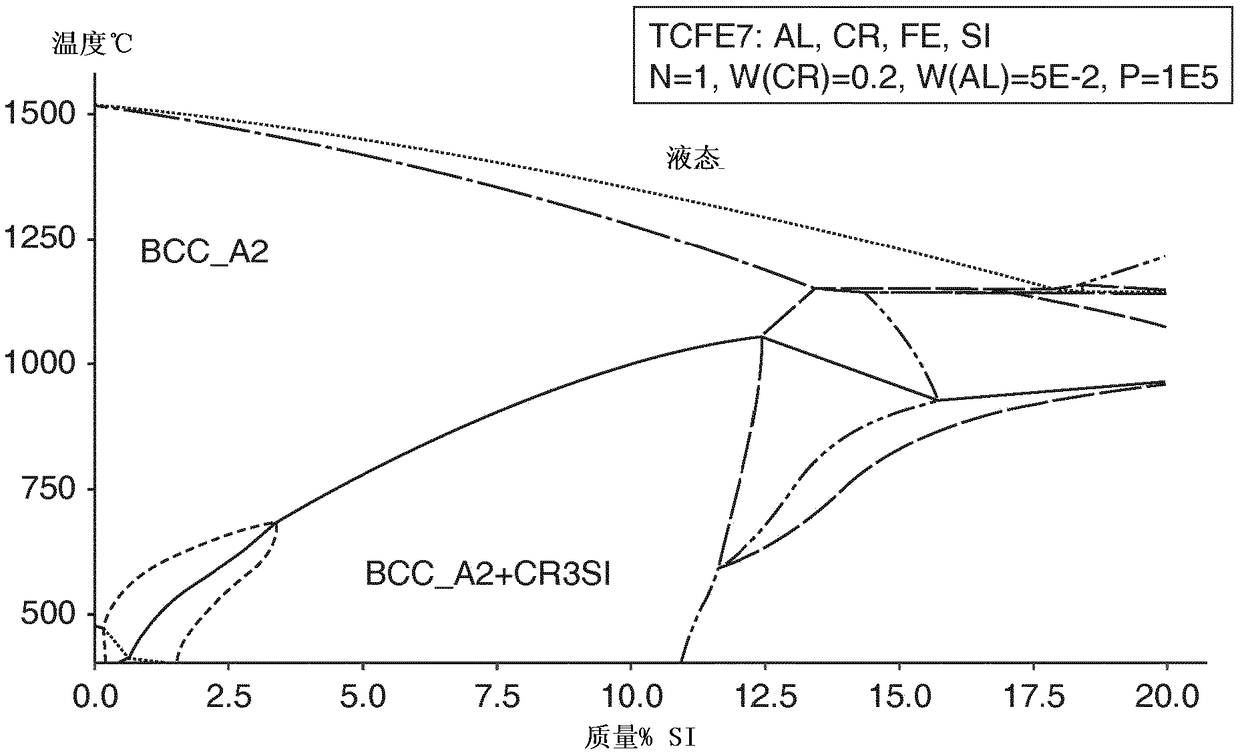

technical field [0001] The present disclosure relates to a ferritic alloy according to the preamble of claim 1 . The present disclosure also relates to the use of ferritic alloys and to articles or coatings made therefrom. Background technique [0002] Ferritic alloys, such as FeCrAl alloys containing chromium (Cr) levels of 15-25% by weight and aluminum (Al) levels of 3-6% by weight, as they form a protective α-alumina (Al 2 o 3 ), the ability of alumina oxide layer is well known. The lower limit of the Al content that forms and maintains the alumina oxide layer varies with exposure conditions. However, at higher temperatures, the effect of too low Al levels is that the selective oxidation of Al will fail and less stable and less protective chromium and iron based oxide layers will form. [0003] It is generally accepted that FeCrAl alloys generally do not form a protective alpha-alumina layer if exposed to temperatures below about 900°C. Attempts have been made to op...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/00C22C38/02C22C38/04C22C38/06C22C38/44C22C38/50

CPCC22C38/06C22C38/02C22C38/04C22C38/005C22C38/34C22C38/22C22C38/28C22C38/18C22C38/001C23C30/00C22C38/44C22C38/50C21D2211/005C22C1/02

Inventor 保·荣松

Owner SANDVIK INTELLECTUAL PROPERTY AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com