Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125 results about "Density separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Density separation is based on the fact that different minerals have different densities. Thus, if a mixture of minerals with different densities can be placed in a liquid with an intermediate density, the grains with densities less than that of the liquid will float and grains with densities greater than the liquid will sink.

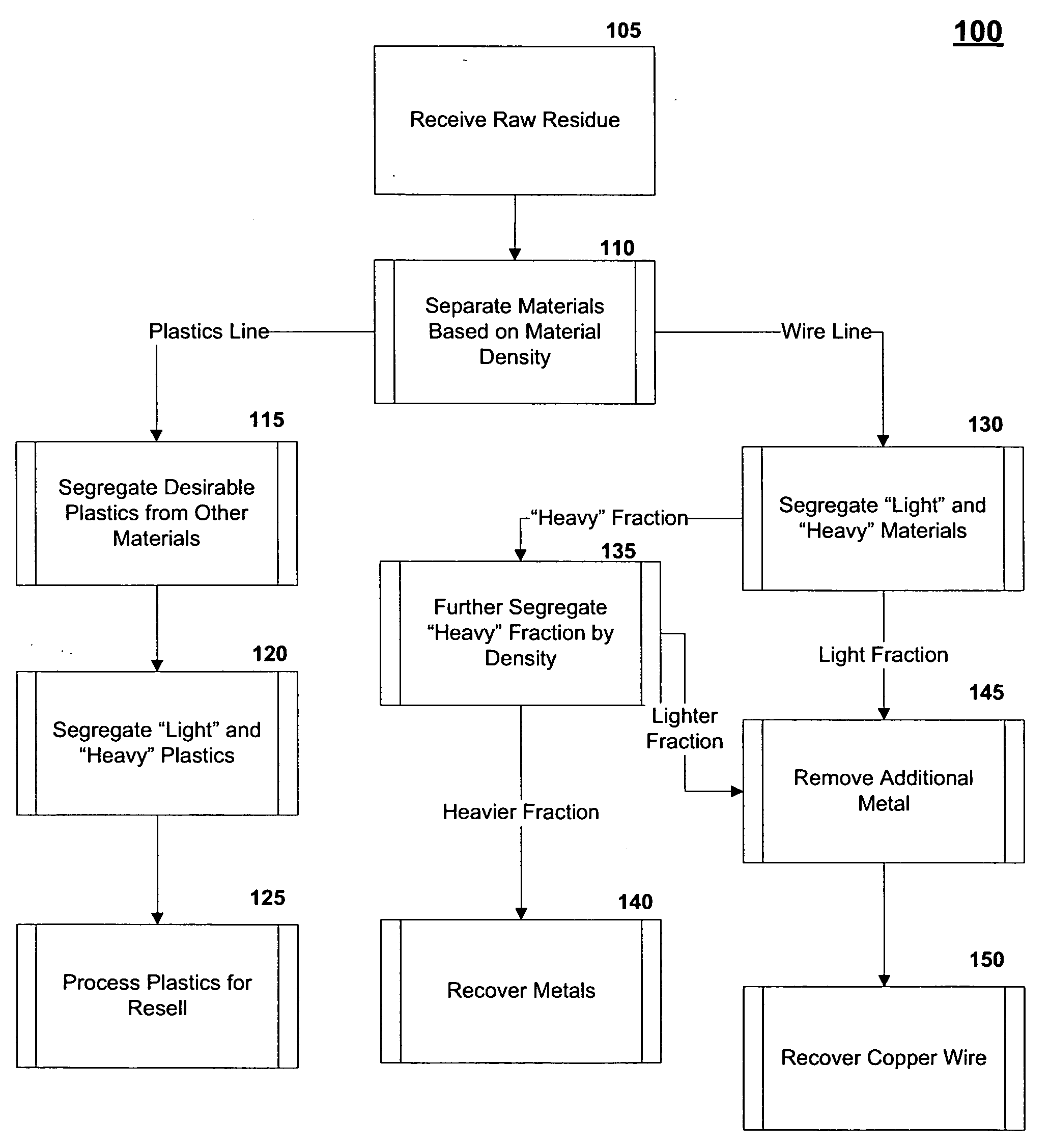

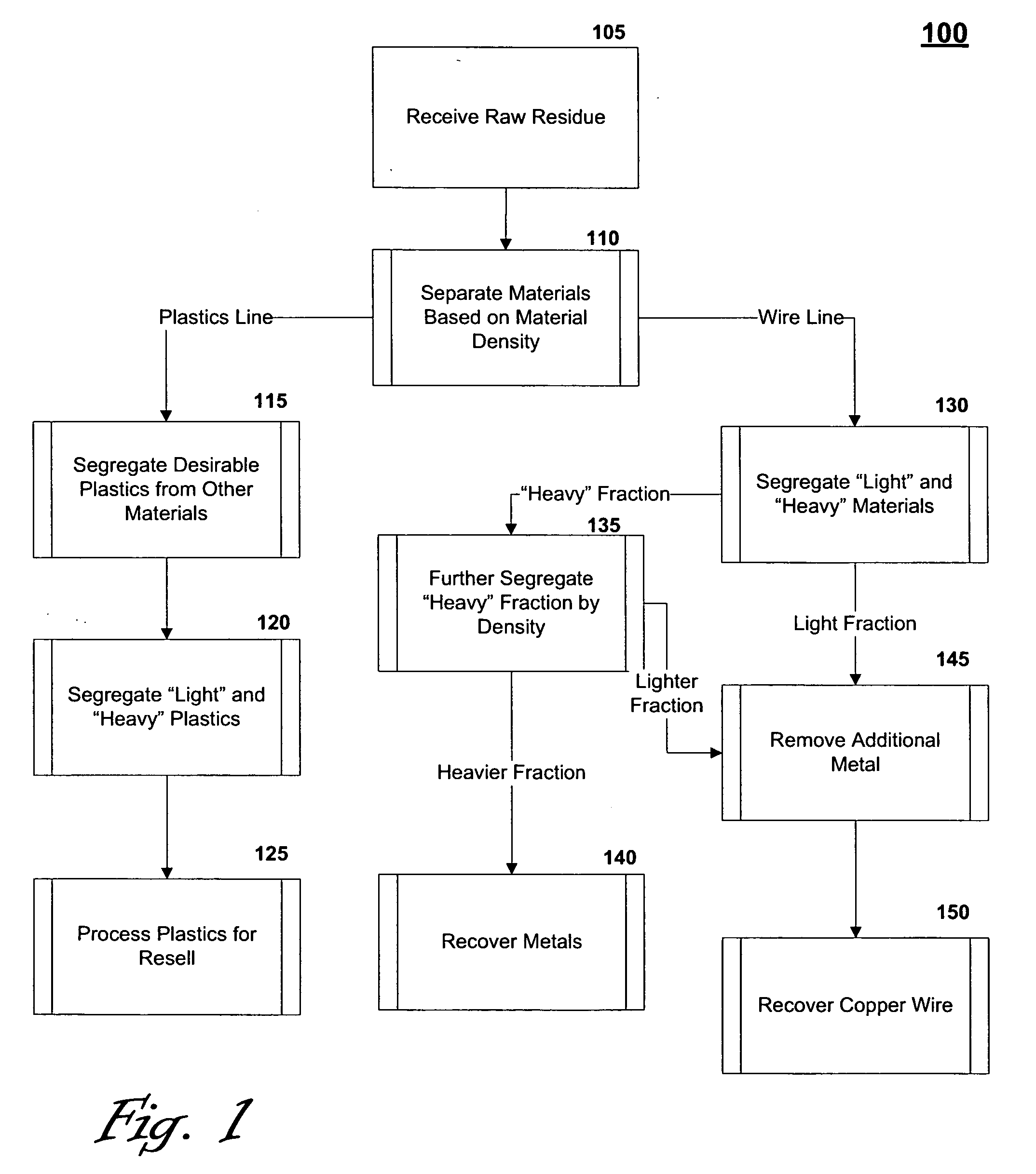

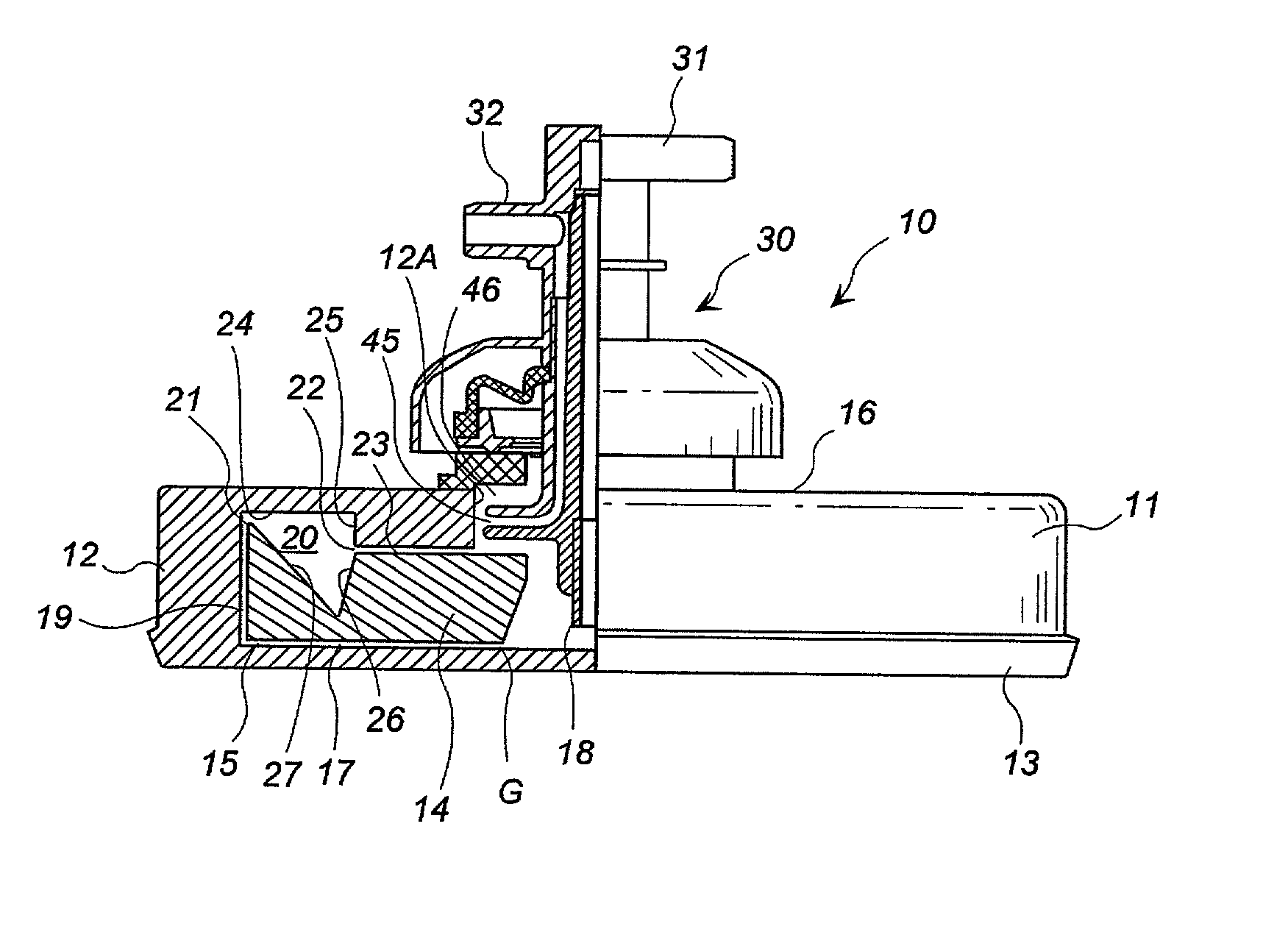

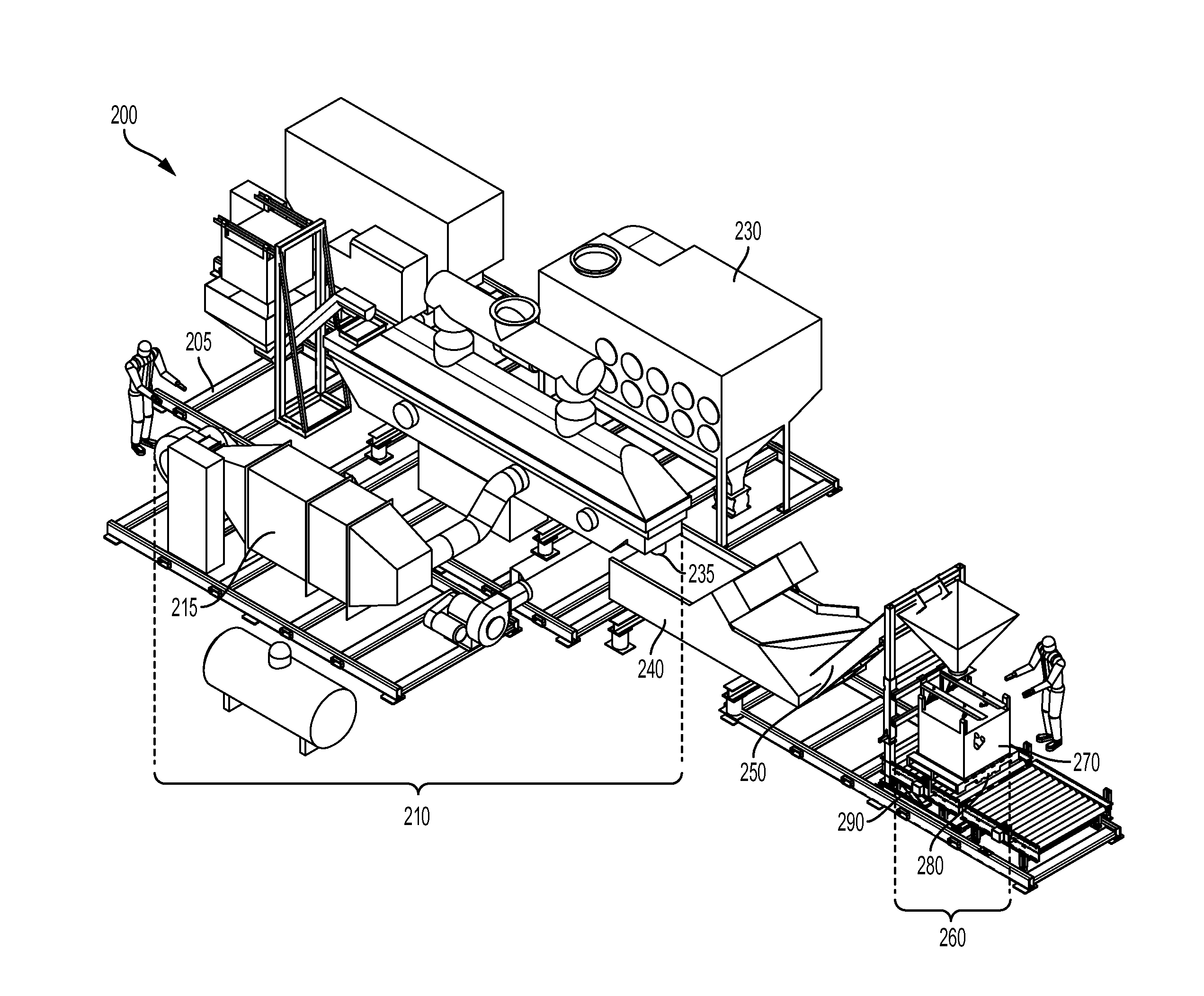

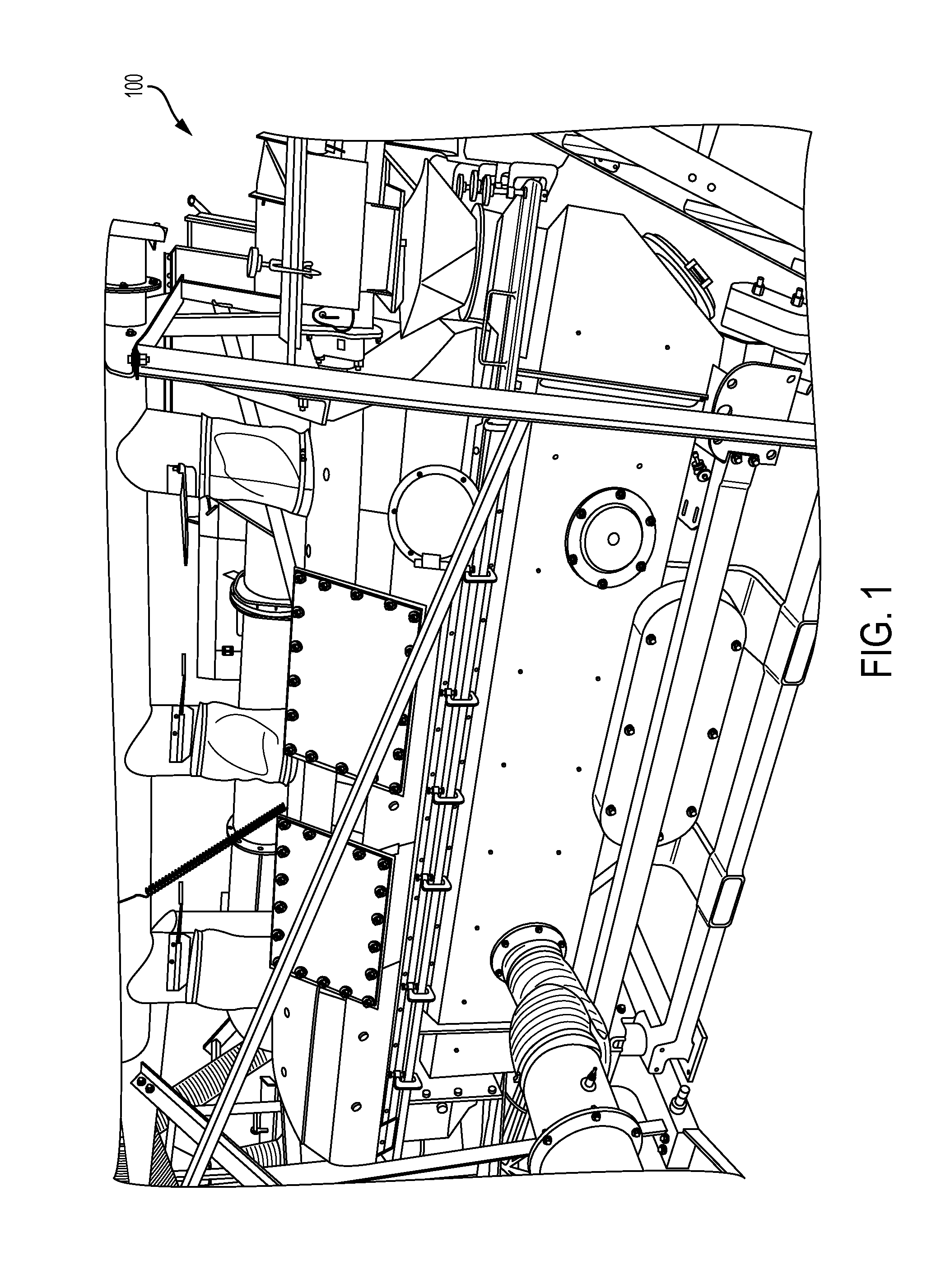

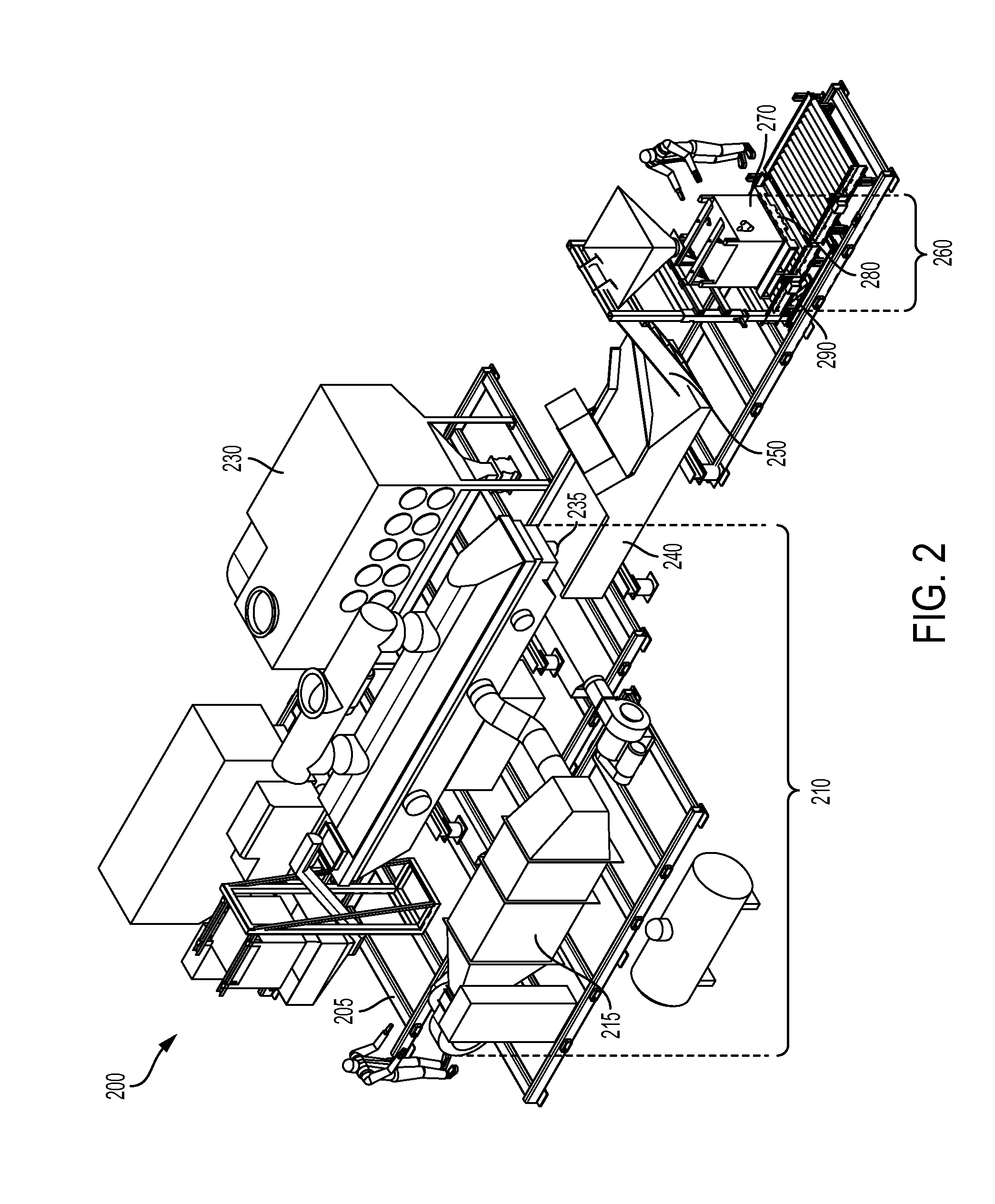

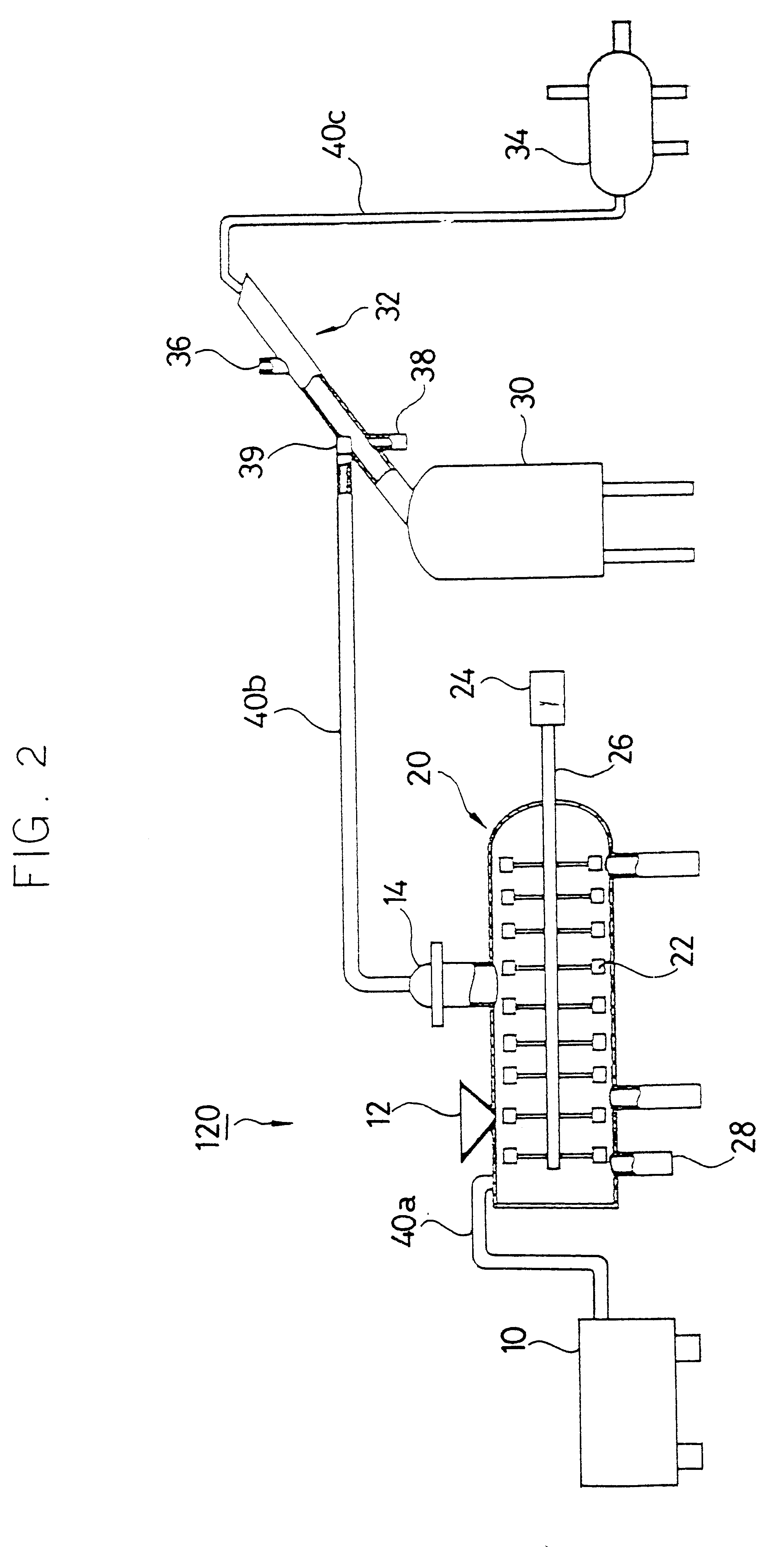

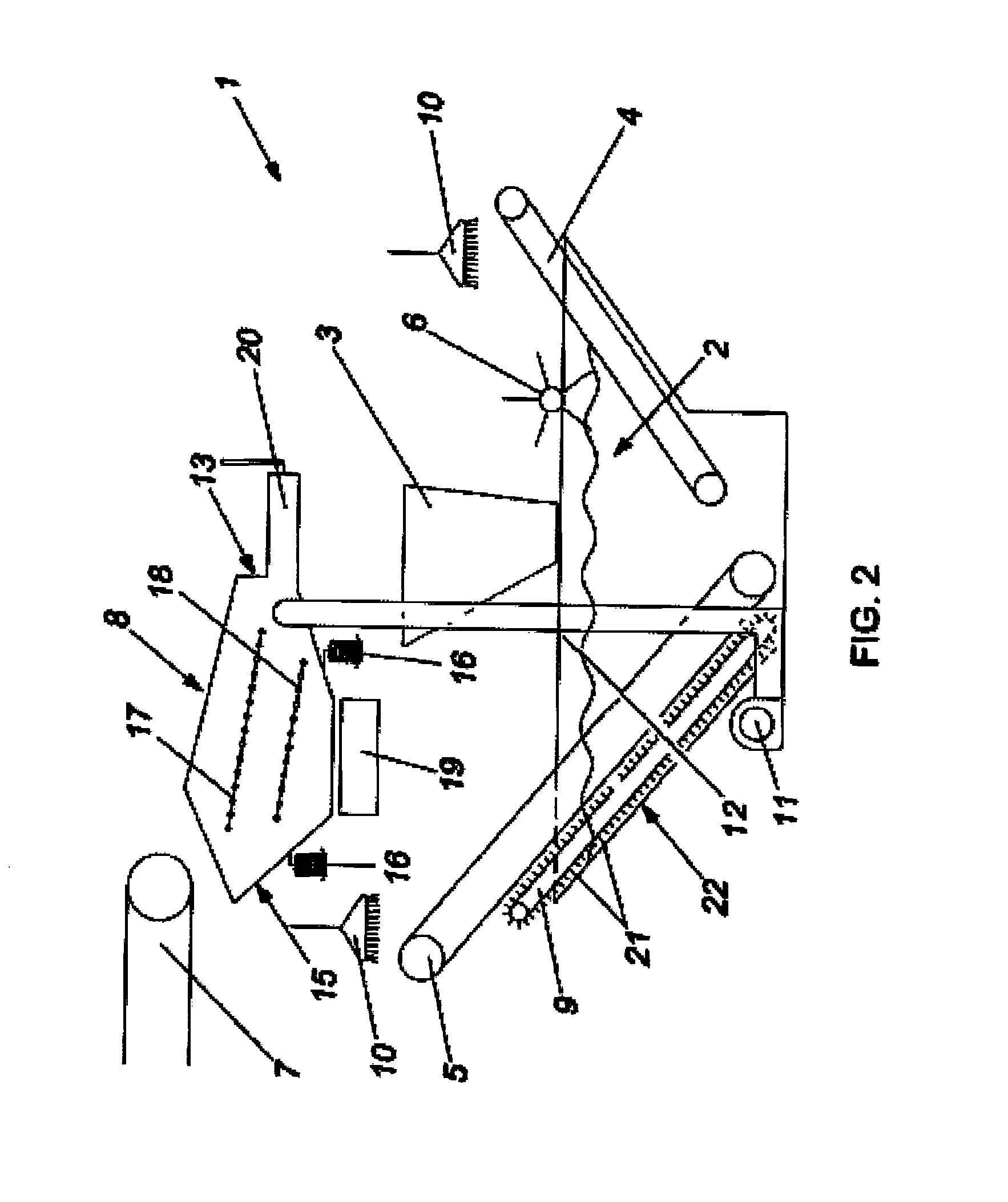

Method and system for sorting and processing recycled materials

InactiveUS20080257794A1Small sizePlastic recyclingAuxillary shaping apparatusCopper wireNonferrous metal

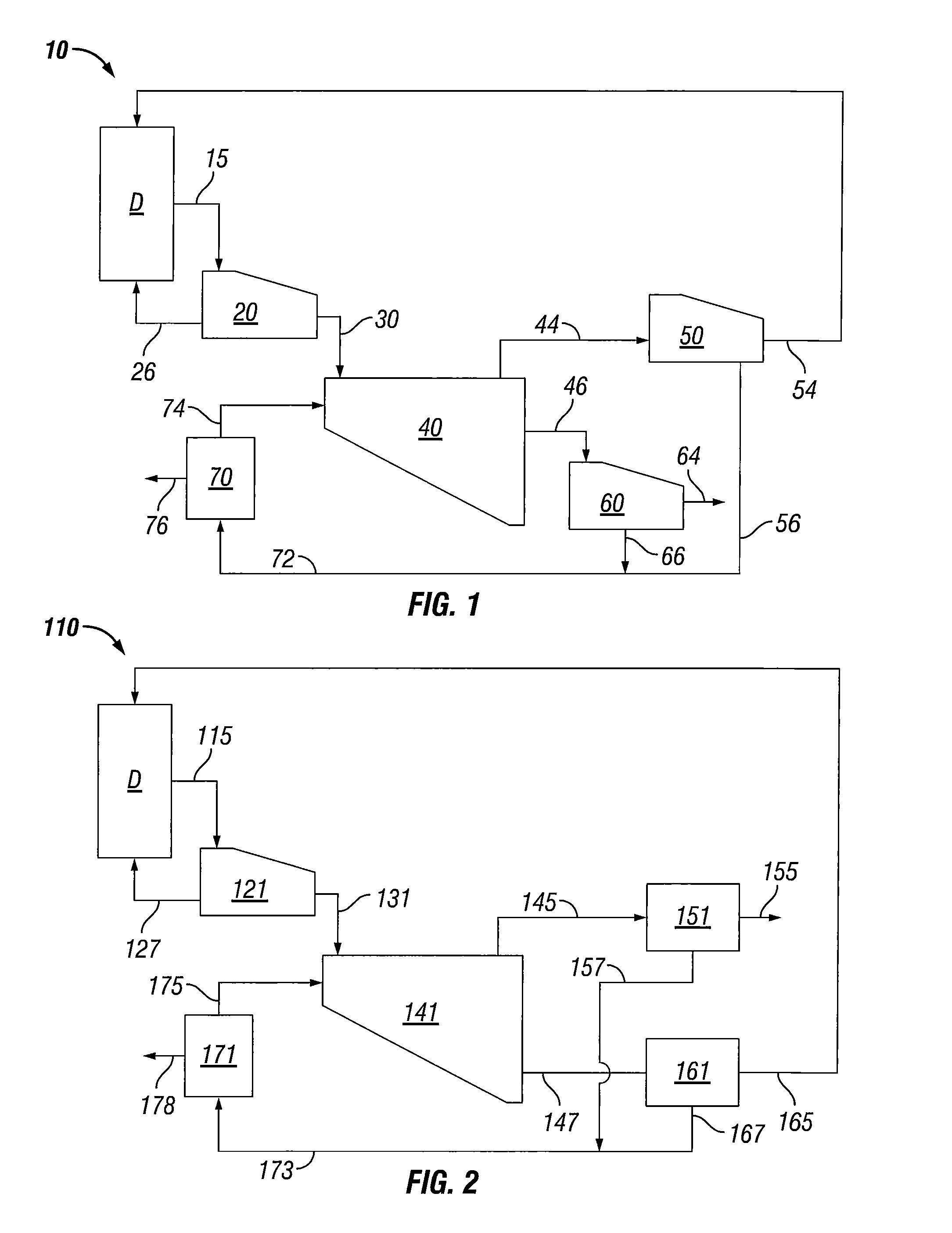

Processing recycled materials to recover plastics, copper wire, and other non-ferrous metals. Aspects of the invention employ density separation to separate plastic-bearing materials from copper-bearing materials. Plastic-bearing materials are further separated to separate light plastics from heavy plastics. Plastics are concentrated, extruded, and palletized. Copper and other valuable metals are recovered from copper-bearing materials using a water separation table.

Owner:VALERIO THOMAS A

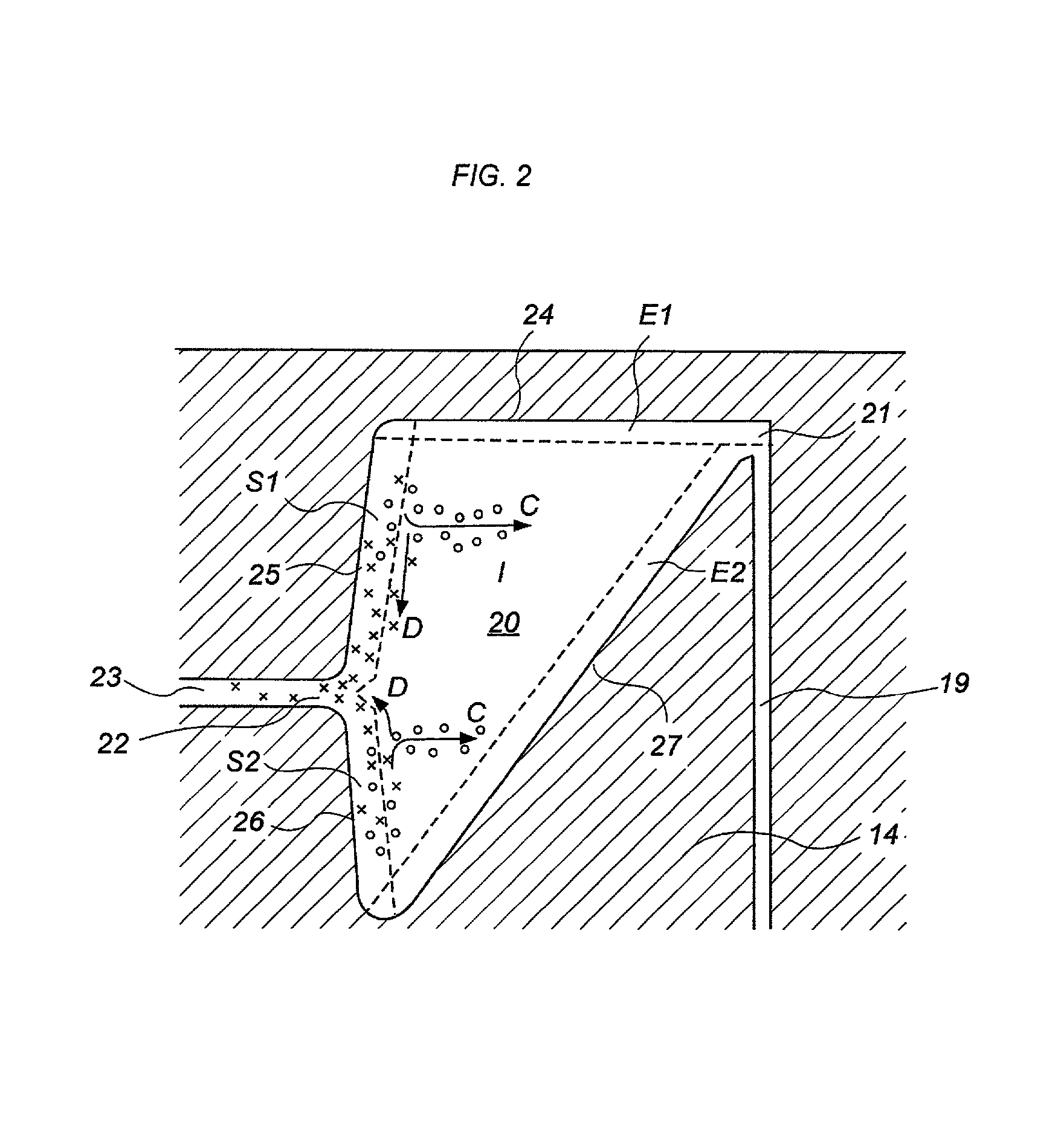

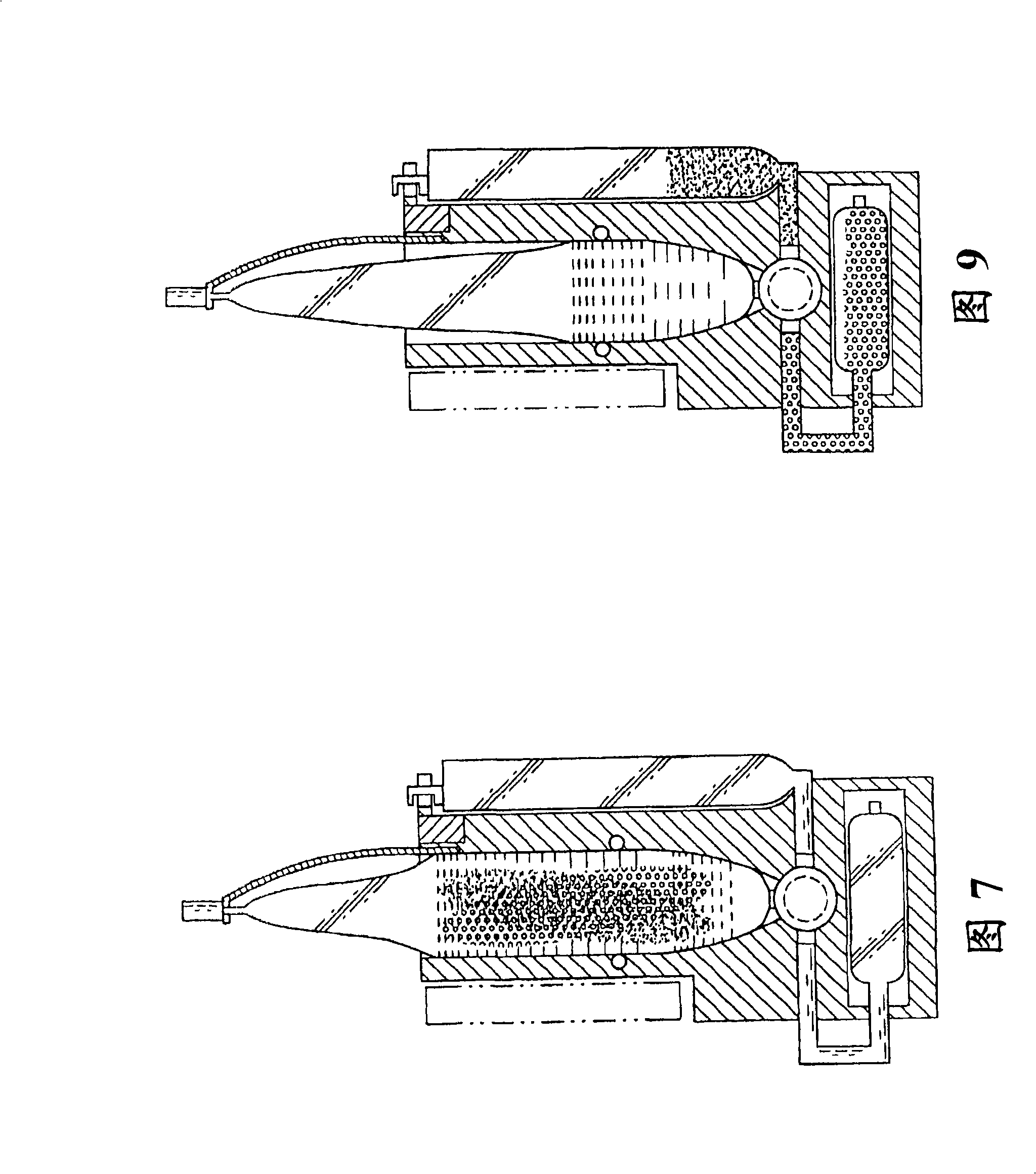

Centrifuge bowl for separating particles

InactiveUS20020142909A1Settling fastEasy to separateRotary centrifugesBiological testingWhite blood cellVolumetric Mass Density

A novel centrifuge bowl for processing particles suspended in a fluid is disclosed. The centrifuge bowl includes an annular cavity concentrically located about the rotation axis for suitably separating particles of similar densities but of different diameters. The cavity is preferably configured to have an annular cross sectional area, which is parallel to the rotation axis, that increases from a centrifugal side of the cavity toward a centripetal side of the cavity. This configuration allows to generate an almost rigidly rotating field upon rotation of the centrifuge bowl, which field helps to uniformly disperse Coriolis force throughout the circumference of the cavity to avoid turbulent mixing of the particles. In an alternative embodiment, the cavity is surrounded by an outer cavity for separating particles according to density before processing them through the inner cavity. This construction is particularly suitable for processing whole blood to harvest platelet-rich-plasma with reduced level of white blood cell contamination.

Owner:HAEMONETICS

Method for separating cells

ActiveUS7316932B2Efficient separationPromote recoveryWithdrawing sample devicesSpecific gravity using centrifugal effectsVolumetric Mass DensityDensity separation

The present invention is related to a method for separating a first population of cells from a second population of cells in a sample by discontinuous density gradient separation using dense particles to target the first population of cells and a density separation medium (DSM) that is at least about 0.001 g / cm3 higher than the density of the second population of cells.

Owner:STEMCELL TECHNOLOGIES

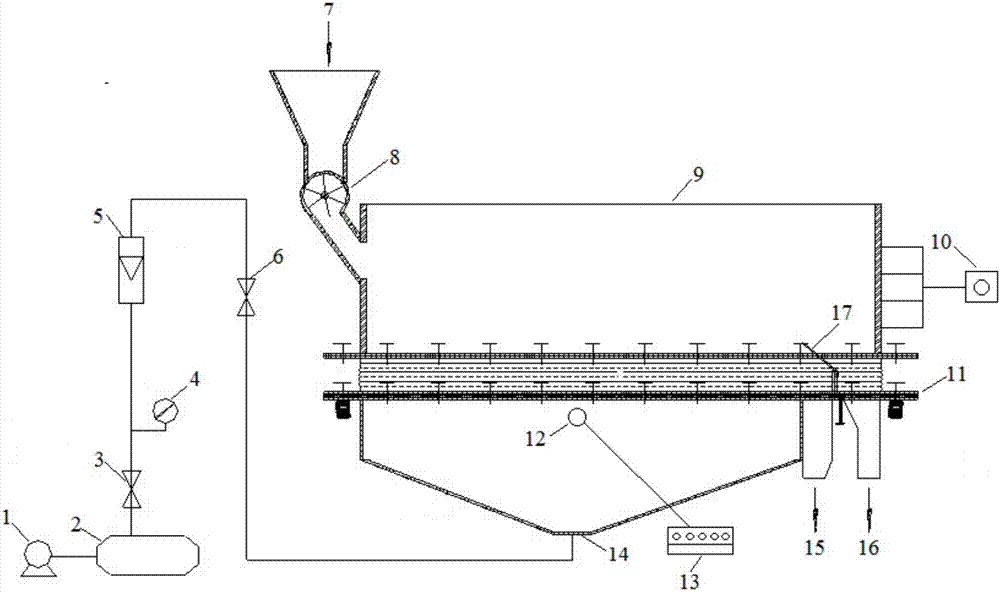

Method and system for processing and recycling infill material of artificial turf

ActiveUS20150209830A1High strengthEasy to set upDrying solid materials with heatGas current separationFluidized bed dryingEngineering

A method and system for processing and recycling infill material of artificial turf. The invention includes drying extracted infill material through a fluid bed dryer, the fluid bed dryer passes a process gas through a bed of solids via a perforated plate. The dried infill material is processed using a plurality of vibrating screens to remove excessively large or small particles from the infill material. The plurality of vibrating screens may be a set of progressively finer mesh screens. The processed infill material is separated by density. The density of the infill material may be determined by a high intensity, uniform sheet of laminar airflow. The separated infill material is discharged and is ready to be used again in another artificial turf. In one embodiment, the infill material includes at least one of graded sand, granulated styrene-butadiene rubber, cork, organic infill, thermoplastic elastomers, or ethylene propylene diene monomers.

Owner:TARKETT INC

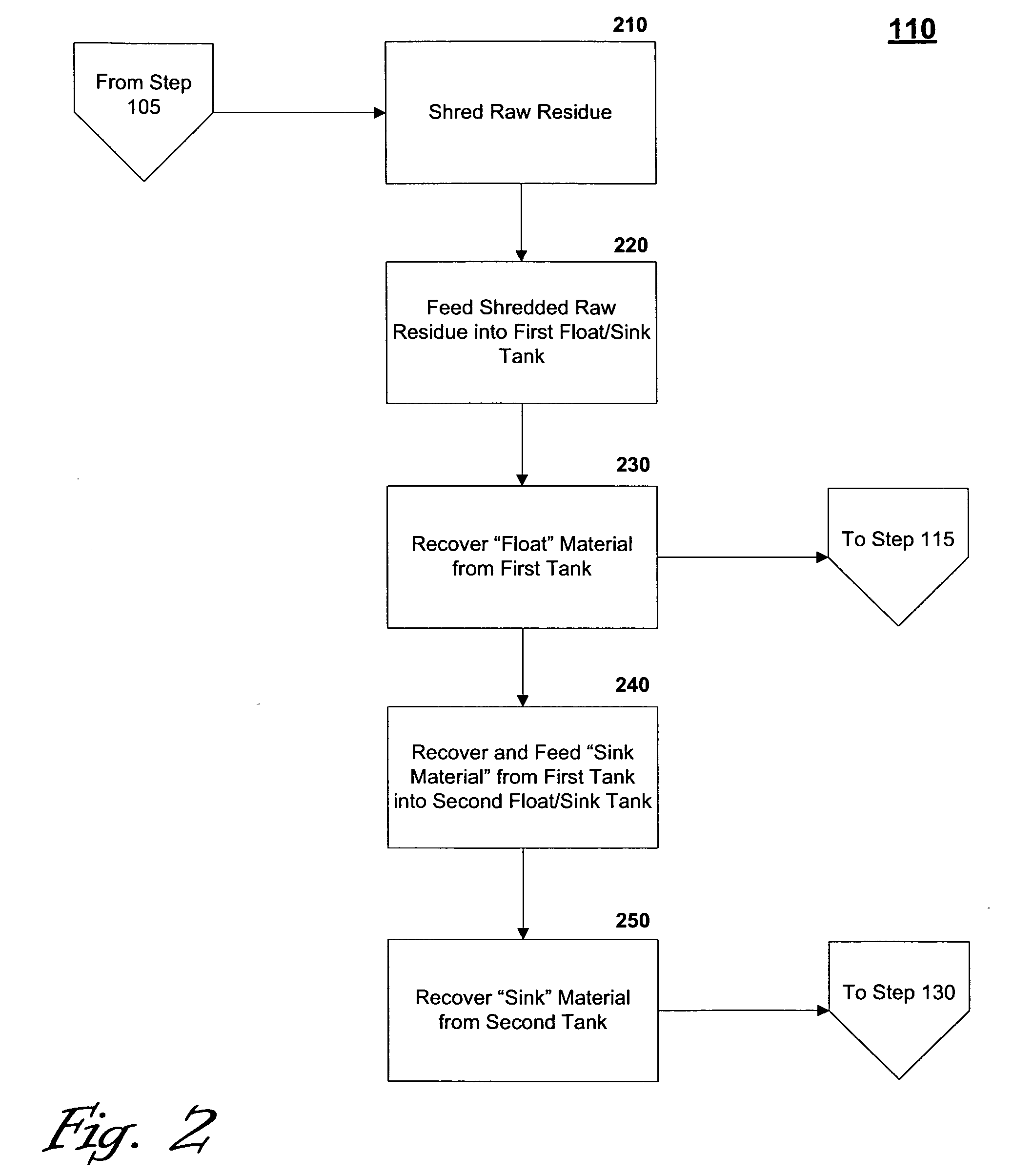

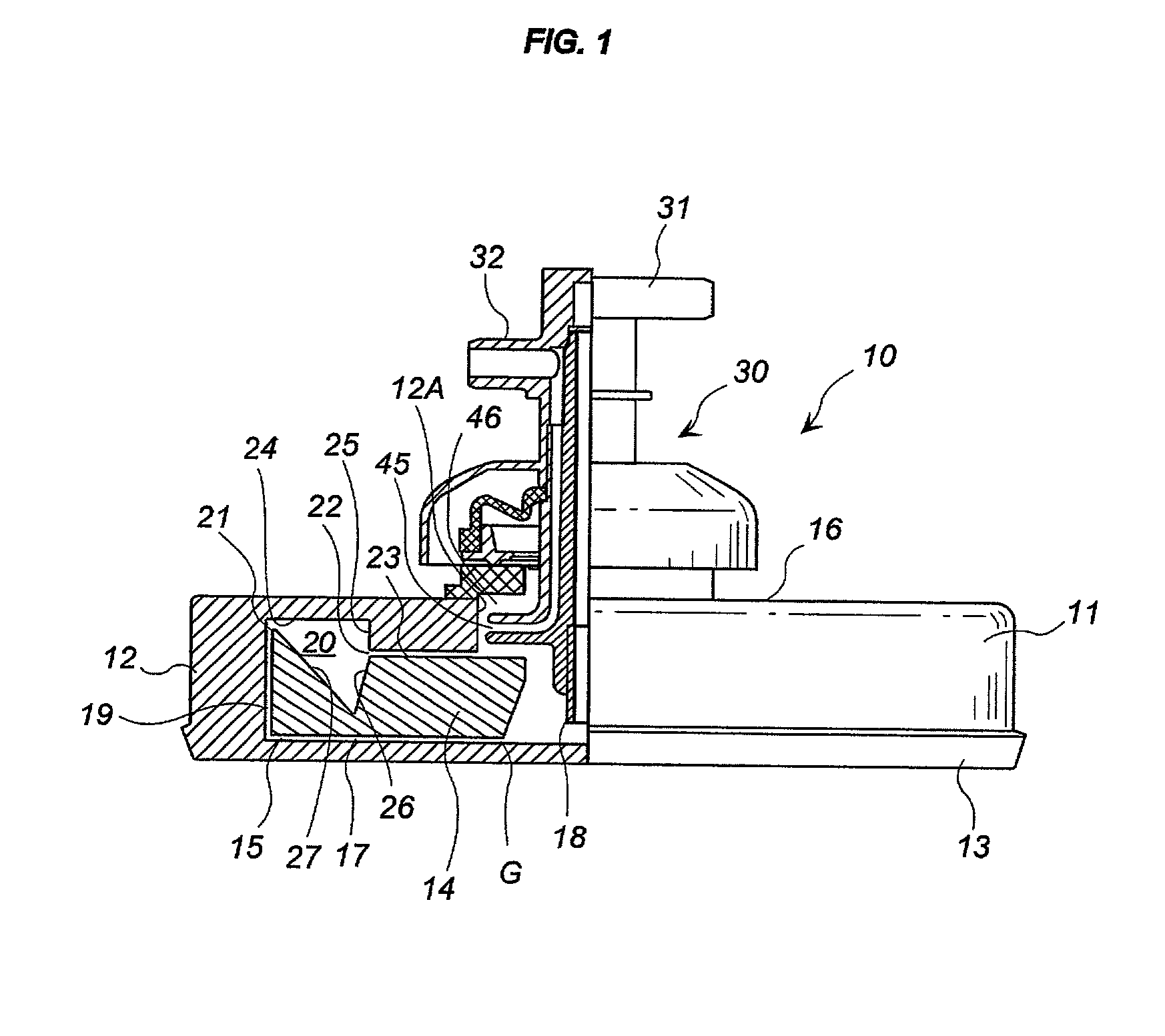

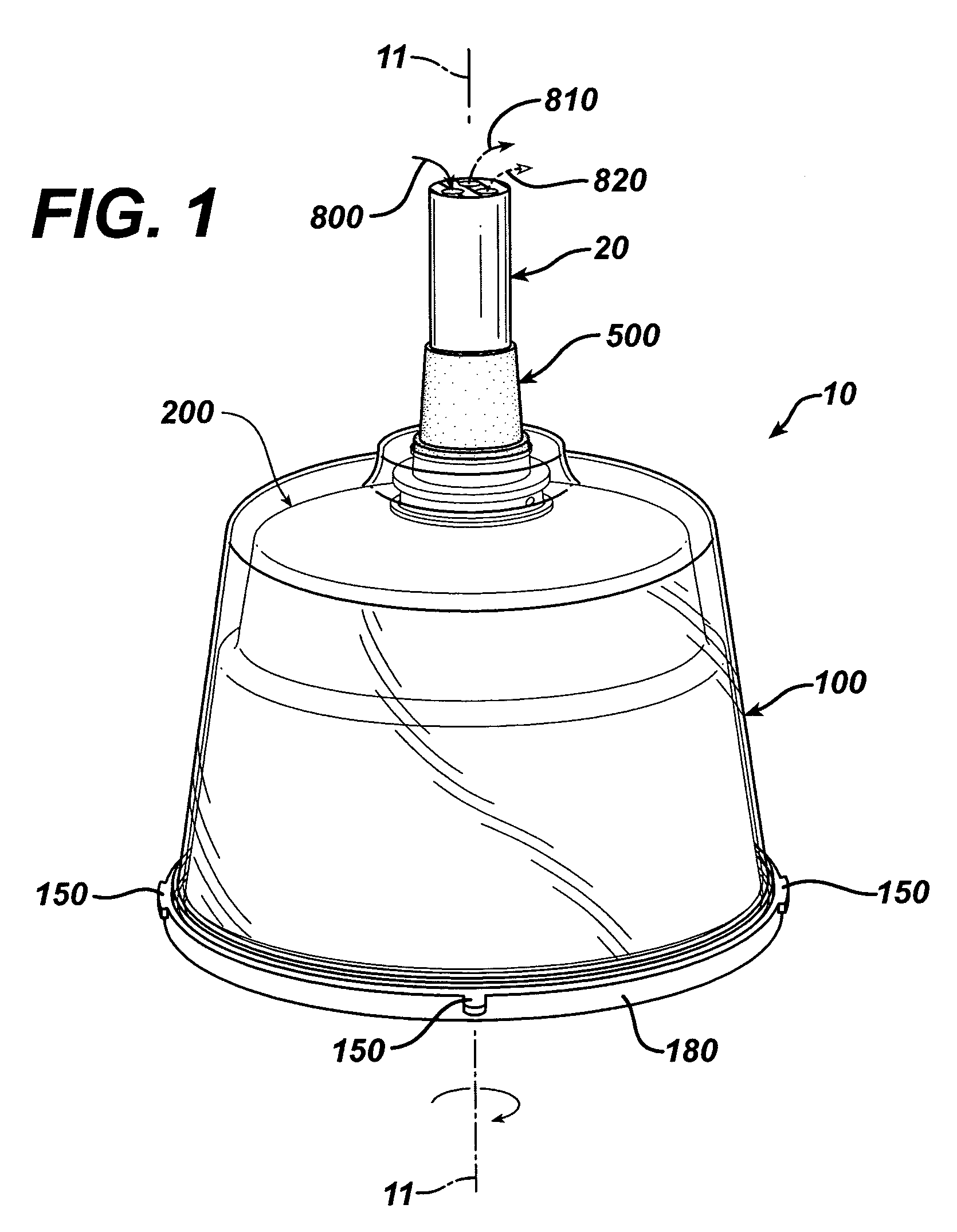

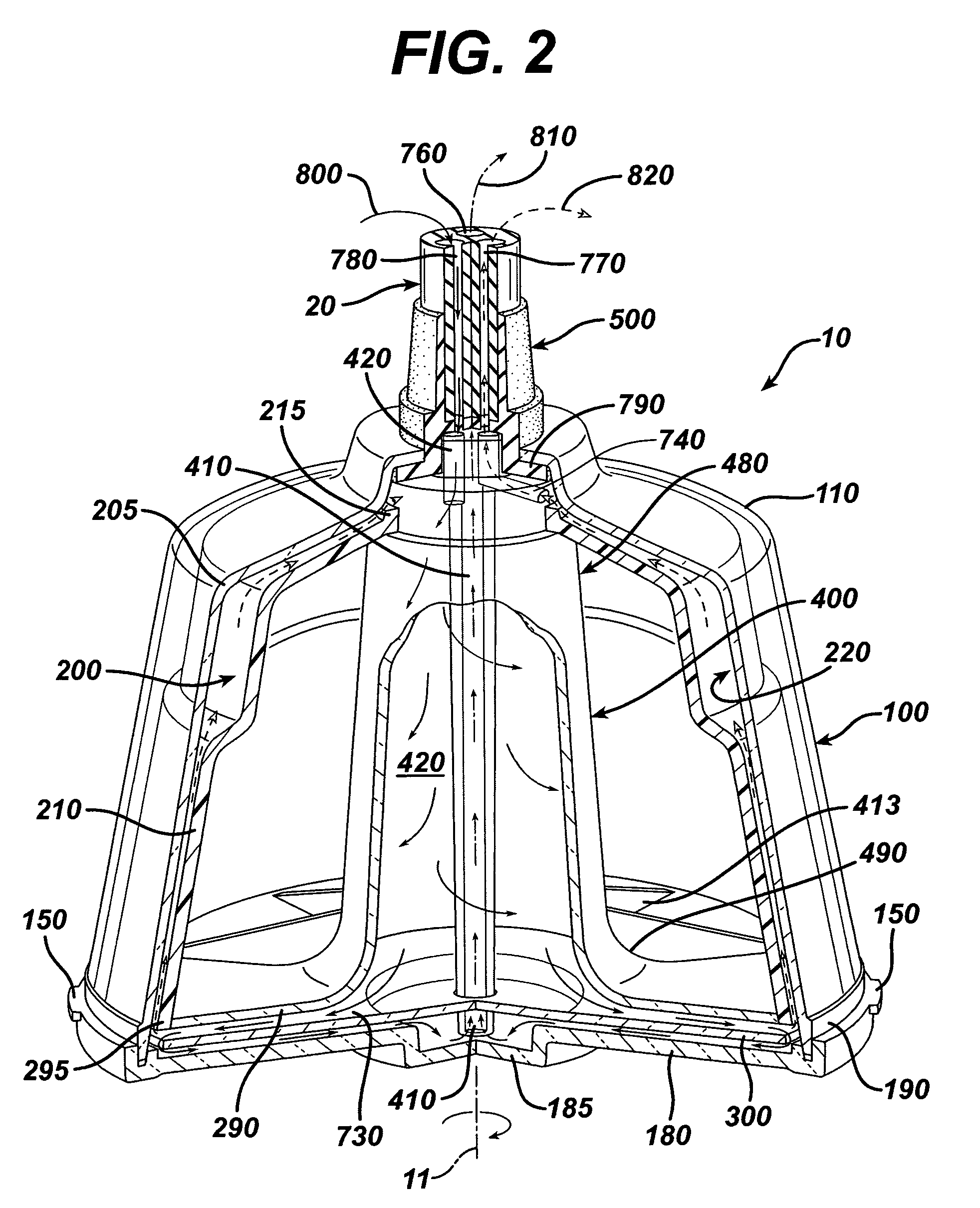

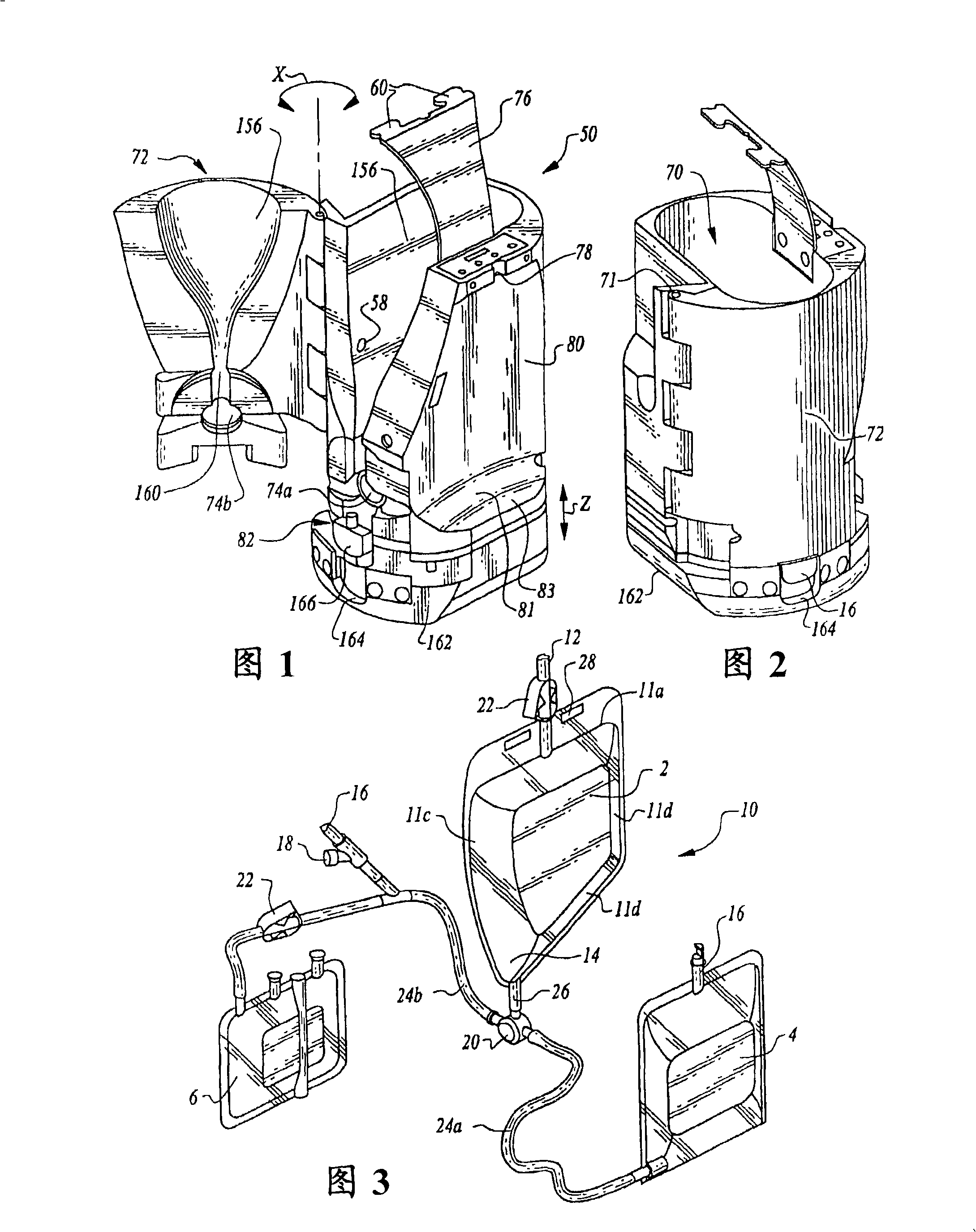

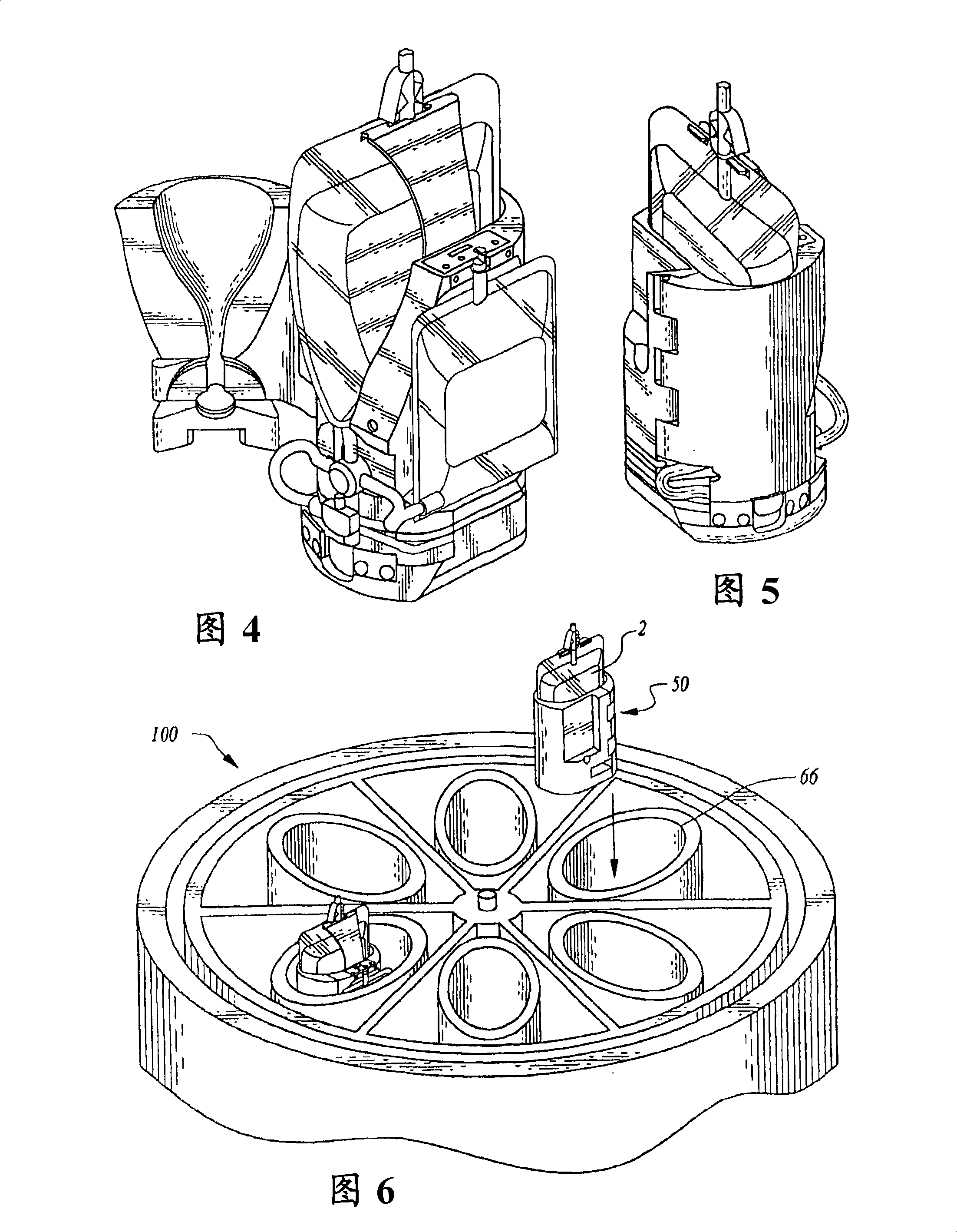

Method and apparatus for the continuous separation of biological fluids into components

ActiveUS7186230B2Improve efficiencyTreat a patient more efficientlyWater/sewage treatment by centrifugal separationOther blood circulation devicesWhite blood cellVolumetric Mass Density

The present invention relates to systems, methods and apparatus for improving the yield for separating components of fluids, for example biological or sensitive fluids such as blood, and improving the component yield, for example, from donated whole blood by separating its components by density in a centrifuge bowl with a multi-axial lumen. The apparatus, system, and method eliminate the need to batch-type separate blood and can reduce the time needed to treat patients suffering from T-cell or white blood cell mediated diseases or conditions to less than 70 minutes. In one aspect, the invention is a centrifuge bowl (10) comprising an outer housing (100); a core (200); a lower plate (300); a lumen (400); a first bowl channel (420) within said lumen (400) for inflowing said fluid (800); a second bowl channel (410) for removing a first separated fluid component (810); and a third bowl channel (740) for removing a second separated fluid component (820).

Owner:MALLINCKRODT HOSPITAL PRODUCTS IP LTD

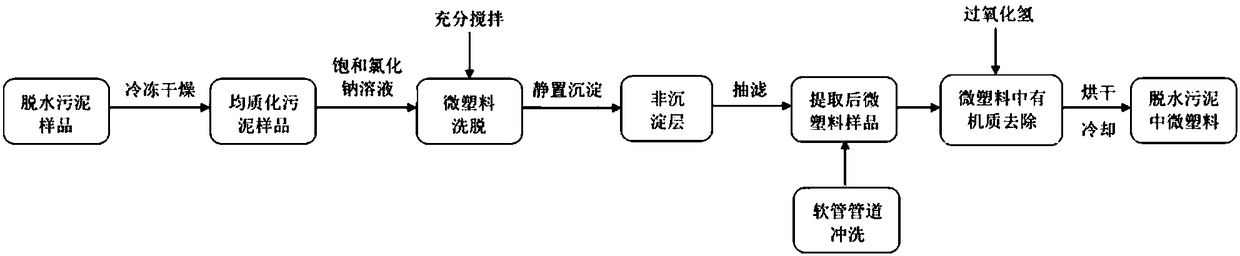

Method for extracting microplastics in dewatered sludge and lab-scale test device

InactiveCN108375670AHigh recovery ratePracticalPlastic recyclingMaterial testing goodsEcological environmentFreeze-drying

The invention discloses a method and device for extracting microplastics in dewatered sludge. The method comprises the following steps: carrying out freeze-drying homogenization on the dewatered sludge, then adding a density solution and stirring to obtain turbid liquid, and standing until the turbid liquid is layered completely; transferring microplastics particles which float in a non-precipitating layer to a filter membrane under the effect of an air pump, and rapidly collecting the microplastics particles; continuously adding the density solution into a filter flask and keeping the solution parallel and level to a suction nozzle, and then washing a pipe for several times to transfer the microplastics particles adhered to the wall of the pipe to the filter membrane; adding the intercepted microplastics particles into a hydrogen peroxide solution, and carrying out shock reaction to remove organic matter impurities in the sludge; and drying to remove residual liquid, and cooling to obtain the final microplastics particles. The method has the advantages that the microplastics particles in the dewatered sludge are extracted on the basis of a density separation principle, and the method is rapid and simple to operate, low in sample demand quantity, high in microplastics particle recycling rate, good in reproducibility, high in practicality and widely applicable to ecological environment risk researches of the microplastics in the dewatered sludge.

Owner:SHANGHAI UNIV

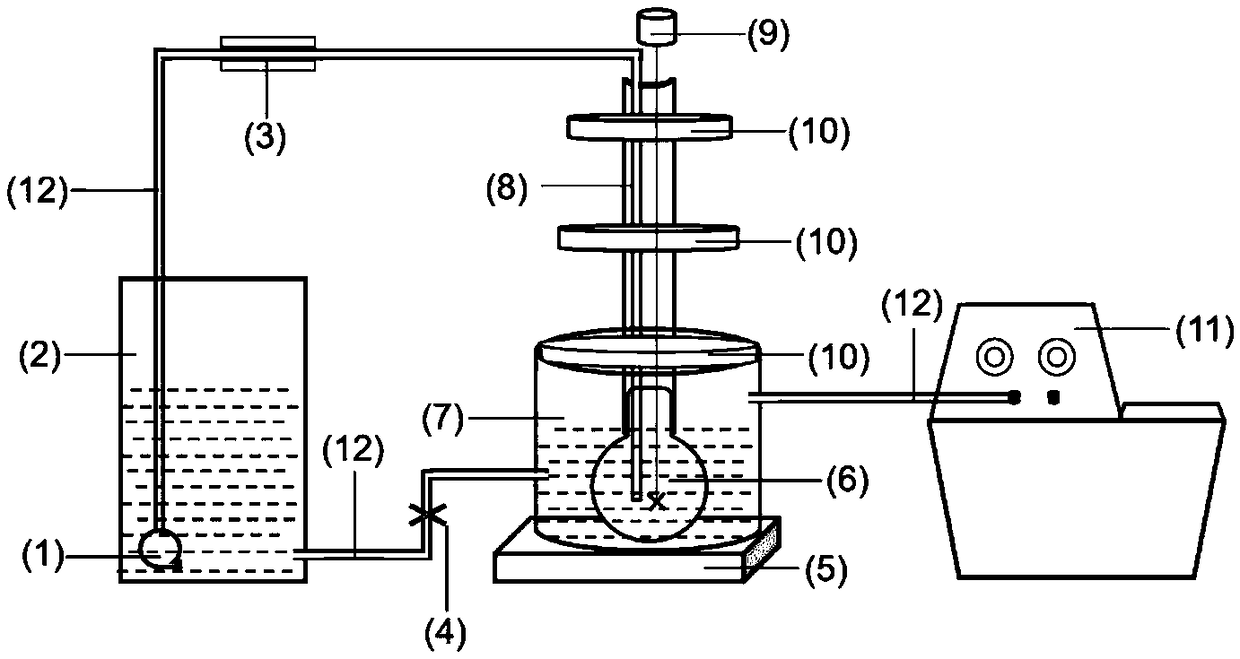

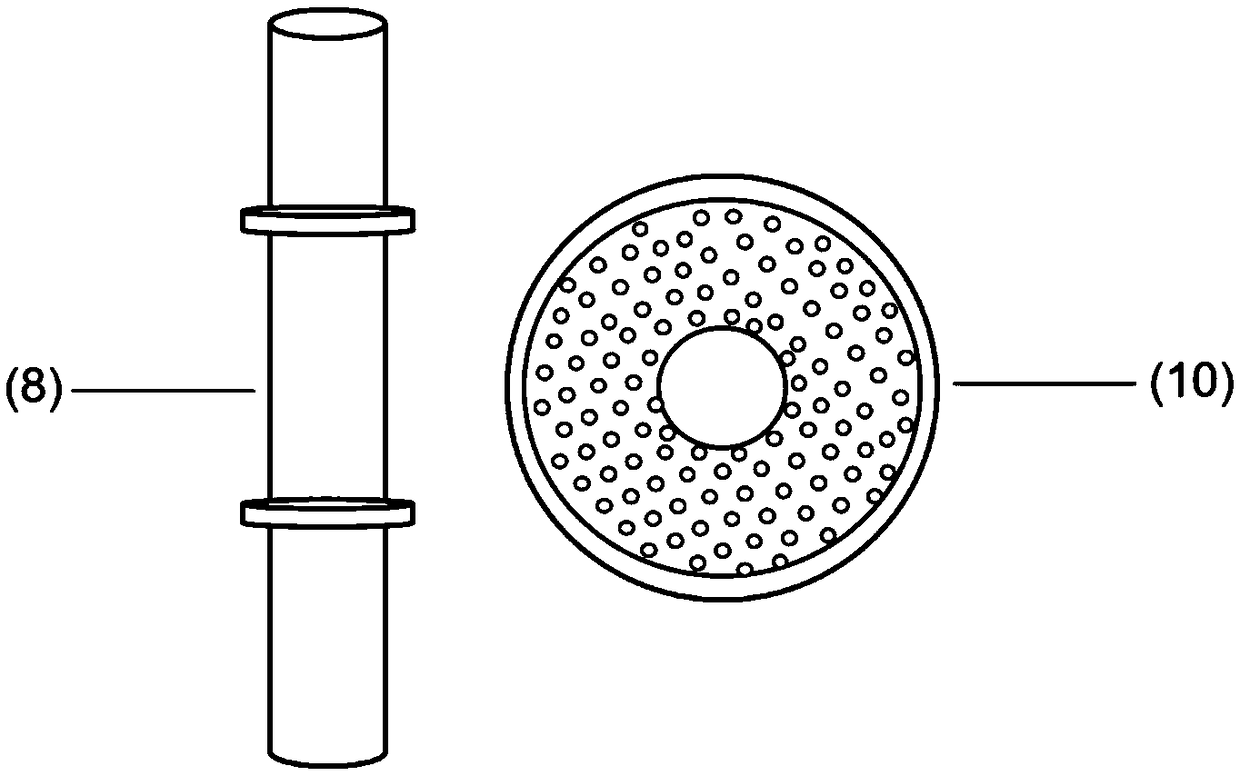

Enrichment device for quickly and continuously separating micro-plastics and use method thereof

PendingCN109228022AReduce economic costsNo secondary pollutionPlastic recyclingMechanical material recoveryPeristaltic pumpFiltration

The invention provides an enrichment device for quickly and continuously separating micro-plastics and a use method thereof. The device comprises a flotation liquid circulating part and a sample separating and enriching part, wherein the flotation liquid circulating part comprises a peristaltic pump, a liquid storing bottle, a flow meter, a suction filtration barrel, a vacuum pump and a guide pipe; the sample separating and enriching part comprises an ultrasonic generating device, a sample bottle, a flotation pipe, a stirring rod and multiple stages of sieving disks; the suction filtration barrel is placed in the ultrasonic generating device; the sample bottle is placed in the suction filtration barrel, the flotation pipe is assembled on the sample bottle, and finally, a plurality of sieving disks are nested outside the flotation pipe; the stirring rod is extended into the sample bottle; the suction filtration barrel is connected with the vacuum pump; and filter screens or filter membranes with different particle sizes are placed in the sieving disks. The device provided by the invention is designed based on the principle of density separation and has the following characteristics:the flotation liquid is circularly used among the three parts, so that the economic cost is lowered, and secondary pollution is avoided; and by the arrangement of the multiple stages of sieving disks, micro-plastic particles with different particle sizes can be continuously subdivided, so that the separation efficiency is high.

Owner:SOUTH CHINA UNIV OF TECH

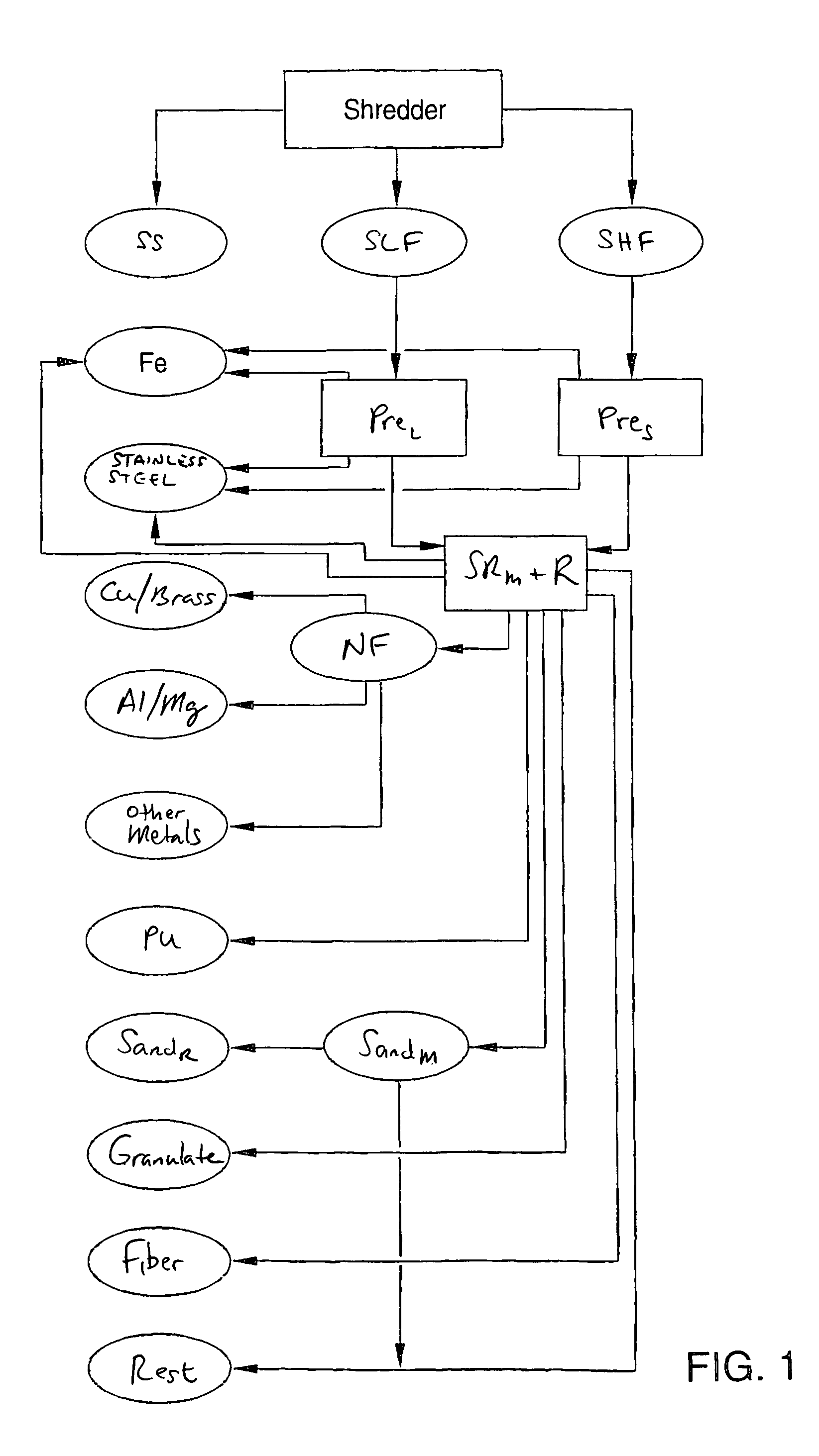

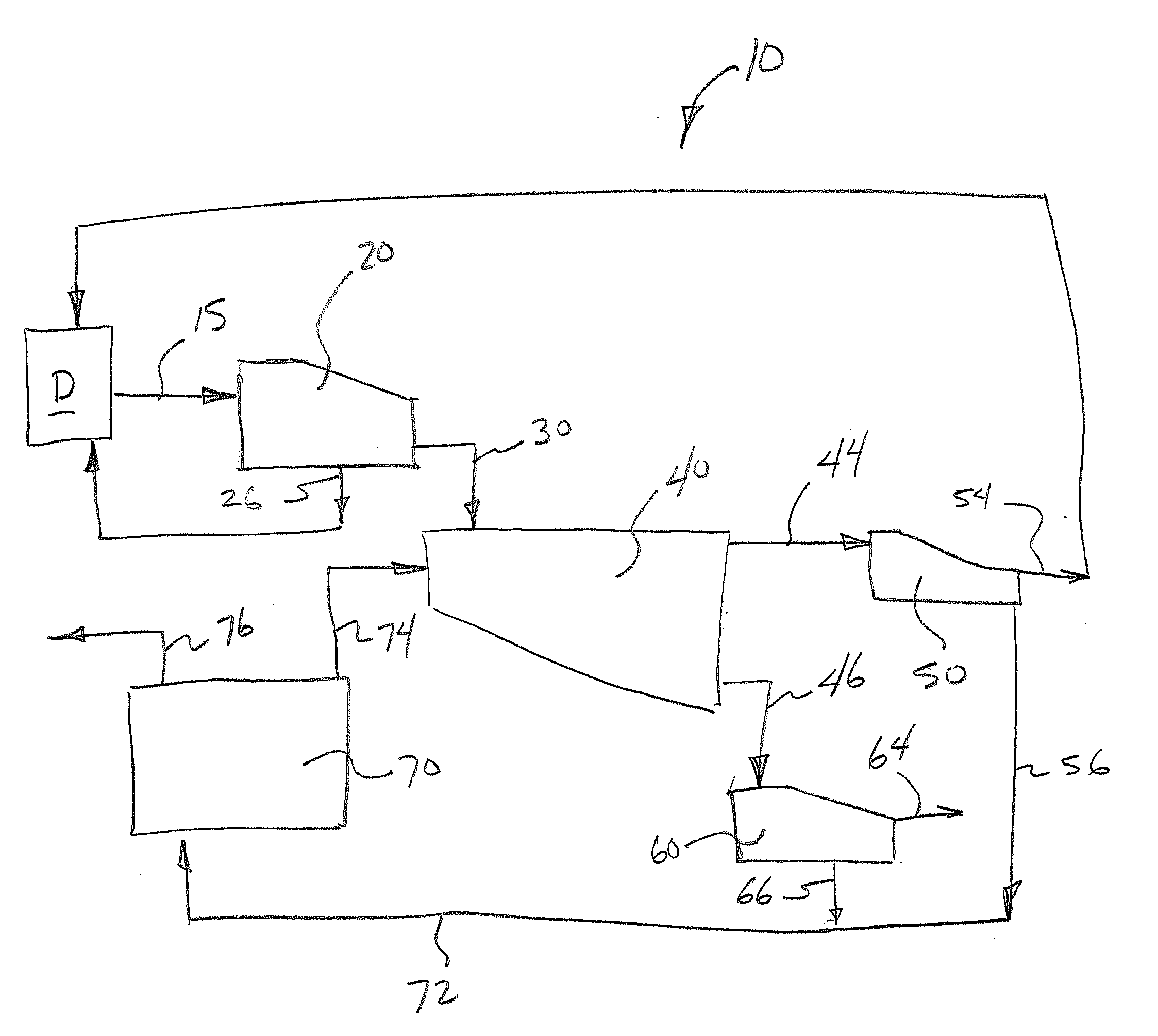

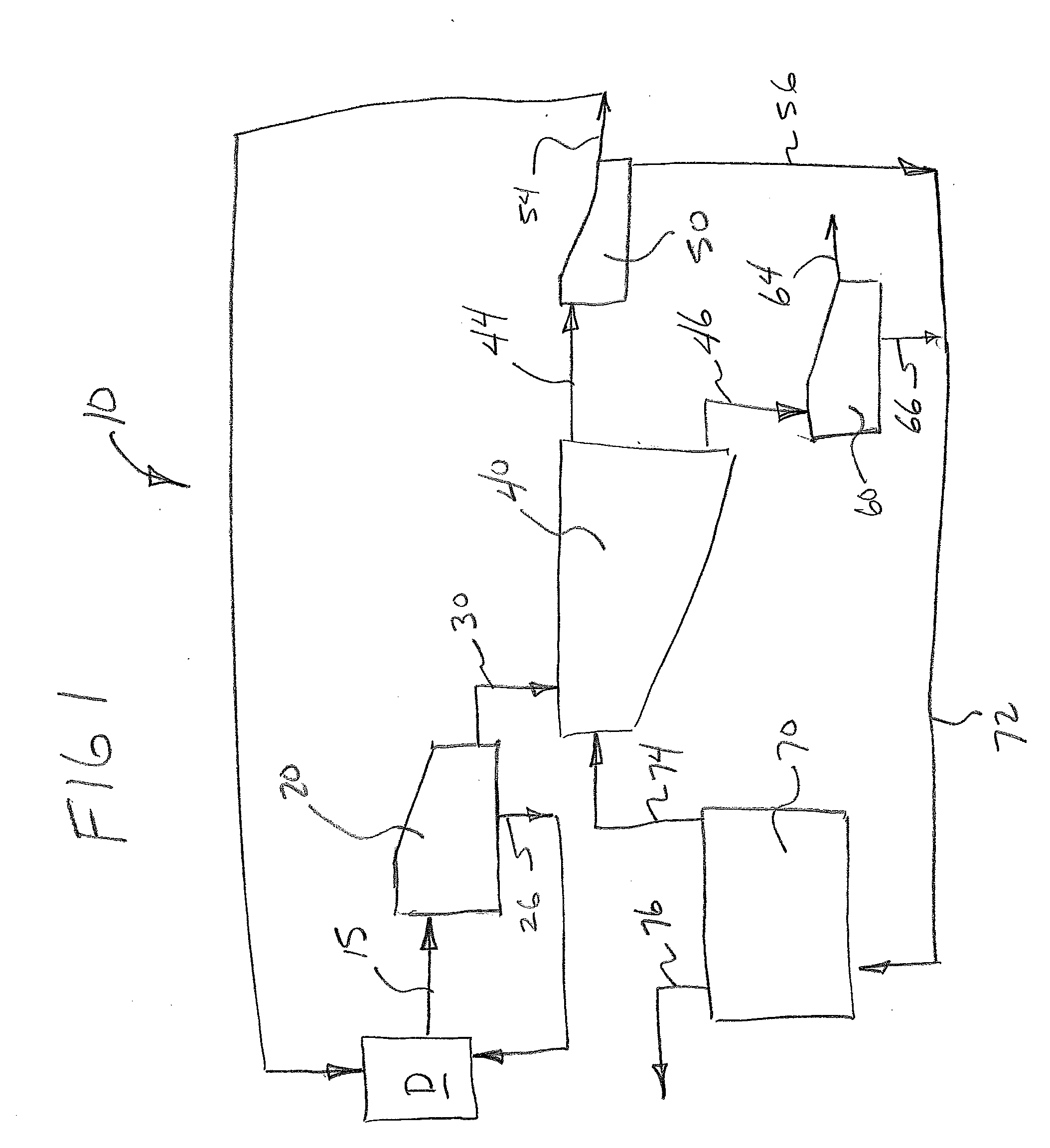

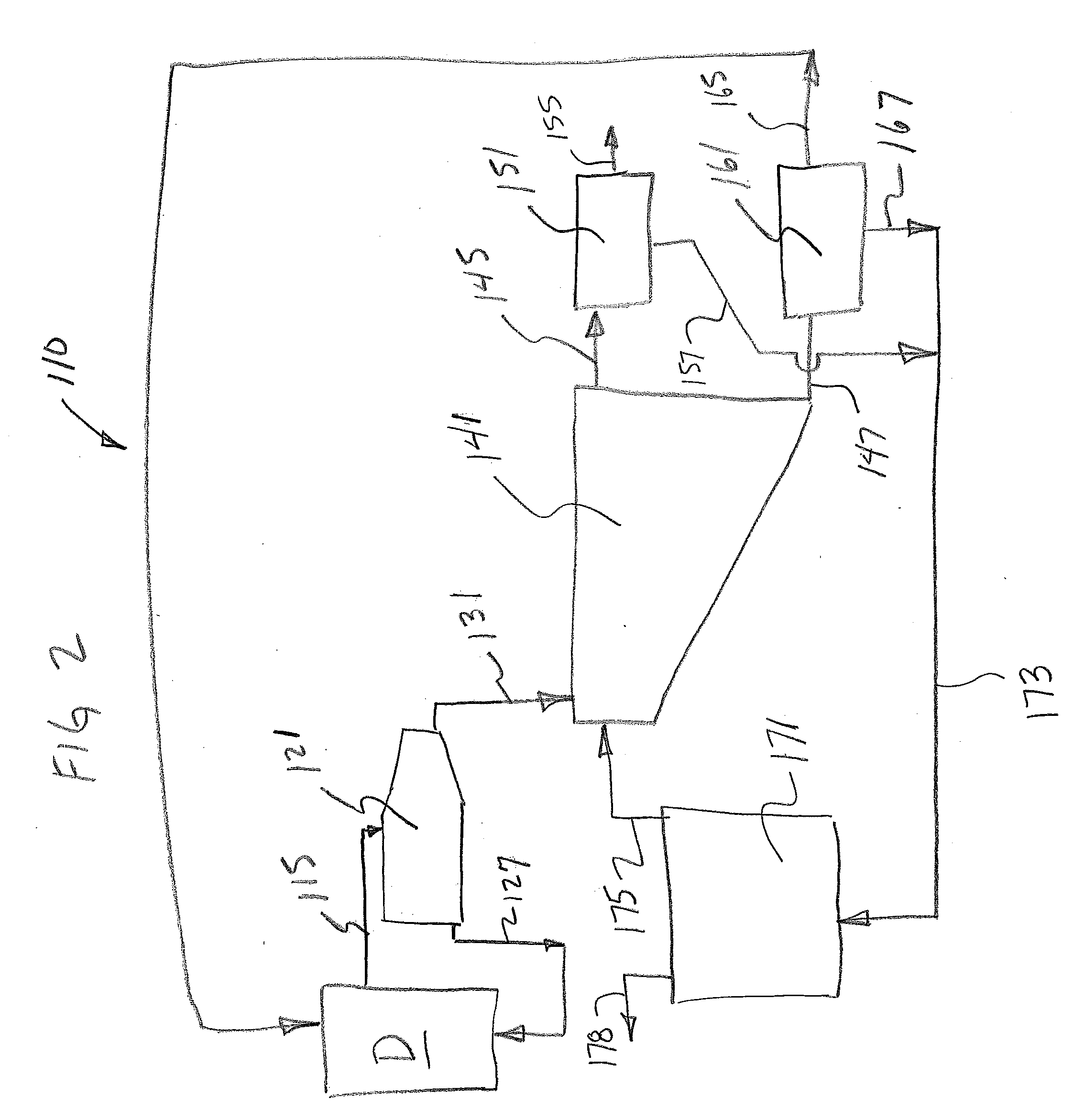

Method and plant for separating polymeric materials

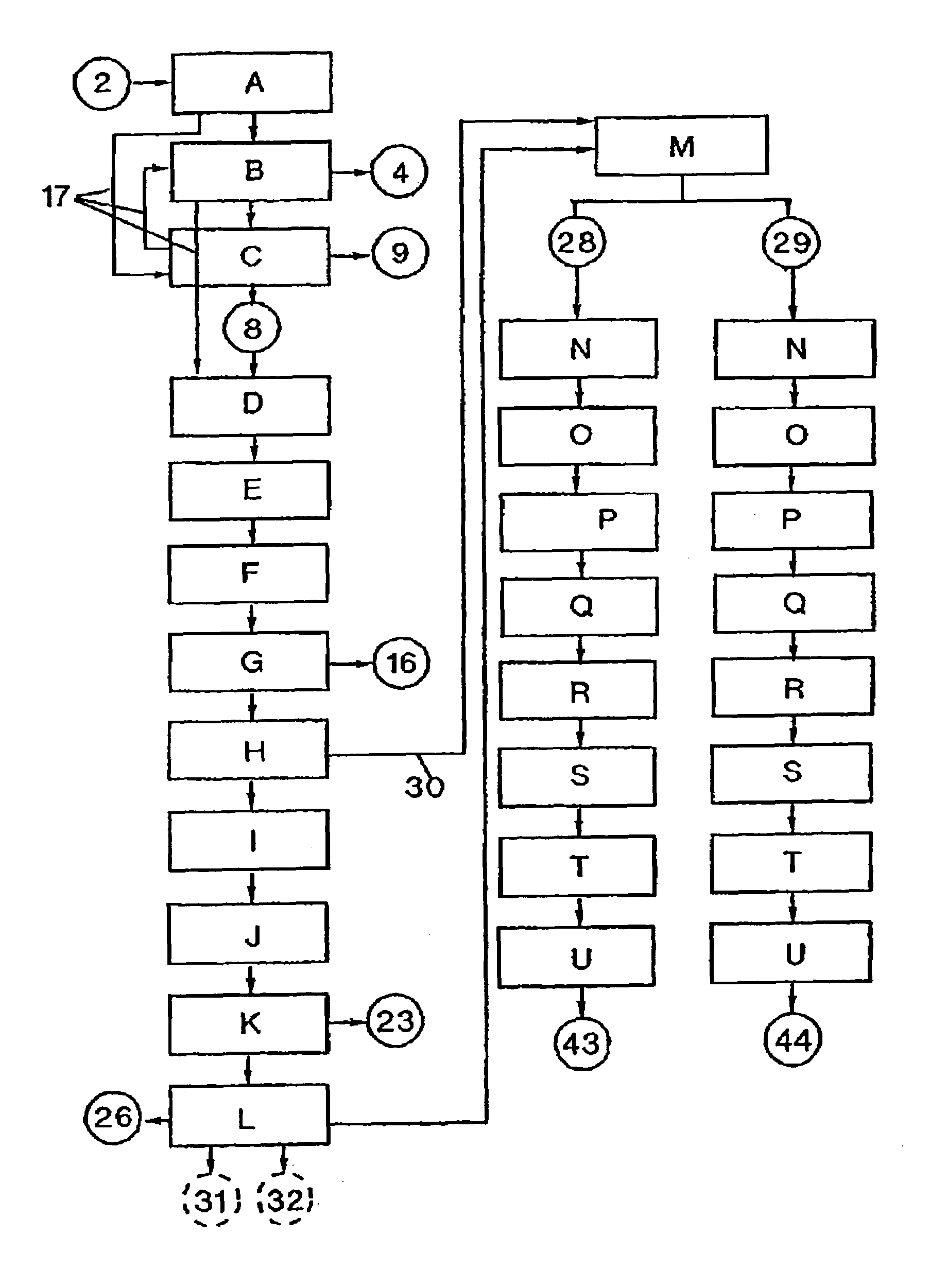

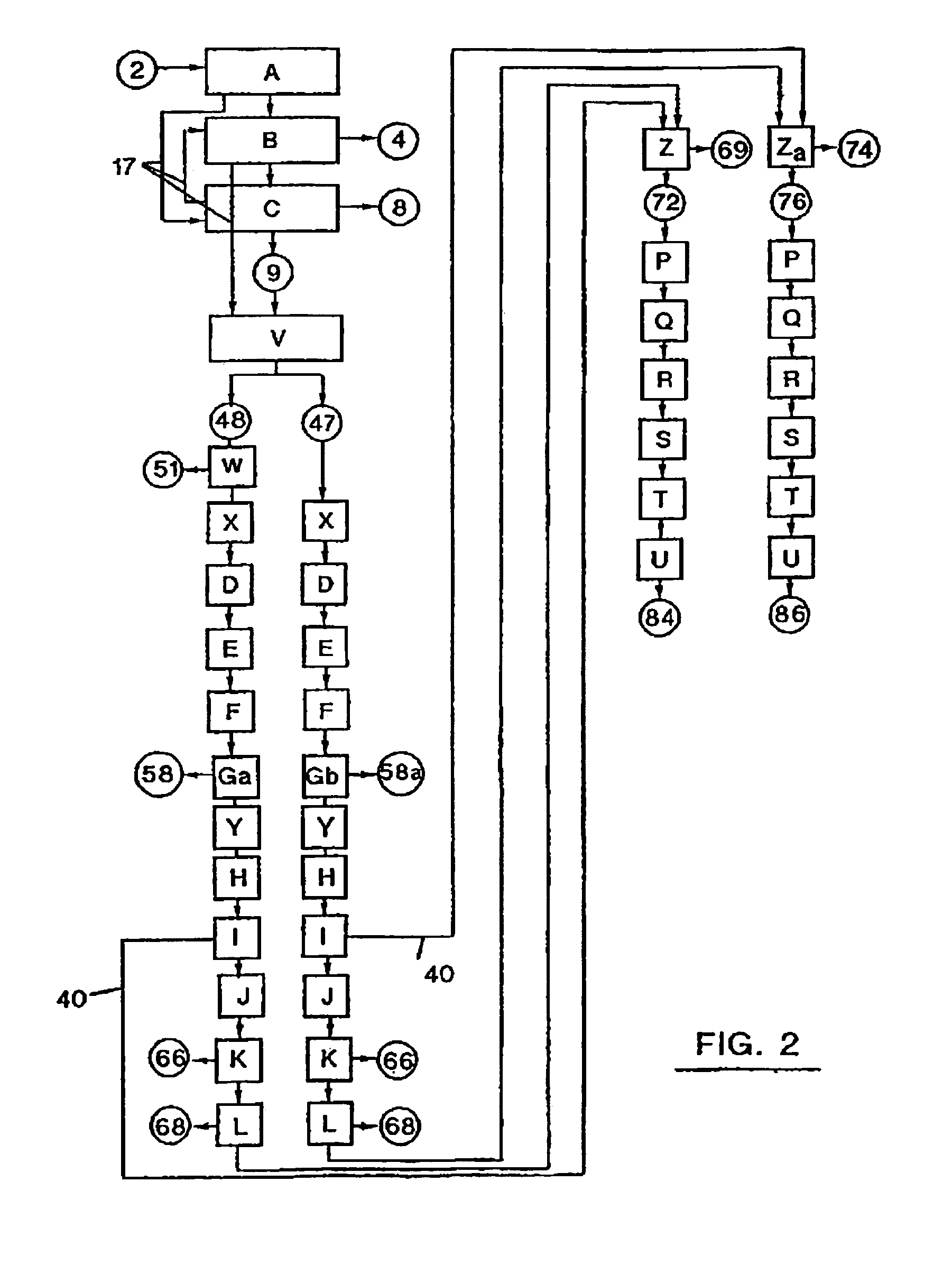

A method for recycling polymeric materials, including a mechanical separation step (B), a first density separation step (C), an intensive cleaning step (E), and a second density separation step (G, V) is described. Additional separation steps, such as a third density separation step (M, W), and optionally a fourth density separation step (Ga, Gb). Further less essential steps such as wetting (A), grinding (D), air flow separation (K), drying (I), electrostatic sorting (Z) and optional sorting (Za) steps may also be carried out to achieve optimized and refined separation. Polymeric materials from refuse or crushed motor vehicles may thus be separated, and polyethylene, polypropylene, polystyrene and acrylonitrile-butadiene-styrene resins may be recycled.

Owner:VANDEPUTTE ANTOINE

Method for Separating Cells

The present invention is related to a method for separating a first population of cells from a second population of cells in a sample by discontinuous density gradient separation using dense particles to target the first population of cells and a density separation medium (DSM) that is at least about 0.001 g / cm3 higher than the density of the second population of cells.

Owner:STEMCELL TECHNOLOGIES

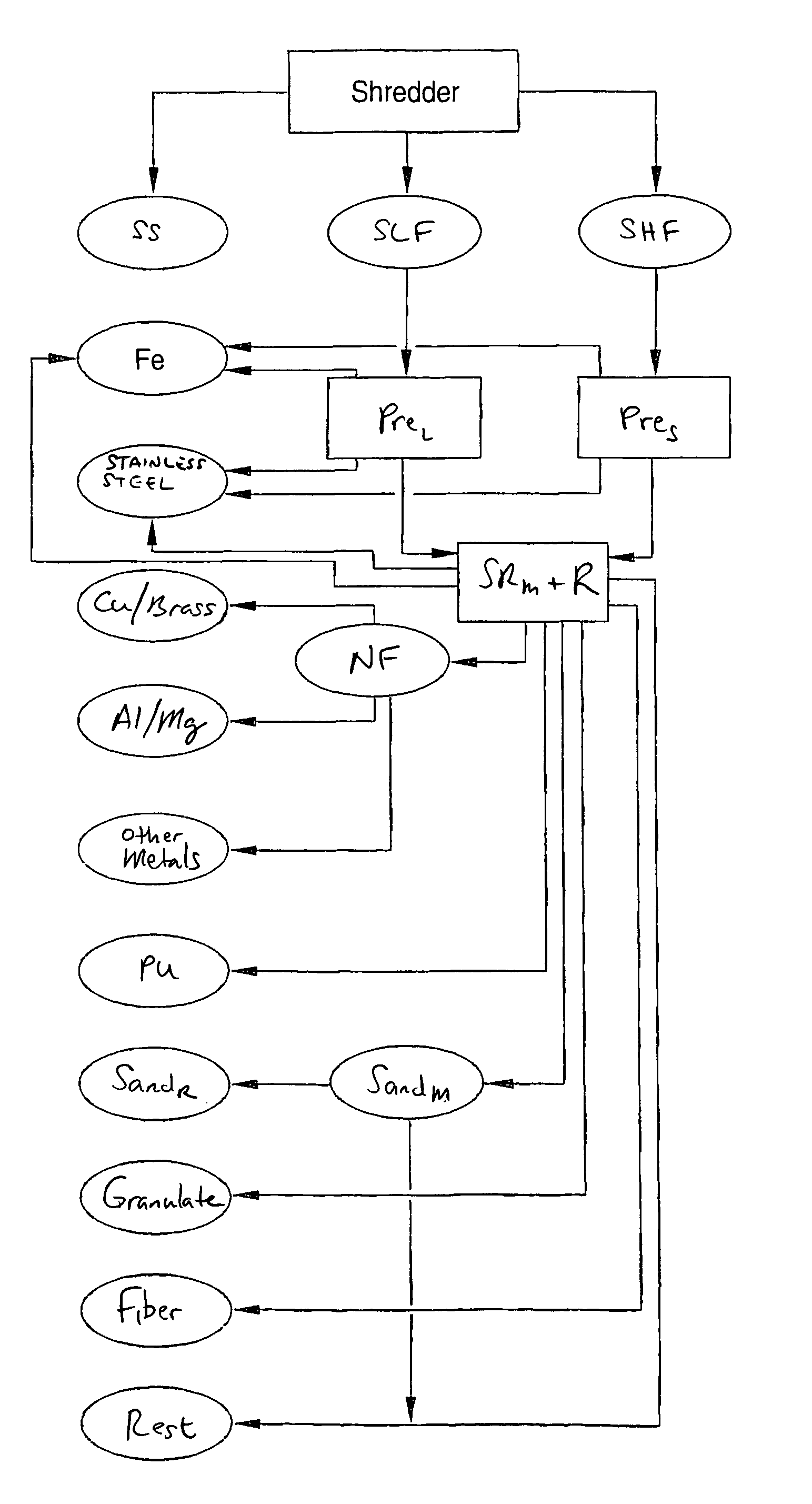

Unit and method for processing of shredder residues and uses of a sand fraction produced thus

A method and system are for sorting shredder residues of metal-containing wastes, in particular of body shells Shredder residues are separated into a shredder light fraction and a non-ferromagnetic fraction (shredder heavy fraction). During the sorting of the shredder light fraction and the shredder heavy fraction in preliminary processes and a main process, a crude-sand fraction is produced by separating out at least a ferromagnetic fraction, a fraction containing nonferrous metals, a fiber fraction, and a granulate fraction. In a refining process, the crude-sand fraction is separated into a residual fraction rich in organics, a dust fraction containing heavy metals, a sand fraction depleted in organics and metals, and a metallic fraction, using the sequential process steps of density separation and metal separation.

Owner:VOLKSWAGEN AG

Method and plant for separating polymeric materials

A method for recycling polymeric materials, including a mechanical separation step (B), a first density separation step (C), an intensive cleaning step (E), and a second density separation step (G, V) is described. Additional separation steps, such as a third density separation step (M, W), and optionally a fourth density separation step (Ga, Gb). Further less essential steps such as wetting (A), grinding (D), air flow separation (K), drying (I), electrostatic sorting (Z) and optional sorting (Za) steps may also be carried out to achieve optimized and refined separation. Polymeric materials from refuse or crushed motor vehicles may thus be separated, and polyethylene, polypropylene, polystyrene and acrylonitrile-butadiene-styrene resins may be recycled.

Owner:GALLOO PLASTICS

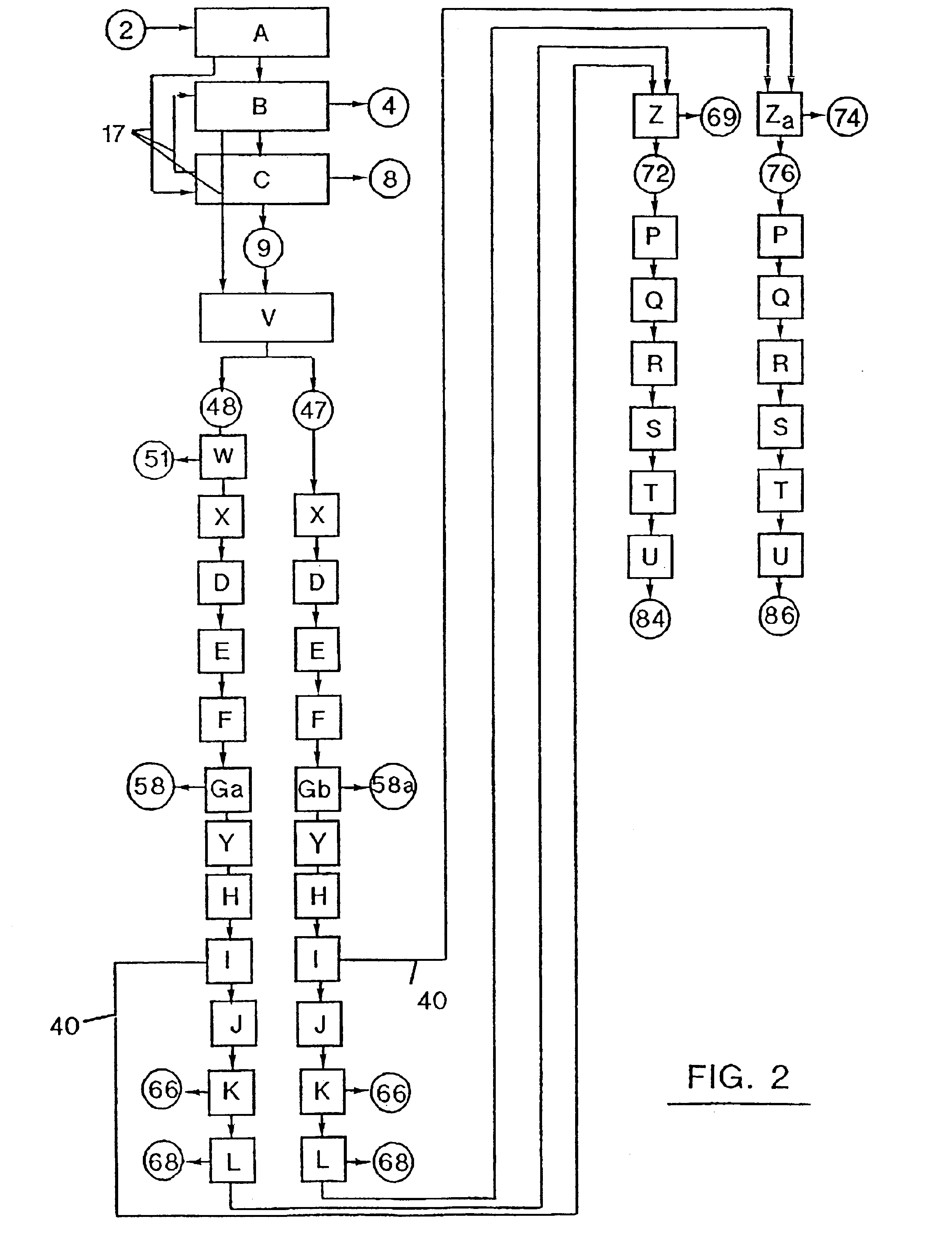

Apparatus and method for recycling waste paint

InactiveUS6311906B1Drying using combination processesLiquid surface applicatorsLacquerDensity separation

There is disclosed apparatus and method for recycling waste paint, for completely removing a bad smell generated in the course of drying up the waste paint and extracting a bad smell from a filler. The method for recycling waste paint comprises the steps of: shaping the waste paint into a cake of a predetermine thickness while removing water from the waste paint using centrifugal force of a dehydrator; drying up and dehydrating the cake-shaped waste paint at about 80° C.~300° C. using a twin screw extruding method to remove water; drying up the waste paint dried up at the above step at about 100° C.~300° C. using a vacuum dry method to remove remaining water; pulverizing the waste paint dried up by the vacuum dry method into minute powder; separating the pulverized waste paint based upon density; and collecting and discharging dust, vapor, and gas generated during the above steps.

Owner:KIM ILL JA +2

Method for recovering valuable drilling mud materials using a binary fluid

Owner:CONOCOPHILLIPS CO

Technique for continuous production of biological diesel oil with propagation waste oil

InactiveCN101173176ALow production costSimple production processBiofuelsLiquid hydrocarbon mixture productionVegetable oilReaction rate

The invention provides a technological method that utilizes the waste oil of animals and plants to continuously produce biodiesel. The technical proposal of the invention is that, waste edible oil, high acid value oil, animal and vegetable oils, oil foot and other components are used as materials; dehydration treatment, esterification and transesterification, methanol recovery, separation of fatty acid methyl ester and glycerol according to densities by a centrifuge, molecule distillation deacidification, high temperature decomposition of ester soluble impurity, and molecule distillation deodorization are directly performed; the finished product, which is light yellow fatty acid methyl ester, namely 0<#> biodiesel, is acquired by continuous production. The method continuously and rapidly semi-automatically completes esterification and transesterification reaction to get fatty acid methyl ester under completely vacuum condition at a certain temperature, and the problems of high production cost, low yield and long reaction time of biodiesel production by common esterification method are effectively solved. The invention has the advantages of no three wastes produced during the whole production process, green environmental protection, obviously lowered labor intensity, easy operation, low energy consumption, effectively reduced production cost of the biodiesel, fast reaction rate, improved productivity, and fitness for large scale industrial production.

Owner:崔明林

System and method for hydrocarbon gas pay zone characterization in a subterranean reservoir

ActiveUS20120065890A1Well formedElectric/magnetic detection for well-loggingGeomodellingWell loggingHydraulic fracturing

A system and computer-implemented method for characterizing hydrocarbon gas net pay zones in a subterranean reservoir including determining a sweet zone indicator from well log data, determining rock properties from well log data, and identifying one or more classes of net pay zones from the sweet zone indicator and rock properties. The sweet zone indicator may be determined by computing neutron-density separation and using the neutron-density separation and the well log data. The rock properties determined from the well log data may include total water saturation, adsorbed gas saturation, total gas content, porosity, propensity for hydraulic fracturing, uncertainty level of the total water saturation, uncertainty level of the total gas content, and baselines for the porosity and total gas content. Using the sweet zone indicator and rock properties, one or more classes of net pay zones can be identified.

Owner:CHEVROU USA INC

Middle and high layer atmosphere density separation type detector

InactiveCN104391299AReduce measurement noiseHigh precisionICT adaptationRadio wave reradiation/reflectionAccelerometerSolar cell

A middle and high layer atmosphere density separation type detector comprises a universal module with a microsatellite platform, and is characterized by further comprising a spherical structural body shell used for simplifying an atmosphere resistance analysis model, an accelerometer, a GPS receiver and an attitude control system, the surface of the special structural body shell is covered with a solar cell, the accelerometer is arranged in the spherical structural body shell, the accelerometer is formed by distributing 4 to 6 static suspension type accelerometers around the axis, the accelerometer is used for measuring the atmosphere resistance, the GPS receiver is arranged in the spherical structural body shell and used for tracking and monitoring the track speed and the position of a microsatellite, the attribute control system is arranged in the spherical structural body shell and used for controlling the attribute of the microsatellite so as to keep the spinning of the satellite stable and ensure the correct directing of a GPS receiver antenna and a data transmission antenna.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Method for resource utilization of fluidized bed combustion ash residues

InactiveCN103011367AReduce adverse effectsImprove use valueCement productionWater/sewage treatment by sorptionResource utilizationSorbent

The invention discloses a method for resource utilization of fluidized bed combustion ash residues. The method comprises the following steps of: mixing the fluidized bed combustion ash residues with water to obtain mortar, and crushing the mortar until the particle size is 1 to 20 micrometers; introducing flue gas of a coal-fired boiler until the pH value of the solution is lower than 7, and filtering to remove water to obtain the ash residues; mixing the ash residues with density separation liquid, collecting and separating out dross which floats on the surface layer of the solution; feeding material liquid into a centrifuge for centrifugally separating centrifugal residues of which the density is greater than that of the separation liquid; and filtering centrifugate in a filter to obtain residues, mxing the residues with the dross to obtain a mixture, activating the mixture in the absence of oxygen at a temperature of 300 to 500 DEG C, cooling and then crushing the mixture, cleaning the crushed mixture by using hydrochloric acid and water, and drying the cleaned mixture to obtain an adsorbent product. By adopting the method, adverse effects caused by calcium sulfite, unburned carbon granules and free calcium oxide on the products such as cement, concrete and the like are eliminated, and the calcium sulfite, the unburned carbon granules and other porous materials are separated from the products and used as useful waste water purification adsorbents, so that the utilization value of the fluidized bed combustion ash residues is improved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Instrumentality for sequestering liquids based on density: method and apparatus

The invention provides a device and method for collecting whole blood and then separating it into components for subsequent use or storage. A self-contained bag set is used to collect the sample, which may then be placed into a device adapted to fit into a centrifuge for separation of components. Each component is then sequentially extracted according to density, with a sensor present in the device to control the operation of valves directing the collection of each component. The sensor is capable of reading one or several characteristics as follows: infrared ray, optics, density, weight, radiation phenomenon, fluorescence, colour, magnetic force, ultrasonic wave and capacitance. The characteristic is inherent characteristic of blood and blood components or additive. Each component may then be separated into its own storage container. Preferable sensor comprises optical and weight sensors. Beside density separation of blood, the device may comprise solution of cells, proteins, sub-cellular particles or viruses which are capable of mixing with affinity medium or antibody before separation.

Owner:THERMOGENESIS

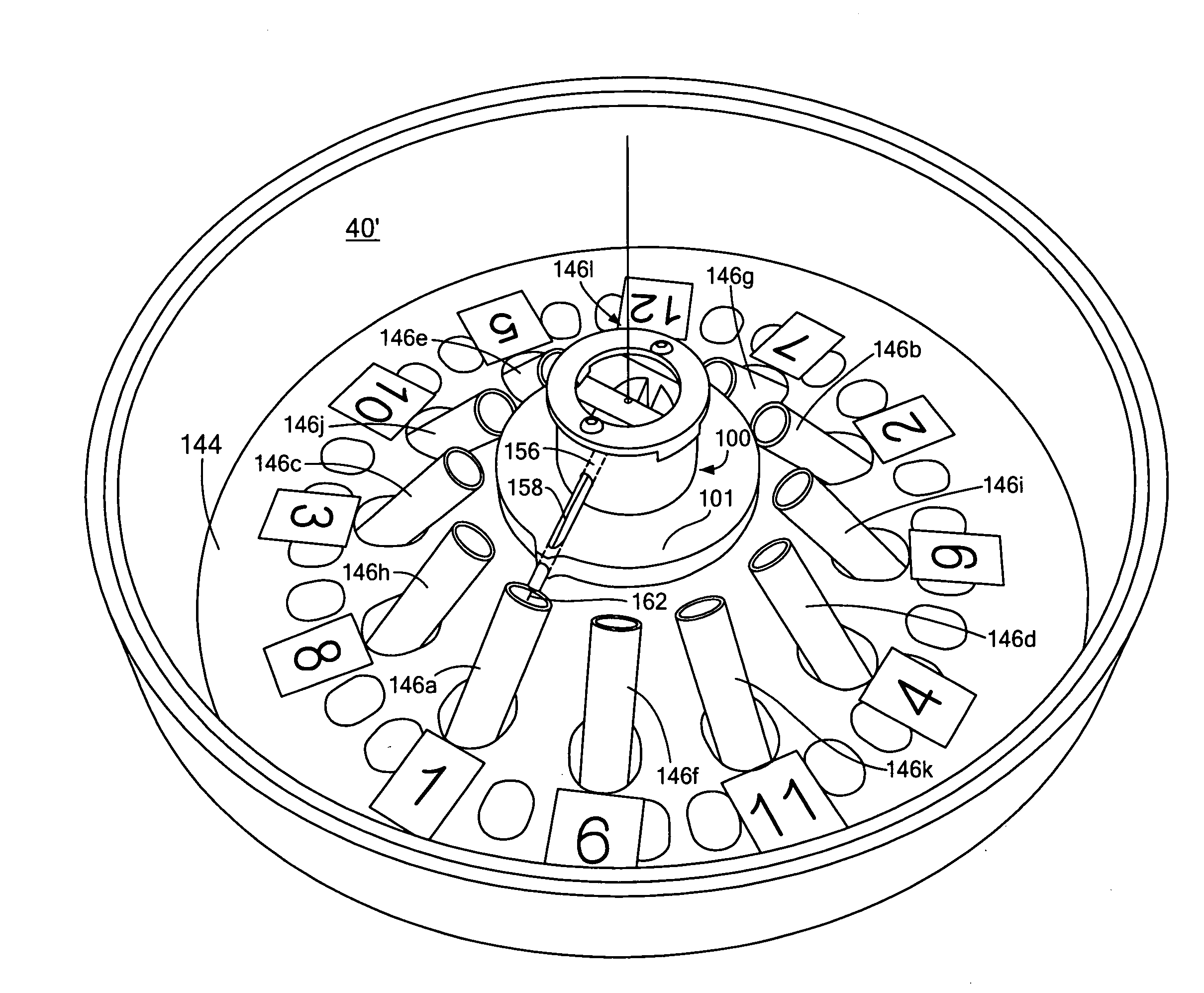

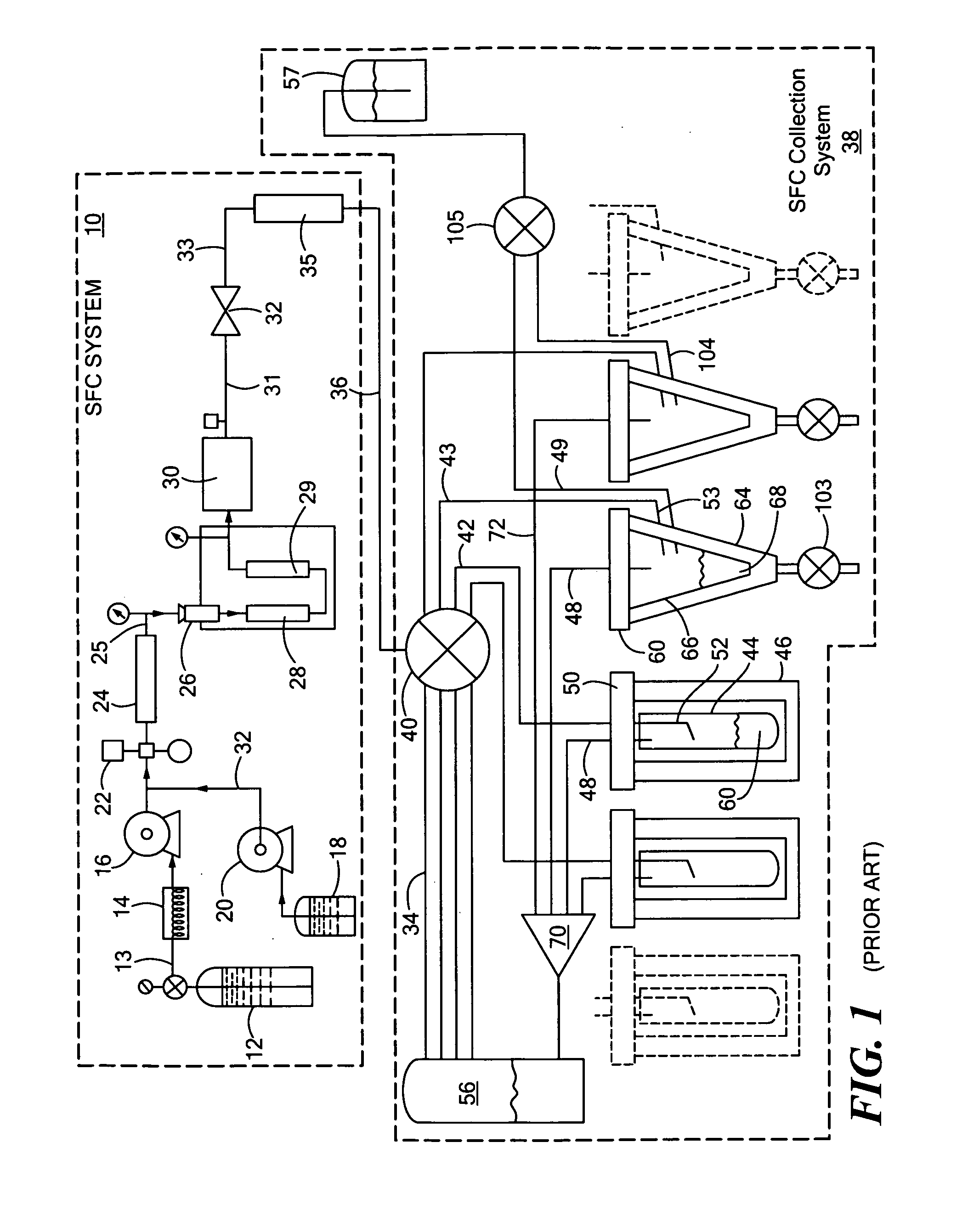

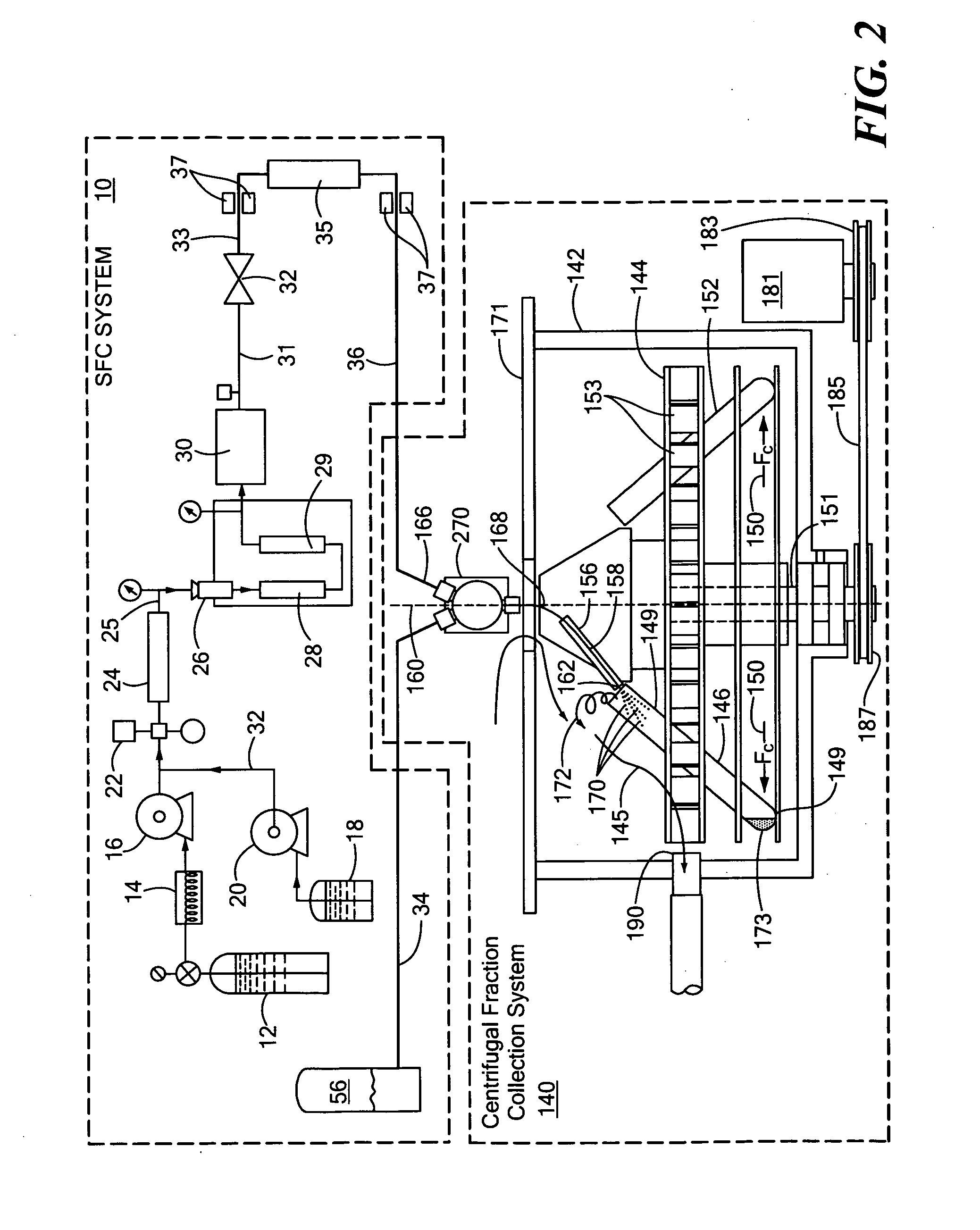

Centrifugal fraction collection system and method

InactiveUS20080164194A1Less complexReduce pressureLiquid degasificationComponent separationCollection systemVolumetric Mass Density

A centrifugal fraction collection system including a rotating carrier for holding at least one sample collection container and inducing a centrifugal force, a guide disposed on the rotating carrier, and a flexible eluant tube disposed over the rotating carrier and through the guide for receiving a flow of eluant having volatile and non-volatile components and directing the flow of eluant into at least one sample collection container wherein the centrifugal force separates the non-volatile and volatile components based on their respective densities and collects the non-volatile components in at least one sample collection container.

Owner:BANK OF AMERICA NAT TRUST & SAVINGS ASSOC

Apparatus and method for drilling fluid density separator utilizing rotating disks

InactiveUS20110017600A1Minimal interferenceElectrostatic separatorsSludge treatmentWell drillingEngineering

The present invention discloses a system for separating minerals in drilling fluid based primarily on density. The separator creates and maintains a slurry with a controllable density for separating minerals from drill cuttings. The density if controlled through the use of an electrode array. The separator comprises a primary separation chamber containing the dense slurry, and a multiple number of secondary separation chambers used to separate cuttings from the drilling fluid. The invention also contains inlet hardware allowing the mixed mineral suspension to enter the first separation chamber, and hardware allowing the three outlet (separated) streams to exit the device. One of the three outlet streams carries the minerals that have a density greater than the user selectable density set point, while the second carries the minerals that have a density less than the density set point, and the third carries clean drilling fluid.

Owner:NAT OILWELL VARCO LP

Dry separation device and method of ultrasonic vibration microbubble fluidized bed

InactiveCN107442416AEasy to sortEliminates phenomena that are not conducive to density segregationGas current separationPyriteFluidized bed

The invention discloses a dry separation device and method of an ultrasonic vibration microbubble fluidized bed. The dry separation device comprises an air supply system and a fluidized bed body, wherein air enters an air chamber below an air distribution plate through the air supply system; the air passes through the air distribution plate and forms a stable upflow in the fluidized bed body. A material forms a fluidized bed layer under the joint action of the upflow and a vertical component force from an ultrasonic vibration force field, and is separated and layered according to density in a fluidizing process; the layered materials enter a light product collection port and a heavy product collection port respectively under the dividing effect of a discharge baffle at the tail end of the bed layer so as to obtain a light product and a heavy product. According to the invention, the fine-particle pulverized coal of -0.5mm is directly separated without dense medium, and the harmful minerals such as pyrite in coal are removed; compared with existing device, the fluidizing environment is better, the phenomena such as 'agglomeration', 'short circuit' and 'backmixing' adverse to density separation in the bed layer are eliminated, and the density separation of the fine-particle pulverized coal is promoted.

Owner:CHINA UNIV OF MINING & TECH

Density separation system based on light substances and heavy substances in household waste

ActiveCN103785613AEfficient separationImprove fertilizer qualityGas current separationEngineeringAir separation

The invention relates to a density separation system based on light substances and heavy substances in household waste. The density separation system comprises an air separator, a cyclone separator and an induced draft fan. The air separator comprises a heavy substance collecting hopper and an air separation bin, the heavy substance collecting hopper is fixedly installed at the lower end of the air separation bin, an air inlet is formed in the connecting position of the heavy substance collecting hopper and the air separation bin, a heavy substance outlet is formed in the lower end of the heavy substance collecting hopper, a light substance outlet is formed in the upper end of the air separation bin, and a feed port is formed in the inclined lateral wall of the air separation bin. The light substance outlet of the air separator is connected with a tangent material inlet of the cyclone separator through a pipeline and an air outlet of the cyclone separator is connected with the induced draft fan through a pipeline. The density separation system is scientific and reasonable in structural design, stable in running, high in screening efficiency, high in processing speed and capable of effectively separating the light substances from the heavy substances.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

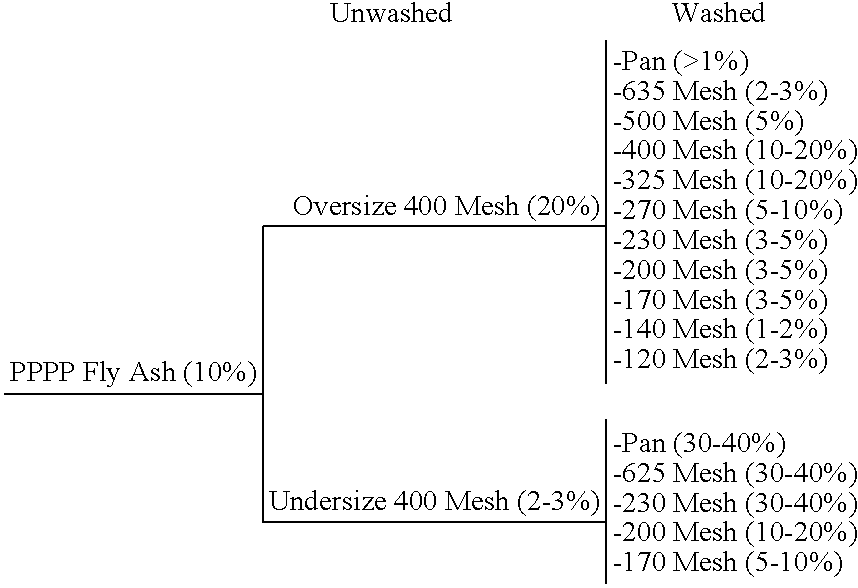

Separation Of Cenospheres From Fly Ash

InactiveUS20080190327A1Increase volumeGas current separationSolid waste managementMicrosphereDensity separation

Methods for increasing the amount of cenospheres in a fly ash sample are disclosed. The cenospheres are obtained in a dry state by using air as the “fluid” media for separation. In one version, the invention is a two step process, that is, screen by size followed by density separation such as in a fluidizing vertical column by density. In another version of the invention, the separation by density is followed by screening by size. Additional cycles can improve purity as defined by concentration of cenospheres.

Owner:WISCONSIN ELECTRIC POWER

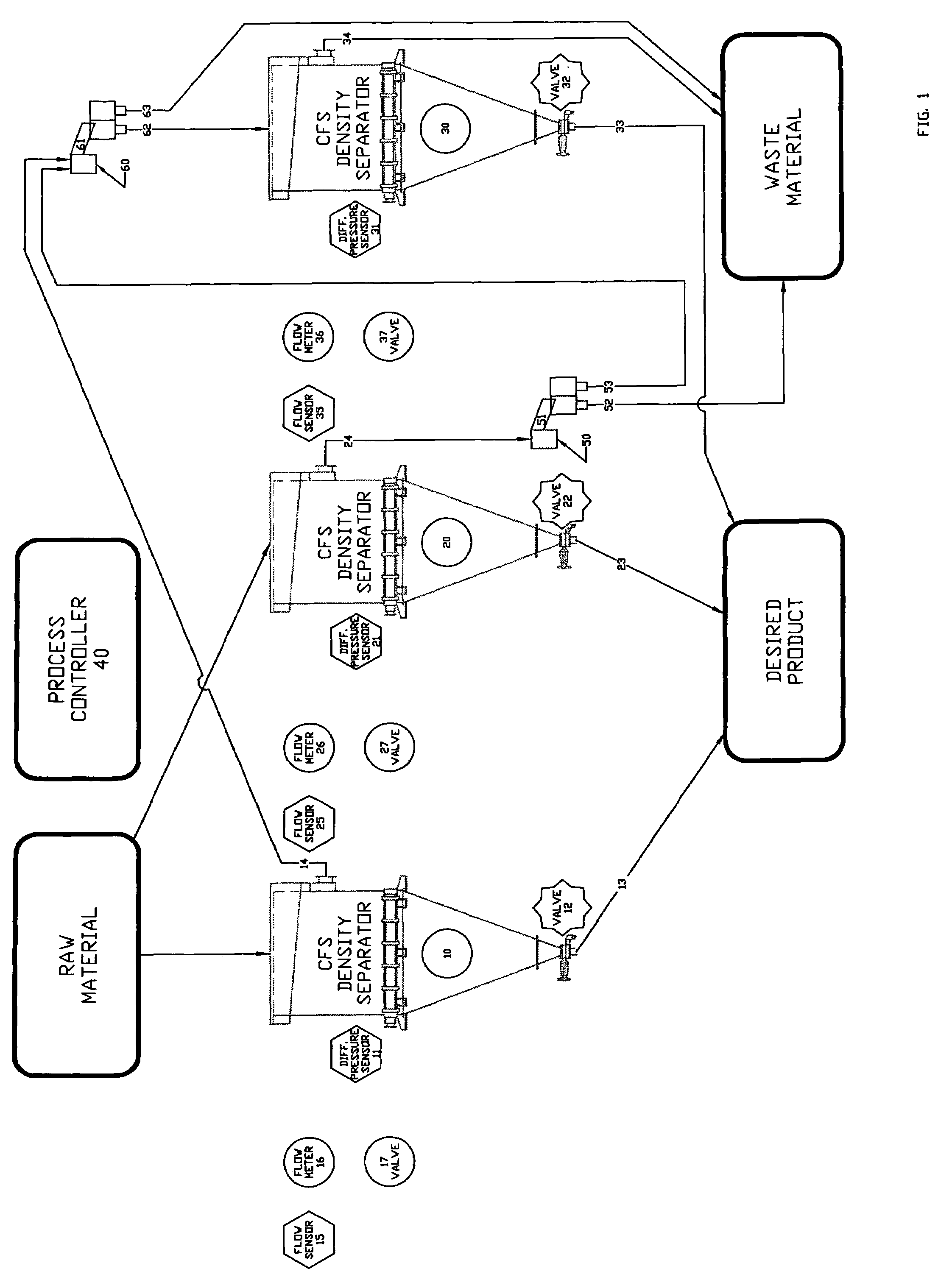

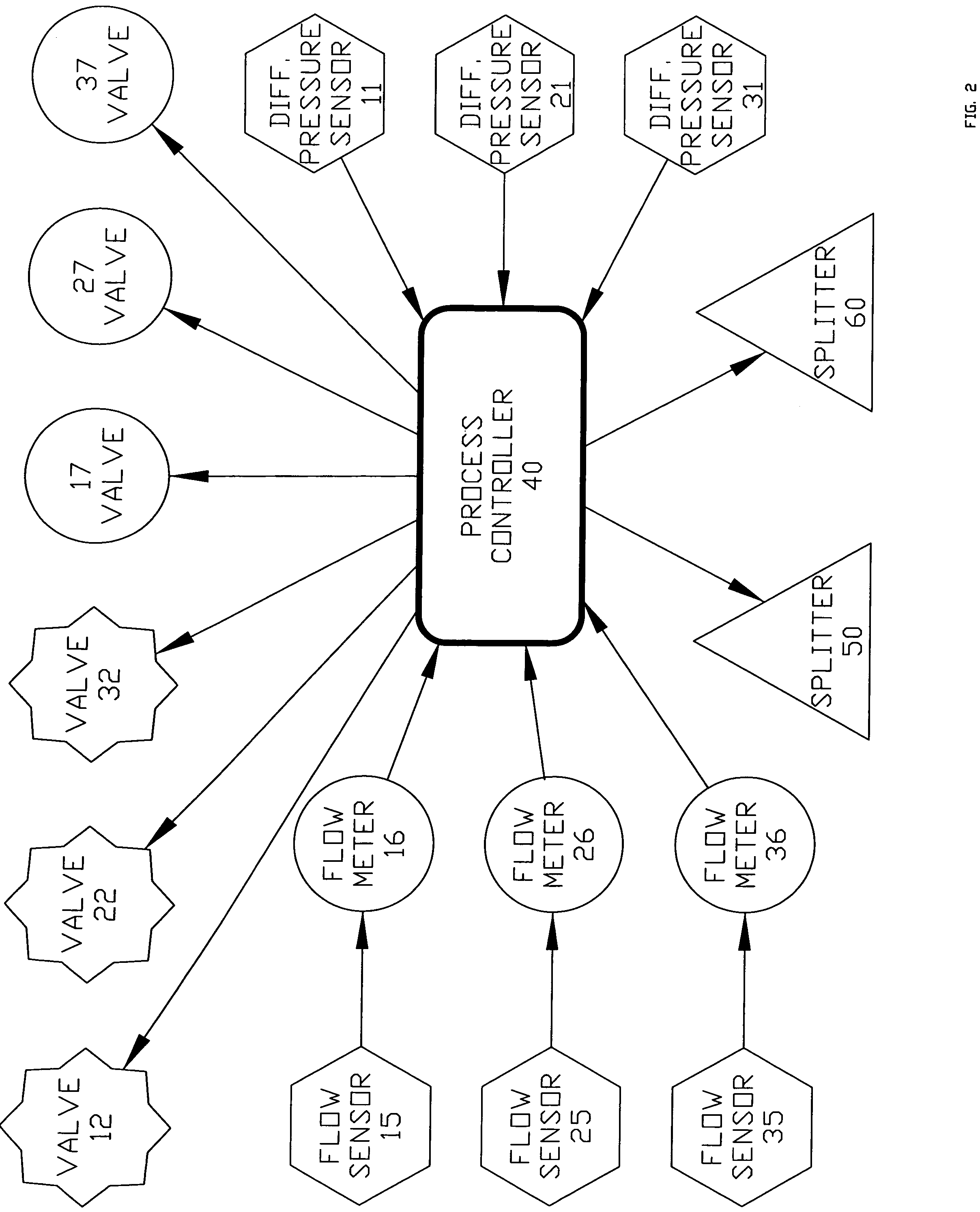

Apparatus and method for sorting and recombining minerals into a desired mixture

A method and apparatus is employed to create a mixture having a desired composition. A raw material is separated in a pair of density separators into constituent parts. Those parts are then recombined in a desired fashion using a pair of splitters to create an intermediate mixture and delivered to a third density separator. The third density separator processes the intermediate mixture to create a final mixture having the desired composition.

Owner:HACKING JR EARL L +1

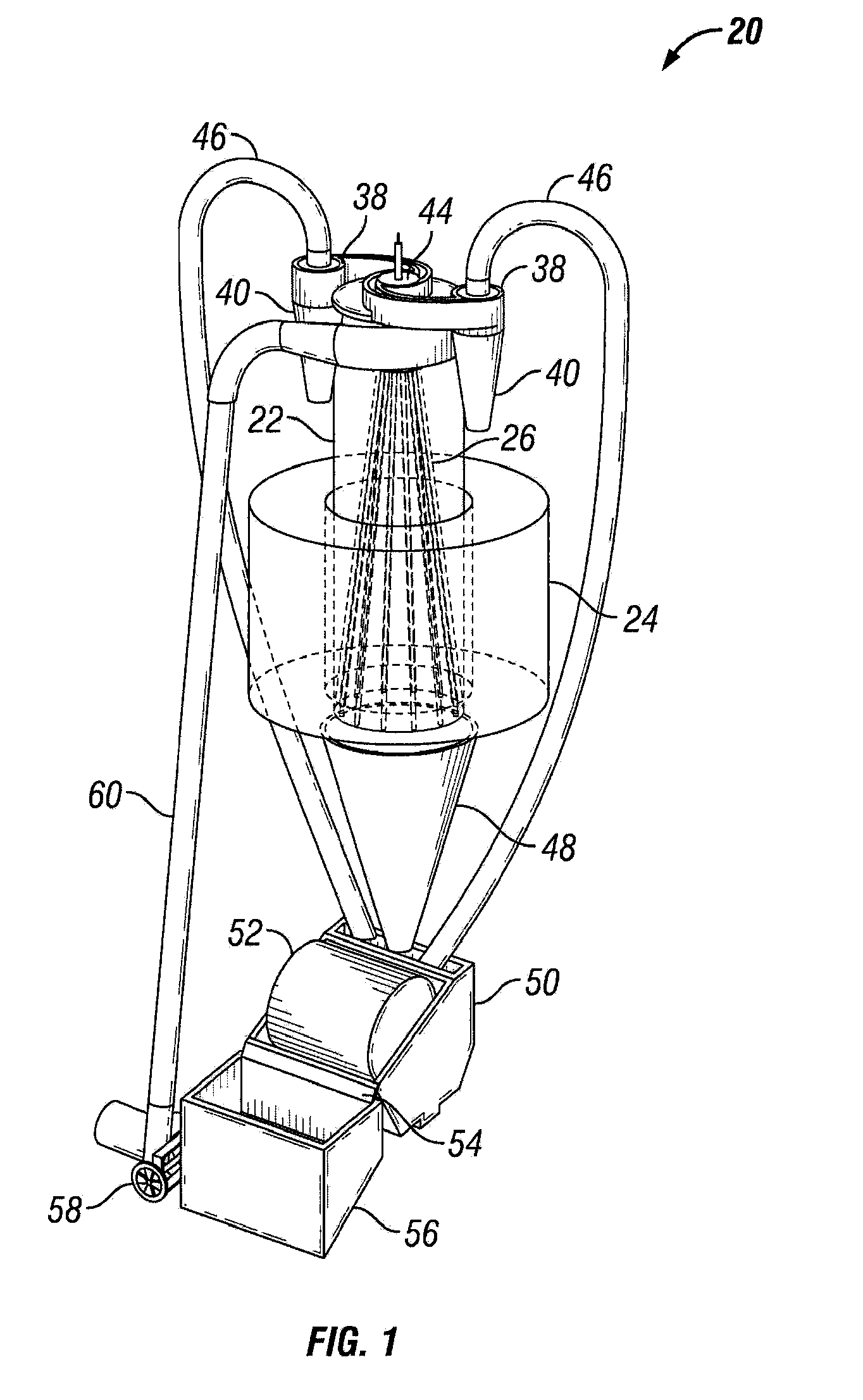

Thin film tube reactor with rotating reservoir

InactiveUS7875248B1Minimize turbulenceSemi-permeable membranesGaseous chemical processesEngineeringVolumetric Mass Density

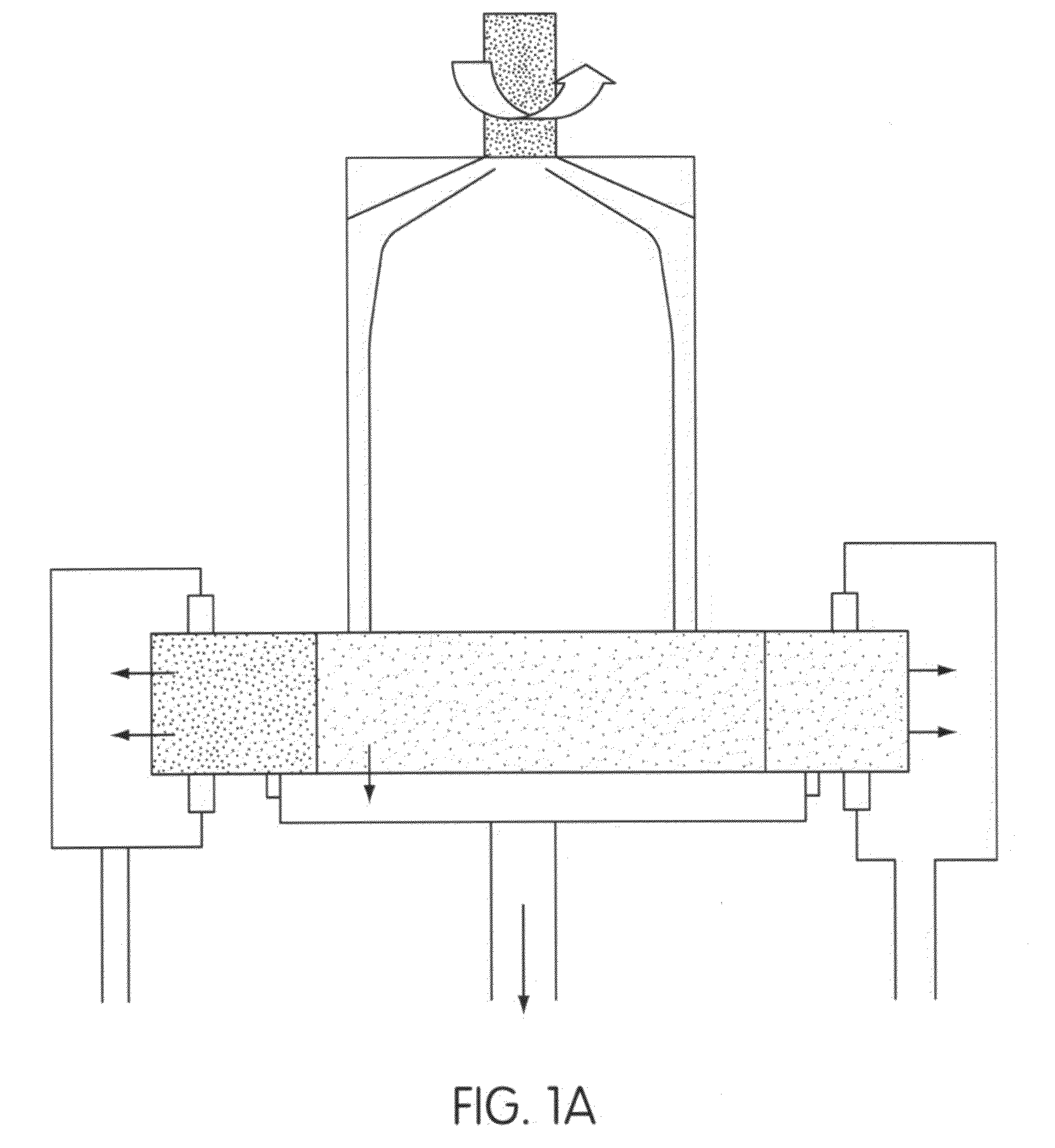

A tube reactor having a substantially tubular body portion including a conical section, an entry port, an opposing exit port, and an axis extending between the ports through the body portion. The tubular body portion being rotatable about the axis. At least one reactant can be fed into the tubular body portion and directed toward the conical section. An inner surface of the tubular body portion receives the reactants from the conical section, and processes the reactants. An insert may be positioned within the tubular body portion to further process the reactants along the inner surface. A rotating reservoir having a damper can be coupled to the rotating tubular body portion. The damper receives the processed reactants from the inner surface of the tubular body portion, and guides the processed reactants into the rotating reservoir to minimize turbulence. The rotating reservoir then separates the processed reactants by density.

Owner:CLARKSON UNIVERSITY

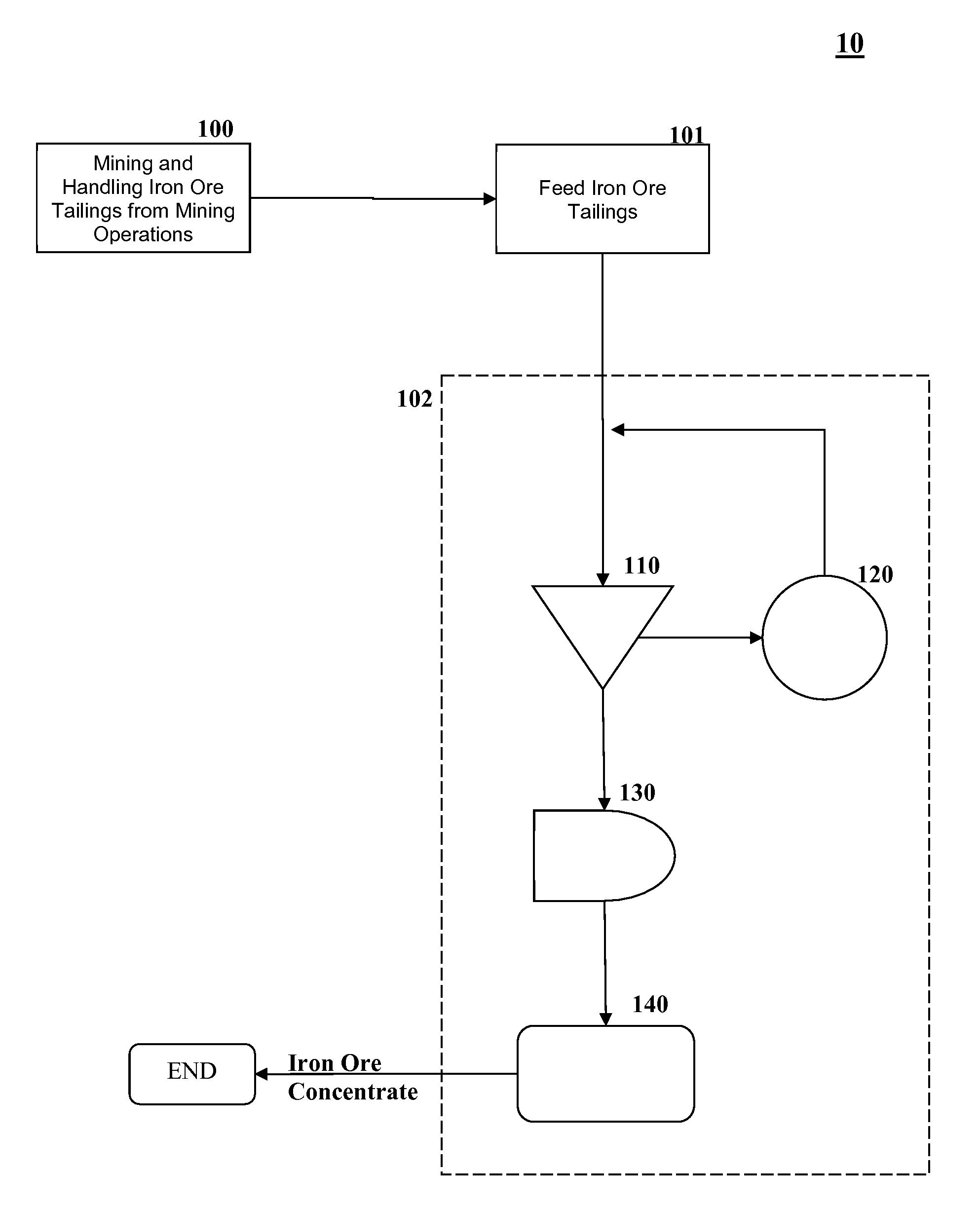

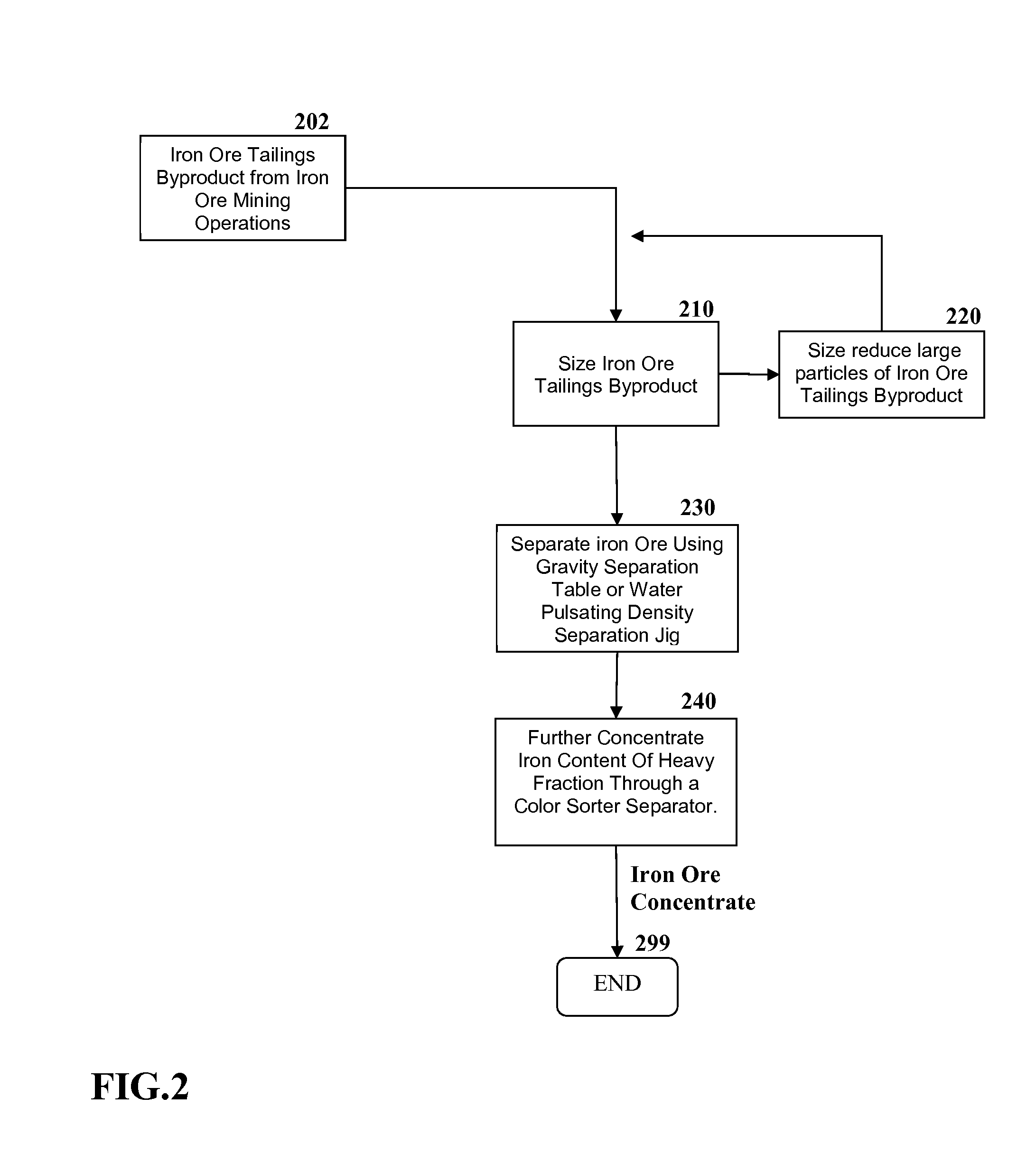

System and Method For Iron Ore Reclaiming From Tailings Of Iron Ore Mining Operations

A method for processing low grade iron ores includes a step of receiving iron ore tailings. The method further includes separating the iron ore tailings into two or more groups based on sizes of the iron ore tailings. Each group includes a respective portion of the iron ore tailings. The method also includes processing the portion of the iron ore tailings in at least one group using a density separation process to generate iron ore concentrate.

Owner:VHIP

Method for recovering valuable drilling mud materials using a binary fluid

This invention relates to a system and process for recovering and recycling valuable target recycle materials such lost circulation material and weighting agents from drilling fluid used in hydrocarbon drilling operations. The system and process includes use of a binary fluid that is separate from the drilling fluid and has a designed density that allows separation of the valuable target recycle materials from drill cuttings. The solids are separated from the drilling fluid in a primary separation step and then mixed with the binary fluid in a density separation or enhanced mass separation device. The binary fluid density allows the separation device to distinguish the target recycle material from drilling solids and recycles the target material to the drilling operations for re-use in drilling fluid. The binary fluid is recovered and refreshed to maintain a generally continuous process of targeted recycling.

Owner:CONOCOPHILLIPS CO

Device for the separation of waste materials in accordance with their densities

InactiveUS20080121574A1Eliminating excessively large and smallSievingScreeningSludgeVolumetric Mass Density

A device for the separation of waste materials in accordance with their densities is provided and includes a vat which is fillable with a fluid for the separation of detritus by means of floatation and decantation. Conveyer belts are provided for the removal of the supernatant and decanted materials. A vibrating sieve is provided for the pre-separation of debris prior to introduction into the vat. The vibrating sieve extracts large materials and small materials which tend to produce silt in the vat. Means are provided for the removal of the decanted sludge.

Owner:TORRES JES S SANCHEZ

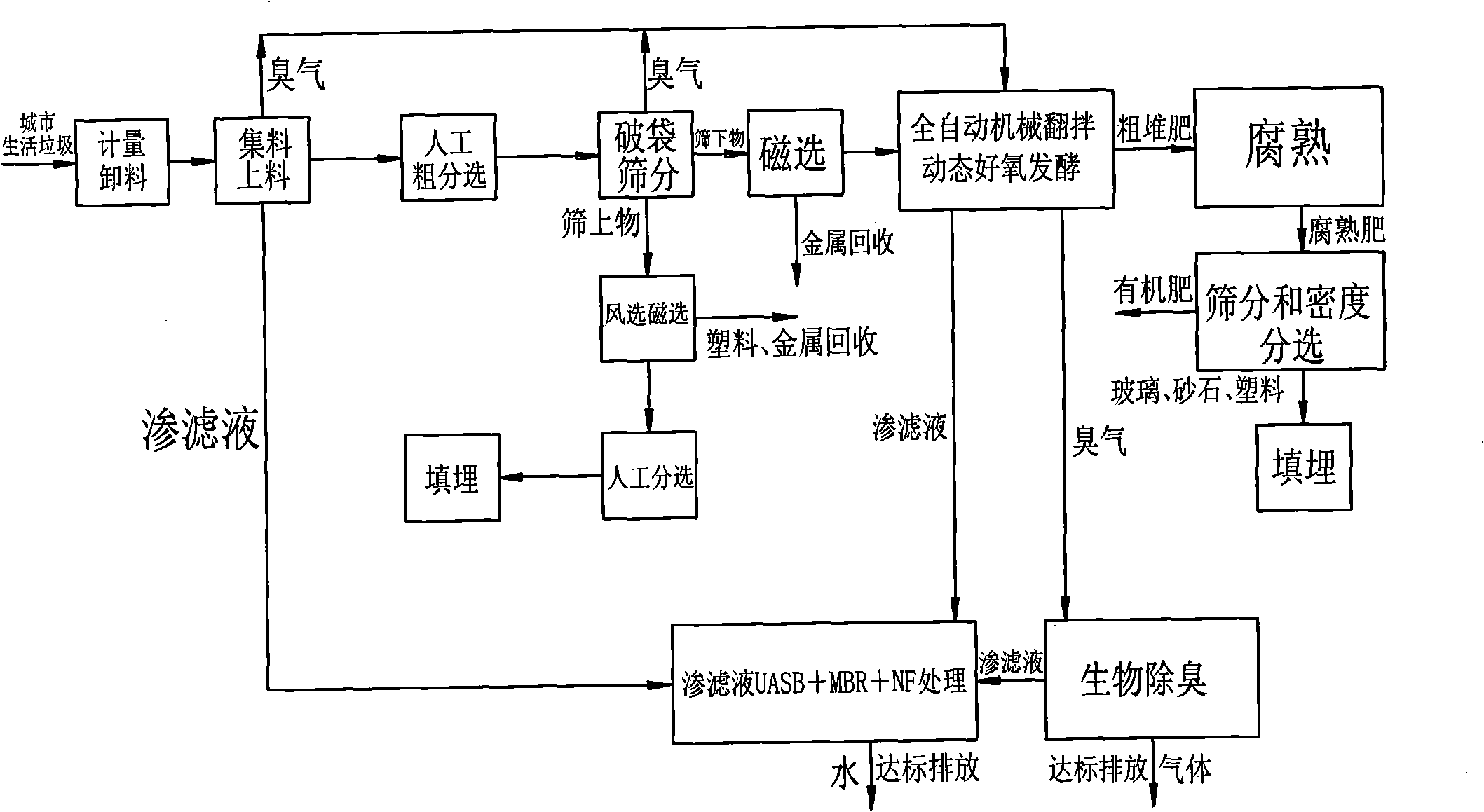

Method for treating municipal domestic wastes

InactiveCN101973793AIncrease heap heightThe overall impact is smallClimate change adaptationOrganic fertilisersFermentationImpurity

Owner:SOUND ENVIRONMENTAL RESOURCES

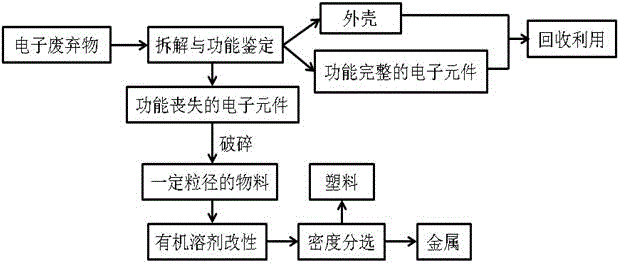

Method for separating plastics from metals in electronic waste

ActiveCN106111673AImprove separation rateImprove use valueSolid waste disposalPlastic recyclingKeroseneEngineering

The present invention provides a method for separating plastics from metals in an electronic waste. The method comprises the following steps: (1) disassembling an electronic waste, performing functional detection on electronic elements in the electronic waste, and directly recovering electronic elements that are still functional; (2) breaking electronic elements that are already nonfunctional from step (1) to obtain materials having a grain size of 0.02 to 0.4 mm; (3) soaking the broken materials from step (2) in diesel oil and / or kerosene for 10-30 min; and (4) putting the soaked materials from step (3) in CaCl2 solution for density separation to separate plastics from metals. The method provided by the present invention allows a significant increase in the rate of separation of the plastics from metals and an increase in comprehensive use value of the electronic waste, and is simple in operation, environmentally friendly, and highly practical.

Owner:朱建裕 +7

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com