Method for separating plastics from metals in electronic waste

A technology for electronic waste and materials, applied in the direction of electronic waste recycling, solid waste removal, wet separation, etc., can solve the problems of inability to completely separate plastics and metals, environmental hazards, etc., to increase comprehensive utilization value, environmental friendliness, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

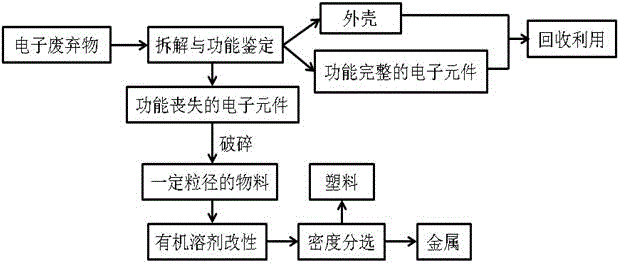

[0020] The method described in this embodiment mainly proceeds according to the following steps:

[0021] (1) Manually disassemble electronic waste from a certain source, recycle the shell, conduct functional testing on its electronic components, and directly recycle electronic components that have not lost their functions;

[0022] (2) Cut the disassembled and disabled electronic components in (1) into fragments with a diameter of < 3cm and mix them, then crush the fragments with an ore crusher to a powder with a particle size of about 0.1 mm and mix them evenly;

[0023] (3) The material crushed in step (2) was modified with diesel oil for 10 minutes;

[0024] (4) Density sort the material modified in step (3) in a 2 L container, and the container contains 1 L of CaCl with a density of 1.30g / ml 2 Sorting liquid, 50 g of electronic waste material, and use a mechanical stirrer to fully stir it, and then let it stand until the plastic is fully floating and the metal is fully s...

Embodiment 2

[0027] The method described in this embodiment mainly proceeds according to the following steps:

[0028] (1) Manually disassemble electronic waste from a certain source, recycle the shell, conduct functional testing on its electronic components, and directly recycle electronic components that have not lost their functions;

[0029] (2) Cut the disassembled electronic components that have lost their function in (1) into fragments with a diameter of < 3cm and mix them, and then use an ore crusher to crush the fragments into powders with a particle size of about 0.1 mm and mix them evenly;

[0030] (3) The material crushed in step (2) was modified with diesel oil for 20 minutes;

[0031] (4) Density sort the material modified in step (3) in a 2 L container, and the container contains 1 L of CaCl with a density of 1.30g / ml 2 Sorting liquid, 75 g of electronic waste material, and use a mechanical stirrer to fully stir it, and then let it stand until the plastic is fully floating ...

Embodiment 3

[0034] The method described in this embodiment mainly proceeds according to the following steps:

[0035] (1) Manually disassemble electronic waste from a certain source, recycle the shell, conduct functional testing on its electronic components, and directly recycle electronic components that have not lost their functions;

[0036] (2) Cut the disassembled and disabled electronic components in (1) into fragments with a diameter of < 3cm and mix them, then crush the fragments with an ore crusher to a powder with a particle size of about 0.1 mm and mix them evenly;

[0037] (3) The material obtained by crushing in step (2) is modified with diesel oil for 30 minutes;

[0038] (4) Density sort the material modified in step (3) in a 2 L container, and the container contains 1 L of CaCl with a density of 1.30g / ml 2 Sorting liquid, 75 g of electronic waste material, and use a mechanical stirrer to fully stir it, and then let it stand until the plastic is fully floating and the meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com