Washable photo-catalytic super-hydrophobic cotton fabric, and preparation and application thereof

A photocatalytic and water-resistant technology, applied in chemical/physical processes, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve high energy consumption, poor durability, cumbersome preparation process, etc. problems, to achieve the effect of expanding the application field, improving the micro-roughness, and high response to visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation method of washable photocatalytic superhydrophobic cotton fabric, comprises the steps:

[0043] (1) Add acetone to the round bottom flask until the volume of acetone accounts for one-third of the volume of the round bottom flask, place the cotton fabric in the Soxhlet extractor, and connect the Soxhlet extractor to the above round bottom filled with acetone Connect the flask, then heat it in a water bath at 80°C for 4.5 hours, take it out and dry it;

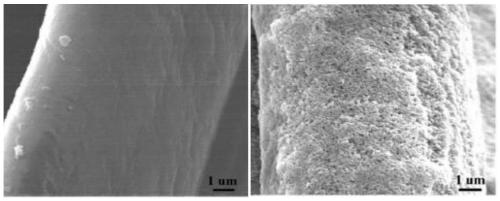

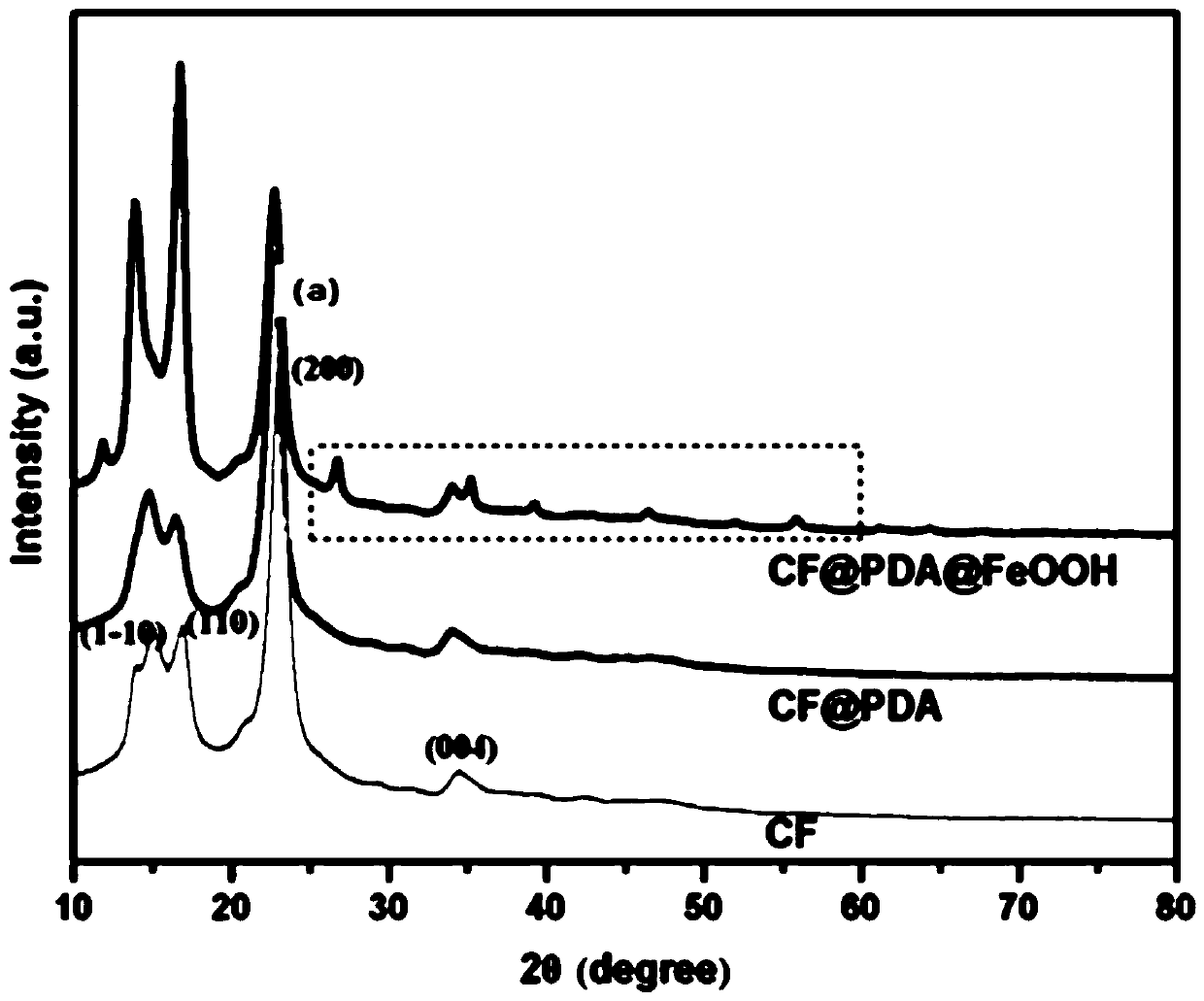

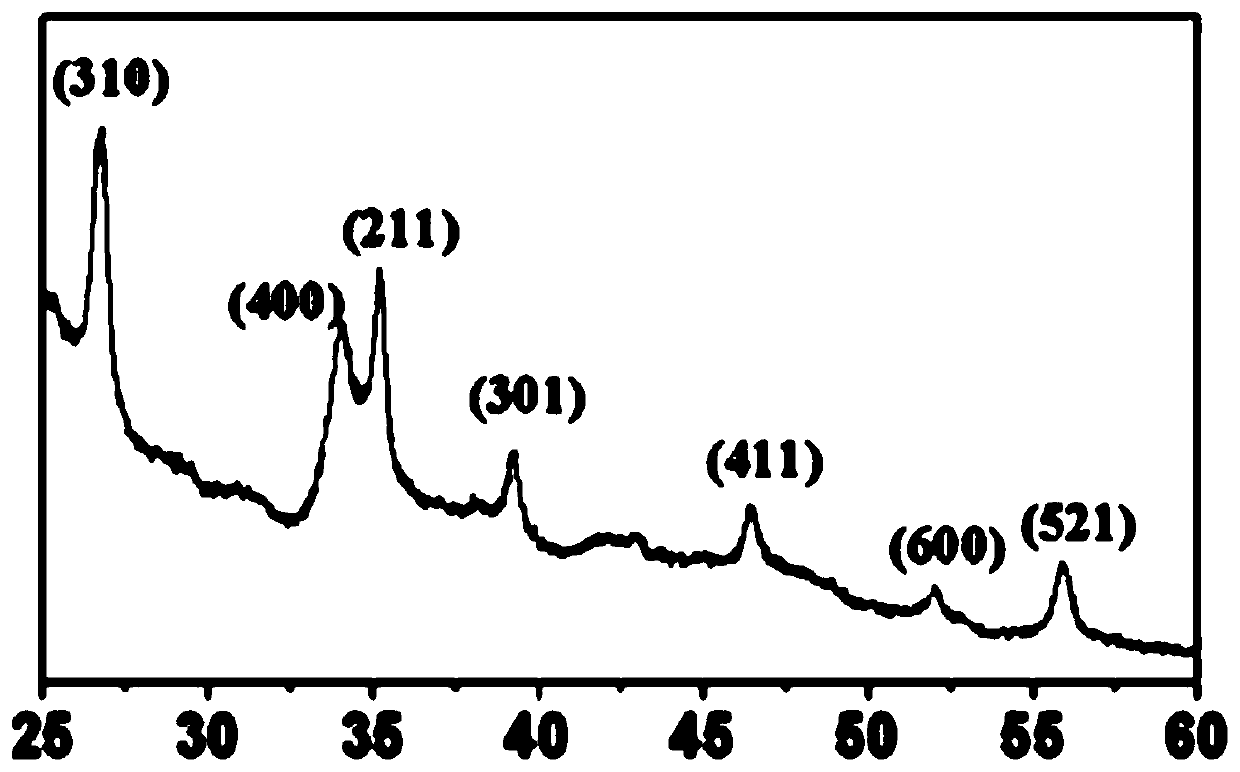

[0044] (2) Adjust the pH value of 100mL Tris-HCl buffer solution to 8.5, then add 0.1g dopamine to the buffer solution, and then add the cotton fabric after impurity removal, place the system in a water bath at 20°C for 20h, take out and dry .

[0045] (3) Mix ferric nitrate solution with a concentration of 0.055 mol / L and hydrochloric acid with a concentration of 0.005 mol / L, then immerse the dopamine-modified cotton fabric, treat it in a water bath at 50°C for 8 hours, and dry it.

[0046](4) Ult...

Embodiment 2

[0048] A kind of preparation method of washable photocatalytic superhydrophobic cotton fabric, comprises the steps:

[0049] (1) Add acetone to the round bottom flask until the volume of acetone accounts for one-third of the volume of the round bottom flask, place the cotton fabric in the Soxhlet extractor, and connect the Soxhlet extractor to the above round bottom filled with acetone Connect the flask, then heat it in a water bath at 100°C for 5.5 hours, take it out and dry it;

[0050] (2) Adjust the pH value of 100mL Tris-HCl buffer solution to 8.5, then add 0.2g dopamine to the buffer solution, then add the cotton fabric after impurity removal, place the system in a 30°C water bath for 17h, take out and dry .

[0051] (3) Mix ferric sulfate solution with a concentration of 0.074mol / L and hydrochloric acid with a concentration of 0.008mol / L, then immerse the dopamine-modified cotton fabric, treat it in a water bath at 80°C for 5 hours, and dry it.

[0052] (4) Ultrasonic...

Embodiment 3

[0054] A kind of preparation method of washable photocatalytic superhydrophobic cotton fabric, comprises the steps:

[0055] (1) Add acetone to the round bottom flask until the volume of acetone accounts for one-third of the volume of the round bottom flask, place the cotton fabric in the Soxhlet extractor, and connect the Soxhlet extractor to the above round bottom filled with acetone Connect the flask, then heat it in a water bath at 85°C for 5 hours, take it out and dry it;

[0056] (2) Adjust the pH value of 100mL Tris-HCl buffer solution to 8.5, then add 0.15g of dopamine to the buffer solution, then add the cotton fabric after impurity removal, place the system in a water bath at 40°C for 20h, take out and dry .

[0057] (3) Mix ferric chloride hexahydrate solution with a mass fraction of 20 mg / mL and hydrochloric acid with a concentration of 0.01 mol / L, then immerse the dopamine-modified cotton fabric, treat it in a water bath at 60°C for 10 h, and dry it.

[0058] (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com