A solid-liquid-gas three-phase split rumen simulation continuous fermentation system and method

A fermentation system and fermentation method technology, applied in the field of continuous fermentation system, can solve problems such as occupation of manpower and heavy work, and achieve the effects of high degree of automation, high separation rate and automatic monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

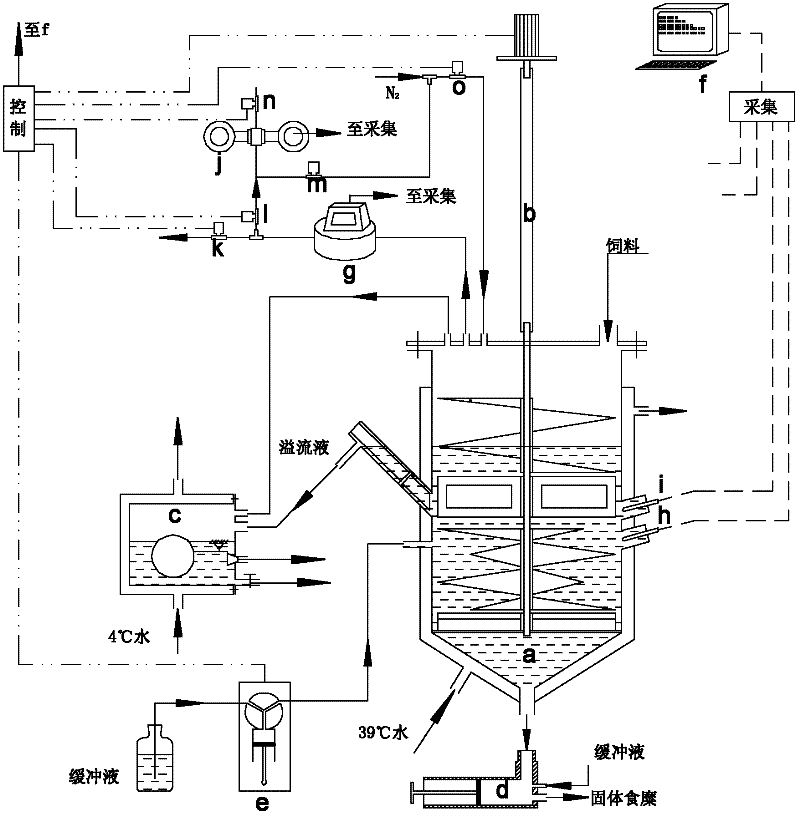

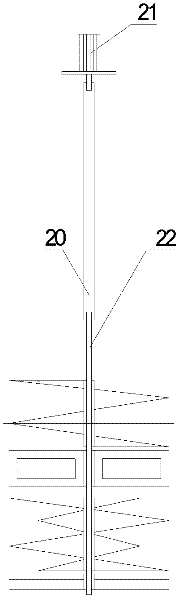

[0054] figure 1 It is a schematic structural diagram of a solid-liquid-gas three-phase split rumen simulation continuous fermentation system of the present invention. As shown in the figure, the fermentation system includes: fermentation tank a, stirring device b, liquid discharge valve c, solid discharge device d, syringe pump e, computer f, CH 4 , CO 2 Detector j.

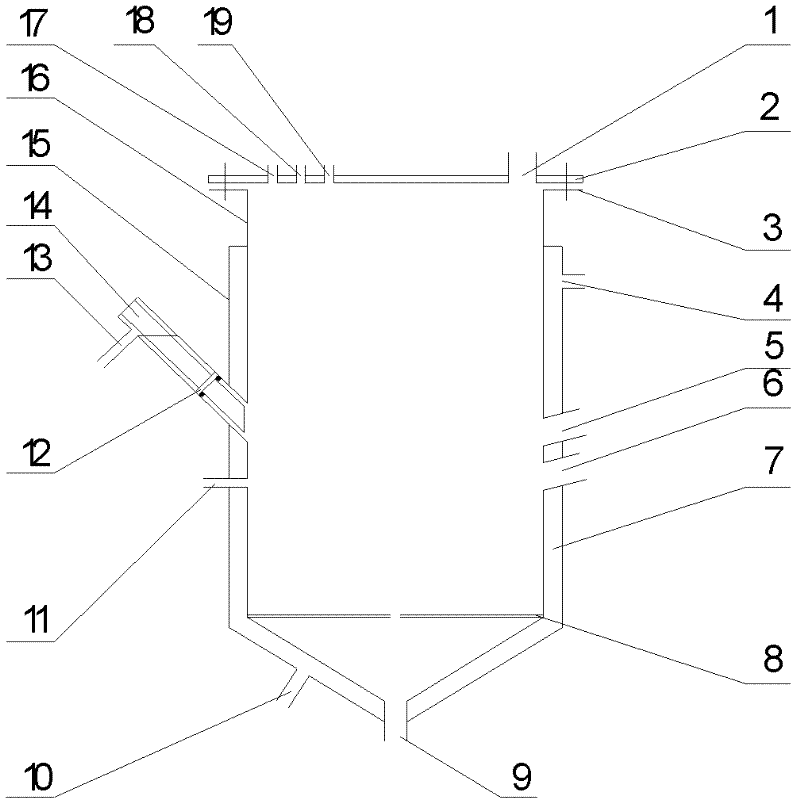

[0055] The fermenter body a is the core reaction device of the entire fermentation system, and other devices are used to coordinate the reaction work in the fermenter body a. figure 2 Schematic diagram of the structure of the fermentation tank. see figure 1 , figure 2 , the fermenter body a is composed of a tank body 3 and a fermenter cover 2 that are closed and sealed. The outer wall of the fermenter body a adopts a double-layer structure, and an insulating water layer 7 is sandw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com