Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

180 results about "Defined process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are two schools of thought about what a defined process is.

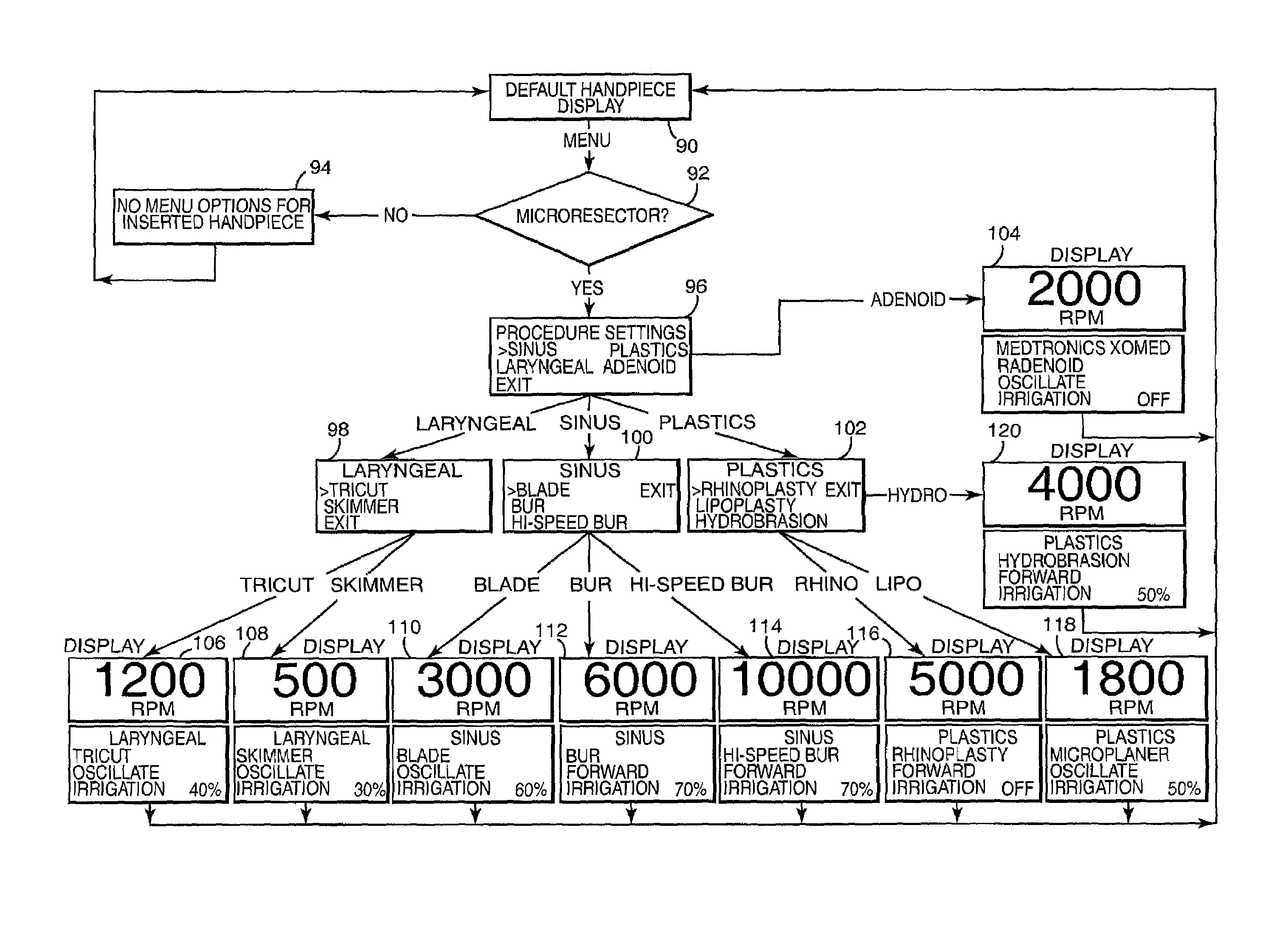

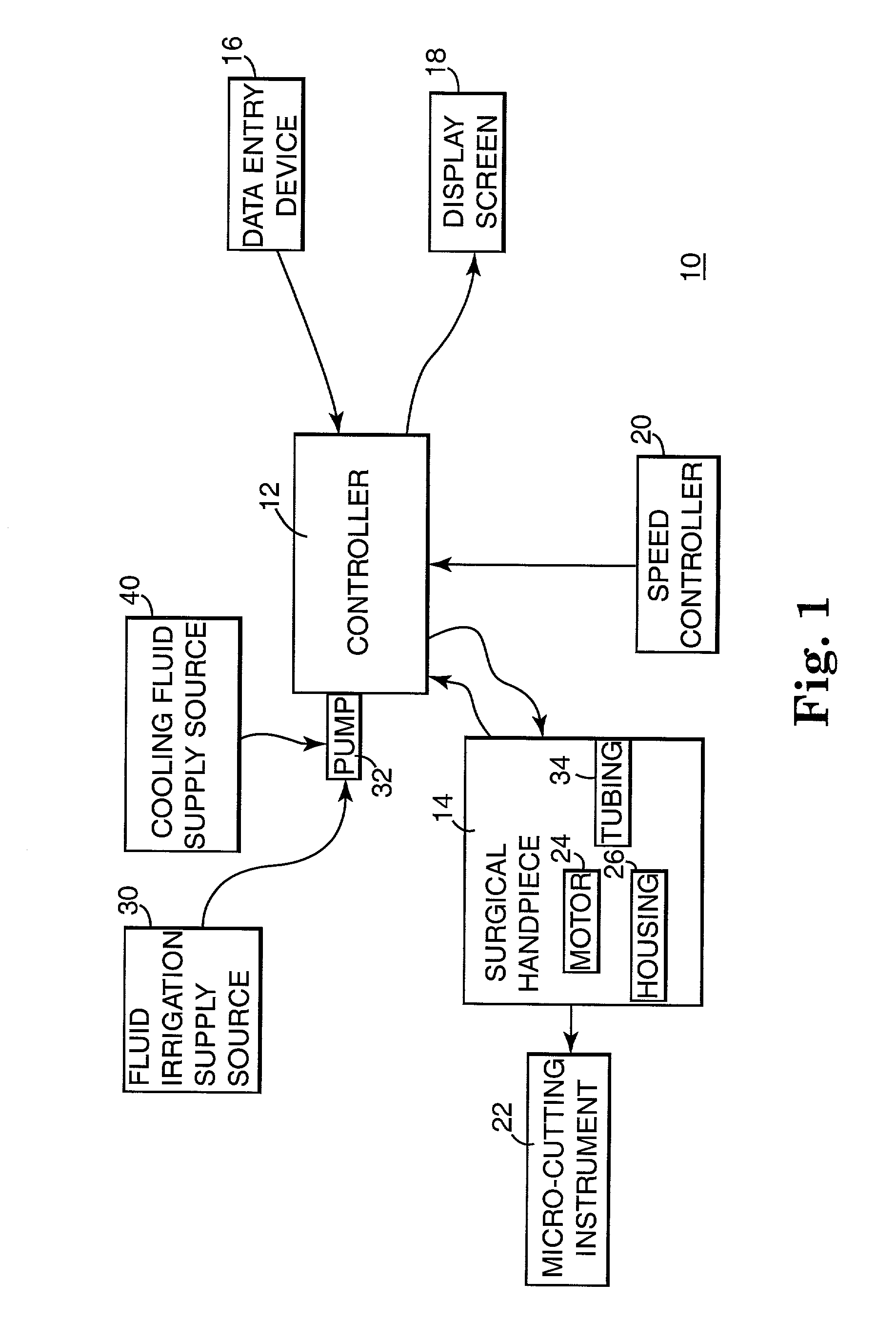

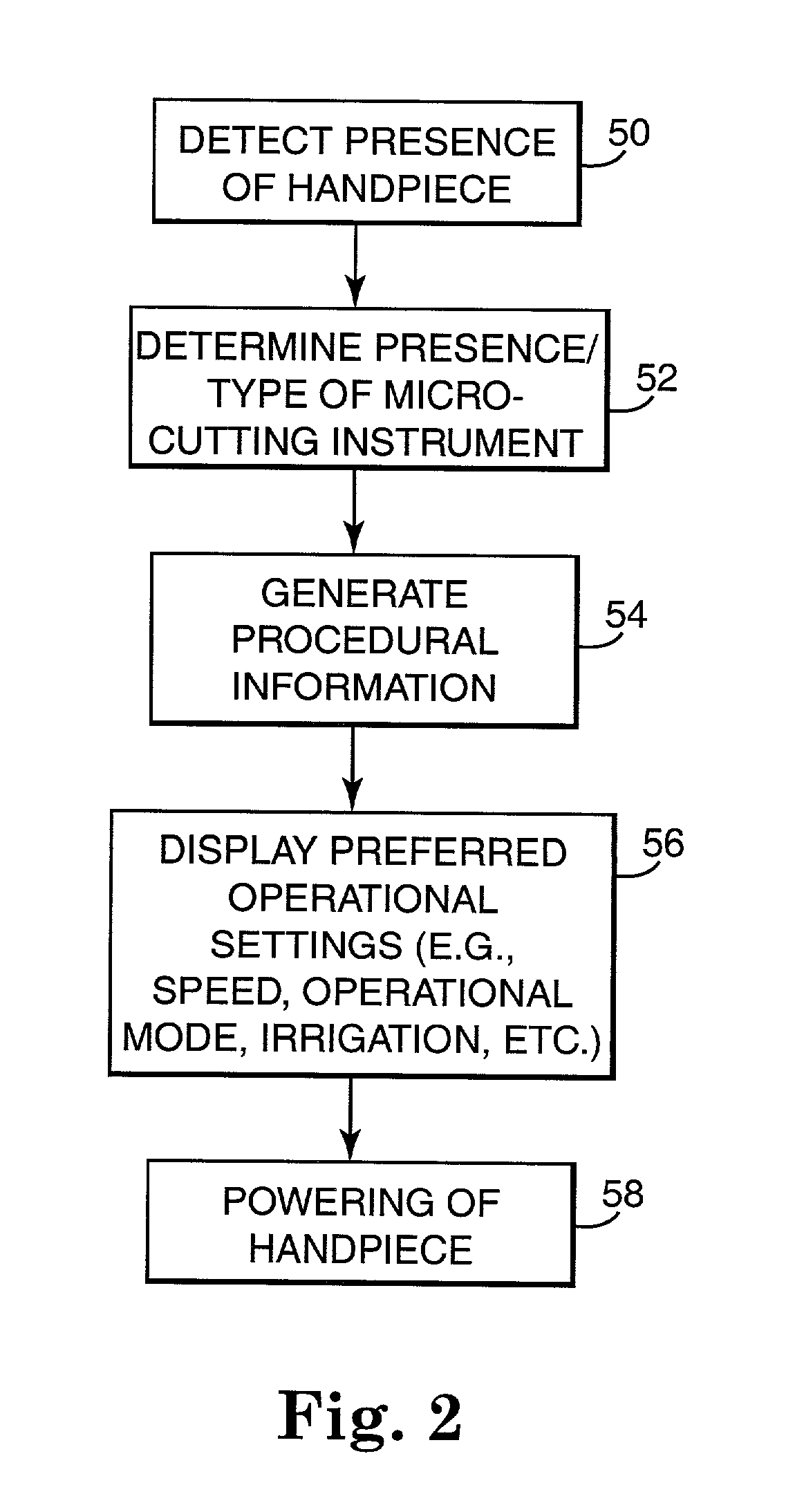

Motor control system for a surgical handpiece

A system and method for powered surgical handpiece capable of powering various micro-cutting instruments is described. The system is comprised of a controller adapted for controlling / interfacing with a powered surgical handpiece based upon user-defined procedural information. A data entry device is used for entering the user-defined procedural information used by the controller for configuring and operating the motor control system.

Owner:MEDTRONIC INC

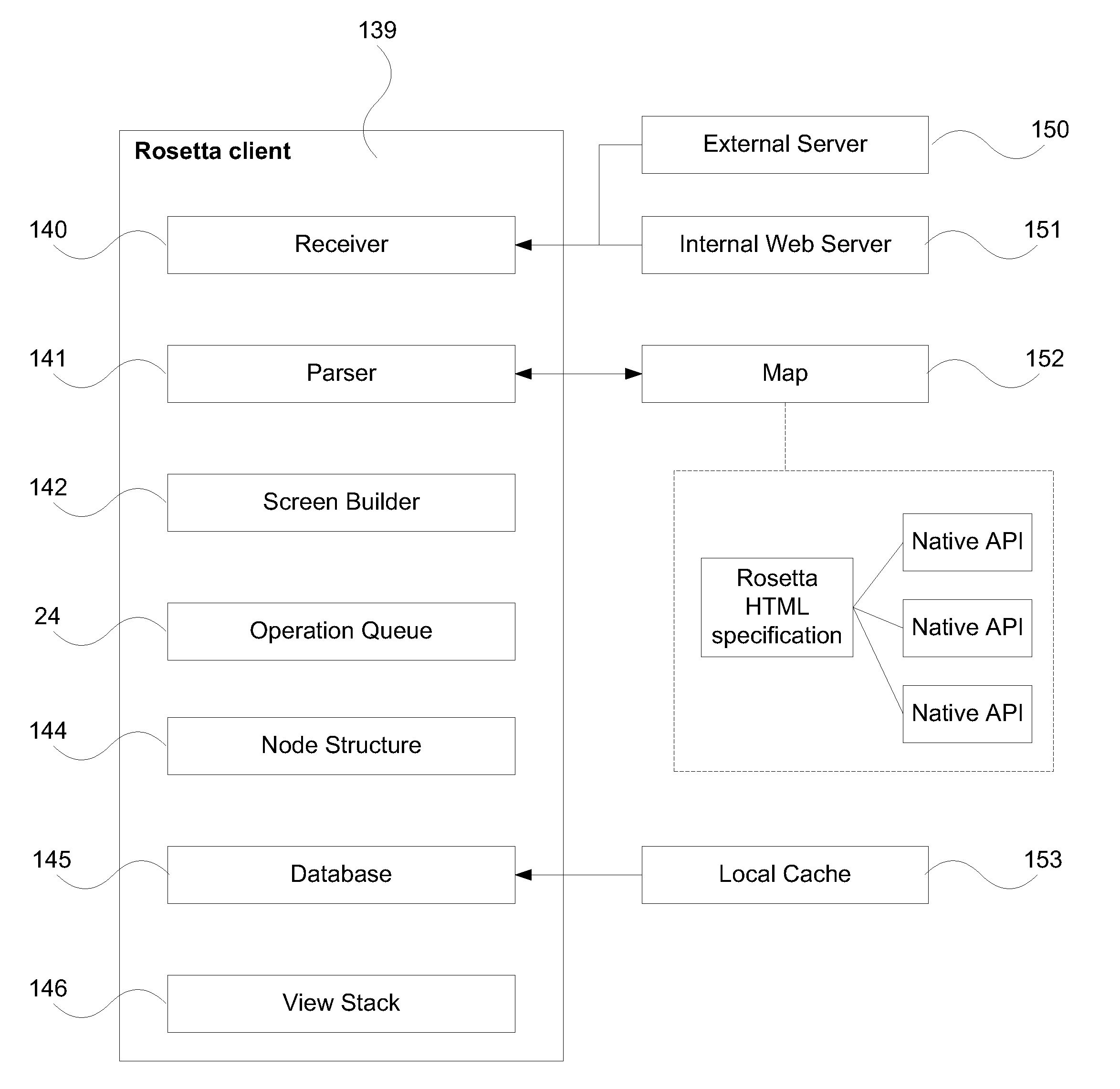

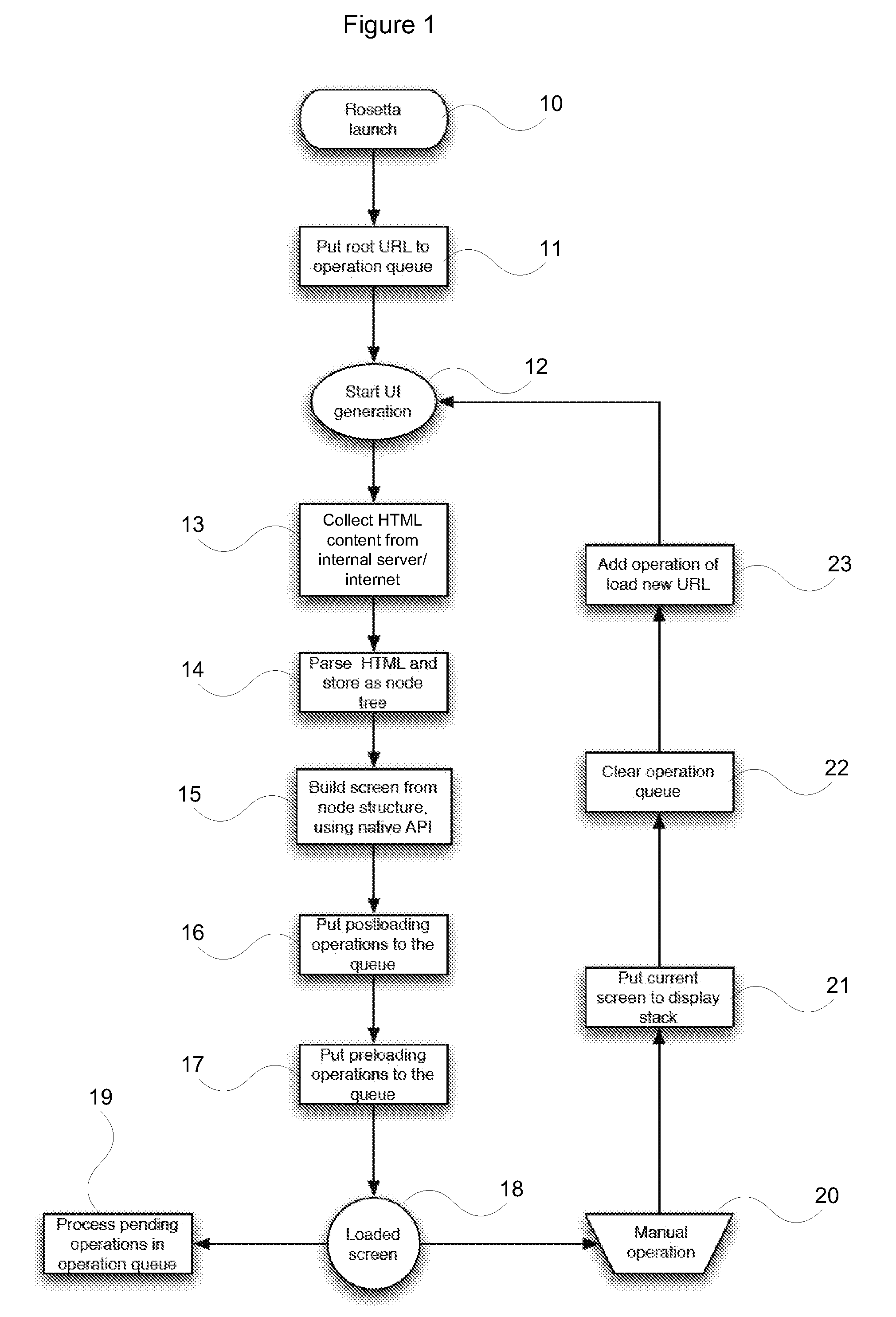

Method for creating a native application for mobile communications device in real-time

ActiveUS20090241135A1Interprogram communicationExecution for user interfacesApplication programming interfaceClient-side

A software client (139) for executing an application on a mobile communications device, the software client (139) comprising: a receiver module (140) to receive a file containing mark up language to define the application; a parser (141) to parse the file in order to generate the application during run time to create a native application for the mobile communications device; a screen builder (142) to generate UI components for the native application by mapping procedures defined by the mark-up Language to native application programming interface (API) calls of the operating platform of the mobile communications device.

Owner:WILLFLOW +1

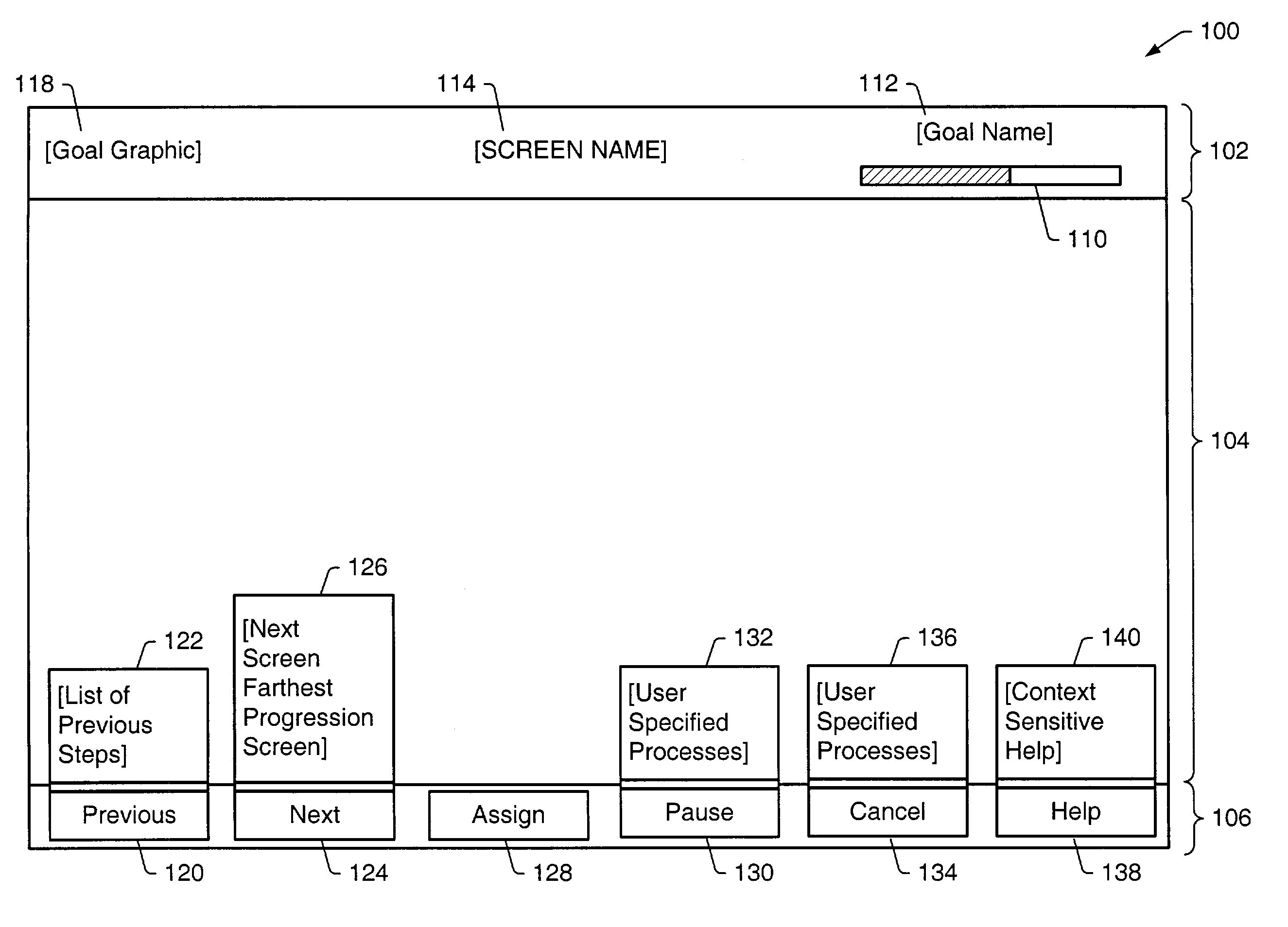

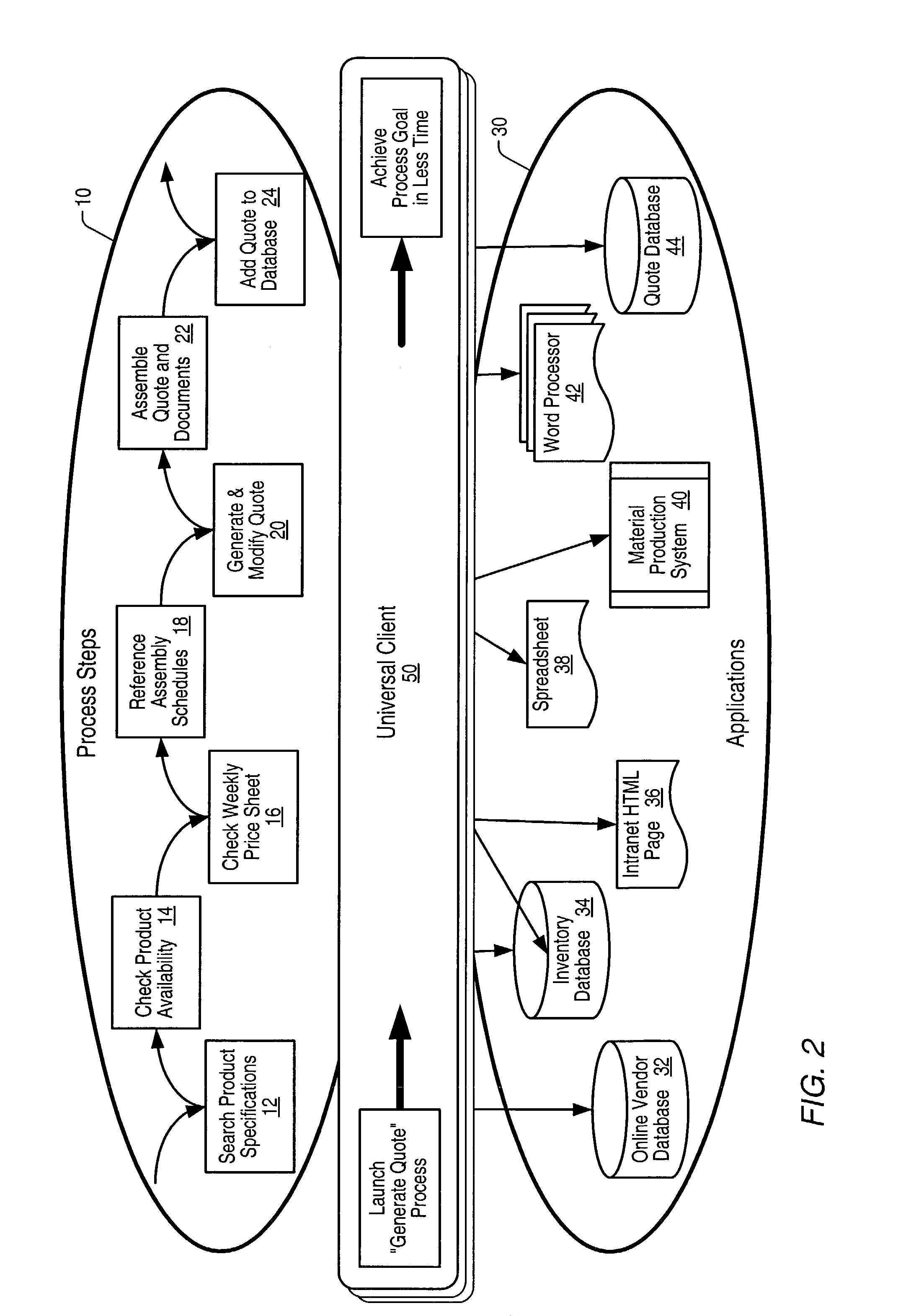

Enterprise workflow screen based navigational process tool system and method

InactiveUS6990636B2Improve developmentLess expenseCathode-ray tube indicatorsOffice automationClient server systemsApplication software

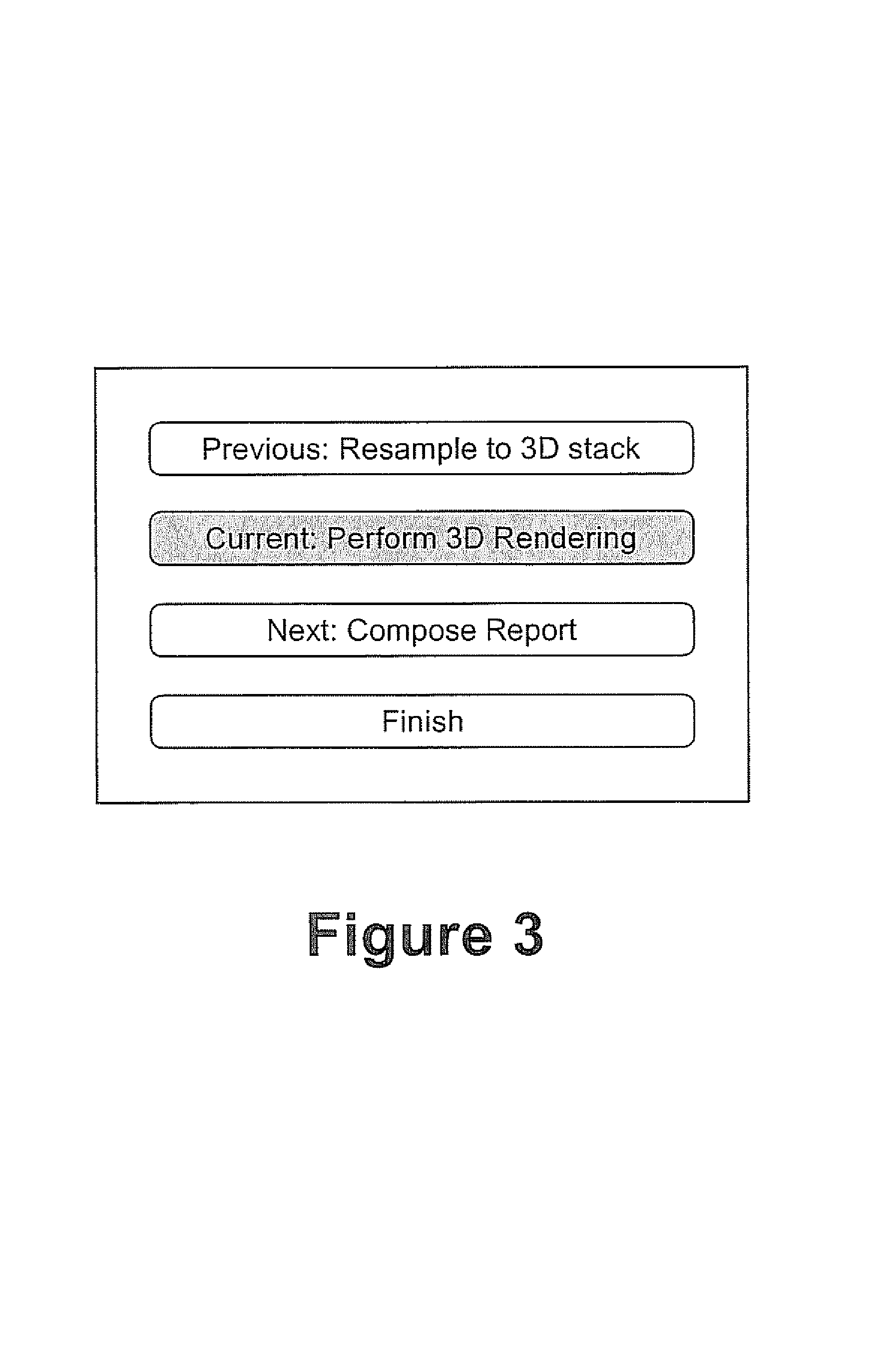

Computer processes for carrying out almost any process may be defined as a series of steps using a plurality of standardized user-interface screens. These standardized interface screens may be linked together in predetermined orders to implement on a client computer activities for which the standardized screens are appropriate to accomplish a pre-defined process. Any number of computer processes may be developed and deployed using the standard interfaces. The computer process automatically takes a user from screen to screen, prompting the user to review or provide information or take appropriate action. Processes may be represented using metadata. Metadata may provide data to a screen rendering process running on a user's workstation with details on how to render one of a plurality of standard screens in a manner which is specific to a particular process. Metadata may be provided to define the steps of the process for enabling navigational capabilities. Metadata may stored in a database and communicated by a process server to a client computer, which acts as a user's workstation. This client-server system architecture allows maintenance of the computer processes in a central location and remote management of their use within a network. Furthermore, any number of application-specific computer processes may be made available and distributed to users without detailed programs for those processes having to be stored at each user workstation. Furthermore, basic interface functions with legacy databases and back-end systems may be provided to each user workstation in a network through the server system.

Owner:IBM CORP

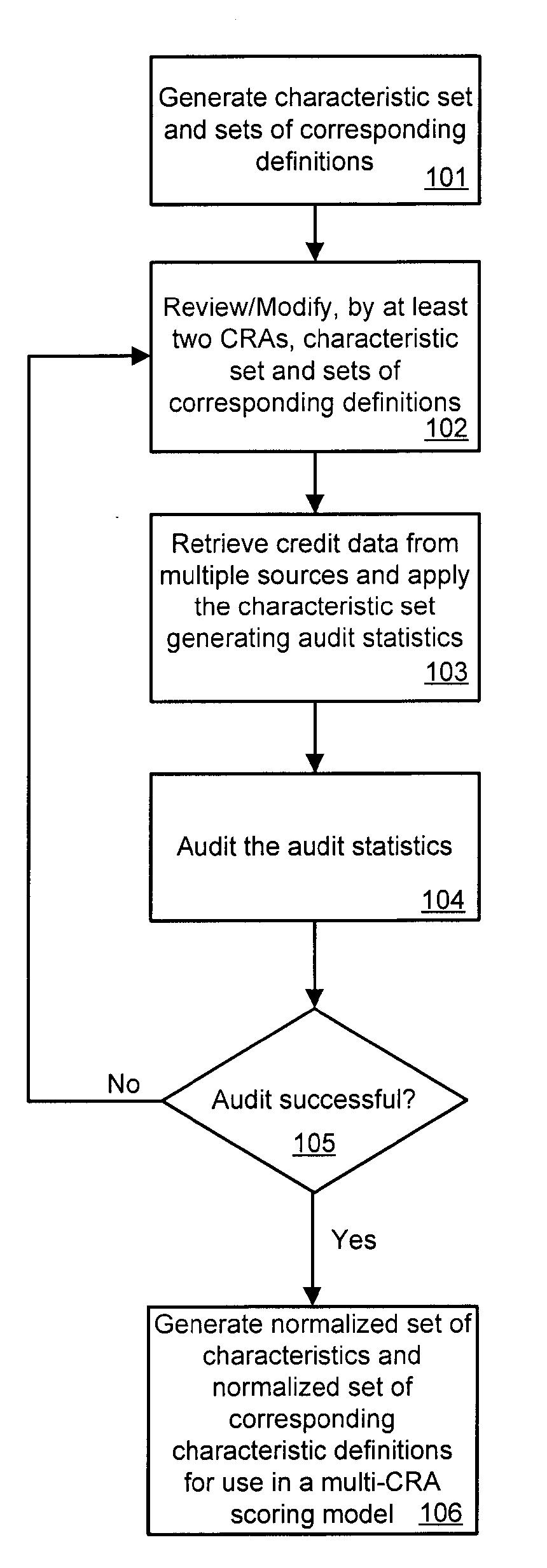

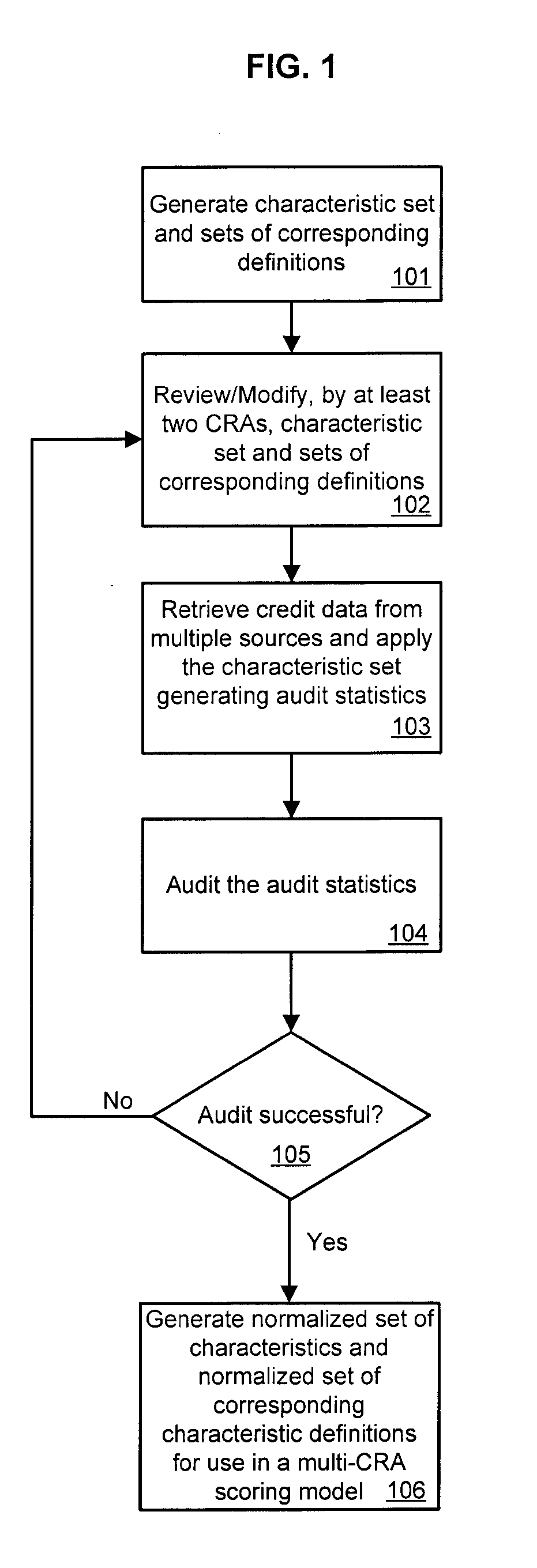

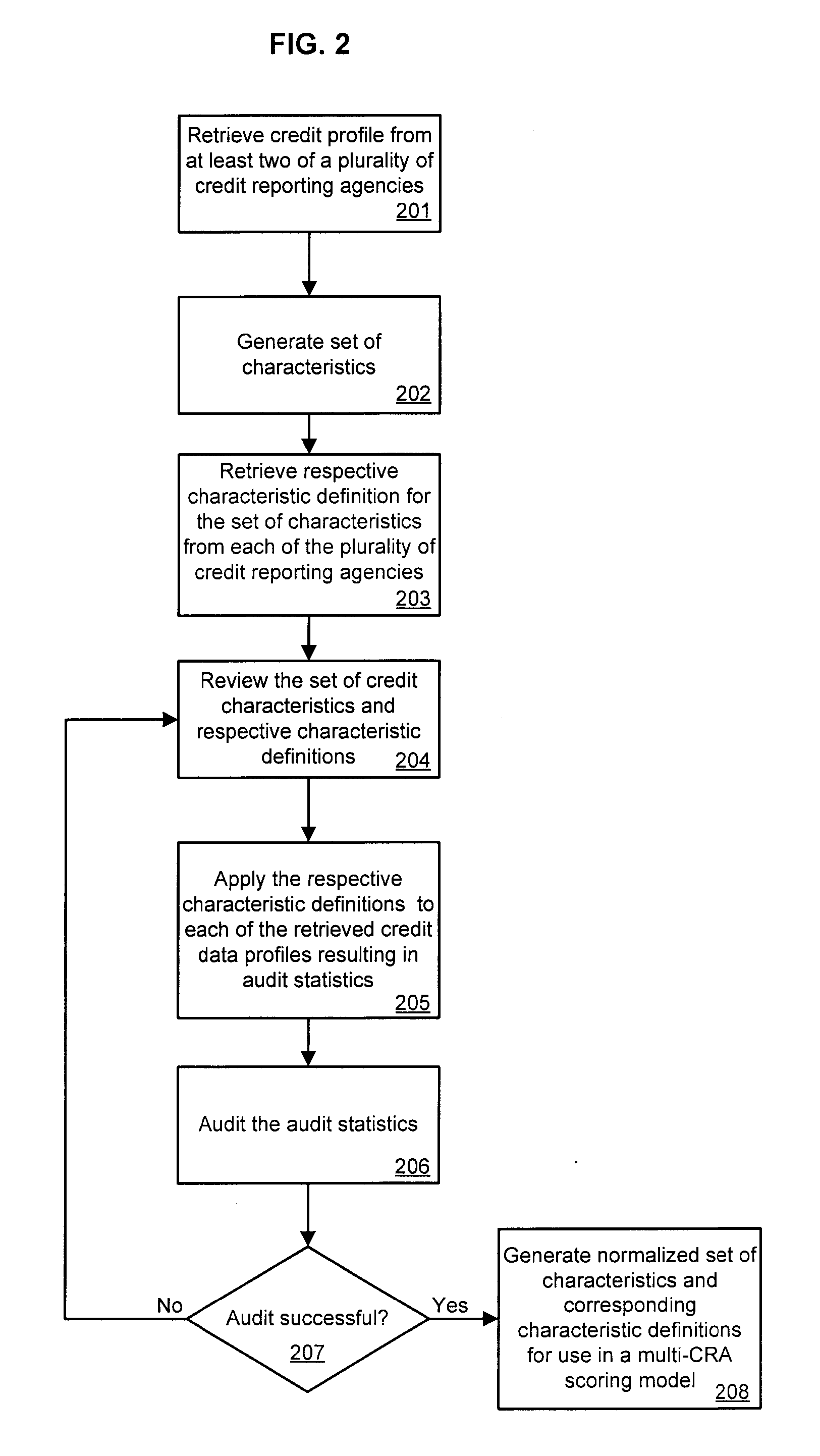

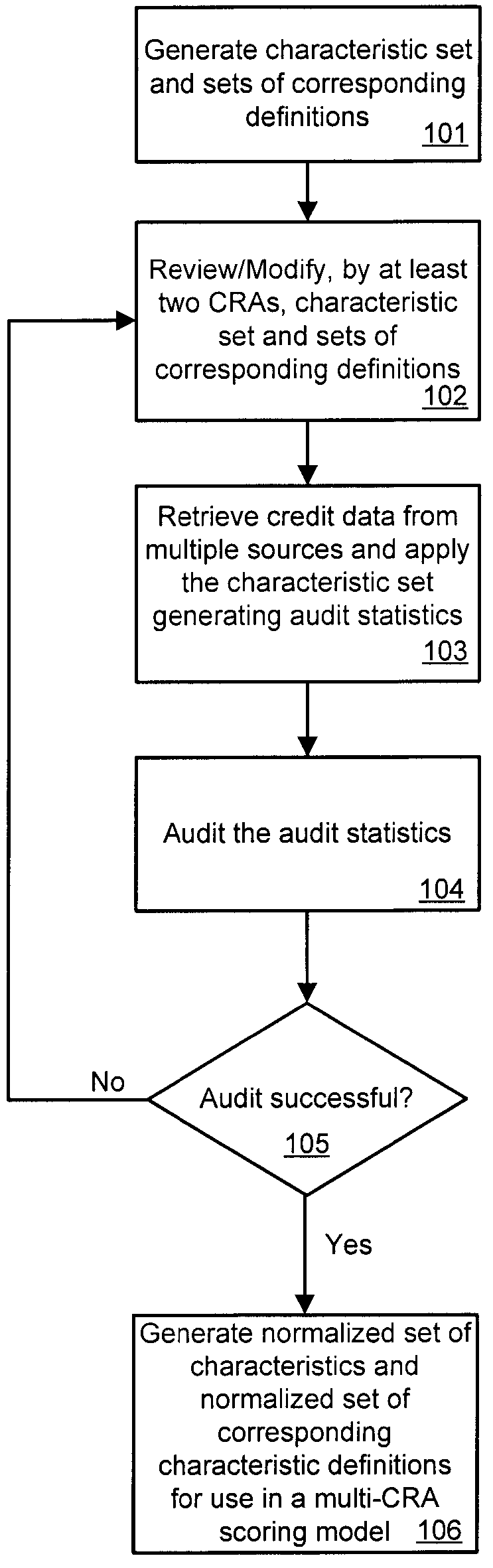

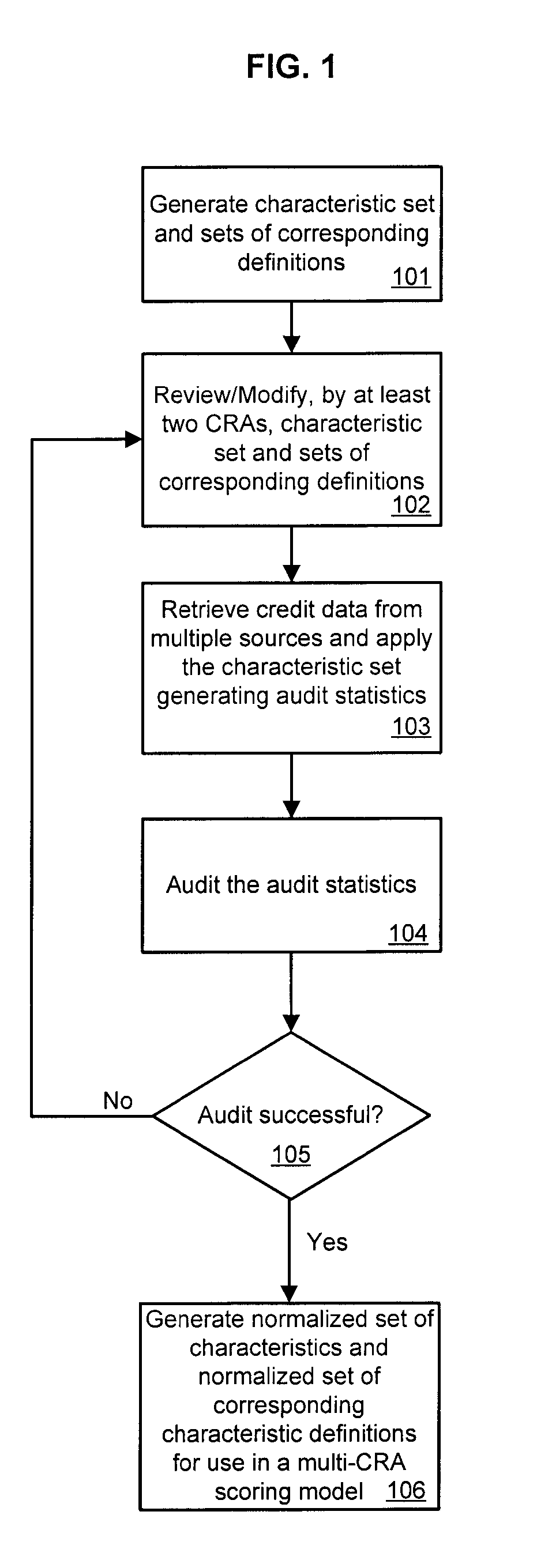

Methods and Systems for Characteristic Leveling

ActiveUS20070282736A1Small investmentMore confidenceMarket predictionsFinanceCanonicalizationData science

Owner:VANTAGESCORE SOLUTIONS

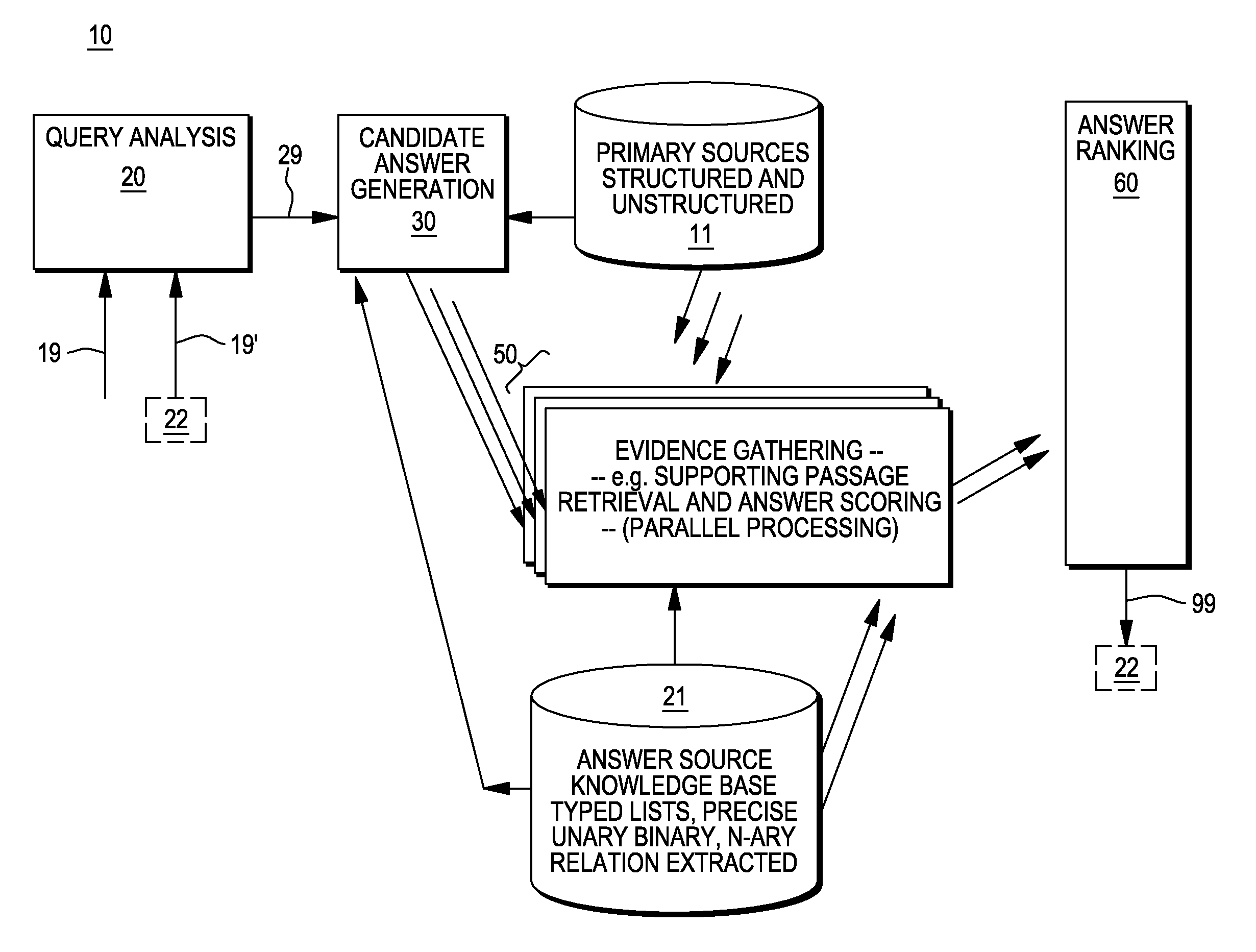

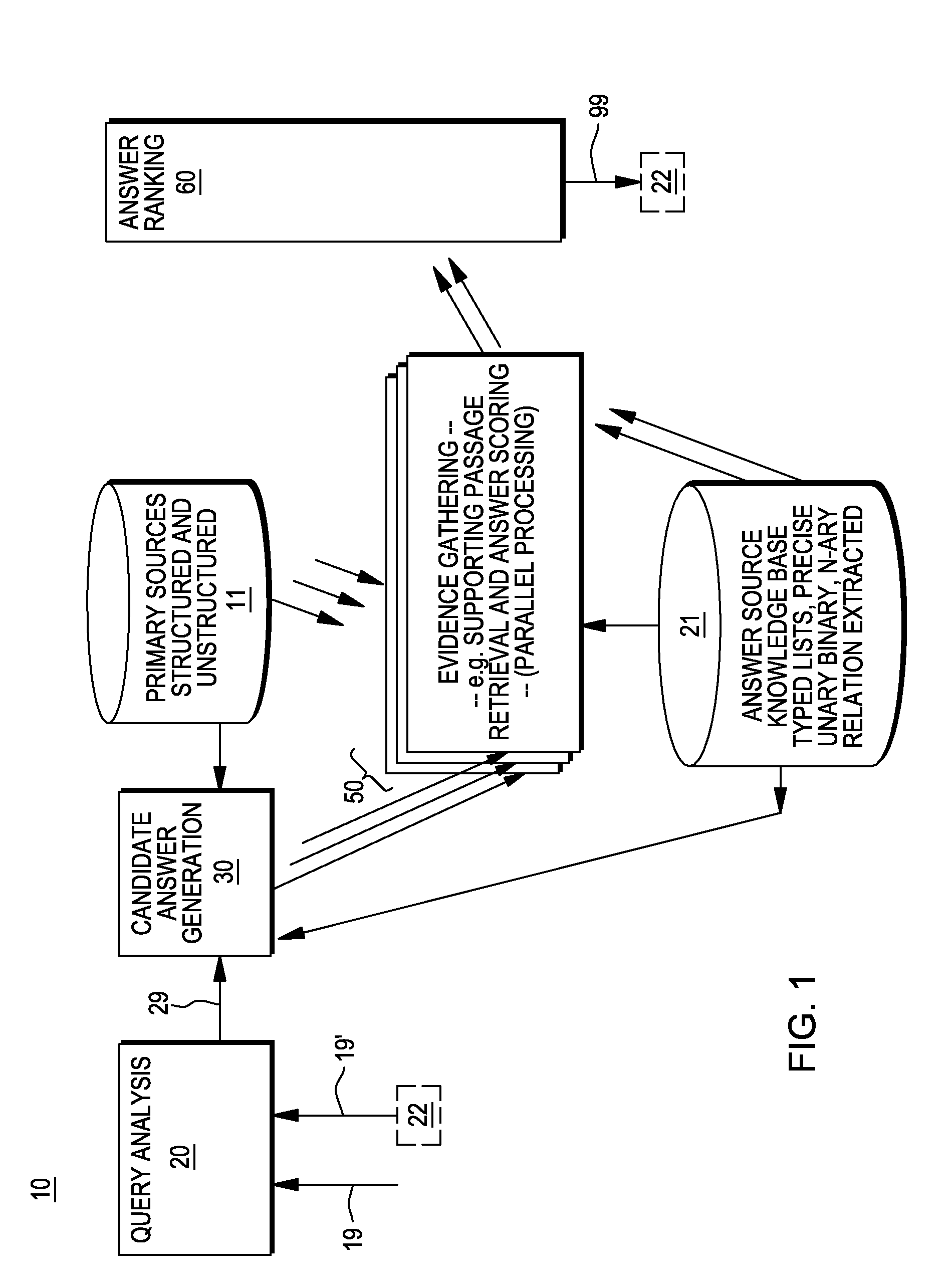

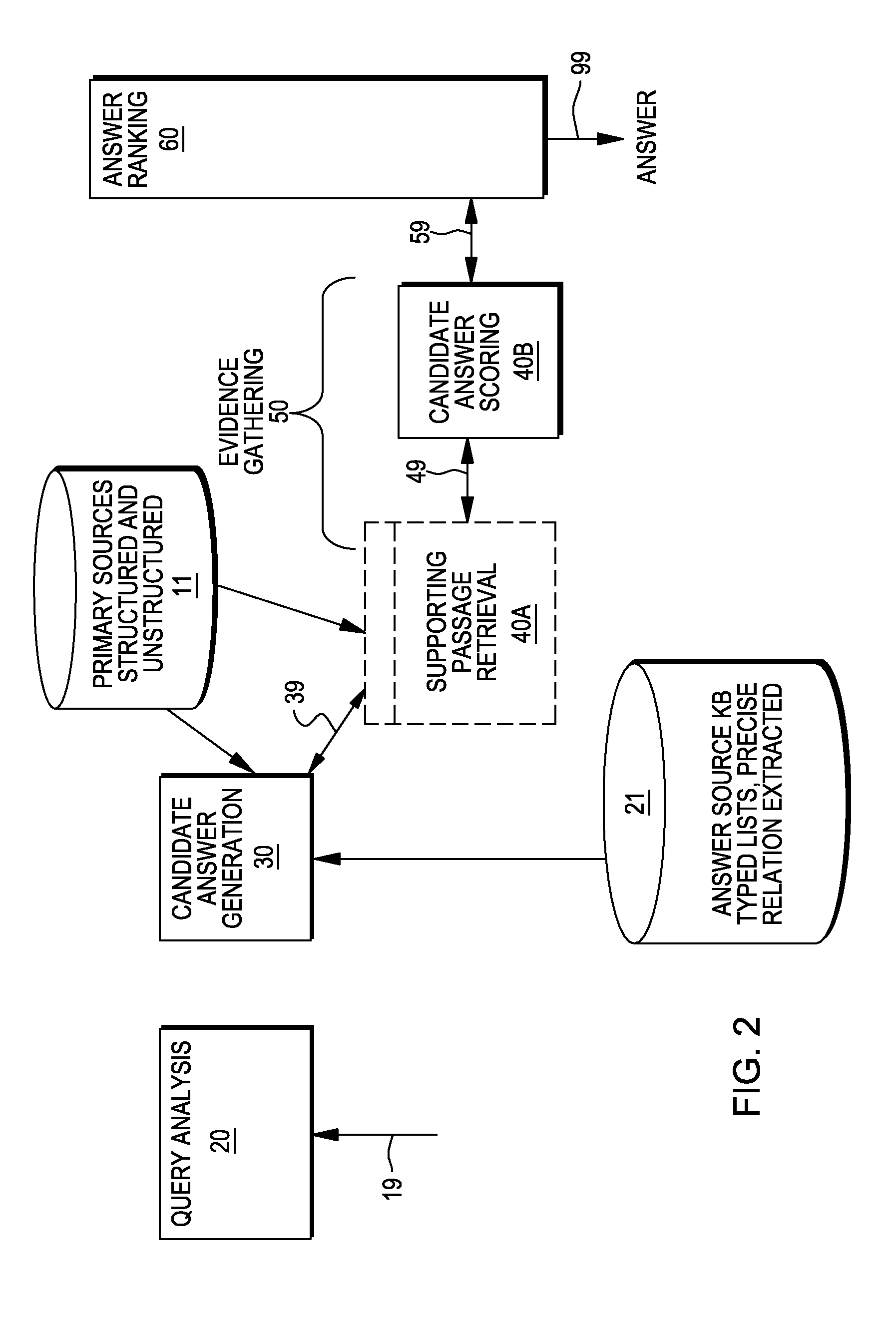

Providing answers to questions including assembling answers from multiple document segments

InactiveUS20120084293A1Digital data processing detailsComputer-assisted medical data acquisitionDefined ProcedureRanking

A method, system and computer program product for generating answers to questions. In one embodiment, the method comprises receiving an input query, identifying a plurality of candidate answers to the query; and for at least one of these candidate answers, identifying at least one proof of the answer. This proof includes a series of premises, and a multitude of documents are identified that include references to the premises. A set of these documents is selected that include references to all of the premises. This set of documents is used to generate one or more scores for the one of the candidate answers. A defined procedure is applied to the candidate answers to determine a ranking for the answers, and this includes using the one or more scores for the at least one of the candidate answers in the defined procedure to determine the ranking for this one candidate answer.

Owner:IBM CORP

Methods and systems for characteristic leveling

ActiveUS7801812B2Small investmentMore confidenceMarket predictionsFinanceData scienceStandardization

Owner:VANTAGESCORE SOLUTIONS

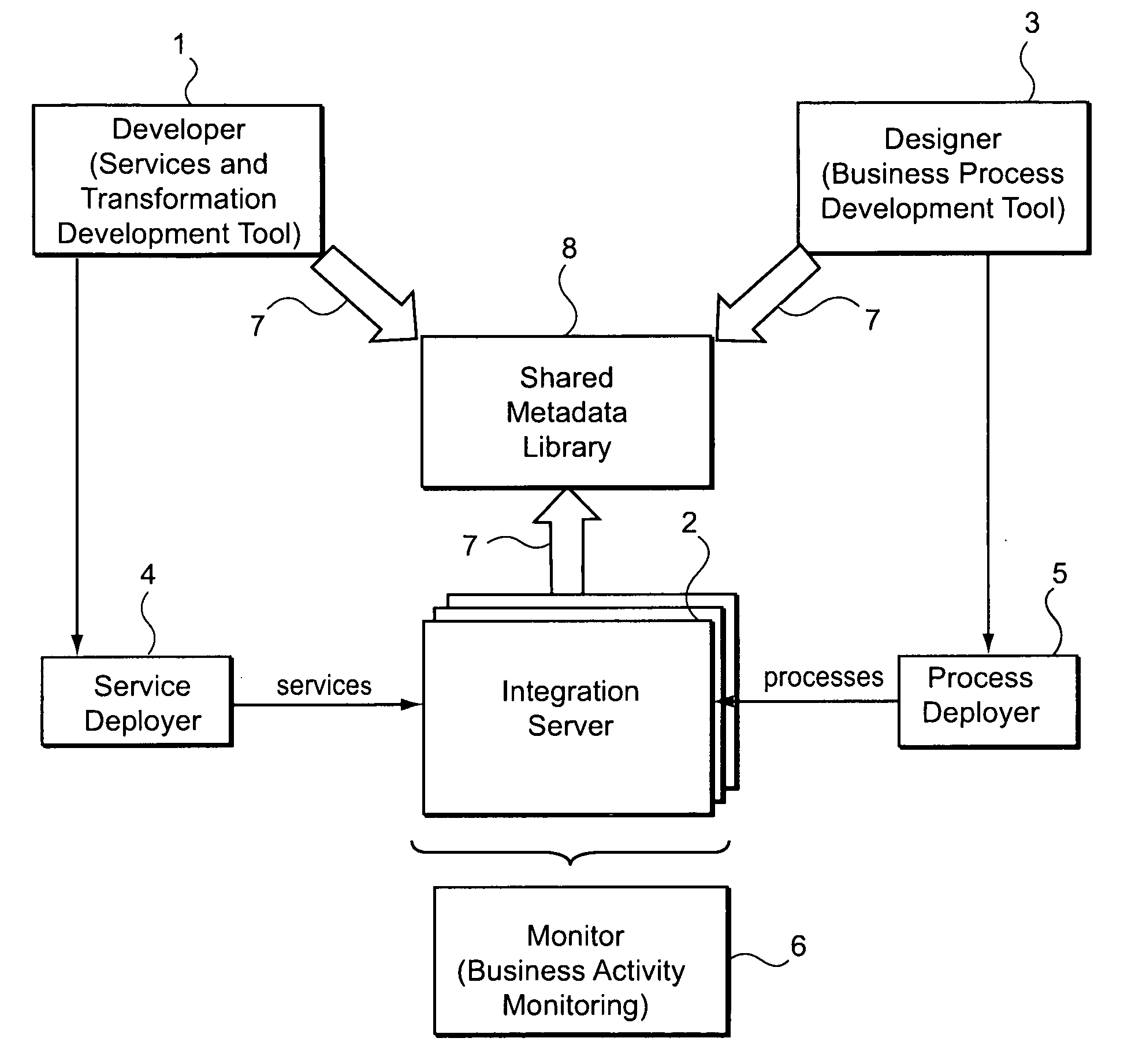

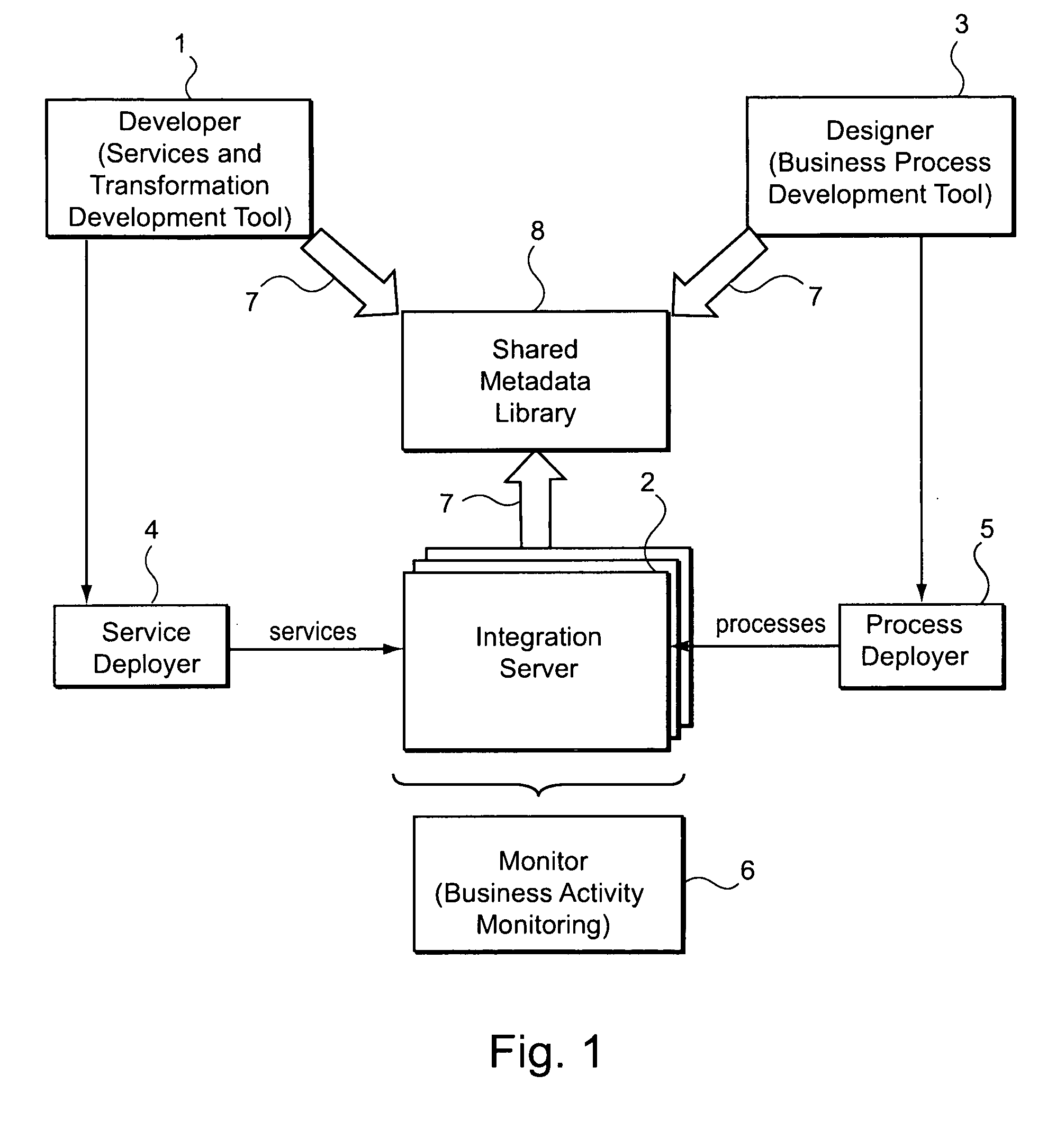

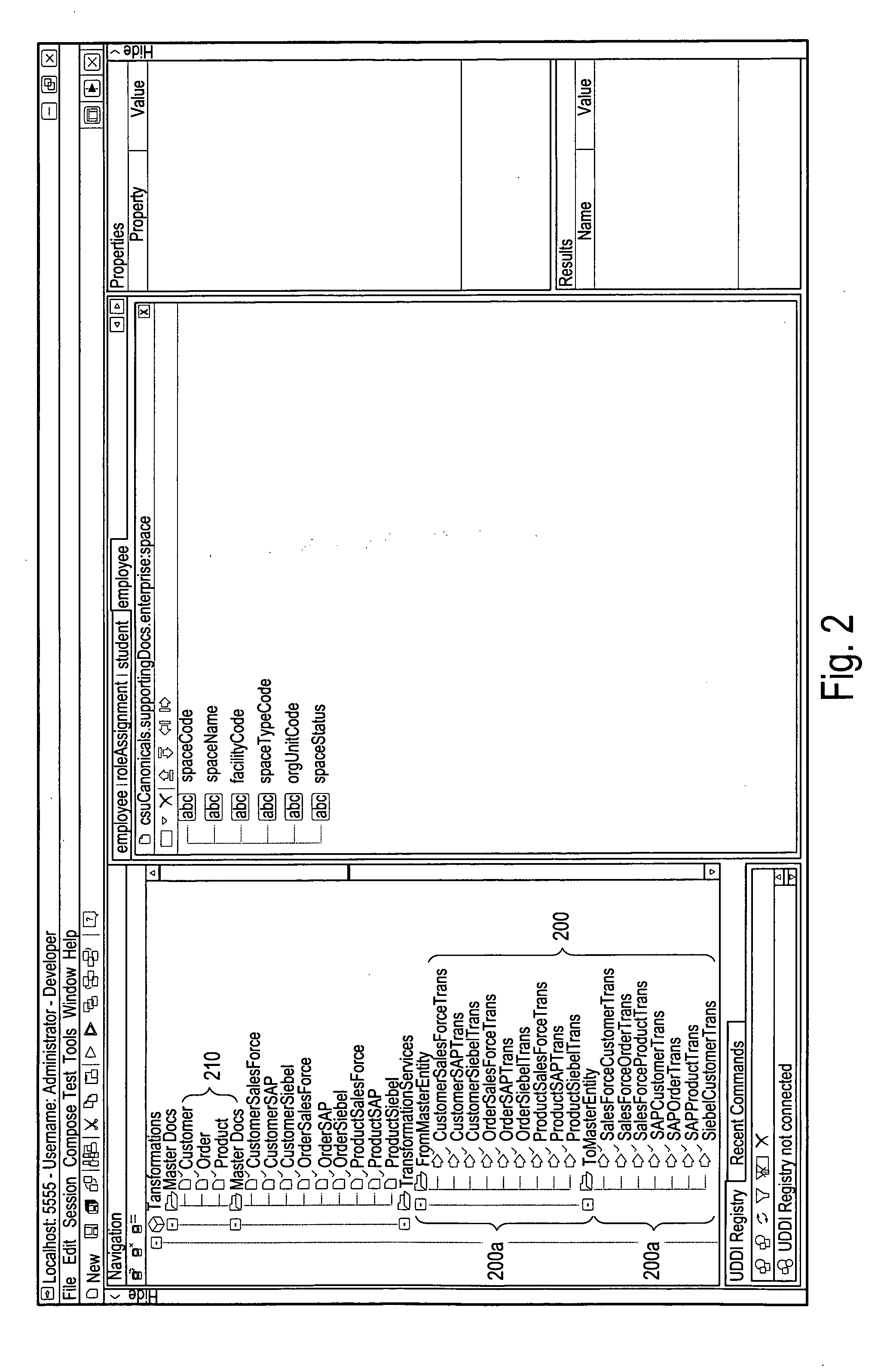

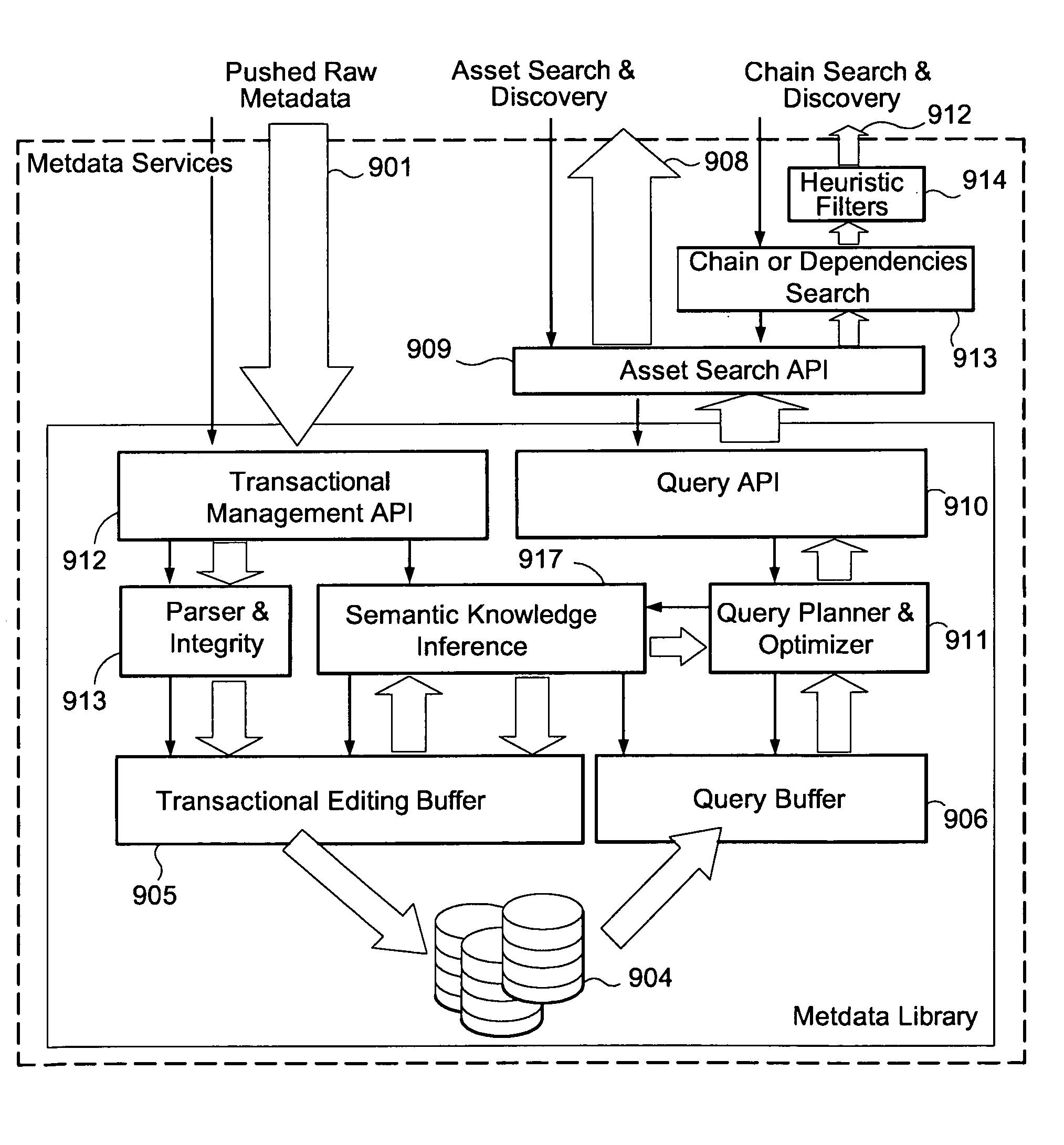

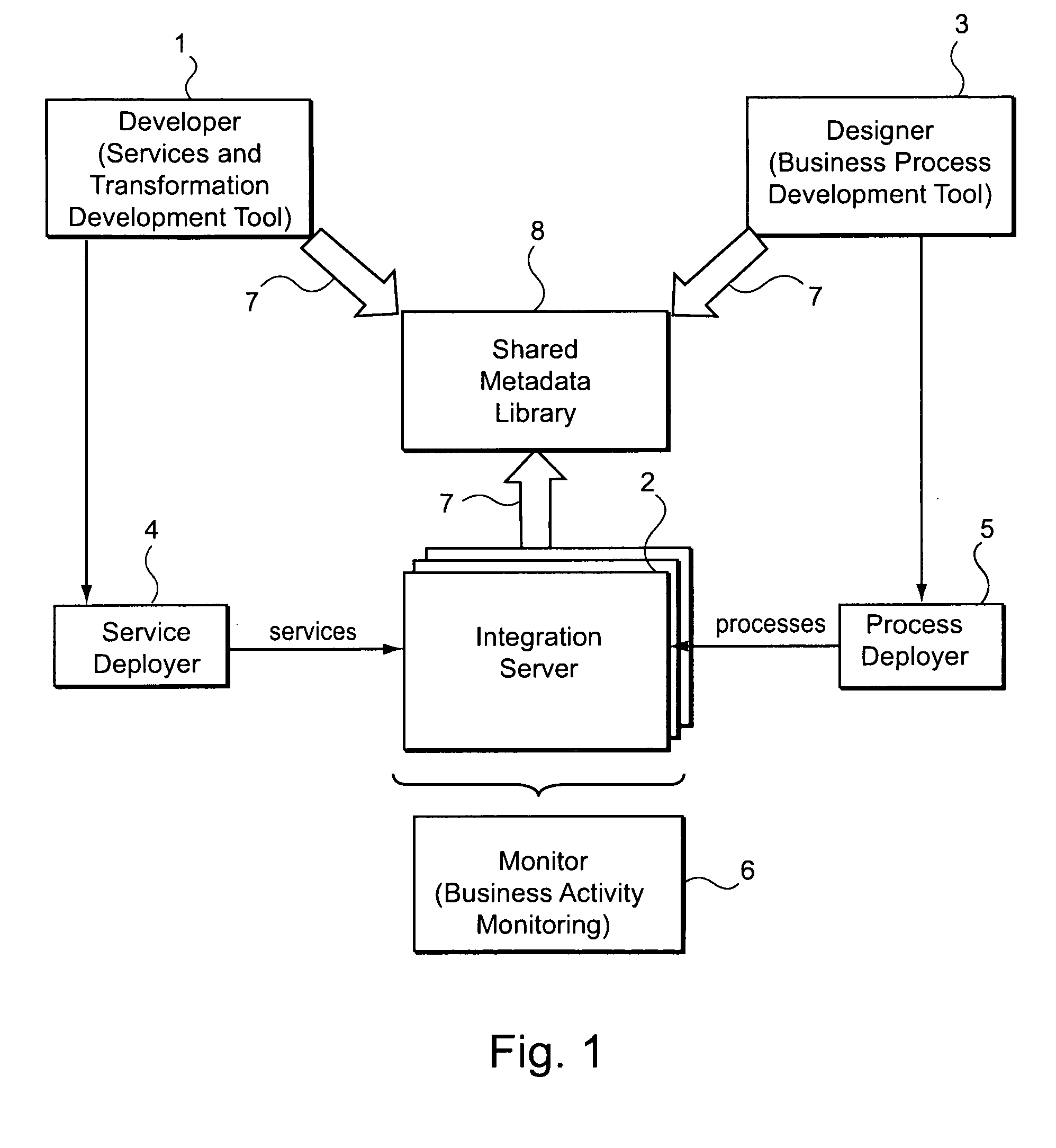

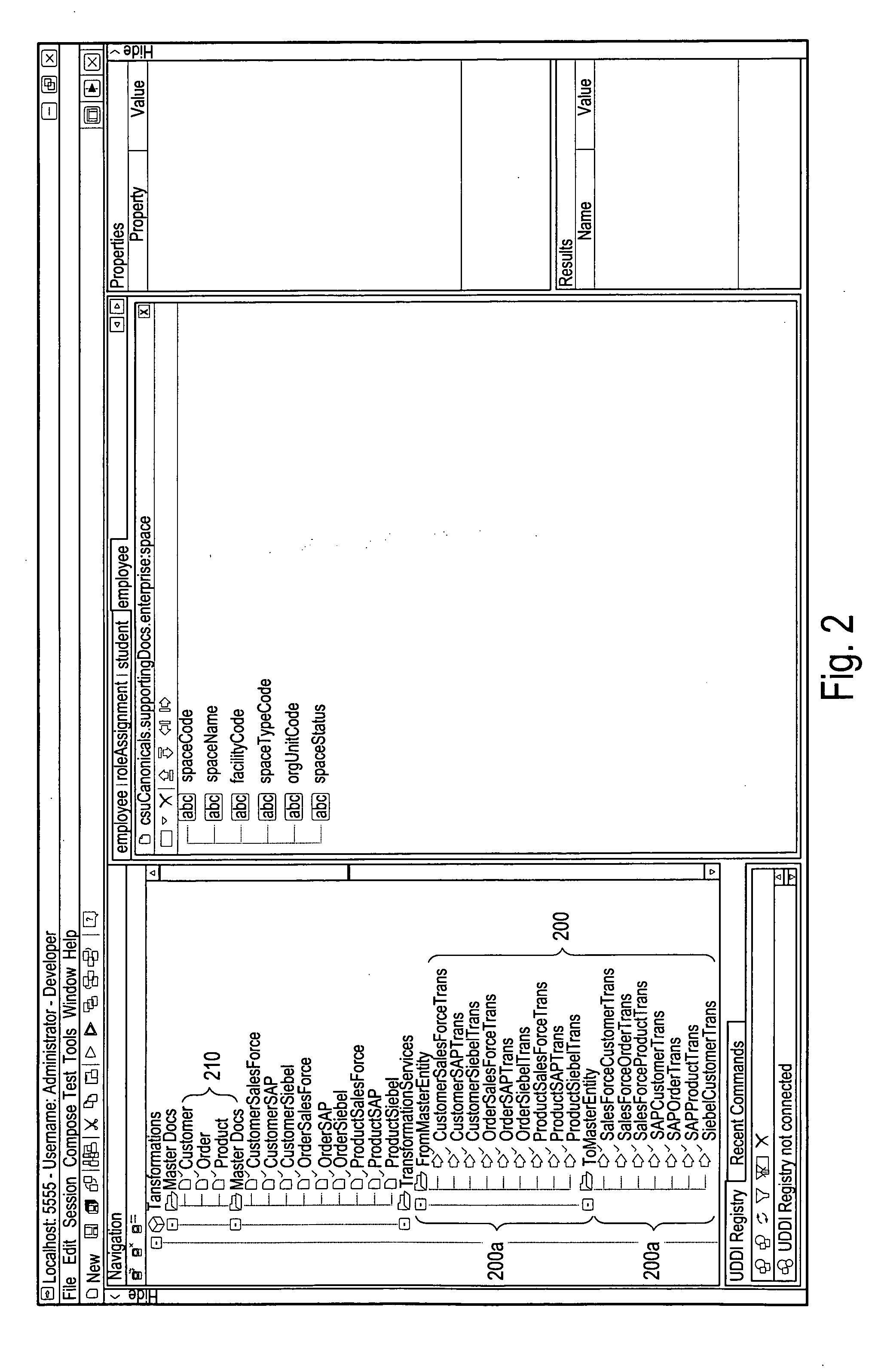

Systems and/or methods for managing transformations in enterprise application integration and/or business processing management environments

ActiveUS20090171720A1Increase the number ofFinanceForecastingEnterprise application integrationHeuristic

In certain example embodiments of this invention, systems and / or methods for managing transformations in Enterprise Application Integration (EAI) and / or Business Process Management (BPM) Environments are provided. In certain example embodiments of this invention, when a process and / or transform is defined, design-time encoding data is extracted and stored as metadata. When the process or transform is implemented, runtime data is captured and / or managed, and also stored as metadata. When new processes and / or transforms are defined, and / or when an already-defined process and / or a transform is executed, heuristics may be applied so as to suggest one or more already-existing transformation chains for use in accomplishing at least a part of the same and / or a similar process or transform.

Owner:SOFTWARE AG

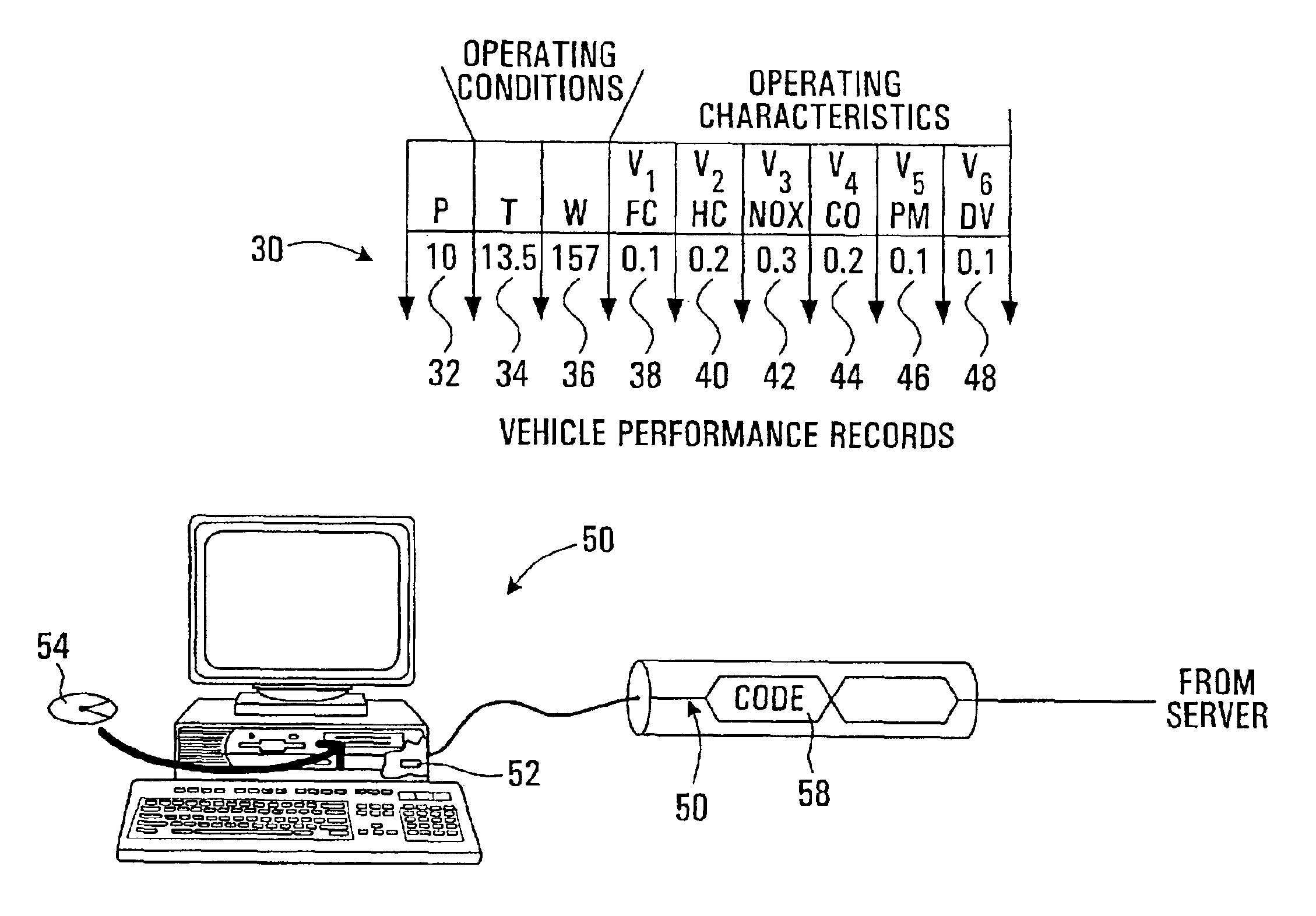

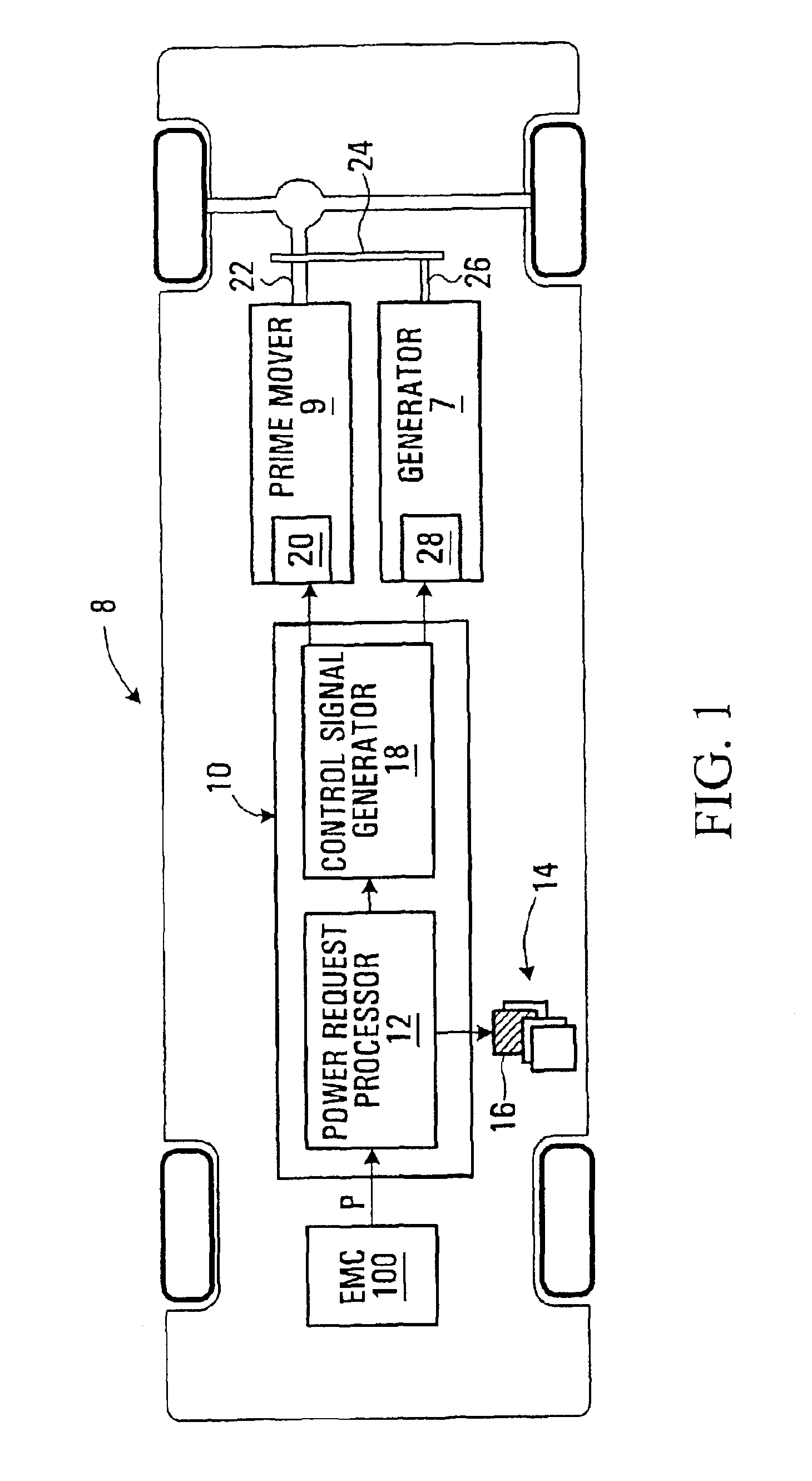

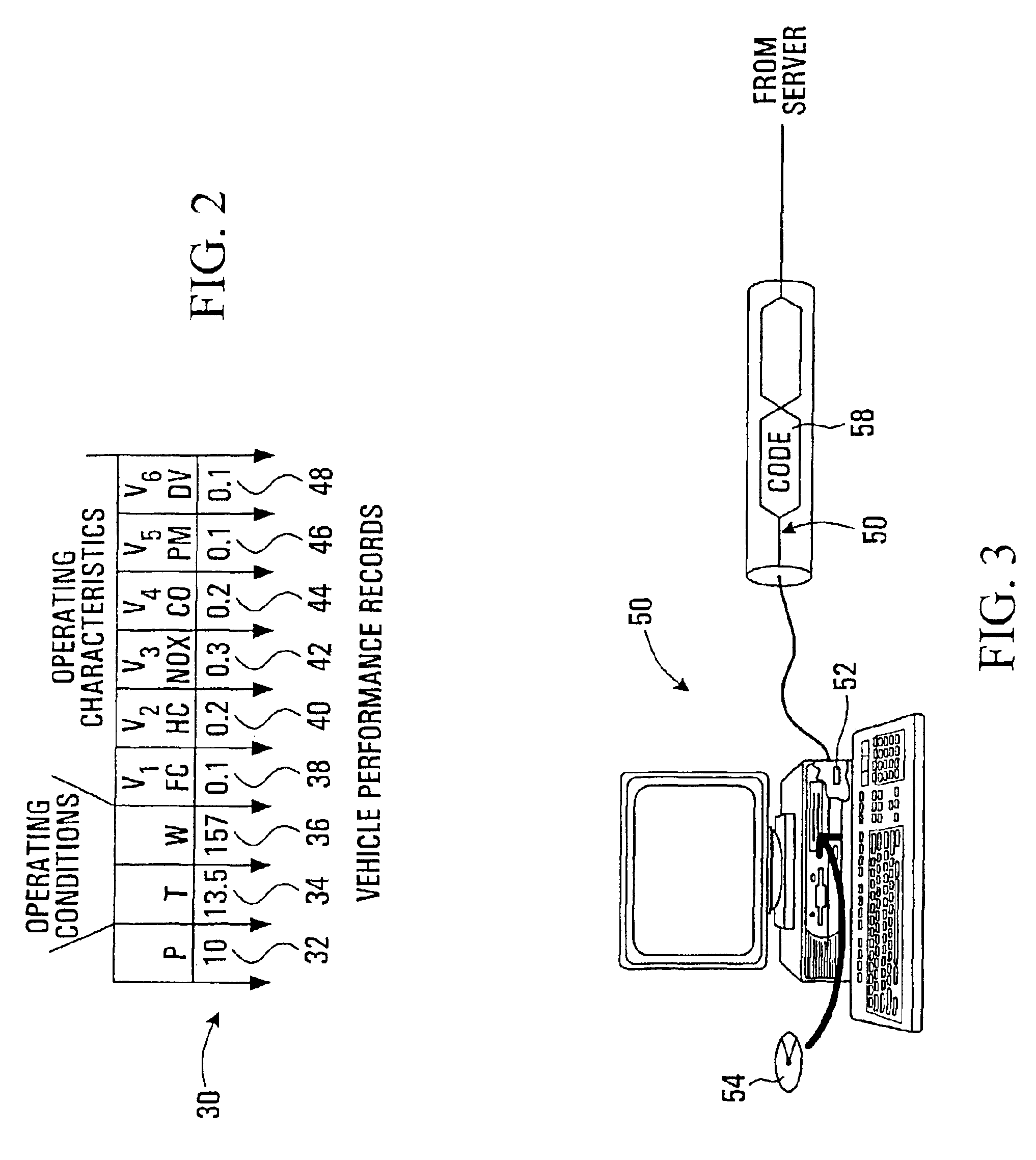

Process, apparatus, media and signals for controlling operating conditions of a hybrid electric vehicle to optimize operating characteristics of the vehicle

InactiveUS6879054B2Easy to operateInternal combustion piston enginesEngine controllersMechanical energyEngineering

Process, apparatus, media and signals are disclosed for controlling a supply of power from an electric generator in a hybrid electric vehicle having a prime mover supplying mechanical energy to the generator. The process carried out by the apparatus and defined by codes on the media and in codes in the signals involves locating, from among a plurality of sets of vehicle operating conditions associated with a requested generator power value, an optimal set of operating conditions that optimizes operating characteristics of the vehicle and producing signals for controlling the prime mover and the generator to operate the vehicle at the optimal set of operating conditions, to supply power at the requested generator power value. The present invention also provides a way of producing vehicle performance records for use in producing signals for controlling the prime mover and the generator to achieve the optimized operating characteristics.

Owner:GE HYBRID TECH

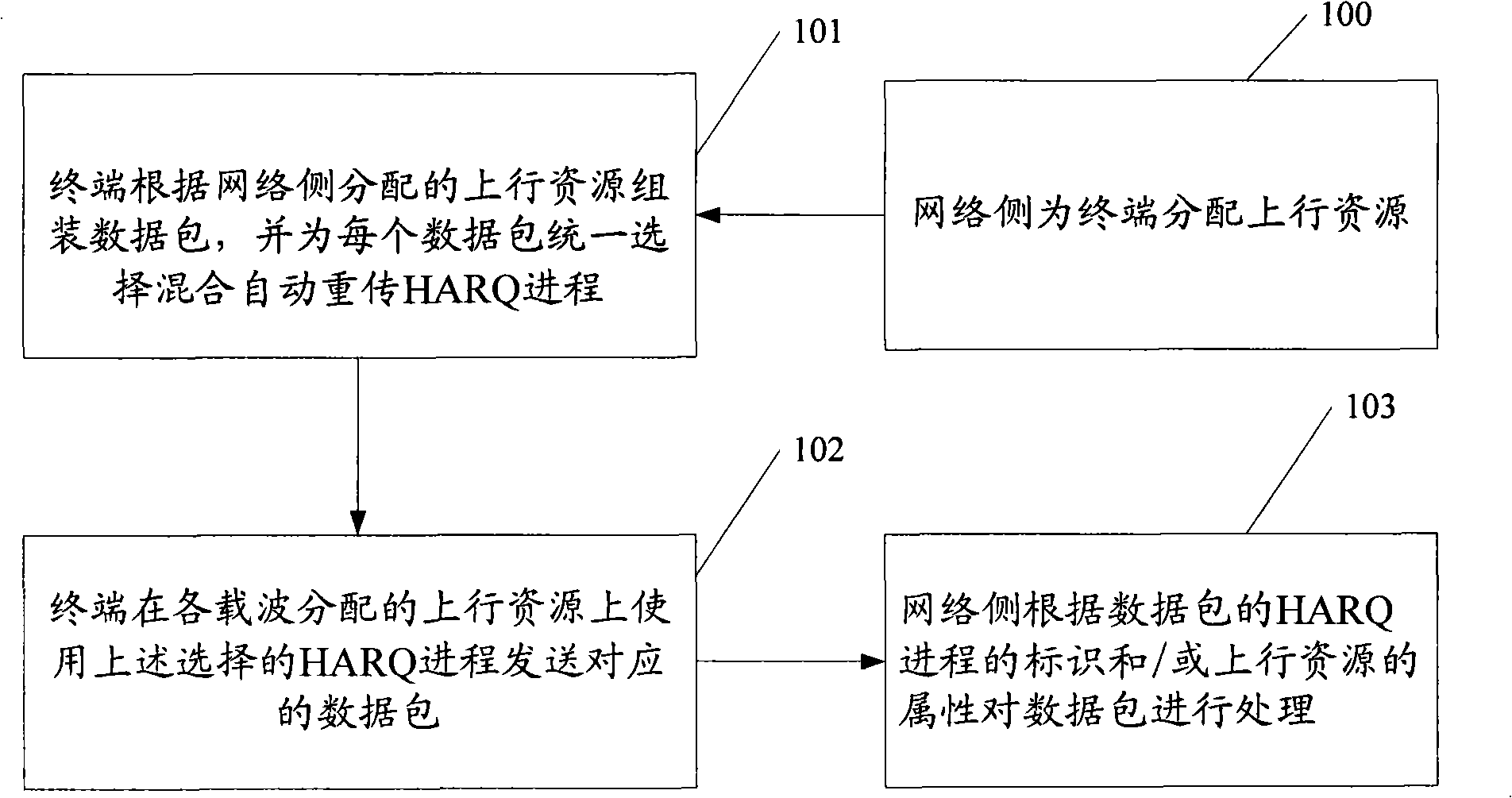

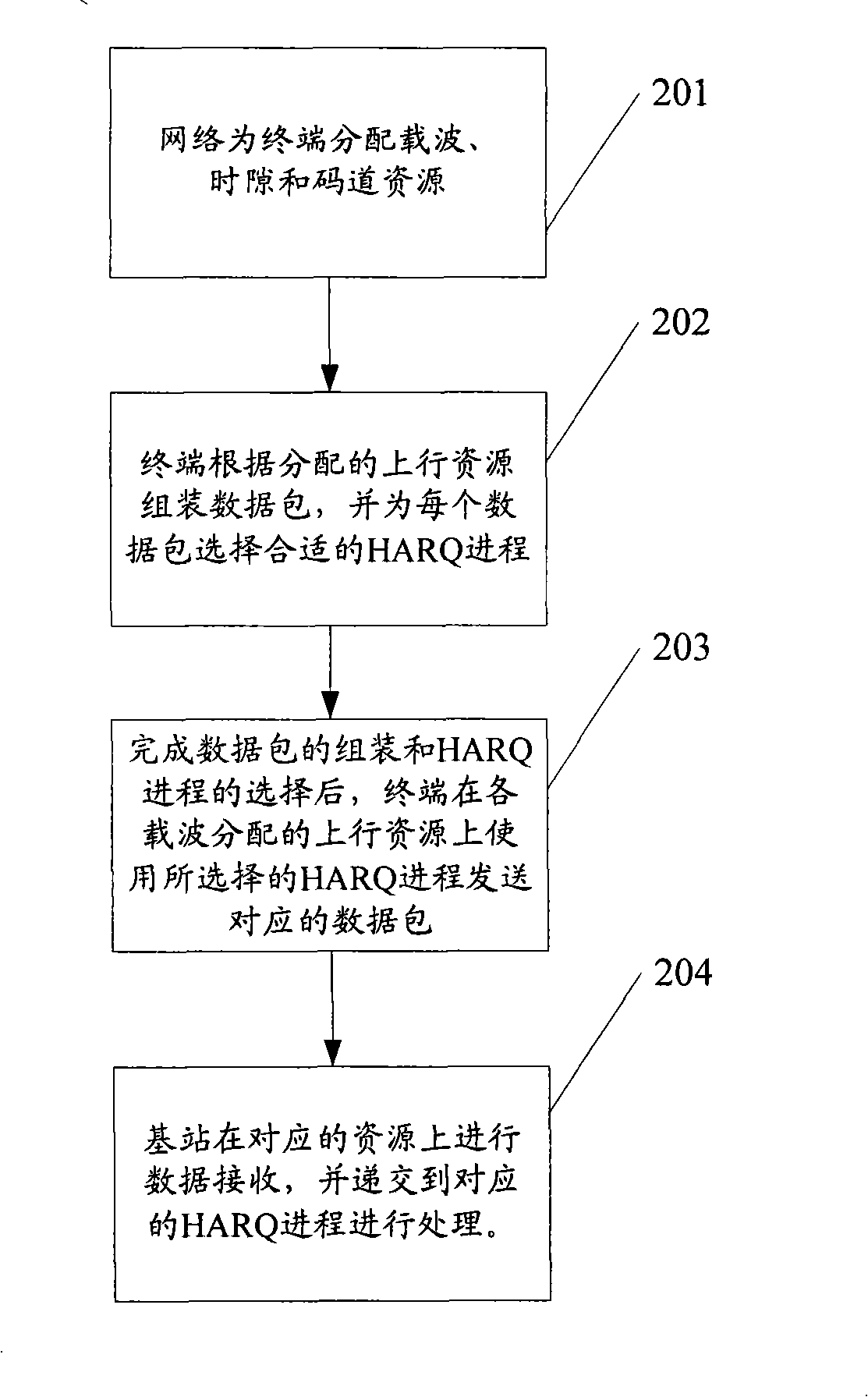

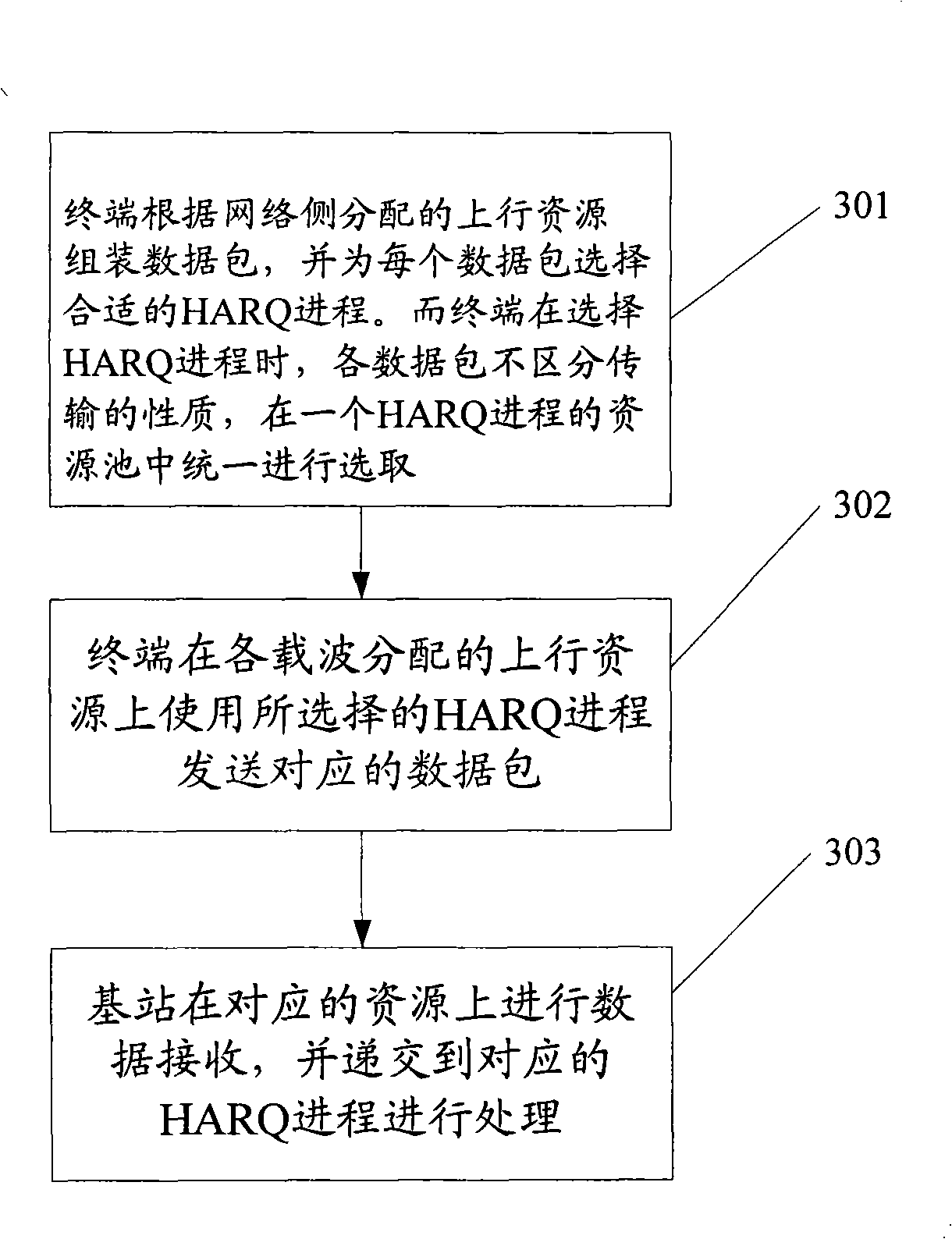

Method and apparatus for managing multi-carrier TDD ascending HARQ course

InactiveCN101345608ARealize unified managementFlexible transmissionError prevention/detection by using return channelNetwork packetCarrier signal

The invention discloses a method for managing multi-carrier TDD uplink HARQ to solve problem that existing single-carrier system defined process number and process management method can not directly apply to multi-carrier system. The method comprises that terminal assembles data pack according to uplink resource network side allocates, and unitedly selects mixed automatic retransmission HARQ process for each data pack; terminal transmits corresponding data pack on uplink resource each carrier allocates using above selected HARQ process. The invention also provides terminal and network side device for managing multi-carrier TDD uplink HARQ process, thereby accomplishing united management for multi-carrier HARQ process in HSUPA system, promoting system transmission efficiency.

Owner:CHINA ACAD OF TELECOMM TECH

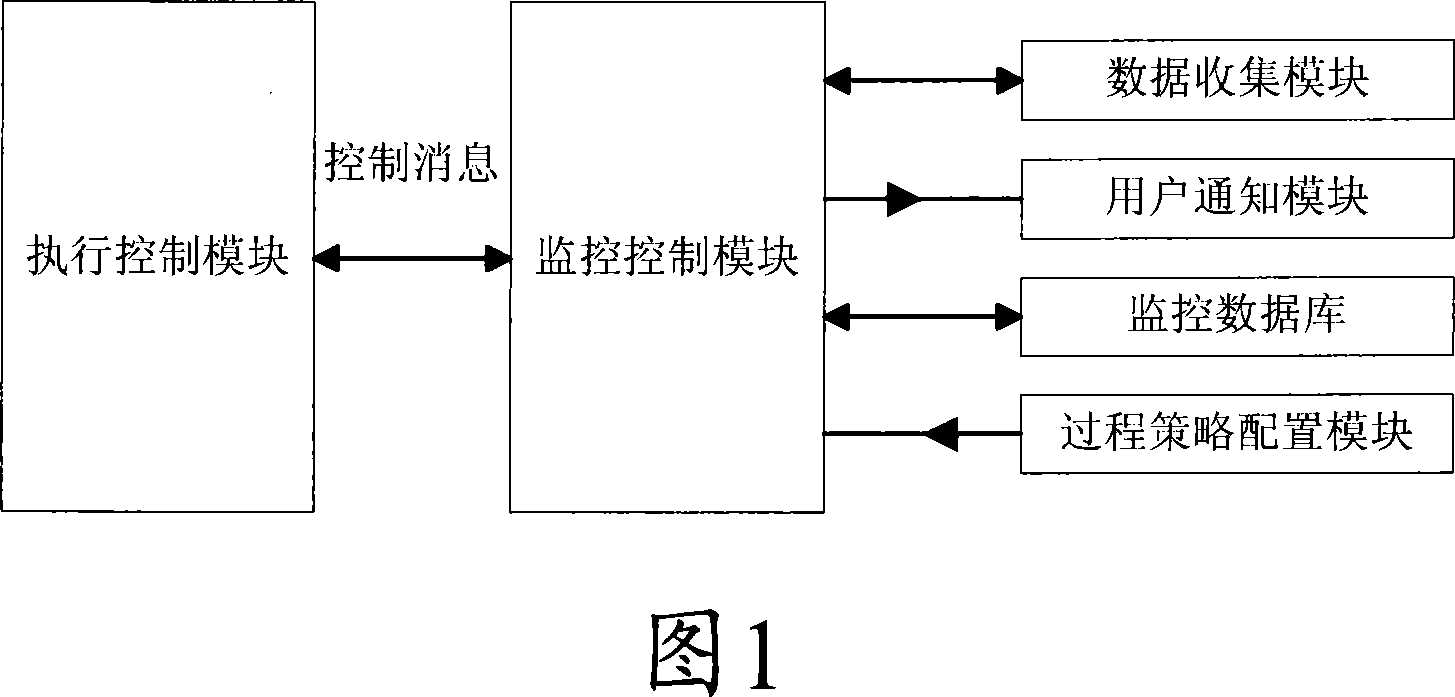

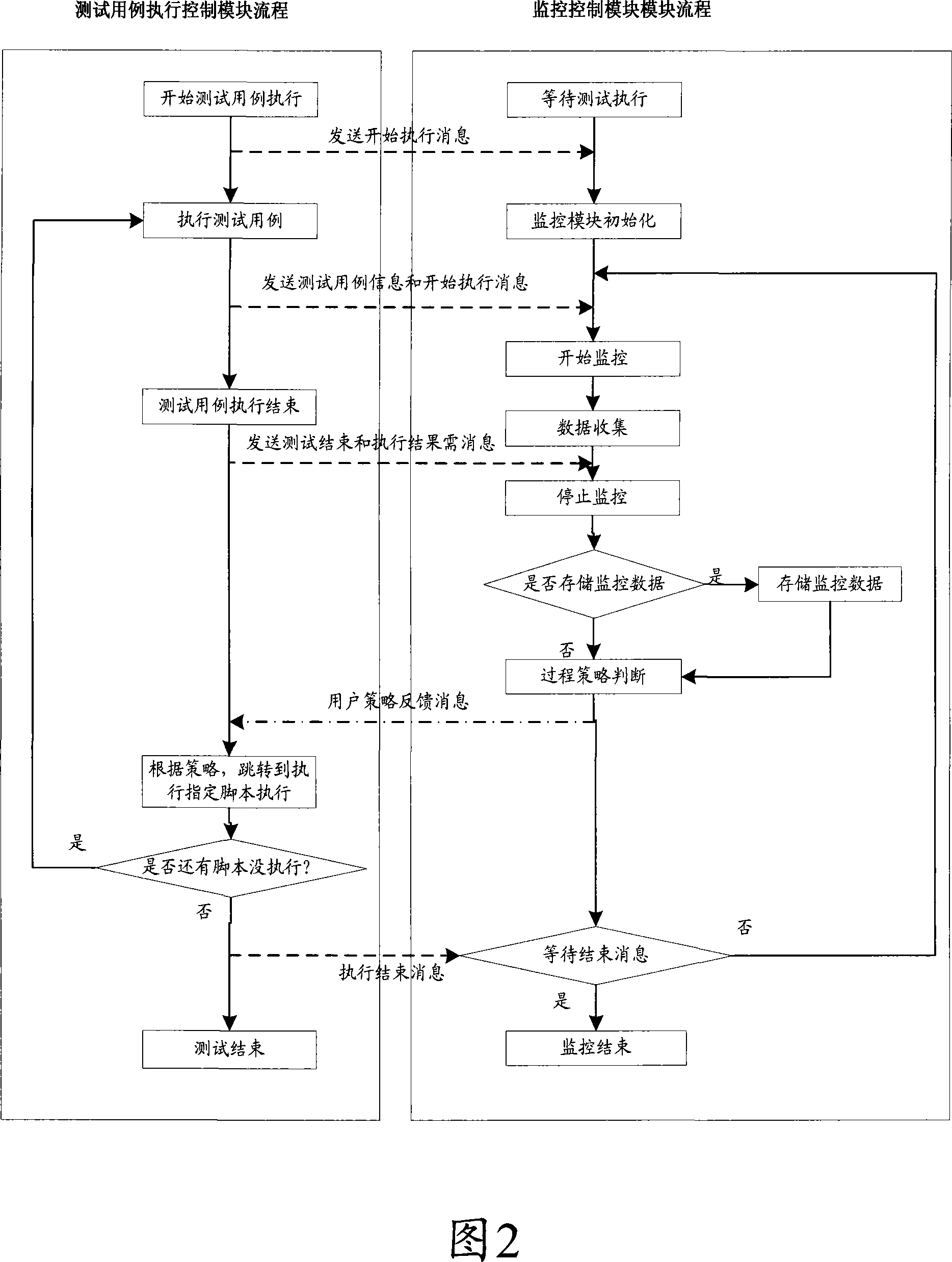

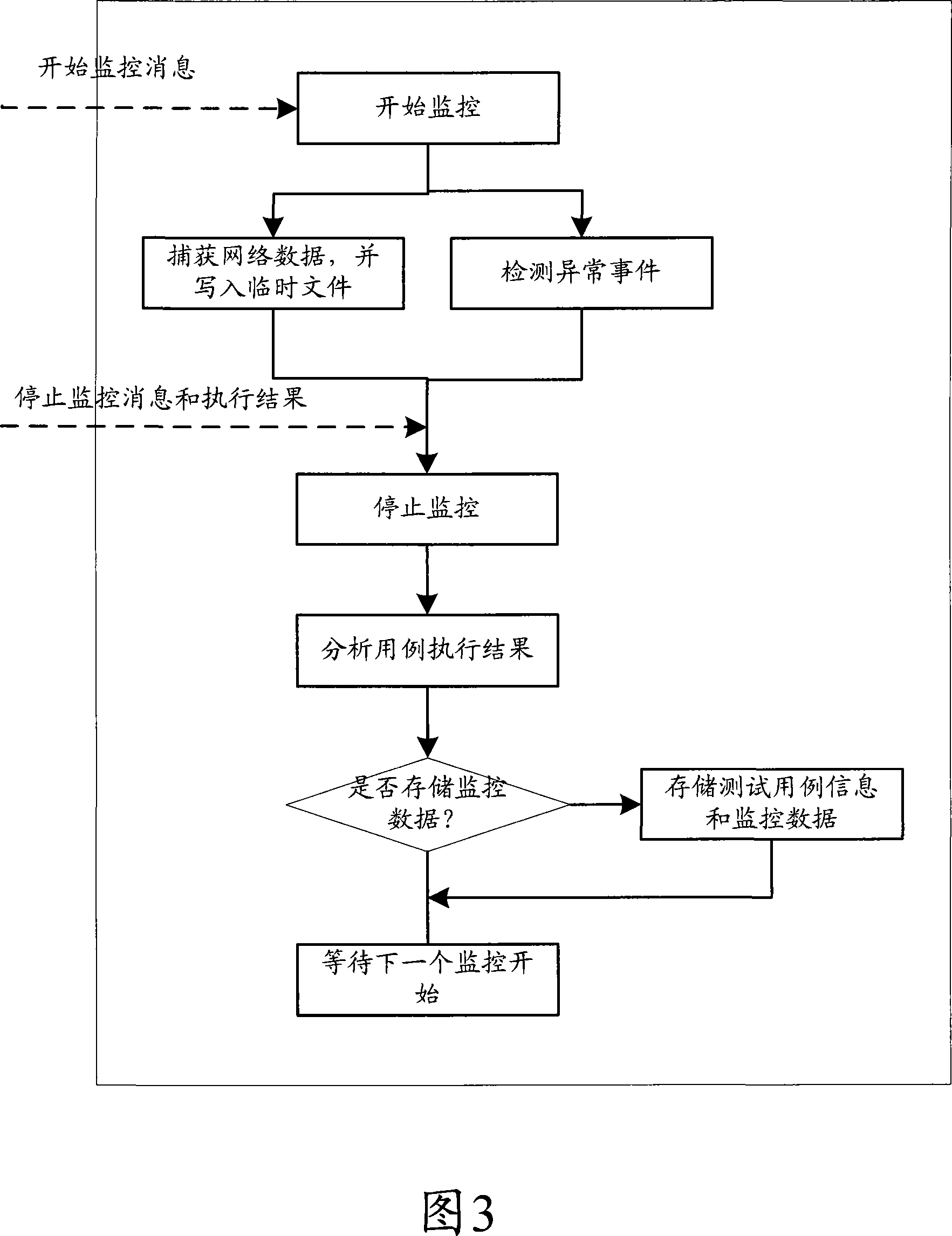

Monitor method and system for automatically measuring executing process

ActiveCN101052020AReduce wasted testing timeImprove test efficiencyData switching networksExecution controlTest timing

The system comprises a control execution module used for testing, and also comprises a monitor-controlling module, a control data collection module, a monitor database module, a procedure strategy configuration module, a user-informing module. Wherein, the monitor-controlling module communicates with the execution-controlling module to monitor the test process; the control data collection module is used for collecting the test data, analyzing execution result and controlling the control execution module to adjust the test sequence according to the procedure strategy defined by user.

Owner:ZTE CORP

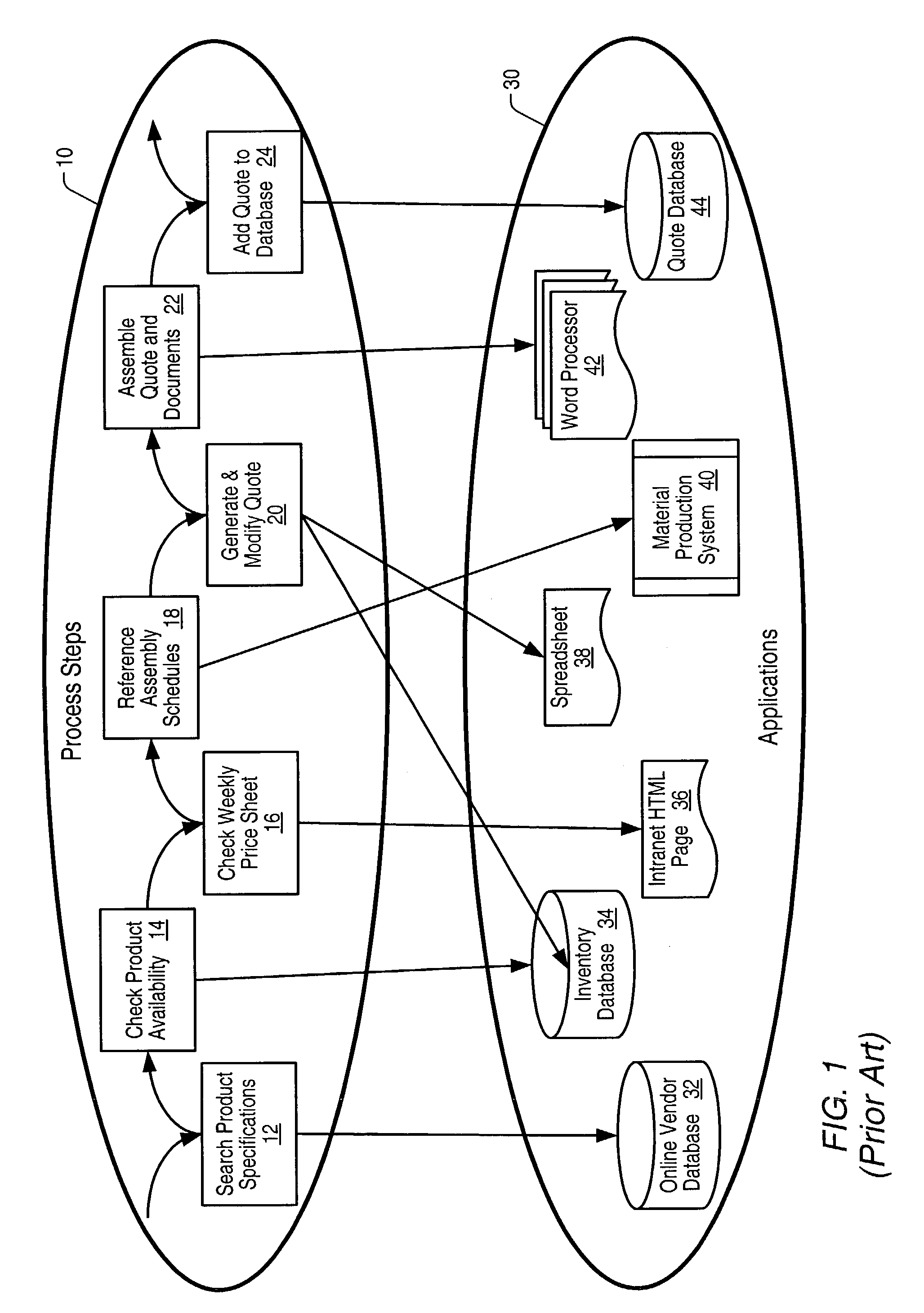

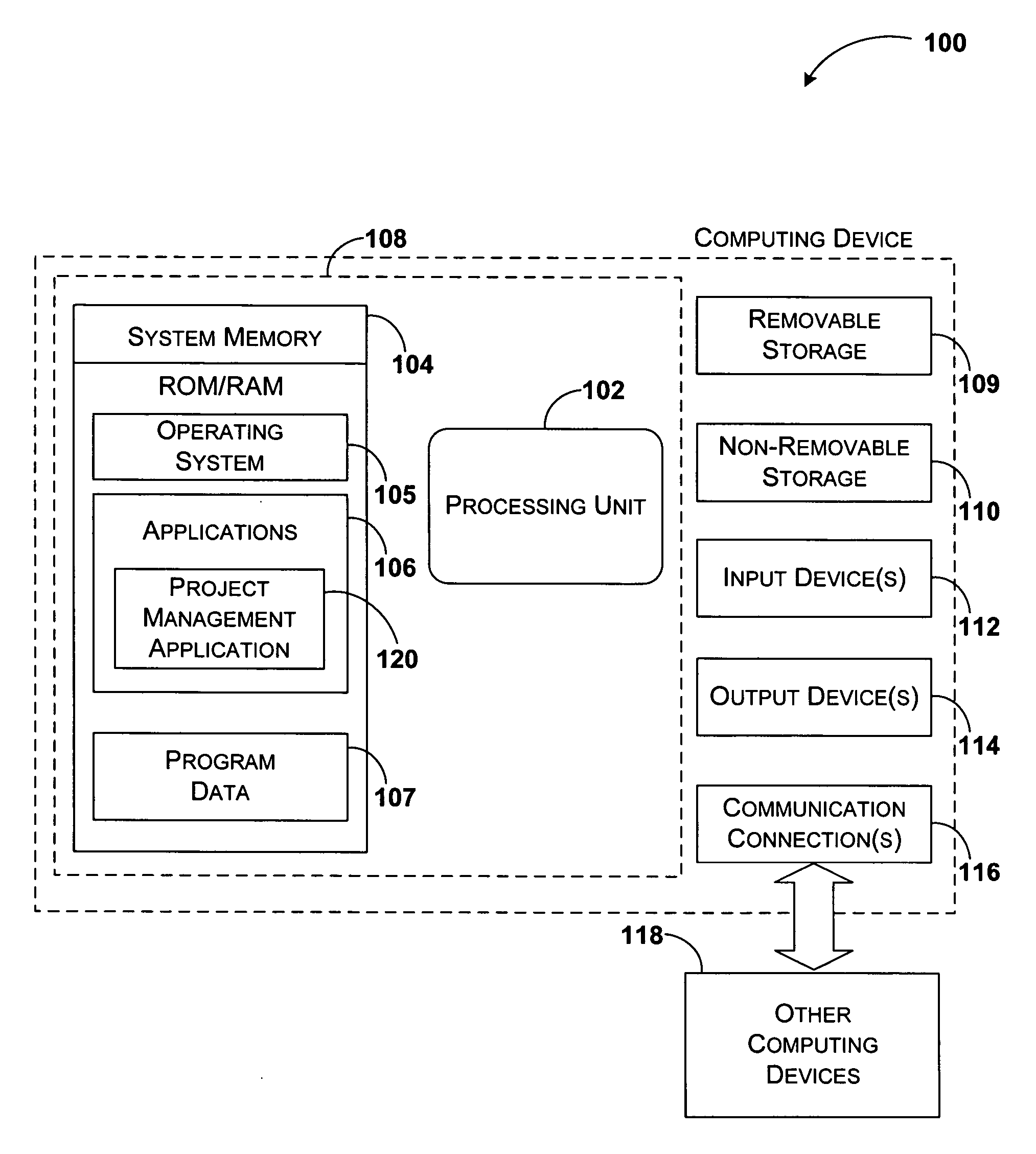

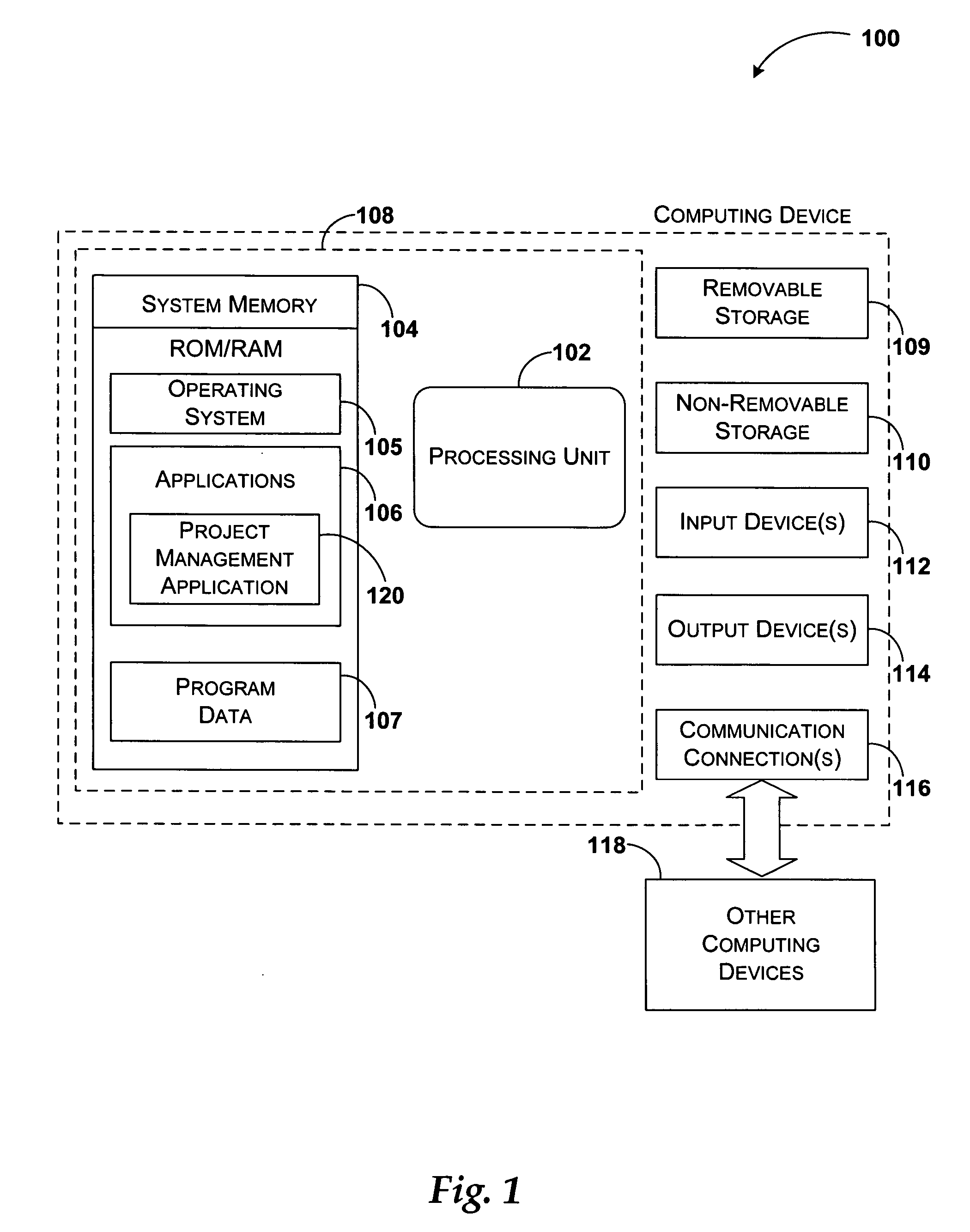

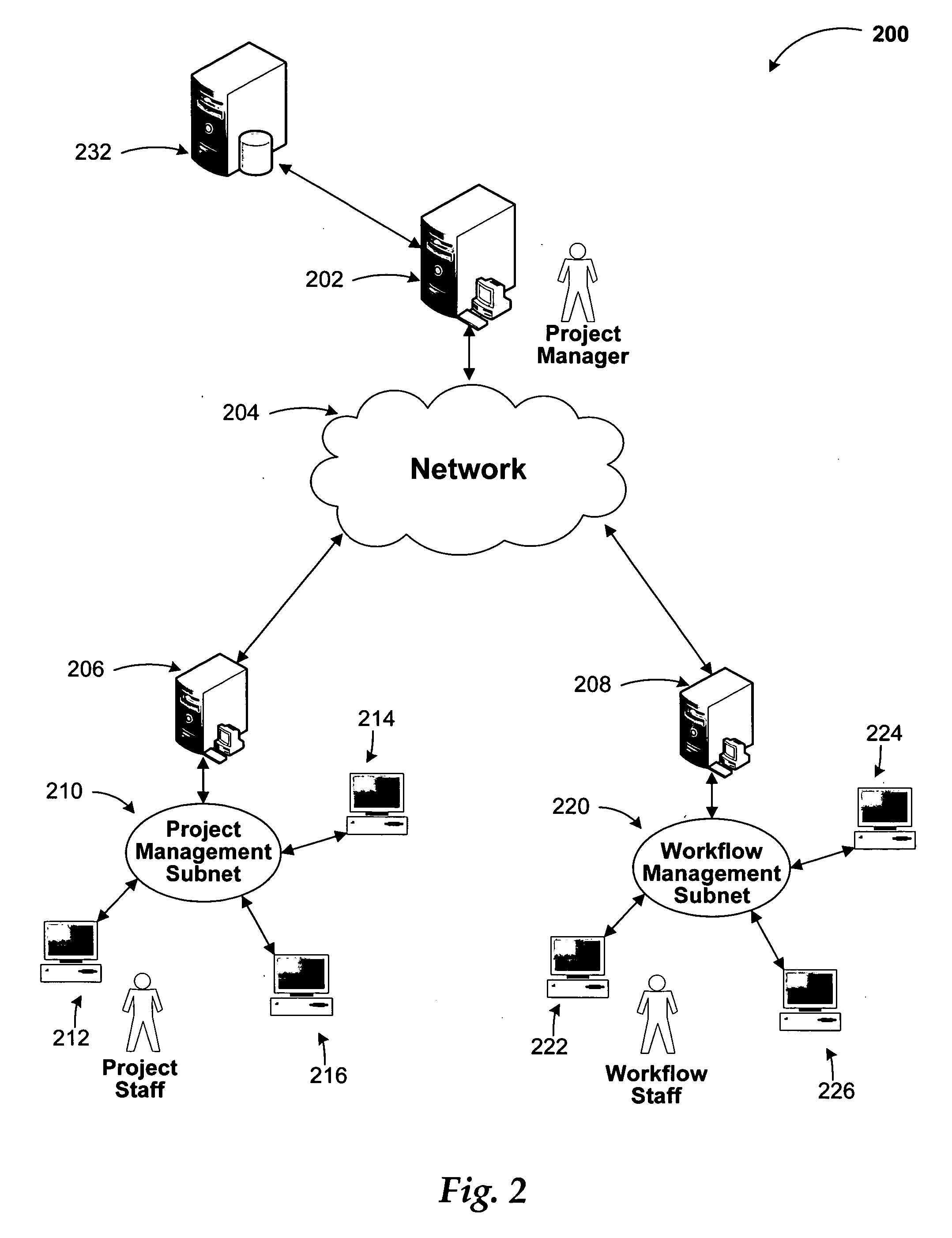

System and method for integrating workflow processes with a project management system

A project management system is integrated with a workflow engine to provide automatic coordination of project tasks and workflow processes. The workflow engine provides support for defining logical expressions that determine a path of execution for the defined workflow tasks. In addition to composition capabilities, the workflow engine may execute and track the defined processes. The project management system provides a platform for defining the project plan that includes tasks and resources. Tasks are annotated defining their behavior and implementation and exported to the workflow system. The workflow system substitutes project tasks with the appropriate workflow activities and provides feedback upon execution of the activities.

Owner:MICROSOFT TECH LICENSING LLC

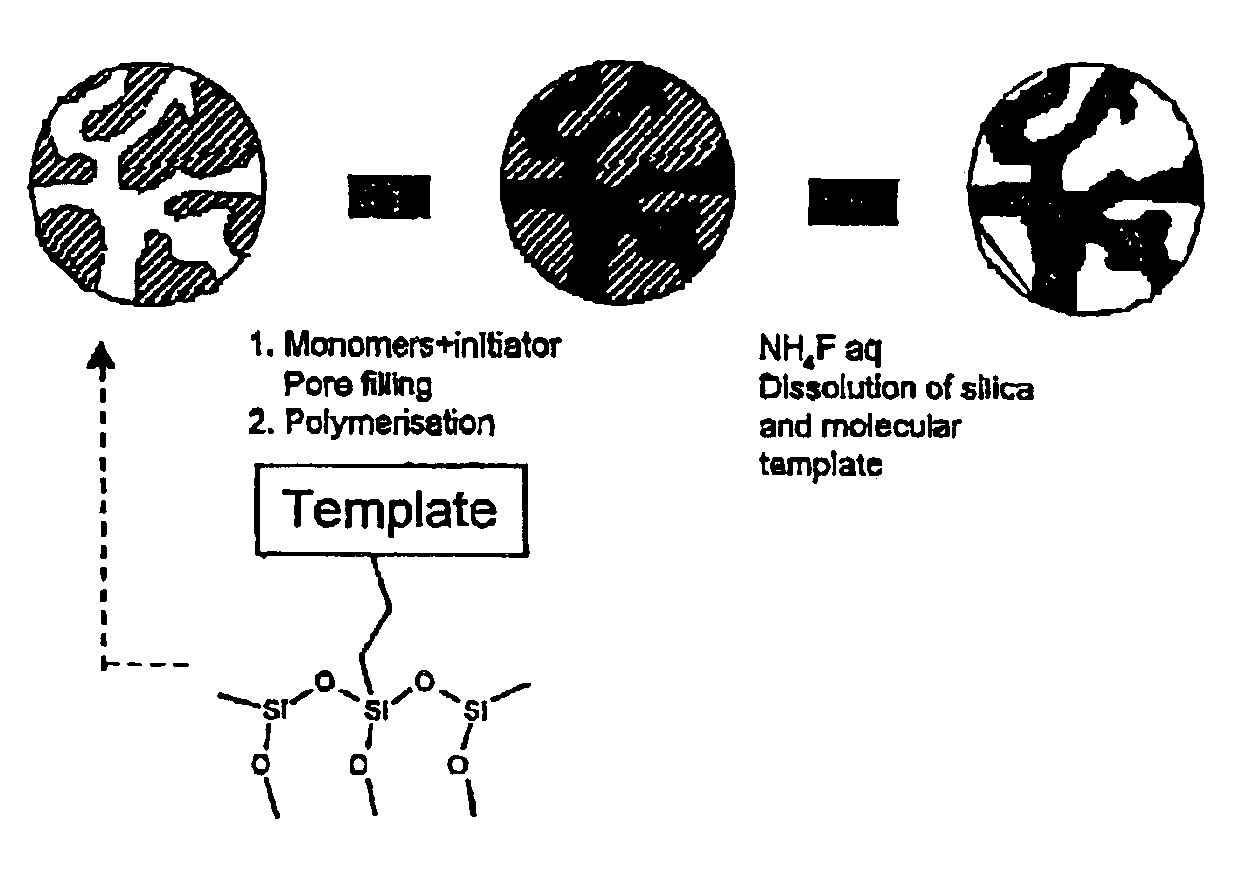

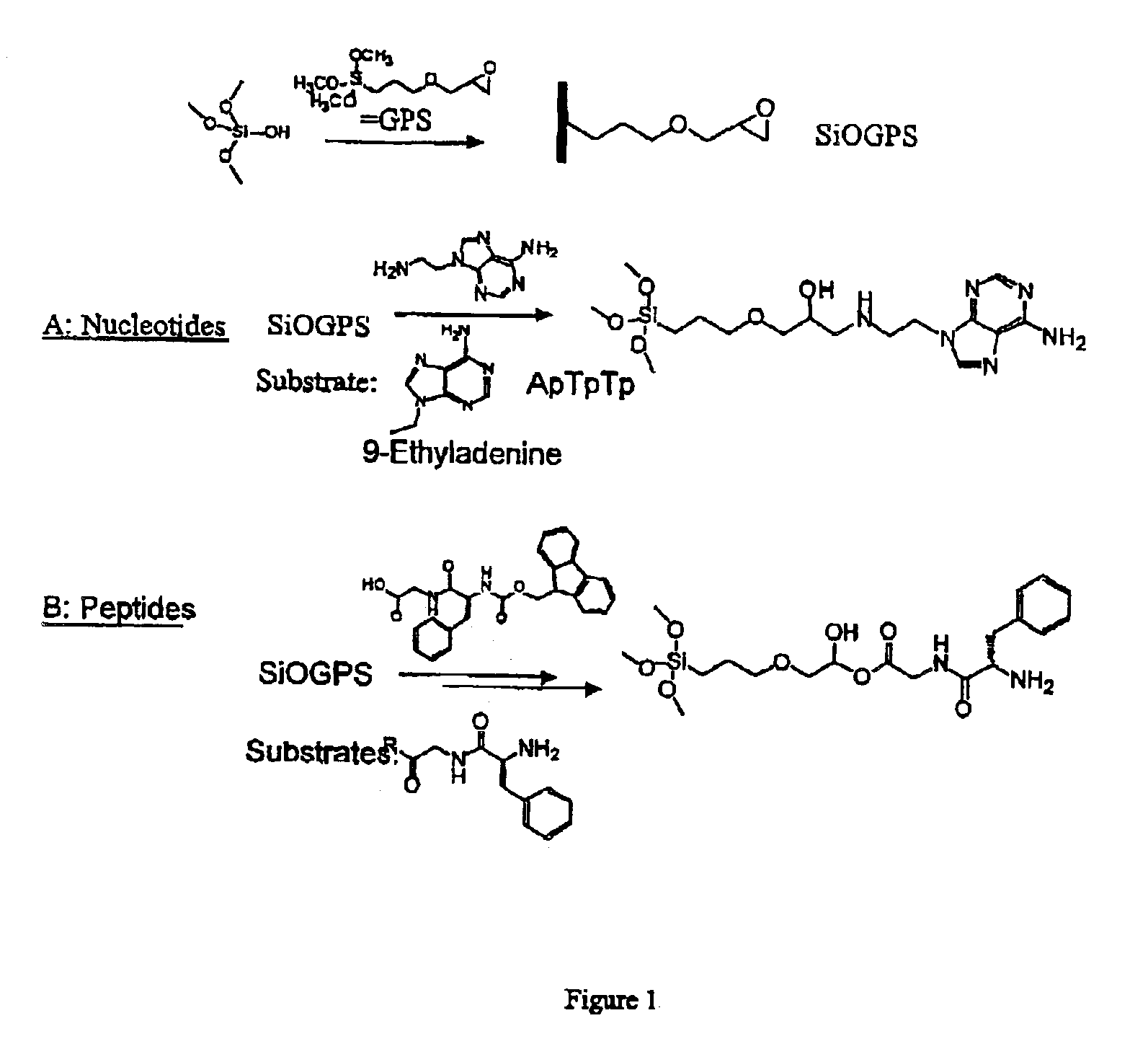

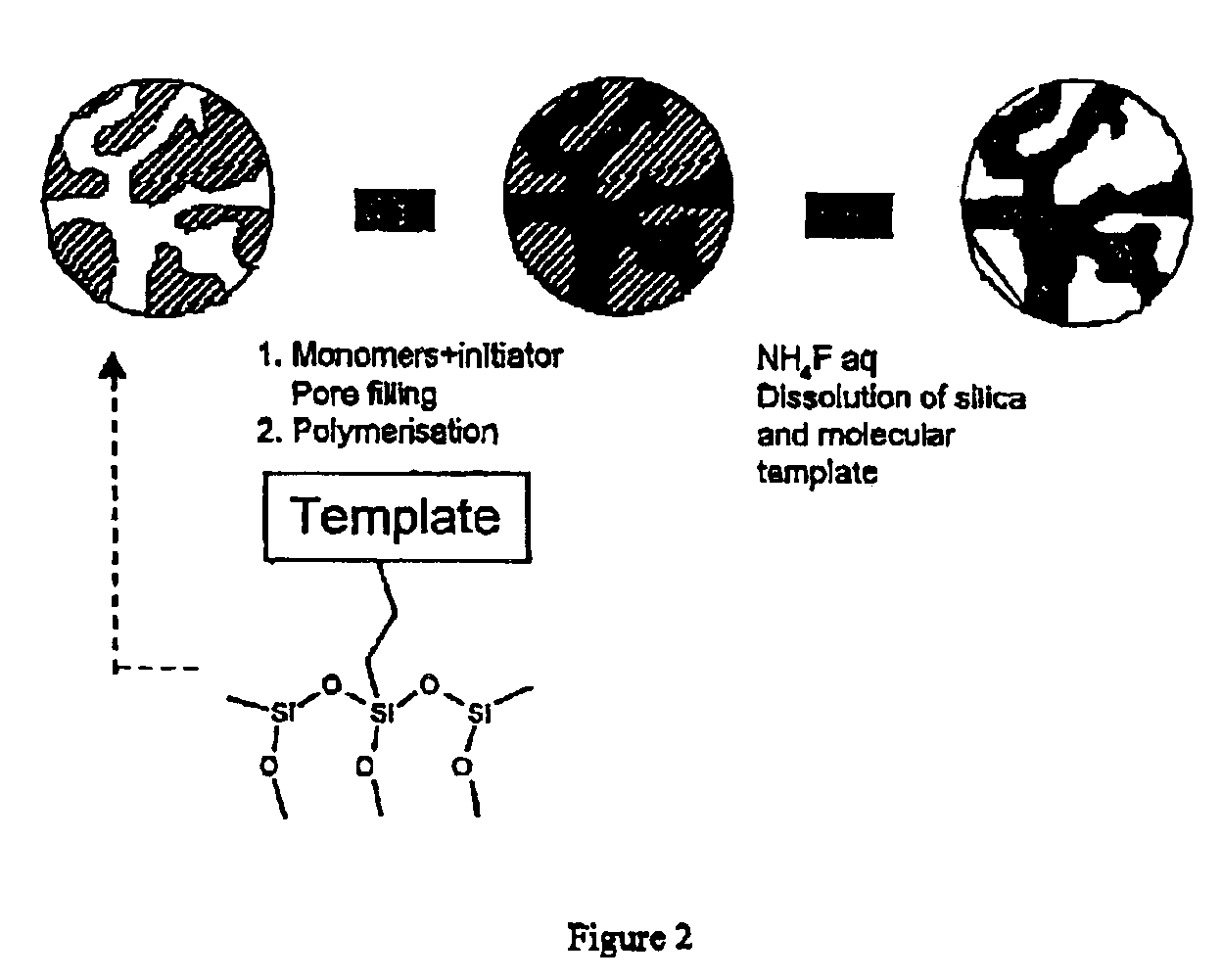

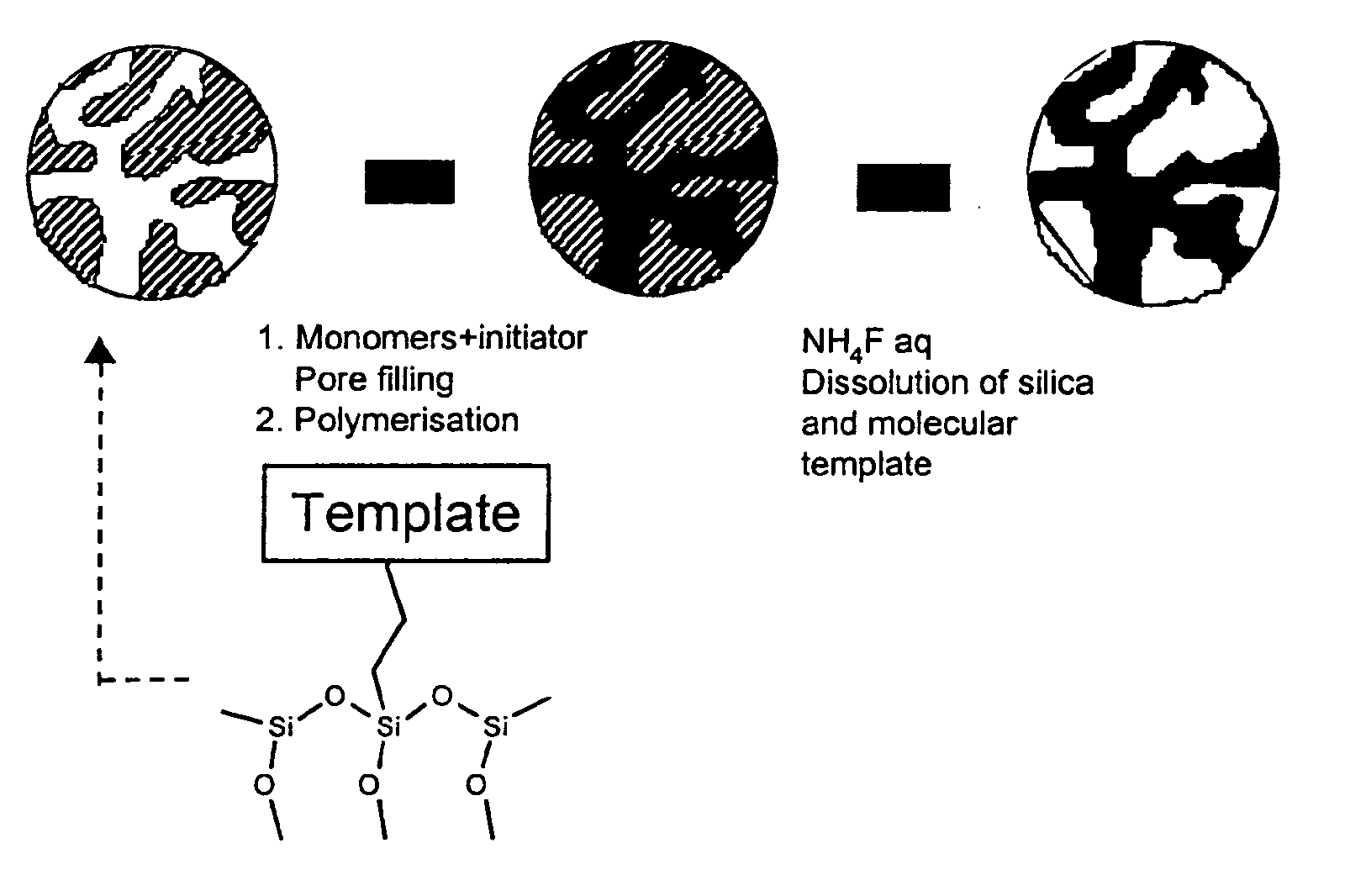

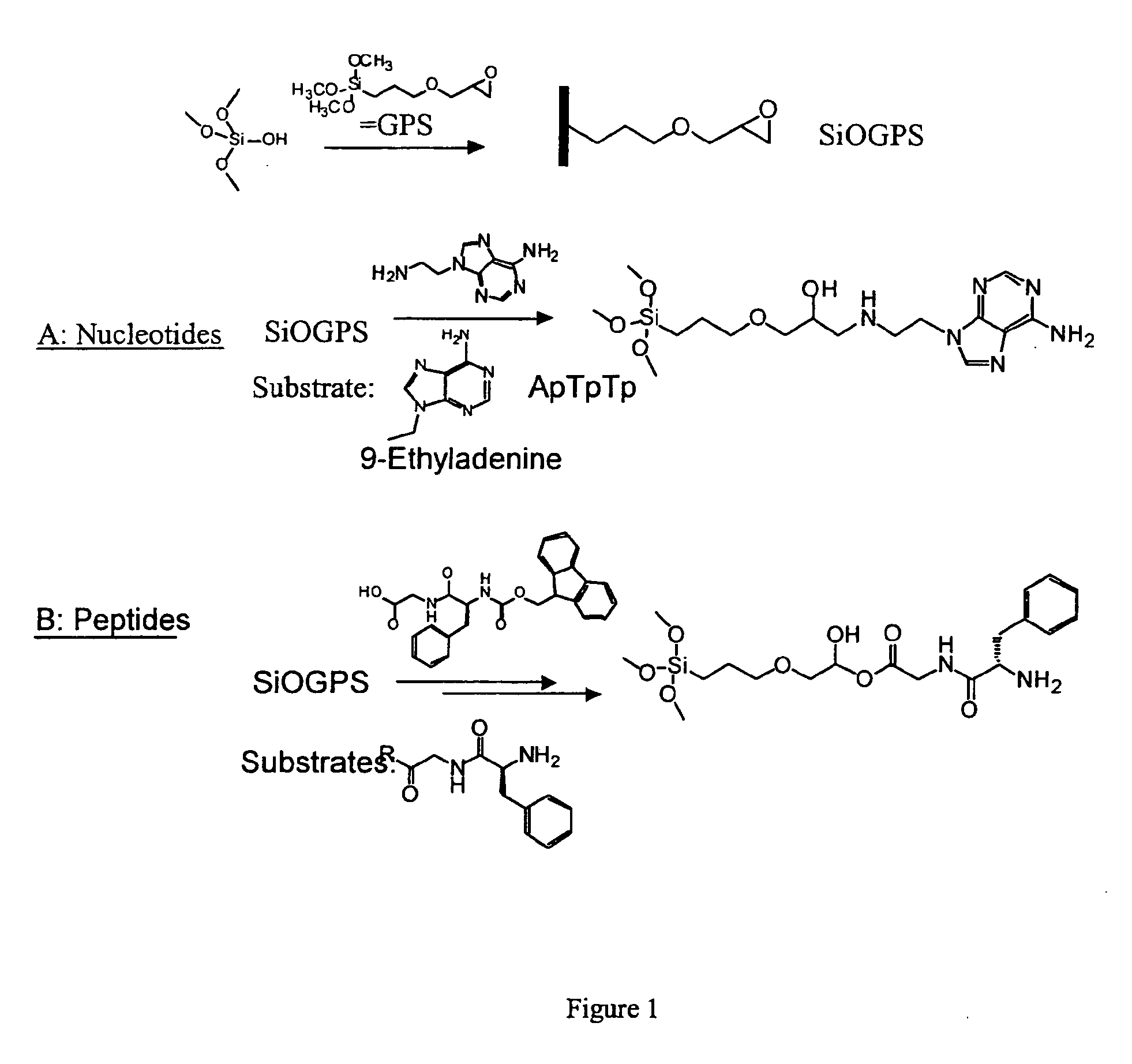

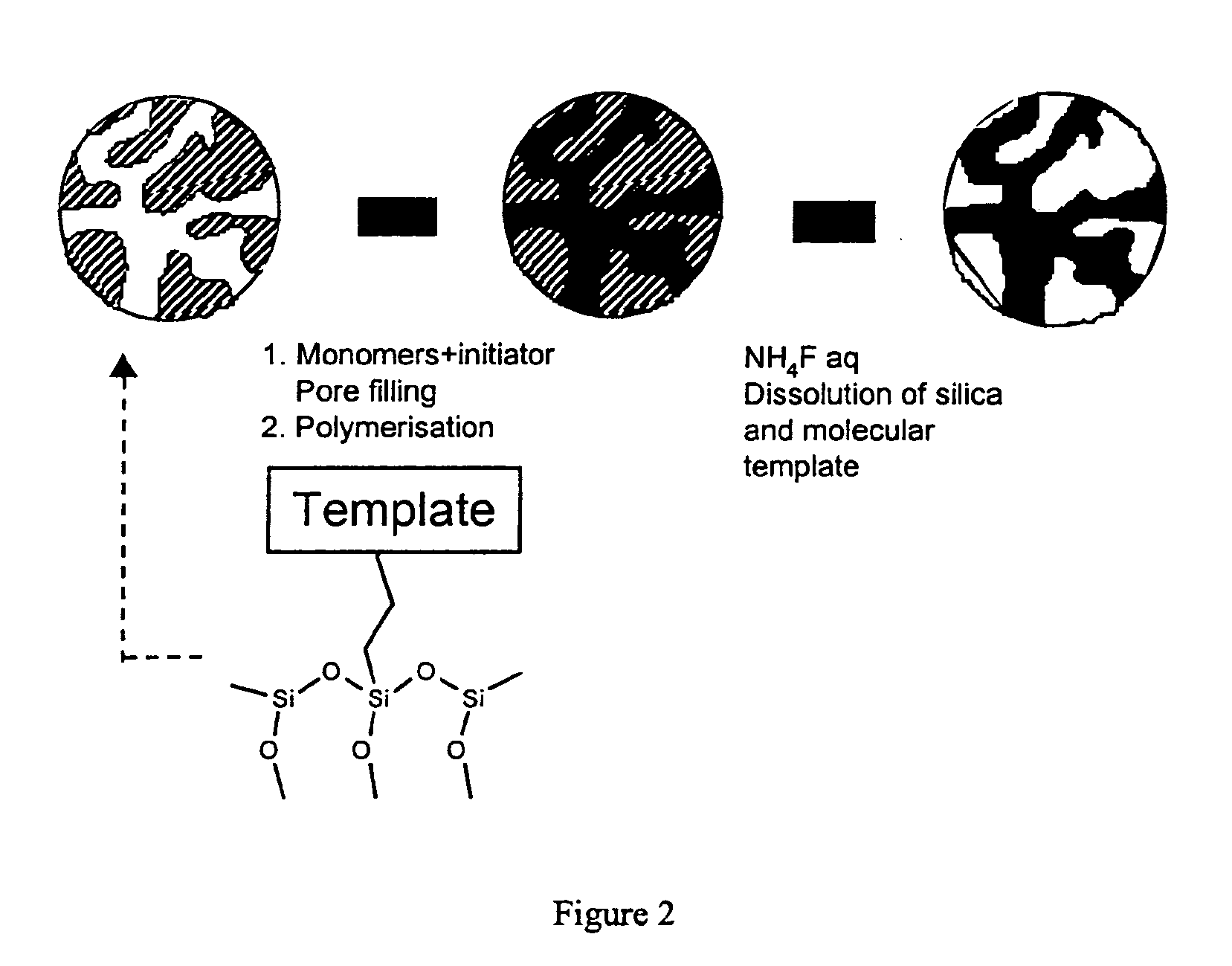

Porous, molecularly imprinted polymer and a process for the preparation thereof

InactiveUS6881804B1Other chemical processesCarrier-bound/immobilised peptidesPolymer scienceSilicon dioxide

A porous, molecularly imprinted polymer and a process for its preparation are described. The porous, molecularly imprinted polymer is characterised in that it is obtainable by providing a porous silica; attaching a molecular template to the surface of the porous silica; filling the pores of the porous silica with a polymer, removing the silica and the molecular template, thereby leaving a porous, molecularly imprinted polymer. The process is characterised by the above defined process steps. Also described are a porous polymer vesicle and its preparation with the same features as defined for the porous, molecularly imprinted polymer and its preparation, except for the lack of the molecular template and thus the lack of the molecular imprint in the porous polymer.

Owner:MIP TECH AB

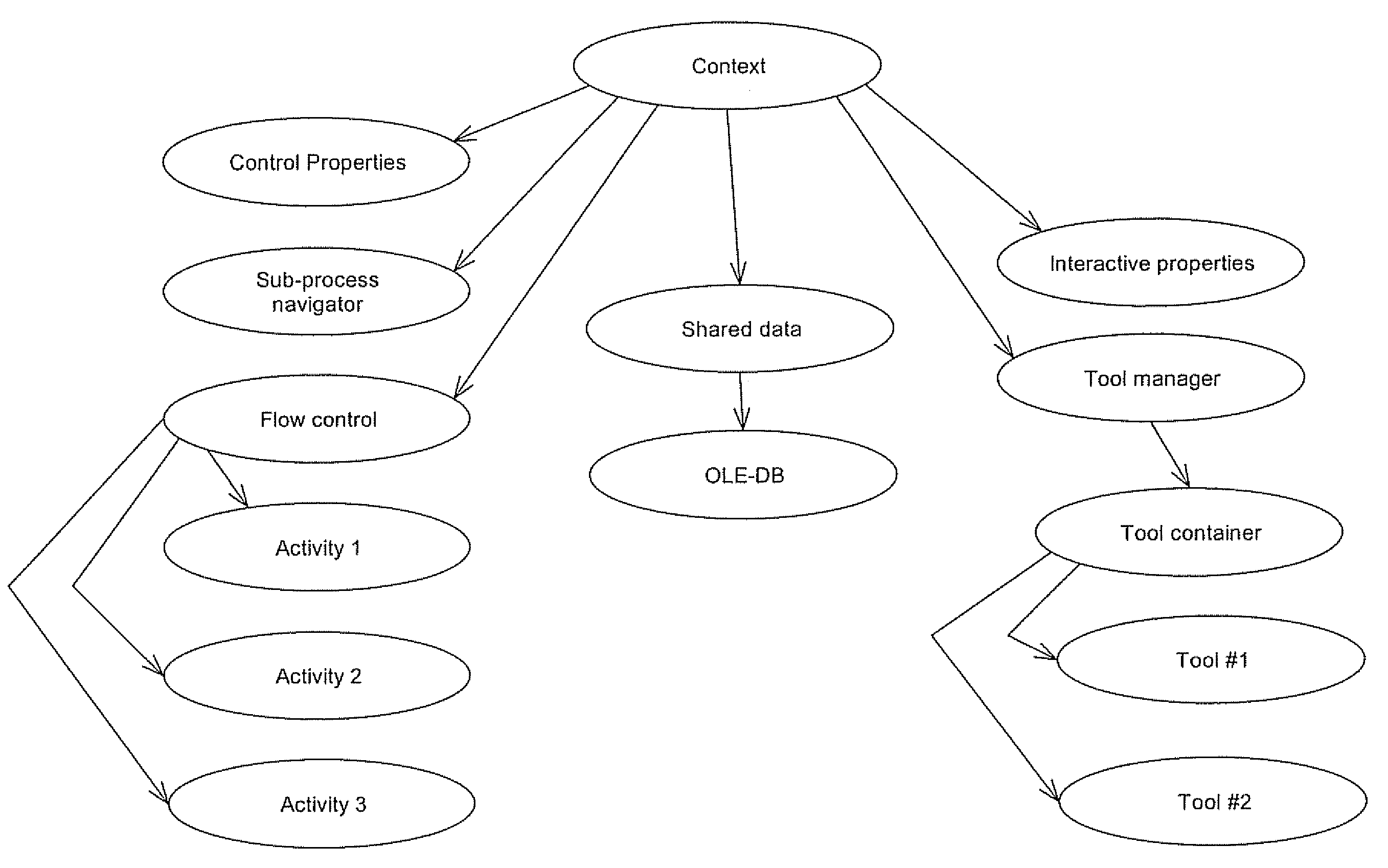

Architecture for an application framework

InactiveUS7237199B1Data processing applicationsMultiple digital computer combinationsData setApplication software

The present invention discloses a framework for monitoring workflow within an application having multiple levels of functionality, the framework being capable of combining a plurality of components from different sources and comprising a process level for selecting a set of defined process steps to be applied to a data set associated with a set of activities, a sub-process level including an aggregation of selected activities from the set of activities and facilitating navigation between the selected activities, and an activity level wherein an activity's property in the data set is modified as a result of the applied processing of the activity level to produce an output data set.

Owner:MIND FUSION LLC

System and methods for data-driven control of manufacturing processes

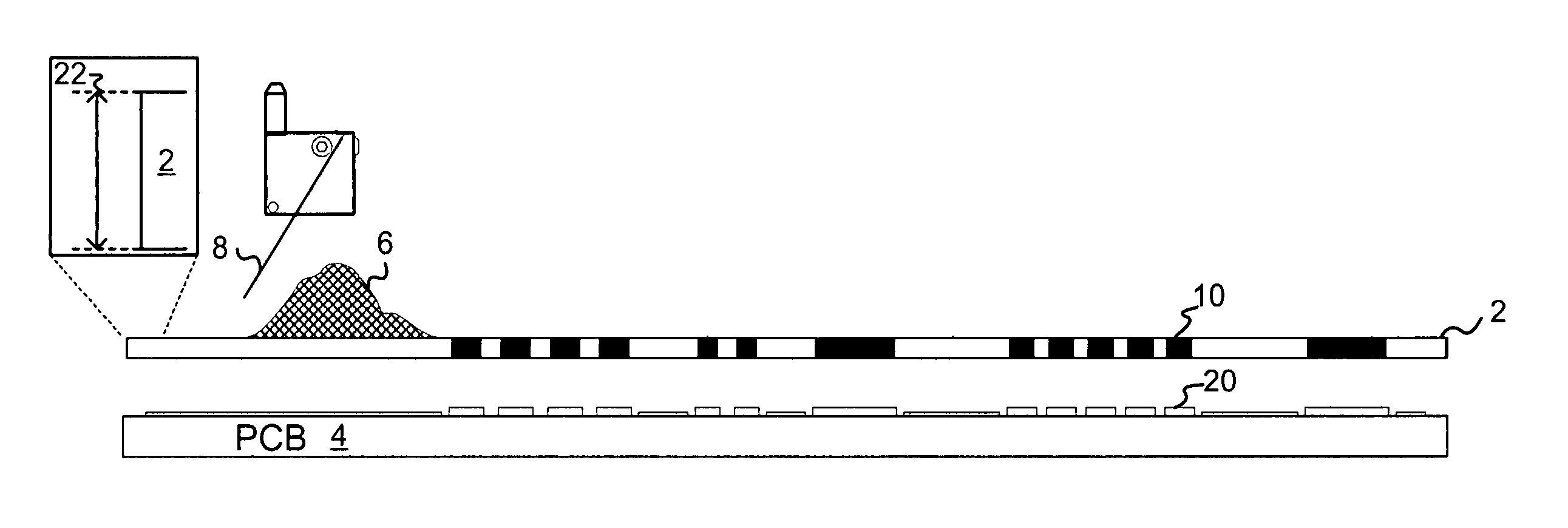

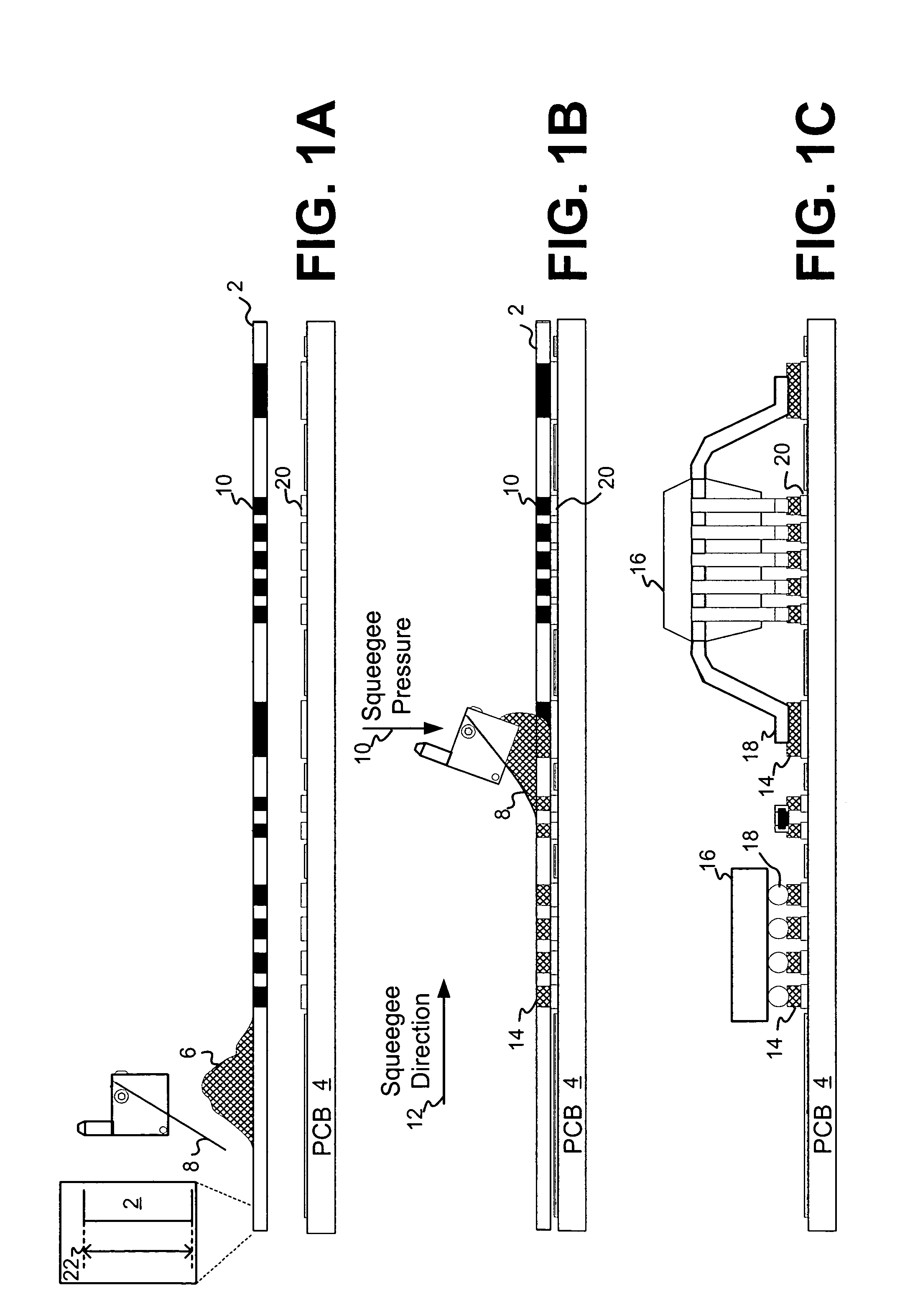

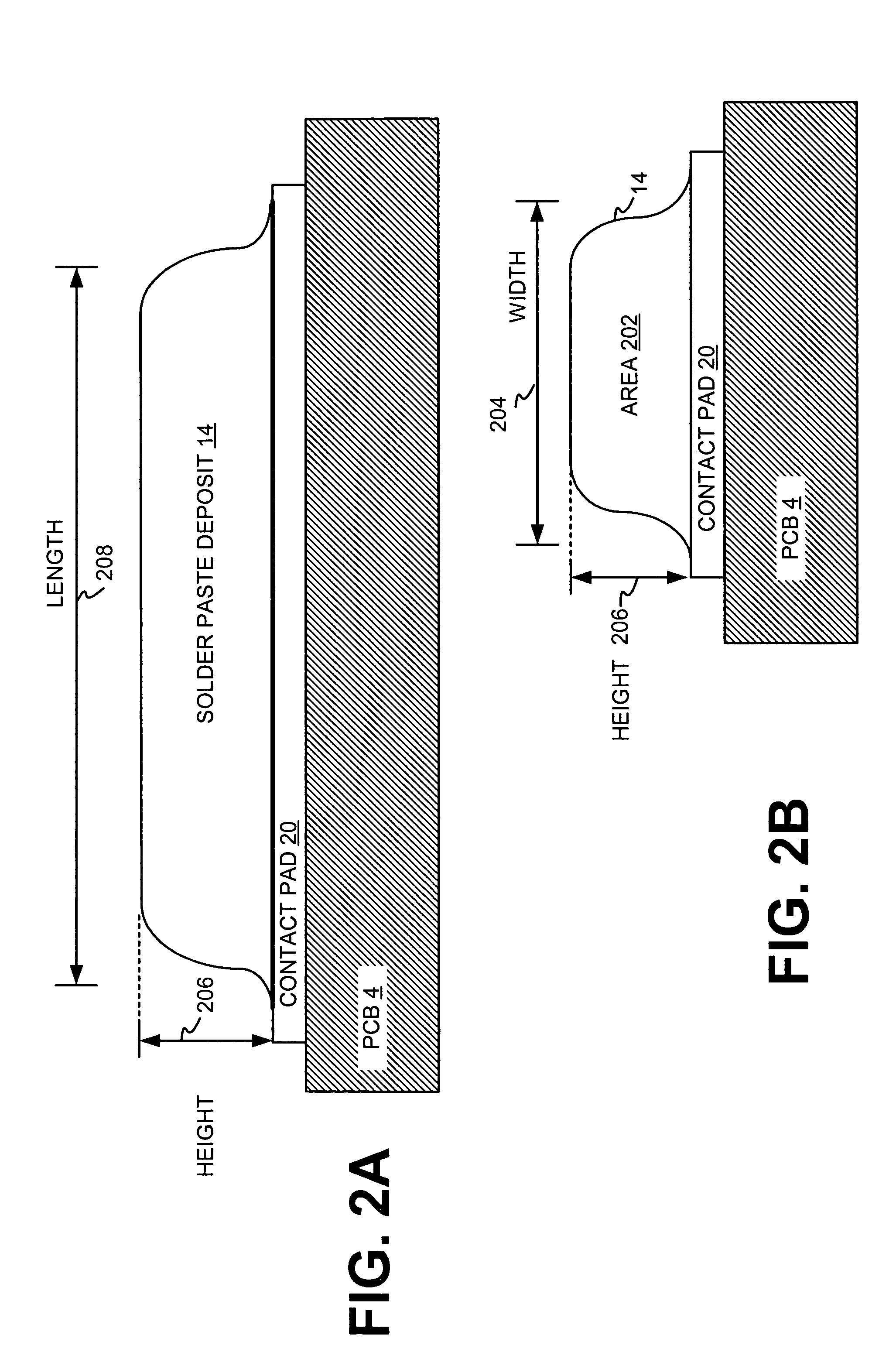

Systems and methods for implementing hybrid, closed-loop control that generates control values for processes defined by a limited number of function evaluations and large amounts of process and measurement noise. The described control system is applied to a stencil printing process for applying solder paste to an electronic medium such as a printed circuit board or semiconductor wafer. The control system is defined by a hybrid approach. A first, coarse algorithm is used to rapidly produce the value of a stencil printer control value resulting in a solder paste deposit having a volume within predetermined acceptable limits. After the coarse algorithm no longer produces solder paste deposits closer to a desired volume, a second, more refined estimator is used to fine tune the process. An additional transitional algorithm may be added between the coarse algorithm and refined estimator. The coarse algorithm may be implemented with a constrained-conjugated gradient search, and the refined search may be a implemented using a least-squares affine estimator or a quadratic estimator. The transitional algorithm may be implemented using a block version of a least-squares affine estimator.

Owner:GEORGIA TECH RES CORP

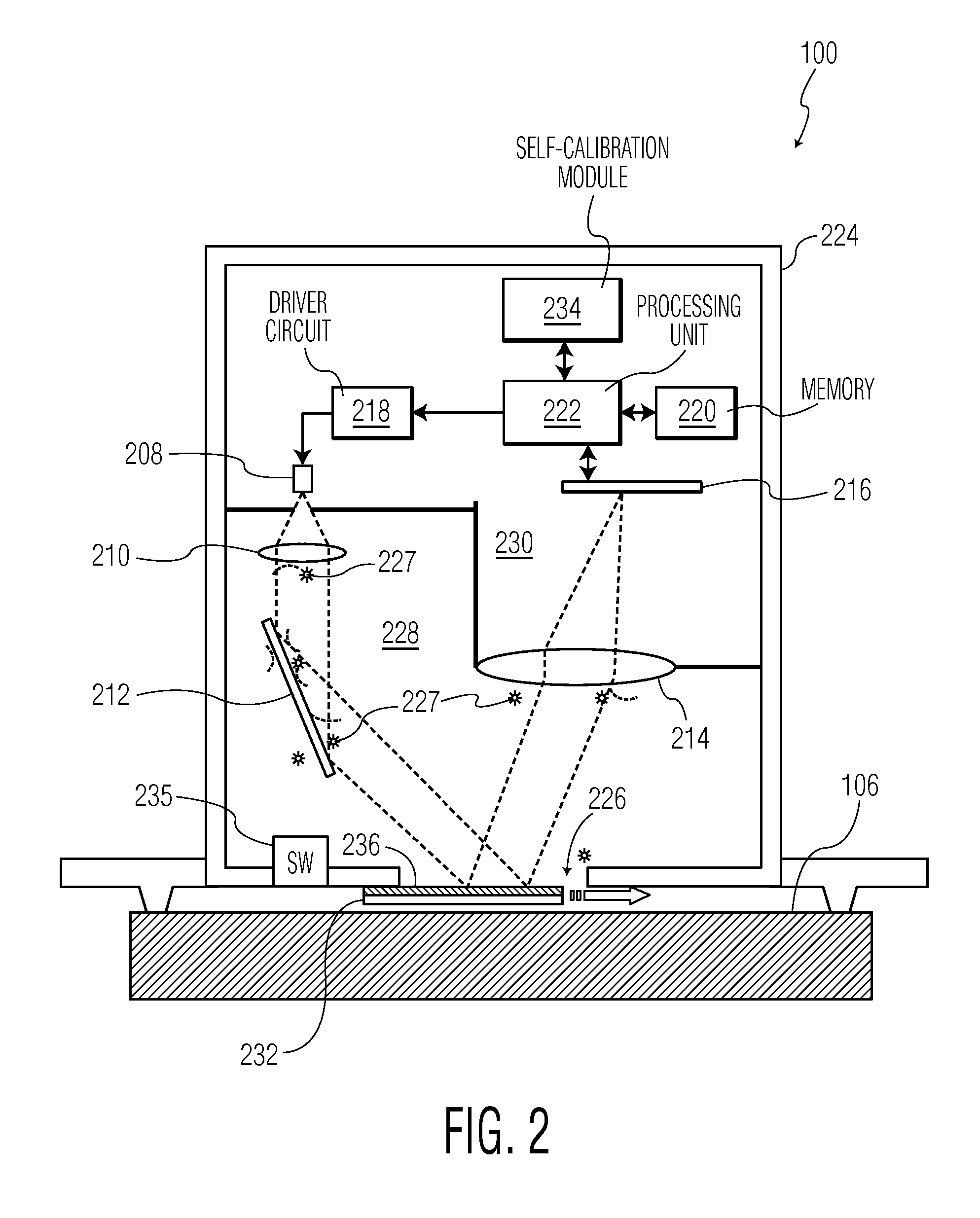

Optical navigation system and method for performing self-calibration on the system using a calibration cover

An optical navigation system and method for performing self-calibration on the system uses captured frames of image data of an interior surface of a calibration cover of the system to detect a performance-related change of the system. In response to the detected performance-related change, a predefined procedure is then initiated.

Owner:PIXART IMAGING INC

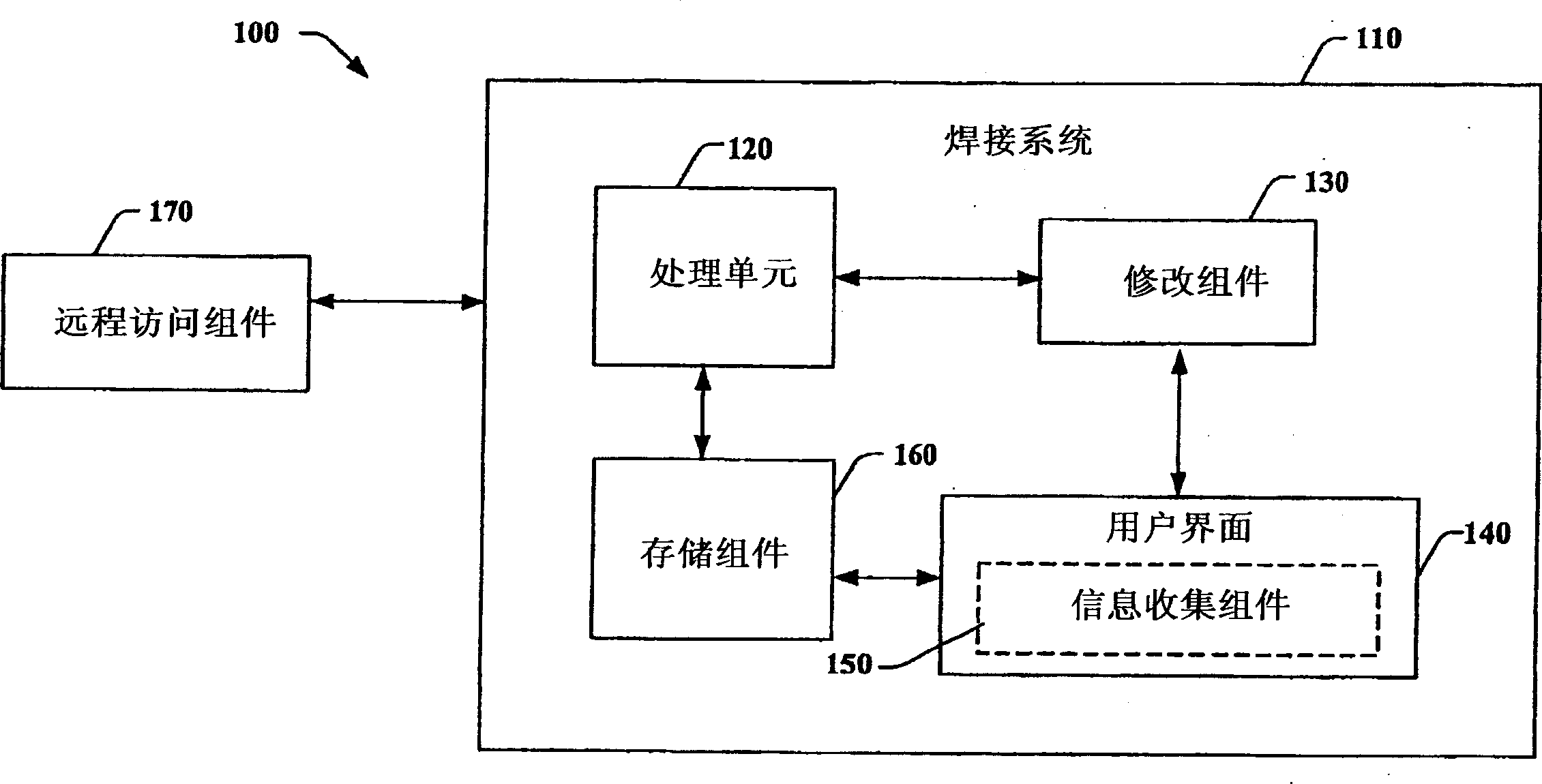

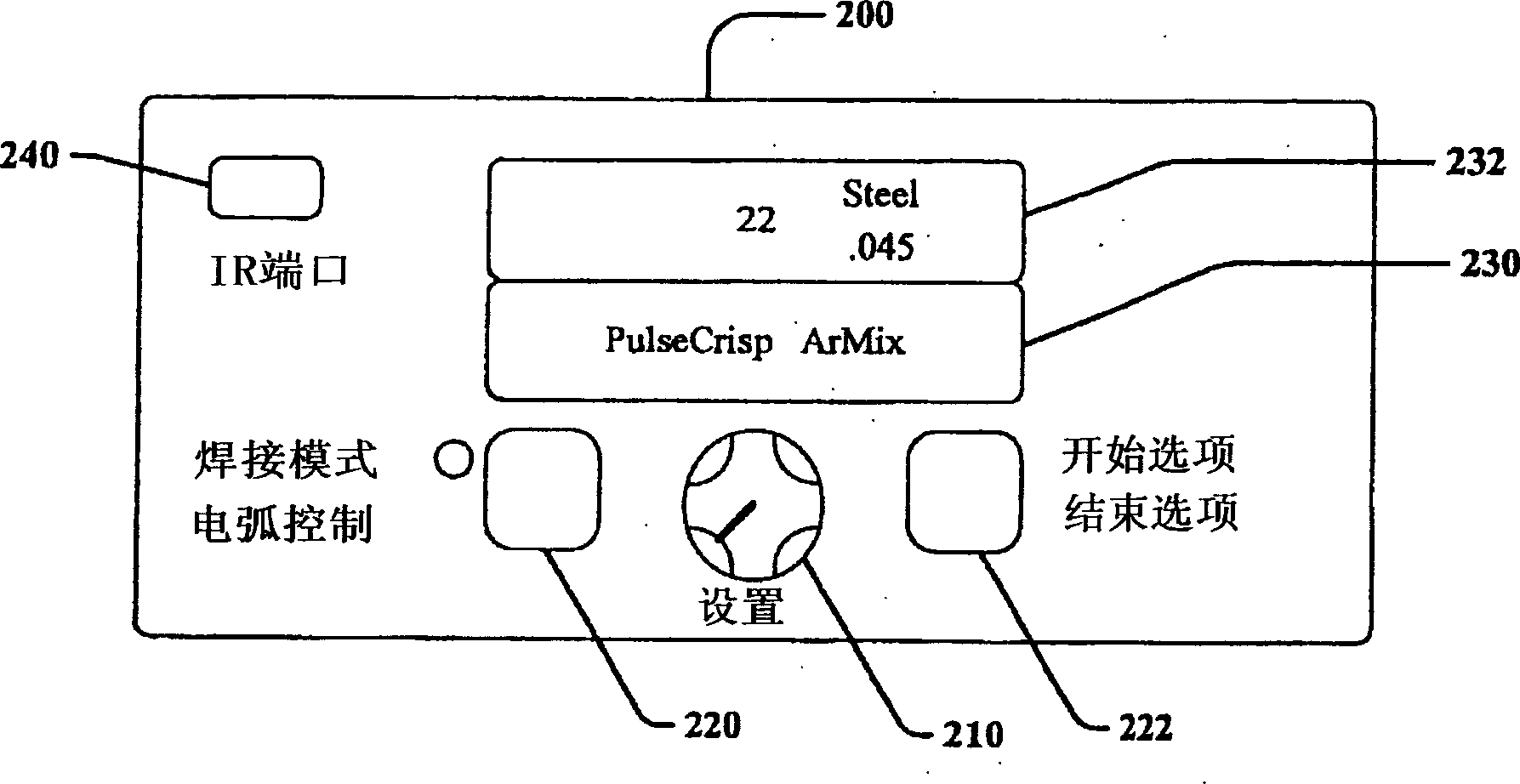

Comprehensive identification and designation of welding procedures

System(s) and method(s) that facilitates comprehensive identification and designation of welding procedures. A configuration component facilitates configuring the welding system with respect to pre-defined procedures and / or parameters and facilitates naming of the configured welding system. A storage component that stores the configured welding system in a readily accessible memory location. A remote access component can facilitate remotely accessing the welding system, the configuration of the welding system alterable by way of the remote access component.

Owner:LINCOLN GLOBAL INC

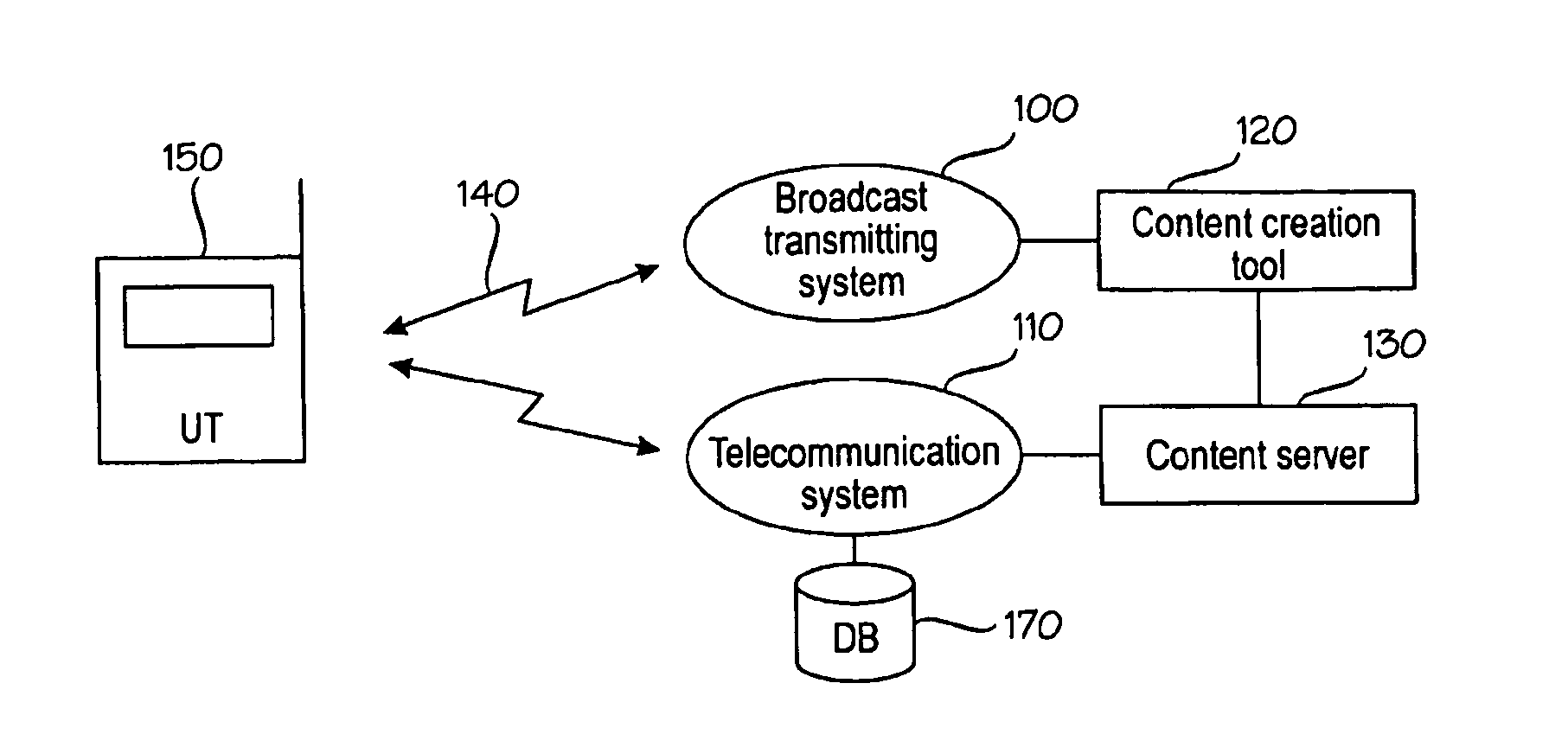

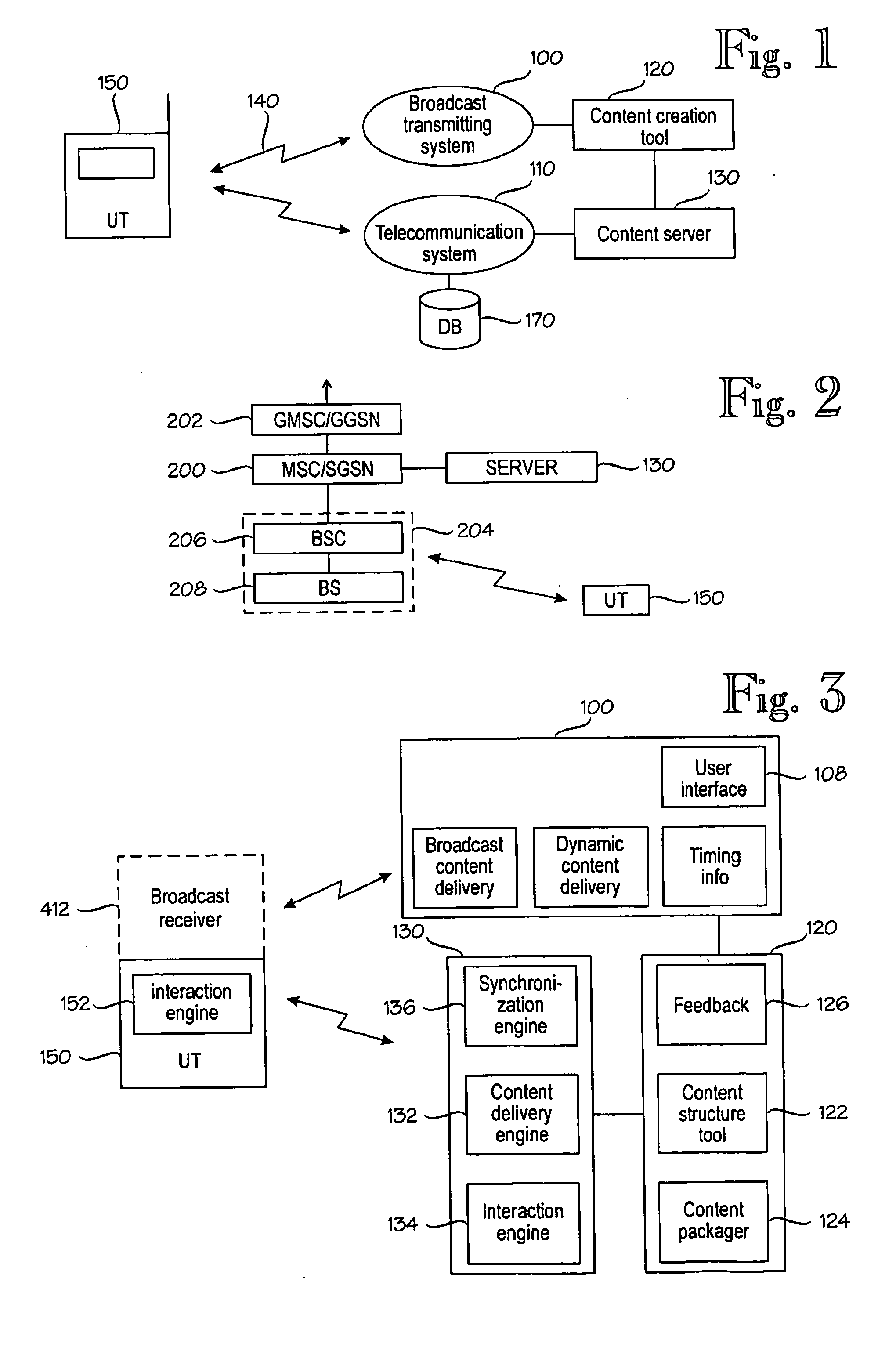

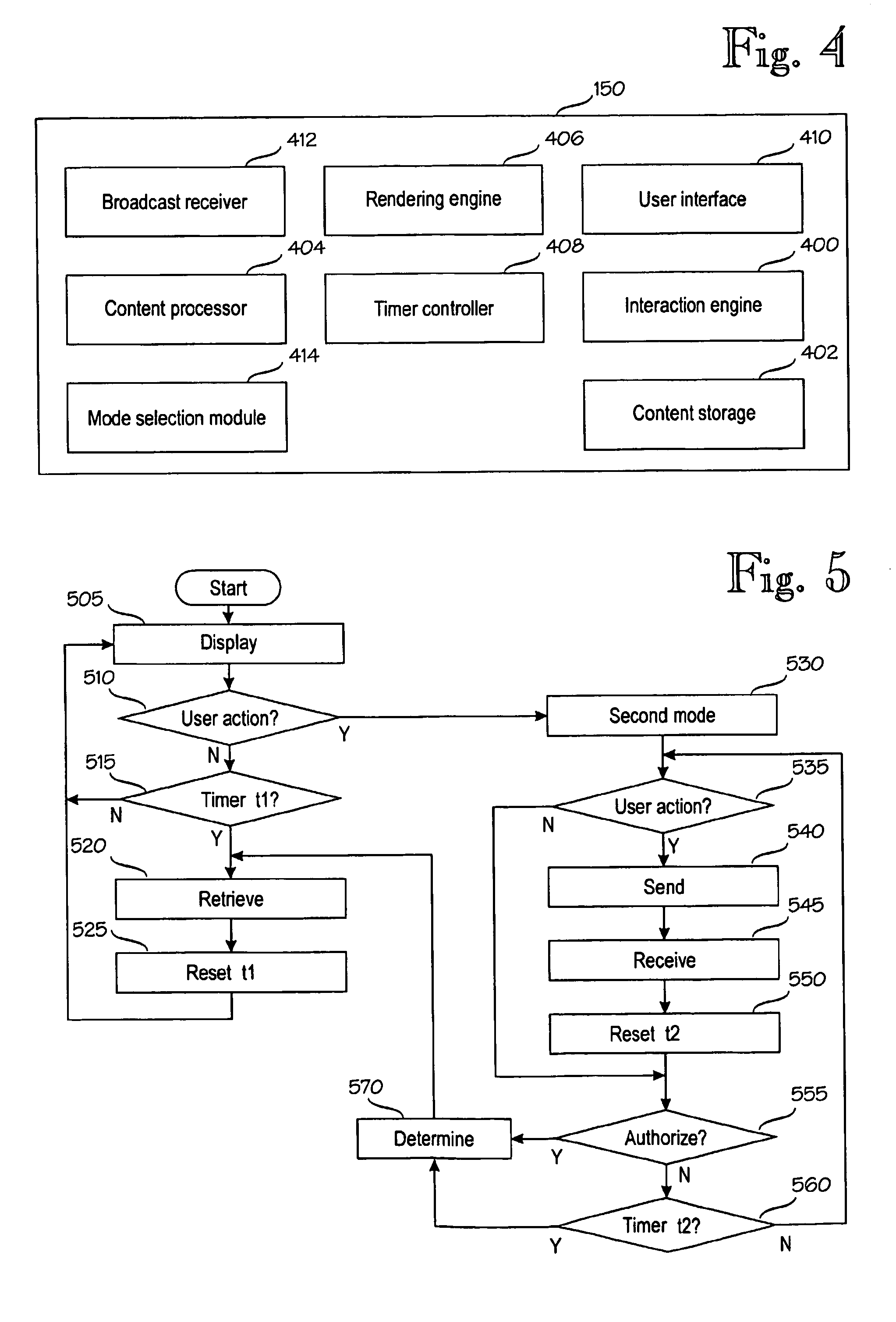

Method and system of displaying content associated with broadcast program

ActiveUS20060014490A1Broadcast transmission systemsBroadcast services for monitoring/identification/recognitionDefined ProcedureContent Time

A media system comprising a broadcast system, a telecommunication system, a content processing system, and a user terminal. While a media stream is broadcast, a group of content items associated with the media stream are generated. The content items are presented in the user terminal in a first mode, wherein a presentation element corresponding to a content item is changed to another presentation element according to the timing information of the content item, or in a second mode wherein a presentation element is changed to another presentation element in response to a user action. Transition from the second mode is allowed only by authorization according to a pre-defined procedure. The interactive operations are thus controlled by the user and thus not overridden by content timed or pushed to the user terminal for display.

Owner:RPX CORP

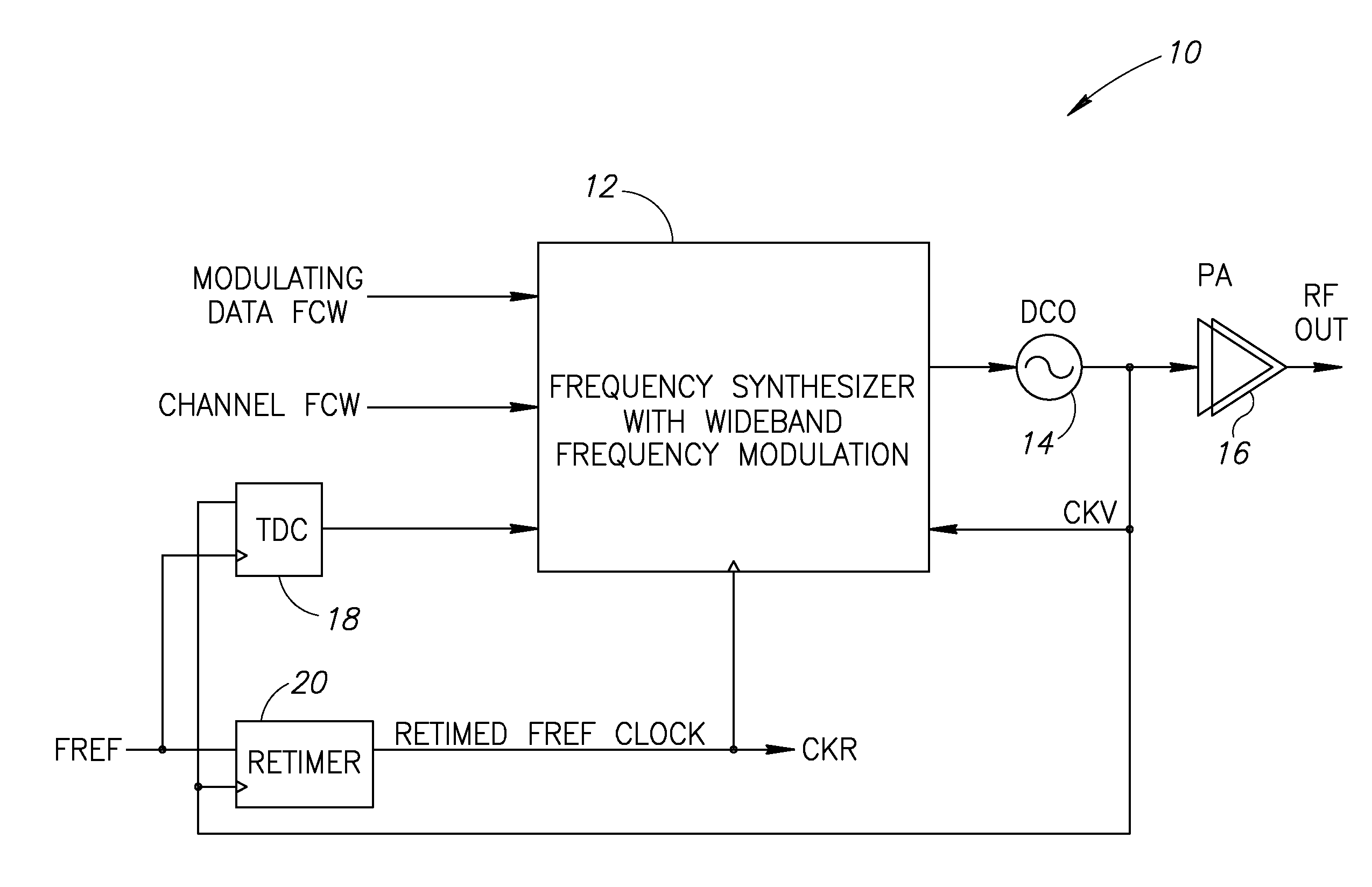

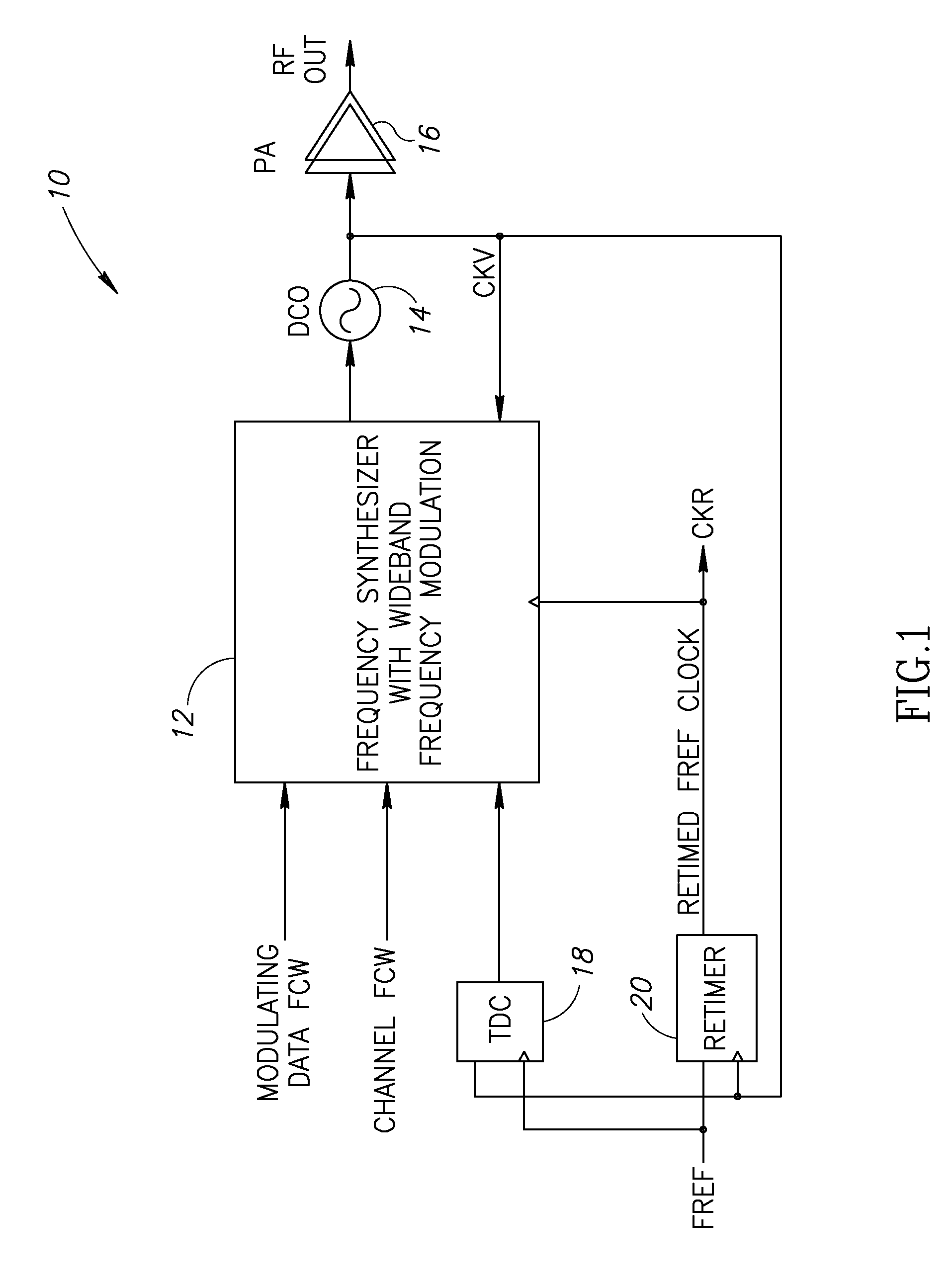

Method of defining semiconductor fabrication process utilizing transistor inverter delay period

ActiveUS20070110194A1Improve performanceError preventionPulse automatic controlManufacturing technologyTime delays

A novel method and apparatus for defining process variation in a digital RF processor (DRP). The invention is well suited for use in highly integrated system on a chip (SoC) radio solutions that incorporate a very large amount of digital logic circuitry. The method and apparatus provide direct measurement of fabrication process variation in circuits without requiring any additional test equipment by utilizing a time to digital converter (TDC) circuit already present in the chip. The TDC circuit relies on the time delay in an inverter chain to sample a high speed CKV clock using a slow FREF clock. Calculation of inverse time provides a direct correlation for fabrication process variation in each die.

Owner:DE OBALDIA ELIDA ISABEL +3

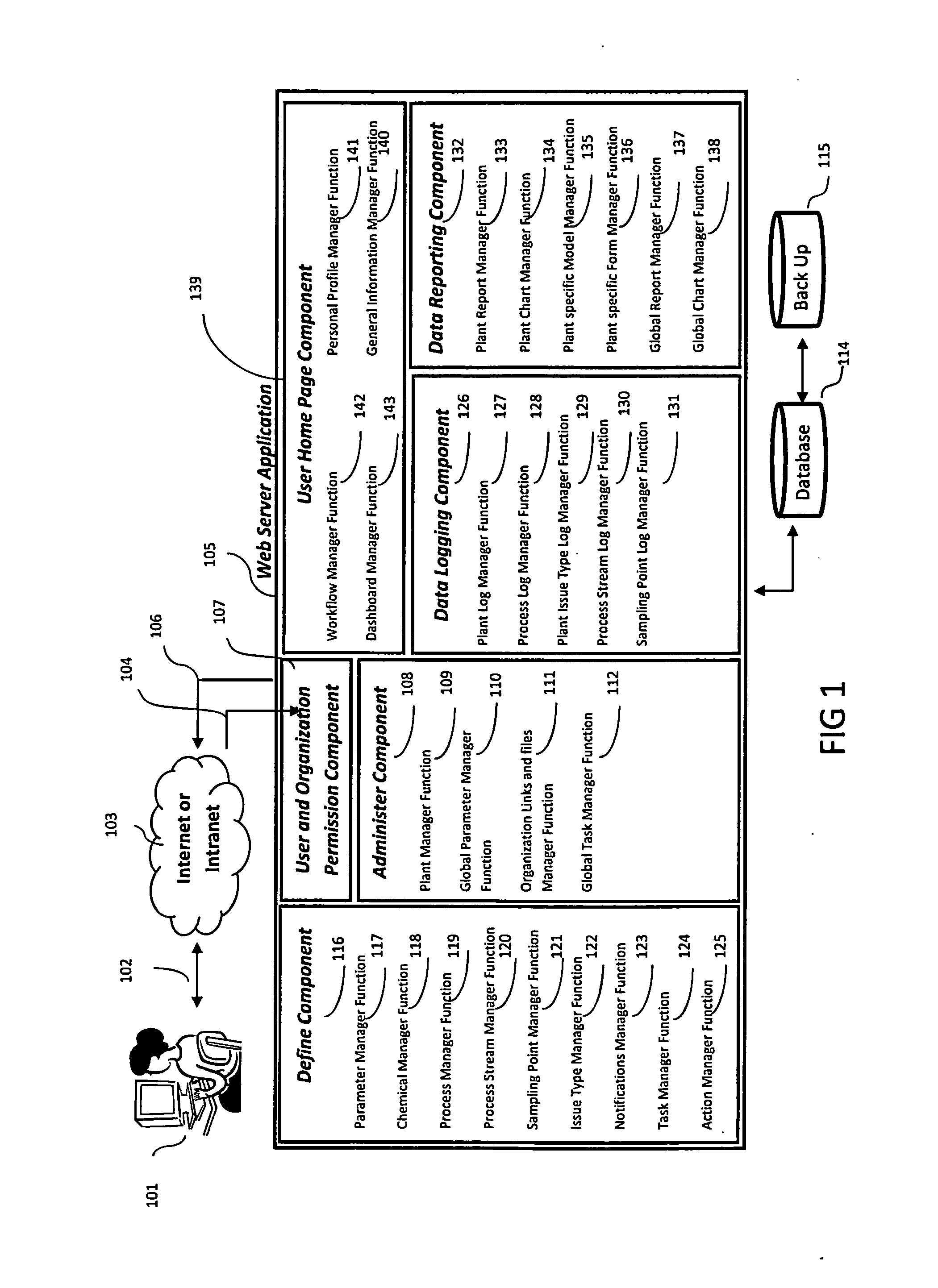

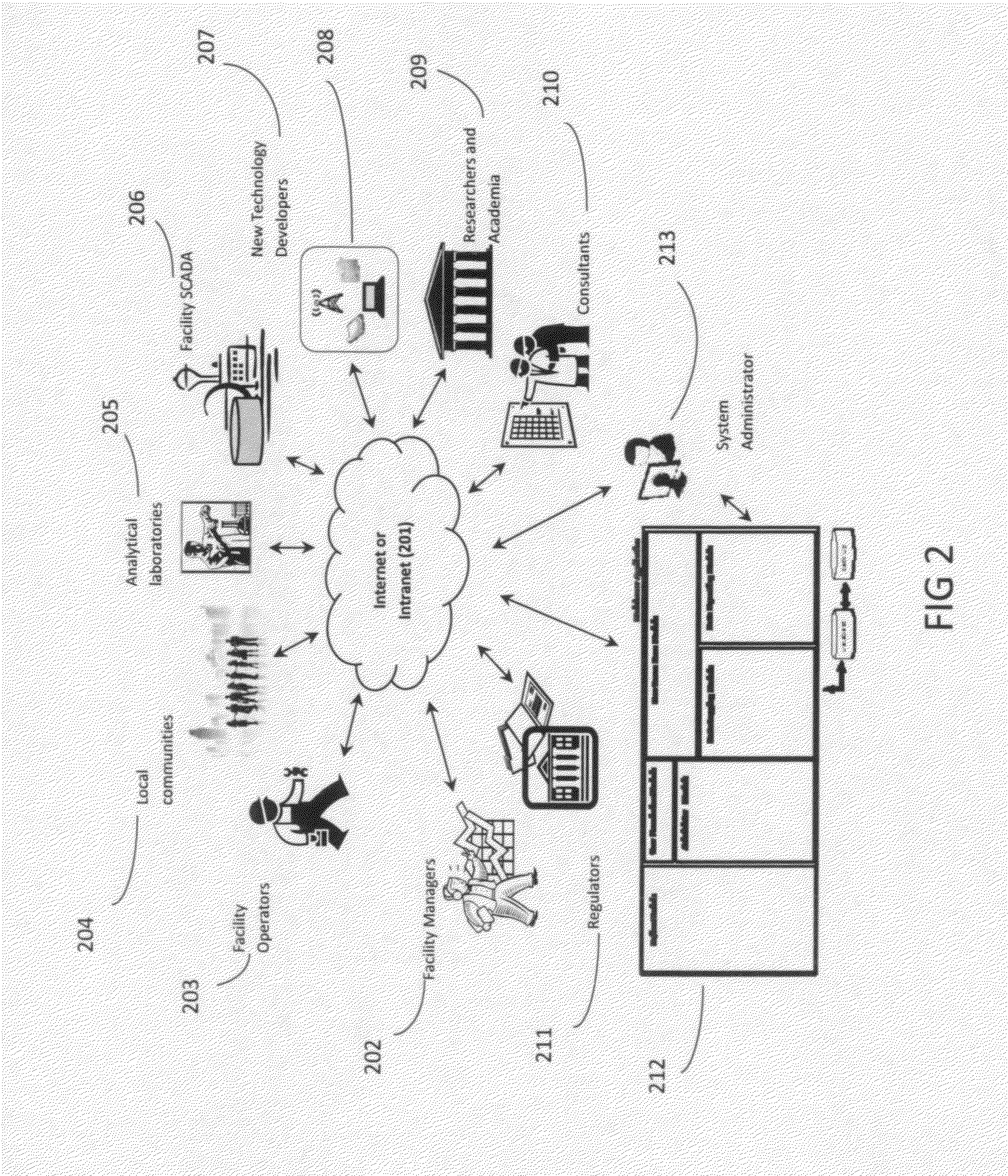

Form-based user-configurable process information system and method

ActiveUS20140325331A1Natural language data processingSpecial data processing applicationsData miningProcess information

A machine-implemented system and method for defining process information is disclosed. In one embodiment, the system or method allows a user to list processes, define processes using an input form, list process parameters, list sampling points, define sampling points using an input form, and list sampling point parameters for a chemical process or processes. Enhancements can include functionality that allows a user to list process streams, define process streams using an input form, list process stream parameters, list process stream chemicals, and list process chemicals. Other enhancements can include functionality that allows a user to list reports, render reports using an input form, and list sampling point logs. The objective is to allow users to log, report, and chart process data using electronic input forms that do not require the writing of programming code by the person defining the process or processes.

Owner:FLOWATCH

Porous, molecularly imprinted polymer and a process for the preparation thereof

InactiveUS20050189291A1Semi-permeable membranesOther chemical processesPolymer scienceSilicon dioxide

A porous, molecularly imprinted polymer and a process for its preparation are described. The porous, molecularly imprinted polymer is characterised in that it is obtainable by providing a porous silica; attaching a molecular template to the surface of the porous silica; filling the pores of the porous silica with a polymer; removing the silica and the molecular template, thereby leaving a porous, molecularly imprinted polymer. The process is characterised by the above defined process steps. Also described are a porous polymer vesicle and its preparation with the same features as defined for the porous, molecularly imprinted polymer and its preparation, except for the lack of the molecular template and thus the lack of the molecular imprint in the porous polymer.

Owner:MIP TECH AB

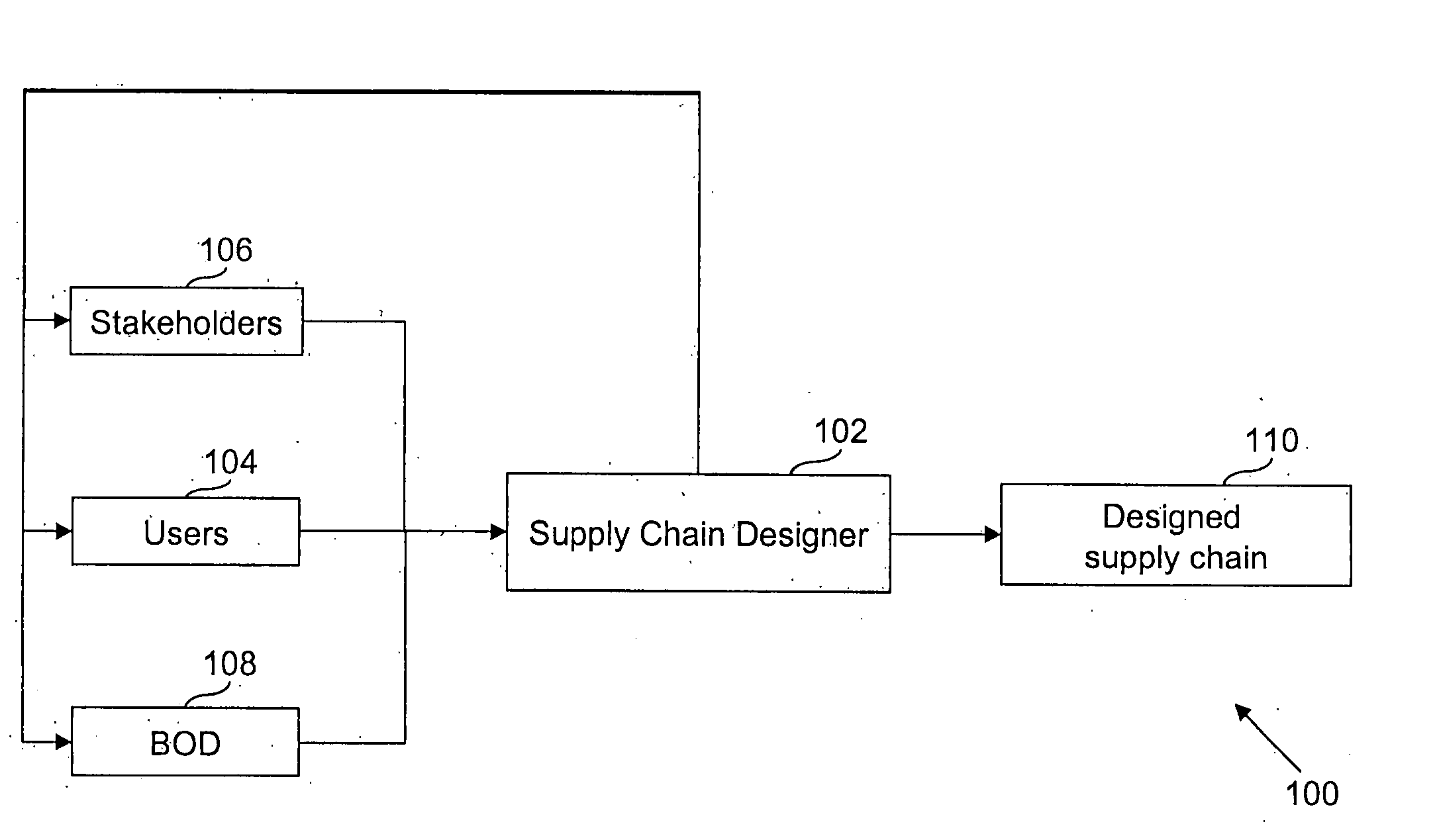

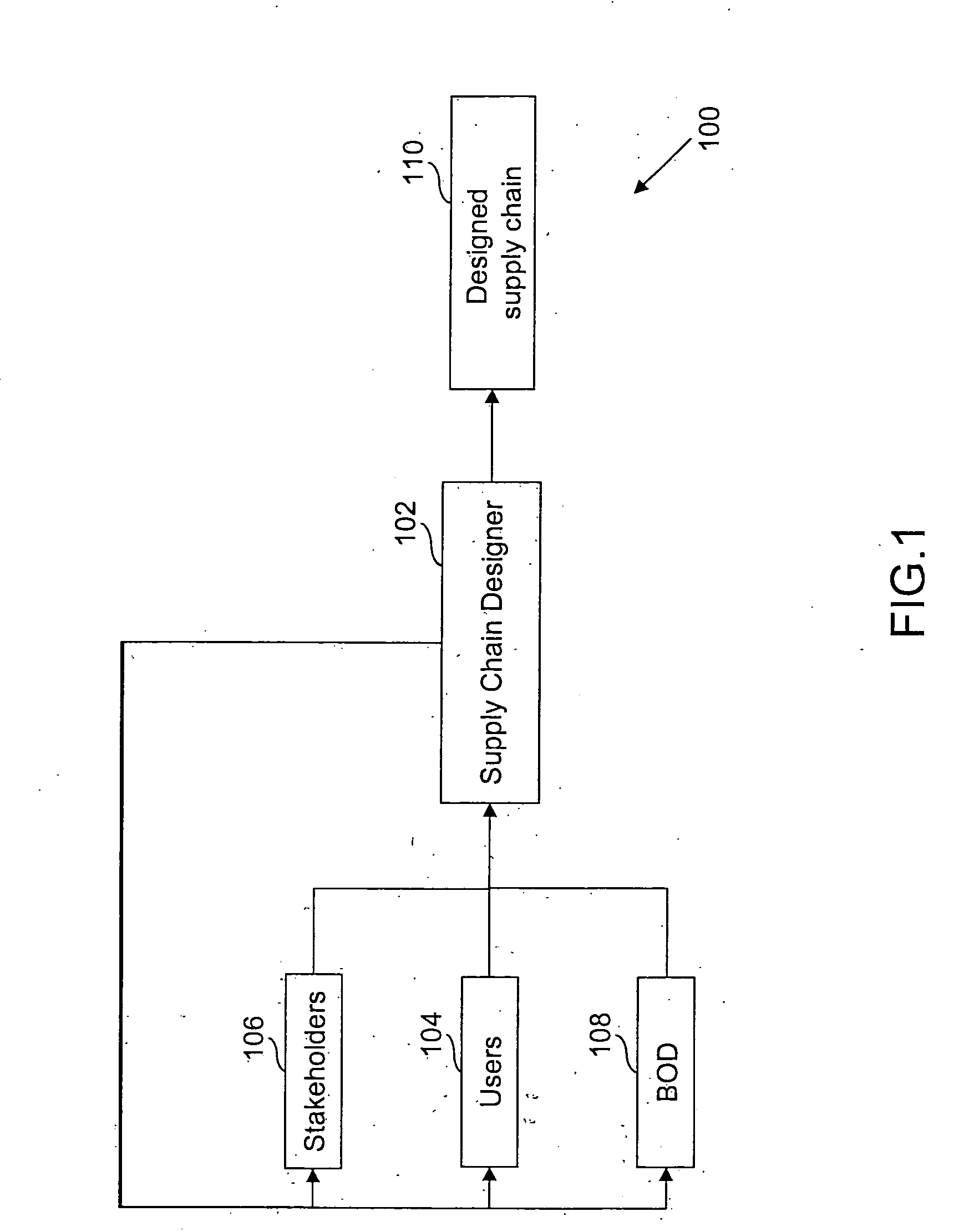

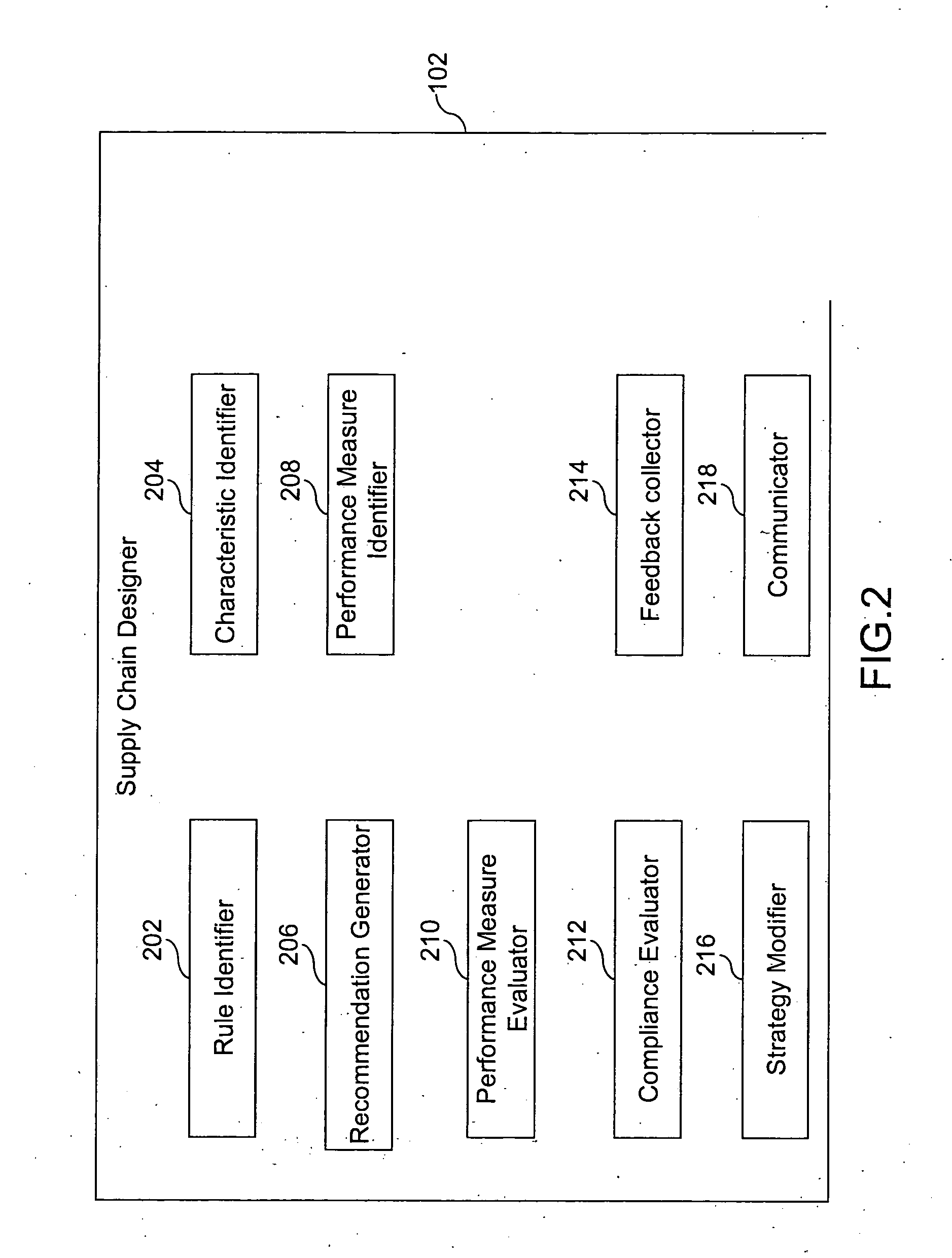

System and method for designing a supply chain

A system, method and apparatus are provided for designing and evaluating a supply-chain architecture and strategy, and communicating the architecture to concerned parties. The supply chain is designed by combining business strategies and analytical modeling in a well-defined process. Key product and market attributes are combined with defined supply-chain processes and strategies, to identify a preferred supply chain architecture and strategy. Feedback from the concerned parties is collected, and modifications are made iteratively to the supply chain architecture and strategy, based on the collected feedback.

Owner:CISCO TECH INC

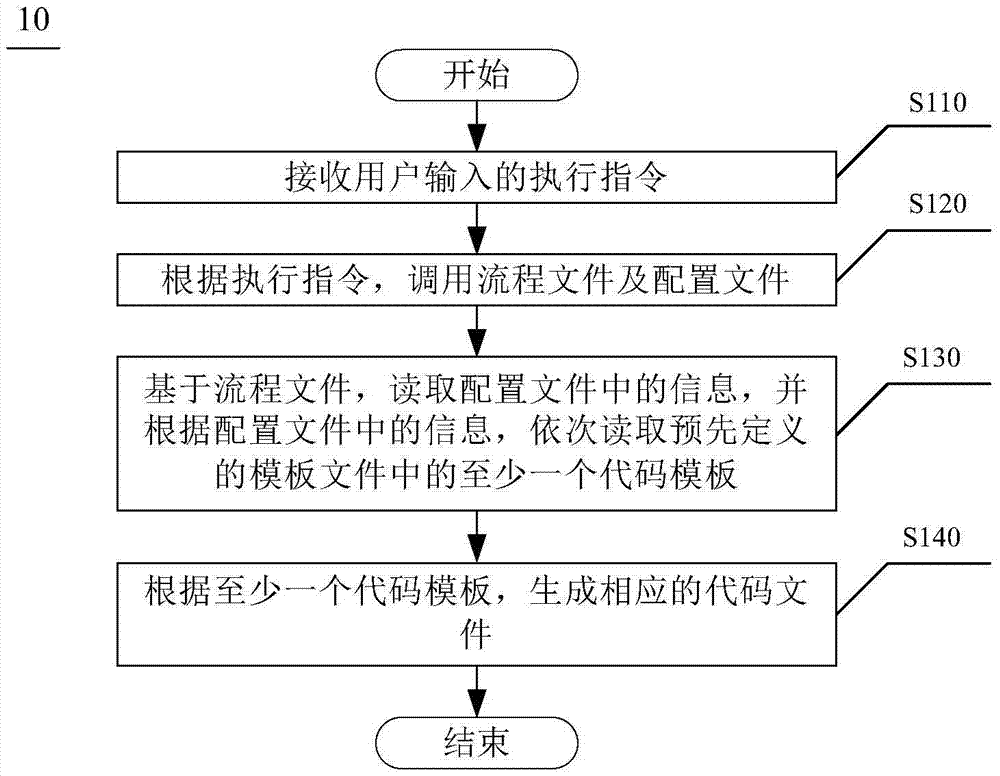

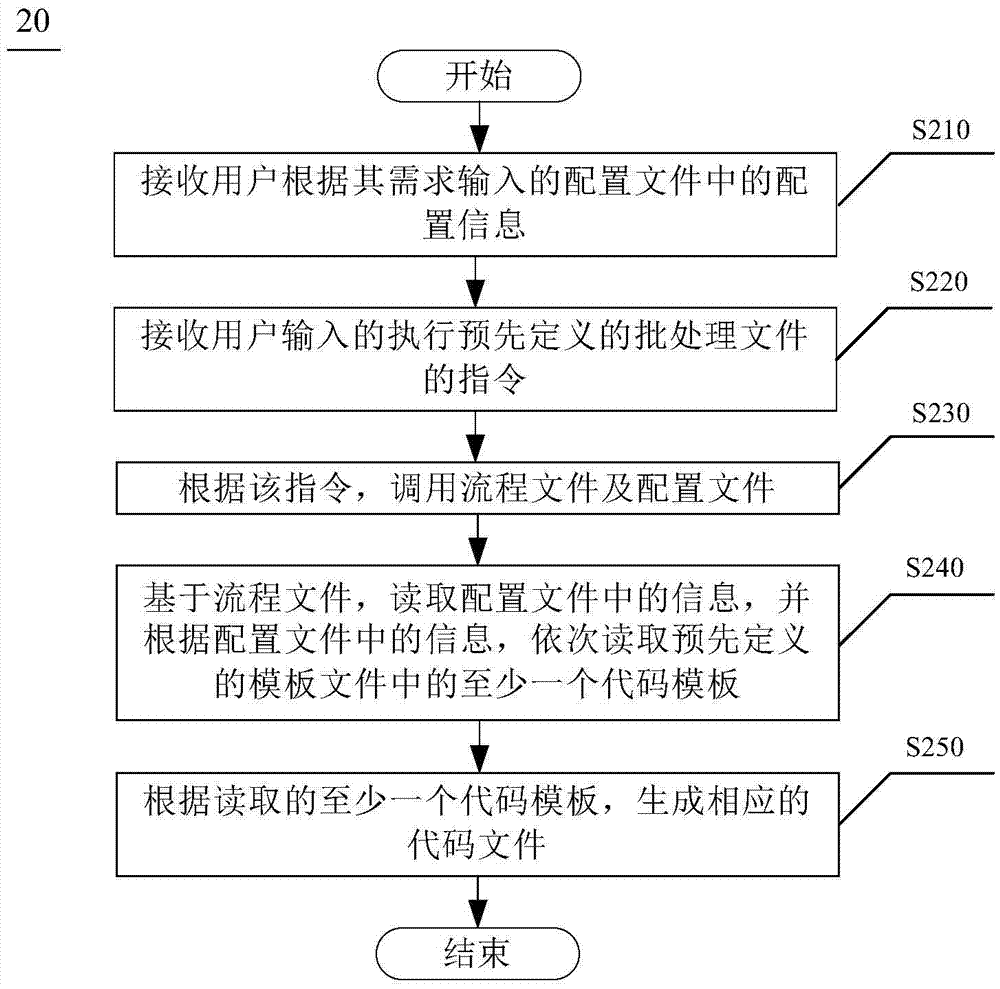

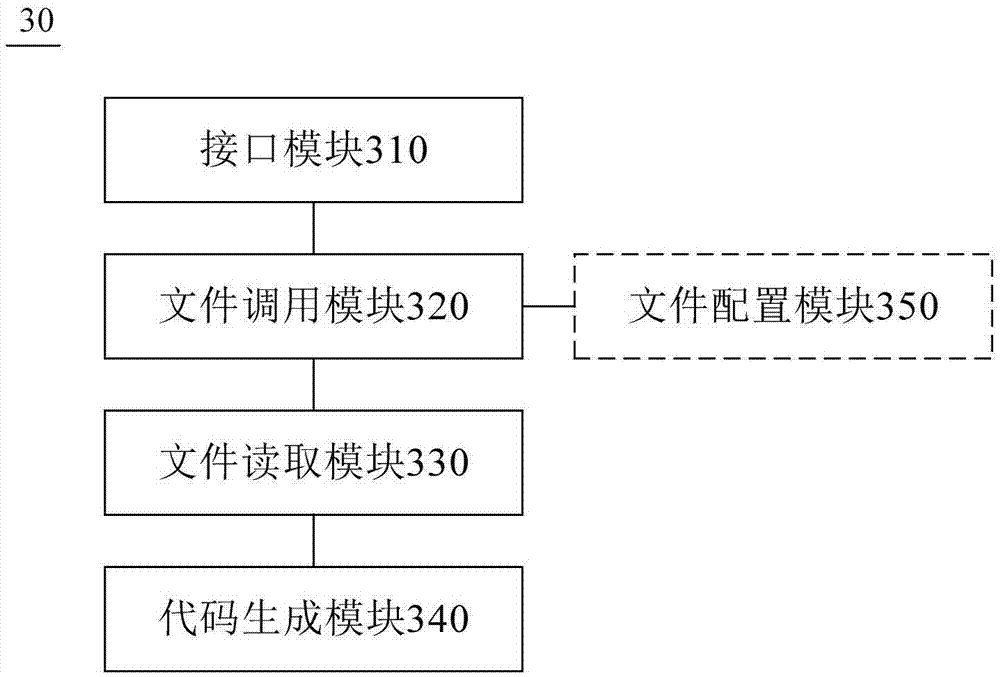

Code generating method and device

InactiveCN106873949AReduce workloadShorten the timeProgram documentationProgramming languages/paradigmsUser needsUser input

The invention discloses a code generating method and device. The code generating method comprises the following steps: receiving an executing instruction input by a user, recalling a process file and a configuration file according to the executing instruction, wherein the process file is pre-defined; reading information in the configuration file on the basis of the process file, and successively reading at least one code template in a pre-defined template file; and generating a corresponding code file according to the code templates. The pre-defined process file, the pre-defined template file and the configuration file which can be configured according to demands of the user are adopted, and normative code files which execute corresponding tasks are generated on the basis of the demands of the user. On one hand, the workload of code developers is reduced, time and effort are saved, and the working efficiency is improved; and on the other hand, the problem that codes of various application modules of a system are not unified or normative enough is solved.

Owner:TAIKANG LIFE INSURANCE CO LTD

Systems and/or methods for managing transformations in enterprise application integration and/or business processing management environments

In certain example embodiments of this invention, systems and / or methods for managing transformations in Enterprise Application Integration (EAI) and / or Business Process Management (BPM) Environments are provided. In certain example embodiments of this invention, when a process and / or transform is defined, design-time encoding data is extracted and stored as metadata. When the process or transform is implemented, runtime data is captured and / or managed, and also stored as metadata. When new processes and / or transforms are defined, and / or when an already-defined process and / or a transform is executed, heuristics may be applied so as to suggest one or more already-existing transformation chains for use in accomplishing at least a part of the same and / or a similar process or transform.

Owner:SOFTWARE AG

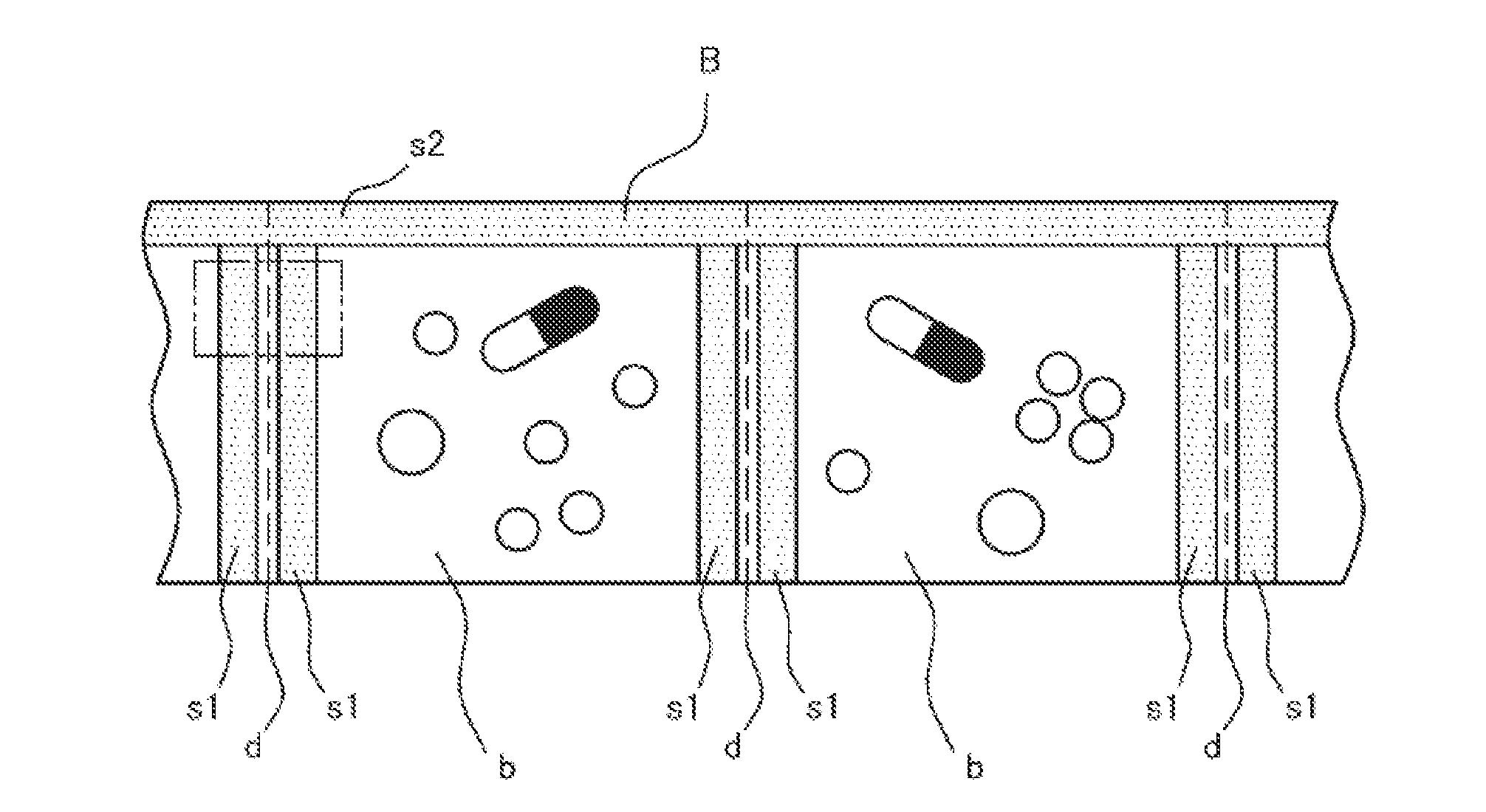

Medicine inspection device, and medicine packaging device

ActiveUS20140002631A1Improve detection accuracyInspection is accuratePharmaceutical product form changeMaterial analysis by optical meansImage InspectionBiomedical engineering

A medicine inspection device includes: an inspection unit on which a medicine for inspection is disposed, the medicine being contained in a sachet; a shooting means capable of photographing the sachet disposed on the inspection unit; and a medicine information detector capable of detecting at least either of a quantity or type of the medicine based on an image obtained by the shooting means. The inspection unit includes a backlight with illumination areas located dottedly per predetermined pitch which is capable of illuminating the sachet from backside when photographing. The medicine information detector is further configured to implement: a basic image acquisition process for acquiring a basic image; an inspection area defining process for defining the area of inspection; an inspection image acquisition process for acquiring the inspection image; and an image inspection process for performing image inspection.

Owner:YUYAMA MFG CO LTD

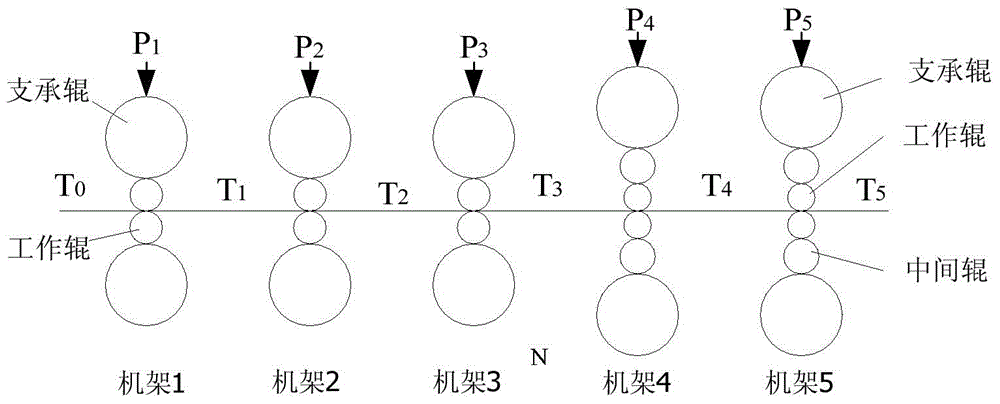

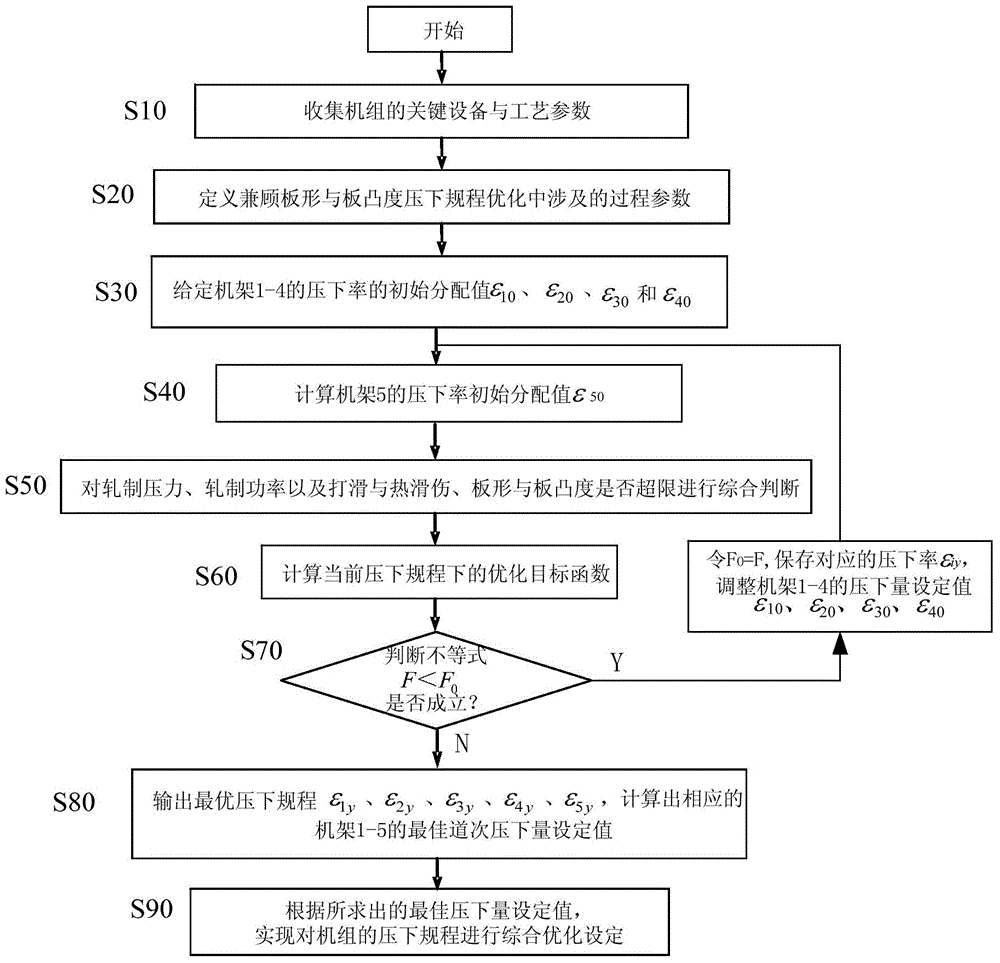

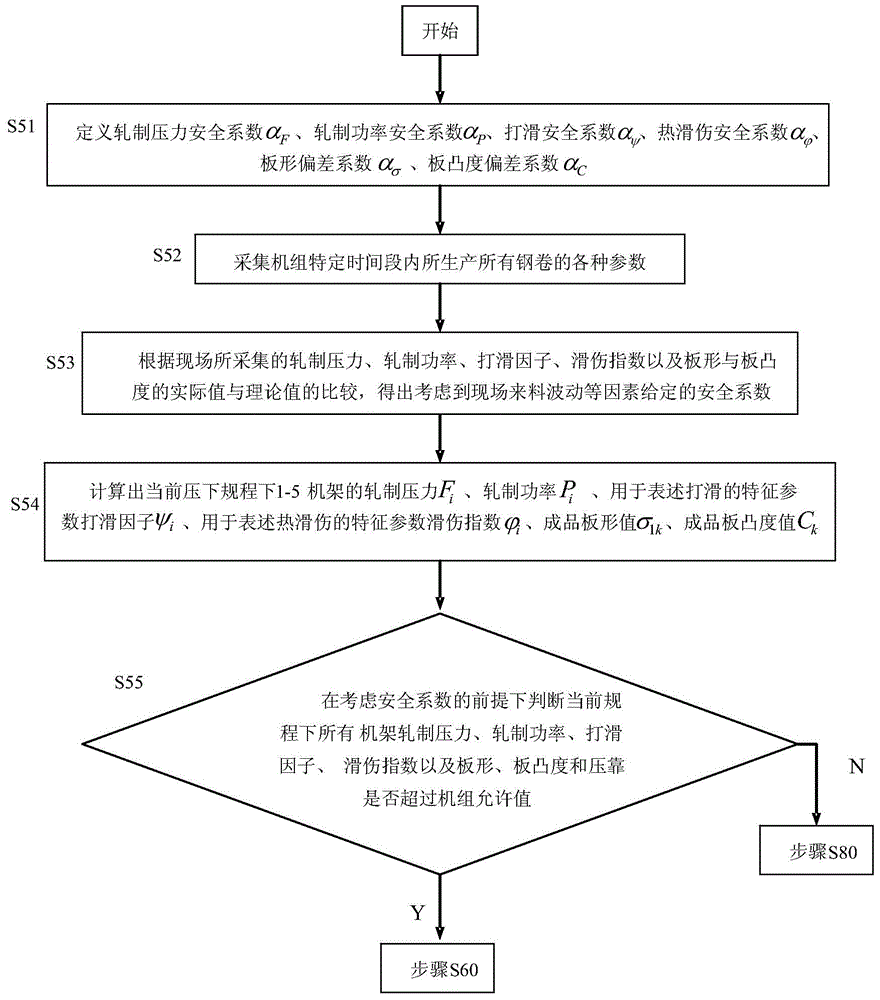

Reduction schedule optimization method for rolling ultrathin strip steel by cold continuous rolling set

ActiveCN104785538AClosure rate downRolling load balanceRoll force/gap control deviceTension/compression control deviceControl systemStrip steel

The invention discloses a reduction schedule optimization method for rolling ultrathin strip steel by a cold continuous rolling set, and relates to special control equipment or a method for a metal rolling machine or other processed products, in particular to a reduction schedule optimization method for rolling ultrathin strip steel by a cold continuous rolling set; traditional equipment parameters and process parameter data of a cold continuous rolling set control system are used for defining process parameters giving consideration to the plate shape, the plate convexity and the reduction control and related to the reduction schedule optimization to calculate optimized target functions under present reduction schedule; the reduction schedule optimization is realized through the computer program control; and under the precondition of considering the safety coefficient, the reduction schedule comprehensive optimization setting of the ultrathin strip steel rolling is realized through judging if the rolling pressure, the rolling power, the slip factor, the slip index, the plate shape, the plate convexity and the reduction are excessive. After the method is adopted, the plate shape in an outlet of a tail frame representing the strip quality is obviously reduced, the plate convexity pass percent is prominently improved, and the strip quality is obviously improved compared with a traditional method.

Owner:BAOSHAN IRON & STEEL CO LTD

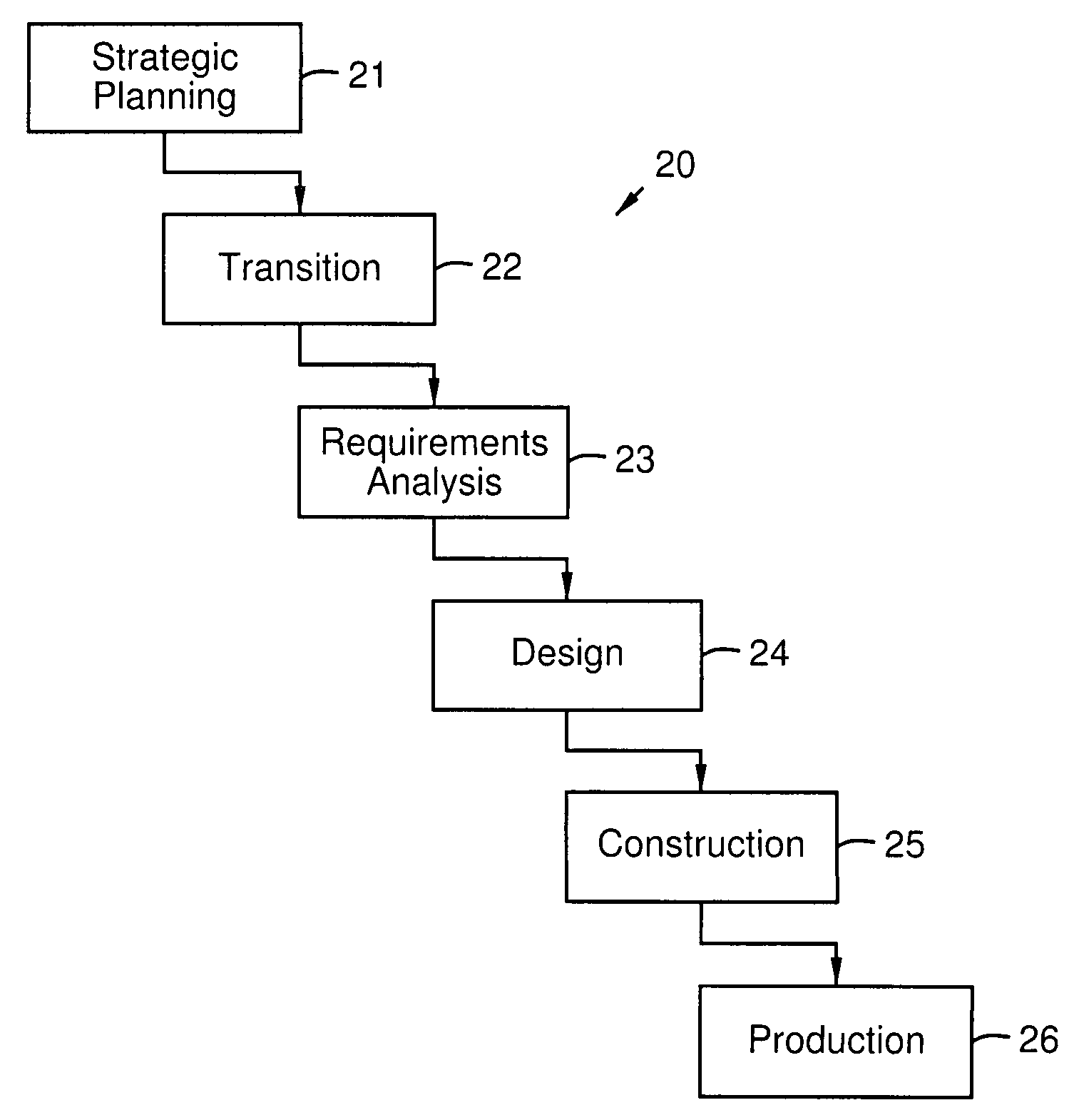

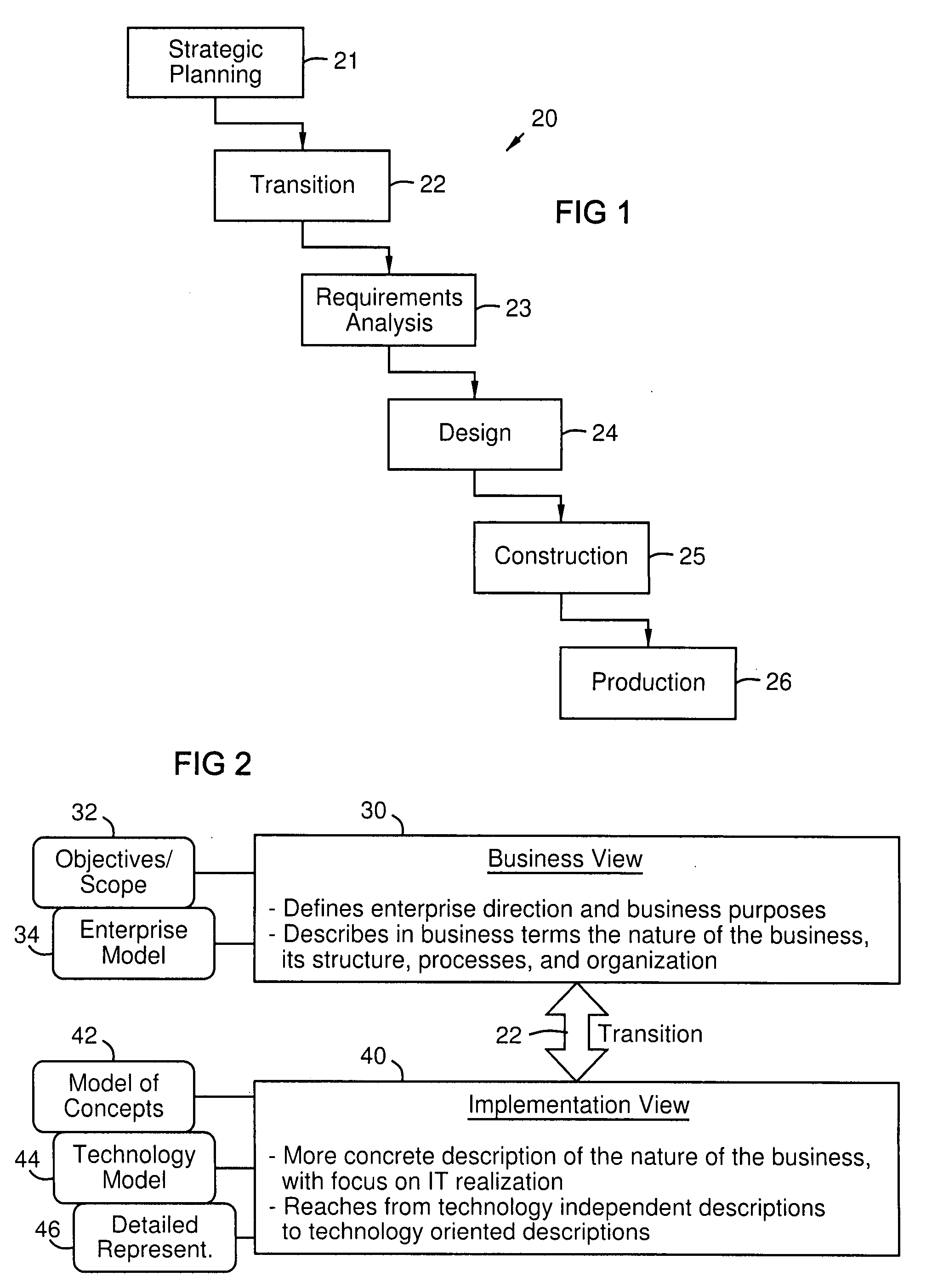

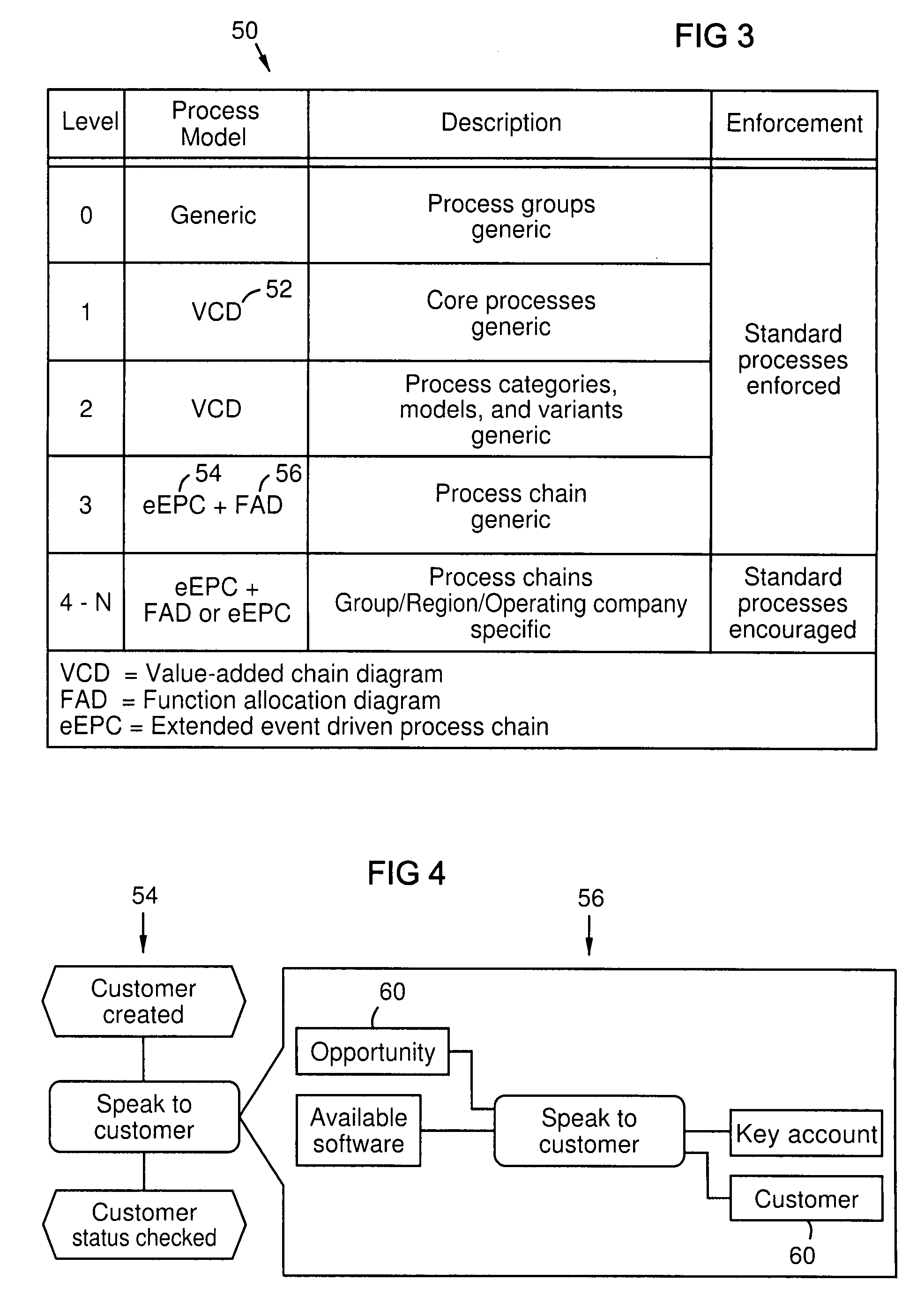

Enterprise-wide data standardization structure and method

A method and structure for data standardization as a basis for a service-oriented architecture in an enterprise. A logical business model (30) defines processes and organization of an enterprise. An implementation model (40) defines an information technology to support the business model (30). Standard core language elements (60) communicate and transition reliably between the business and implementation models, and are understandable in the same way by all responsible parties in a business. Business object types (60) and technical term models (66) define core elements with semantics, synonyms, and interrelationships of this standard language. The models (30, 40) as encoded in a database coordinate the parties and departments in implementing a product life cycle in the enterprise.

Owner:SIEMENS ENERGY INC

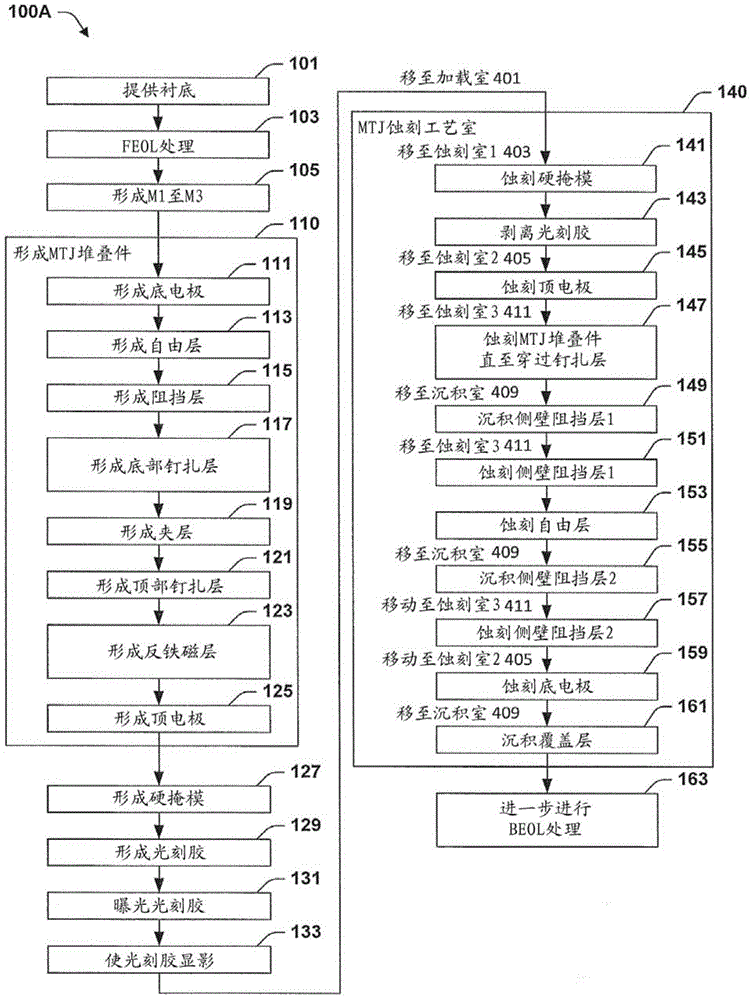

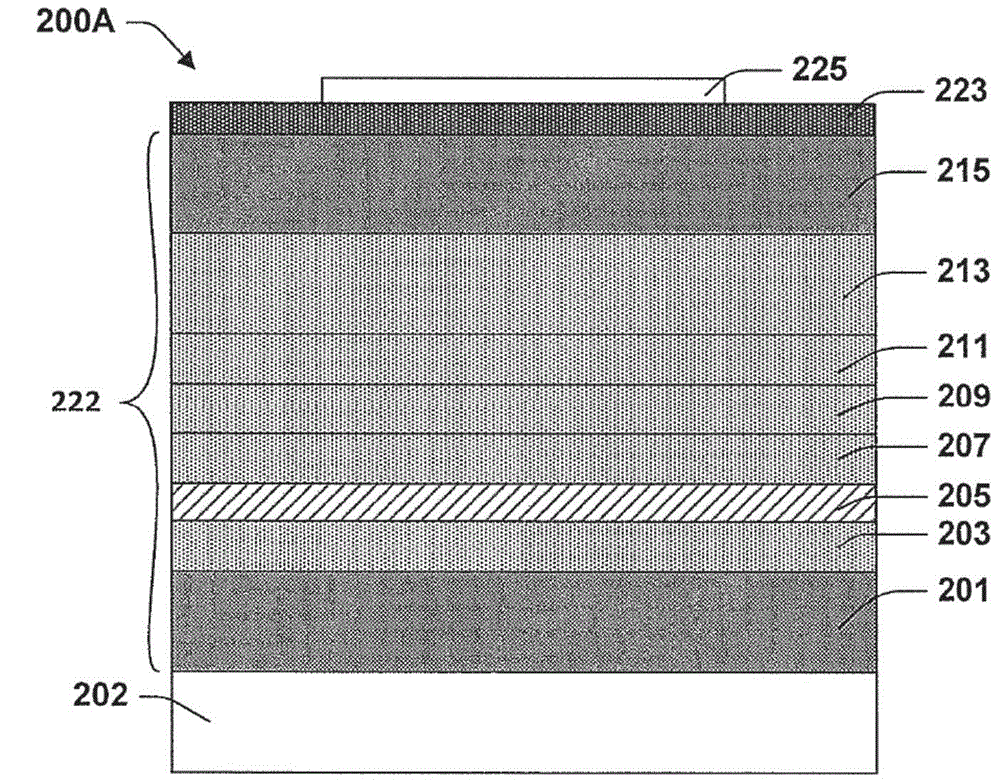

Reversed stack MTJ

ActiveCN104425706AMagnetic-field-controlled resistorsSolid-state devicesIntegrated circuitDefined process

An integrated circuit device includes a substrate and a magnetic tunneling junction (MTJ). The MTJ includes at least a pinned layer, a barrier layer, and a free layer. The MTJ is formed over a surface of the substrate. Of the pinned layer, the barrier layer, and the free layer, the free layer is formed first and is closest to the surface. This enables a spacer to be formed over a perimeter region of the free layer prior to etching the free layer. Any damage to the free layer that results from etching or other free layer edge-defining process is kept at a distance from the tunneling junction by the spacer.

Owner:TAIWAN SEMICON MFG CO LTD

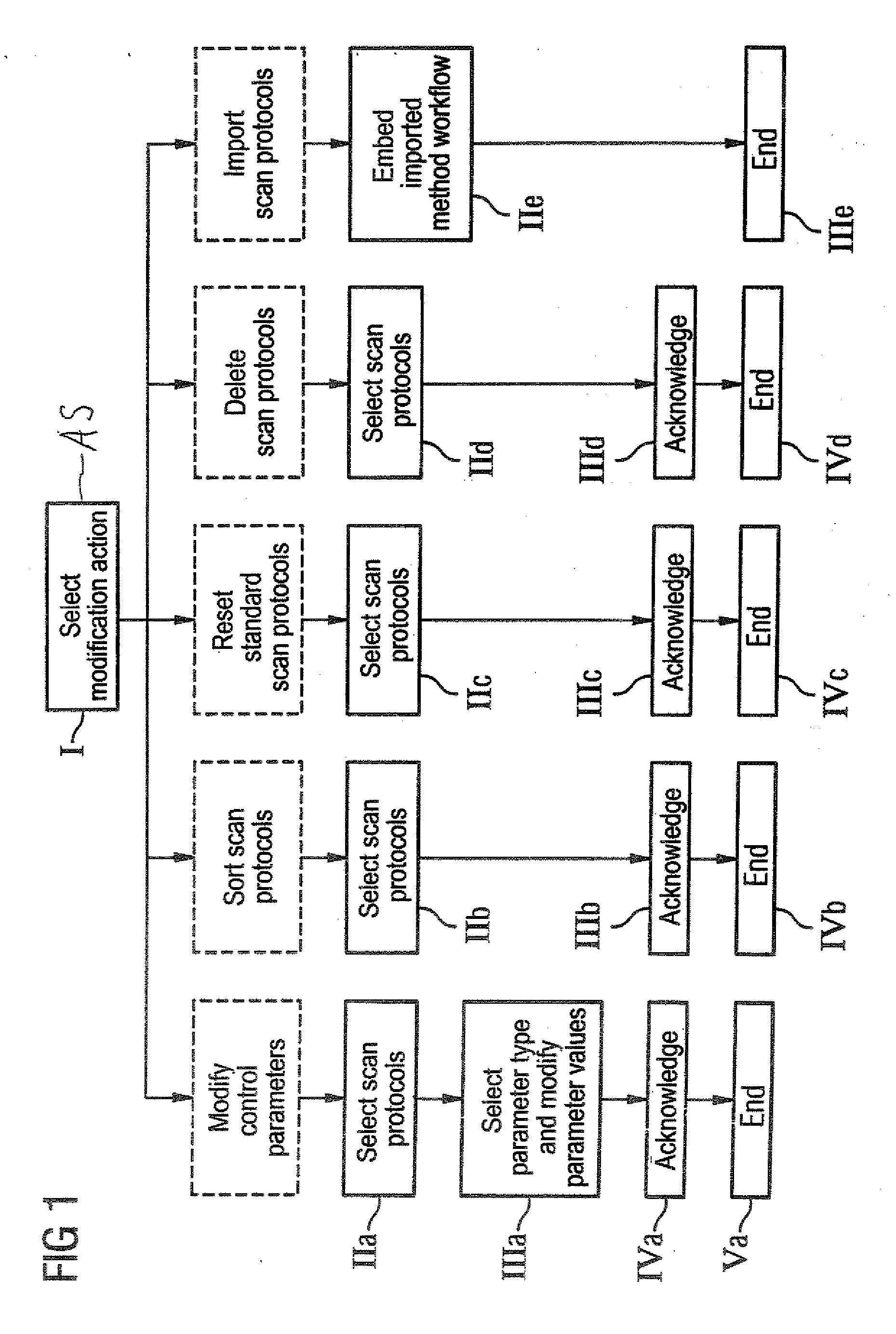

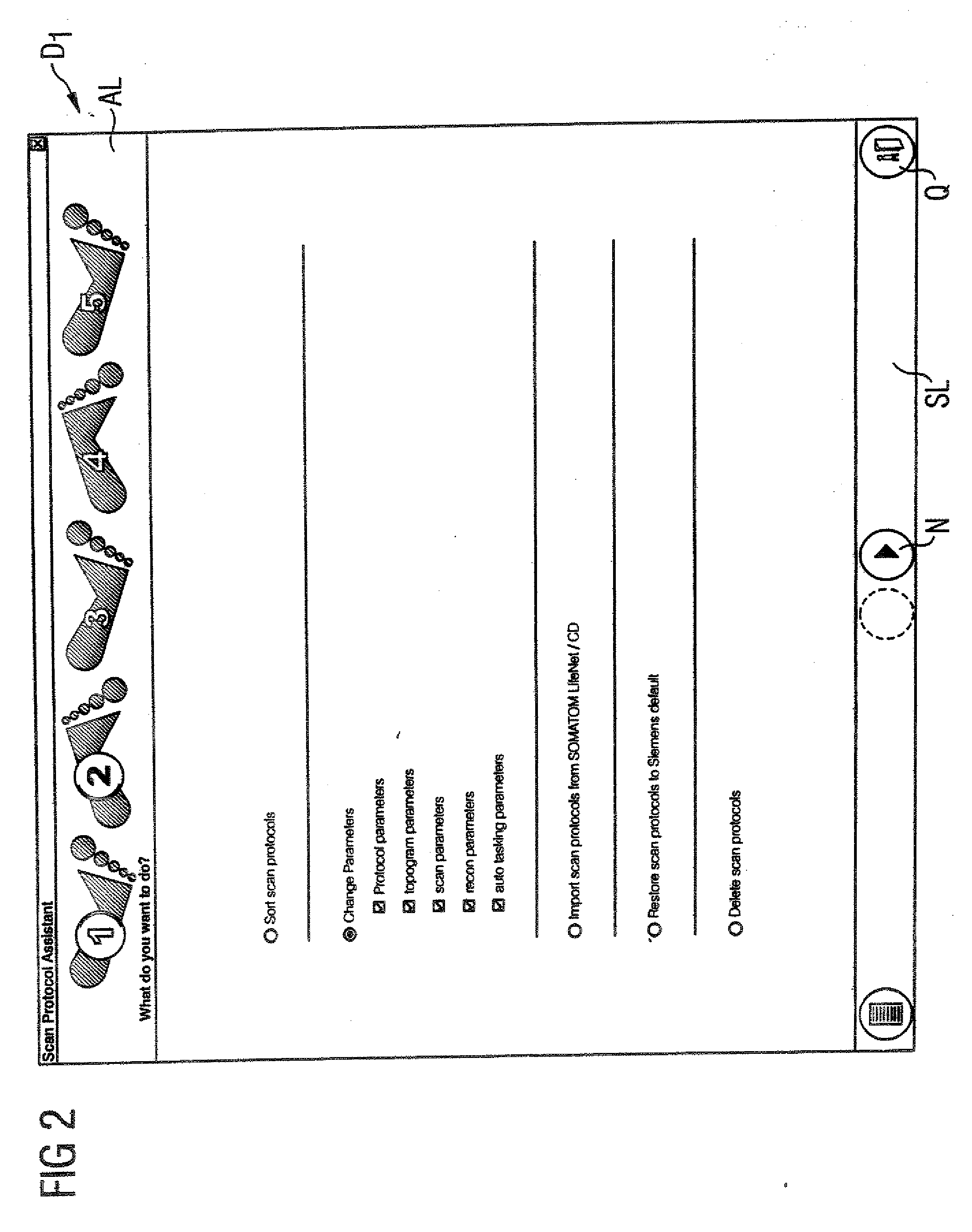

Method for modification of a number of process control protocols

A method for modification of a number of process control protocols of a set of defined process control protocols for control of a medical-technical system is provided. Within a modification process protocol selection signals are thereby detected for selection of a number of process control protocols with regard to which a modification action is to be implemented; the control parameters that can be changed in the selected process control protocols are thereupon displayed and parameter values are detected according to which the control parameters are to be changed in the selected process control protocols. A display of the changes to be implemented in the selected process control protocols within the modification process then ensues. After detection of an acknowledgement signal the automatic implementation of the modifications ensues with regard to the selected process control protocols. Moreover, a method for modification of a set of defined process control protocols is described in which an action signal for selection of a specific modification action is initially detected and then a modification process is selected (dependent on the selected modification action) from a number of predefined modification processes. A workflow of the selected modification process is then initiated and further modification specification signals are detected within this modification process, according to which modification specification signals the modifications are implemented. Moreover, a corresponding protocol modification unit and a protocol set modification device are described.

Owner:SIEMENS AG

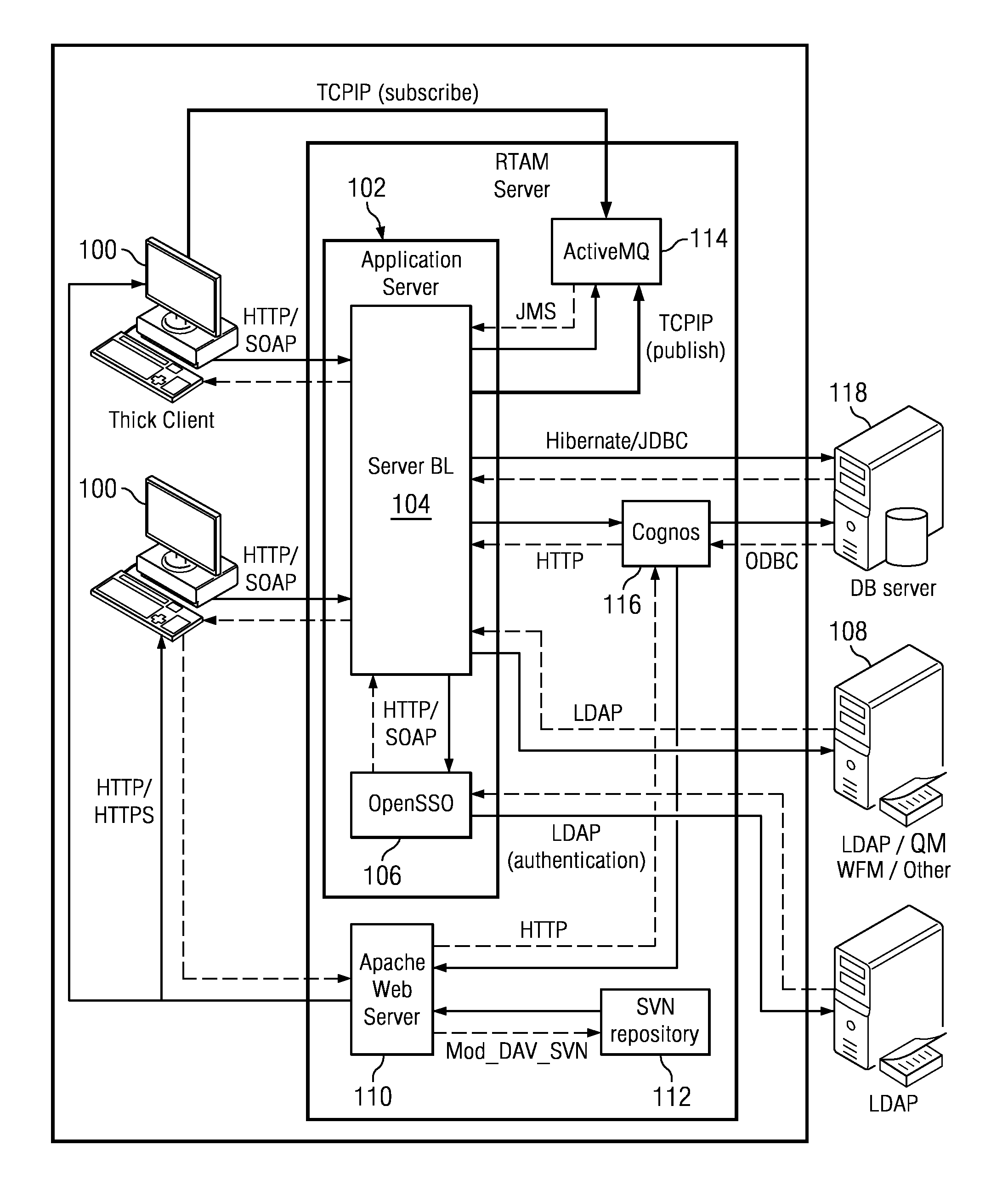

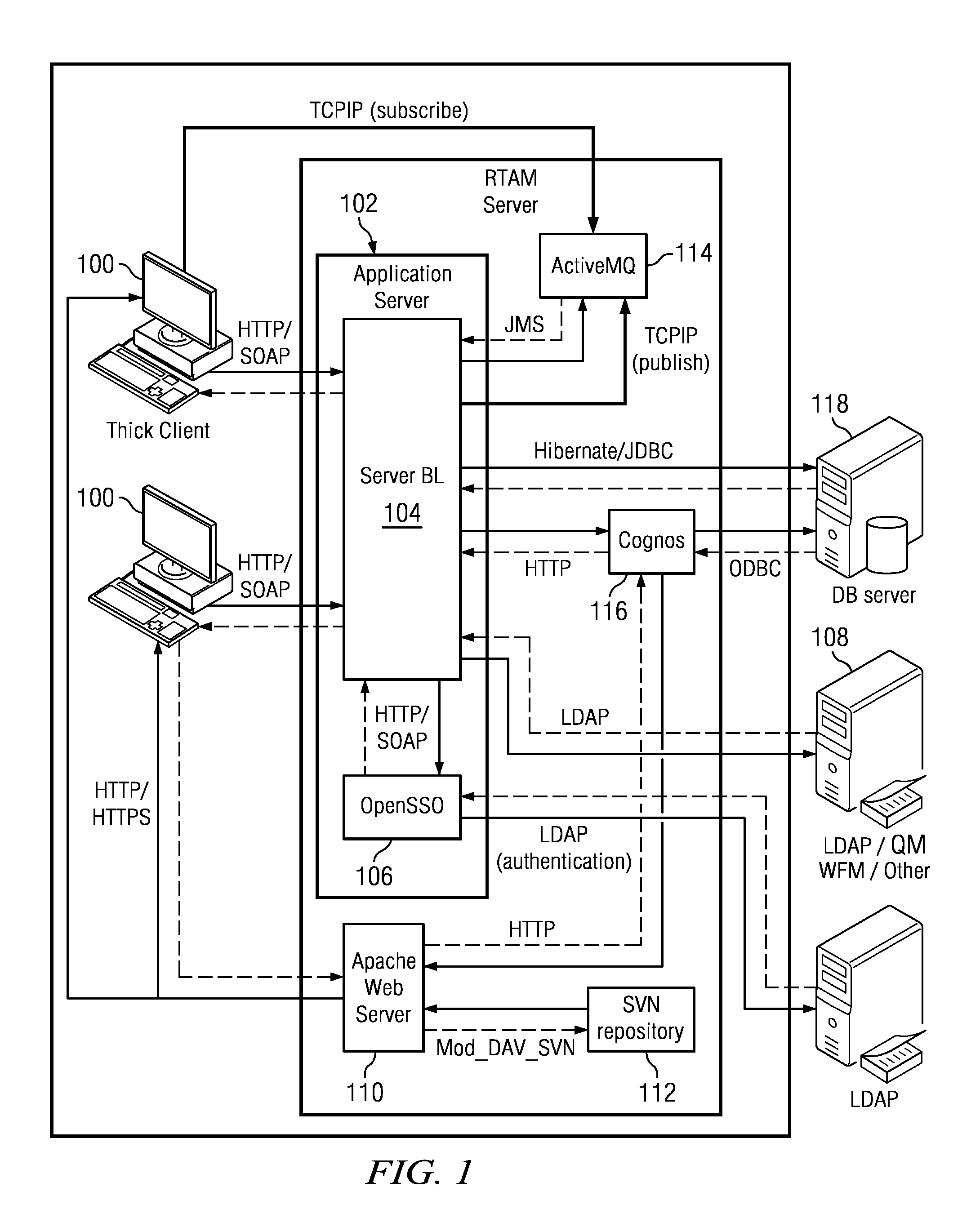

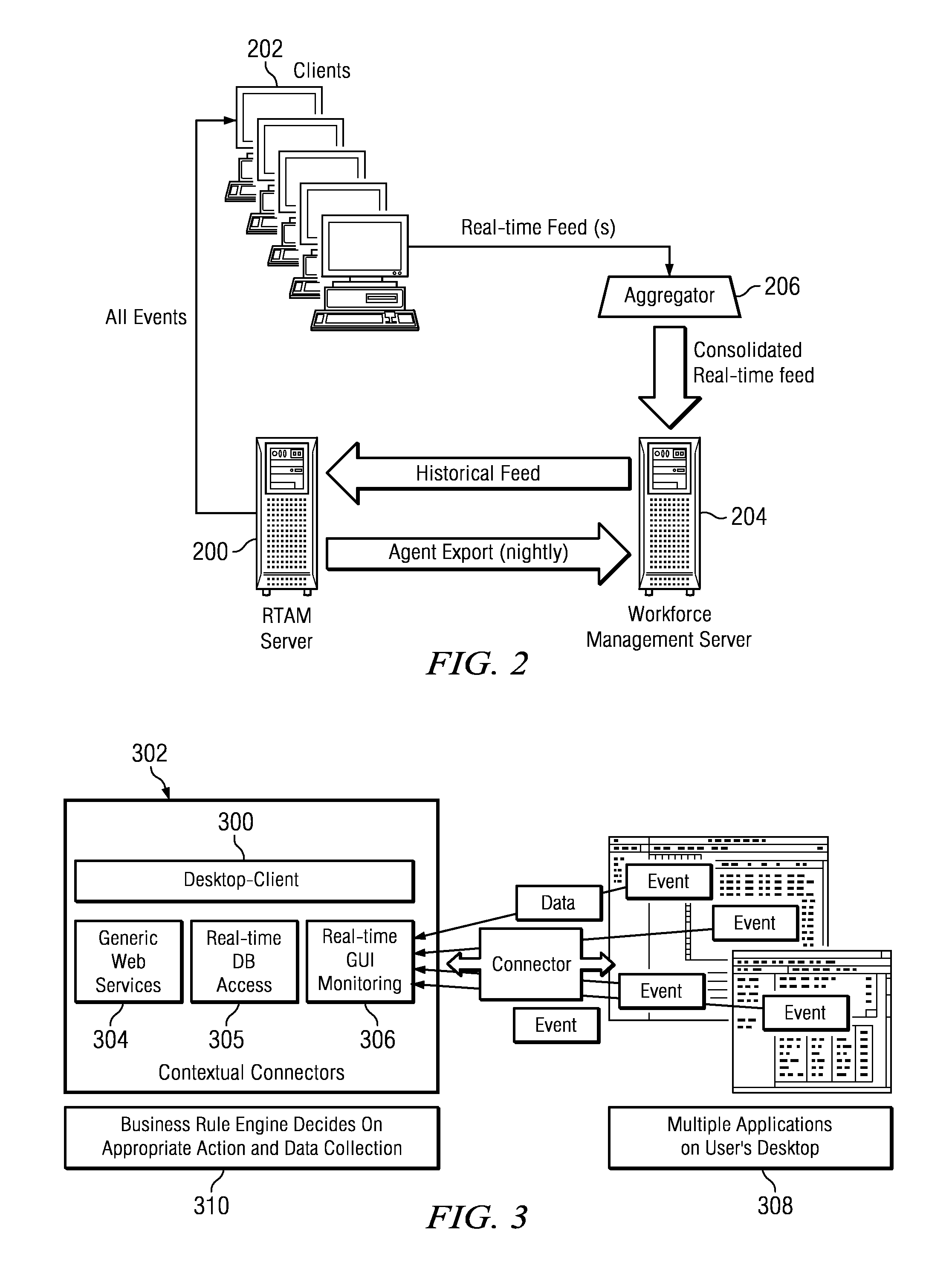

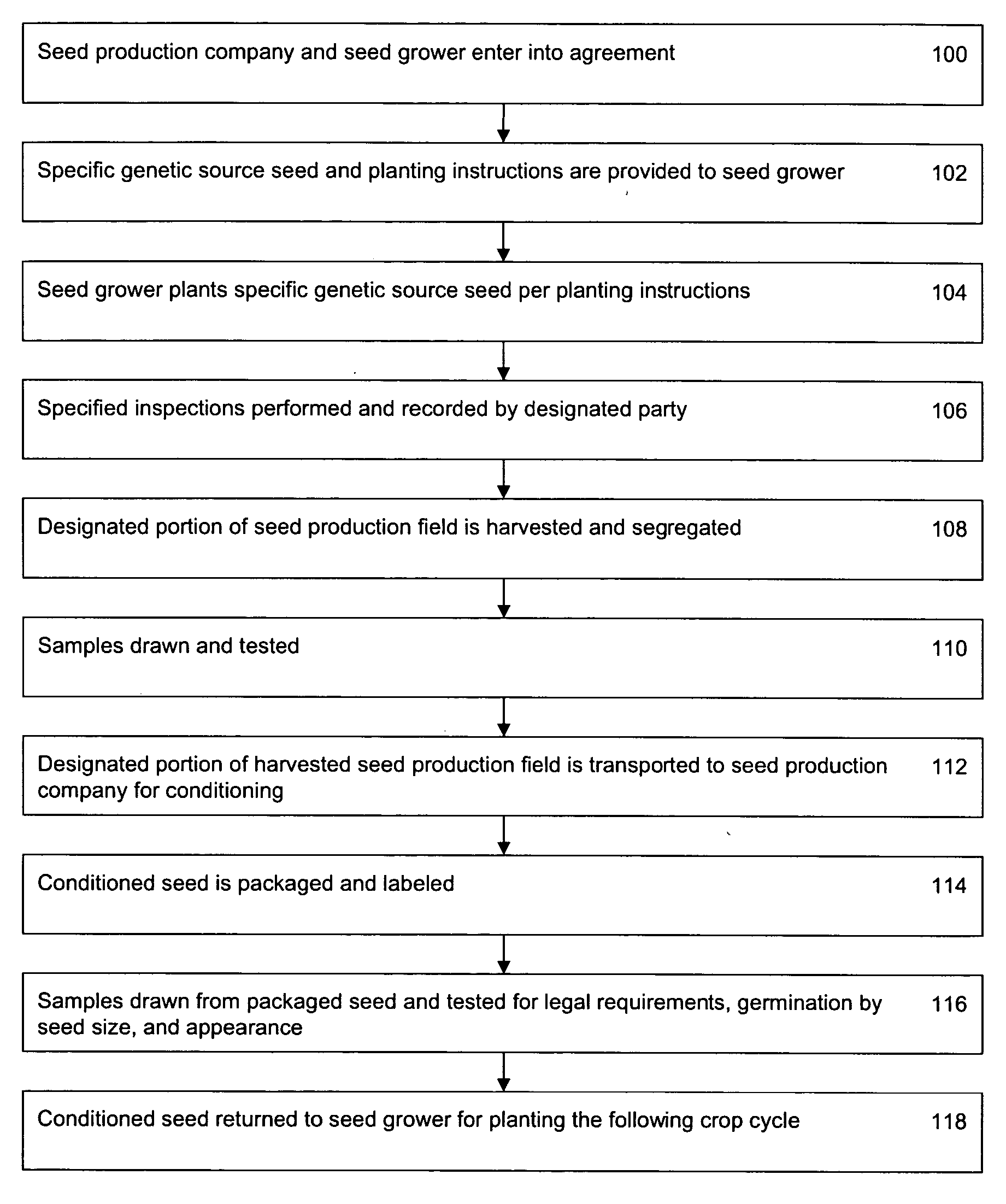

Application usage and process monitoring in an enterprise environment having agent session recording for process definition

A real-time activity monitor (RTAM) operates within or in association with a machine (such as a desktop) within a back office environment to automatically track and record desktop processing activities, application usage, as well as manual processing. The real-time activity monitor provides visibility into real-time task processing at the client desktop to enable an enterprise to address back office operational inefficiencies that are exposed by the data. According to a further feature, a recording approach is used to enable a user of the system to automatically define processes and tasks to be monitored. The approach obviates manual configuration by recording application usage actions and then using these interactions as a template for a new process object to be monitored. In an alternative embodiment, the process recorder captures screenshots and enables screen element bookmarking.

Owner:IEX CORP

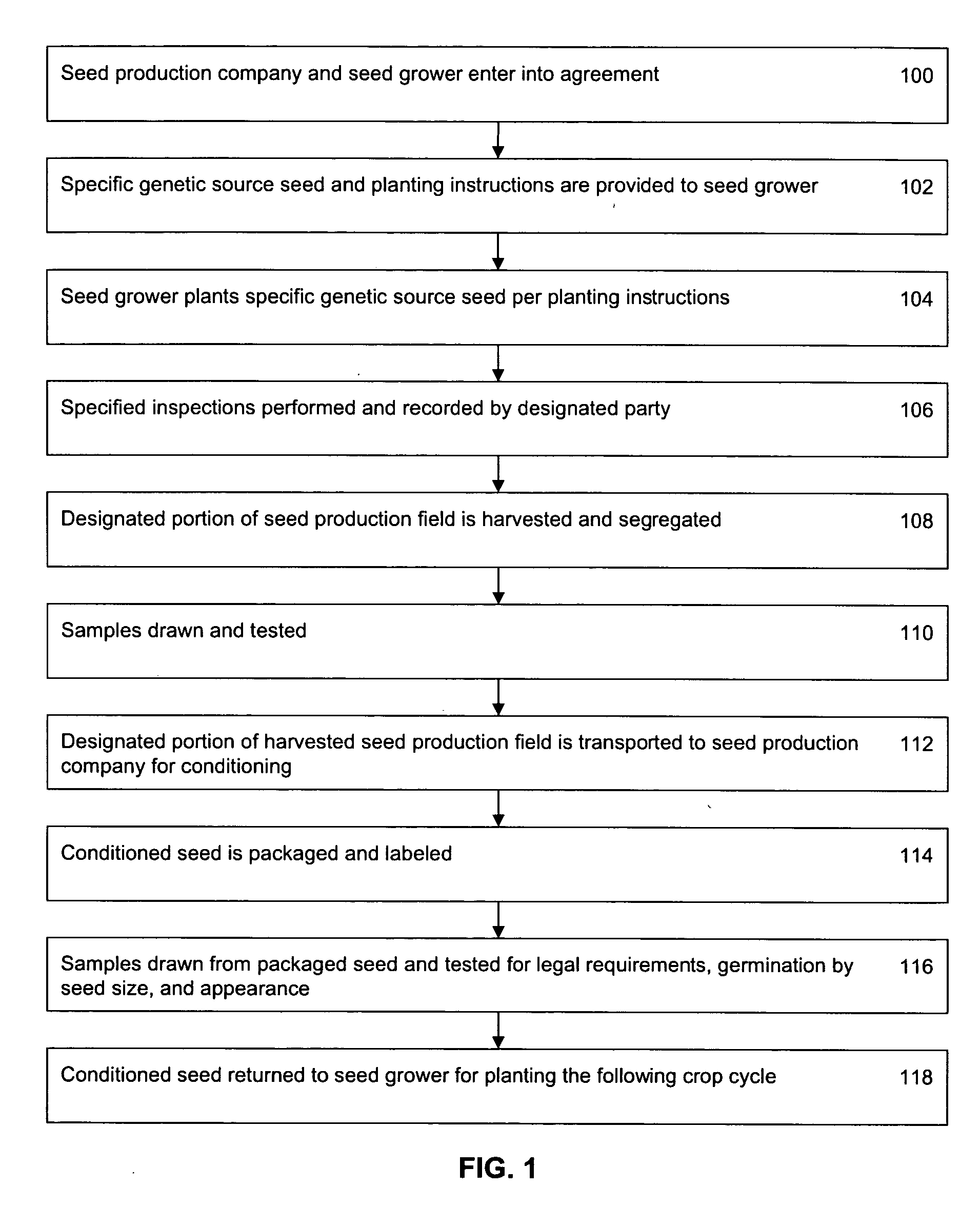

Method for varietal crop seed production and identity preserved grain system

InactiveUS20050050796A1Preserve seed qualityReduce the risk of contaminationSeed and root treatmentHorticulture methodsSeeds sourceAdemetionine

The present invention provides a system for providing a seed grower with conditioned seed for planting the following cropping cycle from a portion of the harvested crop from a single seed production field. In one embodiment, the system includes an agreement between the seed production company and seed grower to plant and produce a varietal crop for seed purposes with specific genetic characteristics. The seed grower is initially furnished with source seed from the seed production company that matches these specified genetic characteristics and required to meet defined process specifications and results. At appropriate corresponding times during the planting, growing and harvesting processes, a seed production company representative and / or grower may inspect the seed grower's seed source, planting, cultivating, machinery, transport and storage. The results of these inspections, along with recorded seed grower information and data are put into a database which is used to track the criteria the seed grower and seed production company will reference to determine if conditioned seed fulfills agreement specifications. An ensuing agreement is negotiated each subsequent year between the seed production company and the seed grower to allow the seed grower to select a specified conditioned portion of the crop harvested from his / her seed production field for purchasing for planting the following cropping cycle.

Owner:PRECISION ALLIANCE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com