Reduction schedule optimization method for rolling ultrathin strip steel by cold continuous rolling set

A technology of cold tandem rolling mill and reduction schedule, applied in the direction of rolling force/roll gap control, tension/pressure control, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

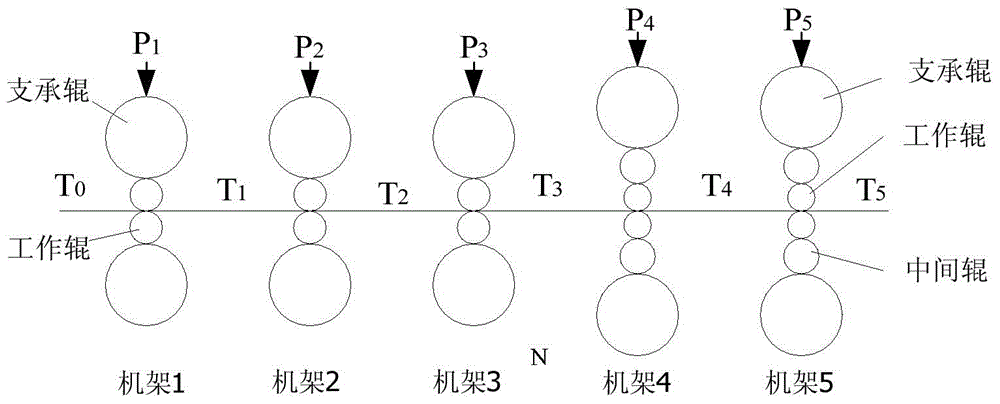

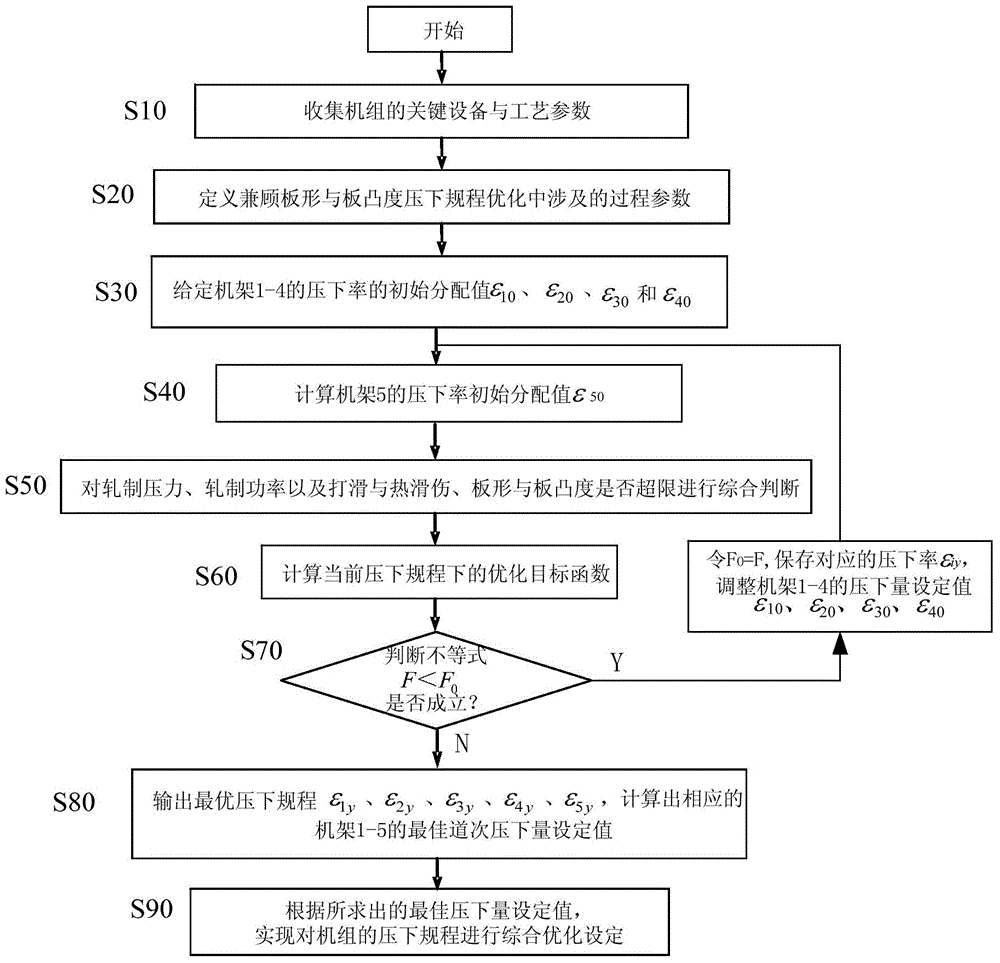

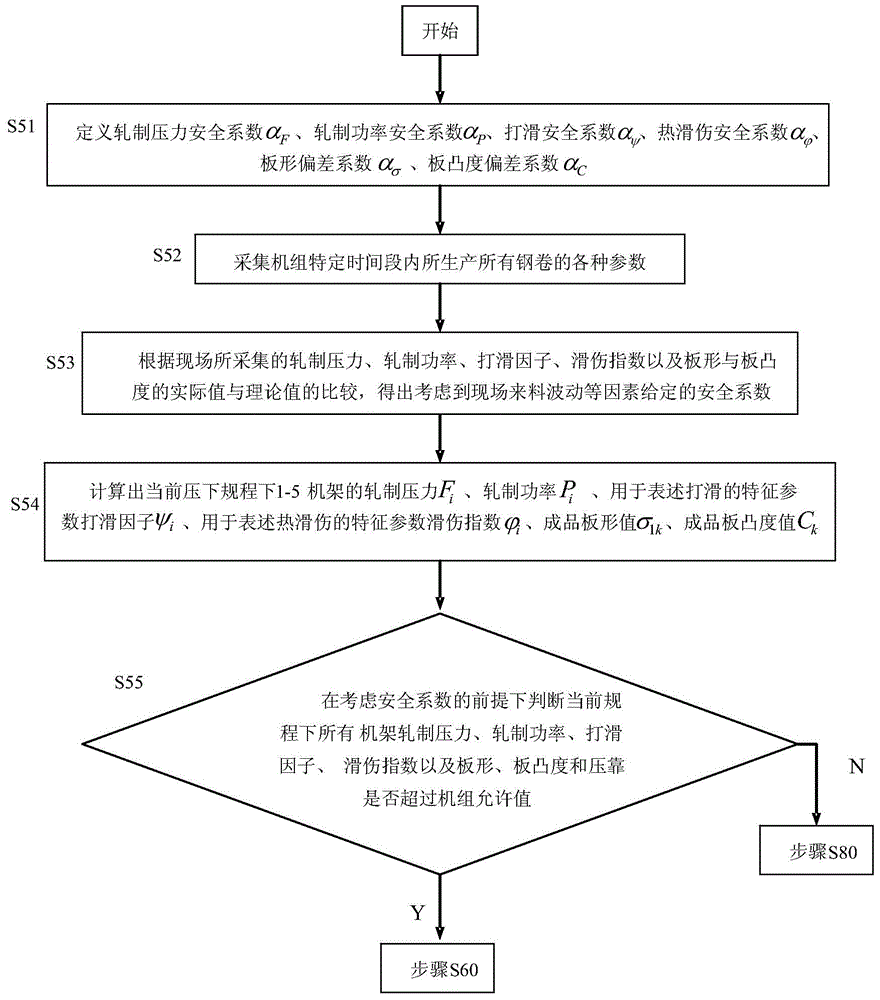

[0058] figure 2 It is an embodiment of the reduction schedule optimization method for the rolling of extremely thin strip steel in the cold tandem rolling mill of the present invention. Taking a CVC tandem cold rolling mill as an example, it introduces in detail the setting process of the reduction schedule optimization method in the ultra-thin strip rolling process of a 3+2 type CVC tandem cold rolling mill. exist figure 1 In the shown control flow diagram, the method for optimizing the pressing procedure of the present invention includes the following steps:

[0059] In step S10, the key equipment and process parameters of the unit are collected, and the specific processing process is as follows:

[0060] S11: Collect the equipment parameters of the five-stand 3+2 type CVC tandem cold rolling mill, including:

[0061] a) Equipment parameters of the first three racks: work roll diameter Support roller diameter D' bi =1250mm, work roll profile distribution value ΔD' wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com