Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93 results about "Cotton wool roll" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

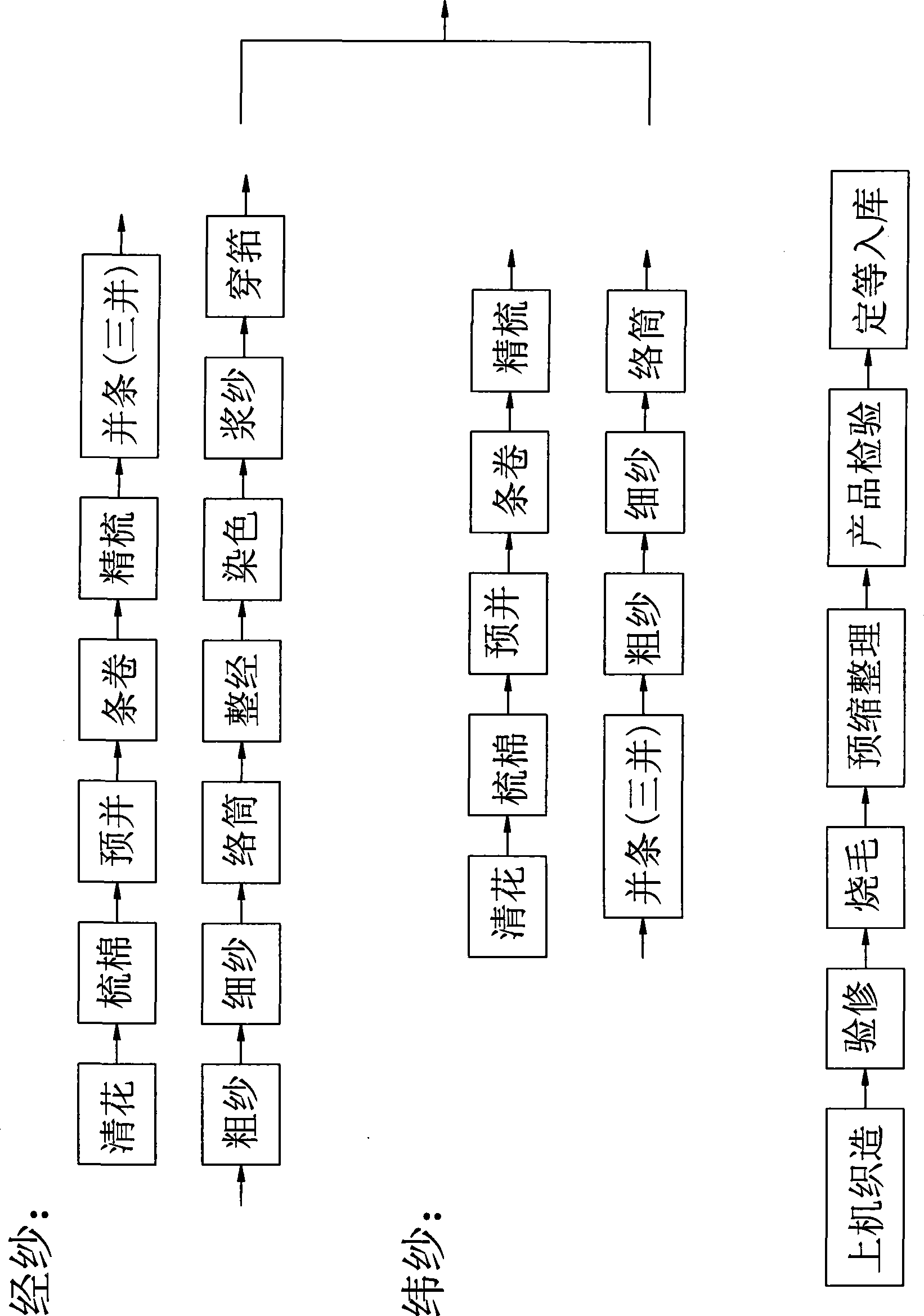

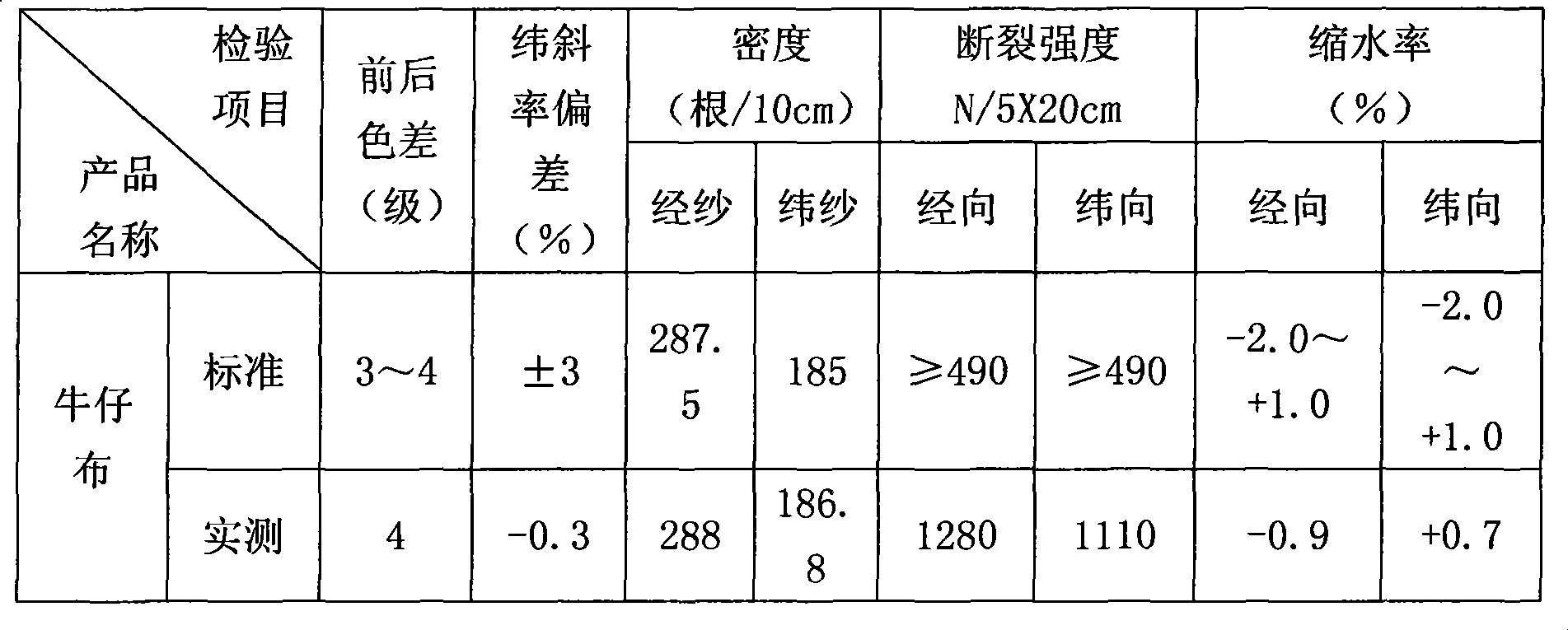

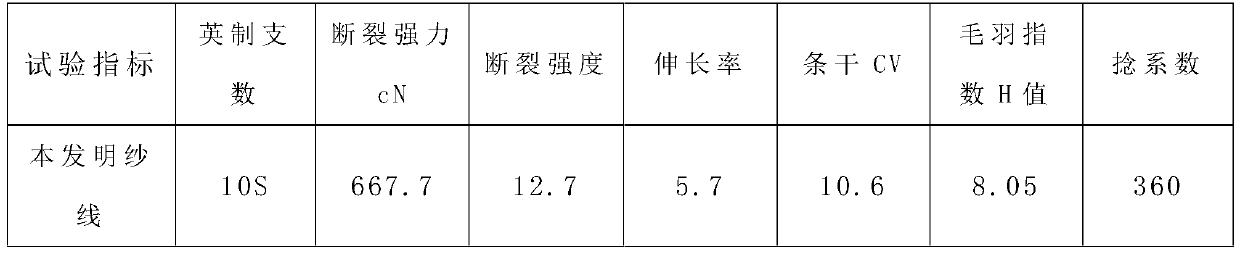

Viloft shengma smooth edge denim and production technology thereof

The invention relates to VILOFT sunn crotataria plain edge jean which comprises the following components by weight percentage: 20-40% of VILOFT fiber, 20-40% of sunn crotataria, 20-40% of one or multiple of cotton fiber, color cotton fiber, prolivon, cashmere, milk fiber, soybean fiber, tencel yarn, flax, silk, etc. In the picking process, the lap pressure is weighted, multi-combing and little beating, combing instead of beating are adopted, the speed of each beater is reduced, and the gauge of the beater and grid bars is enlarged. In the carding process, the lap is fully carded and the card sliver quota is increased; in the drawing process, the clockwise drawing process is adopted, the gauge is enlarged; the pressurizing quantity is improved and the vehicle speed is reduced, the combination process and the three blending combination process are adopted, and the first tension drawing multiple is grasped in a slightly large way; in the spinning process, large postzone roller gauge, small postzone draft multiple and small nip gauge are required, the vehicle speed is reduced, and the pressure is increased. The fabric of the jean has the advantages of environment protection, moderate elastic, soft texture, good luster and drapability, and obviously bamboo joint effect.

Owner:山东万泰创业投资有限公司

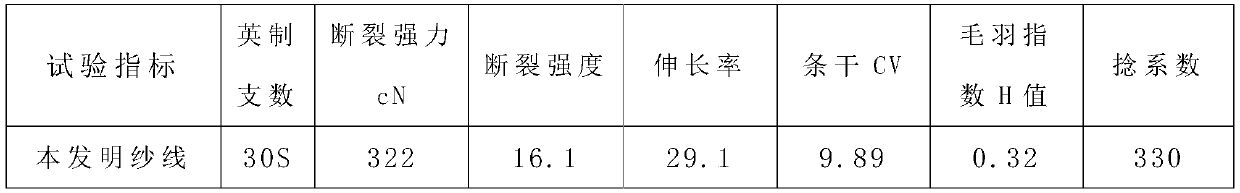

Spinning method of spun-dyed hemp/cotton blended yarn

InactiveCN102021702AGood moisture absorption and perspirationSolve the problem that the length becomes shorter and the strength dropsYarnYarnCotton fibre

The invention discloses a spinning method of spun-dyed hemp / cotton blended yarn. The blended yarn is prepared by spinning the yarn which is formed by blending the dyed hemp fibre and cotton fibre at a ratio of (40-50):(50-60). The spinning method specifically comprises an opening picking process, a cotton carding process, a drawing process, a roving process and a spinning process, wherein the opening picking process is as follows: the dyed hemp fibre and the cotton fibre are manufactured into lap or cotton stream; and the cotton carding process is as follows: the lap or cotton layer is fed into a carding machine to be prepared into cotton strips, five-point gauge between a cylinder and a cover board is 0.22mm, 0.2mm, 0.18mm, 0.18mm, 0.2mm respectively, the rotation speed of the cylinder is 330-360r / min, and the speed of discharging strips is 65-75m / min. The blended yarn produced by the spinning method has bright color and has the advantages of good sterilization bacteriostasis and good wet-absorbing sweat-discharging property, and is a novel generation environment-friendly product.

Owner:SUNVIM GROUP

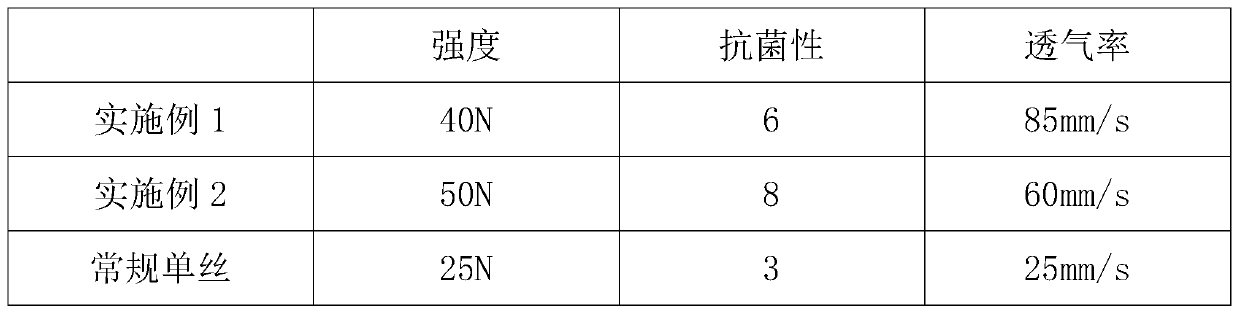

Hygroscopic, breathable and antibacterial ultra-high molecular weight polyethylene blended core spun yarn and production method thereof

InactiveCN104805560AGood high polyImprove the protective effectYarnMoisture absorptionCotton wool roll

The invention relates to a hygroscopic, breathable and antibacterial ultra-high molecular weight polyethylene blended core spun yarn and a production method thereof. The yarn consists of a core yarn and a cladding yarn, wherein the core yarn is an ultra-high molecular weight polyethylene filament double-twisted yarn; the cladding yarn is a blended yarn consisting of the following three components: 55 to 65 percent of bamboo fiber, 25 to 30 percent of long lint cotton and 10 to 15 percent of terylene; the weight of the cladding yarn is 1.5 to 2 times that of the core yarn. A process for producing the yarn comprises the following steps of blending the bamboo fiber and the terylene fiber, and manufacturing the bamboo fiber and the terylene fiber into a first cotton roll; manufacturing the long lint into a second cotton roll; manufacturing the first cotton roll into card slivers; manufacturing the second cotton roll into combing slivers; manufacturing the first card slivers and the combing slivers into drawing slivers through three drawing procedures, manufacturing drawing slivers into roving; double-twisting ultra-high molecular weight polyethylene filaments into a double-twisting yarn; taking the roving as the cladding fibers, taking the double-twisting yarn as the core yarn, and manufacturing the roving and the double-twisting yarn into the blended core spun yarn. The advantages of high strength, high modulus and good protecting performance of the core yarn, the advantages of moisture absorption, breathability, bacterium resistance and ultraviolet radiation resistance of the bamboo fiber, the characteristic of comfort of the cotton and the characteristic of stiff and neat property of the terylene are combined, so that the quality of the finished yarn is better.

Owner:广东天情织绣有限公司

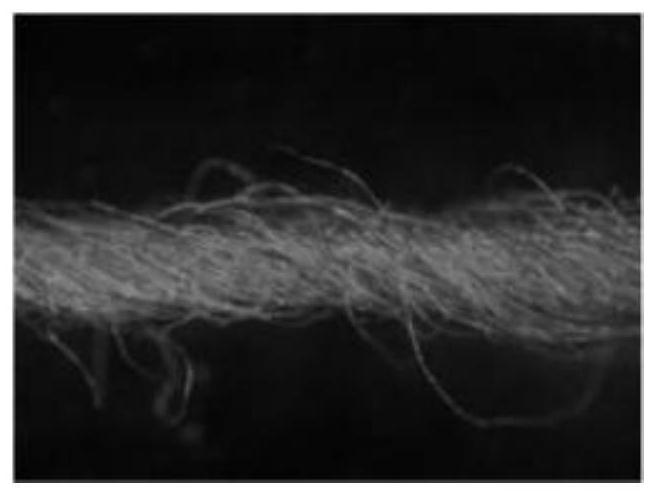

Method for producing slurry-free self-sizing fabric containing low-melting fiber yarn

InactiveCN108893833ALow costIncreased strength and wear resistanceWoven fabricsYarnThermal bondingYarn

Provided is a method for producing slurry-free self-sizing fabric containing low-melting fiber yarn. The method for producing the slurry-free self-sizing fabric containing low-melting fiber yarn is characterized in that the method includes the following steps of opening and cleaning cotton, carding, drawing, roving, spinning, winding, warping, yarn thermal bonding and weaving; for opening and cleaning the cotton, main fibers and low melting point fibers conduct disc mixing to be made into cotton rolls; for carding, the rolls with the main fibers and the low melting point fibers mixed well arecombed, the fibers are separated into a single state to form silver blended with the main fibers and the low melting point fibers; for drawing, the blended sliver is blended through a drawing machinewith low melting point fiber mass percentage to be 5-35% and the main fiber mass percentage 65-95% to prepare mixed drawn sliver. With a certain proportion of the low melting point fibers added to thefibers during spinning, yarn containing the low melting point fibers heated during subsequent processing, and low melting point fibers melted as an adhesive for the yarn, the method for producing theslurry-free self-sizing fabric containing the low-melting fiber yarn has the advantages of improving the strength and wear resistance of the yarn and attaching hairiness, and improving yarn weavability with no use of slurry.

Owner:SHIJIAZHUANG CHANGSHAN BEIMING TECH CO LTD

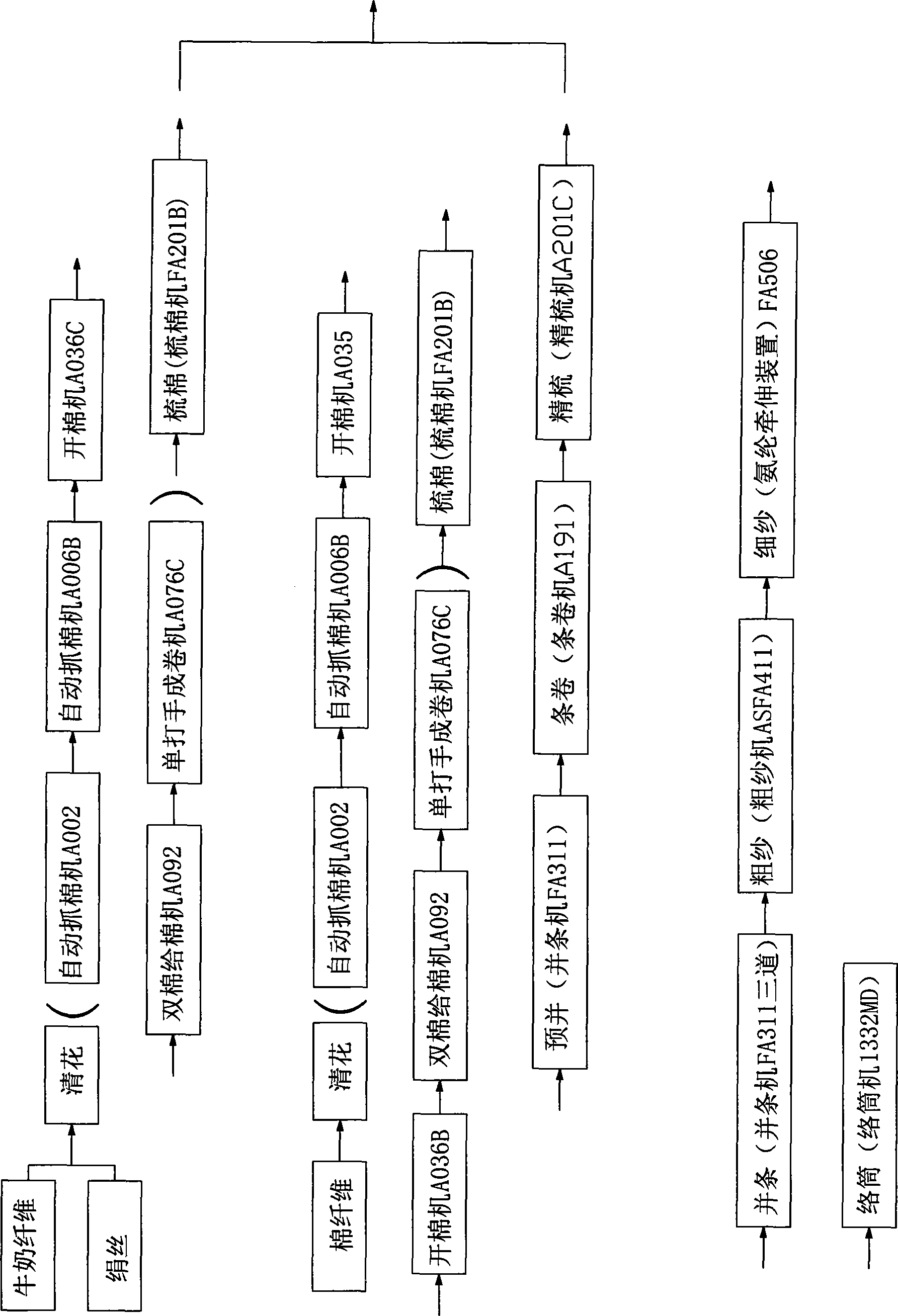

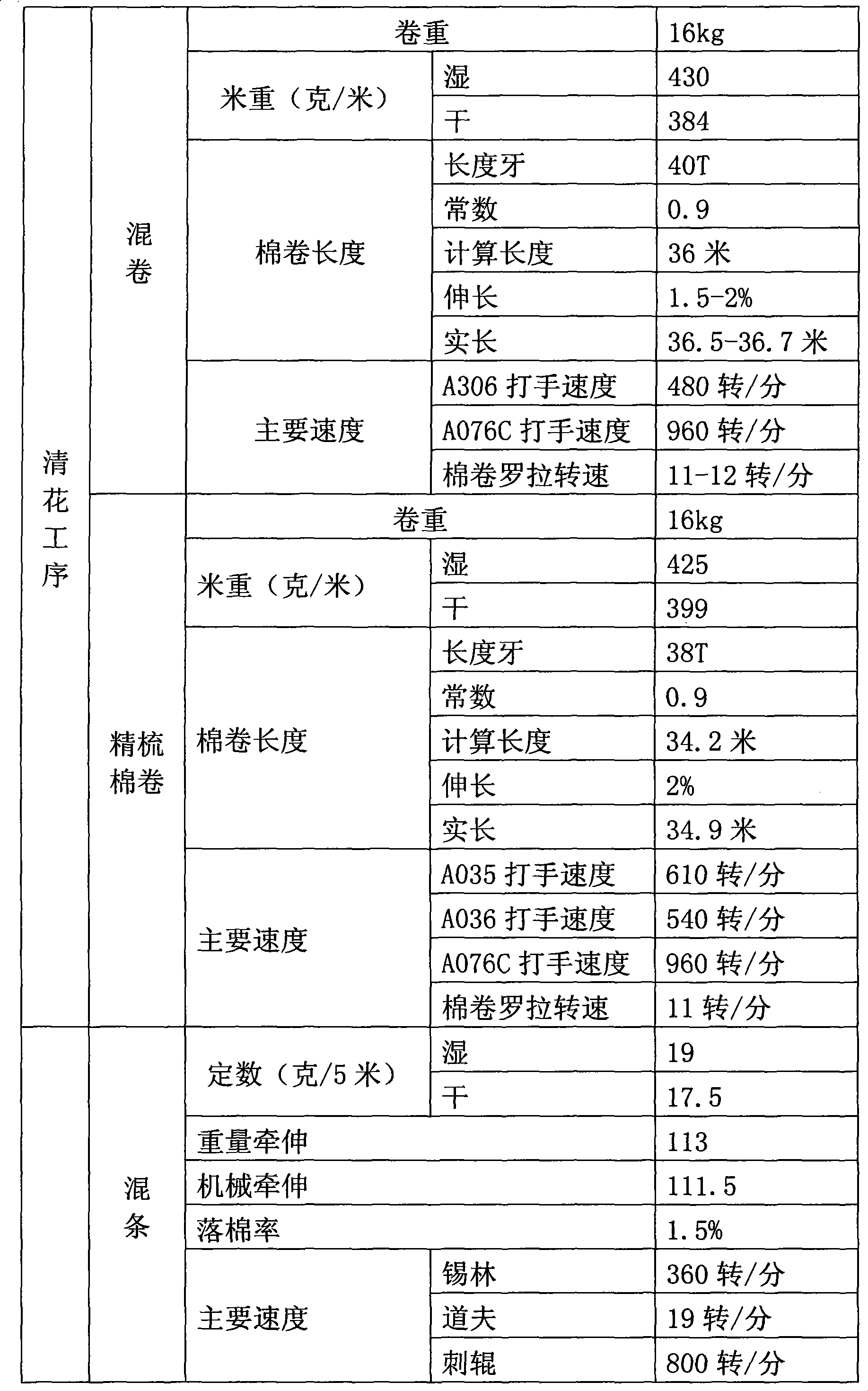

Blended elastic yarn of milk fiber, silk yarn, leica and cotton and production technology thereof

The invention relates to a blended stretch yarn which is formed by blending milk fiber, spun silk, Le Car and cotton fiber blended fabric; wherein, the yarn comprises the following component by weight percentage: 19-30% of milk fiber, 25-43% of spun silk, 5-8% of Le Car, 20-50% of cotton fiber. The blowing process adopts the technological principle of light ratio, low speed and anti-licking, the speed of beater is reduced, the fiber damage is reduced, the moderate antistatic agent is sprayed on the cotton roll, and the cotton roll is wrapped. In the carding process, the speed ration of a cylinder and cubing rolls is improved, and the gauge of a cover board and the cylinder is enlarged. In the doubling process, a first rear draft multiple is grasped in the slightly larger way; the clockwise drafting three combination process is adopted. A spinning machine dismantles a cross traverse gear, so as to avoid spandex deviation, and the twist factor is grasped in the slightly larger way. In the cheese winding process, the cheese winding adopts the techniques of the low speed, light tension, small elongation and elastic security. The yarn has health care function on the nervous system, and significantly improves indicators of color fastness, brightness, strength, etc.

Owner:山东万泰创业投资有限公司

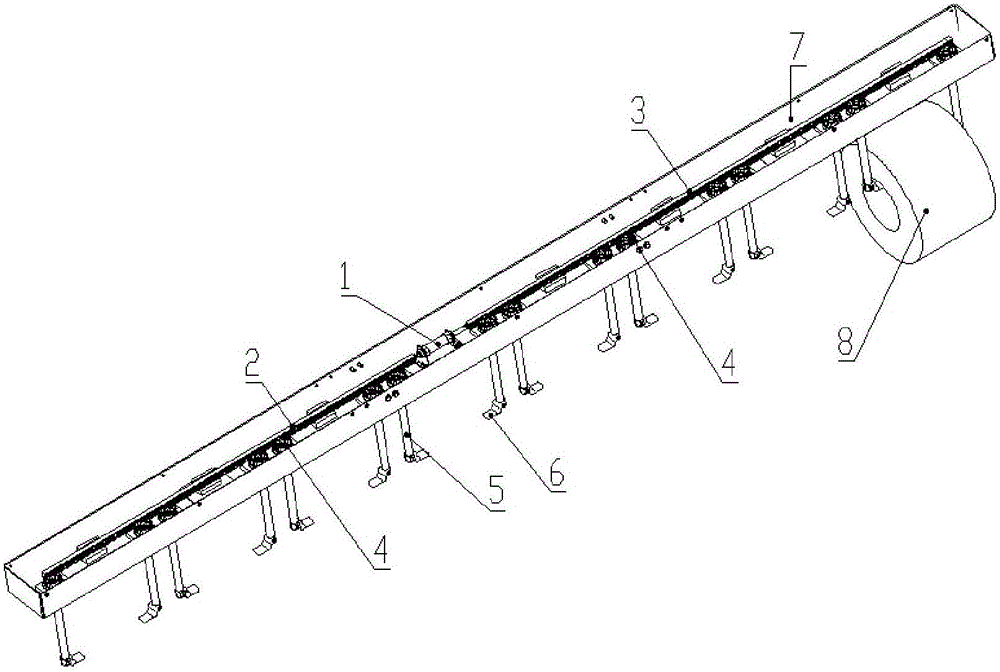

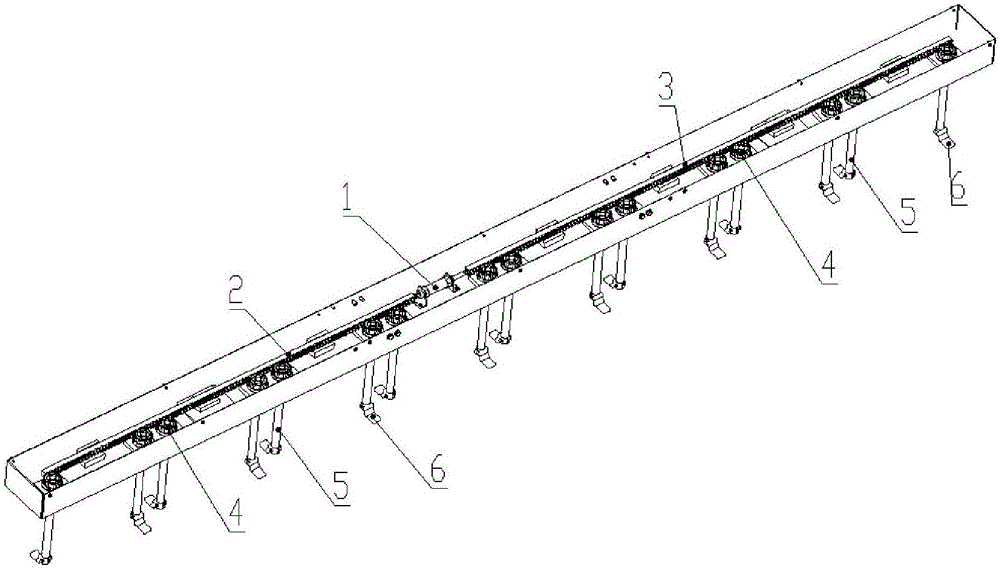

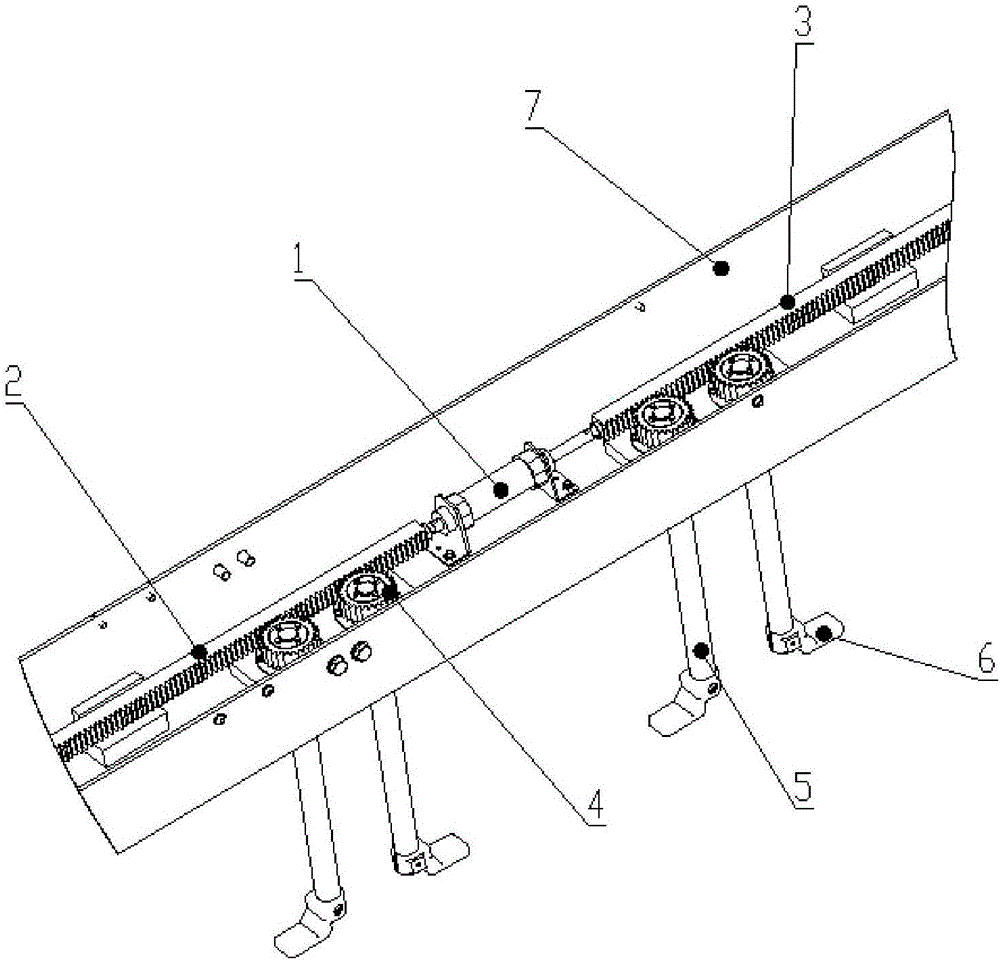

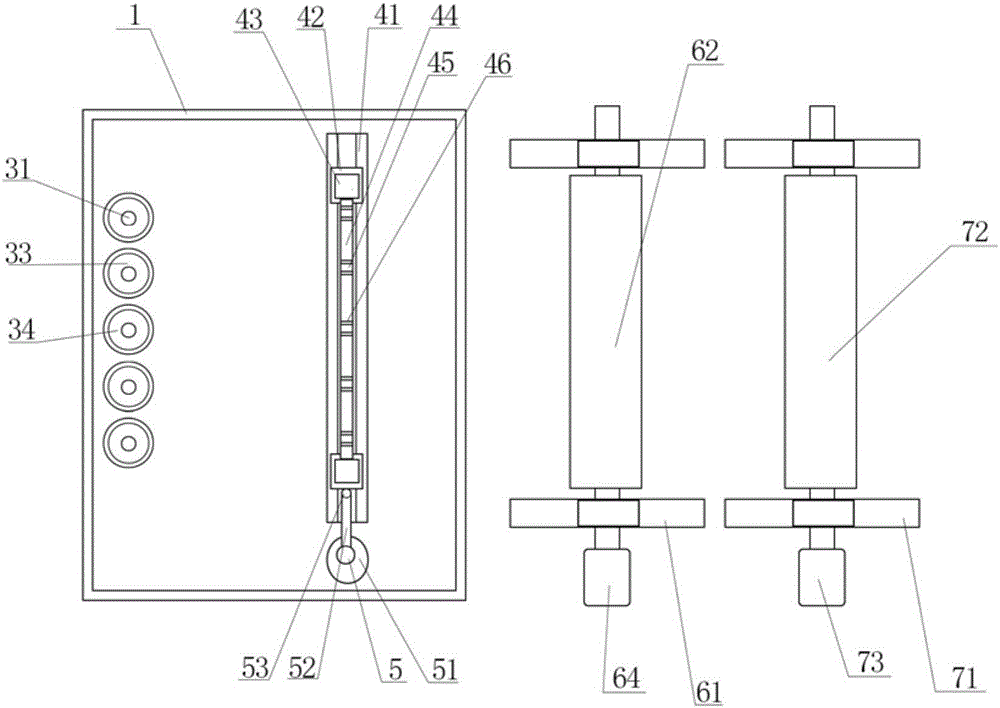

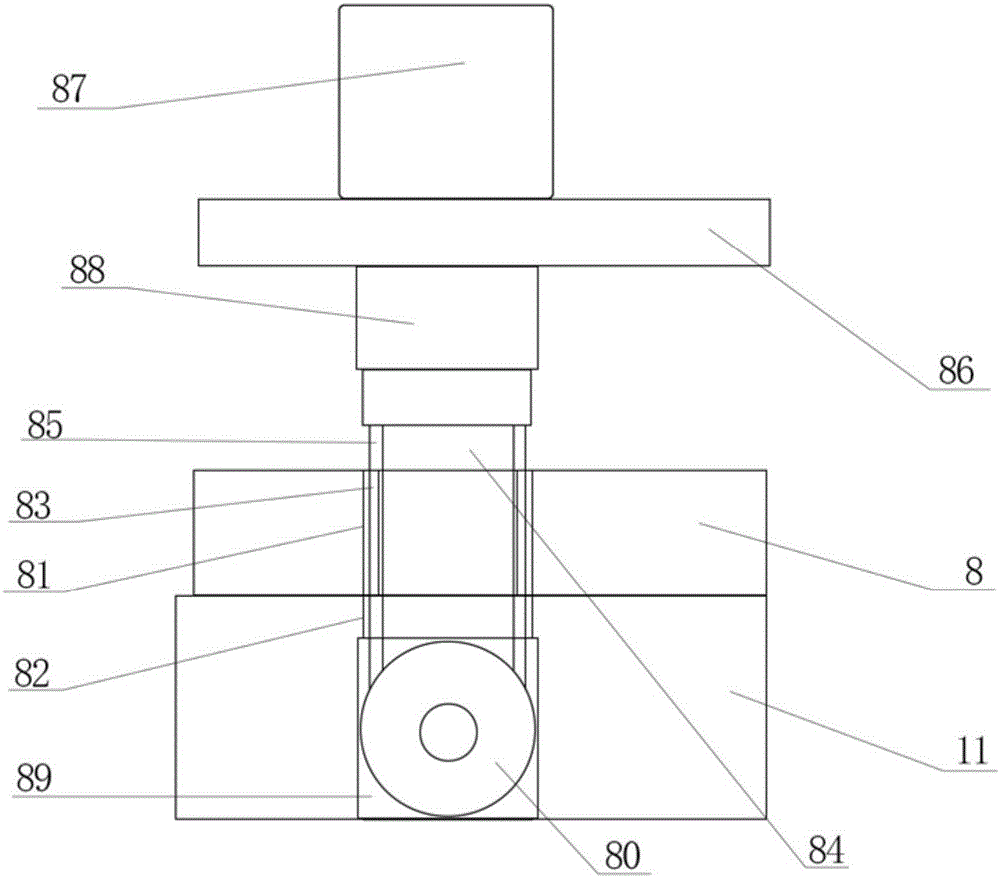

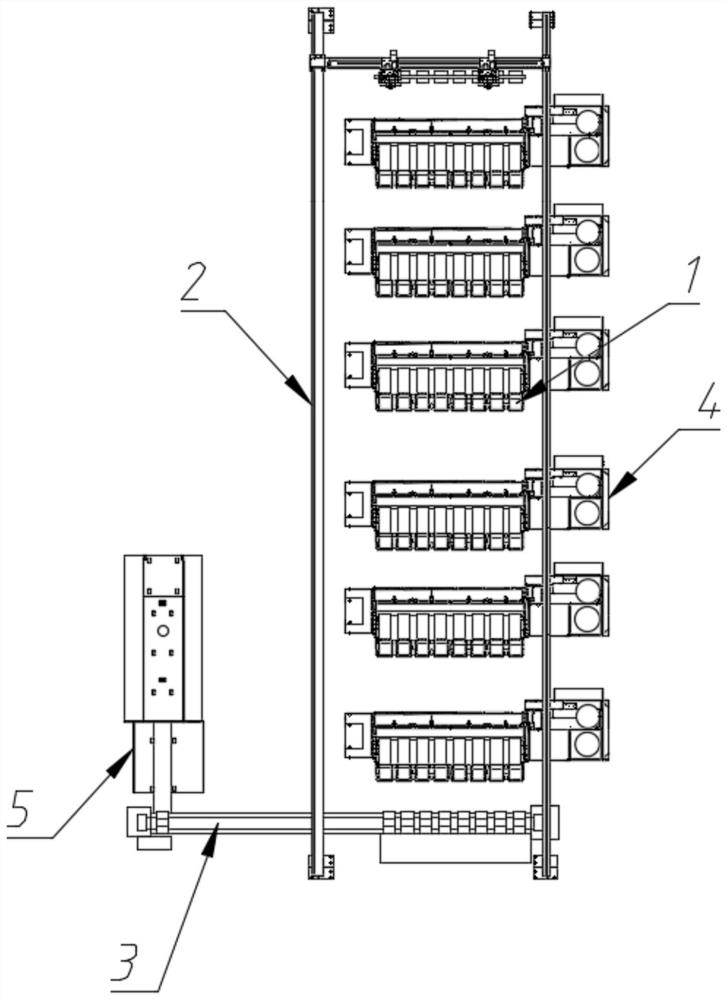

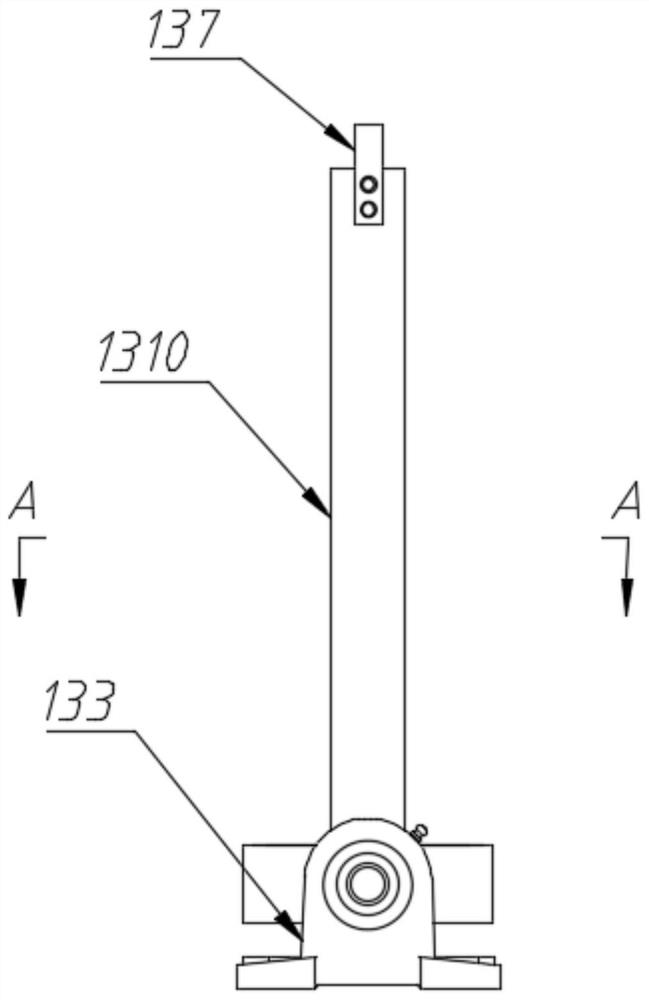

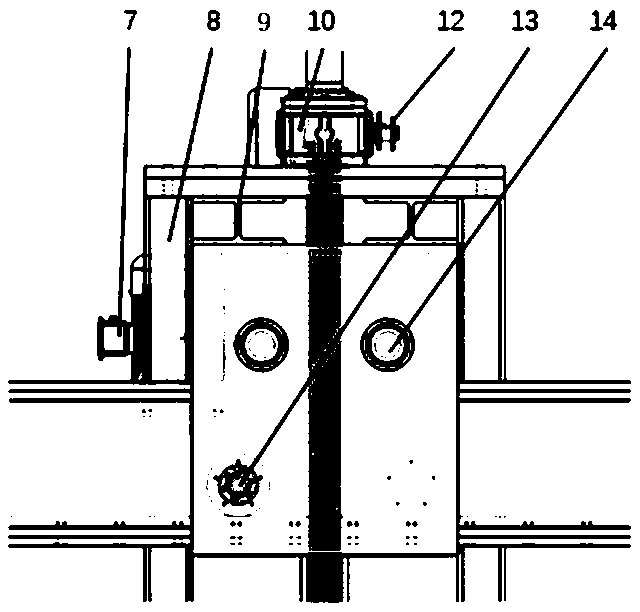

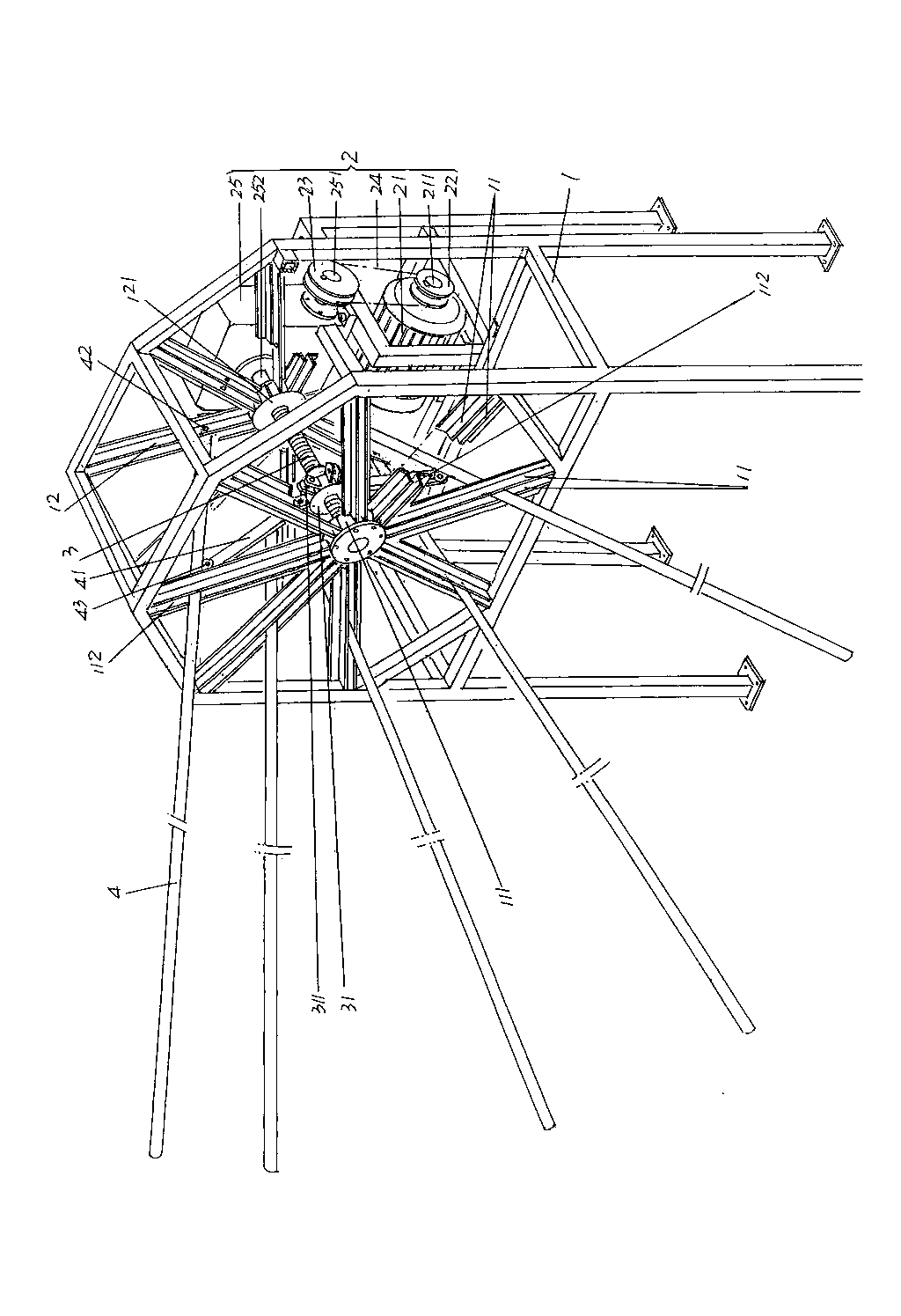

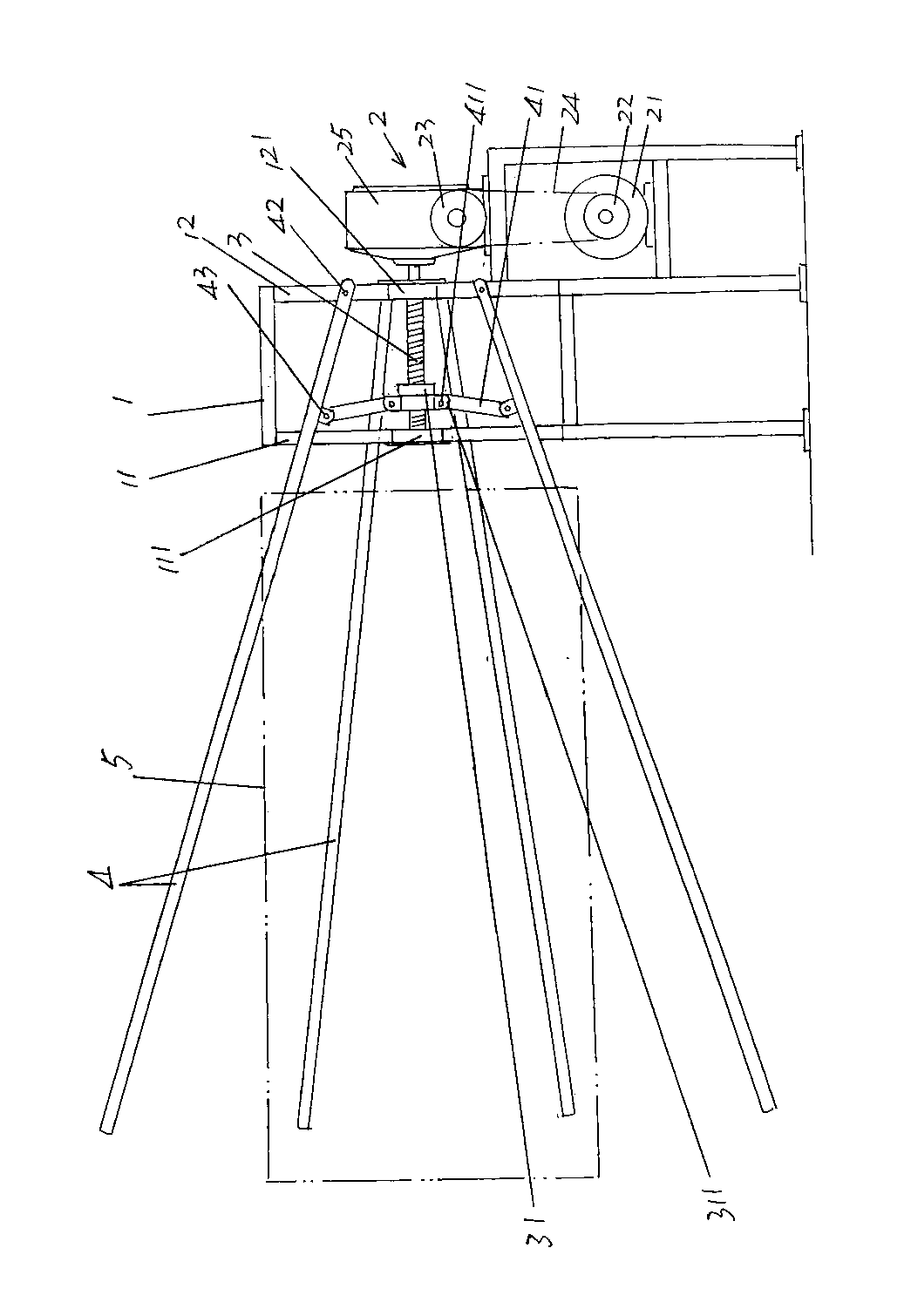

Intelligent material picking and releasing device of combing machine

The invention discloses an intelligent material picking and releasing device of a combing machine. The intelligent material picking and releasing device comprises a supporting frame, pull rods, grippers, a transmission mechanism and a driving device, wherein the multiple pull rods can be located on the supporting frame in a rotatable manner; all the pull rods are arrayed along the length direction of the supporting frame in a spacing manner; every two adjacent pull rods form a group; the grippers are fixedly mounted at the lower ends of the pull rods and extend along a direction perpendicular to the axial direction of the pull rods; the driving device drives all the pull rods to rotate through the transmission mechanism. The intelligent material picking and releasing device disclosed by the invention can complete automatic conveying of materials with the cooperation with a truss mechanism, a conveying device and a lifting device, so that intellectualization of the combing machine is realized, and intelligent connection of bobbins and cotton rolls between a ribbon lap machine and the combing machine is realized; unmanned production in a workshop is met, the cost is reduced, halt due to replacement of the rolls can be reduced, and the operation efficiency of a combing procedure is improved.

Owner:JIANGSU KAIGONG MACHINERY

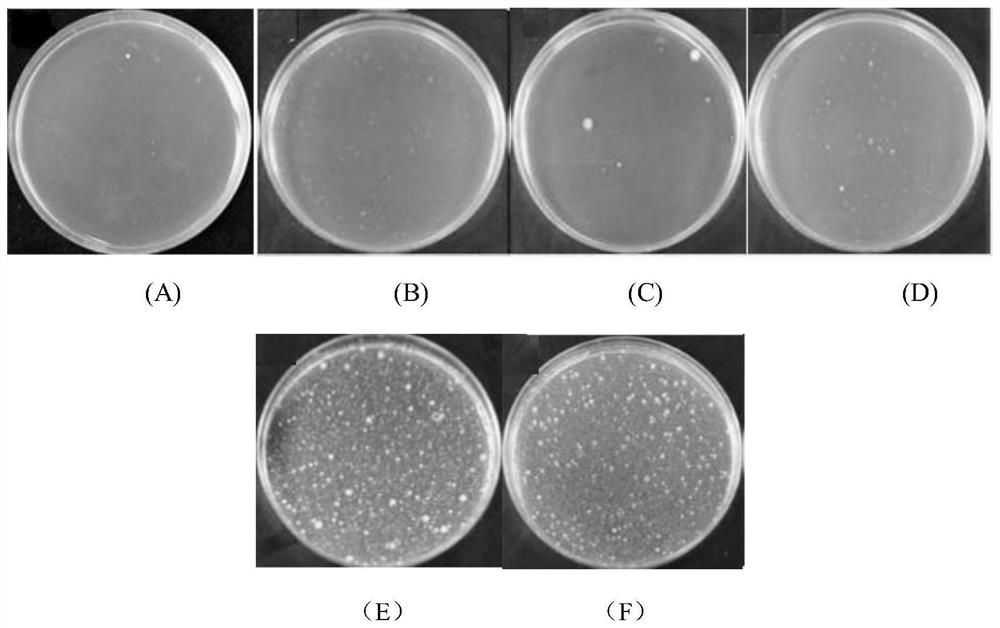

Antibacterial yarn and making method thereof

InactiveCN106676694APineapple is high in fiberHigh in fiberVegetable materialYarnYarnPolymer science

The invention provides a making method of antibacterial yarn. The antibacterial yarn is made by blending, by weight, 45%-60% of pineapple leaf fibers, 40%-50% of long-staple cotton and 5%-15% of spandex. The making method comprises the following steps that the pineapple leaf fiber and the long-staple cotton are mixed and made into a first cotton roll in an opening and cleaning process, the first cotton roll is made into first card silver through a cotton carding process, and the spandex is made into second card silver through a cotton opening and carding combination machine, wherein the length of the long-staple cotton is larger than 35 mm, the first card silver is quantified as 15-17 g / 5 m, and the second card silver is quantified as 15-17 g / 5 m; the first card silver and the second card silver are made into drawn silver through a drawing process; the drawn silver is sequentially subjected to a rough yarn process and a spun yarn process, and the antibacterial yarn is made.

Owner:FOSHAN CHAOYIHUI CLOTHING CO LTD

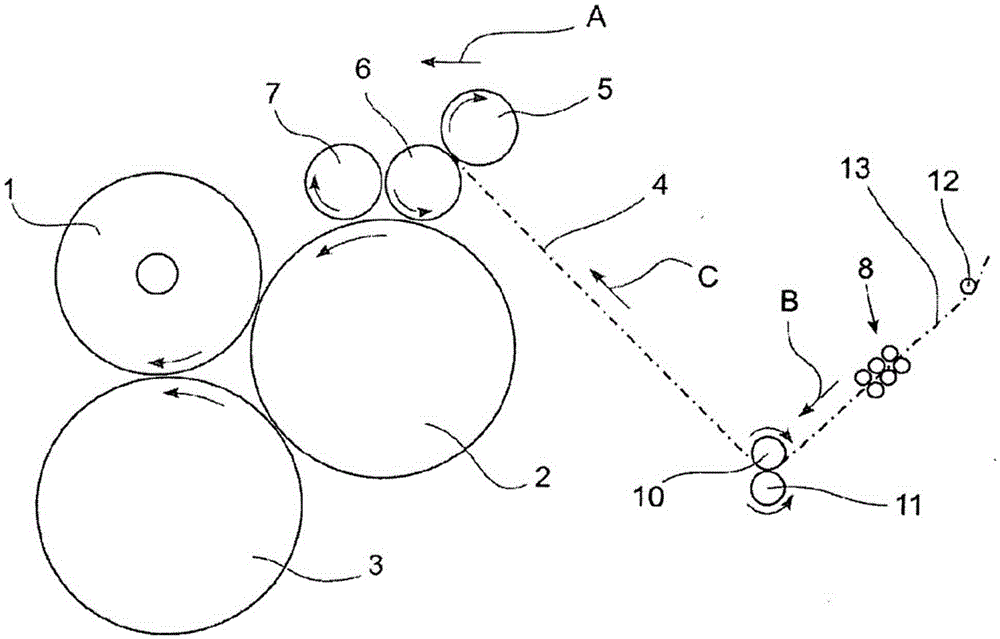

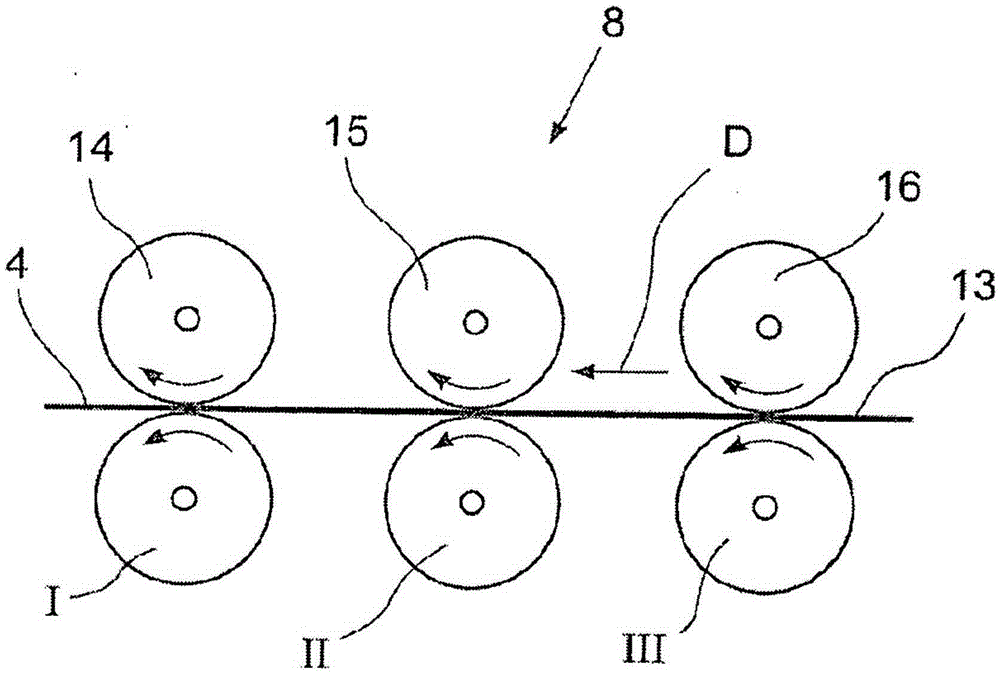

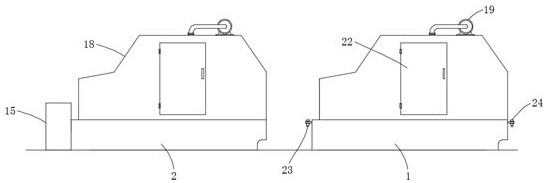

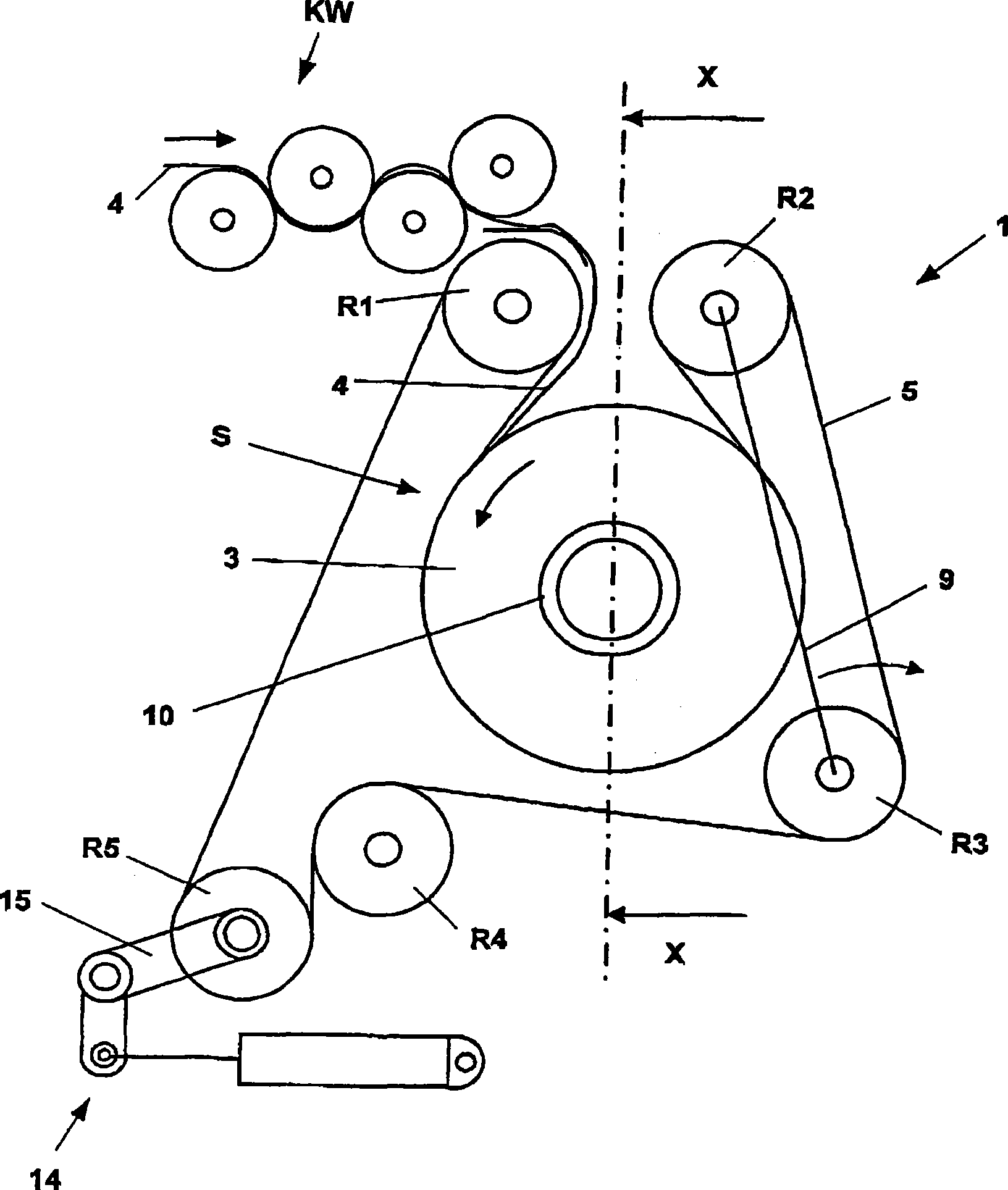

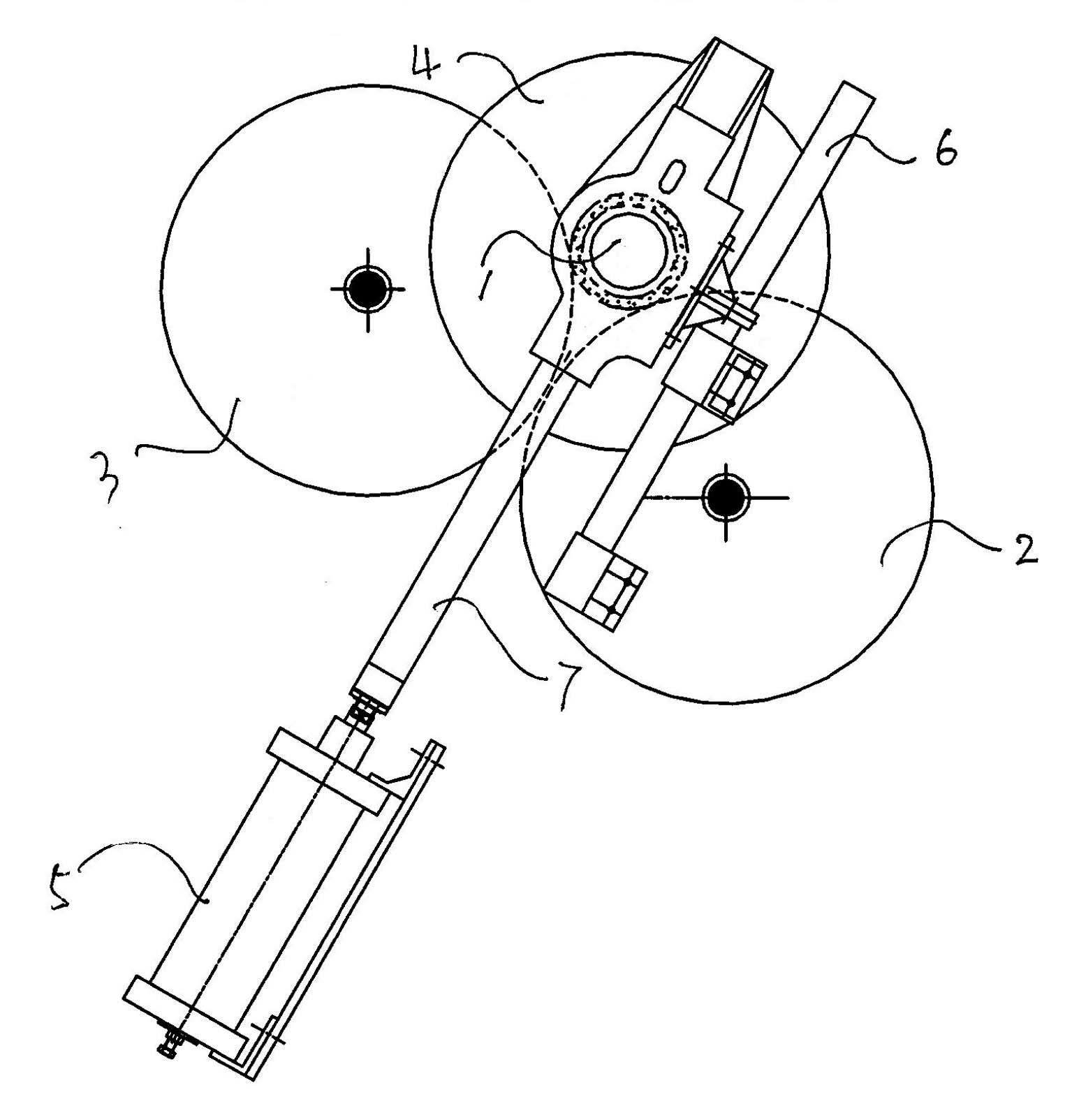

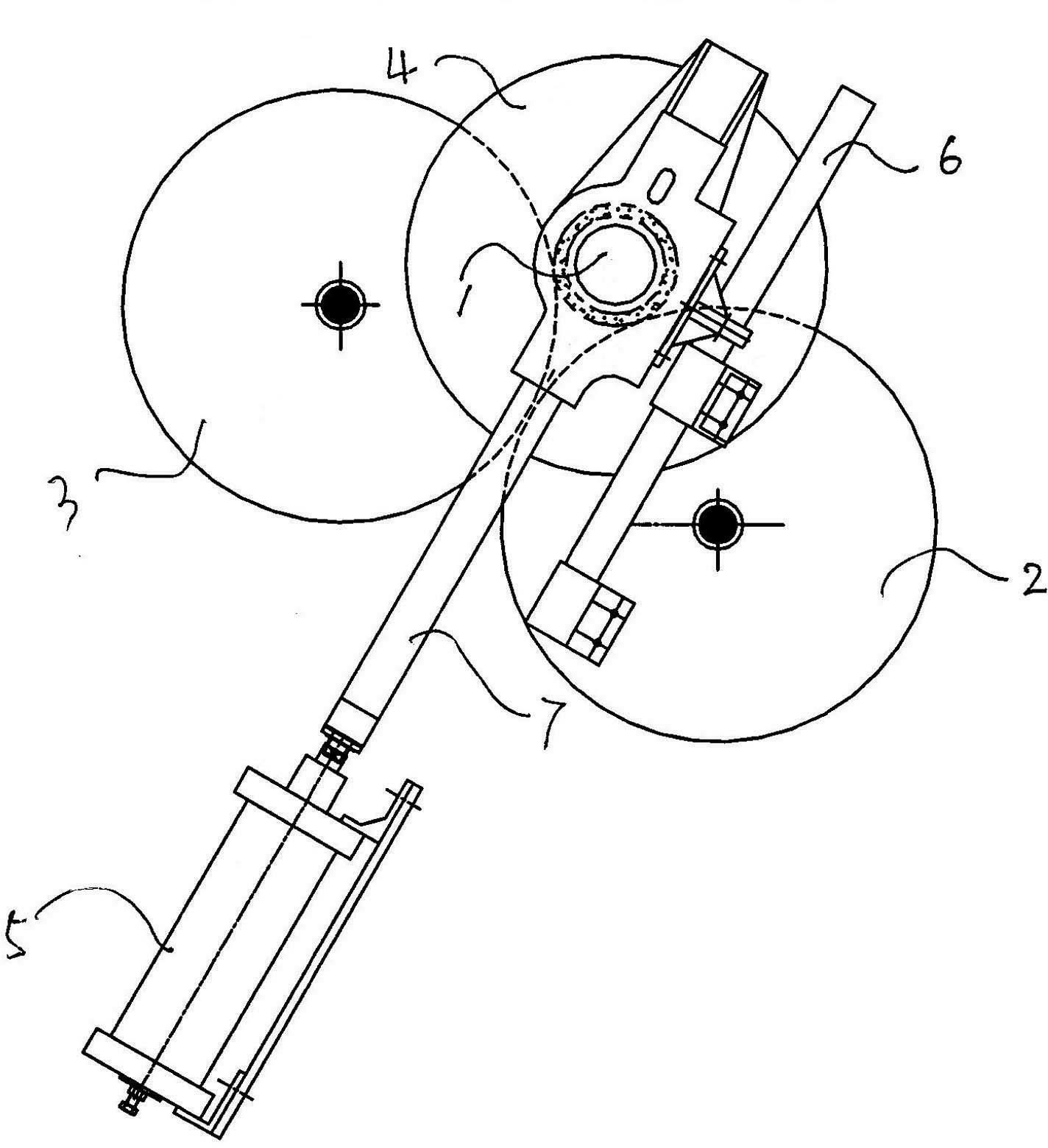

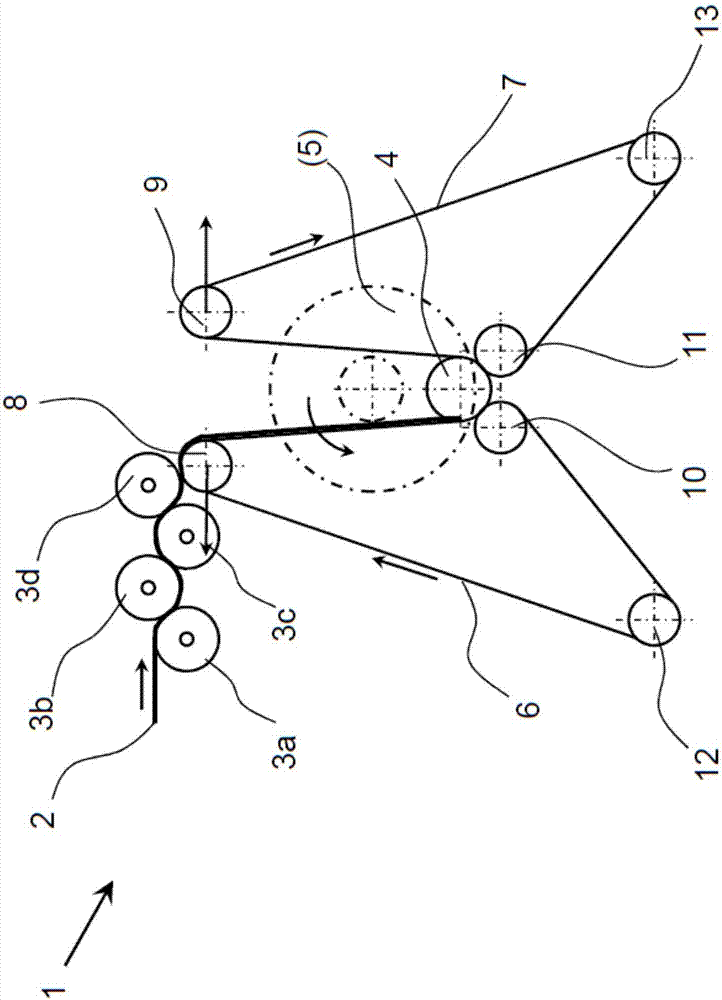

Lap winder for winding strips of cotton wool to lap rolls

ActiveCN105324522ARun fastReduce distractionsFunction indicatorsLap-winding devicesCotton wool rollEngineering

The invention relates to a lap winder for winding strips of cotton wool to lap rolls, said lap winder comprising lap rollers (2, 3) for carrying one lap roll (1) each, pressure rollers (5, 6, 7) for calendering a strip of cotton wool (4) supplied thereto, which pressure rollers are mounted upstream of the lap rollers (2, 3), and at least one drawing system (8) having drawing roller pairs which system is mounted upstream of the pressure rollers (5, 6, 7). The invention is characterized in that each lap roller (2, 3) has a separate drive, and at least one drive can be controlled or regulated by a control unit.

Owner:TRUETZSCHLER GRP SE

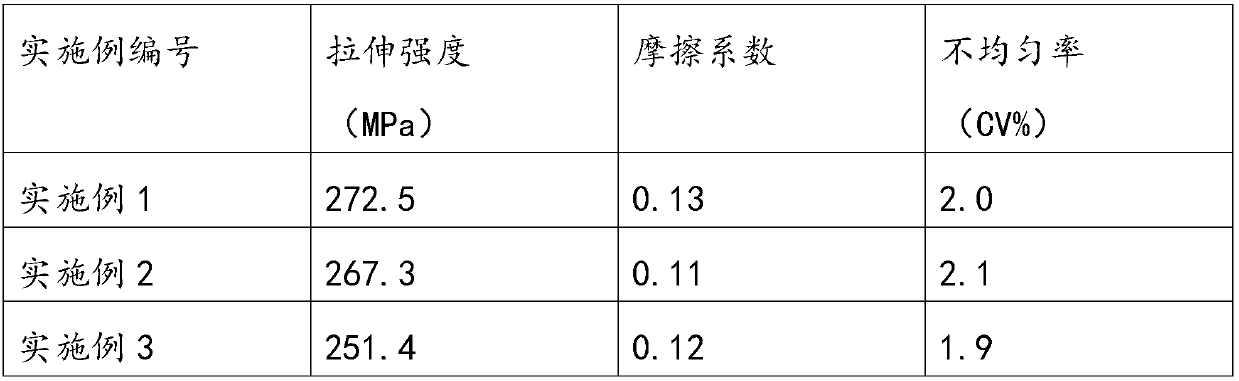

Production method of flame-retardant high-temperature resistant pre-oxidized fiber aramid fiber blended yarn

The invention relates to a flame-retardant high-temperature resistant pre-oxidized fiber aramid fiber blended yarn and a production method thereof. The blended yarn is composed of 50-90mass% of pre-oxidized fiber chopped fibers and 50-10mass% of aramid fiber 1313 chopped fibers; the production process flow comprises the following steps of carrying out pretreatment on the pre-oxidized fiber choppedfibers and the aramid fiber chopped fibers separately; performing cotton package mixing on the pre-oxidized fiber chopped fibers and the aramid fiber 1313 chopped fibers in an opening picking procedure to prepare cotton rolls; preparing the cotton rolls into carding silvers in a cotton carding procedure; preparing the carding silvers into drawing silvers through two drawing procedures; preparingthe drawing silvers into roving through a roving procedure; preparing the roving into spun yarns through a spinning procedure; and preparing the spun yarns into a pre-oxidized fiber aramid fiber blended yarn spool through a spooling procedure. The method combines the pre-oxidized fiber and aramid fiber 1313 flame-retardant high-temperature resistant advantages, overcomes the shortcoming of poor spinning performance of the pre-oxidized fiber, and the woven pre-oxidized fiber aramid fiber 1313 blended yarn has excellent quality.

Owner:YANCHENG INST OF IND TECH

Cotton-cloth-attachment-yarn winding device bringing convenience to position transformation

The invention discloses a cotton-cloth-attachment-yarn winding device bringing convenience to position transformation. The cotton-cloth-attachment-yarn winding device comprises a machine frame, a bottom plate is arranged at the bottom of the machine frame, a transverse plate is arranged in the middle of the machine frame, a cotton roll conveying assembly is arranged at the upper portion of the bottom plate, a yarn unwinding assembly is arranged on the transverse plate, a swinging mechanism is arranged on one side of the yarn unwinding assembly, a pressing mechanism and a winding mechanism are respectively arranged on one side of the machine frame, fixing strips are horizontally arranged on two sides of the top of the bottom plate respectively, through grooves are formed in the two ends of the fixing strips, through holes corresponding to the through grooves are formed in the bottom plate in a penetrating mode, four sliding strips are arranged on the side faces of the through grooves at equal intervals, movable rods are arranged in the through grooves, four sliding grooves corresponding to the sliding strips are arranged on the side faces of the movable rods, supporting plates are horizontally arranged at the upper portions of the fixing strips, hydraulic cylinders are arranged at the tops, of the through grooves, on the supporting plates, stretchable columns are arranged at the bottoms of the hydraulic cylinders and connected with the movable rods, circular grooves are formed in the portions, located at the lower portions of the through holes, in the bottom plate, and universal wheels are arranged in the circular grooves and connected with the movable rods.

Owner:苏州市朗润纺织科技有限公司

Preparation method of durably antibacterial air-jet vortex spun covering yarn

ActiveCN113174664AImprove physical and mechanical propertiesStrong antibacterial durabilityContinuous wound-up machinesMonocomponent synthetic polymer artificial filamentYarnPolymer science

The invention relates to a preparation method of durably antibacterial air-jet vortex spun covering yarn. The method comprises the steps that viscose staple fiber is made into a viscose cotton roll according to opening and cleaning procedures; through a cotton carding procedure, nanofiber containing an antibacterial agent is sprayed to a cotton web conveying device which is additionally arranged after carding and before bundling and sliver forming, viscose drawn slivers are obtained through horn mouth bundling and two-pass drawing, then the viscose drawn slivers are fed into an air-jet vortex spinning machine, polyamide filaments are fed into the space between a front roller and a second roller through a filament guide device, and vortex spinning is carried out. The covering yarn prepared by the method has good antibacterial durability, and the vortex spun covering yarn can integrate the advantages of high strength and wear resistance of polyamide core filaments, is good in yarn evenness and high in spinning efficiency, and has good economic value.

Owner:DONGHUA UNIV +1

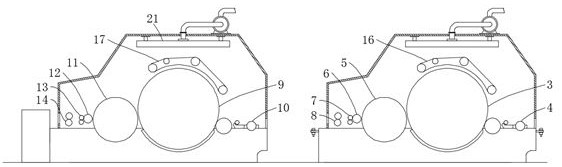

Semi-combing cotton carding equipment

The invention discloses semi-combing cotton carding equipment. The semi-combing cotton carding equipment comprises a first carding machine body and a second carding machine body, wherein a first rackand a second rack are arranged on the first carding machine body and the second carding machine body respectively, a first cylinder is installed on the first rack, a first cotton feeding roller is installed on the right side of the first cylinder, a first doffer corresponding to the first cylinder is installed on the left side of the first cylinder, a second cylinder is installed on the second rack, a second cotton feeding roller is installed on the right side of the second cylinder, a second doffer corresponding to the second cylinder is installed on the left side of the second cylinder, anda coiler is installed on the second rack. The two carding machines are connected in series, cotton rolls can be subjected to semi-combing, normal production from cotton roll feeding to cotton sliver outputting is achieved, cotton textile mills without duplex carding machines, combing machines and sliver lap machines can achieve semi-combing, and meanwhile the semi-combing process is short, the cost is low and the quality is good.

Owner:常州虹纬纺织有限公司

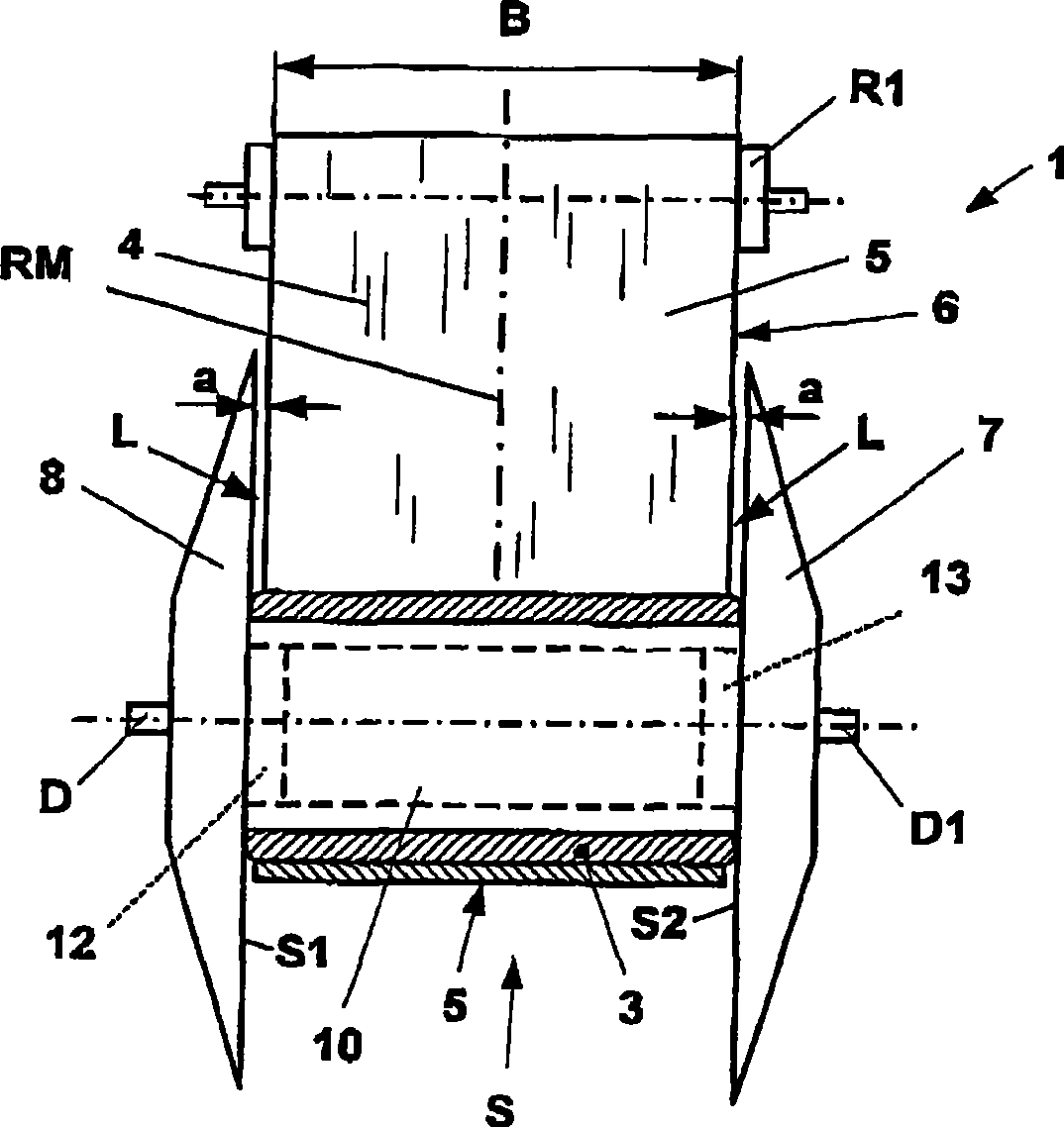

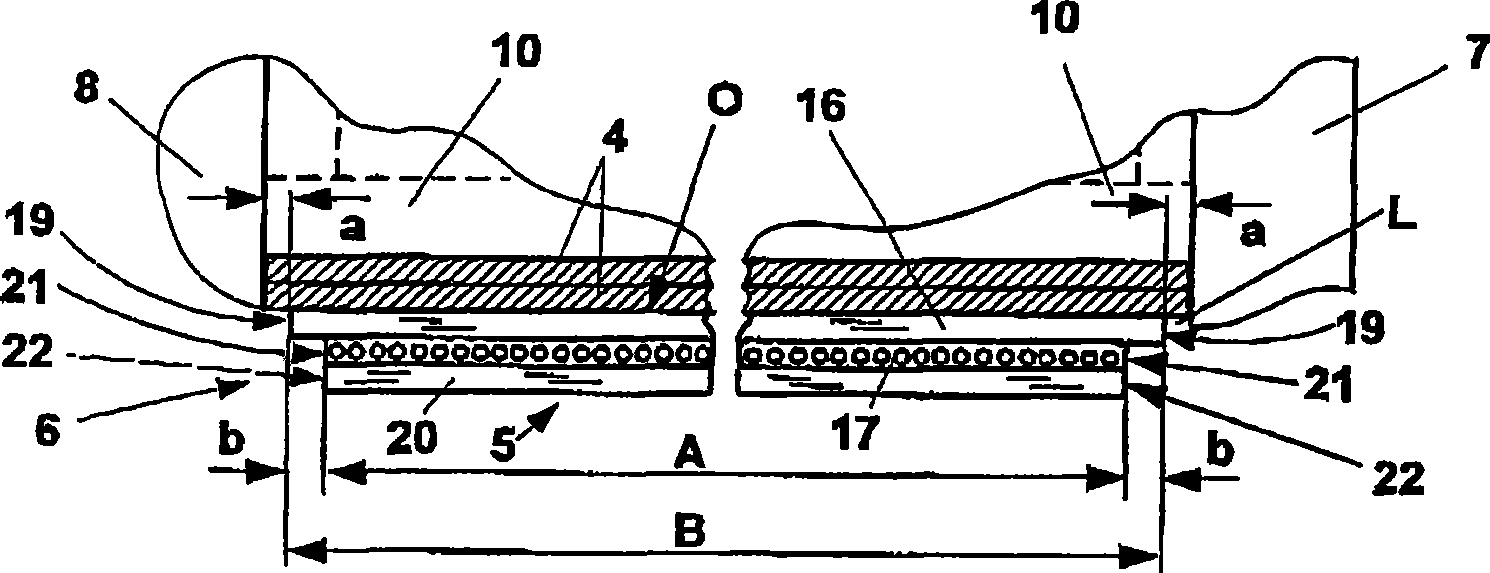

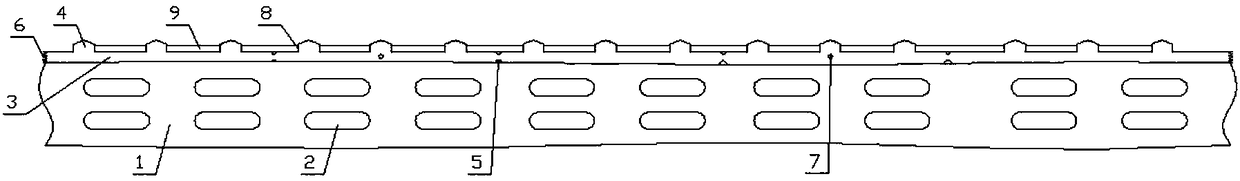

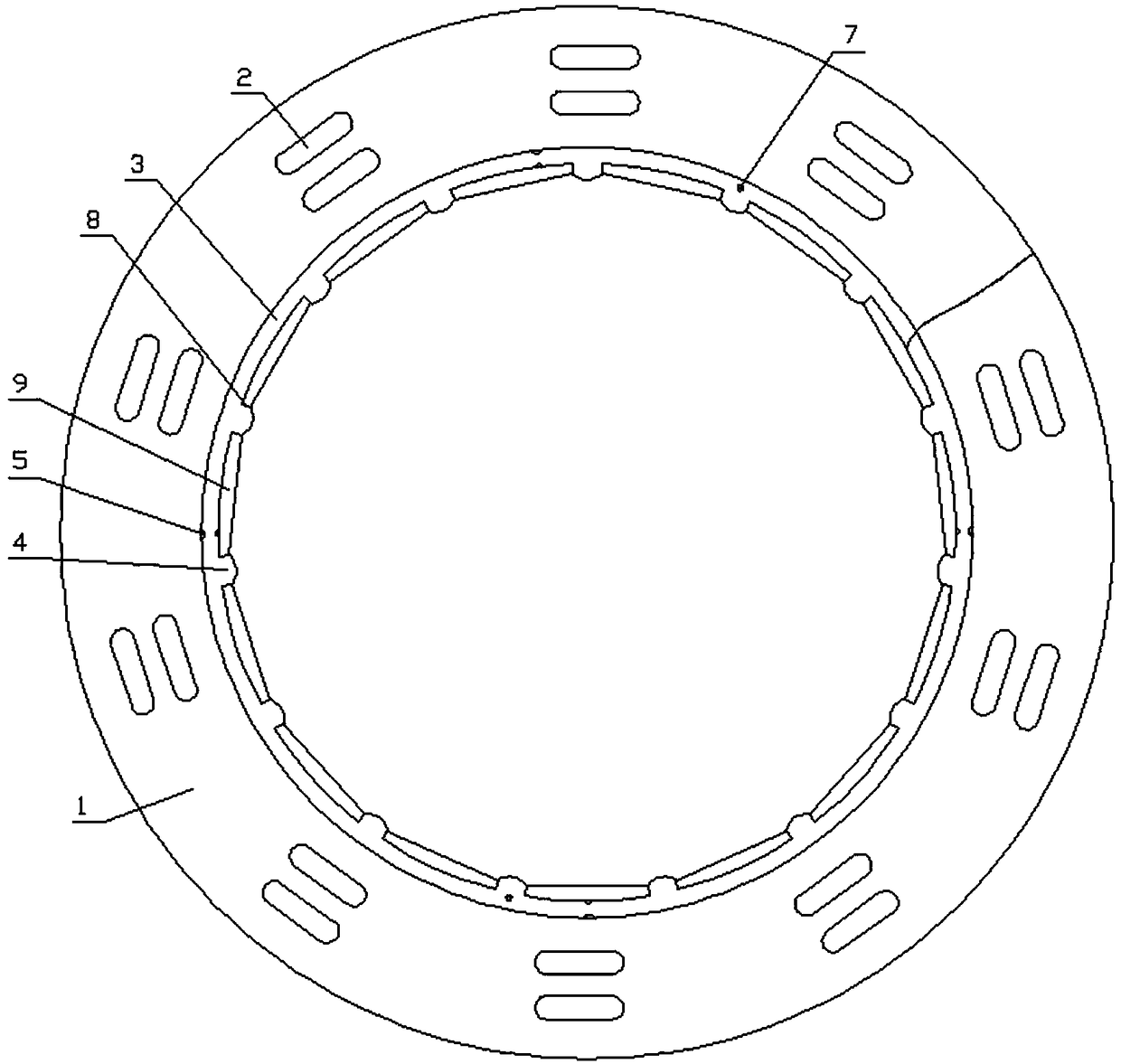

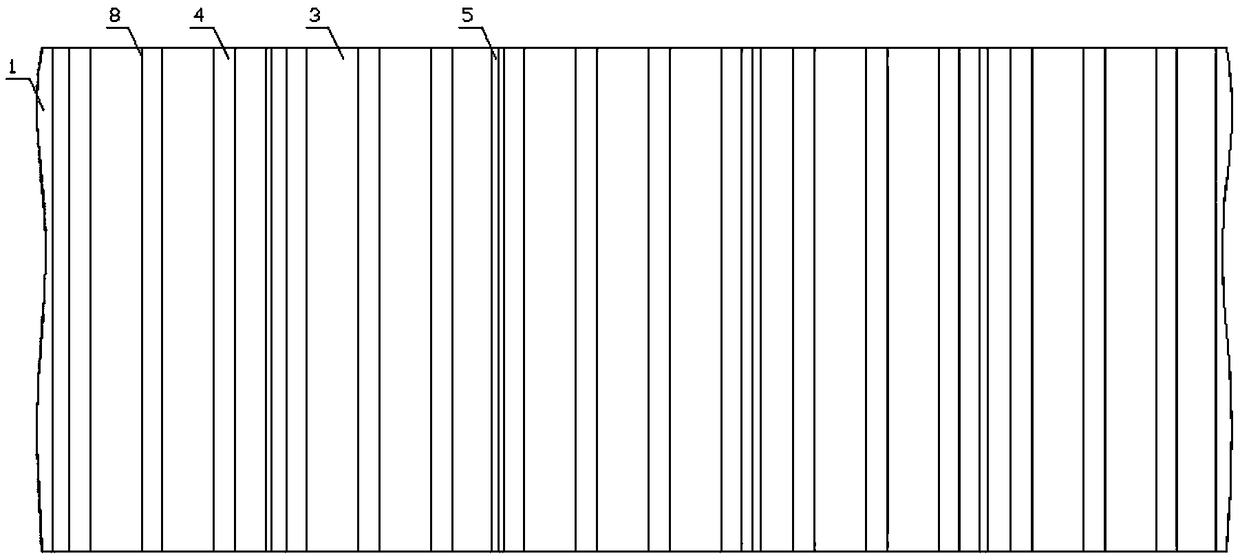

Belt for lap forming device

The present invention relates to a belt of coiling device (1) which is used for producing cotton roll (3), wherein the cotton roll (4) is coiled on a sleeve-shaped central spindle (10) which is driven by a circulating annular belt (5). The belt is provided with a plurality of layers (16, 17, 20) in a laminated mode when the belt is observed from the cross section. The belt comprises a first layer (16) which comprises a smooth surface (O) that is not adhered with fiber for producing a cleaning edge of cotton roll. The batting (4) is guided on the first layer (16) in the coiling process. The side edges (21, 21a, 22, 22a) of the other layers (17, 20) respectively retract from each side edge (19, 19a) of the first layer for a certain distance (b, b1, b2) when the belt is observed along the direction of central line (RM) of belt in the belt breadth (B).

Owner:MASCHINENFABRIK RIETER AG

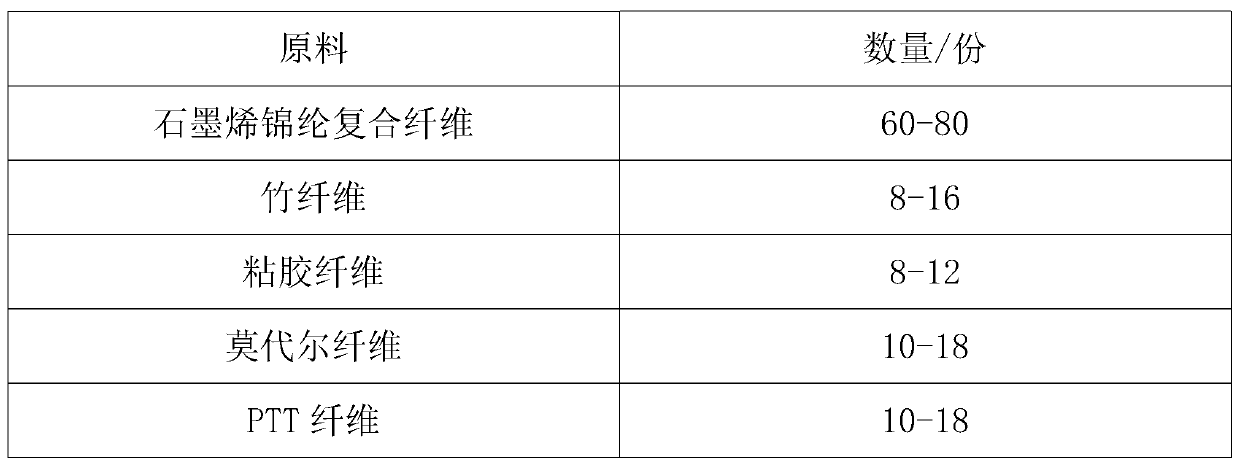

Antibacterial and breathable composite yarn and manufacturing method thereof

The invention discloses an antibacterial and breathable composite yarn and a manufacturing method of the antibacterial and breathable composite yarn, and relates to the technical field of composite yarns. The manufacturing method comprises a raw cotton loosening process, a cotton carding process and a drawing process. In the raw cotton loosening process, graphene nylon composite fiber, Modal fiber, viscose, bamboo fiber and PTT fiber are blended after by weight ratio, 1.5% of an antistatic agent and 1.5% of a humectant are introduced, blended fiber is introduced into a cotton box cotton mixer,and 370-420g / m cotton rolls are formed by using a roll forming machine. In the cotton carding process, manual proportioning and weighing, cotton mixing, cotton opening and cotton carding are sequentially carried out, cotton blending bin continuous weighing and quantitative feeding are carried out, and a fan is used for negative-pressure pumping and soft loosening. In the drawing process, A Truetzschler HSR 1000 drawframe is adopted, two-path combining is adopted by main parameters of the process, the strip feeding speed is 240-260m / min, the drawing multiple is 3-8, the net weight of a strip is 15-18 / 5m, excellent fiber straightness and evenness are obtained, and the drawing roller spacing is 12 mm*19 mm. The antibacterial and breathable composite yarn good antibacterial and air permeability. The manufacturing method is simple and is fast and convenient to adopt. Finished products are aesthetic. The economic values are high.

Owner:骏隆翔(厦门)纤维科技有限公司

T/R yarn blending process

The invention relates to a T / R yarn blending process and belongs to the technical field of blended yarn manufacturing processes. The process includes the steps of firstly, distributing and placing, by weight percentage, 85-95% of simulation chemical polyester stable fibers and 5-15% of viscose into an automatic bale plucker, and allowing the automatic bale plucker to blend the plucked simulation chemical polyester stable fibers and viscose; secondly, by the automatic bale plucker, conveying the blended simulation chemical polyester stable fibers and viscose to a vibration cotton box for opening, blending and being processed into even laps; thirdly, conveying the laps to a carding machine for opening, carding, dust removing and blending to form slivers; fourthly, conveying the slivers into a drawing machine for drawing; fifthly, processing rough yarn; sixthly, processing spun yarn; seventhly, processing spooling. The T / R yarn blending process is high in production efficiency, energy saving, consumption reducing, and good in product performance.

Owner:绍兴柯桥南红纱业有限公司

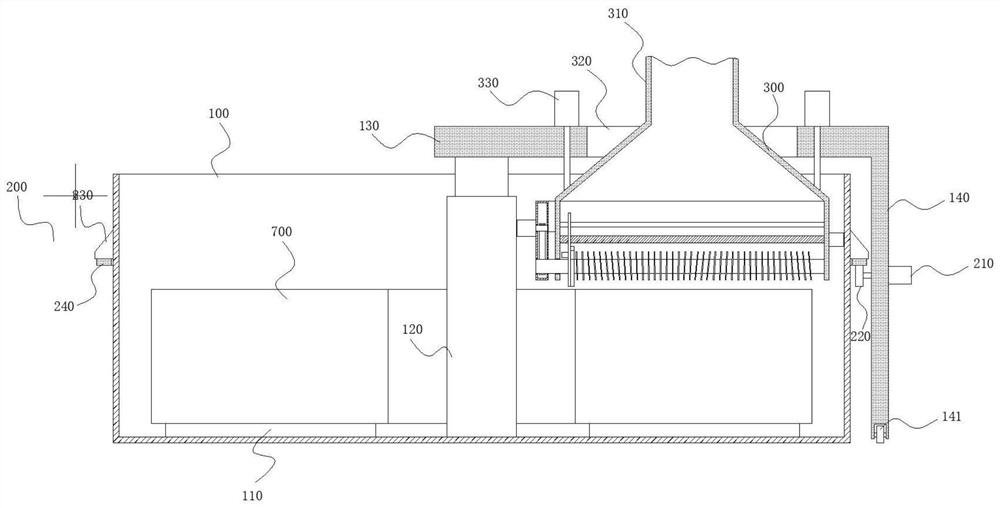

Automatic roll changing system

The invention discloses an automatic roll changing system. The automatic roll changing system comprises an automatic roll changing device, a transverse moving grabbing device and a conveying device. The automatic roll changing device is fixedly mounted on the back side of a combing machine. The traverse moving grabbing device is disposed above the automatic roll changing device. The conveying device is arranged on one side of the automatic roll changing device in parallel. The automatic roll changing device takes an empty cotton cylinder out of the combing machine and places a spare cotton roll on the combing machine. The transverse moving grabbing device grabs an empty cotton cylinder on the automatic roll changing device onto the conveying device, and grab and place a cotton roll on theconveying device onto the automatic roll changing device as a spare cotton roll.

Owner:武汉裕大华纺织有限公司

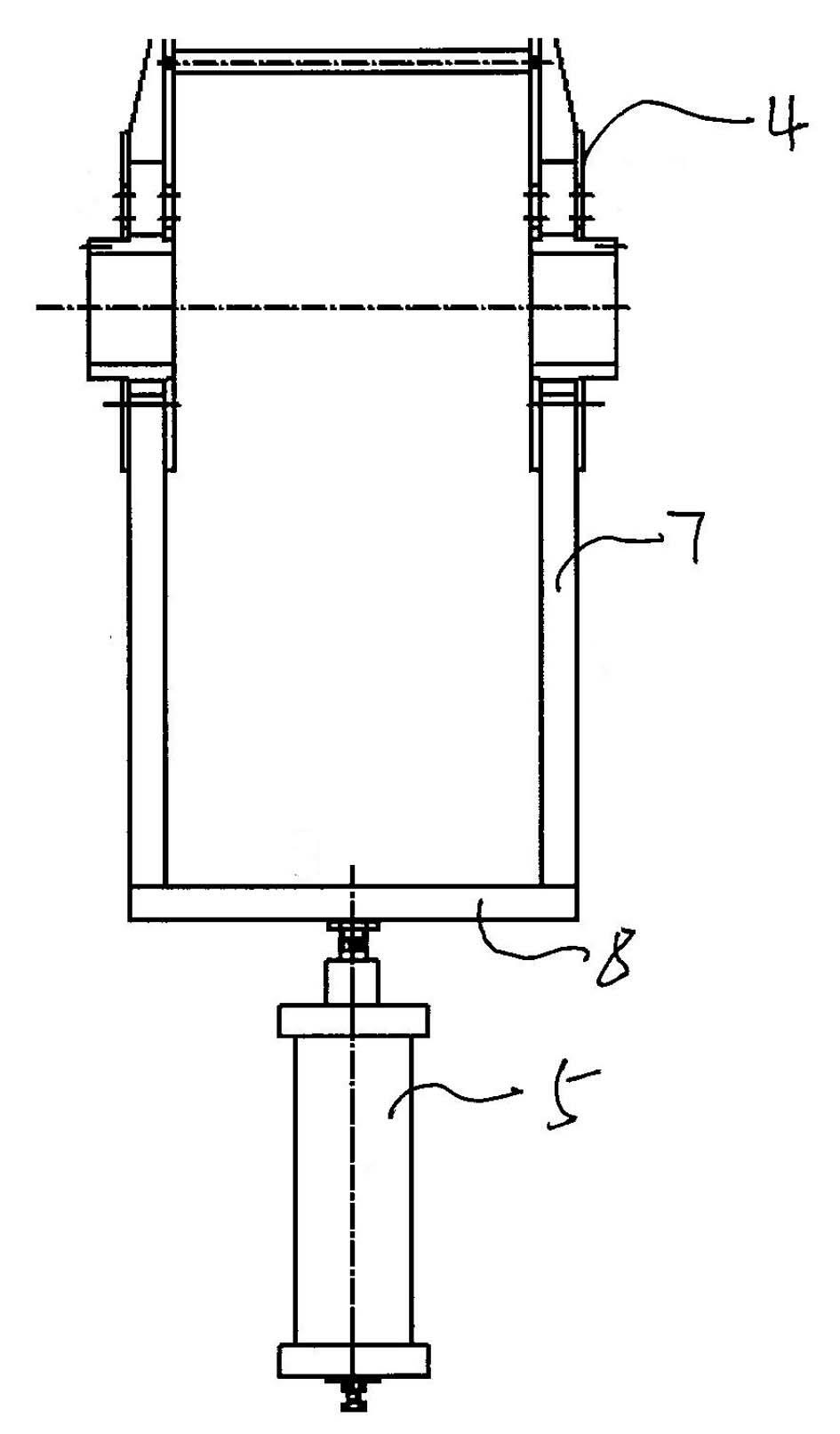

Single-cylinder pressure device applicable to cotton lap pressure of strip and lap combination machine

The invention discloses a single-cylinder pressure device applicable to cotton lap pressure of a strip and lap combination machine. The device is characterized in that the device comprises left and right lifting arms lifting along left and right guide rails, a bobbin for winding a cotton layer and a transverse connecting rod, wherein two ends of the bobbin are embedded in grooves of left and right clamping disks at the upper part of the left and the right lifting arms; the transverse connecting rod is connected with the bottom end of the left and right lifting arms; and the transverse connecting rod is combined with a piston rod of a cotton lap pressure cylinder which is fixedly connected with a rack by a connecting piece. By adopting the device provided by the invention, creeping phenomenon during pressure process can be eliminated and the problems of impact, vibration, noise, power loss during mechanical pressure and pressure law are resolved.

Owner:马驰

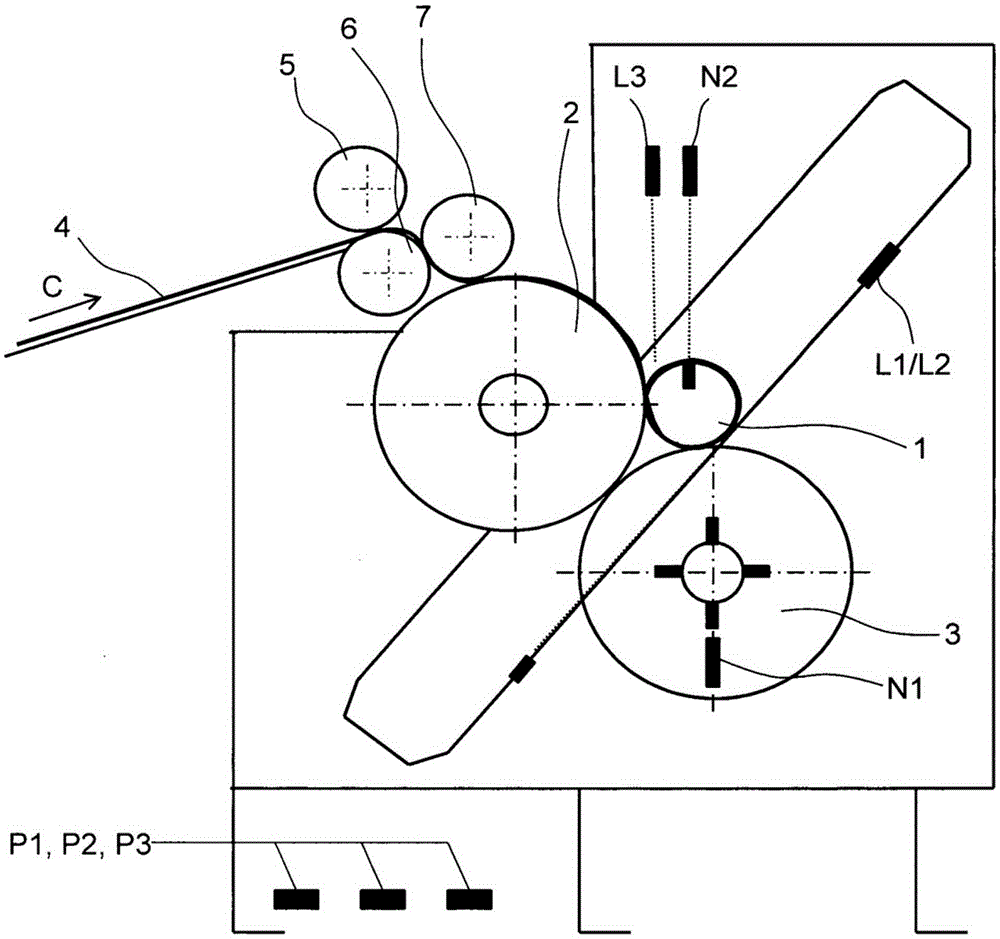

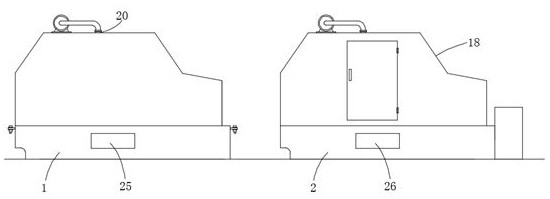

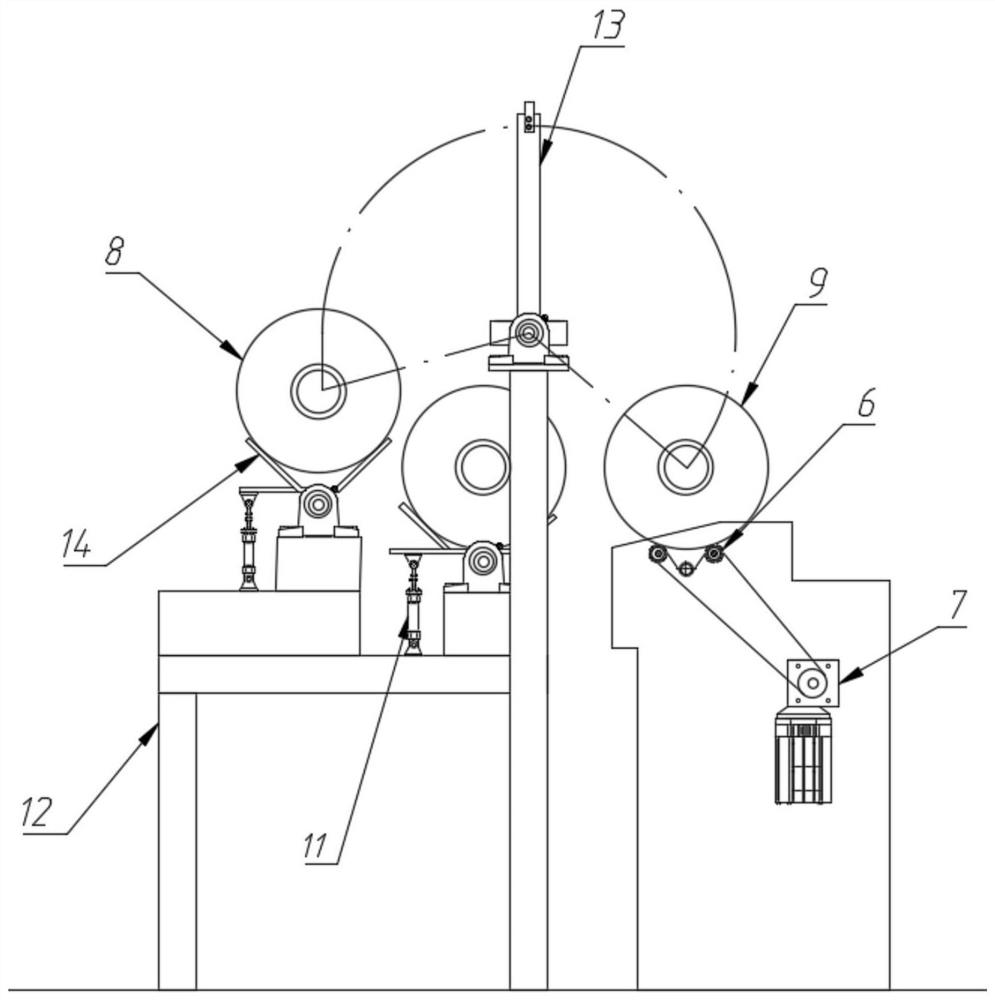

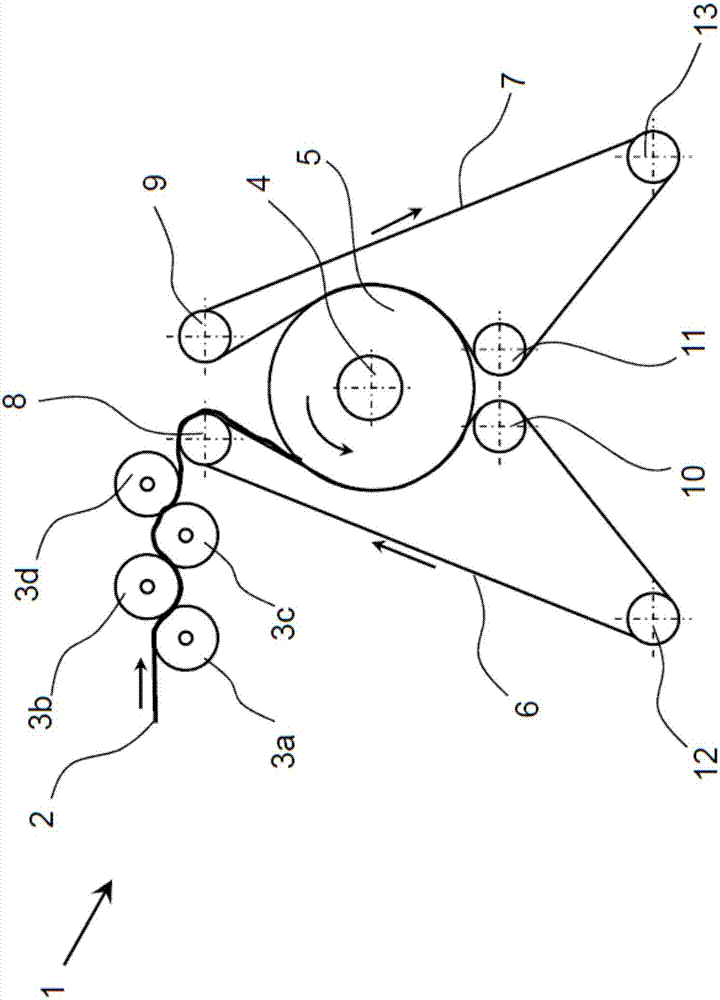

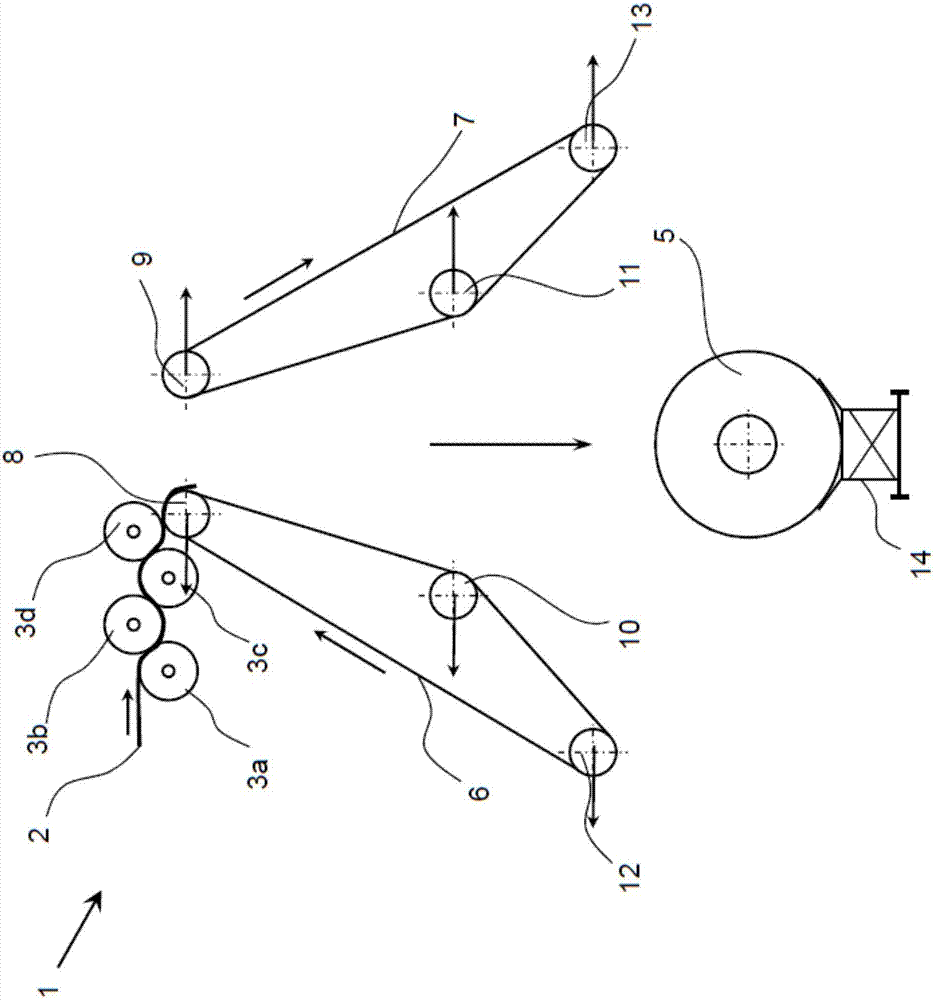

Coiling machine for coiling cotton strips into cotton coils

The invention relates to a coiling machine and method for coiling fiber strips prepared from cotton fibers (2) to bobbins (4). The cotton fibers are led to the bobbins (4) through a continuously rounding first belt (6). The coiling machine and the method are characterized in that a continuously rounding second belt (7) leads the cotton fibers (2) along the bobbins (4).

Owner:TRUETZSCHLER GRP SE

Preparation method of bio-based fiber degradable fabric

InactiveCN113604909APrevent scurryingMovement restrictionsFibre breaking machinesFibre breaking by toothed membersYarnPolymer science

The invention discloses a preparation method of a bio-based fiber degradable fabric, and relates to the technical field of fabric production. The preparation method comprises the steps of firstly, grabbing piled bio-based fiber cotton through a bale plucker; putting the bio-based fiber cotton grabbed by the bale plucker into a cotton blending machine; making the bio-based fiber cotton in the cotton blending machine into cotton rolls by using a lapper; carrying out opening, carding and impurity removal on the cotton rolls in the third step through a carding machine, preparing fiber cotton card slivers, and then carrying out pre-drawing treatment on the fiber cotton card slivers to obtain fiber cotton drawn slivers; performing first to fourth treatments on cotton made of other materials to obtain cotton drawn slivers; drawing the cotton drawn slivers obtained in the step 5 and the fiber cotton drawn slivers obtained in the step 4 by using a drawing frame, firstly spinning into rough yarns, then spinning into spun yarns, and then stranding and twisting through a spooling to prepare plied yarns; and making the plied yarns into a fabric by using a loom. The preparation method of the bio-based fiber degradable fabric provided by the invention has the advantages of convenience in use, high bale plucking efficiency of the bale plucker, difficulty in blockage of a bale plucking blade and the like.

Owner:安徽宜民服饰股份有限公司

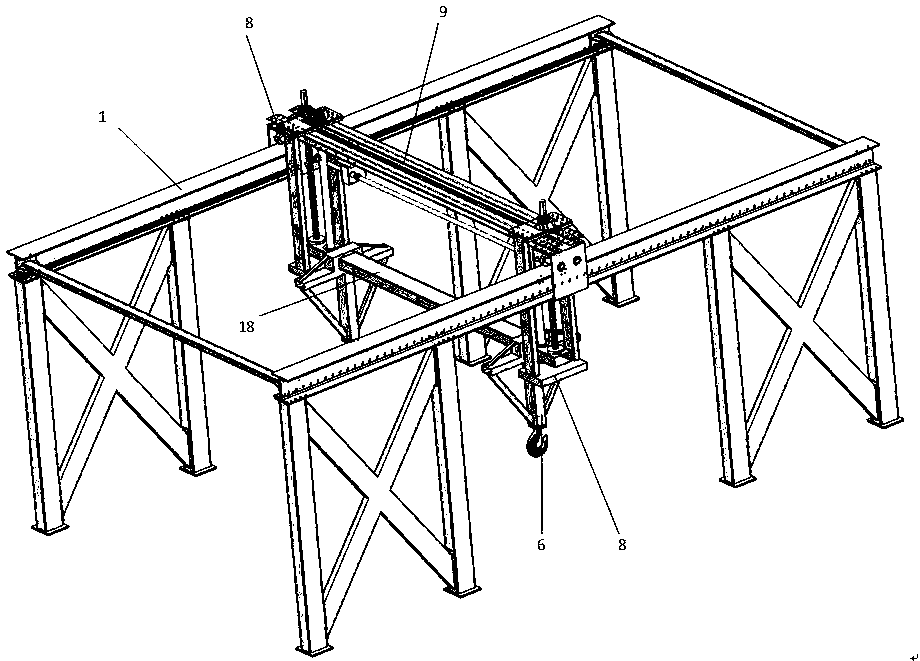

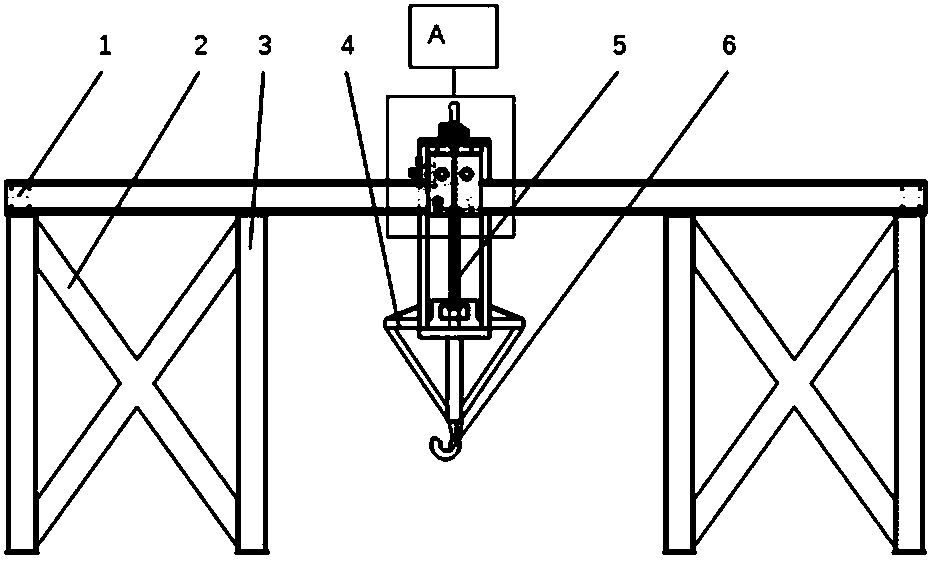

Automatic cotton roll carrying device

InactiveCN110844797ASmall footprintRealize automated productionTrolley cranesTrolleysWinding machineAgricultural engineering

The invention provides an automatic cotton roll carrying device which comprises an upper beam. A movable lifting support is arranged on the upper beam, a movable assembly is arranged between the upperbeam and the lifting support, a lifting lifting-hook cross beam is arranged on the lifting support, a lifting assembly is arranged between the lifting support and the lifting-hook cross beam, and twolifting hooks are arranged on the lifting-hook cross beam. The automatic cotton roll carrying device has the advantages that the integral frame type structure is utilized, so that the occupied area of the whole workshop is reduced, and the utilization rate of the workshop area is improved; the full-roll unloading and automatic carrying of a winding machine and the connection between the full-rollunloading and the automatic carrying and the reset of the hollow mandrel on a splitting machine to the winding machine are realized, and automatic production of a non-woven spunlace production line is realized.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Anion fiber blended yarn and production process thereof

The invention belongs to the technical field of novel spinning and particularly relates to anion fiber blended yarn. The preparation process of the anion fiber blended yarn comprises the following steps: pretreating cotton fibers; carrying out blowing-carding on the cotton fibers pretreated in the step one; taking a part of the cotton fibers subjected to blowing-carding to be mixed with anion fibers and making the mixture into a first cotton roll, and taking a part of bamboo fibers to be mixed with the remaining cotton fibers subjected to blowing-carding in the step two and making the mixtureinto a second cotton roll; taking the remaining anion fibers to be mixed with the first cotton roll in the step three and making the mixture into a first card silver, and making the second cotton rollin the step three into a second card silver; and making the first card silver and the second card silver in the step four into a drawn silver through a drawing procedure, and making the drawn silverinto the blended yarn of the anion fibers, the bamboo fibers and the cotton fibers through a roving procedure and a spinning procedure in sequence. The anion fiber blended yarn has the functions of antibacterial sterilization and deodorization, and the preparation process is simple in procedures and easy to operate.

Owner:JIANGYIN XIANGFEI APPAREL

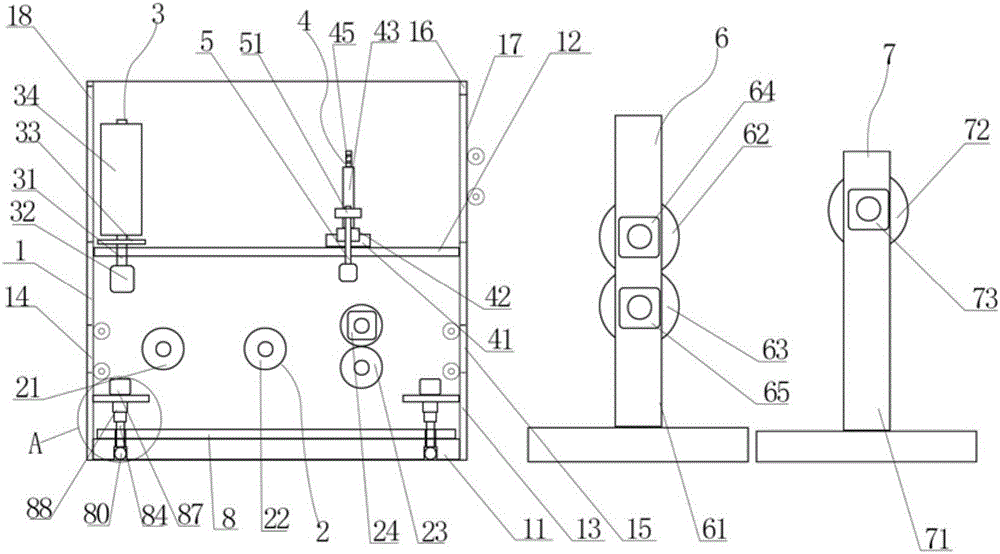

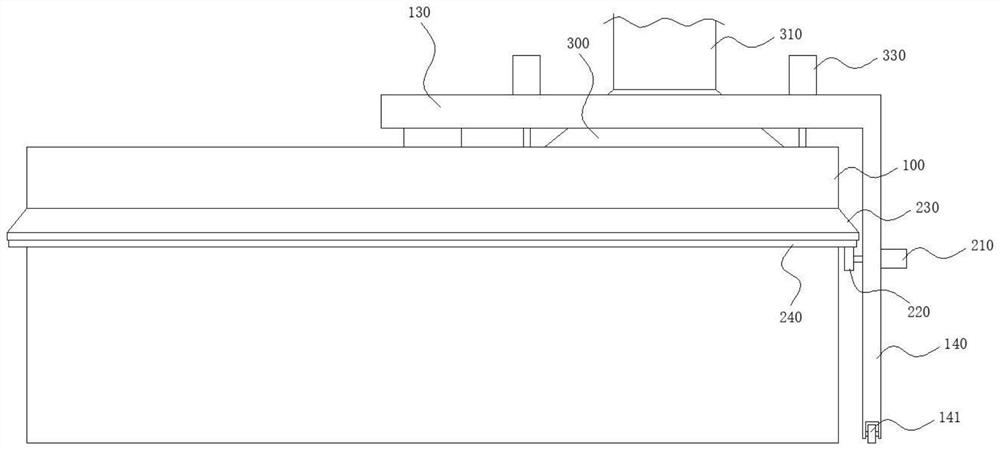

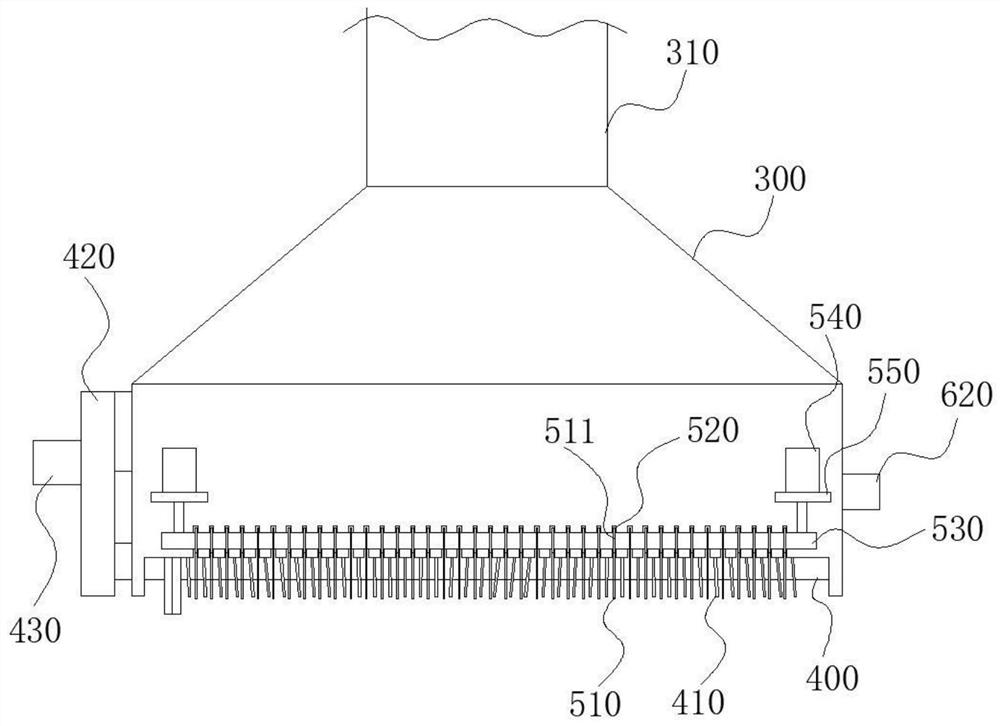

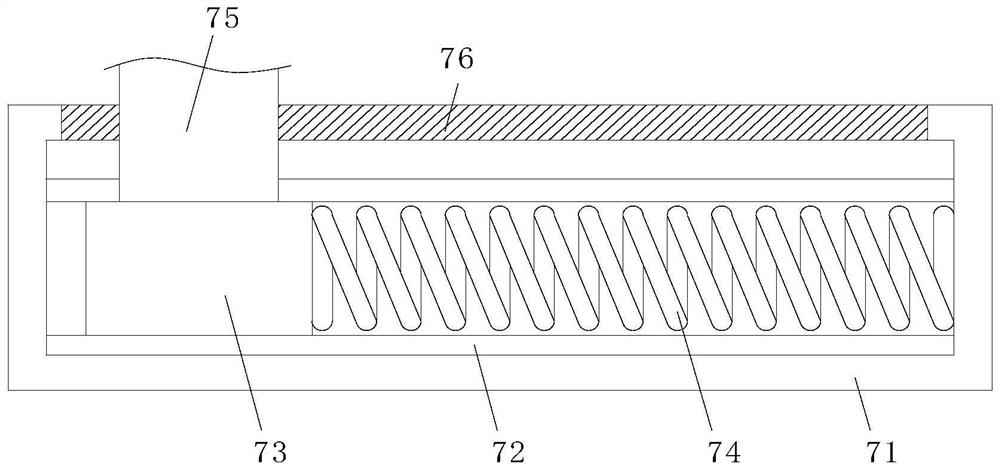

Fluffy fiber cotton roll packaging machine

The invention discloses a fluffy fiber cotton roll packaging machine, and belongs to the technical field of non-textile machinery. The fluffy fiber cotton roll packaging machine comprises a rack, an actuating mechanism, a screw shaft and a group of pressure claw bars, wherein a group of first pressure claw bar guide rails and a group of second pressure claw bar guide rails are fixed on the rack, a front bearing seat is arranged at the joint center of the group of the first pressure claw bar guide rails, a rear bearing seat is arranged at the joint center of the group of second pressure claw bar guide rails, the actuating mechanism is arranged on the rack, one end of the screw shaft is supported on the front bearing seat, the middle of the screw shaft is supported on the rear bearing seat, the other end of the screw shaft is connected with the actuating mechanism, a connecting rod nut is arranged on the screw shaft in a matched mode, one end of each pressure claw bar is matched with the first pressure claw bar guide rails and further connected with the second pressure claw bar guide rails, the other end of each pressure claw bar extends towards the direction deviated from the rack, each pressure claw bar is connected with one end of each connecting rod in a hinged mode, and the other end of each connecting rod is connected with the connecting rod nut in a hinged mode. The fluffy fiber cotton roll packaging machine has the advantages of being capable of being convenient to transport, saving storage space, relieving operating intensity of workers and ensuring process requirements for follow-up processes such as acupuncture or spunlace.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

Sisal-based antibacterial fiber blended yarn and production process thereof

InactiveCN110952194AImprove stain resistanceSimple preparation processBiochemical fibre treatmentYarnYarnPolymer science

The invention belongs to the technical field of novel spinning and particularly relates to sisal-based antibacterial fiber blended yarn. The preparation process comprises the following steps of: pre-treating cotton fibers; carrying out blowing-carding on the cotton fibers pretreated in the step one; taking a part of the cotton fibers subjected to blowing-carding to be mixed with sisal-based antibacterial fibers and making the mixture into a first cotton roll, and taking a part of sea-island fibers to be mixed with the remaining cotton fibers subjected to blowing-carding in the step two and making the mixture into a second cotton roll; taking the remaining sisal-based antibacterial fibers to be mixed with the first cotton roll in the step three and making the mixture into a first card silver, and making the second cotton roll in the step three into a second card silver; and making the first card silver and the second card silver in the step four into a drawn silver through a drawing procedure, and making the drawn silver into the blended yarn of the sisal-based antibacterial fibers, the sea-island fibers and the cotton fibers through a roving procedure and a spinning procedure in sequence. The sisal-based antibacterial fiber blended yarn has the functions of antibacterial sterilization and deodorization, and the preparation process is simple in procedures and easy to operate.

Owner:JIANGYIN XIANGFEI APPAREL

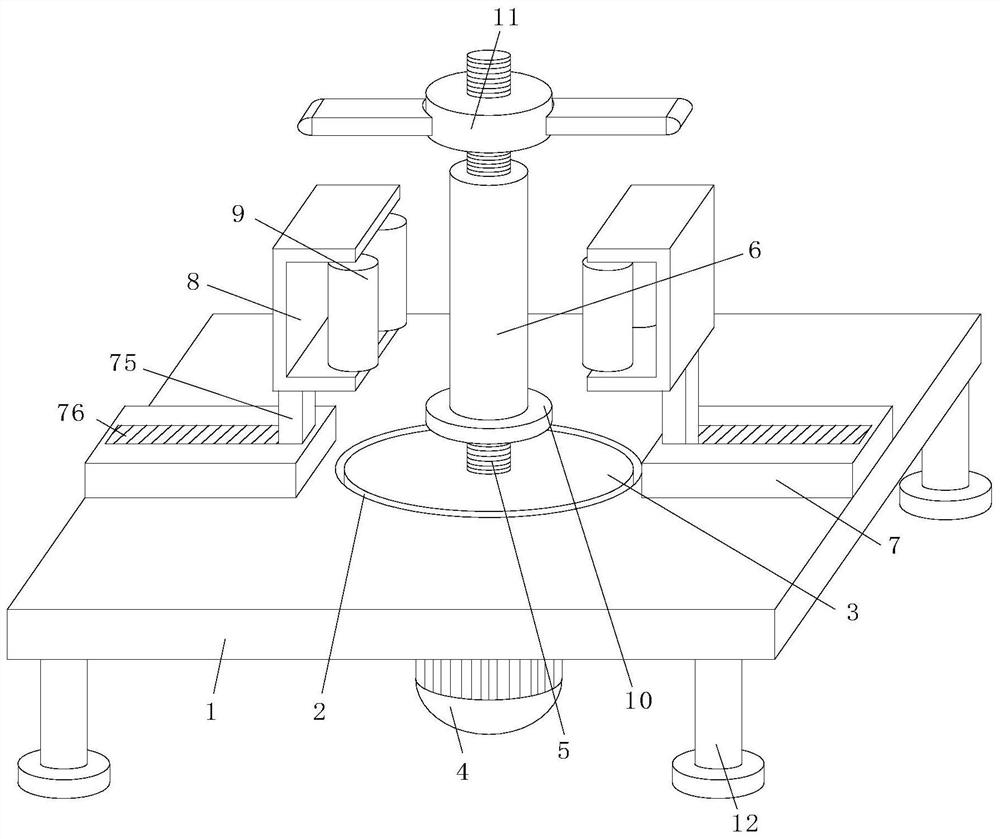

Cotton roll compacting device of lapper for spinning

The invention relates to the technical field of spinning, in particular to a cotton roll compacting device of a lapper for spinning. The cotton roll compacting device comprises a base plate, a turntable, a driving motor, a positioning screw rod, a winding drum, propelling mechanisms, installation frames, pressing rollers, a limiting plate, a fastener and bottom feet, wherein an installation grooveis formed at the middle position of the base plate; the bottom of the turntable is rotatably connected with the base plate through a bearing; the turntable is positioned in the interior of the installation groove; the driving motor is fixedly installed at the middle position of the bottom of the base plate; the output end of the driving motor is in transmission connection with the bottom of the turntable; and one end of the positioning screw rod is fixedly connected with the middle position of the top of the turntable. According to the cotton roll compacting device of the lapper for spinning,the purposes of avoiding the phenomena of loosening and expansion among winding layers of a cotton roll are achieved, the compact state of the cotton roll in the winding process is improved, and thetight fit among the cotton layers is ensured, so that the winding length of each cotton roll is increased, and the attractiveness of the cotton roll and the quality of the finished product are improved.

Owner:YANCHENG INST OF IND TECH

Silver acrylic fiber blended yarn and production technology thereof

InactiveCN110952197AImprove stain resistanceSimple preparation processFibre typesYarnYarnPolymer science

The invention belongs to the technical field of novel spinning, and particularly relates to silver acrylic fiber blended yarn and a production technology thereof. The preparation technology comprisesthe following steps: pretreating cotton fibers; blowing-carding the cotton fibers pretreated in the step 1; mixing a part of cotton fibers after blowing-carding with silver acrylic fibers and forminginto a first cotton roll, and mixing bamboo fibers with the surplus cotton fibers after blowing-carding in the step 2 and forming into a second cotton roll; mixing the surplus silver acrylic fibers with the first cotton roll in the step 3 and forming into a first card sliver, and forming the second cotton roll in the step 3 into a second card sliver; and drawing the first card sliver and the second card sliver to form a drawn sliver, and then sequentially performing roving and spinning processes on the drawn sliver to acquire the blended yarn of the silver acrylic fibers, the bamboo fibers andthe bottom fibers. The silver acrylic fiber blended yarn has the functions of antibacterial, sterilization and deodorization, and the preparation technology is simple in process and easy to operate.

Owner:JIANGYIN XIANGFEI APPAREL

Organic cotton fiber bunchy yarn and manufacturing process thereof

The invention provides an organic cotton fiber bunchy yarn and a manufacturing process thereof. The process includes the procedures of scutching, cotton carding, drawing, roving, spinning and winding.The scutching procedure includes application coordination of an automatic bale plucker, a mixing bale opener and a bale opener after parameter adjustment, a cotton roll enters the cotton carding procedure after the scutching procedure, and is changed into a cotton sliver under the action of a carding machine and then divided into a few parallel slivers, and the parallel slivers enter a drawing frame, are drawn, pass a roving frame and a spinning frame and finally enter a bobbin winder. The yarn made of novel environment-friendly materials is provided for the market by the aid of the manufacturing process, clothes made of the yarn can improve the clothing experience of people, market requirements are met, and economic and social development is promoted.

Owner:上海纺织(集团)大丰纺织有限公司

Abrasion-resistant anti-pill blended yarn and preparation method thereof

InactiveCN109652882AImprove wear resistanceImprove breathabilityYarnVegetal fibresCuprammonium rayonYarn

The invention relates to an abrasion-resistant anti-pill blended yarn which is blended from, by weight, 60-70 parts of cotton fibers, 18-25 parts of polyacrylonitrile fibers, 10-18 parts of copper ammonia fibers, 5-10 parts of linen fibers and 1-2 parts of ultra-high molecular weight polyethylene fibers. The invention further provides a preparation method of the abrasion-resistant anti-pill blended yarn. The method includes the steps: weighing raw materials, and pretreating the cotton fibers; dividing the pretreated cotton fibers into first cotton fibers and second cotton fibers; mixing the first pretreated cotton fibers and the polyacrylonitrile fibers to prepare a first cotton roll, and mixing the second pretreated cotton fibers, the copper ammonia fibers, the linen fibers and the ultra-high molecular weight polyethylene fibers to prepare a second cotton roll; preparing a first carding sliver and a second carding sliver from the first cotton roll and the second cotton roll; performing combination on the first carding sliver and the second carding sliver to prepare a drawing sliver, and sequentially performing a roving process, a spun yarn process and a spraying process to preparethe abrasion-resistant anti-pill blended yarn. The prepared blended yarn is excellent in abrasion resistance and anti-pill performance.

Owner:湖北中天科技有限公司

Antibacterial blended yarn and production process thereof

The invention belongs to the technical field of novel spinning, and particularly relates to an antibacterial blended yarn. The antibacterial blended yarn comprises the following components of 10-20% of chitin fibers, 30-65% of cotton fibers and 20-30% of mint fibers based on weight. A production process comprises the following steps of 1, carrying out pretreatment on cotton fibers; 2, carrying outblowing-carding on the pre-processed cotton fibers; 3, preparing a first cotton roll, and carrying out mixing on a part of the mint fibers and the margin of the blown and carded cotton fibers in thestep 2 to prepare into a second cotton roll; 4, carrying out mixing on the margin of the mint fibers and the first cotton roll in the step 3 to prepare into a first raw strip, and preparing the secondcotton roll in the step 3 into a second raw strip; and 5, preparing the first raw strip and the second raw strip in the step 4 into a processed strip through a drawing process, and then enabling theprocessed strip to be subjected to a roving process and a spinning process in sequence to prepare the blended yarn. The antibacterial yarn provided by the invention has the functions of antibacterialsterilization and deodorization, moisture absorption and heat preservation, green environmental protection and moisture absorption and ventilation, and the preparation process is simple and easy to operate.

Owner:JIANGYIN XIANGFEI APPAREL

Polylactic acid fiber yarn and manufacturing process thereof

The invention provides a polylactic acid fiber yarn and a manufacturing process thereof. The process includes six processes of cotton cleaning, cotton carding, drawing, roving, spinning and winding, wherein the cleaning process includes application cooperation among an automatic cotton grabbing machine, a mixed cotton opener and an cotton opener after parameter adjustment of each device. Lap enters into the cotton carding process after cotton cleaning process, under the action of a carding machine, the lap become cotton slivers and the slivers enter into a drawing frame, then enter into a roving machine and a spinning machine, and finally enter into a winder. The manufacturing process provides a market with a yarn made of a new environment-friendly material, people's dressing experience can be improved, the market demands can be met, and economic and social development can be promoted.

Owner:上海纺织(集团)大丰纺织有限公司

Gypsum cotton roll

InactiveCN108309568AEffective treatmentReduce adverse reactionsPlaster of paris bandagesSkin surfacePulp and paper industry

The invention discloses a gypsum cotton roll. The roll comprises a cotton cloth body, multiple gypsum powder blocks are evenly wrapped in the cotton cloth body, and an air inflation cloth bag is arranged above the cotton cloth body; multiple ballooning air bands are arranged on the air inflation cloth bag, and multiple horizontal inward-concave grooves are formed in the upper and lower surfaces ofthe air inflation cloth bag and are opposite to one another. The gypsum cotton roll is simple in structure, after the gypsum cotton roll is immersed in water, gypsum powder can slowly become hard andwrap or fit the injured bone, and in combination with a bandage, the fixing effect can be achieved; before air inflation of the air inflation cloth bag, the gypsum cotton roll fits the surface of theskin, materials which are soft and do not injure the skin can be selected, the situation is avoided that the cotton cloth body is directly attached to the skin and accordingly heat dissipation is unsmooth, the air permeability of the skin can be improved through the ballooning air bands, and ventilation or additional treatment on the wound surface is conducted conveniently.

Owner:安徽威宇医疗器械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com