Belt for lap forming device

A technology of winding device and cotton roll, which is applied in the belt field of winding device, can solve the problems of increasing fiber loss, machine pollution, frequent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

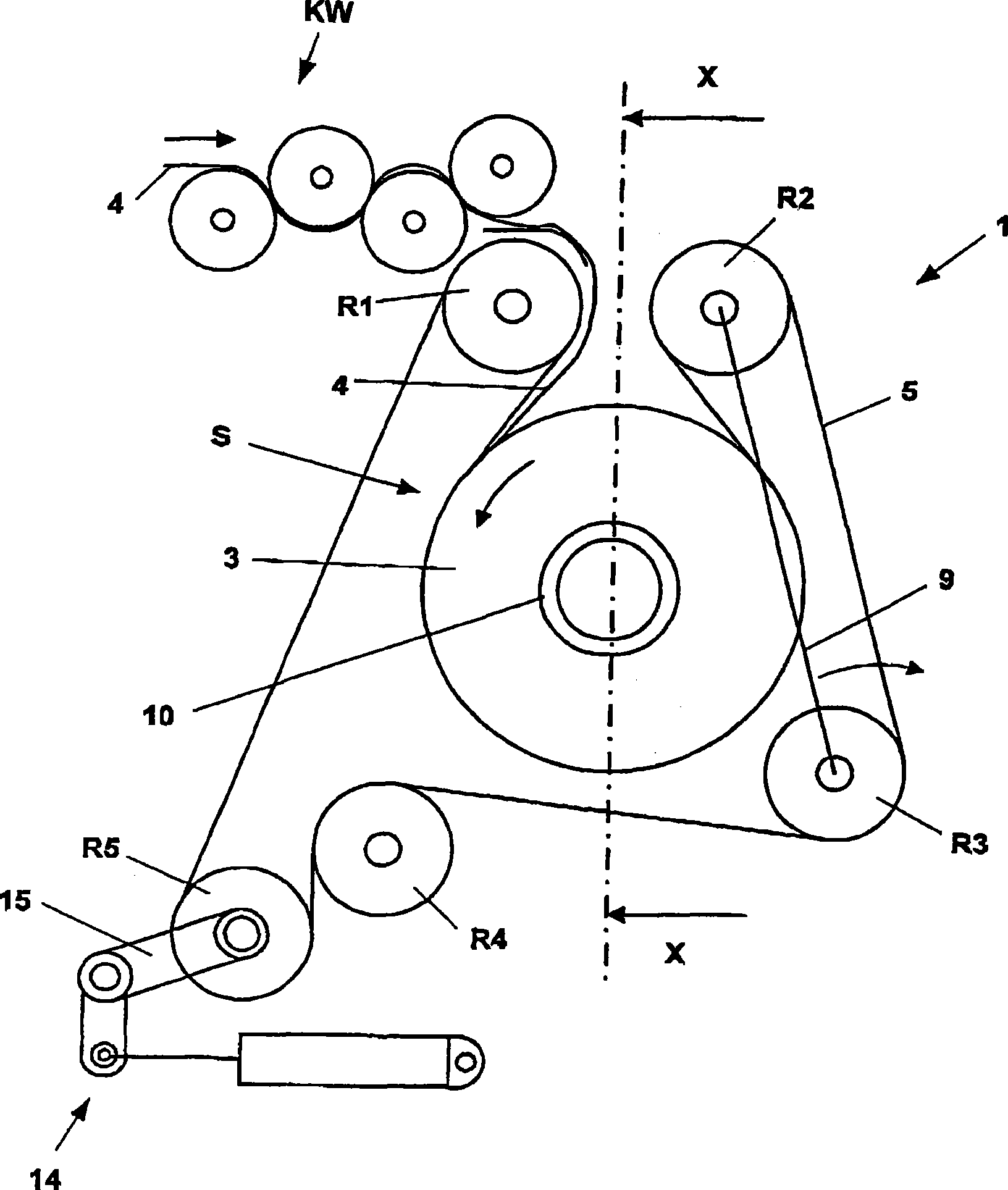

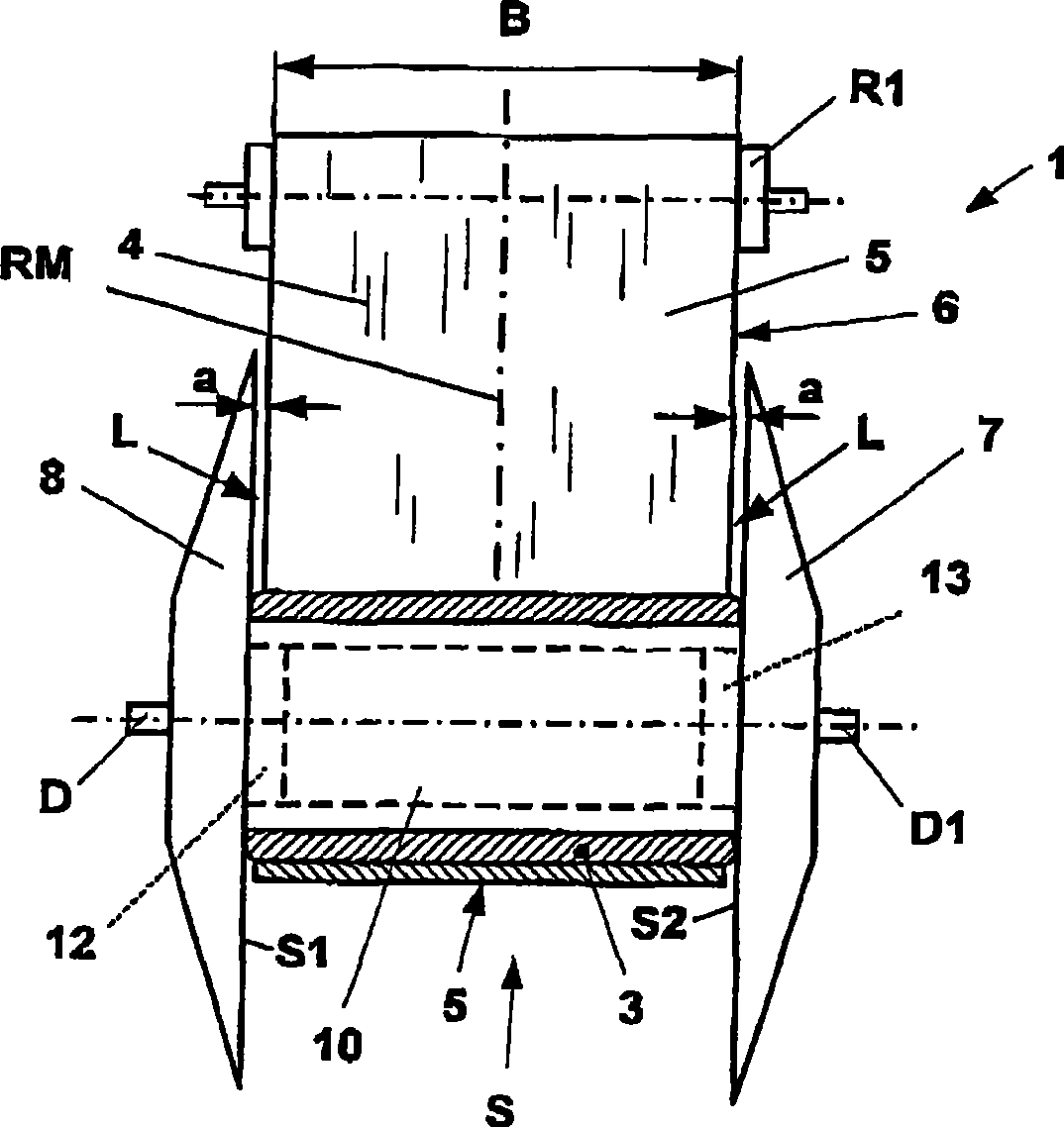

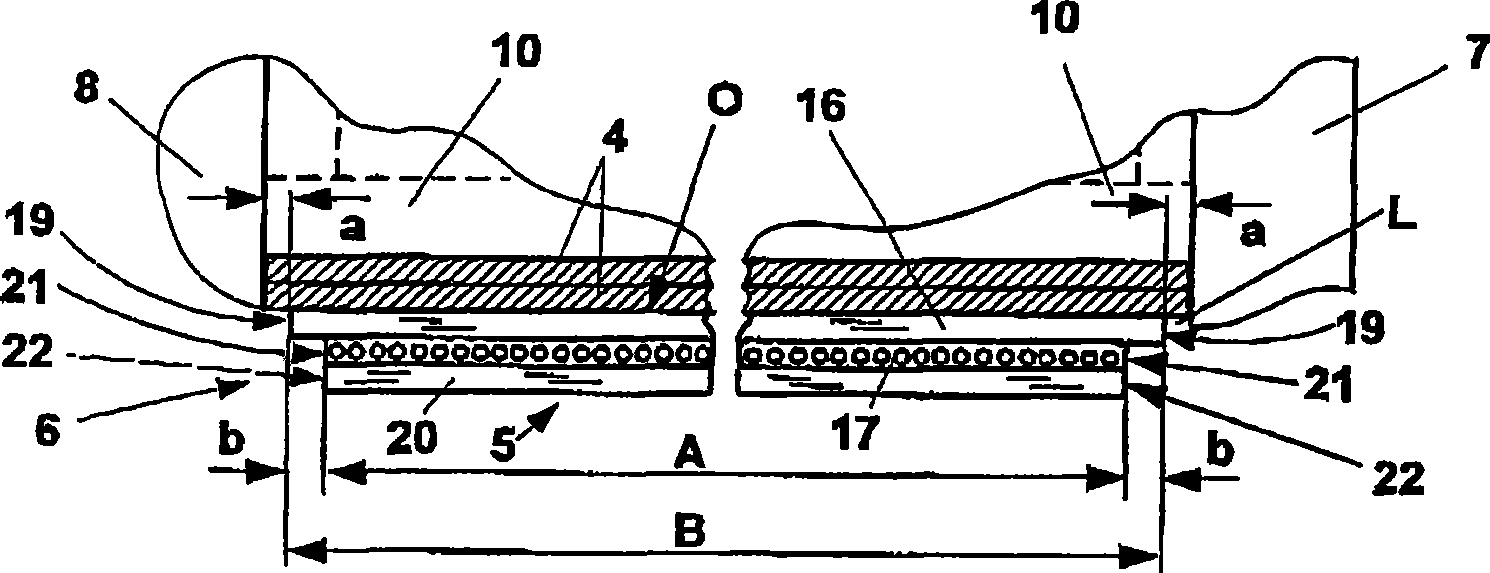

[0029] figure 1 Shown is a winding device 1 with a flat belt 5 guided on a plurality of deflection rollers R1 to R5. Between the deflection rollers R1 and R2, the belt 5 forms a loop S in which the lap 3 is formed. Here, in the winding operation, the lap sheet 4 (also called batt) fed into the loop by the calender rollers KW is wound on the sleeve 10 . Sleeve 10 passes through sockets 12 and 13 (see figure 2 ) is mounted in a fixed manner between the two winding discs 7, 8 so that the sleeve 10 can rotate along the axis of rotation D, D1.

[0030] As the lap 3 becomes larger, the size of the loop S also increases. In order to tension the belt 5 or to compensate for belt movement due to the enlargement of the loop S, a tensioning device 14 is provided. Here, the roller R5 is mounted by means of an arm 15 such that the roller R5 can rotate along the axis of rotation.

[0031] As soon as the lap 3 has reached its final size (determined and monitored by sensors), the batt 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com