Lap winder for winding strips of cotton wool to lap rolls

A technology for winding machines and sliver rolls, applied in winding mechanisms, winding strips, textiles and papermaking, etc., can solve problems such as negative productivity, and achieve the effects of optimizing productivity, optimizing adjustment, and optimizing winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

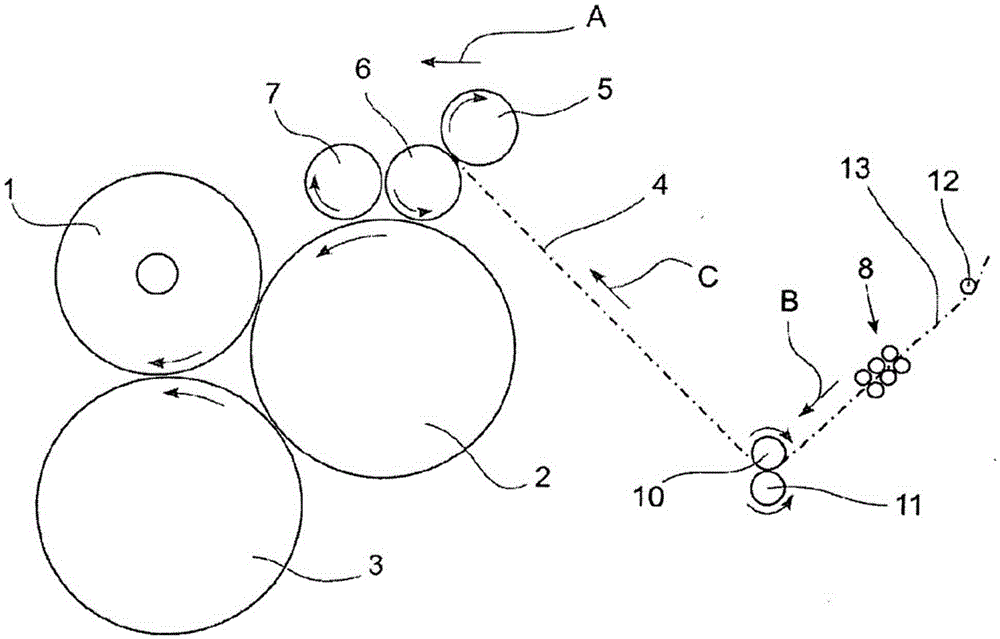

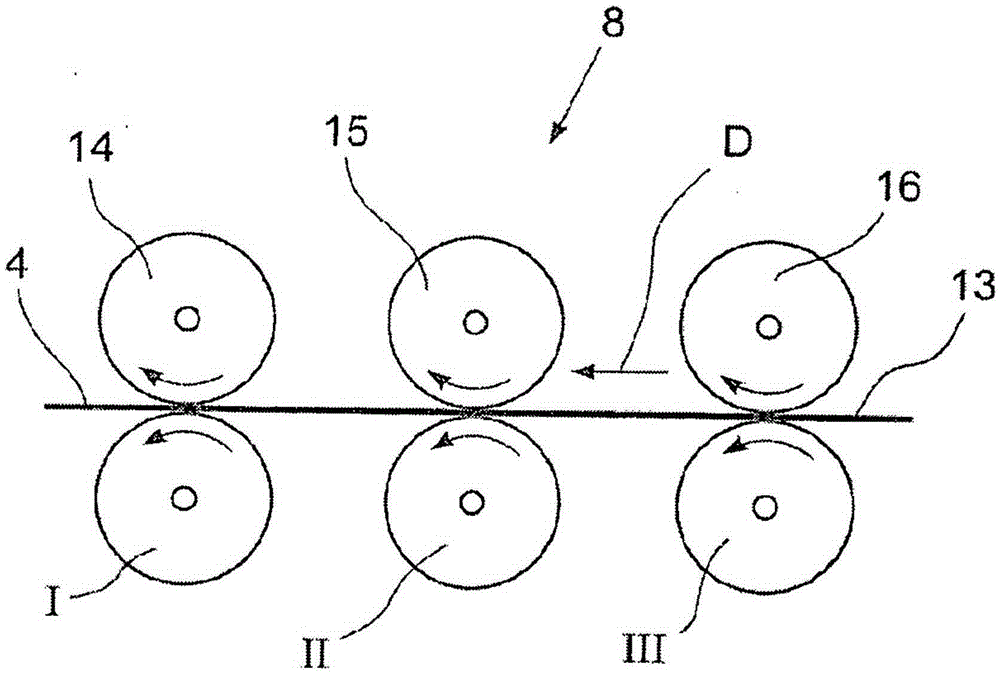

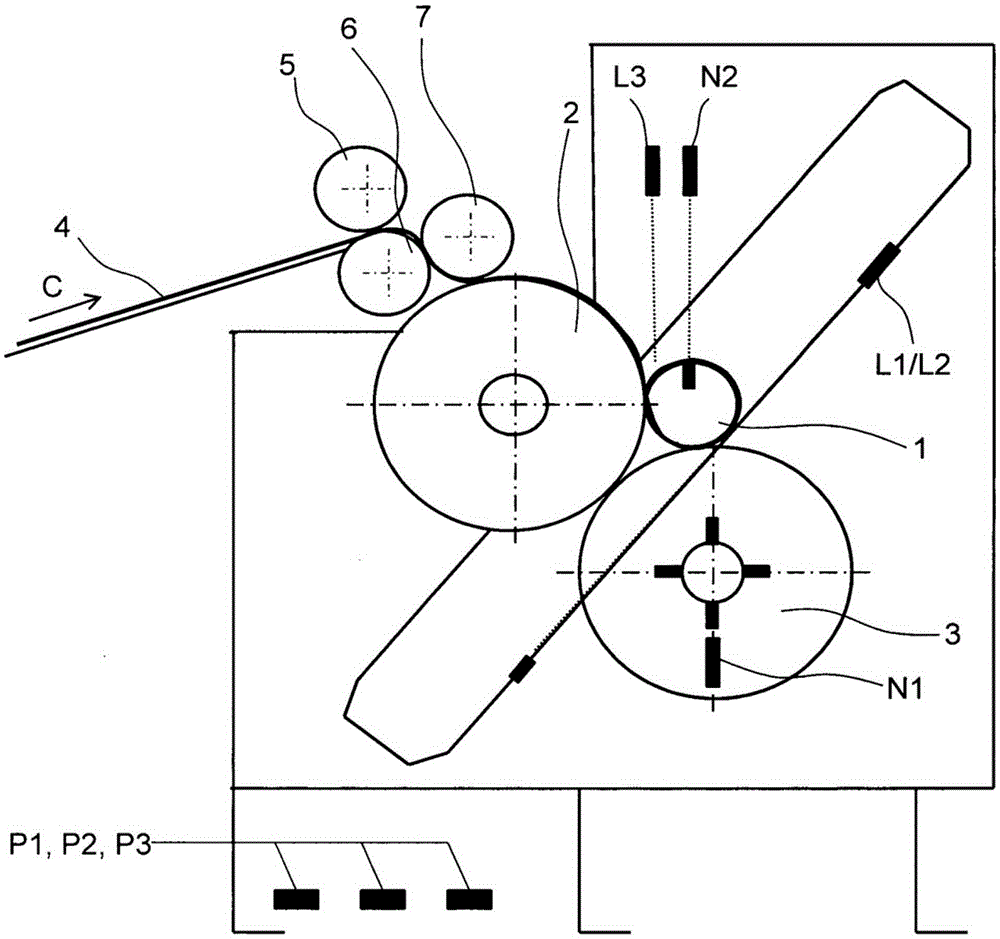

[0023] according to figure 1 , Cotton lap 1 is laid on the two winding rolls 2 and 3 (winding calender) of the belt winding machine which can rotate in the direction of the arrow. The sliver 4 (shown in dashed lines) passes through a calender (pressure calender) consisting of three press rollers 5 , 6 and 7 , then leads to the lap 1 and is wound up on the lap. The sliver 4 is formed in the drafting device 8 of the tape winder from one or more supplied nonwovens or from drafting strips 13 next to each other. One drafting device 8 ′ or several drafting devices can also be connected upstream to the drafting device 8 . A table calender consisting of two rolls 10 , 11 is arranged between the delivery roll 14 / I of the drafting device 8 and the press roll 5 of the pressure calender. The deflection roll 12 is arranged upstream of the feed roll 16 / III of the drafting device 8 , and the fiber sliver 13 from the upstream (not shown) fiber can and (not shown) creel (gatter) is deflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com