Blended elastic yarn of milk fiber, silk yarn, leica and cotton and production technology thereof

A technology of milk fiber and elastic yarn, which is applied in the fields of cotton blended elastic yarn and its production process, Lycra, milk fiber, and spun silk. The effect of raising grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

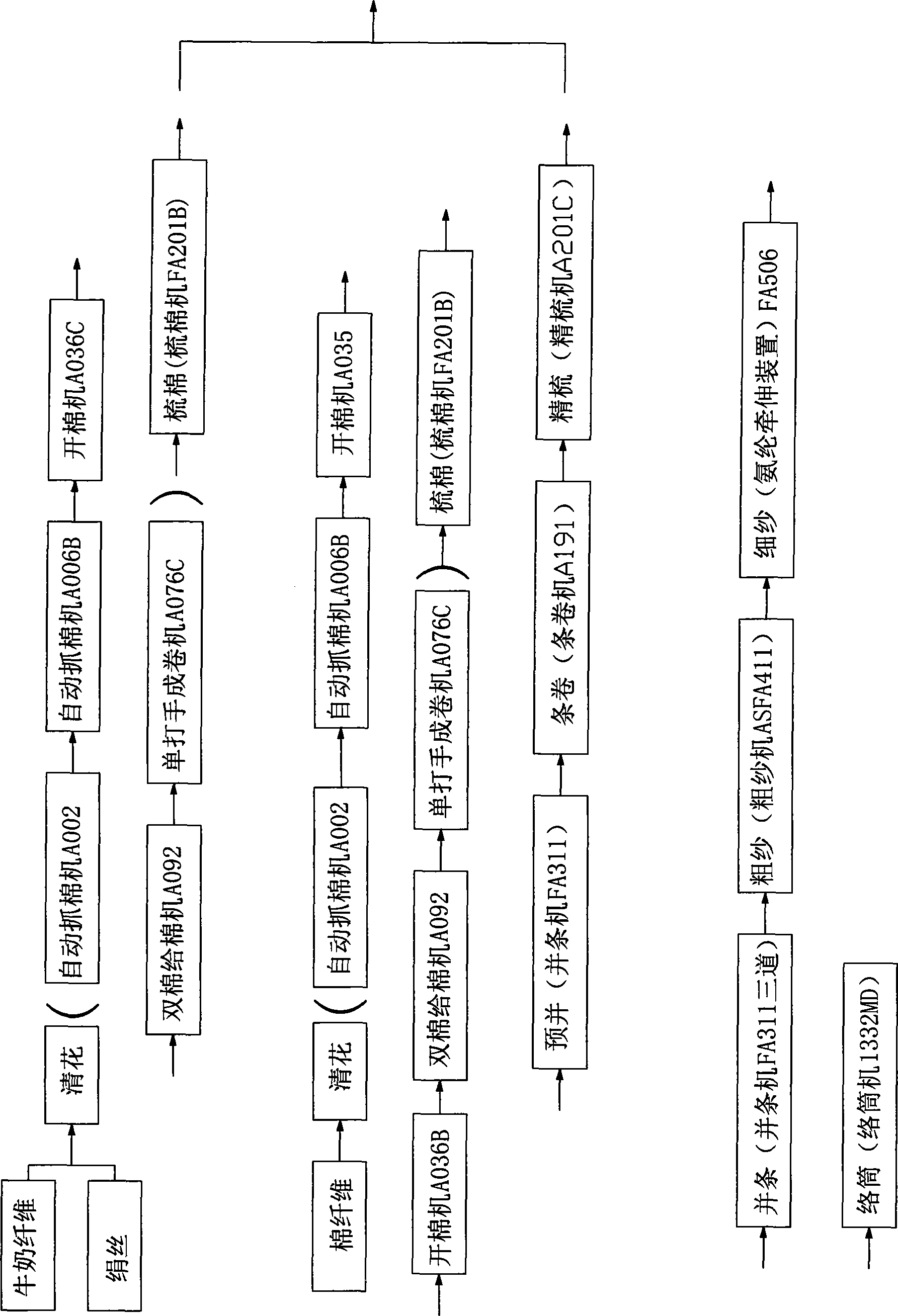

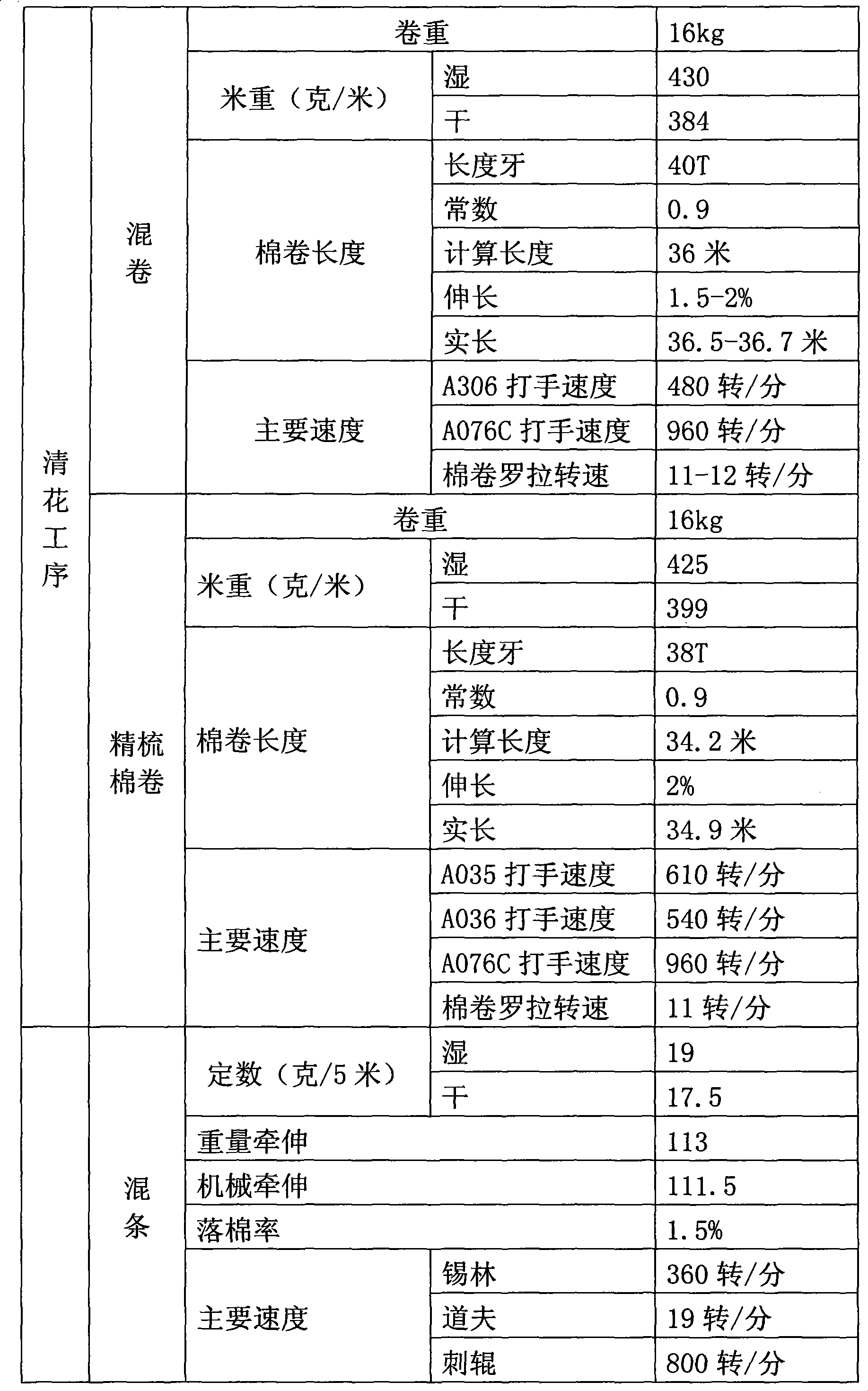

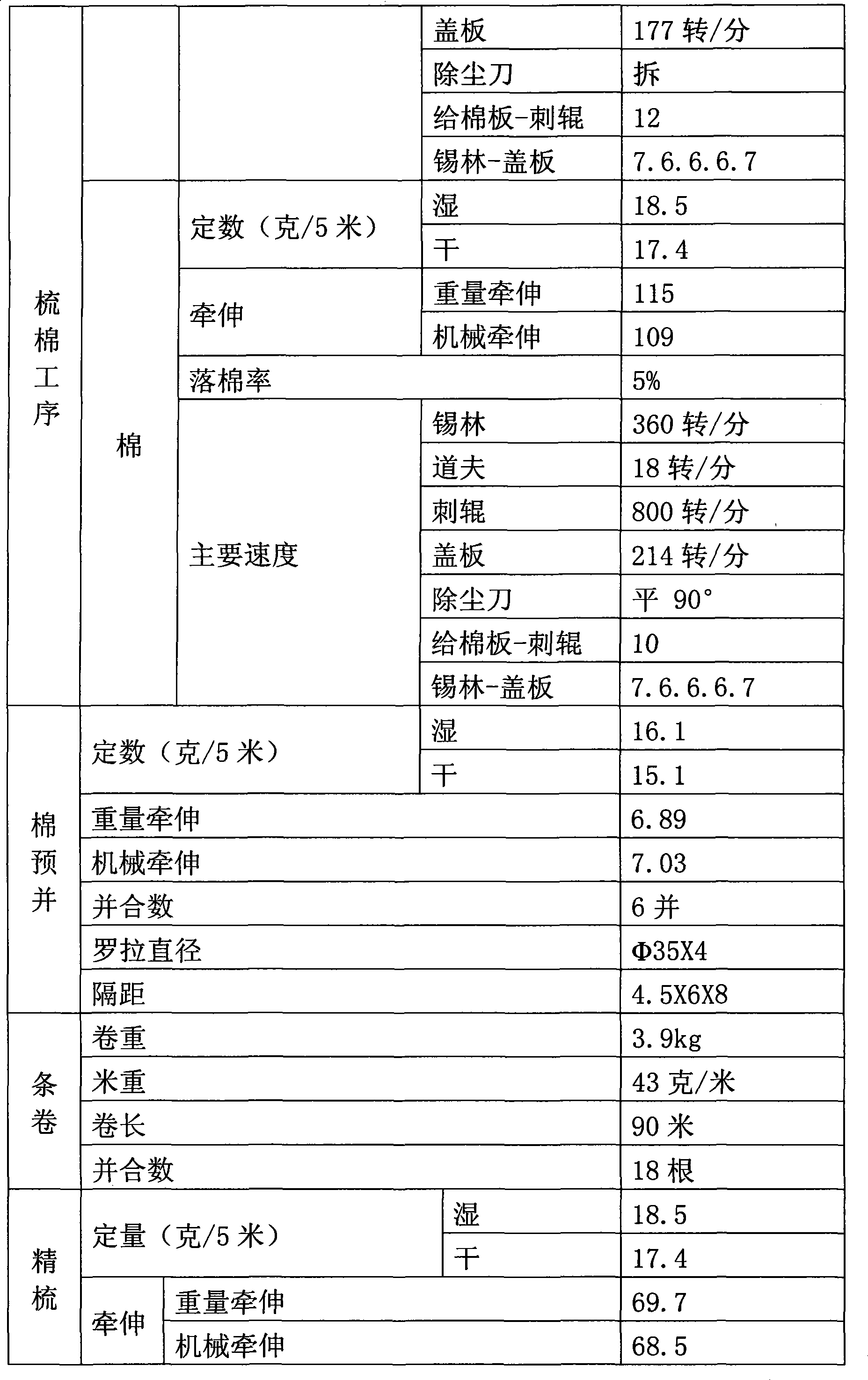

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 (preferred embodiment):

[0052] The percentage by weight of each component in the blended elastic yarn is: 20% of milk fiber; 32% of spun silk; 8% of Lycra; 40% of cotton fiber. In this embodiment, the ratio of each component is rationally selected, so that the health-care and taking properties can be brought into full play, and this ratio receives the best effect, and the comfort and functionality are all best reflected.

Embodiment 2

[0054] The percentage by weight of each component in the blended elastic yarn is: 25% of milk fiber; 35% of spun silk; 5% of Lycra; 35% of cotton fiber. In this embodiment, the specific gravity of various fibers is appropriately selected, and their excellent properties are integrated.

Embodiment 3

[0056] The percentage by weight of each component in the blended elastic yarn is: 30% of milk fiber; 43% of spun silk; 7% of Lycra; 20% of cotton fiber. The present embodiment increases the ratio of milk fiber and spun silk, to improve the health care of product;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com