Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Copper pour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In electronics, the term copper pour refers to an area on a printed circuit board filled with copper (the metal used to make connections in printed circuit boards). Copper pour is commonly used to create a ground plane. Another reason for using copper pour is to reduce the amount of etching fluid used during manufacturing.

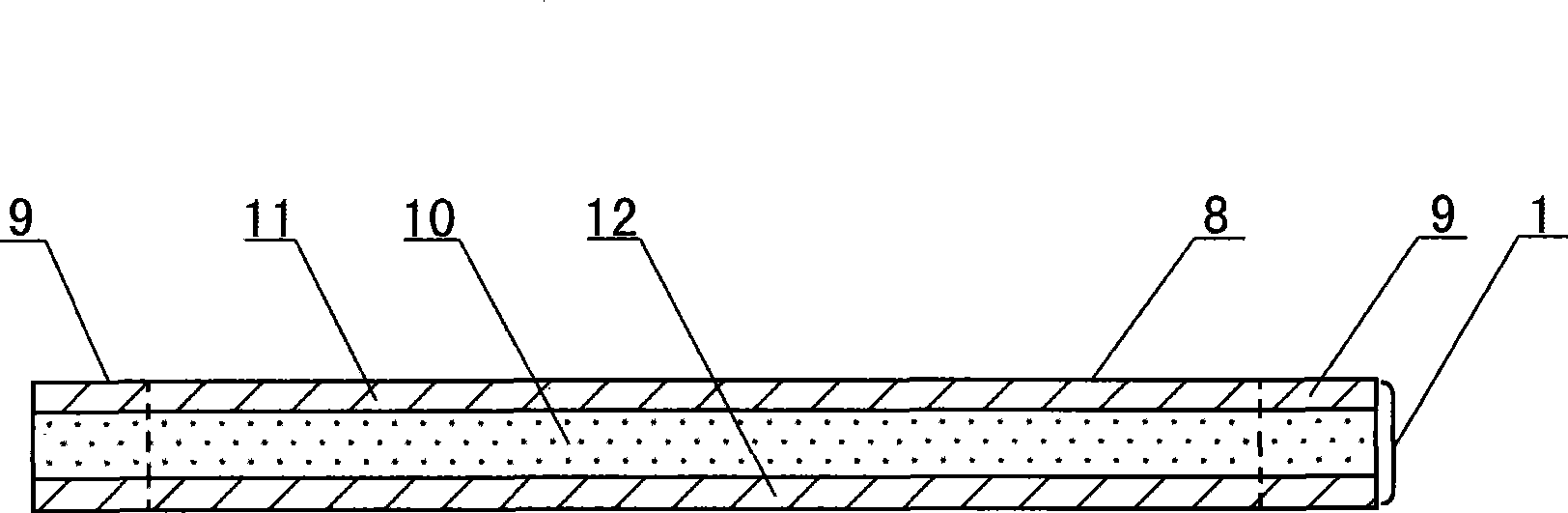

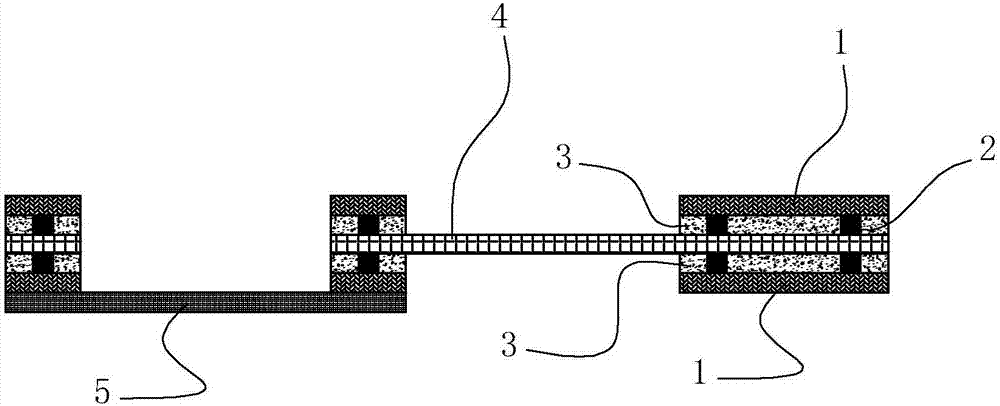

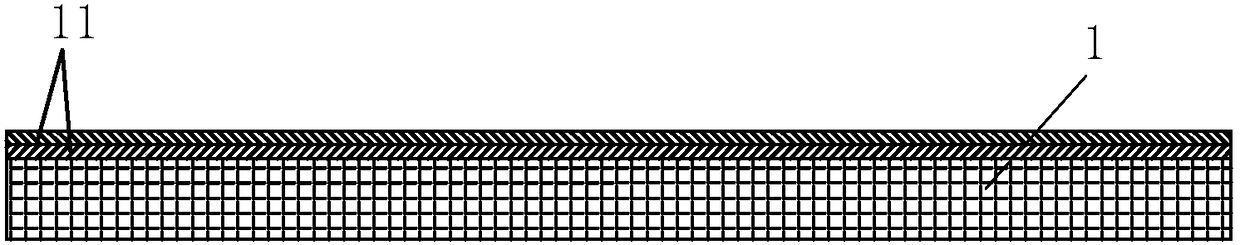

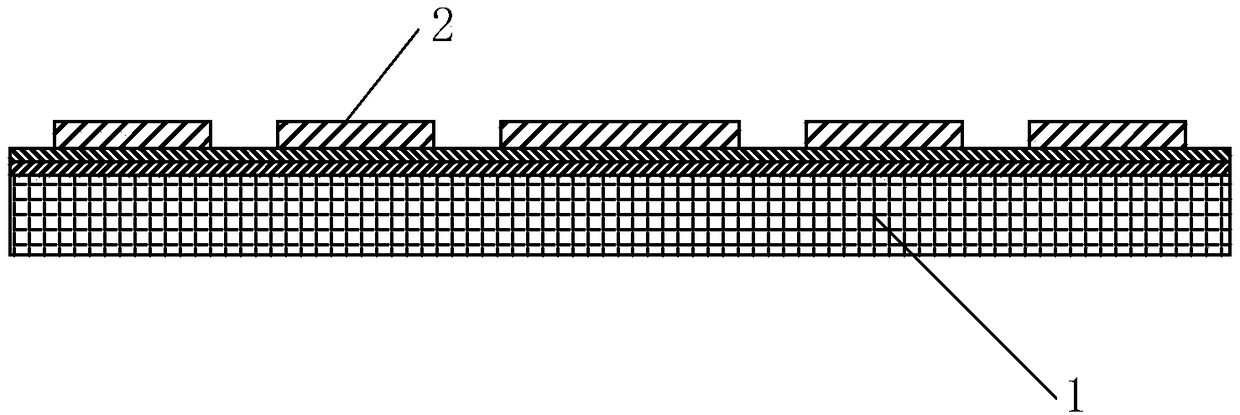

Manufacturing method for semi-flexible printed circuit board

InactiveCN101365298AOvercome the disadvantage of high water absorptionLow costSynthetic resin layered productsPrinted circuit manufactureHigh rateEngineering

A production method of a semi-flexible printed circuit board comprises the following steps of: (1) preparing a sheet metal; (2) dividing the sheet metal into a molding area and a shaping area; (3) dividing the molding area into a plate area and a flexible area in advance in the molding area; (4) processing the sheet medal as follows: (4.1) processing of the pattern of the sheet metal and (4.2) processing the flexible bent area of the sheet metal so that the flexible area becomes thinner and can be bent; and (5) removing the shaping area and getting the semi-flexible printed circuit board. The invention adopts cheap general rigid materials such as glass fabric-epoxide resin copper pour foil, and the like to replace expensive flexible copper pour plate materials such as polyimide, and the like, thereby greatly reducing the cost. At the same time, the invention has the advantages of simple machinery process, high rate of finished products and high reliability. The semi-flexible printed circuit board produced by the method particularly suits vehicle-borne products with higher reliability requirement.

Owner:CHINA CIRCUIT TECH SHANTOU CORP

Methods for preparing continuous casting crystallizer copper plate surface modified W-Cu alloy layer and application thereof

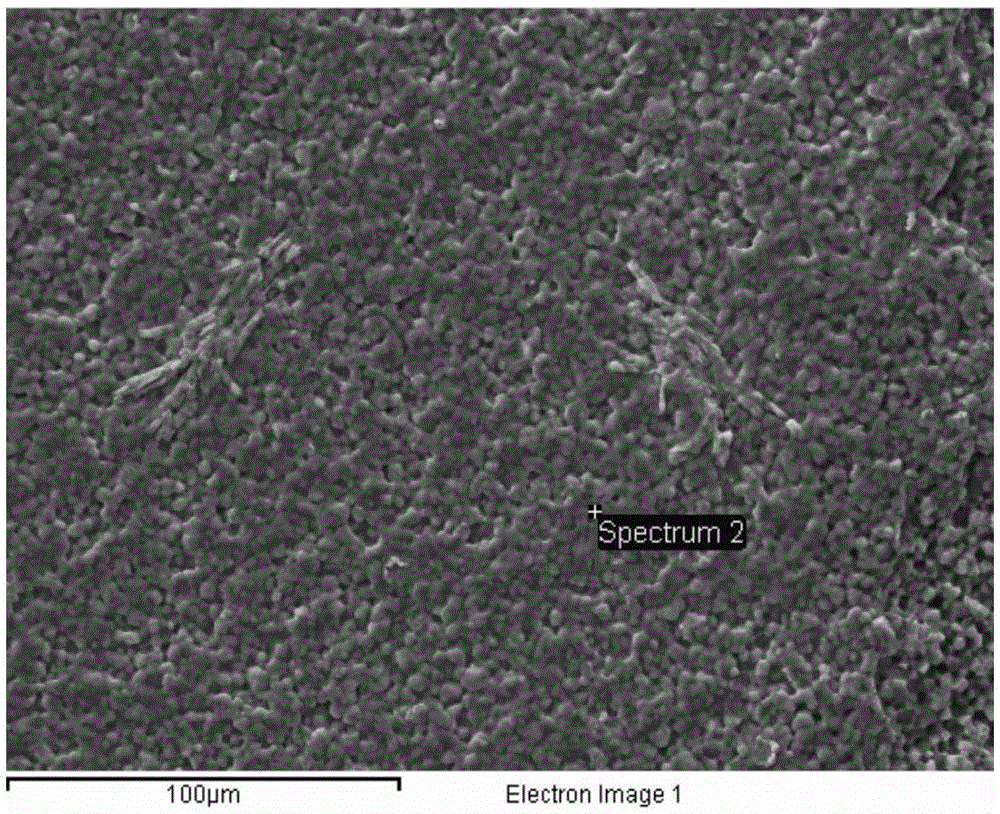

The invention relates to methods for preparing a continuous casting crystallizer copper plate surface modified W-Cu alloy layer and the application thereof, and the W-Cu alloy layer is especially applicable to a steel and nonferrous metal continuous casting crystallizer copper plate modified layer. The modified layer comprises the components by weight percent: 30.0-70.0% of W, 23.0-69.65% of Cu, 0.1-2.0% of Ni, 0.05-2.0% of Ag and 0.2-3.0% of Co. The preparation methods comprise a. hot pressed sintering and b. infiltration method, wherein the hot pressed sintering is characterized by (1) evenly mixing the powder and hot pressed sintering for molding; (2) pouring molten copper on sintered W-Cu alloy or placing a copper plate on the W-Cu alloy, heating and leading copper to be molten and have infiltration together with the W-Cu alloy, and cooling and then obtaining the copper plate product provided with the W-Cu alloy modified layer; and the infiltration method is characterized by (1) evenly mixing the powder, cold pressing into infiltration framework and high temperature sintering; (2) pouring the molten copper on the W-Cu framework for infiltration or placing the copper plate on the W-Cu alloy framework, heating and leading copper to be molten and have infiltration together with the W-Cu alloy framework, and then cooling. The W-Cu alloy layer has the advantages of greatly improving the production efficiency of a crystallizer, solving the problem of electroplating pollution of the crystallizer copper plate and being a high-efficiency and environment-friendly crystallizer surface modification method.

Owner:DALIAN UNIV OF TECH

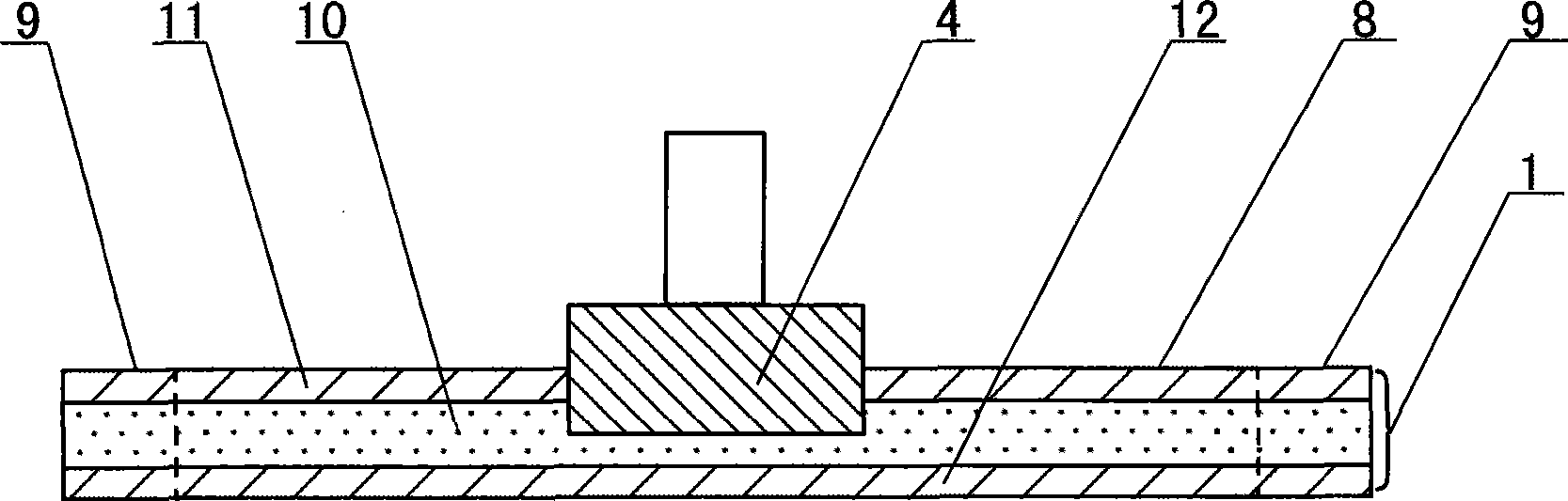

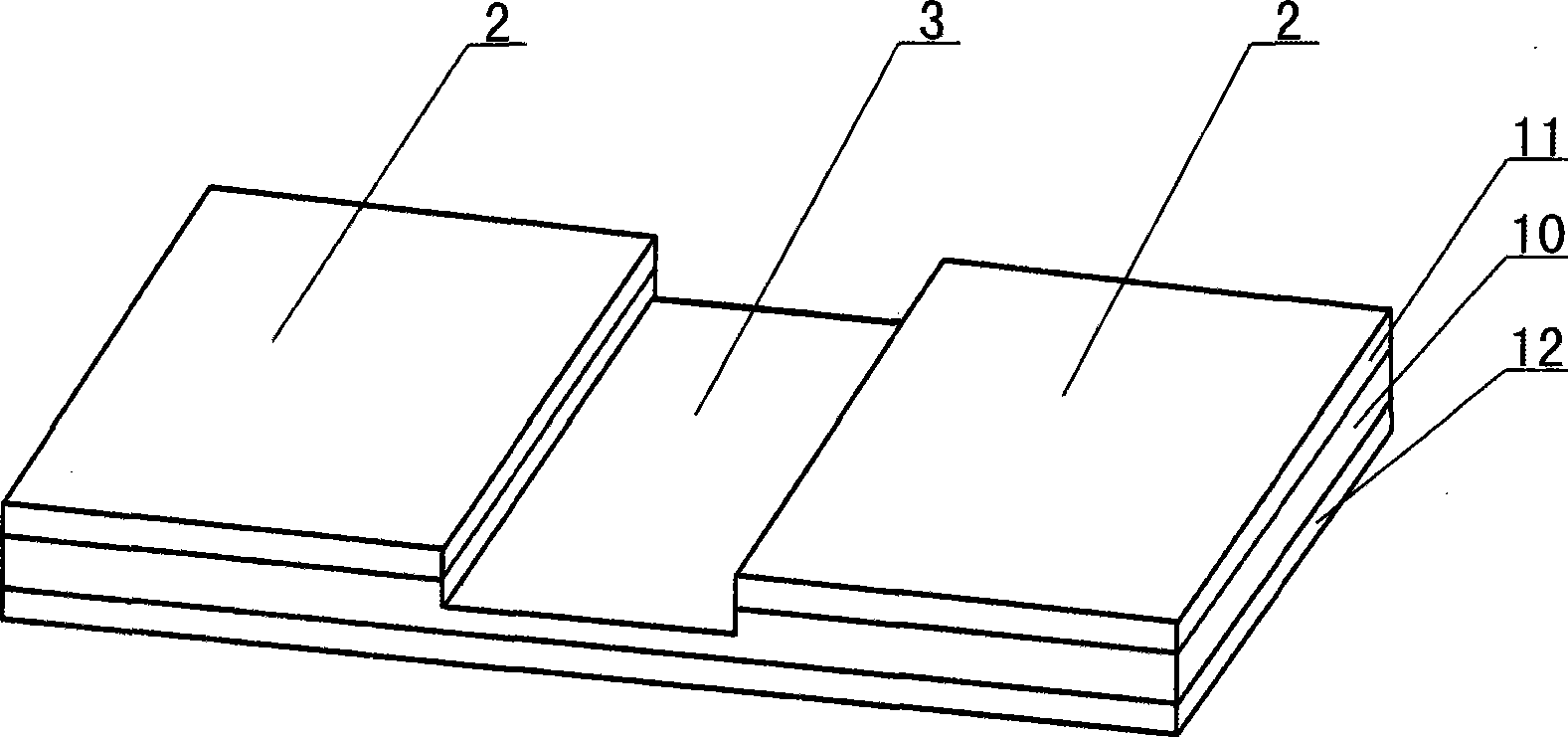

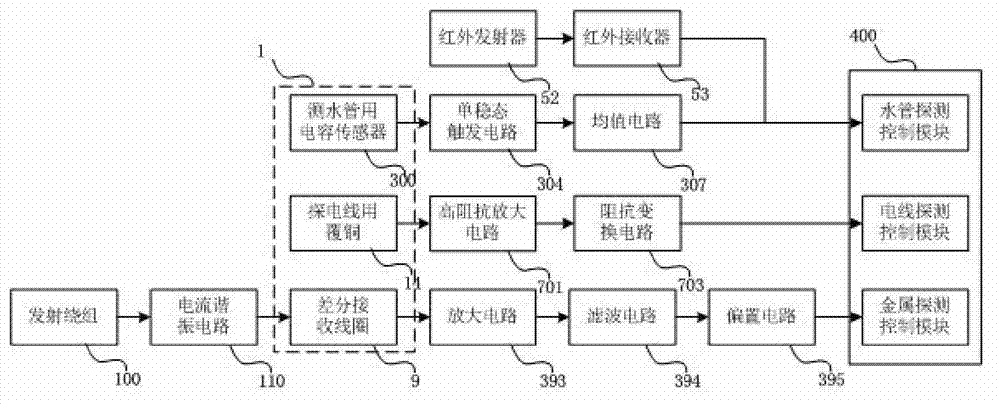

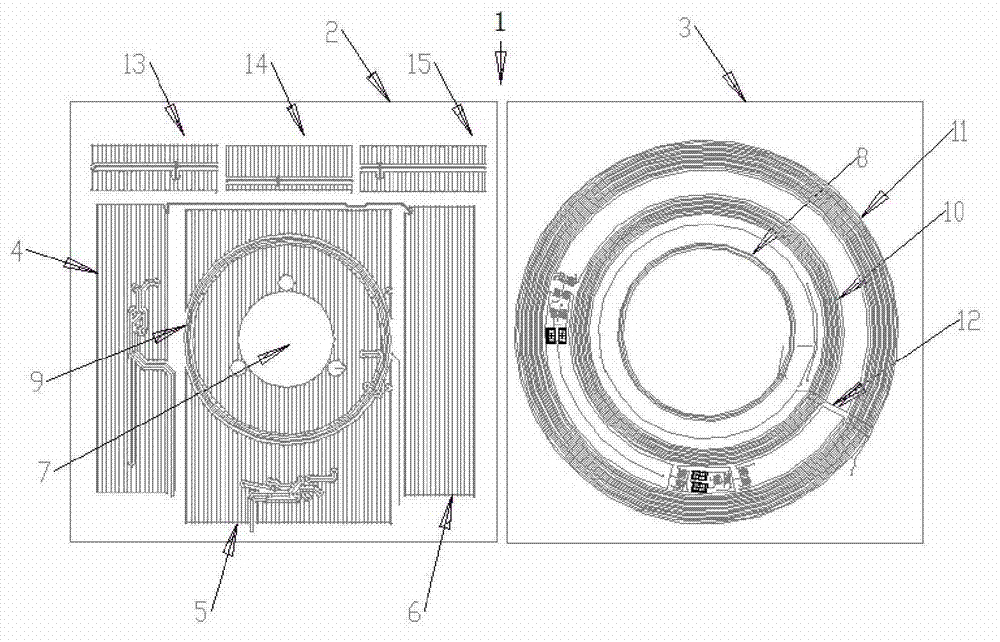

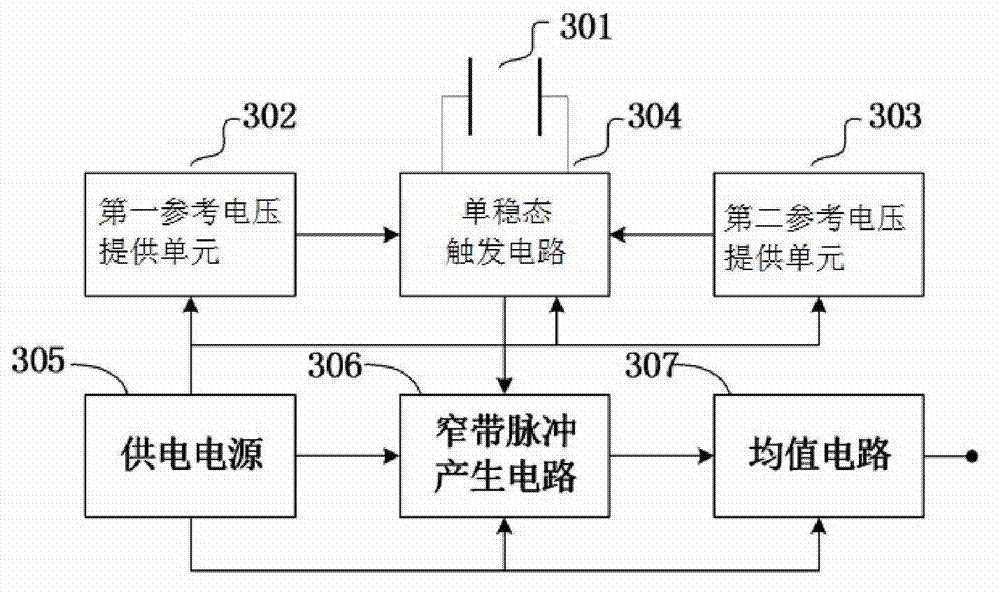

Multifunctional wall body detecting instrument

InactiveCN103197352ASmall sizeReduce manufacturing costOptical detectionElectric/magnetic detectionEngineeringConductor Coil

The invention relates to the field of building structure detection, in particular to a wall body detecting instrument. The multifunctional wall body detecting instrument includes five parts: a first part is a water pipe detection circuit, and the water pipe detection circuit is composed of a capacitive sensor used for detecting a water pipe, a monostable trigger circuit and a mean value circuit which are connected with one another in series sequentially; a second part is an electric wire detection circuit, and the electric wire detection circuit is composed of copper pour, a high-impedance amplifying circuit, an impedance conversion circuit which are connected with one another in series sequentially; a third part is a metal detection circuit, and the metal detection circuit is composed of an emission winding, a current syntonic circuit, a difference receiving coil, an amplifying circuit, a filter circuit and a biasing circuit which are connected with one another in series sequentially; a fourth part is an auxiliary circuit, and the auxiliary circuit is composed of an infrared transmitter and an infrared receiver which are connected with each other in series sequentially; and a fifth part is a control circuit which comprises a controller. The first part, the second part, the third part, the fourth part are connected with the fifth part respectively and independently. The multifunctional wall body detection is compact in size, low in manufacture cost, simple in craftsmanship, and good in manufacture repeatability.

Owner:WUHAN UNIV

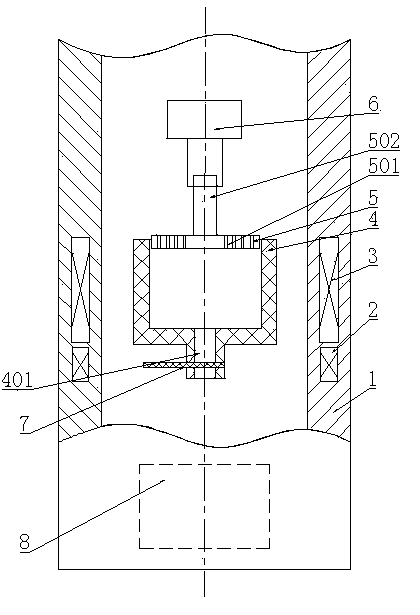

Method for producing high-conductivity oxygen-free copper and smelting device

InactiveCN102994786AIncrease contact areaLess soluble than oxygenStirring devicesIngotElectric conductance

The invention relates to a method for producing high-conductivity oxygen-free copper and a smelting device. According to the method, high-purity electrolytic copper blocks are washed cleanly, dried and fed into a graphite crucible, and is vacuumized, and a main heater is started to smelt the copper blocks into a copper liquid; a graphite mixer suspended in the graphite crucible is started to make up-down reciprocating movement and mixing in the graphite crucible to obtain liquid oxygen-free copper, and the liquid oxygen-free copper is poured in an ingot puller for crystallization and ingot pulling to obtain oxygen-free copper ingots. The smelting device comprises a vacuum smelting furnace body, the main heater and the graphite crucible which is arranged in a receiving cavity of the furnace body, wherein the bottom of the graphite crucible is provided with a liquid discharge port and a liquid discharge control valve. The smelting device is characterized in that the graphite mixer capable of lifting is suspended in the graphite crucible. The method and the smelting device have the advantages that the use of the graphite mixer for mixing increases the contact area between oxygen gas and graphite in copper liquid, and high-efficiency oxygen removal is achieved; and the requirements for the raw materials are not strict, the production cost is low, and the conductivity of the oxygen-free copper produced meets the requirements of high-class conducting wires.

Owner:JINZHOU NEW CENTURY QUARTZ GROUP CO LTD

Manufacture method for subsided high-density mutual connection board

ActiveCN106961808AHigh densityImprove bindingPrinted circuit aspectsMultilayer circuit manufactureWire widthHigh density

A manufacture method for a subsided high-density mutual connection board includes steps of manufacturing an inner layer soft board; manufacturing conducting copper posts in conduction with an outer layer rigid board by utilizing an addition process on the upper side and the lower side of the inner layer soft board or on one side of the inner layer soft board and performing electroplating on the conducting copper posts; filling an insulation bonding layer bonded with the outer layer rigid board on the upper side and the lower side of the inner layer soft board or on the same side of the inner layer soft board and grinding the surface of the insulation bonding layer so as to expose the conducting copper posts; manufacturing an outer layer rigid board circuit by adopting an addition process electroplating technology on the insulation bonding layer; performing hollowing processing on a subsided region; and performing steel board reinforcement processing on the bottom part of the subsided region. According to the invention, the conducting copper posts manufactured through addition electroplating are adopted to replace traditional drilling holes and laser drilling holes for conduction; the minimum diameter of each conducting copper post can be as small as 0.05 mm; wiring can be performed on the conducting posts and the minimum wire width\wire space of the circuit manufactured by using the addition process can be 15\15 micrometers. Therefore, circuit fineness is improved and wiring density is improved substantially. The invention also has characteristics of simple manufacture process and low cost and area available for wiring is enlarged.

Owner:NINGBO HUAYUAN ELECTRONICS TECH

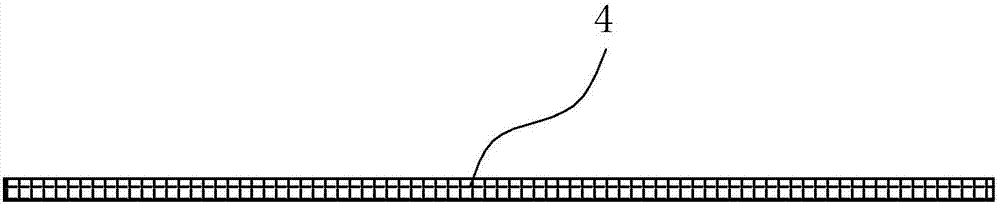

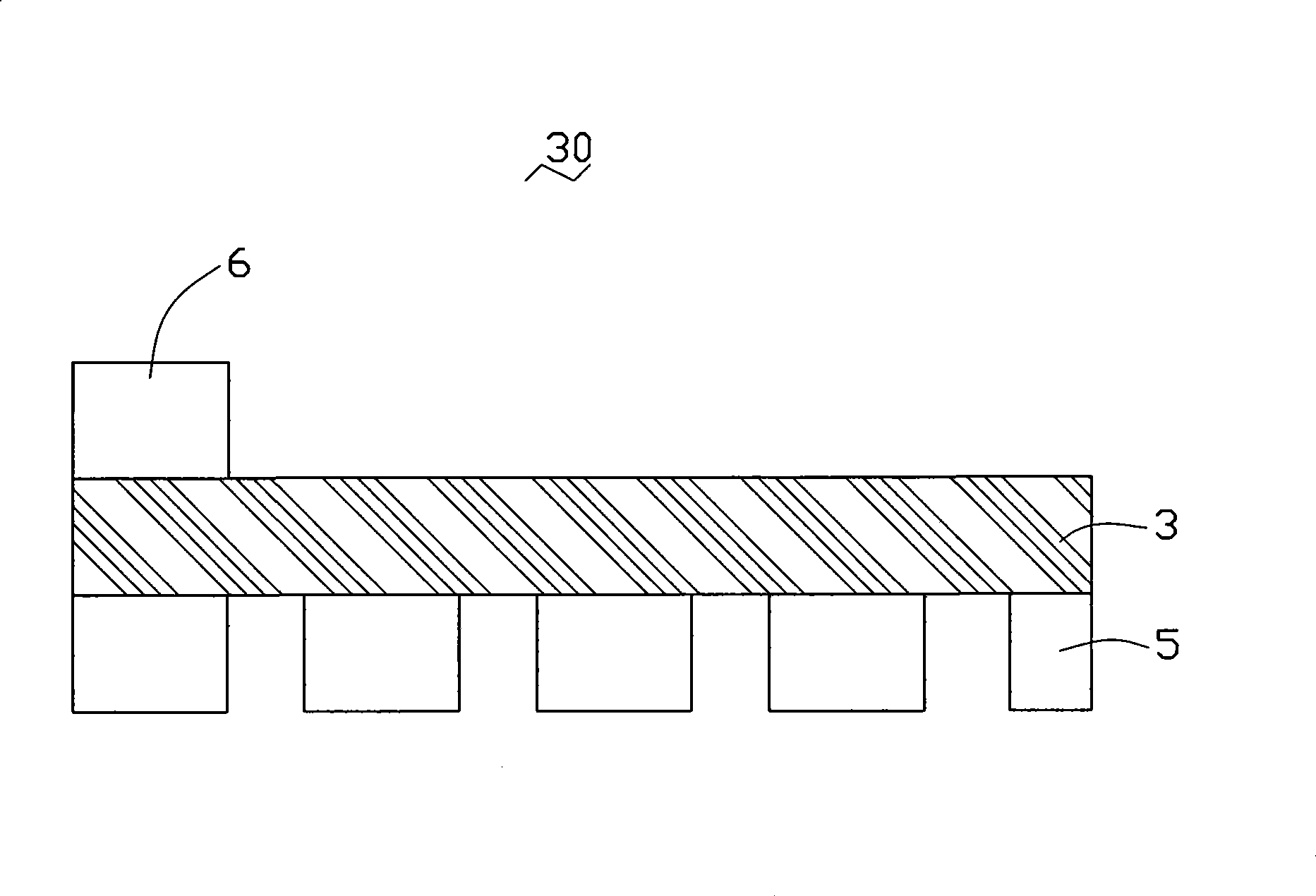

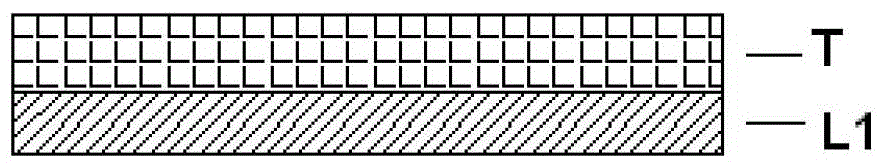

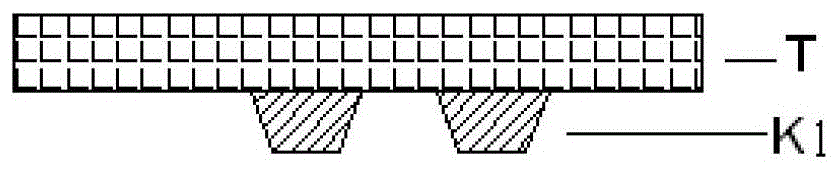

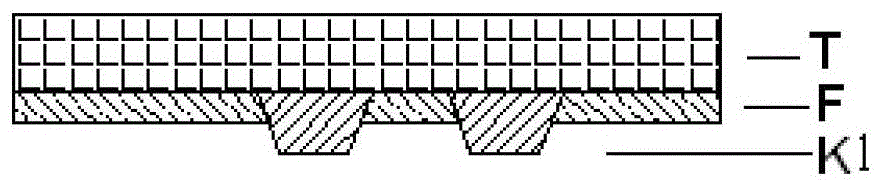

Manufacturing method of flexible circuit board

InactiveCN101640976AImprove manufacturing precisionIncreasing the thicknessMultilayer circuit manufacturePrinted circuit simultaneous processingFlexible circuitsCopper pour

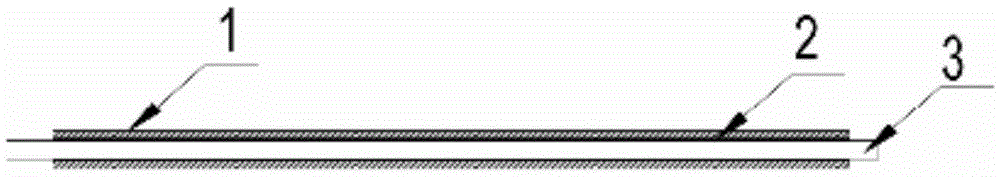

The invention relates to a manufacturing method of a flexible circuit board, comprising the following steps: providing a reinforcing plate and a copper pour base material, and the reinforcing plate comprises a base material layer and an adhesive layer arranged on the surface of the base material layer; the copper pour base material comprises an insulating layer and a conducting layer arranged on the surface of the insulating layer. The manufacturing method in the invention comprises the following steps: adhering the copper pour base material to the reinforcing plate and leading the conductinglayer to be exposed; forming a conducting circuit in the conducting layer to manufacture a circuit board; separating the reinforcing plate from the circuit board. The method can avoid the copper pourbase material from buckling and improve the manufacturing precision of the circuit board.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

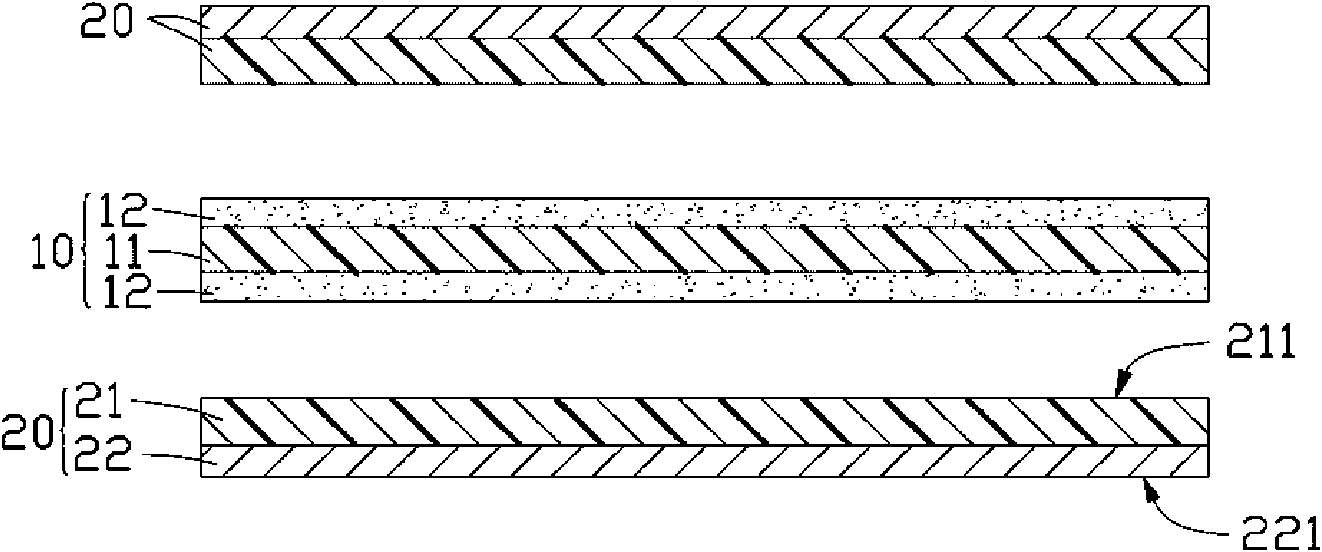

Preparation method of double-face copper pouring ceramic substrate

The invention relates to a preparation method of a double-face copper pouring ceramic substrate. The method comprises the steps that first, a ceramic sheet base material and copper sheets are washed; second, the copper sheets are subjected to annealing treatment in a first protective atmosphere, wherein the annealing temperature is 500-1060 DEG C, and the annealing treatment time is 1-30 min; third, in a second protective atmosphere, a first copper sheet, a ceramic sheet, a second copper sheet are stacked on a shim in sequence for sintering, wherein the sintering temperature is 1065-1082 DEG C, and the sintering time is 1-100 min; fourth, when the sintering ends, the double-face copper pouring ceramic substrate is obtained. According to the preparation method of the double-face copper pouring ceramic substrate, the ceramic sheet base material and the copper sheets are subjected to the sintering on the shim, wherein the shim does not react with the copper and low damage to the copper, so that the product obsolescence caused by the ceramic powder contamination is avoided; the double-face simultaneous sintering is achieved, so that the large heat stress generated by the single-face sintering and the continuous growth of copper grains in the second high temperature process can be avoided, and therefore the production efficiency and the yield are greatly improved.

Owner:SHANGHAI SHENHE THERMO MAGNETICS ELECTRONICS CO LTD

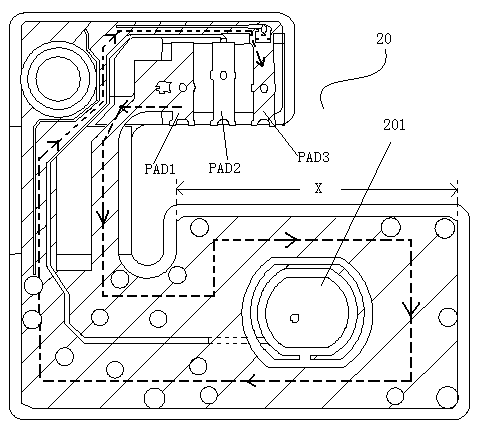

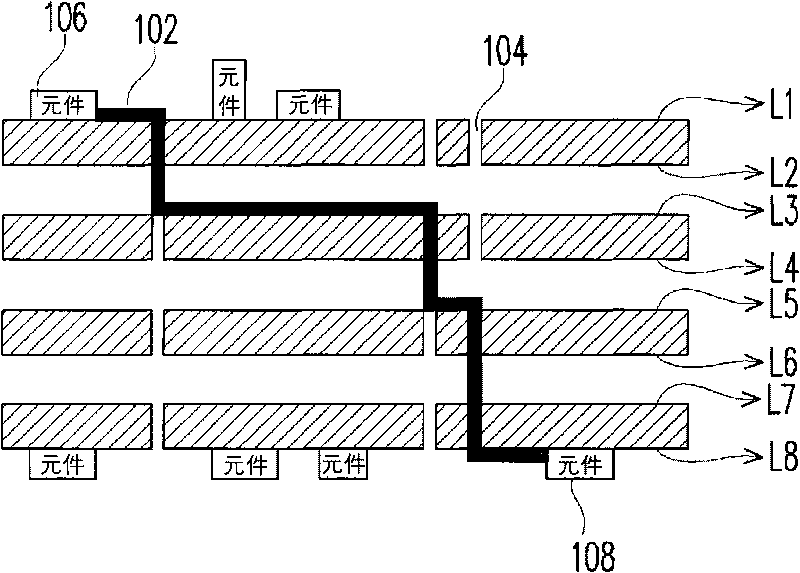

Allocation wiring structure of printing circuit board

InactiveCN1984531AControl transfer directionAffecting workPrinted circuit non-printed electric components associationCooling/ventilation/heating modificationsHeat flowEngineering

The invention is used for overcoming the heat of chip transmitted to PCB. It comprises: the bounding pad of the heated chip and the bounding pad of metallic shielding box, both are connected using copper sheet. The heat via holes or heat buried holes or heat blind holes under the bounding pad of the heated chip has less quantities and densities, and the copper pour on the portion of PCB except the top portion of PCB is less than the top portion of PCB near the heated chip. By the invention the heat from BCP is transmitted to direction of the metallic shielding box.

Owner:HUAWEI TECH CO LTD

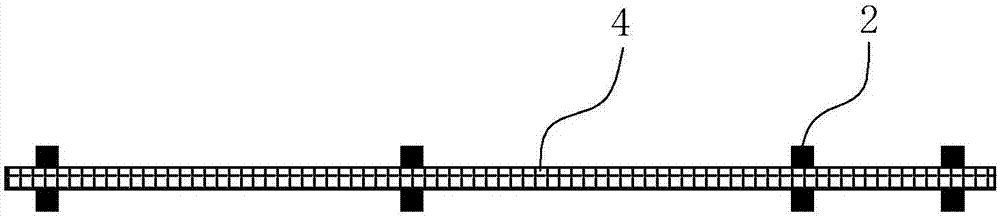

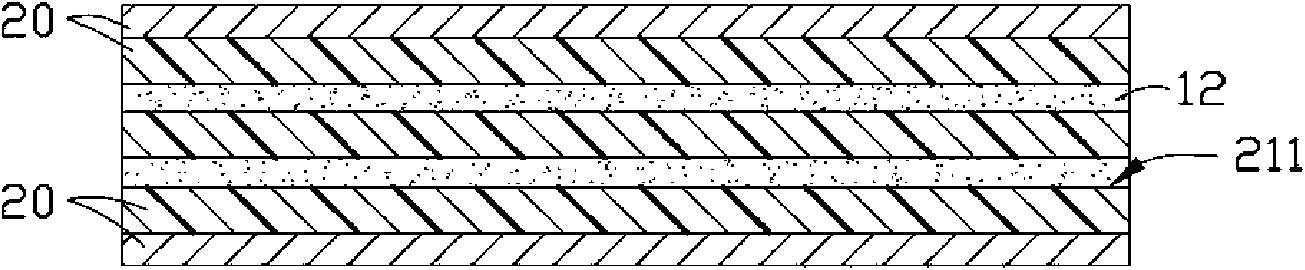

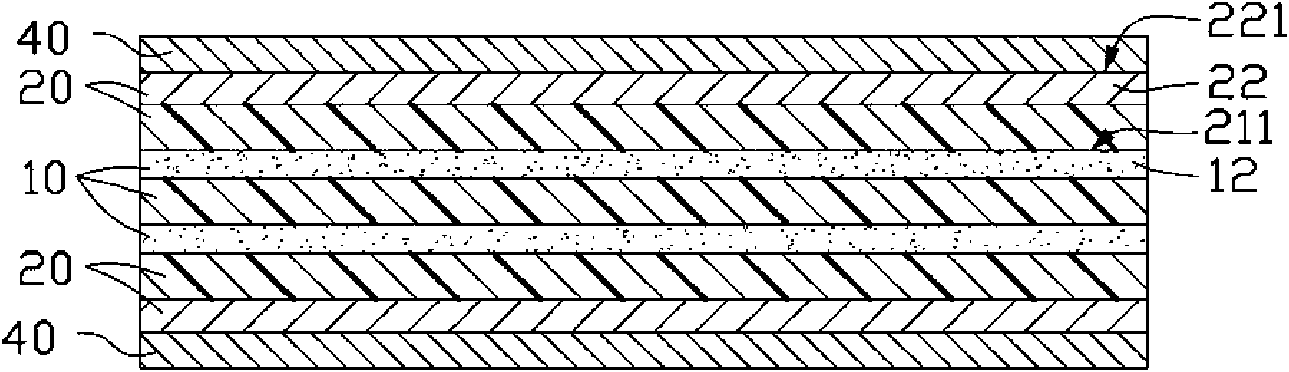

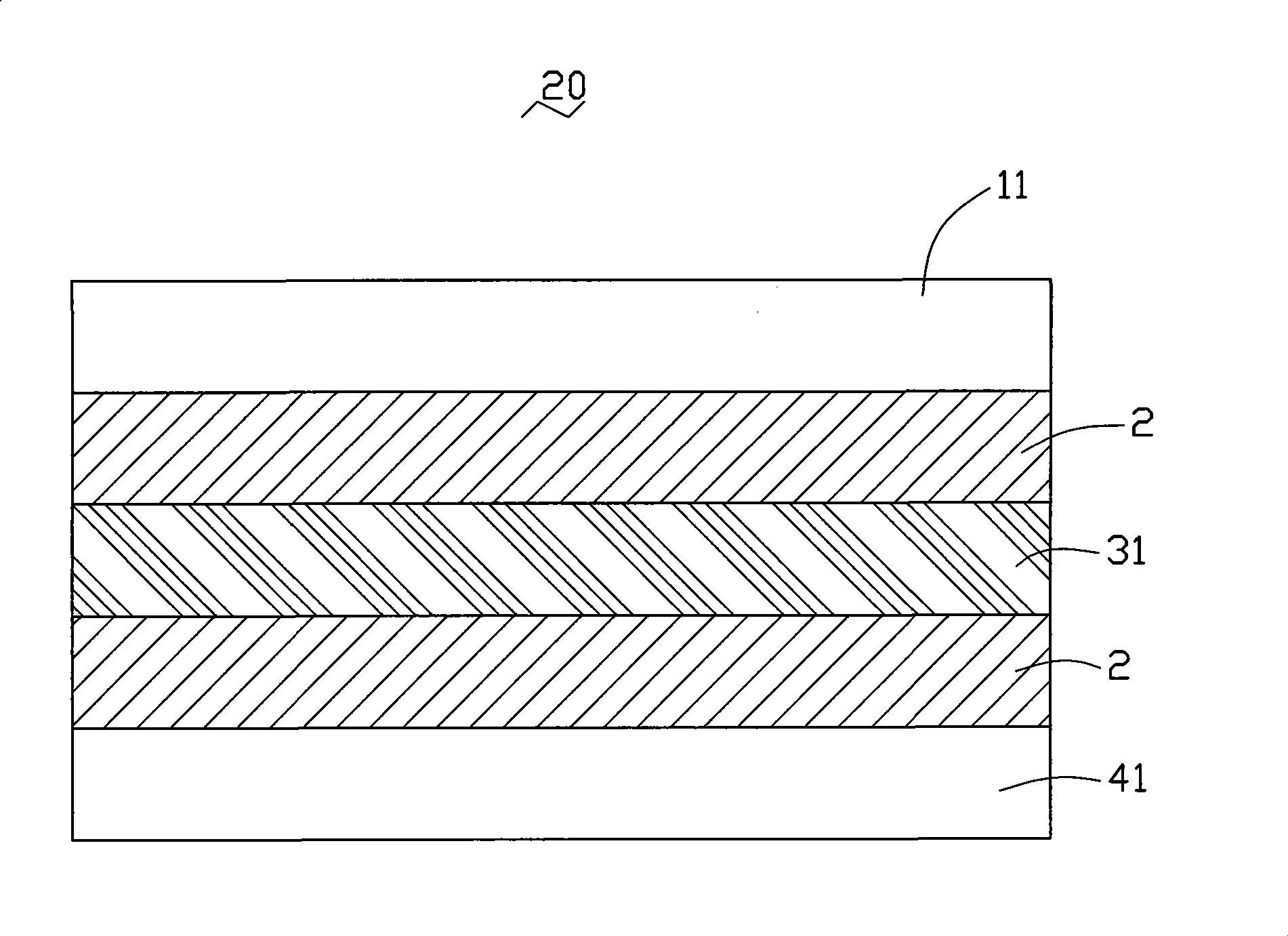

Copper coated substrate material and flexible circuit board having the copper coated substrate material

InactiveCN101365294ANot easy to disconnectLow costPrinted circuit aspectsSynthetic resin layered productsFlexible circuitsCopper foil

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

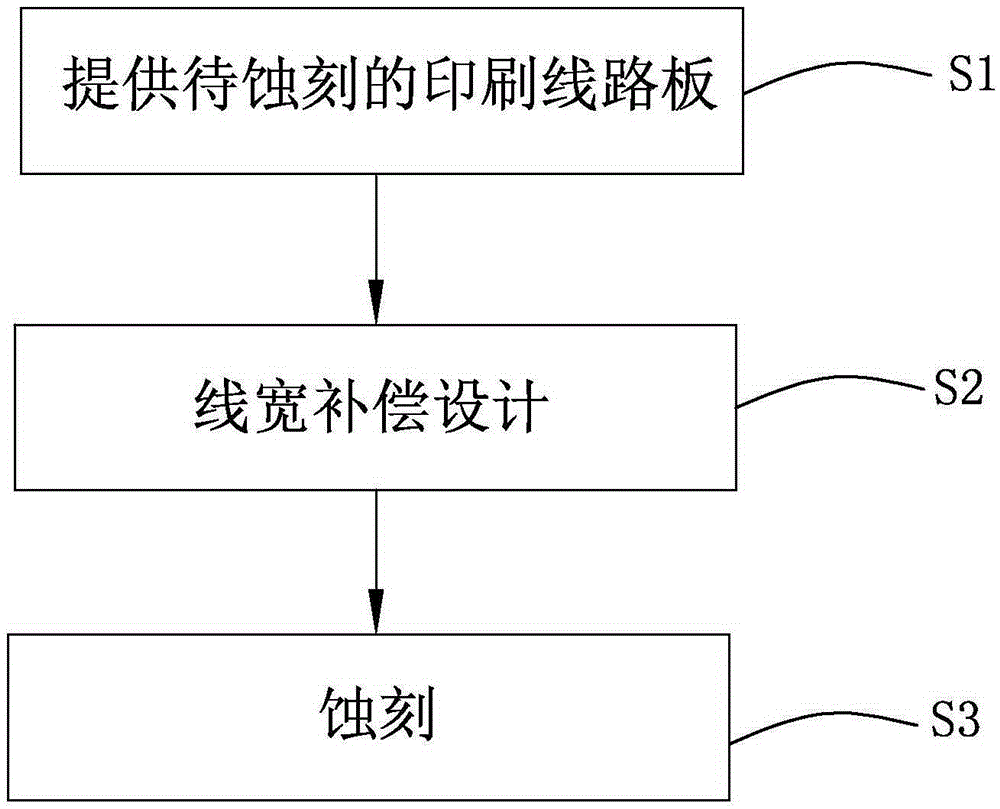

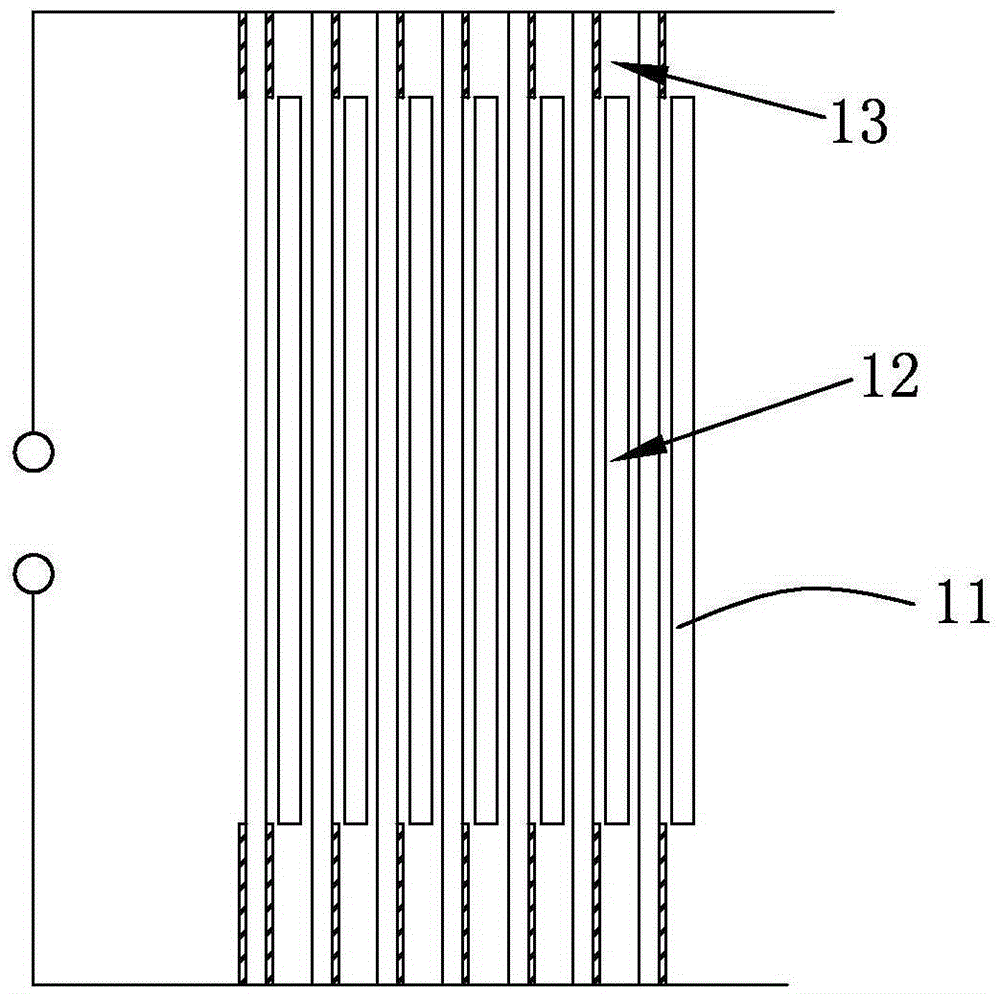

Linewidth compensation method for manufacturing printed circuit board

The invention provides a linewidth compensation method for manufacturing a printed circuit board, comprising: providing a printed circuit board to be etched, which comprises a developing dense line zone and a sparse line zone; designing linewidth compensation: increasing a preset compensation width to the line of the sparse line zone, pasting the copper pouring zone corresponding to the preset compensation width to a dry film, and then performing exposure and development process treatment; and etching: performing etching treatment on the printed circuit board to be etched after a linewidth compensation design step, allowing the copper foil width of the sparse line zone after etching to be equal with the copper foil width of the dense line zone. Compared with the prior art, through the linewidth compensation method for manufacturing a printed circuit board, the linewidth of the dense line zone after printed circuit board etching is the same with the linewidth of the sparse line zone, and the reliability of the printed circuit is improved.

Owner:SHENZHEN WUZHU TECH

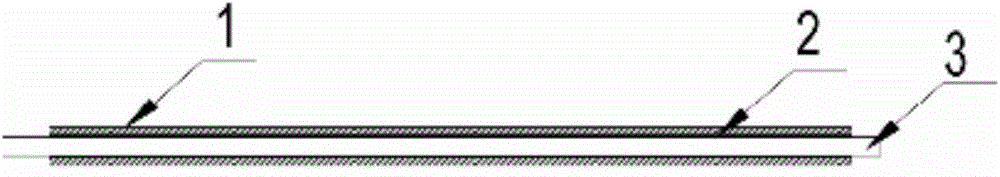

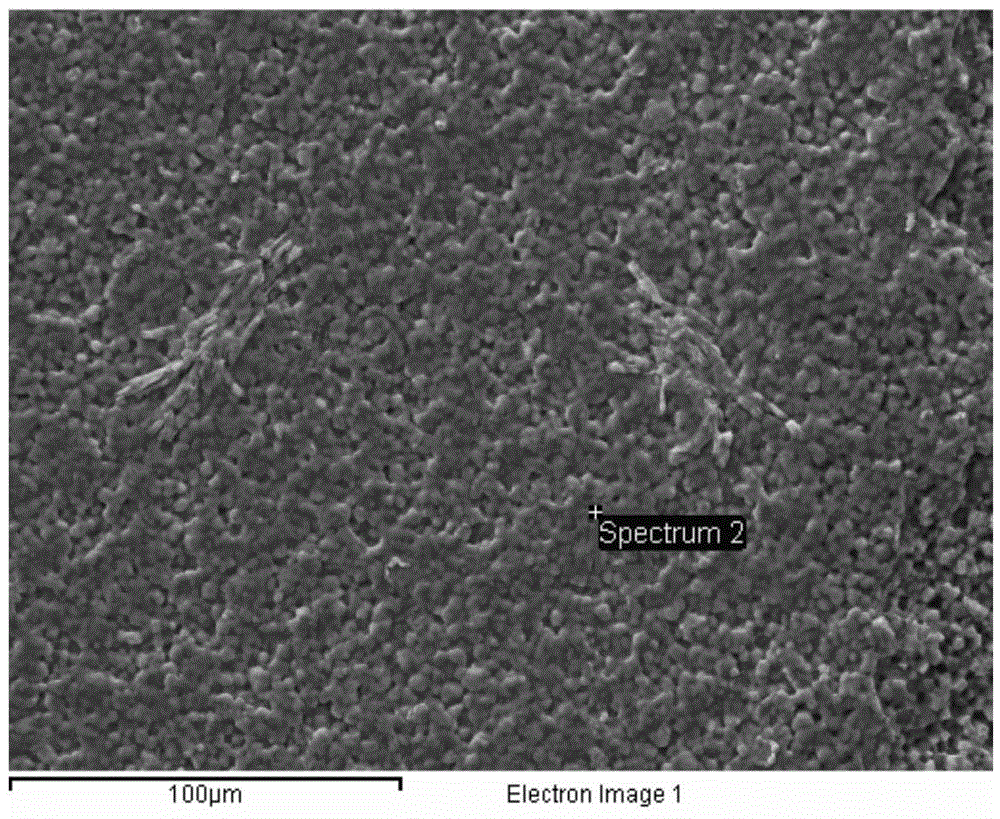

Copper pour use aluminum nitride substrate pretreatment method

The invention discloses a copper pour use aluminum nitride substrate pretreatment method which is a key process in the preparation process of an aluminum nitride DBC (direct bond copper) plate, and the method comprises the following steps: 1, aluminum nitride substrate surface cleaning; 2, aluminum nitride substrate activation for exposure of a new high-activity surface of the aluminum nitride by use of an alkali lye; 3, preparation of an aluminum nitride substrate surface transition layer which is a composite layer containing copper, manganese, calcium, aluminum and other ions; and 4, thermal oxidation treatment of the aluminum nitride substrate surface to form a composite modified layer. The copper pour use aluminum nitride substrate pretreatment method reduces the harsh conditions of aluminum nitride surface pretreatment in the aluminum nitride DBC process; the prepared aluminum nitride transition layer is a composite oxide layer, can smoothly and fully wet copper oxide on the surface of an oxygen-free copper sheet and spread at high temperature, and reacts to bond, adhesion strength of the aluminum nitride and the copper sheet is high, the hole rate is low, and the product anti temperature cycle performance is good.

Owner:HEFEI SHENGDA ELECTRONIC TECH IND CO LTD

Methods for preparing copper-plate surface modifying WC-Cu alloy layer for continuous-cast crystallizer and application thereof

The invention relates to methods for preparing a copper-plate surface modifying WC-Cu alloy layer for a continuous-cast crystallizer and an application thereof. The WC-Cu alloy layer is especially suitable for a copper plate modifying layer of a crystallizer for continuously casting steel and nonferrous metal. The modifying layer comprises 30.0-70.0wt% of WC, 23.0-69.65wt% of Cu, 0.1-2.0wt% of Ni,0.05-2.0wt% of Ag and 0.2-3.0wt% of Co. The following two methods can used for preparing the WC-Cu alloy layer: a. hot pressed sintering which is characterized by (1) uniformly mixing power and forming by hot pressed sintering; and (2) casting molten copper on the sintered WC-Cu alloy, or placing a copper plate on the WC-Cu alloy, heating to melt down the copper, carrying out infiltration with the WC-Cu alloy, cooling, and then obtaining a copper plate product with the WC-Cu alloy modification layer; and b. infiltration method which is characterized by (1) uniformly mixing power, cold pressing the power into infiltration frame and sintering the infiltration frame at a high temperature; and (2) casting the molten copper on the WC-Cu alloy frame for infiltration, or placing a copper plate on the WC-Cu alloy frame, heating to melt down the copper, carrying out infiltration with the WC-Cu alloy frame and cooling. The WC-Cu alloy layer has the advantages of greatly improving the productivity of the crystallizer and solving the problem of pollution caused by copper plate galvanization of the crystallizer, and the invention provides a high-efficiency and environment-friendly crystallizersurface modification method.

Owner:DALIAN UNIV OF TECH

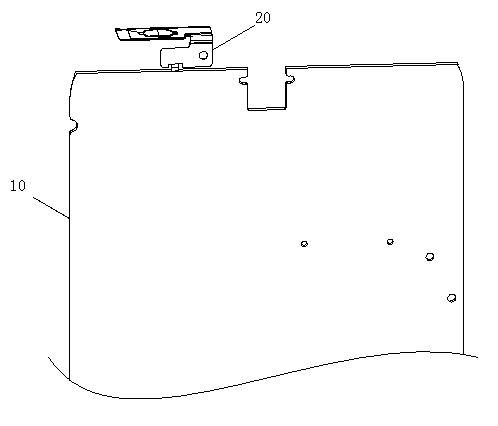

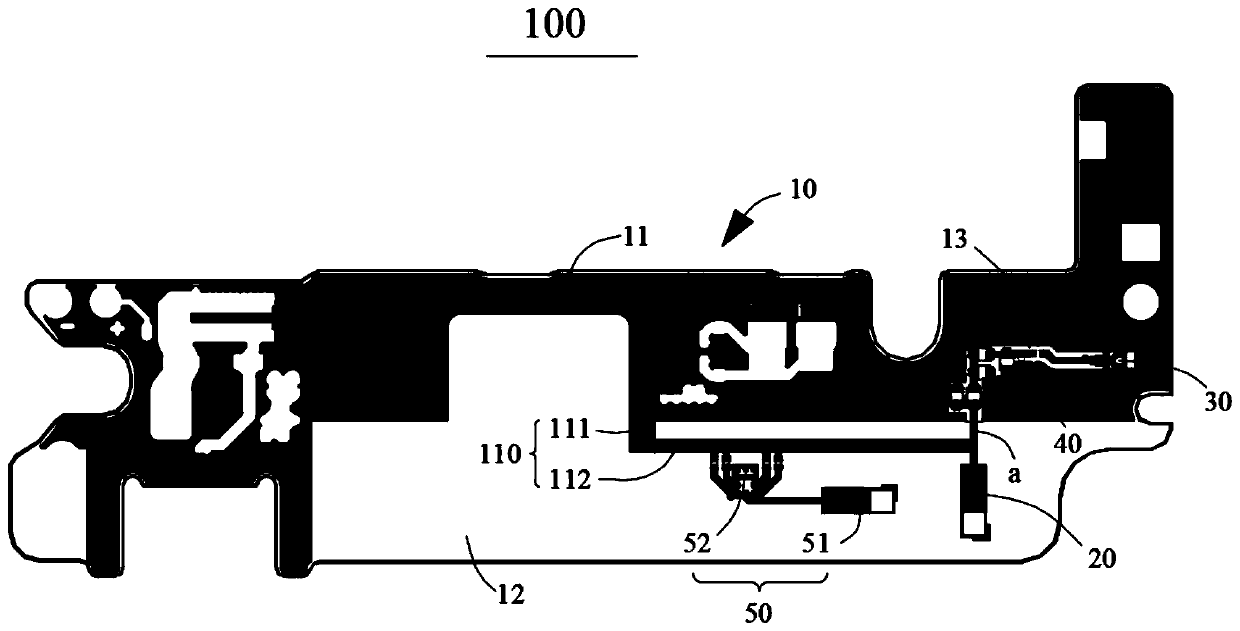

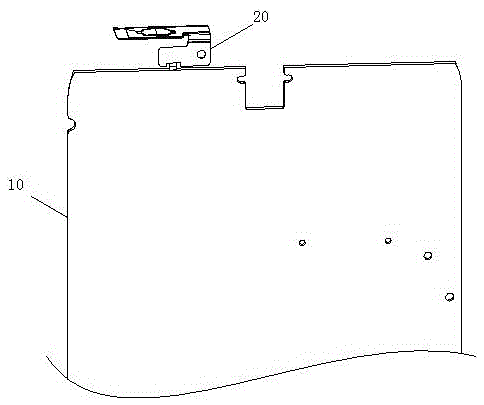

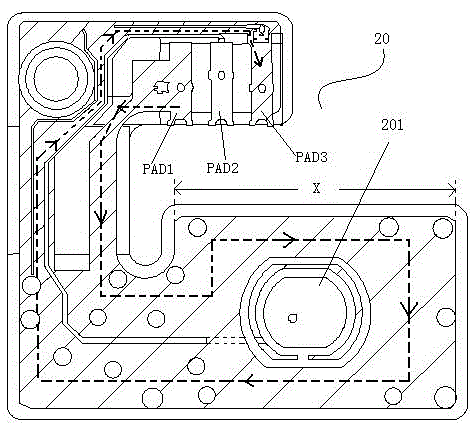

Antenna and on-off key integrated FPC (flexible circuit board) and mobile terminal

ActiveCN103178326ASave internal spaceLow costPrinted electric component incorporationAntenna supports/mountingsFlexible circuitsEngineering

The invention relates to the technical field of a mobile terminal and discloses an antenna and on-off key integrated FPC (flexible circuit board) and the mobile terminal. The FPC comprises a copper pouring region, an antenna energy feed point, an on-off key energy feed point, a grounding bonding pad and an on-off key spring sheet. The FPC of the on-off key is used; the antenna energy feed point and a main body are arranged on the FPC, wherein the antenna energy feed point, the copper pouring region and the grounding bonding pad are connected to form the main body of the antenna, equivalently, the FPC of the on-off key is transformed into the antenna; the on-off key energy feed point is also electrically connected with the on-off key spring sheet, so that the functions of the on-off key are maintained on the FPC; and the antenna and on-off key integrated FPC has the advantages that the antenna and the on-off key of power source share the FPC, so that a conventional BT / WIFI (British Telecom / Wireless Fidelity) antenna can be saved, the cost of the antenna is reduced, the antenna and on-off key integrated FPC is easy to realize and is suitable for mass production, and an ultra-thin mobile phone is prevented from limiting the antenna region to influence the normal working of the antenna.

Owner:TCL COMM NINGBO

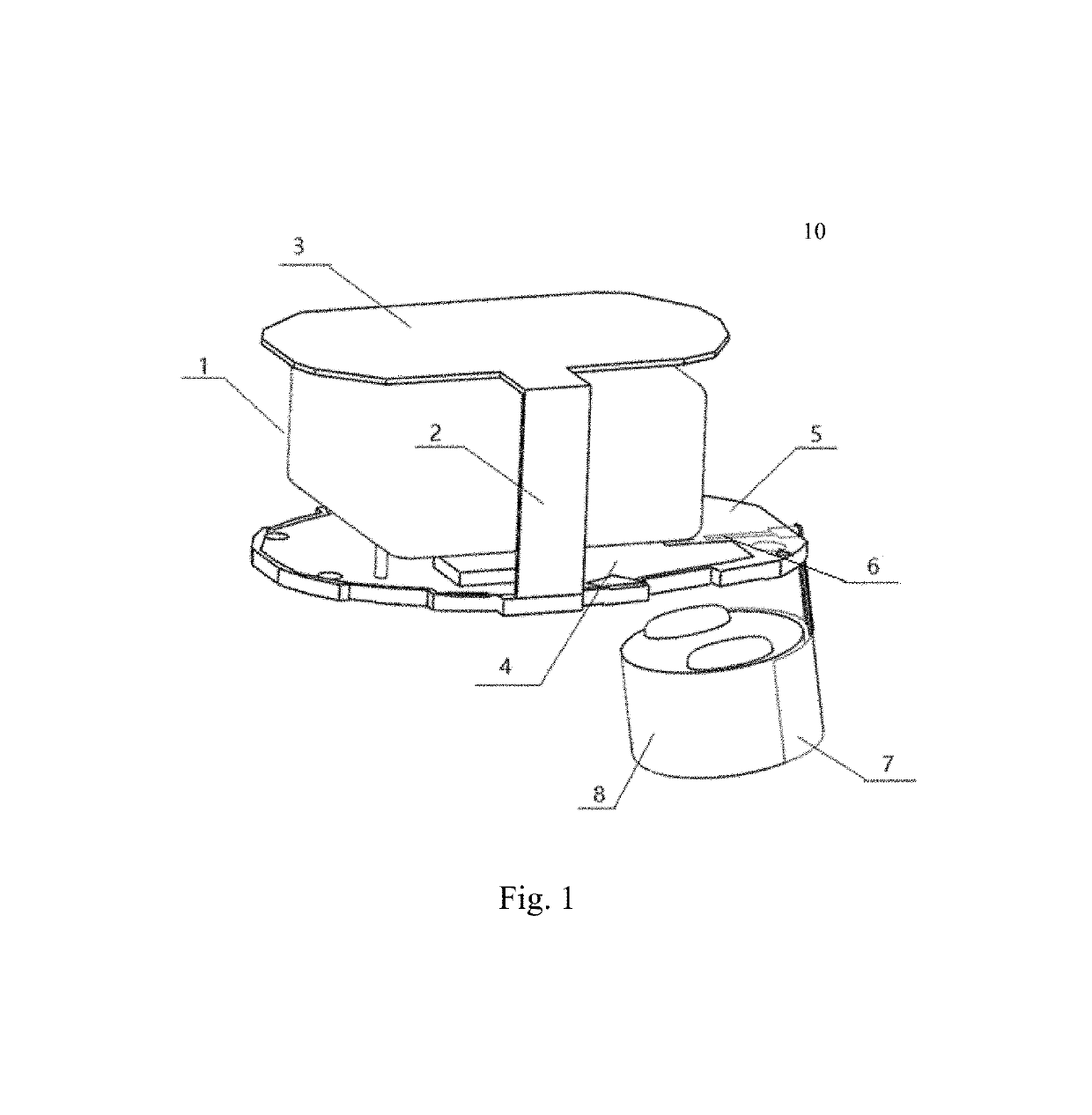

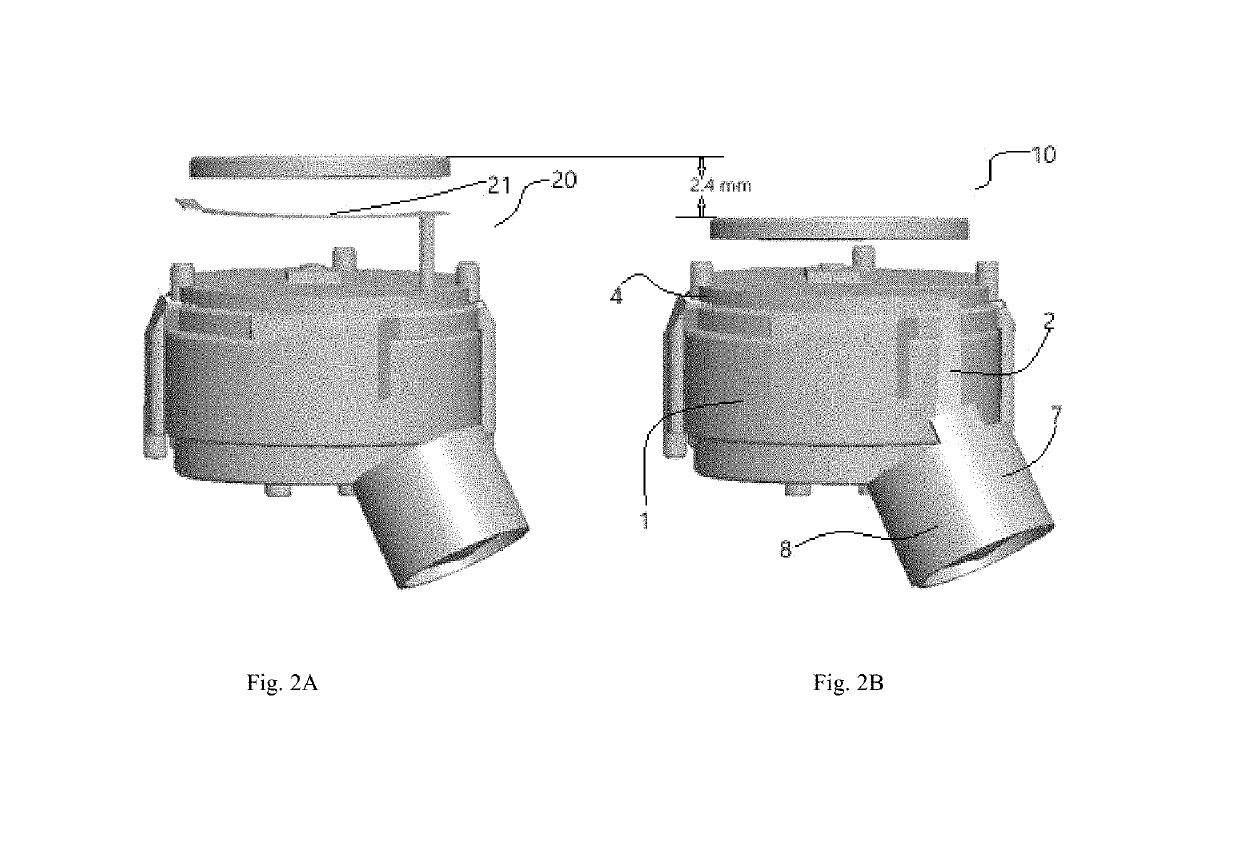

In-ear bluetooth headset

ActiveUS10244303B2Improve efficiencySave spaceAntenna adaptation in movable bodiesRadiating elements structural formsHeadphonesBluetooth

An in-ear BLUETOOTH® headset antenna for single-ear and double-ear BLUETOOTH® headset. The antenna includes a radiation unit and a ground unit, both utilizing components that make up the headset. The radiation unit is composed of a horn of the BLUETOOTH® headset and a conductive foil attached to the horn surface. One end of the conductive foil is attached to the surface of the headset horn and the other end is connected to the feed point of the RF circuit antenna of the BLUETOOTH® headset. The ground unit includes copper pouring on a main printed circuit board connected to copper pouring a key printed circuit board by a cable. No additional antennas are required, and the in-ear BLUETOOTH® headset antenna reduces costs, saves space, and improves the radiation efficiency of the antenna due to the increased effective radiation area of the antenna.

Owner:SHENZHEN ATX TECH CO LTD

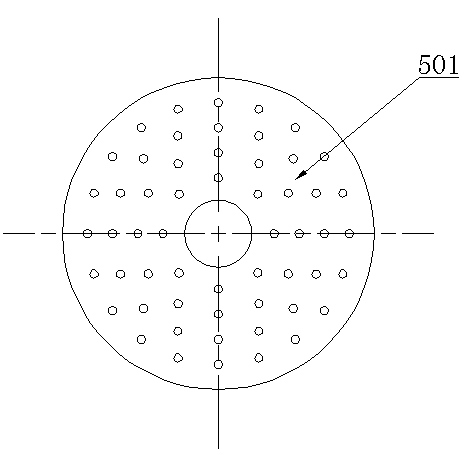

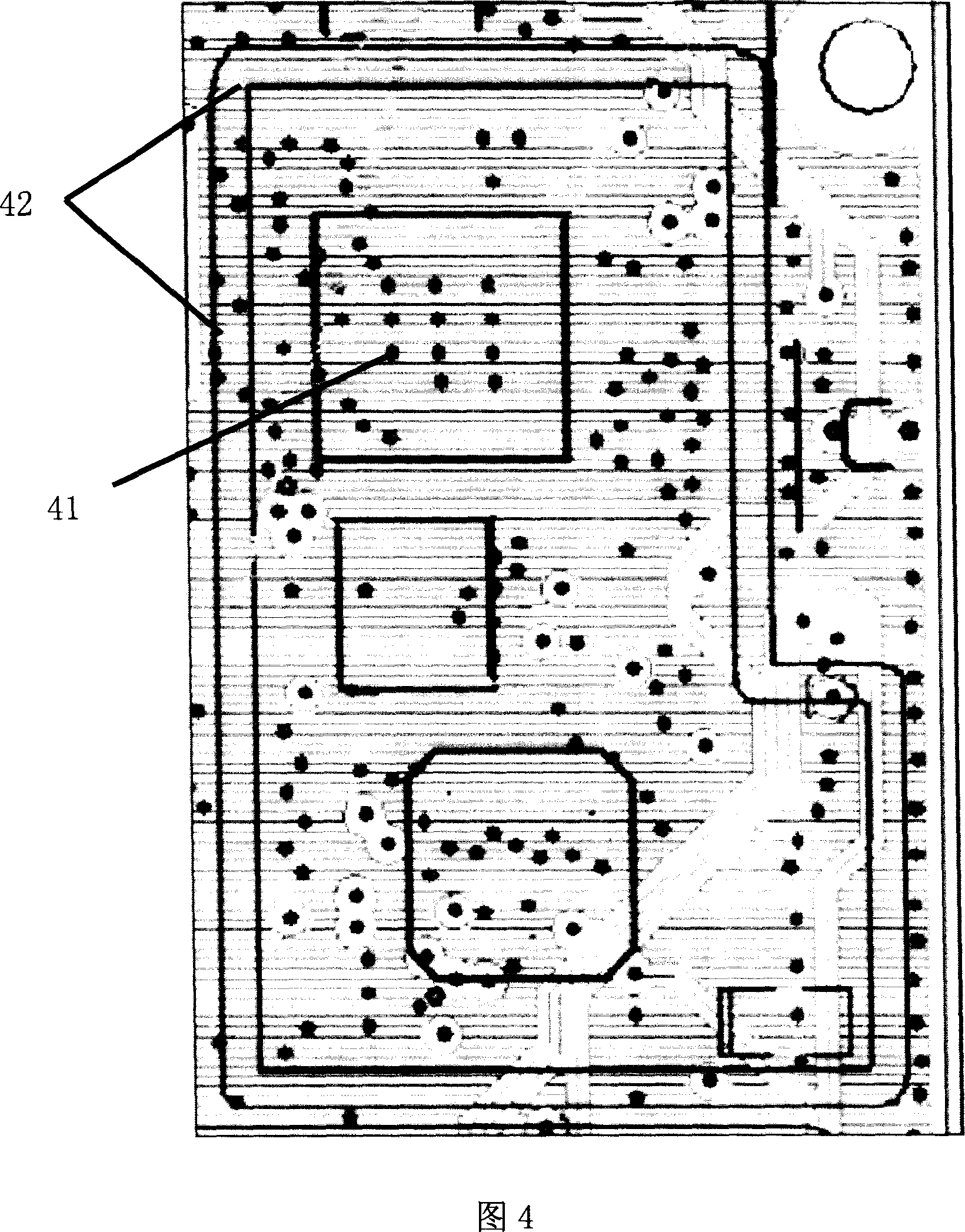

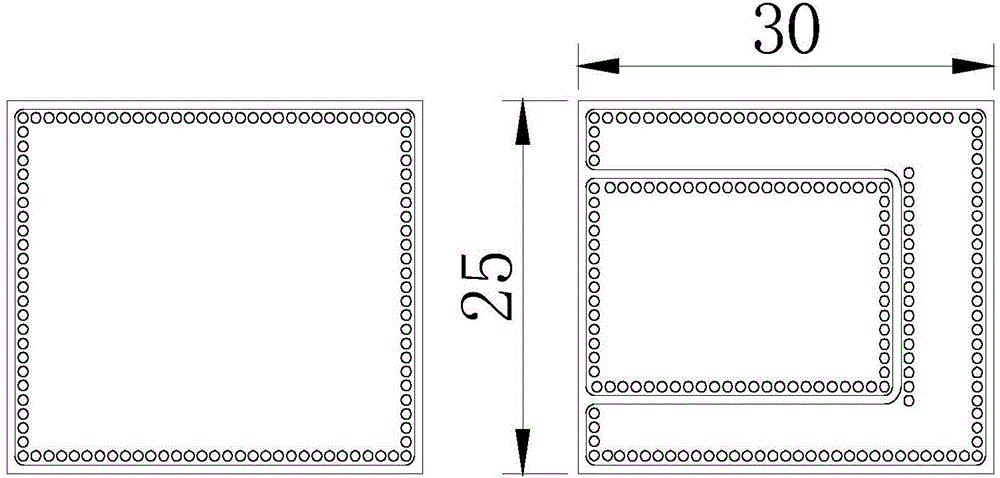

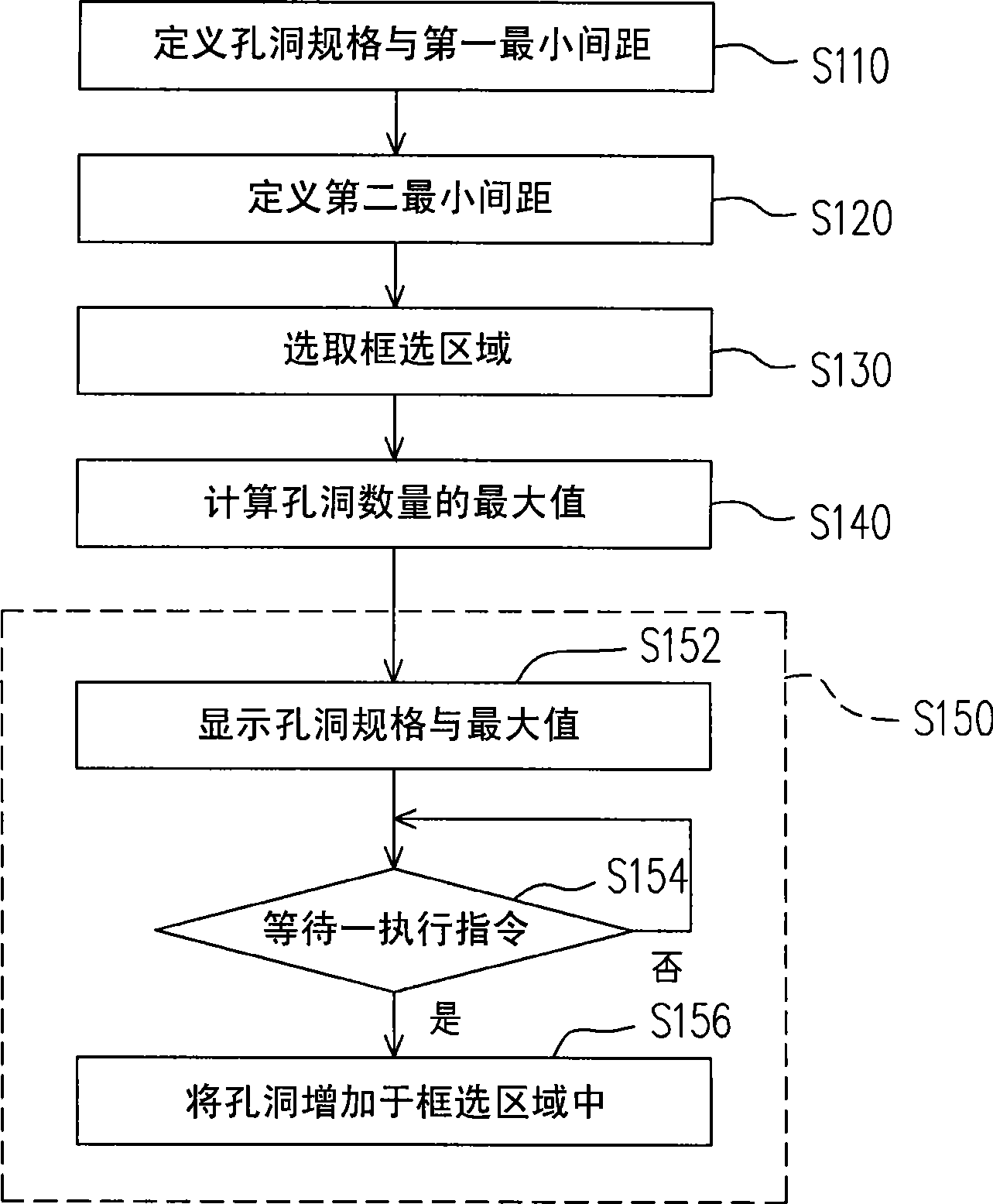

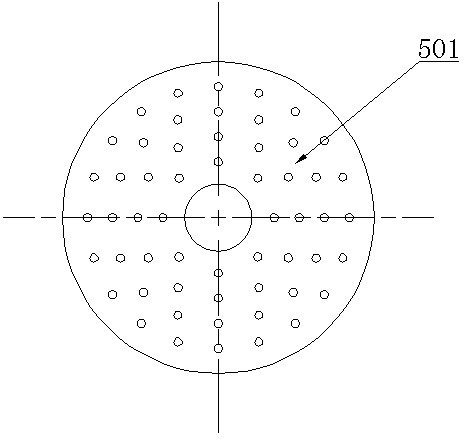

Batch allocating pore and method for predicting pore quantity

InactiveCN101436215AConfigure automaticSave human effortSpecial data processing applicationsCopper pourComputer engineering

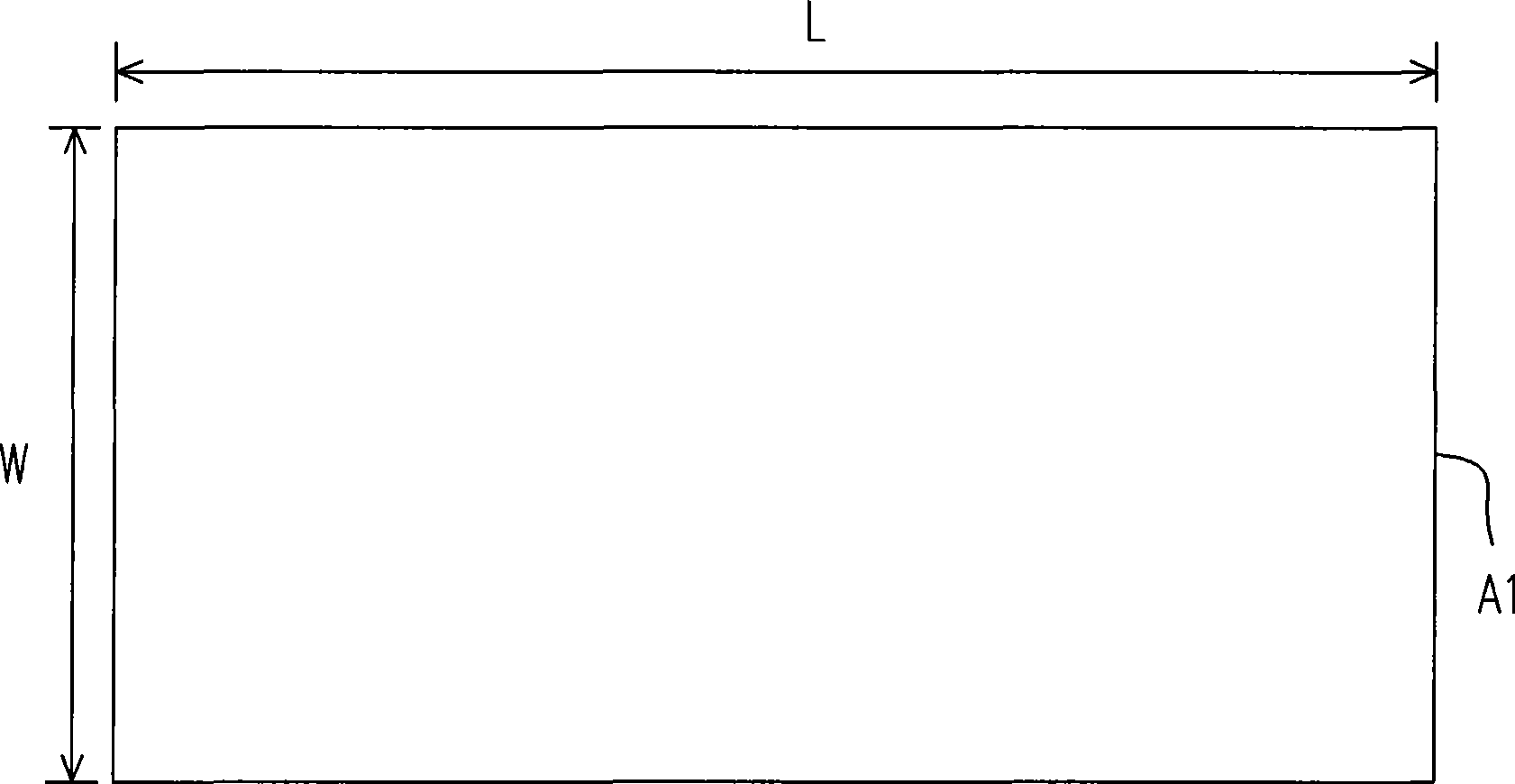

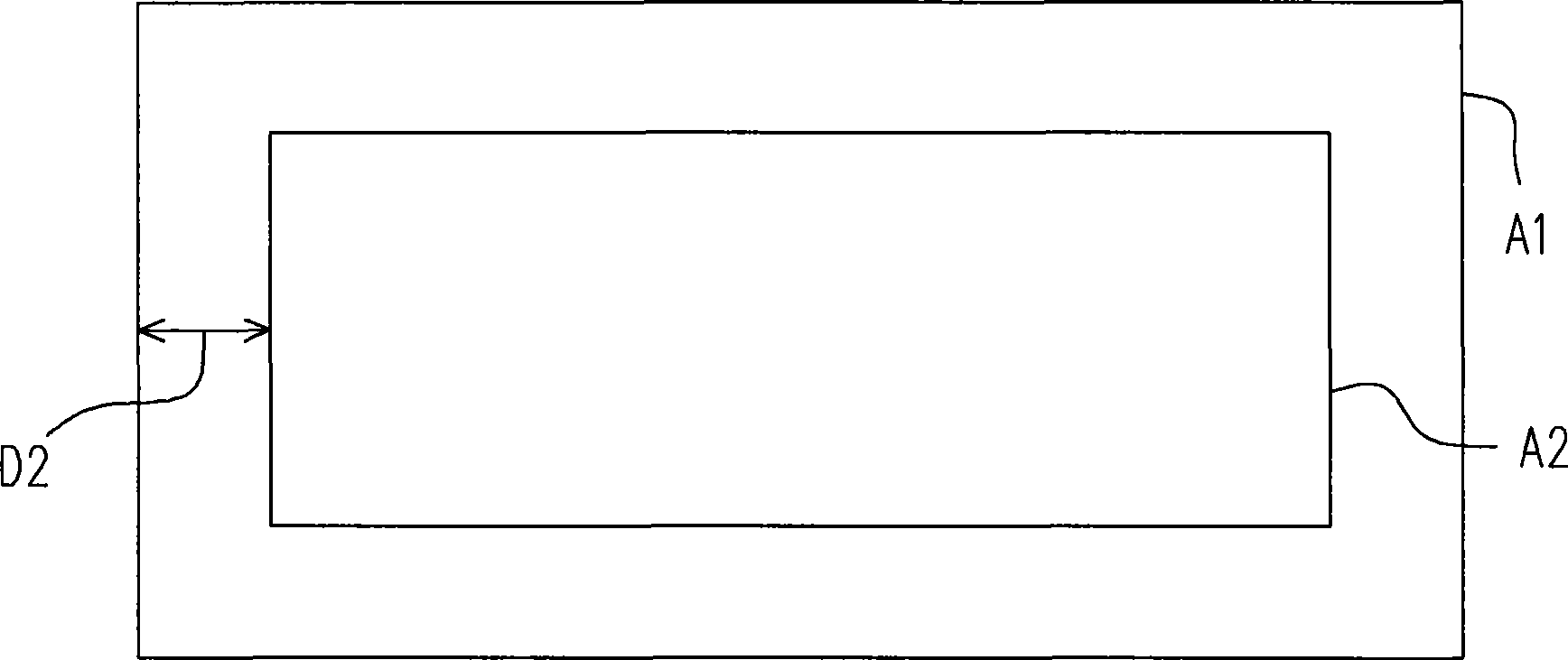

The invention relates to a method for configuring holes in batch, which is suitable to configure a plurality of holes in a copper-pouring area of a circuit board. The method for configuring the holes in batch comprises: firstly, defining the specification of at least one hole and the first minimum spacing between adjacent holes; secondly, selecting a frame selection area on the copper-pouring area; thirdly, calculating the maximum number of the holes capable of being configured in the frame selection area according to the specification of the hole, the first minimum spacing and the area of the frame selection area; and fourthly, configuring the holes in the frame selection area according to the maximum value. Moreover, the invention also provides a method for predicting the number of the holes.

Owner:INVENTEC CORP

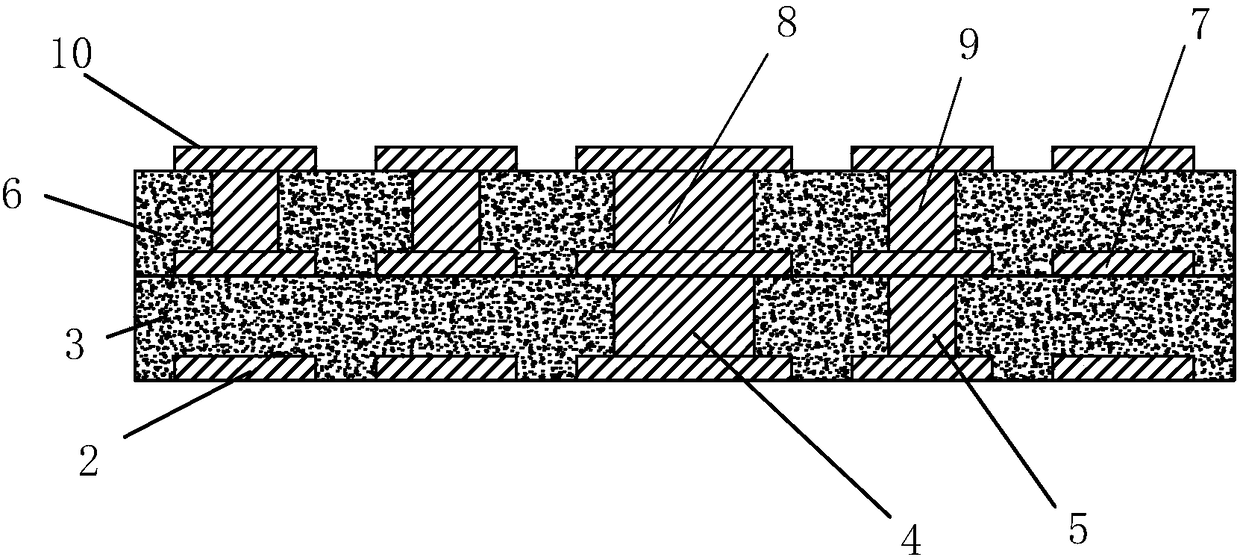

High thermal conductivity package substrate and preparation method thereof

PendingCN108575048ADimensionally stableHigh densityCircuit thermal arrangementsCopper pourElectroplating

A high thermal conductivity package substrate and a preparation method thereof are disclosed. The preparation method includes the steps of: electroplating a copper substrate with a metal protective layer; addition-electroplating the copper substrate with a first line layer; forming a first conductive copper post and a first heat-dissipating copper post on the first line layer, and electroplating the first conductive copper post and the first heat-dissipating copper post; pressing a first insulating layer on the first line layer and performing grinding; forming a second line layer on the firstinsulating layer; forming a second conductive copper post and a second heat dissipating copper post on the second line layer, and pressing a second insulating layer on the second line layer and performing grinding; forming a third line layer on the second insulating layer; and etching the copper substrate. The heat-dissipating copper posts can allow a simple heat conductive path, and the heat dissipating effect is improved; the preparation process is simple, the cost is low, the prepared high thermal conductivity package substrate is stable in size, the conductive path is simple, and the heatdissipating performance is excellent.

Owner:NINGBO HUAYUAN ELECTRONICS TECH

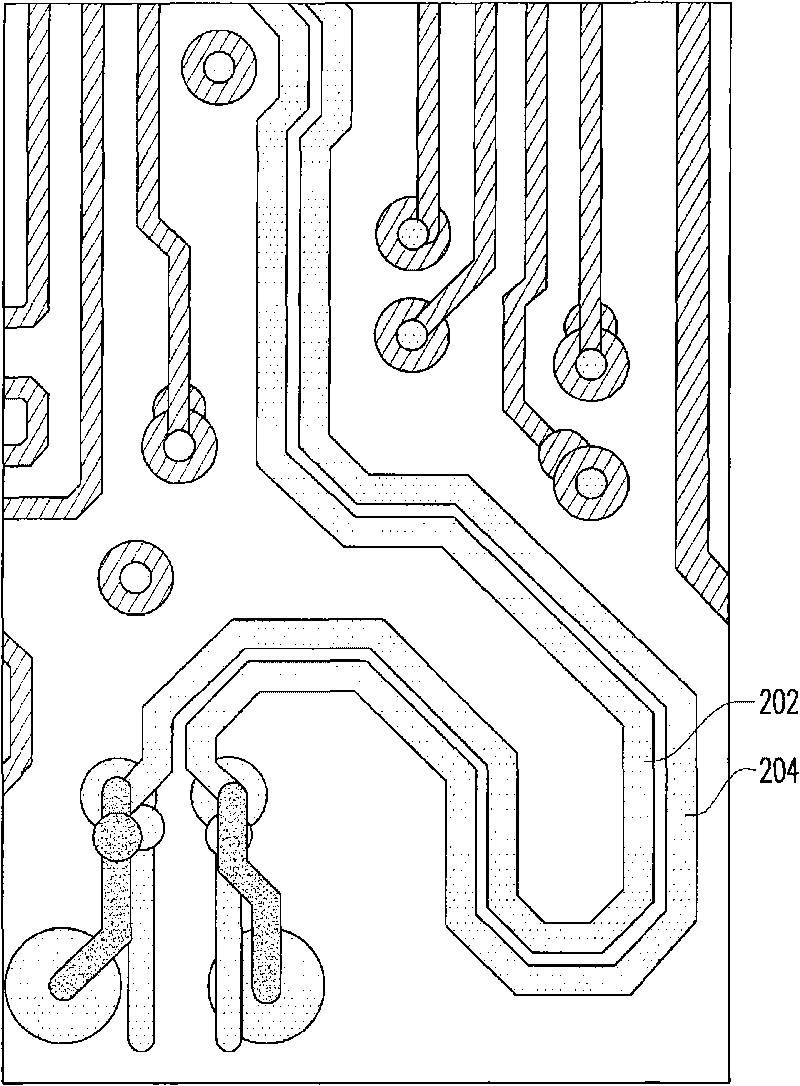

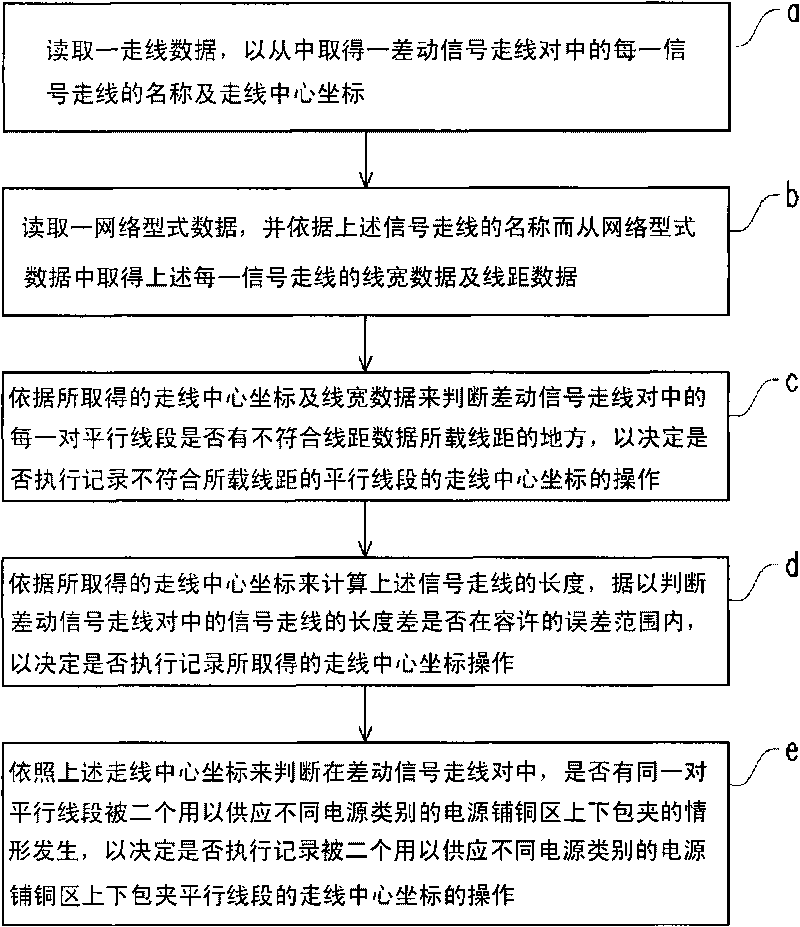

Layout method capable of automatically executing layout rule detection for line pair of differential signal

InactiveCN101751483ADon't Worry About Poor QualityImprove work efficiencySpecial data processing applicationsLine pairLine width

The invention relates to a layout method capable of automatically executing the layout rule detection for a line pair of a differential signal. The method comprises the following steps of: a, obtaining a line name and a line central coordinate of each signal in the line pair of the differential signal from line data; b, obtaining the line width data and the line spacing data of each signal from network-type data according to the line name of the signal; c, judging that whether each pair of parallel line segments in the line pair of the differential signal accord with the line spacing carried by the line spacing data or not according to the obtained the line central coordinate and the line width data; d, calculating the length of the line of the signal according to the obtained the line central coordinate, so as to judge that whether the length of the line of the signal in the line pair of the differential signal is within the allowable error range or not; e, judging that whether the same pair of parallel line segments in the line pair of the differential signal are trapped by two power copper-pouring areas used for supplying different powers according to the obtained the line central coordinate.

Owner:嘉兴金日升工具股份有限公司

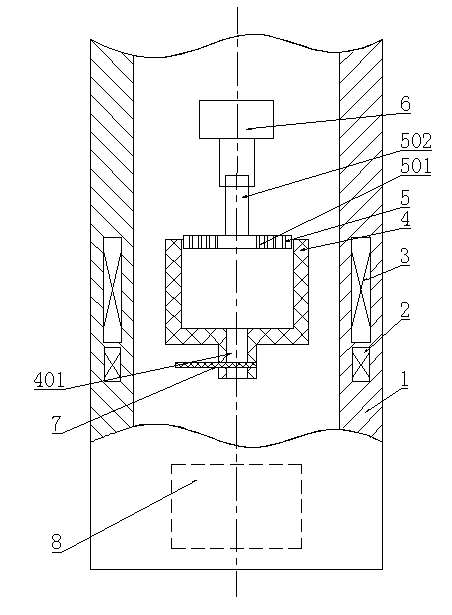

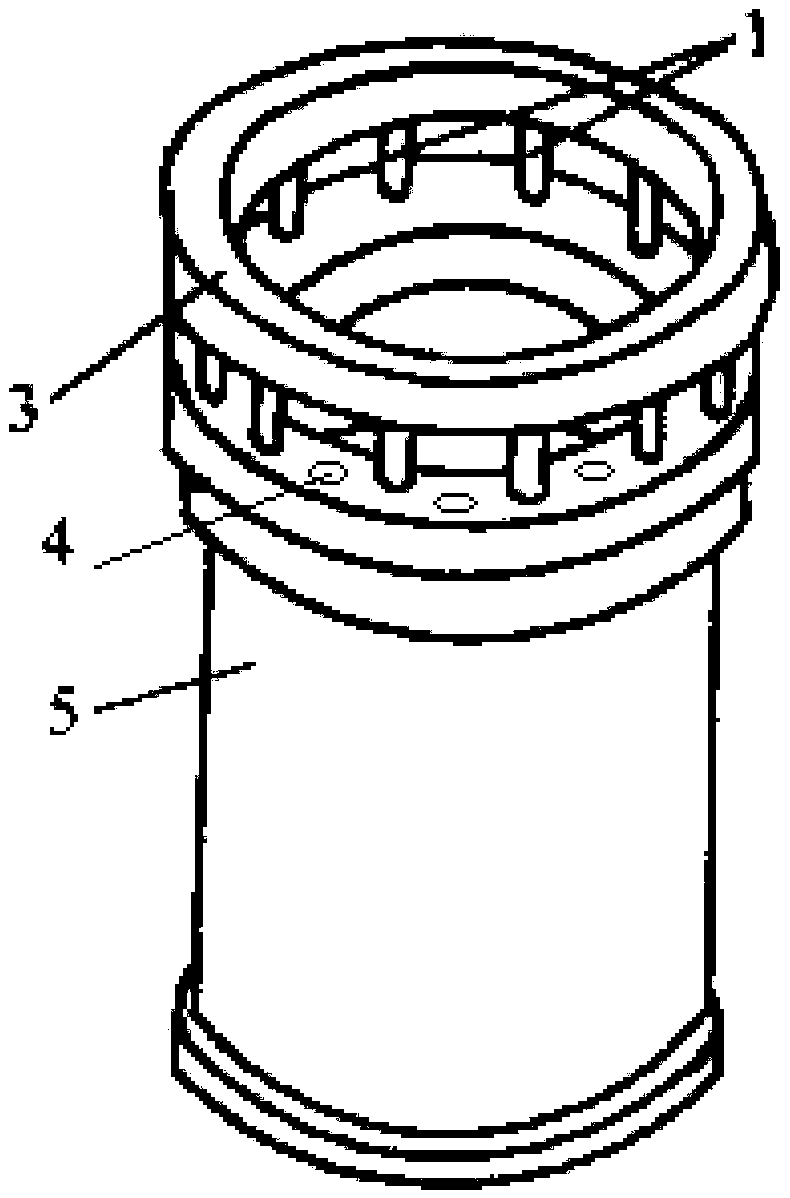

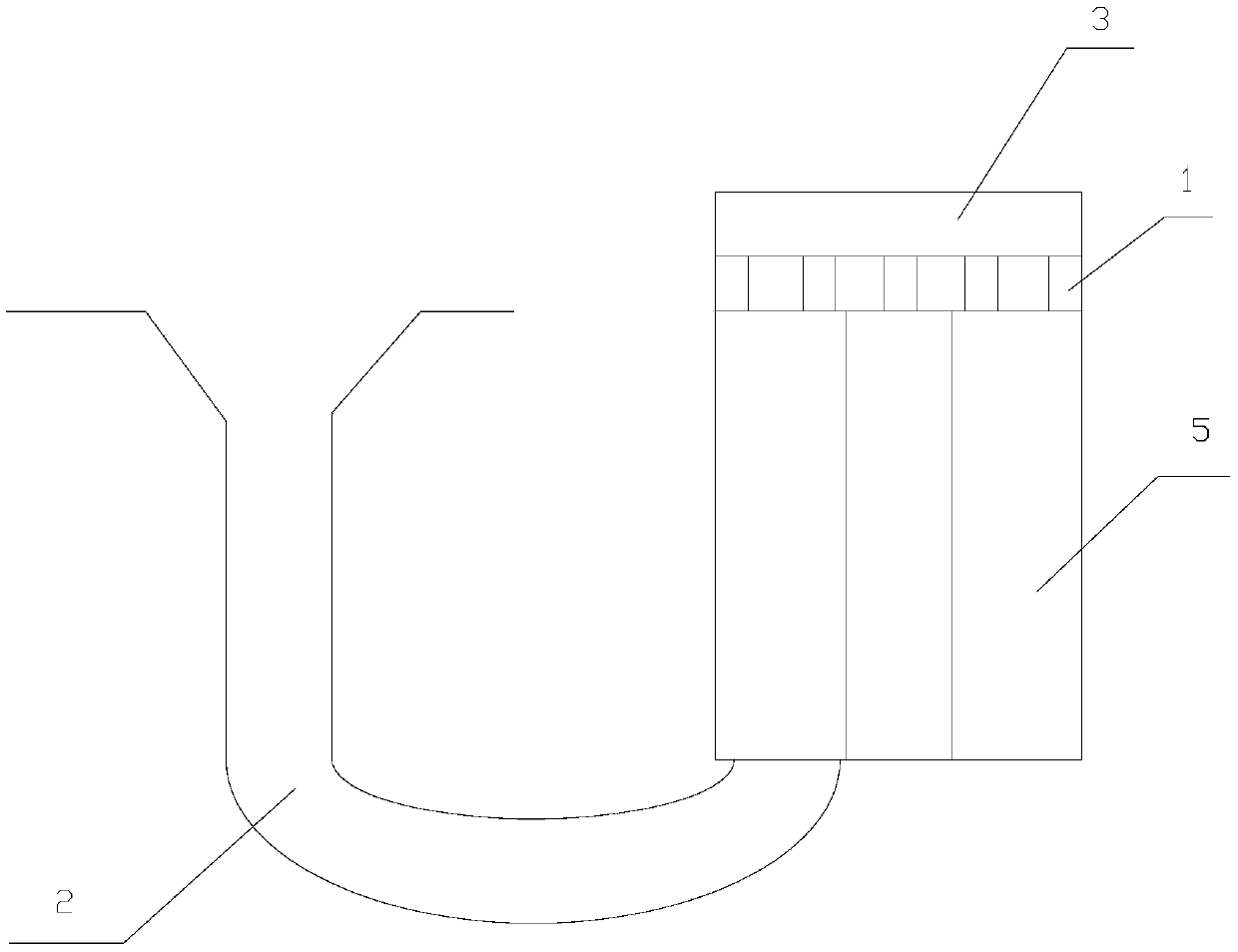

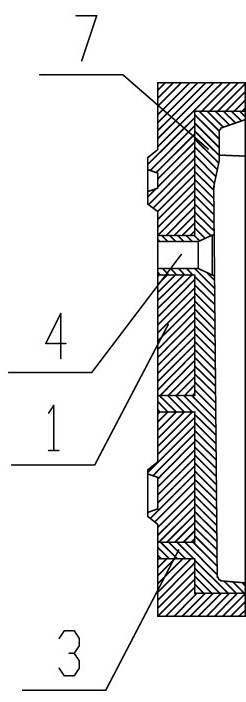

Pouring system for copper artware

InactiveCN105499507AOvercoming easy oxidation,Overcome the problem of easy cavity damageFoundry mouldsFoundry coresEngineeringCopper pour

The invention discloses a pouring system for copper artware. The pouring system comprises an annular runner (3), a semicircular runner (2), a cavity (5) and a plurality of vertical runners (1), wherein the annular runner (3) is arranged vertically above the cavity (5), and communicated to the top end of the cavity (5) through the plurality of vertical runners (1), and a first pouring inlet is arranged in the annular runner (3); and the first end of the semicircular runner (2) is communicated to the bottom end of the cavity (5), a second pouring inlet is arranged in the second end of the semicircular runner (2), and the second end is as high as the cavity (5). The pouring system for the copper artware overcomes the problems that damages of the cavity are liable to cause, and molten copper is liable to oxidize during a pouring process in the prior art, and realizes the functions of protection and anti-oxidation during the copper pouring process.

Owner:铜陵铜官府文化创意股份公司

Antenna small panel, antenna structure and mobile terminal

ActiveCN109742518ARadiation Hotspot EqualizationAvoid Poor Antenna PerformanceRadiating elements structural formsAntennas earthing switches associationCopper pourFeed line

The invention discloses an antenna small panel, an antenna structure and a mobile terminal. The antenna small panel comprises a panel body, an antenna feed point and a radio frequency connector, wherein one surface of the panel body includes a copper-poured area, a wiring area and a clearance area which are arranged up and down, and the copper-poured area and the wiring area are arranged at the same side and are respectively adjacent to the clearance area; the antenna feed point is arranged in the clearance area; the radio frequency connector is arranged in the wiring area and is connected with the antenna feed point by virtue of a feed wire; and one side of the copper-poured area extends toward the clearance area to form an extended section, and the tail end of the extended section is connected with the feed wire. The invention aims at providing the antenna small panel, the antenna structure and the mobile terminal, so as to solve the problem that antenna performance at a certain sideis poor due to influence of the head and hands.

Owner:张大鸣

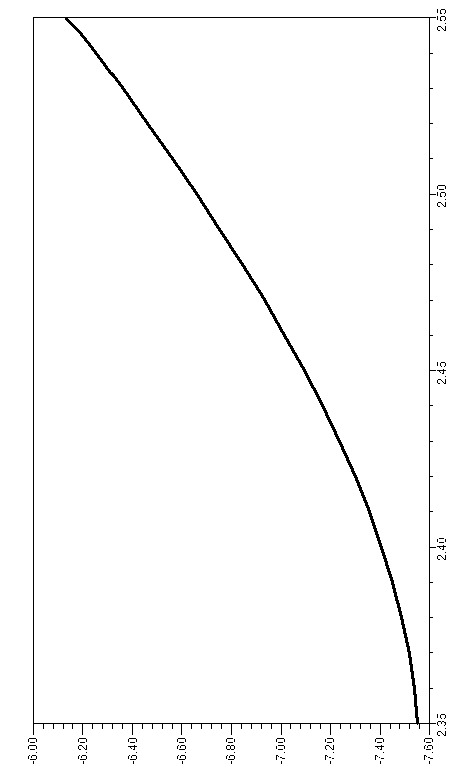

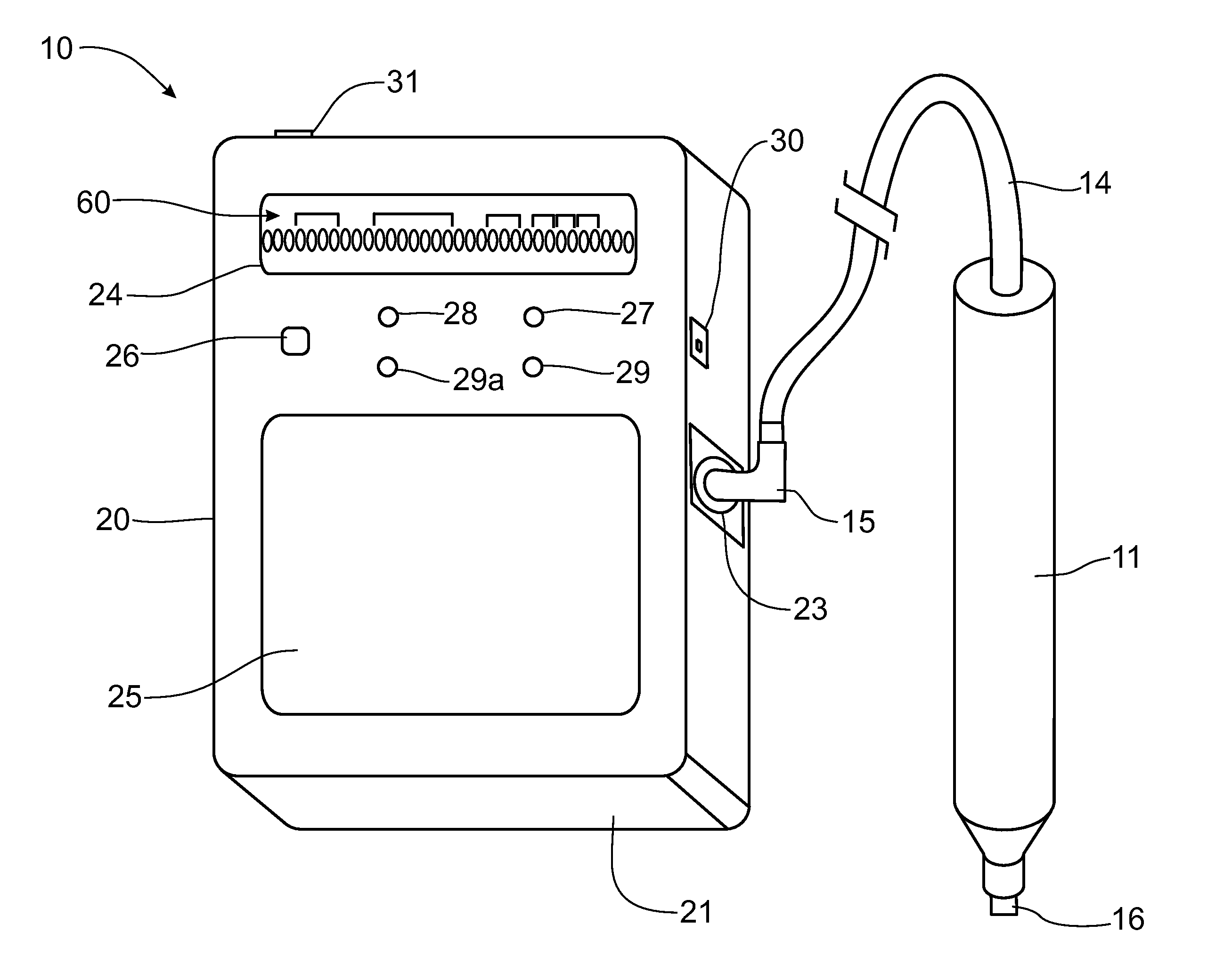

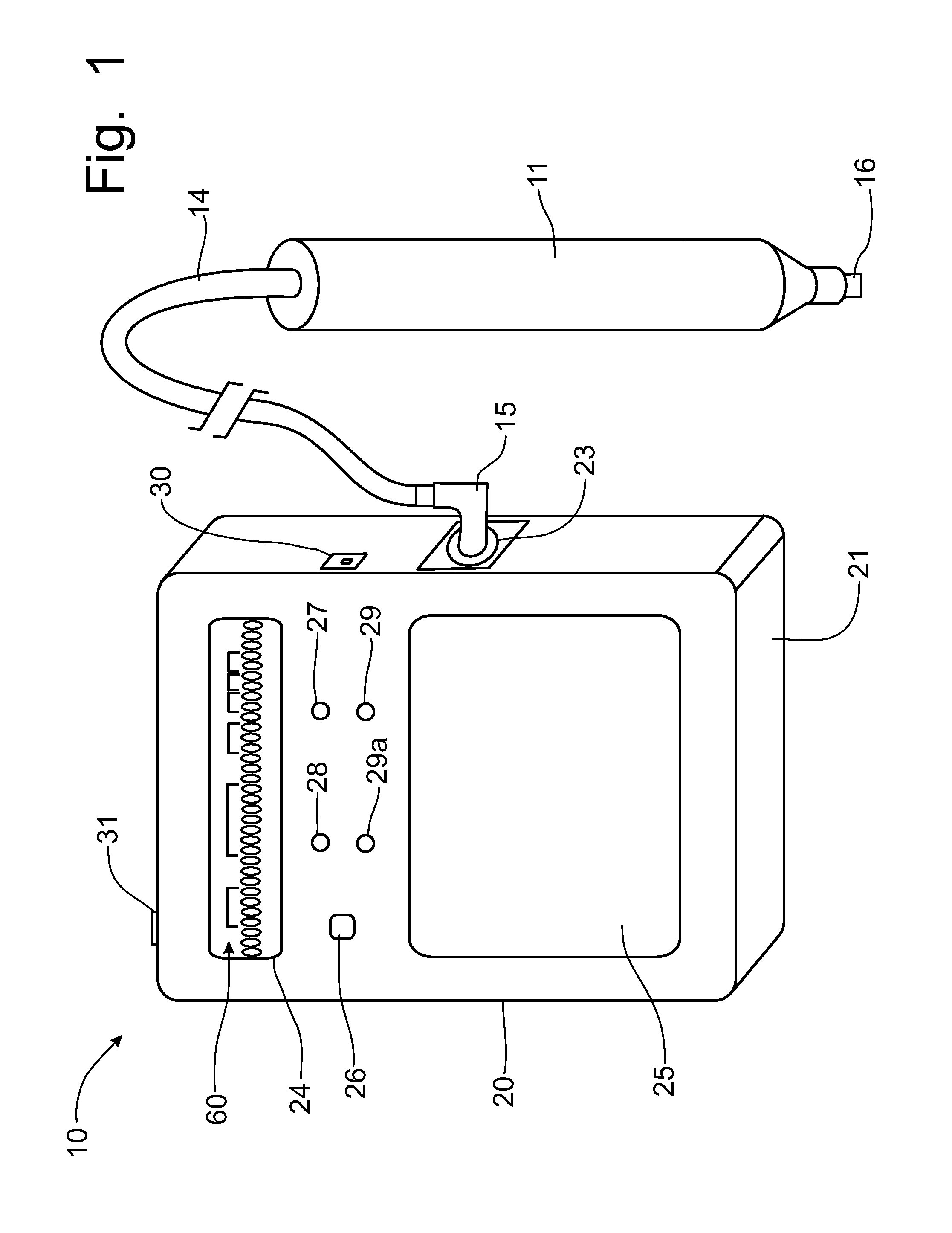

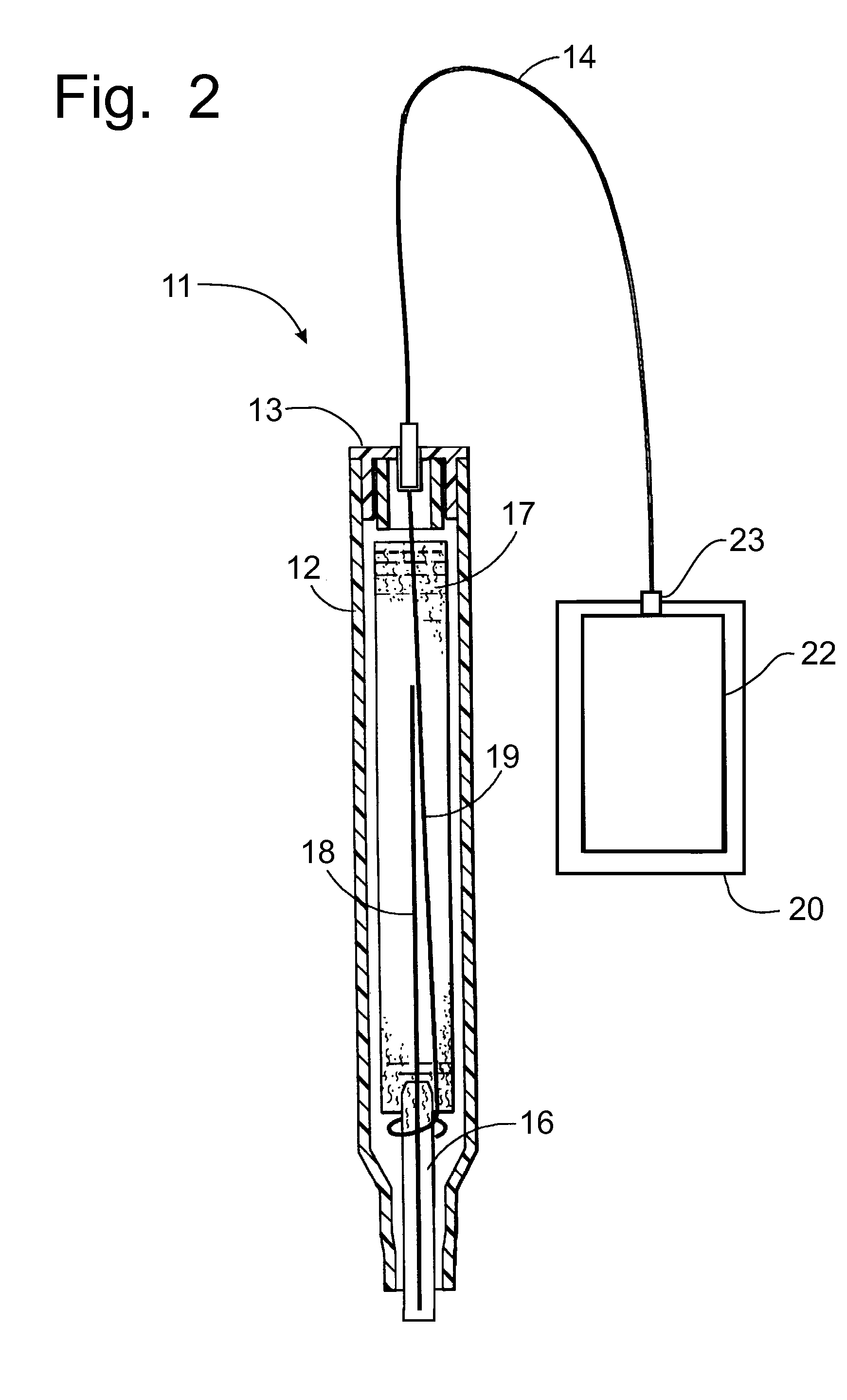

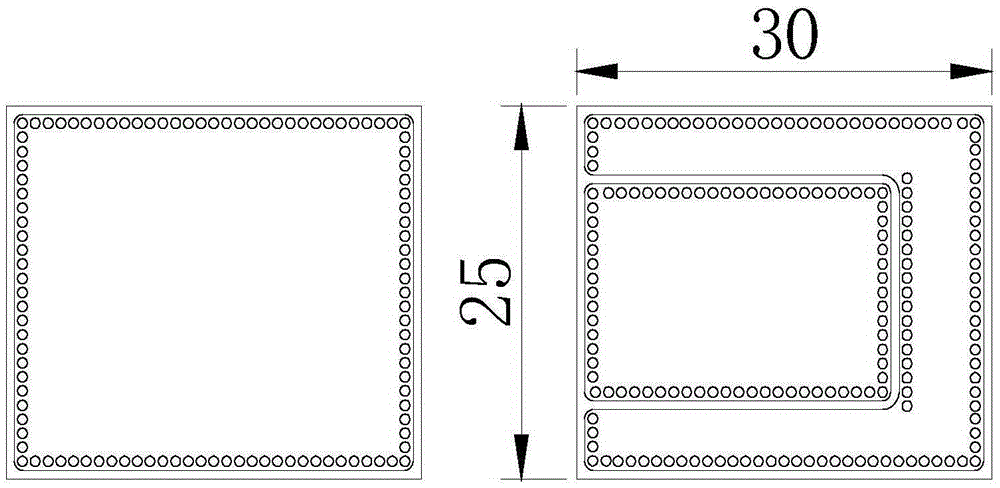

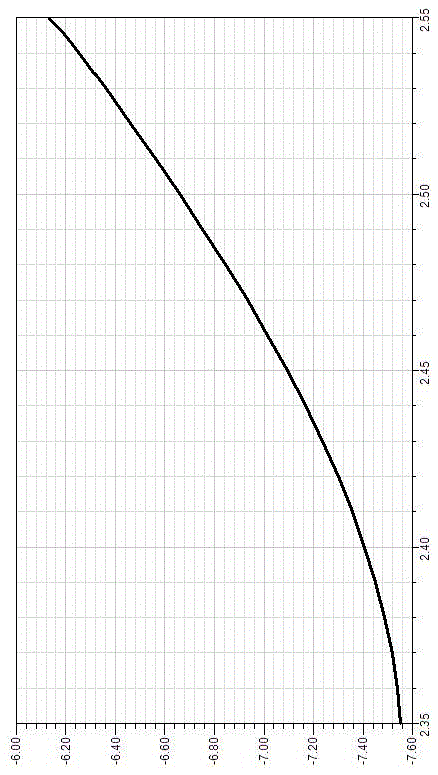

Precious Metal Testing Apparatus with Calibration System

ActiveUS20130030716A1Stabilizes galvanic reactionCancel noiseMaterial analysis by electric/magnetic meansElectrical measurementsTest sampleCalibration curve

A digital precious metal testing apparatus utilizes a probe that generates a galvanic voltage when an electrical circuit is completed with the object being tested being placed between the probe and the meter test pad formed of a copper pour with a gold coating. A microprocessor signals the percentage of precious metal through an indicator bar of LEDs. A calibration system is provided to enhance the accuracy of the testing apparatus by comparing a test reading from a known test specimen with a corresponding theoretical reading for that specimen. The calibration procedure establishes a recalibration curve from the test reading against which all subsequent readings will be compared to determine the content of precious metal. Calibration of the testing apparatus is initiated with the depression of a calibration switch and is undertaken with each power-up of the meter, with each probe replacement and with any substantial change in environmental conditions.

Owner:SCHAFFER JARRETT +1

PCB (printed circuit board) isolation graph copper pouring and distributing secondary etching method

InactiveCN108200729AReduce dosageLow densityConductive material chemical/electrolytical removalEtchingCopper pour

The invention relates to the technical field of PCB (printed circuit board) processing, and discloses a PCB isolation graph copper pouring and distributing secondary etching method which includes thesteps: a copper pouring film optimization; b graph transfer; c graph electroplating; d graph etching; e secondary graph transfer; f secondary etching. The method is applicable to secondary etching ofcopper pouring and distributing of PCBs with locally isolated graphs and the copper thickness smaller than 2OZ, production defect rate is greatly reduced, and the method is low in cost, high in efficiency and suitable for large-scale popularization.

Owner:奥士康精密电路(惠州)有限公司

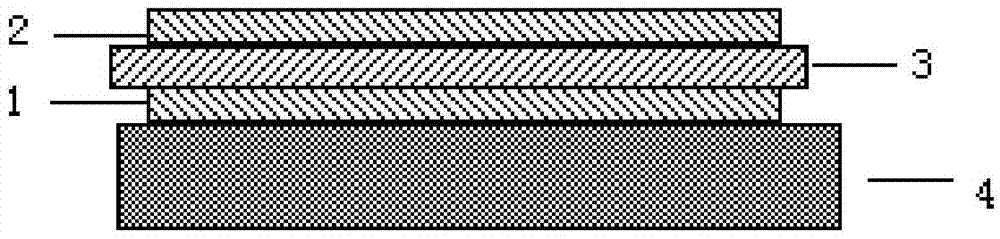

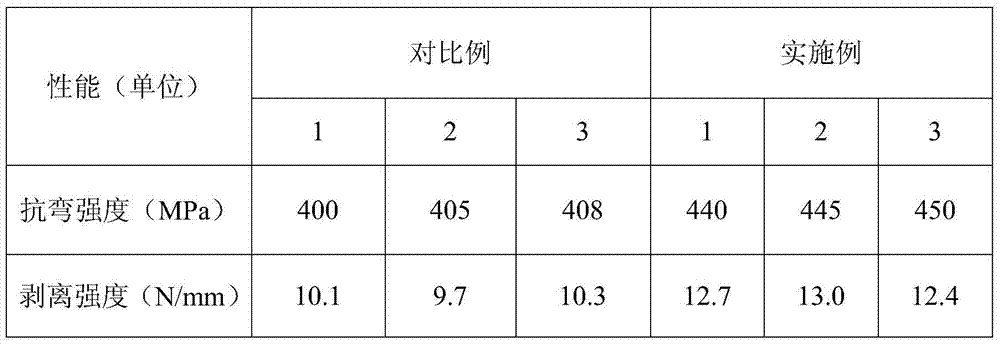

Pretreatment method of aluminum nitride substrate for copper cladding

ActiveCN104402488BReduce porosityHigh peel strengthSemiconductor/solid-state device detailsSolid-state devicesDBcPretreatment method

The invention discloses a copper pour use aluminum nitride substrate pretreatment method which is a key process in the preparation process of an aluminum nitride DBC (direct bond copper) plate, and the method comprises the following steps: 1, aluminum nitride substrate surface cleaning; 2, aluminum nitride substrate activation for exposure of a new high-activity surface of the aluminum nitride by use of an alkali lye; 3, preparation of an aluminum nitride substrate surface transition layer which is a composite layer containing copper, manganese, calcium, aluminum and other ions; and 4, thermal oxidation treatment of the aluminum nitride substrate surface to form a composite modified layer. The copper pour use aluminum nitride substrate pretreatment method reduces the harsh conditions of aluminum nitride surface pretreatment in the aluminum nitride DBC process; the prepared aluminum nitride transition layer is a composite oxide layer, can smoothly and fully wet copper oxide on the surface of an oxygen-free copper sheet and spread at high temperature, and reacts to bond, adhesion strength of the aluminum nitride and the copper sheet is high, the hole rate is low, and the product anti temperature cycle performance is good.

Owner:HEFEI SHENGDA ELECTRONIC TECH IND CO LTD

Method for producing high-conductivity oxygen-free copper and smelting device

InactiveCN102994786BIncrease contact areaLess soluble than oxygenStirring devicesIngotElectric conductance

Owner:JINZHOU NEW CENTURY QUARTZ GROUP CO LTD

Printed circuit board and manufacturing method thereof

The invention provides a manufacturing method for a copper pillar of a PCB. The manufacturing method comprises the steps that a first copper foil layer is formed on the first surface of a carrier; the first copper foil layer is etched to form a first copper pillar, and a part of the first surface is exposed; an anti-adhesion material layer is formed on the exposed part of the first surface, and the first copper pillar is exposed; a dielectric layer is formed on the anti-adhesion material layer and the first copper pillar; a hole is formed in the position, corresponding to the first copper pillar, of the dielectric layer, and the first copper pillar is exposed; a second copper pillar connected with the first copper pillar is formed in the position where the hole is formed, and a first copper layer connected with the second copper pillar is formed on the dielectric layer; the carrier and the anti-adhesion material layer are removed; then copper plating is conducted, and an outer-layer circuit is manufactured, so that the PCB is manufactured. The invention further provides the PCB with the protruding copper pillar manufactured based on the method. The protruding copper pillar manufactured based on the method has higher reliability during welding.

Owner:NEW FOUNDER HLDG DEV LLC +1

An fpc board with integrated antenna and switch key and mobile terminal

ActiveCN103178326BSave internal spaceLow costAntenna supports/mountingsPrinted electric component incorporationFlexible circuitsEngineering

Owner:TCL COMM (NINGBO) CO LTD

Composite copper anode mold with improved service life and production method thereof

ActiveCN109853004BHigh mechanical strengthImprove thermal fatigue resistancePhotography auxillary processesProcess efficiency improvementChemical compositionCopper anode

The invention relates to the technical field of mold production in the metallurgical industry, in particular to a composite copper anode mold with improved service life, which includes a mold body on which a copper pouring cavity is opened, and the mold body is located on the upper part of the copper pouring cavity and is provided with a mold lifter The top mold hole, the mold body is located in the copper pouring cavity and is compounded with a layer of chromium-zirconium-copper alloy. The chemical composition weight percentage of the chromium-zirconium-copper alloy is: Cr:0.75-0.85, Zr:0.15-0.25, Mn< 0.0013, Mo<0.0003, Ni<0.0005, Fe<0.037, and the balance is Cu; the service life of the copper anode mold of the present invention is greatly extended, and the average copper pouring amount can reach more than 1000 tons / block.

Owner:湖北钜神材料科技有限责任公司

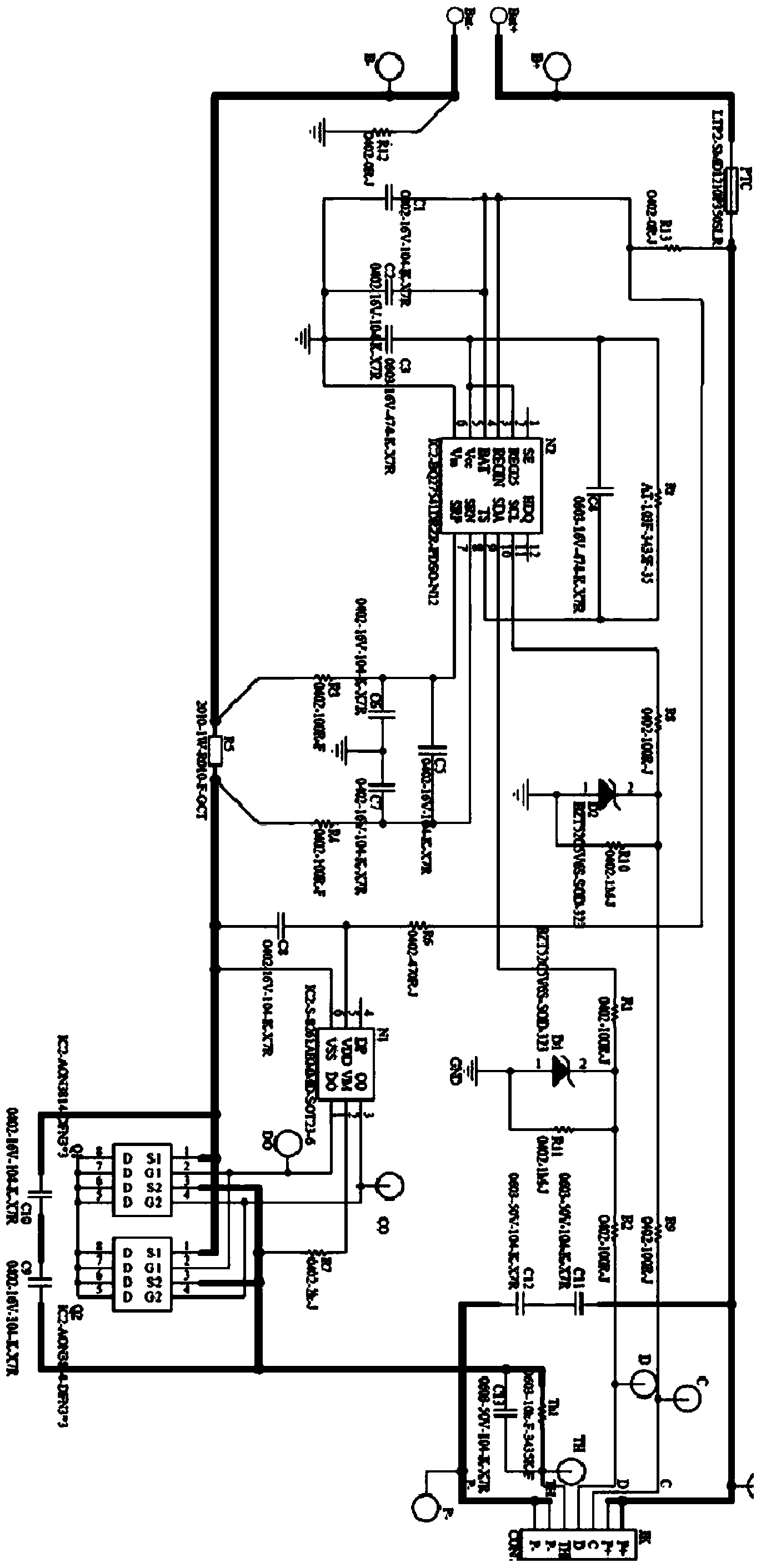

Lithium battery protection board circuit based on zero-ohm resistance element

InactiveCN104300510ASimple manual welding jump pointReduce processing timeEmergency protective circuit arrangementsCapacitanceMicrocontroller

The invention discloses a lithium battery protection board circuit based on a zero-ohm resistance element. The lithium battery protection board circuit based on the zero-ohm resistance element comprises a first control switch, a second control switch, a PTC overcurrent temperature protector, a first microcontroller, a second microcontroller, an interface circuit, resistors from a first one to a fourteenth one, capacitors from a first one to a thirteenth one, a first diode and a second diode, wherein the twelfth resistor is in single point grounding, the thirteenth resistor is a jump-joint, and both the twelfth resistor and the thirteenth resistor are zero-ohm resistors. According to the lithium battery protection board circuit based on the zero-ohm resistance element, direct SMT can be achieved when the zero-ohm resistors play the role of the jump-point, traditional manual welding jump-points are simplified, and therefore machining time in the production and manufacturing process is shortened; when the zero-ohm resistors are all in jump-point single point grounding, in the process of a PCB design, a ground line is divided into two networks, errors are not prone to occur in the process of processing like large-area copper pouring, and in addition, the ground line can be used as a fuse; when the zero-ohm resistors play a role in crossover, in the process of the PCB design, the number of layers of PCBs can be reduced, and therefore machining cost of the PCBs is saved, and the PCBs are relatively attractive and convenient to install.

Owner:四川鑫远志空间信息科技有限公司

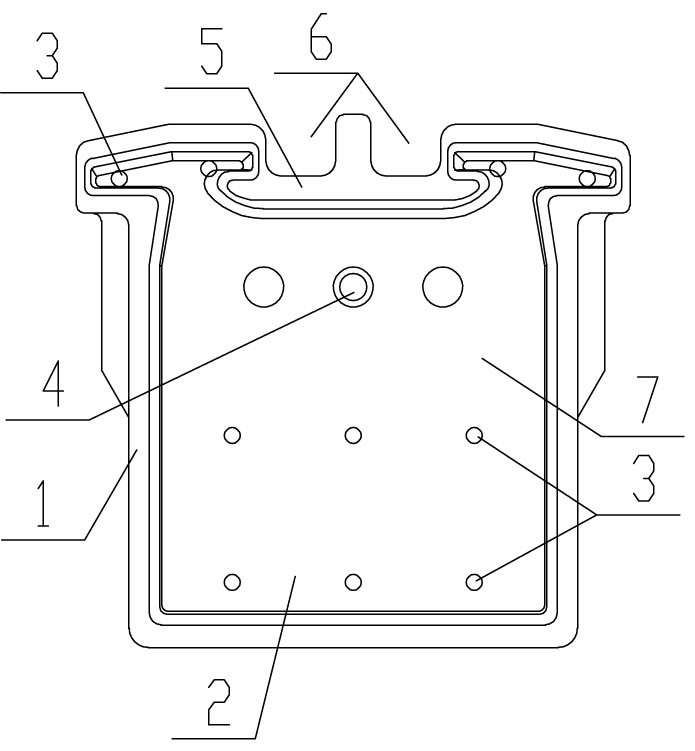

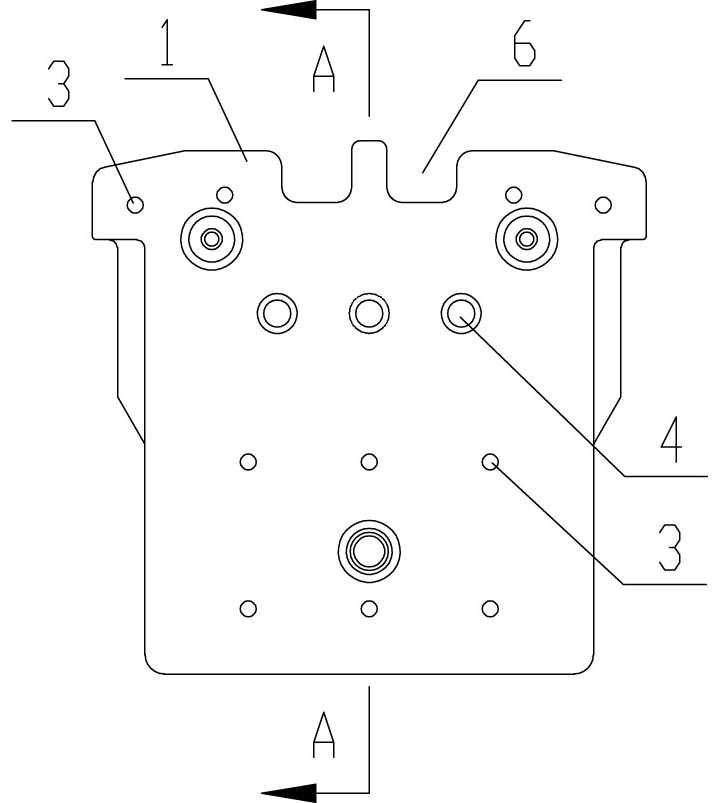

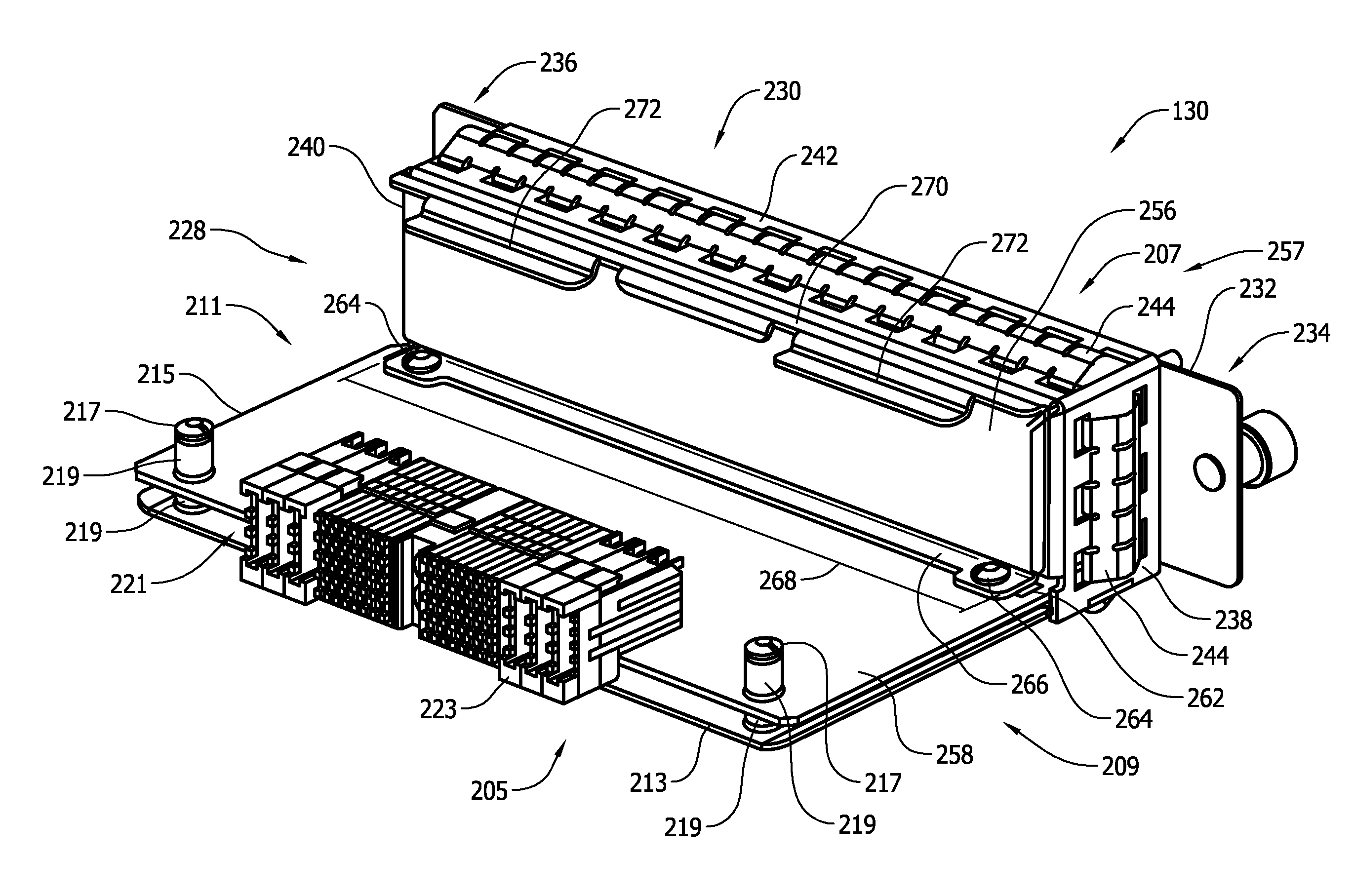

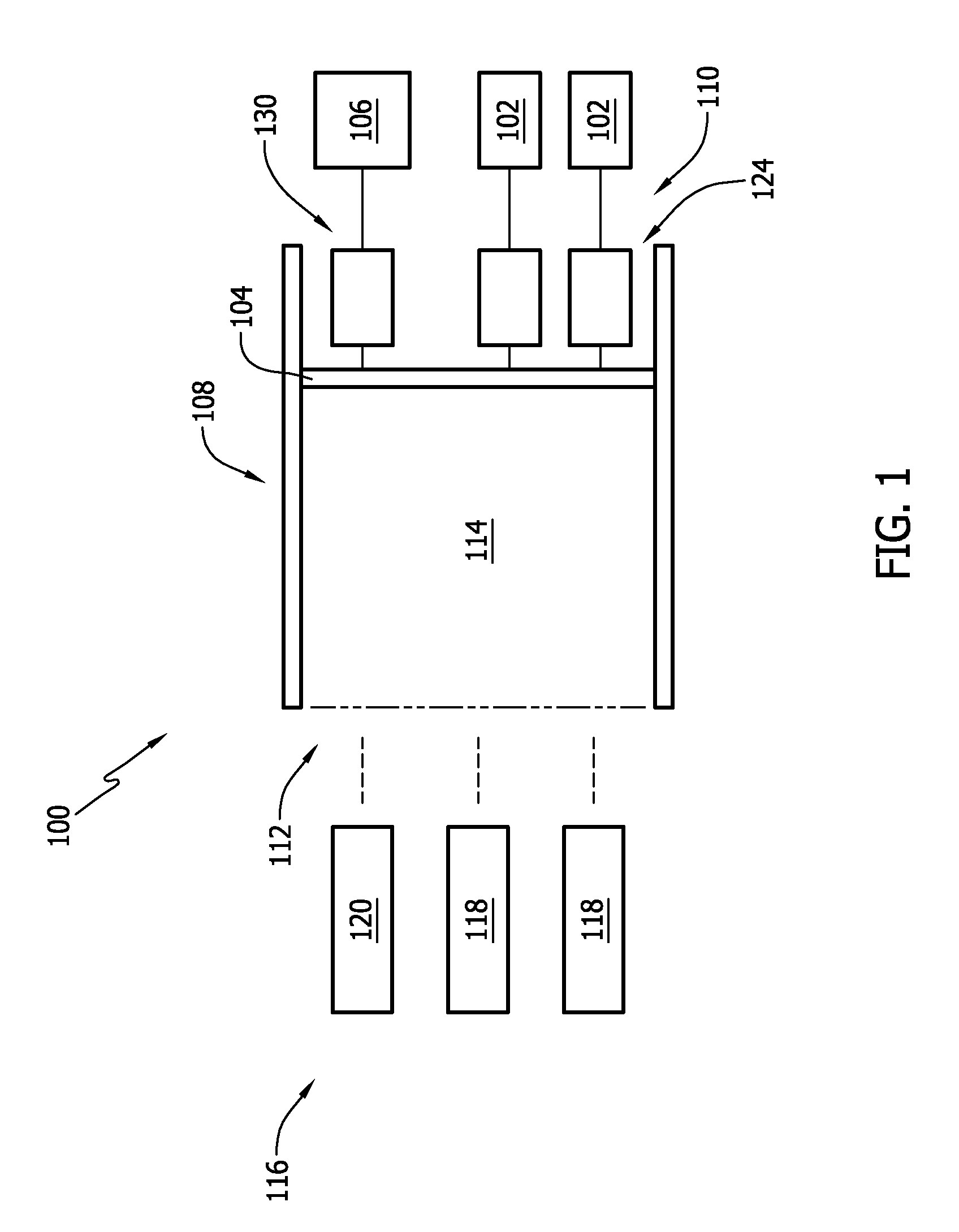

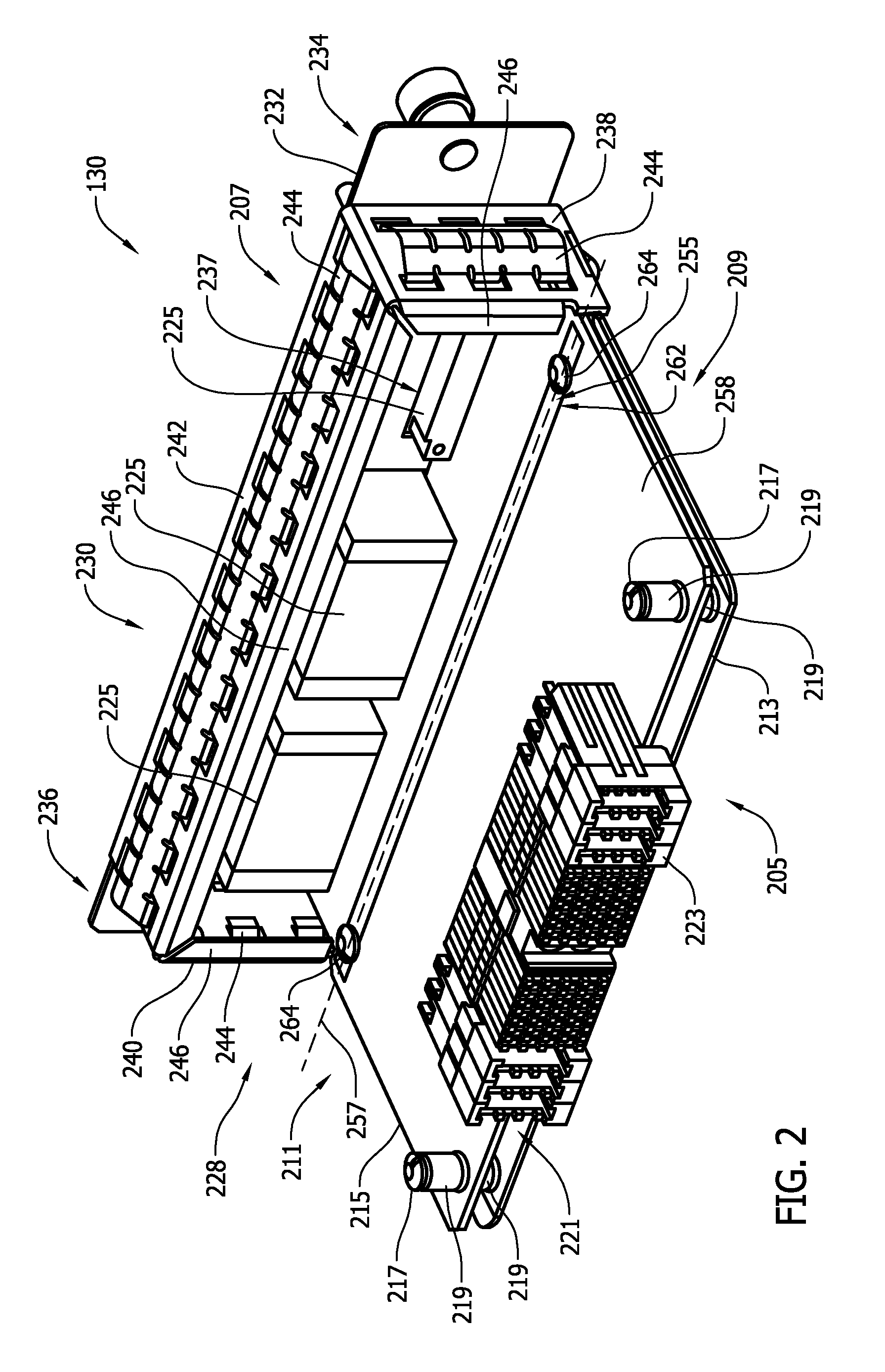

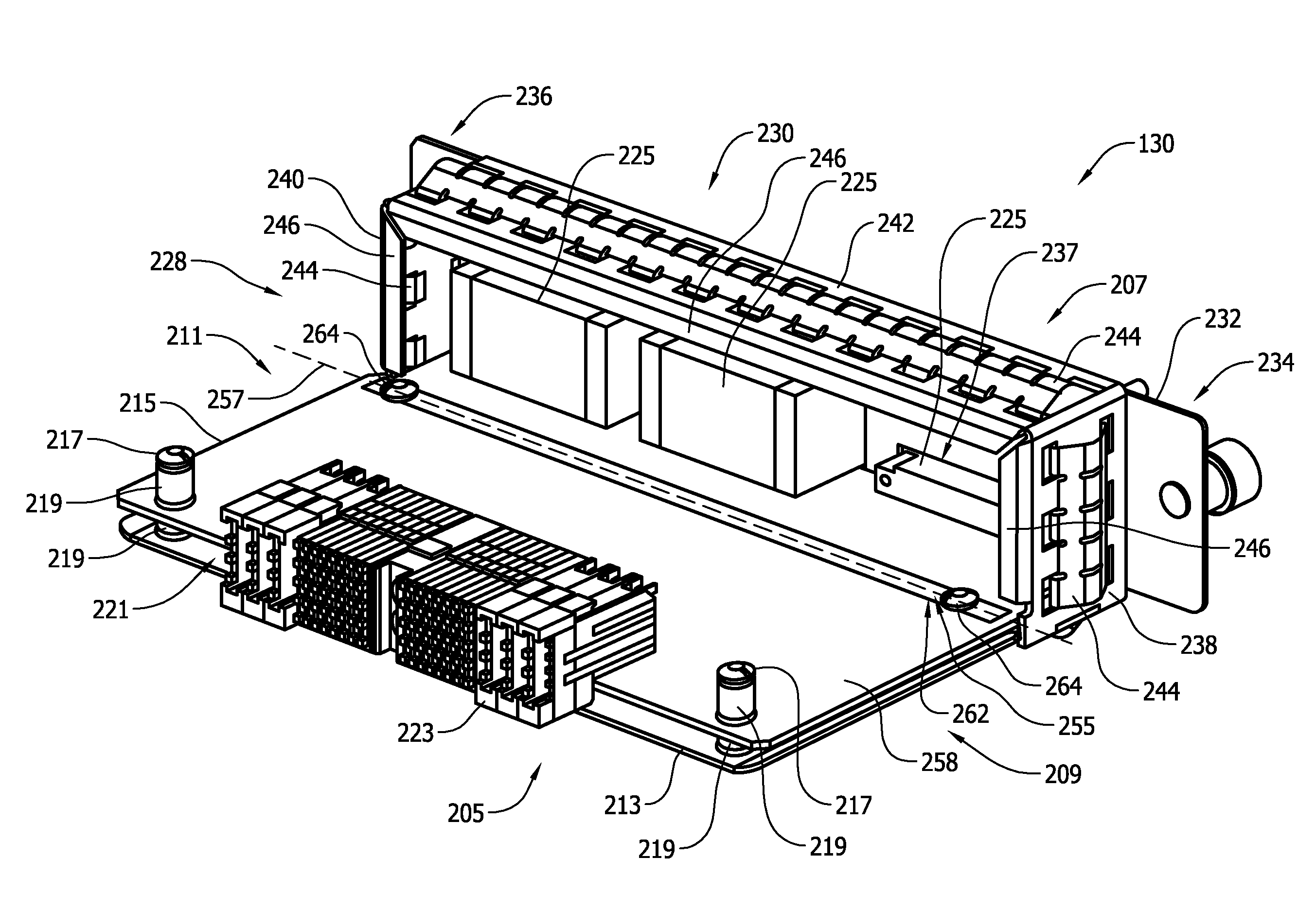

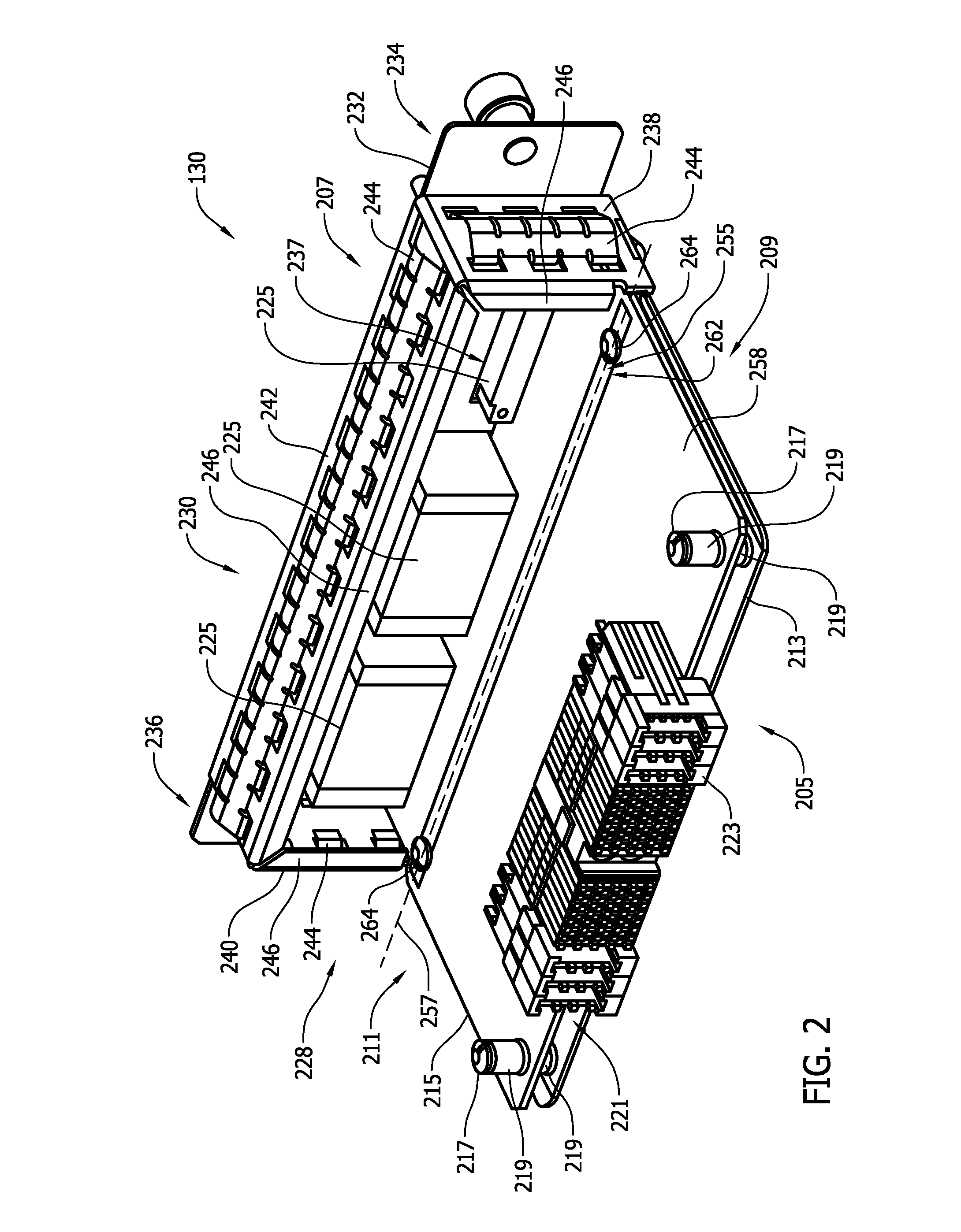

Module for use with a monitoring system and method of assembling same

ActiveUS9095056B2Line/current collector detailsElectrically conductive connectionsMonitoring systemEngineering

A module for use with a monitoring system is provided. The module includes a circuit board that includes a plurality of ground planes. At least two of the plurality of ground planes are coupled using a plurality of vias. The module further includes a copper pour coupled to the circuit board adjacent to the plurality of vias. The module further includes a housing that includes a dam wall that is coupled to the copper pour.

Owner:BAKER HUGHES HLDG LLC

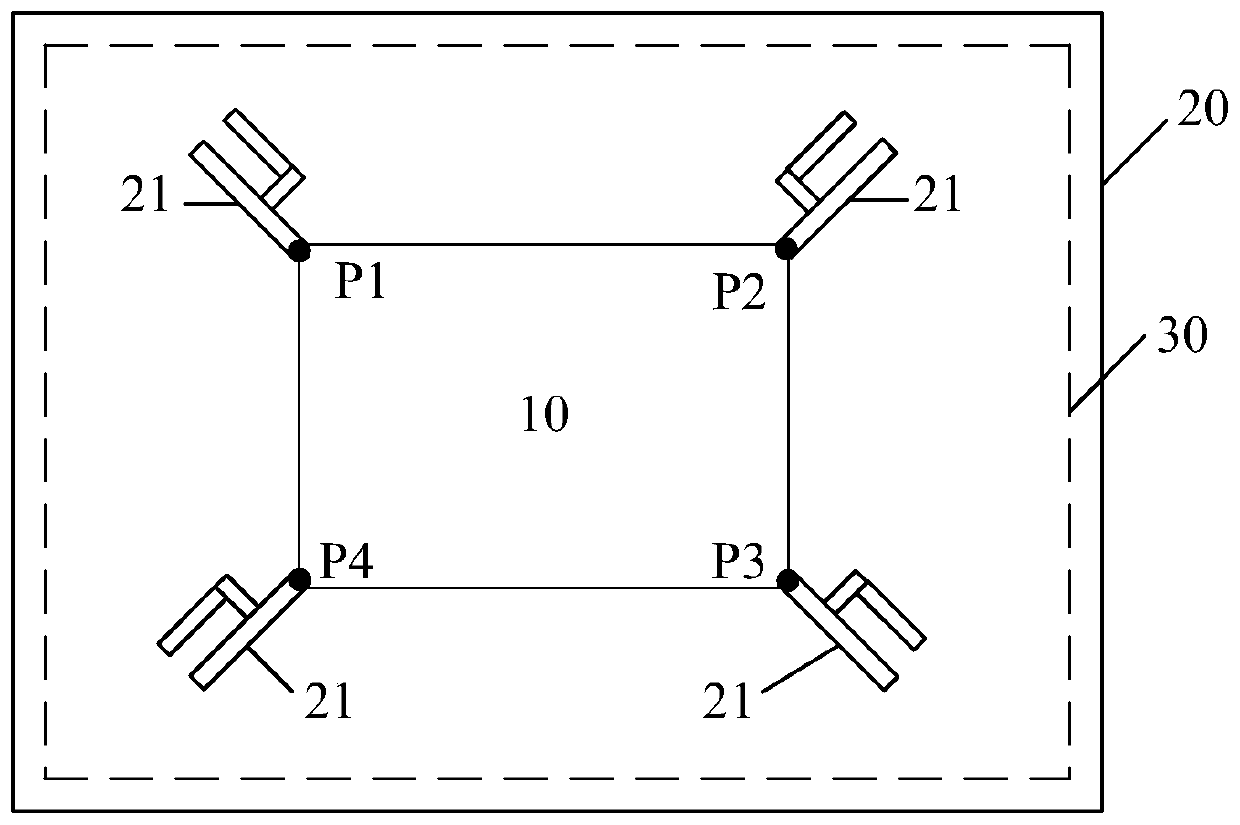

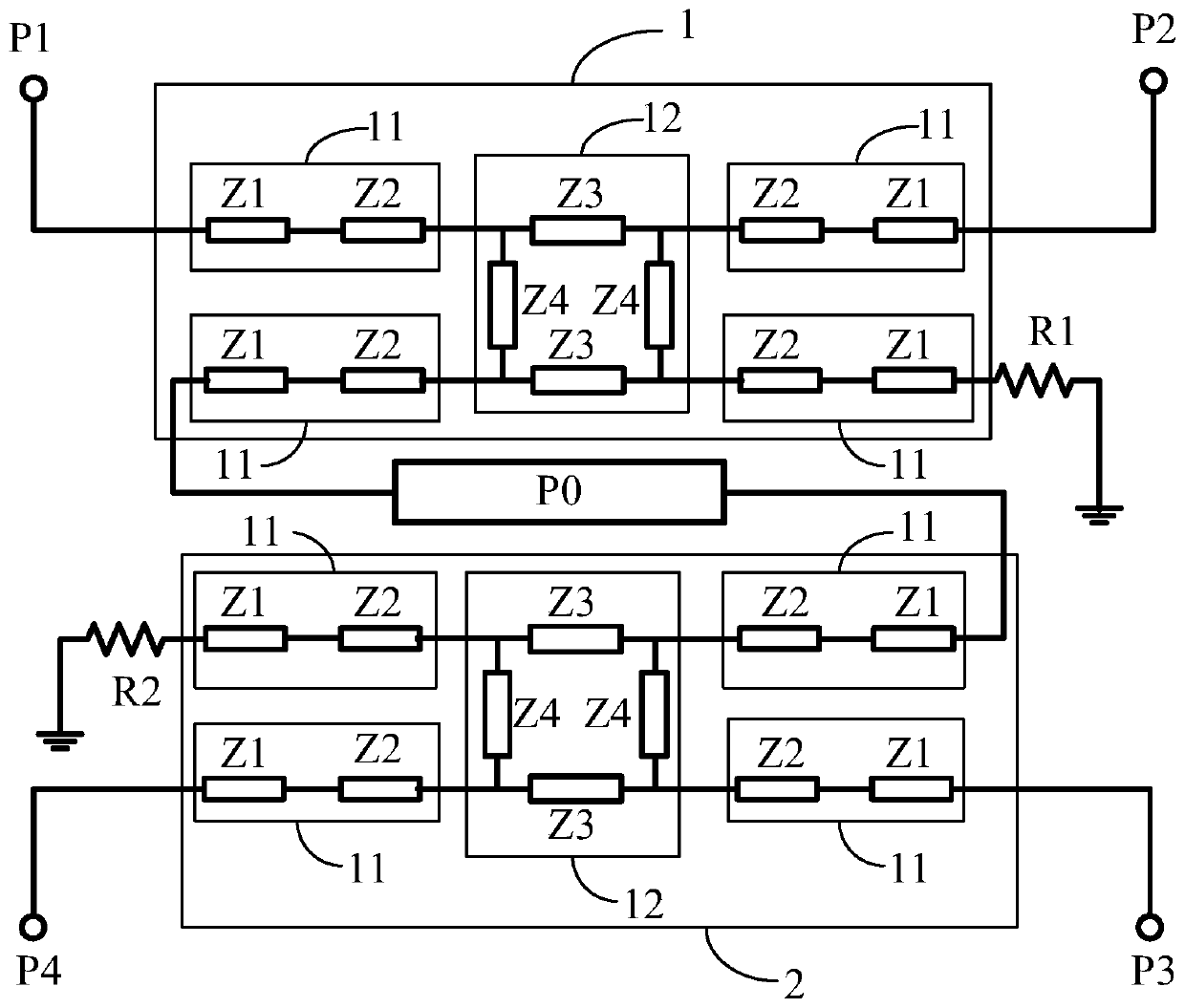

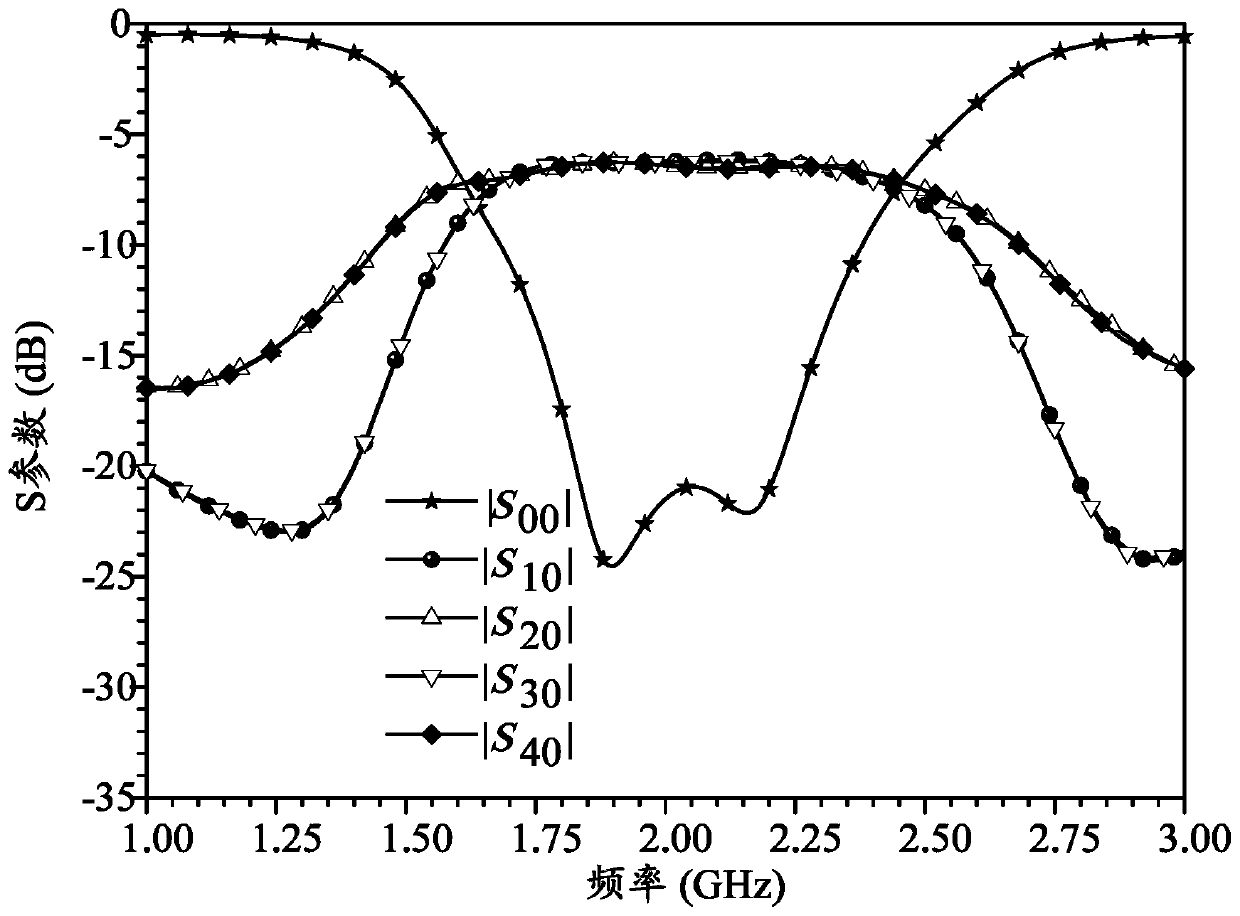

Dual-band Broadband Patch Circularly Polarized Antenna

InactiveCN108258416BGood circular polarization performanceMiniaturizationSimultaneous aerial operationsAntennas earthing switches associationCircularly polarized antennaDielectric plate

The invention discloses a dual-frequency broadband patch circularly polarized antenna, which includes a dielectric plate and a copper-clad metal ground. Four dual-frequency monopole radiation patches and a feeding network are arranged on the dielectric plate. The four dual-frequency monopoles are The radiation patch is connected to the four ports of the feed network in turn. The feed network includes a coaxial connector, a first dual-frequency coupler and a second dual-frequency coupler. The signal line of the coaxial connector is connected to the first dual-frequency coupler. The input end of the coaxial connector is connected to the input end of the second dual-band coupler. The through end of the first dual frequency coupler is connected to the first port, the coupling end of the first dual frequency coupler is connected to the second port, the isolation end of the first dual frequency coupler is connected to the first resistor; the through end of the second dual frequency coupler is connected to the first port. The terminal is connected to the fourth port, the coupling terminal of the second dual-frequency coupler is connected to the third port, and the isolation terminal of the second dual-frequency coupler is connected to the second resistor. The present invention realizes the miniaturization, dual-frequency characteristics or broadband characteristics of the circularly polarized antenna through the reasonable layout of the feed network.

Owner:X TRIP INFORMATION TECH CO LTD

Module for use with a monitoring system and method of assembling same

ActiveUS20130294036A1Printed circuit assemblingLine/current collector detailsMonitoring systemEngineering

A module for use with a monitoring system is provided. The module includes a circuit board that includes a plurality of ground planes. At least two of the plurality of ground planes are coupled using a plurality of vias. The module further includes a copper pour coupled to the circuit board adjacent to the plurality of vias. The module further includes a housing that includes a dam wall that is coupled to the copper pour.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com