Copper coated substrate material and flexible circuit board having the copper coated substrate material

A technology for flexible circuit boards and substrates, which is applied in the directions of printed circuits, printed circuits, and printed circuit manufacturing, and can solve the problems of low substrate yield, easy disconnection, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution will be further described below in conjunction with multiple embodiments and drawings.

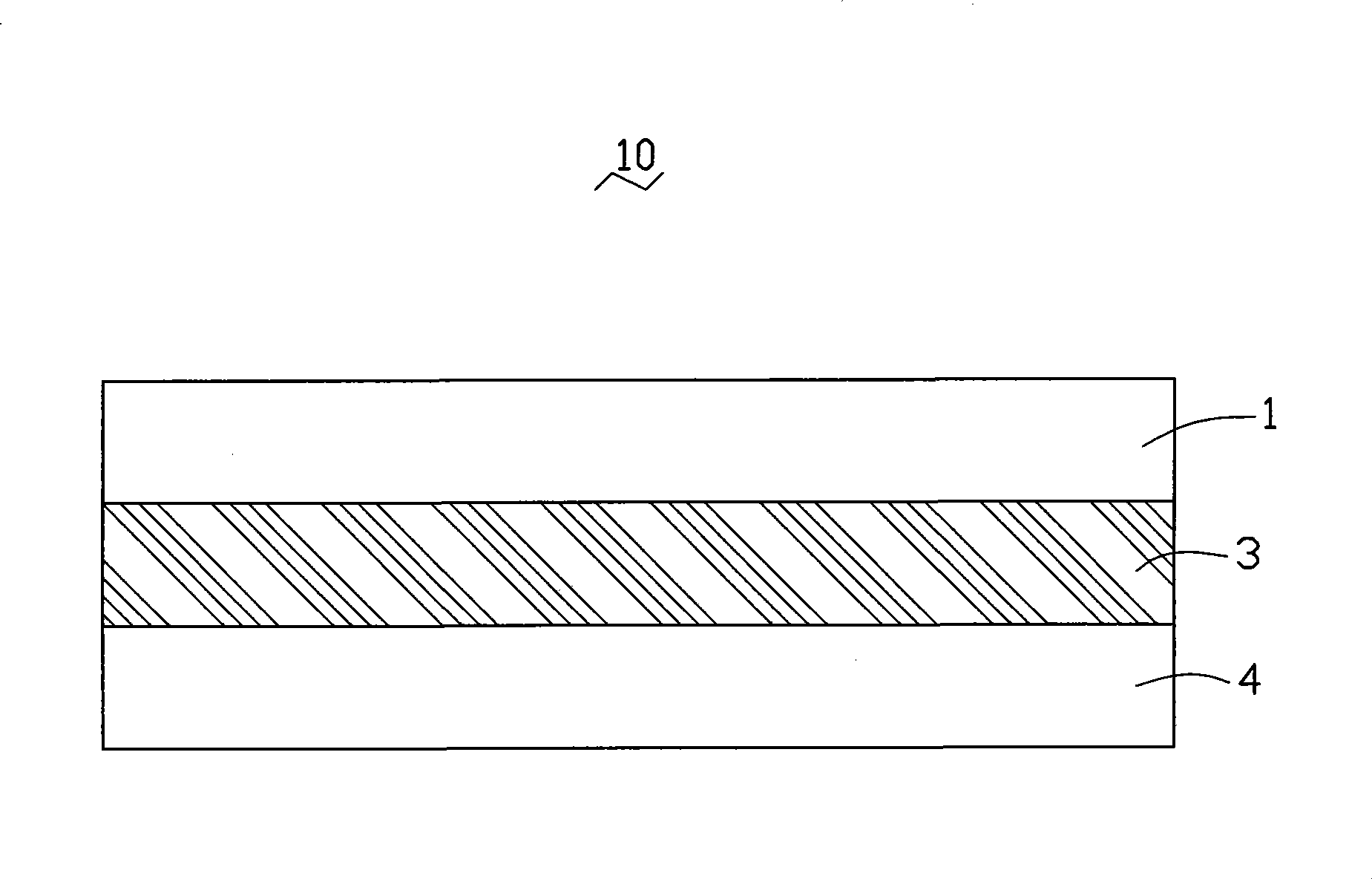

[0015] see figure 1 , which is the first embodiment of the copper-clad substrate provided by the technical solution. The copper-clad substrate 10 includes an insulating substrate 3 , a first copper foil 1 and a second copper foil 4 located on opposite sides of the insulating substrate 3 . The first copper foil 1 is an electrolytic copper foil, and the second copper foil 4 is a rolled copper foil. The insulating substrate 3 is polyimide resin or other insulating resin commonly used in flexible circuit boards, such as polyethylene, polyethylene terephthalate, polytetrafluoroethylene, polythioamine, polymethacrylate ester, polycarbonate or polyimide-polyethylene-terephthalate copolymer, etc. The first copper foil 1 can be directly formed on one surface of the insulating substrate 3 by hot pressing, and the second copper foil 4 can be directly formed on the oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com