Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

159 results about "Color Stone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High ornamental environment-friendly type integral seamless grinding stone terrace and manufacturing technique thereof

ActiveCN101168997AImprove wear resistanceExtended service lifeSolid waste managementOrnamental structuresEpoxyWax

The invention discloses a highly decorative environment-friendly integral seamless burrstone terrace and a manufacturing process thereof. After the ground is pretreated through burnishing, etc., epoxy resin varnish is used for bottoming and then epoxy mortar paint is used for basal plane alignment; a die is positioned according to pre-designed patterns, then epoxy burrstone terrace pulp including burrstone aggregate such as shell chips, glass fragments, plastic chips, stained stone chips, etc. is poured into the die, after the pulp is solidified, epoxy burrstone terrace pulp, the colors and (or) the burrstone aggregate of which is obviously different from the pattern layer, is poured outside the pattern layer; after the pulp is solidified, a buffing machine is used for buffing; epoxy resin clear lacquer is coated integrally; finally floor wax is applied all over for maintenance. The process can enable that almost any pattern can be presented on the terrace unrestrictedly, thereby high-lighting the decorative effect of the terrace. The terrace has the advantages of environmental protection, firmness, wear resistance, long service life and chemicals resistance, etc., thereby being widely applied to the decoration and the fitment of the ground of large public buildings and exclusive private residences such as airports, guesthouses, hotels, conference centre, exhibition halls, etc.

Owner:广州秀拍化工涂料有限公司

Inorganic dry powder sand textured architectural coating and production method thereof

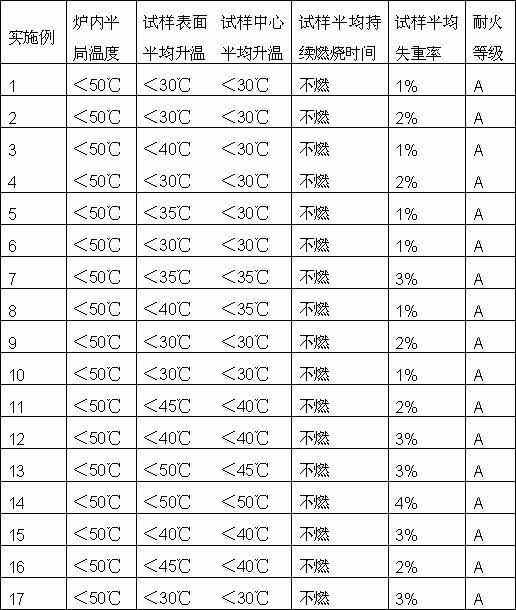

InactiveCN102617104AImitation stone effect is goodThere will be no color coverageLatex rubberFirming agent

The invention discloses an inorganic dry powder sand textured architectural coating which comprises the components of colored sand, colored stone flour, alkali metal silicate, a curing agent and organic redispersible latex powder. The bonded substance of the inorganic dry powder sand textured architectural coating provided in the invention is transparent, and the color of the colored sand and the colored stone flour is fully showed; therefore, the inorganic dry powder sand textured architectural coating has a good texture effect similar to stone, and fire resistance of the coating satisfies the A grade of PRC GB50222 standard, i.e., the coating is an incombustible inorganic dry powder sand textured coating.

Owner:SHANGHAI GIANT ENERGY SAVING MATERIALS

A new type of real stone paint

InactiveCN102277059ASolve environmental pollutionHigh simulationAnti-corrosive paintsCelluloseEnvironmental resistance

The invention relates to the field of paints, in particular to a new type of real stone paint, which contains: 80-120 parts by weight of water, 3-10 parts by weight of film-forming aids, 1-3 parts by weight of cellulose, 1-3 parts by weight of preservatives, 1-5 parts by weight of mold agent, 10-15 parts by weight of propylene glycol, 100-200 parts by weight of silicon-acrylic emulsion, and 650-800 parts by weight of stone powder. The stone waste is crushed and processed separately, and ground into a powder with a fineness of 60-100 mesh. First, add water into the batching tank, and then add film-forming aids, cellulose, preservatives, anti-fungal agents, propylene glycol, and silicon-acrylic emulsion while stirring. , stone powder, and finally stirred evenly, it is the finished product. The real stone paint prepared by the above process solves the environmental pollution problem of stone waste; the simulation effect is realistic, and the texture look and feel is the same as that of natural stone; water-based environmental protection is non-toxic and non-combustible, energy-saving and environmentally friendly; construction Simple and easy to change colors.

Owner:吴锦章 +1

Anti-cracking environment-protection paint and method for preparing the same

The invention discloses an anti-cracking environmental-friendly coating, which is characterized in that the anti-cracking environmental-friendly coating is formed by components with the following percentage by weight, such as water 30-35%, promoter 5-10%, powder 20-30%, elastic pure acrylic emulsion and silicon dissolvent 20-30%, strong anti-cracking fiber 5-10% and colored stone sand 20-30%. The invention also discloses a process for preparing anti-cracking environmental-friendly coating. The anti-cracking environmental-friendly coating has the advantages of excellent anti-cracking effect, low production cost and the like.

Owner:刘春雨

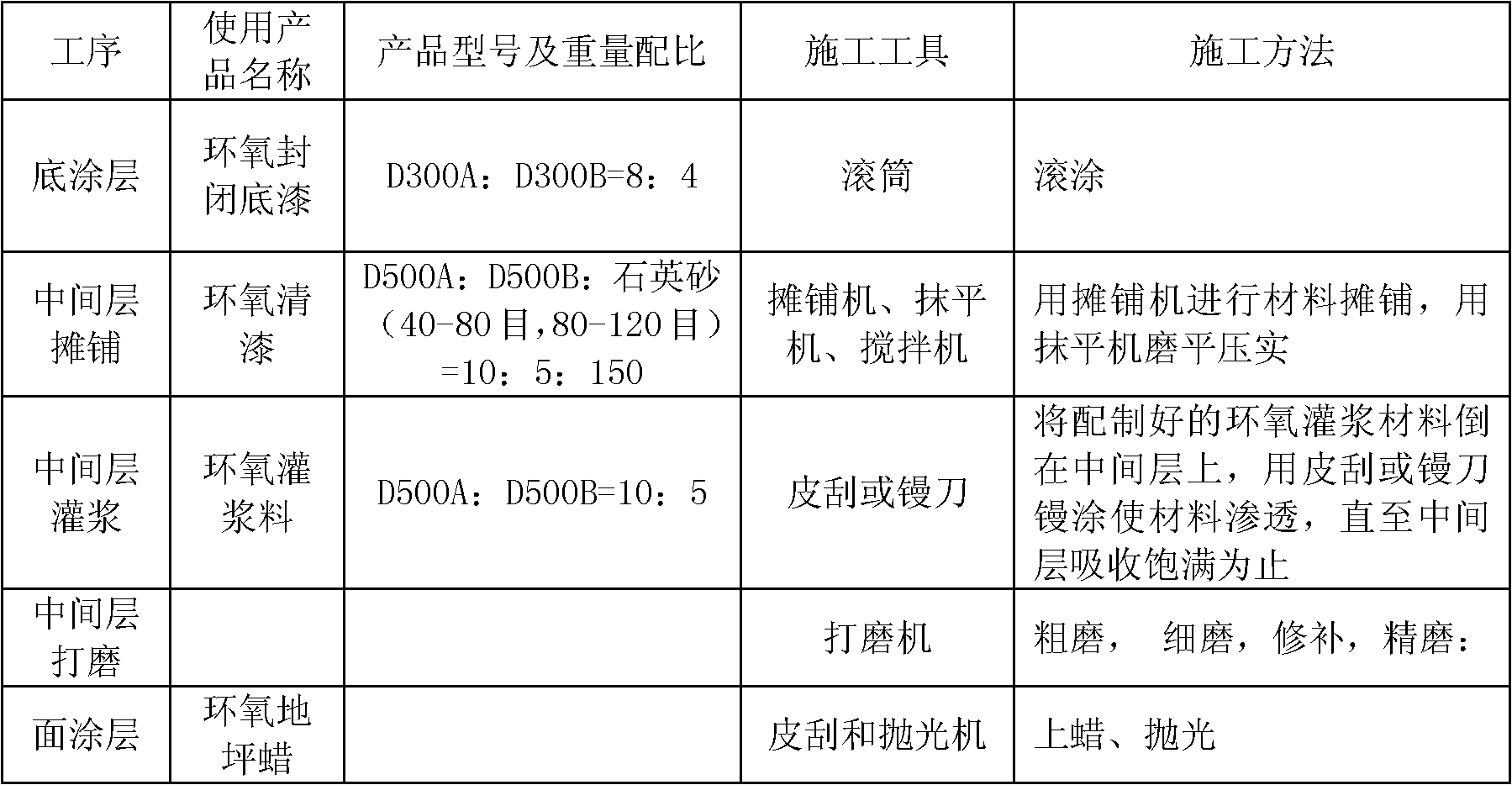

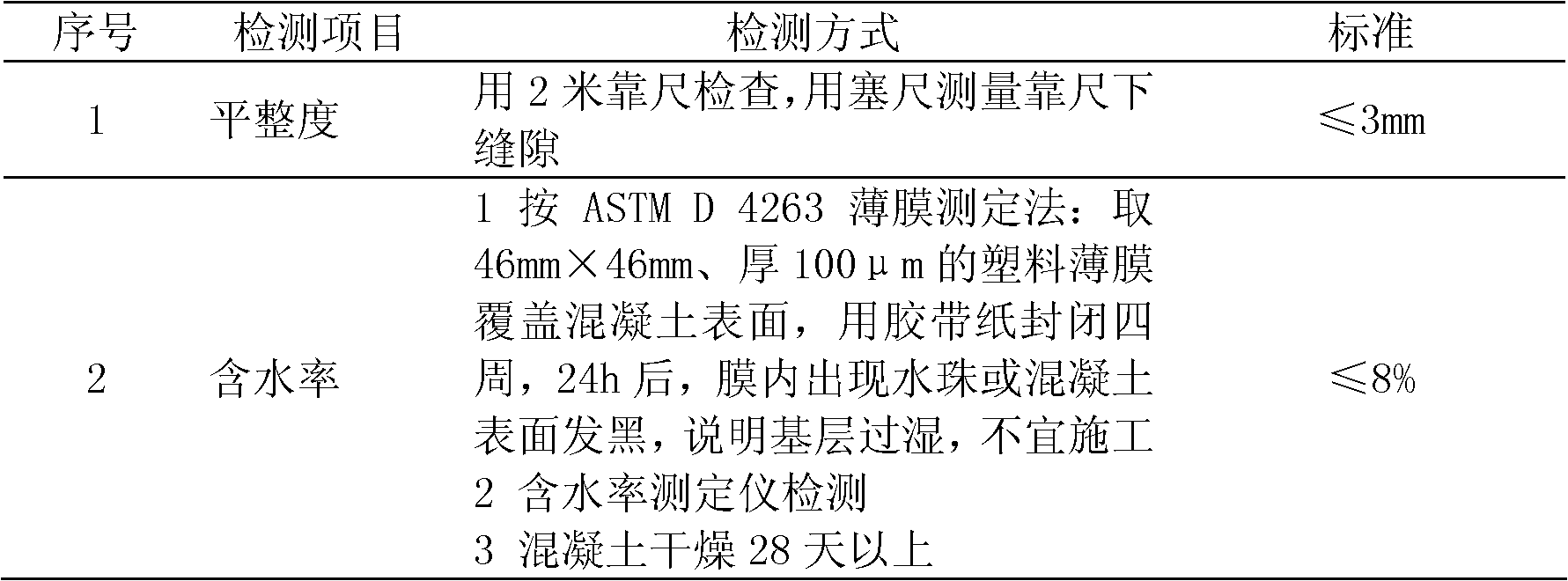

Method for manufacturing epoxy colored-stone terrace

The invention discloses a method for manufacturing an epoxy colored-stone terrace, and belongs to the field of building construction. The method comprises the following steps of: treating a base layer, coating priming coat, paving, grouting, polishing, and coating finish coat to obtain the epoxy colored-stone terrace on the ground. According to the epoxy colored-stone terrace, colored quartz sand which has one or more colors are freely matched so as to form rich decoration colors and colorful patterns; and the epoxy colored-stone terrace has the advantages of grace and vivid decoration texture, wear resistance, compression resistance, chemical resistance, temperature variation resistance, skid resistance, fire protection, water resistance and the like, can be used as an industrial terrace, and also can be used in commercial and civil building ground.

Owner:FIRST NEW MATERIAL TECH DEV

Basic paint of spotted colored stone-like coating, preparation method and spotted colored stone-like coating

ActiveCN113429849AImprove water whitening resistanceImprove toughnessCoatingsPolymer scienceEthyl(hydroxyethyl)cellulose

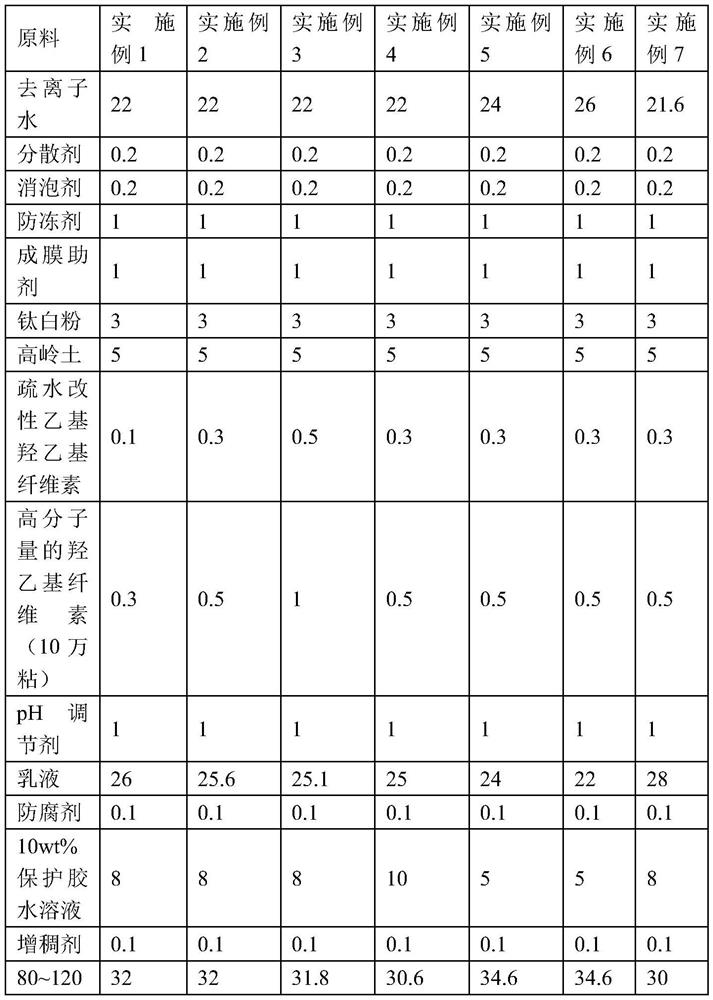

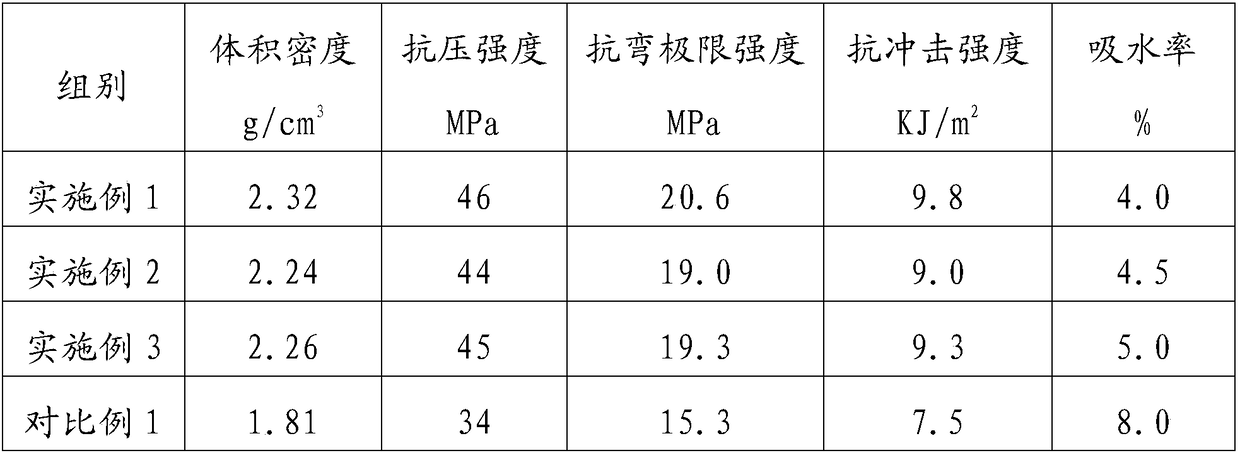

The invention relates to the field of stone-like coatings, and particularly discloses a basic paint of a spotted colored stone-like coating, a preparation method and the spotted colored stone-like coating. The basic paint improves the content of emulsion, cellulose is compounded by hydrophobic modified ethyl hydroxyethyl cellulose and high-molecular-weight hydroxyethyl cellulose, the toughness of the basic paint is remarkably improved, the prepared paint film is continuous and compact, the surface is smooth, and the stain resistance is excellent; the preparation method of the basic paint comprises the following steps: firstly, adding auxiliaries, a powder, the hydrophobic modified ethyl hydroxyethyl cellulose and the high-molecular-weight hydroxyethyl cellulose into the deionized water, and stirring at a low speed; then adding a pH regulator, and carrying out high-speed stirring at a rotating speed of 1500r / min; reducing the rotating speed to 1000 r / min or below, and adding the emulsion to prepare basic paint of the spotted colored stone-like coating; the spotted colored stone-like coating can be prepared by matching the basic paint with a granulation liquid and a continuous phase, the spotted colored stone-like coating has the stone imitation effect of real stone paint, the surface of a paint film is smooth, and has excellent stain resistance.

Owner:河北莱恩斯新材料科技有限公司

Waste earth and coal gangue fired hollow brick

InactiveCN105669167AReduce consumptionIntrinsic quality is stableCeramic materials productionClaywaresFiberCarbon fibers

A waste earth and coal gangue fired hollow brick is characterized by being made from the following components according to parts by weight: 40% of sludge, 25% of waste rock flour, 20% of coal gangue, 0.5% of plant straw powder, 3% of modified ceramic powder, 3% of sea mud, 1.5% of colored stone sand, 1.5% of violet sand, 0.5% of polyurethane powder, 0.5% of wood-plastic powder, 1.5% of aluminum silicate fiber, 1.5% of borax, 0.5% of sepiolite powder, 0.5% of carbon fiber, and 0.5% of kaolin.It is possible to save consumption of raw materials and ensure intrinsic quality stability of a formed blank; forming pressure is high, and blank strength is high; self-heat of the coal gangue is used in combustion, saving energy and reducing pollution; the coal gangue hollow brick produced by the process of the invention reduces self-weight of a building structure, improves building functionality and has good thermal insulation and acoustic insulation.

Owner:JINZHAI GAOFENG NEW BUILDING MATERIAL CO LTD

Sand-in-sand stone-like coating and preparation method thereof

The invention relates to a sand-in-sand stone-like coating. The sand-in-sand stone-like coating comprises water, a bactericide, a powdery thickener, a dispersing agent, a defoaming agent, a coalescingagent, propylene glycol, a pH regulator, a film forming matter, a liquid thickener, sintered color sand, a cross-linking agent and a protective adhesive. According to the sand-in-sand stone-like coating provided by the invention, the strength of color points is improved, and a ceramic color stone coating and a sand-in-water coating are combined into a whole. The sand-in-sand stone-like coating prepared by a method disclosed in the invention is formed by batch coating once. The sand-in-sand stone-like coating retains flatness of the ceramic color stone coating, maintains color diversity of thesand-in-water coating, and is shortened in a construction period.

Owner:上海贝塔建筑科技有限公司

Decorative concrete floor structure and manufacturing method thereof

ActiveCN103806356AImprove bearing capacityExquisite structureIn situ pavingsClimate change adaptationSurface layerCarrying capacity

The invention discloses a decorative concrete floor structure and a manufacturing method thereof. The decorative concrete floor structure is formed by lamellar pavement. The decorative concrete floor structure is characterized in that a lamellar structure is sequentially composed of a plain oil rolling base layer, a graded broken stone layer, a sand-free macro-porous pervious concrete layer and a decorative concrete surface layer from bottom to top, wherein the decorative concrete surface layer is divided into three parts along the driving direction; the distances from the two sides to a roadside are the same and are 300-500mm; a colored pervious concrete surface layers is paved on the decorative concrete surface layer; the residual part is a middle part and is internally paved with an aggregate-exposed natural colored stone concrete surface layer; a part from the middle line of the aggregate-exposed natural colored stone concrete surface layer to the two sides and a part from the colored stone concrete surface layer to the roadside are inclined downwards and the slope is 1%-2%. The road surface is attractive in appearance, anti-skidding and pervious; meanwhile, the decorative concrete floor structure has green functions of high carrying capacity, good durability and the like; rainwater can rapidly permeate to supplement underground water; the decorative concrete floor structure is applied to places including side pavements, roadways and the like of landscape garden paths, parking lots, fire fighting accesses, municipal side roads, residential districts, villa districts and the like.

Owner:BEIJING XI AO XING YE GARDEN LANDSCAPE ENG

Colored stone and fiber concrete artistic board as well as manufacturing method and application thereof

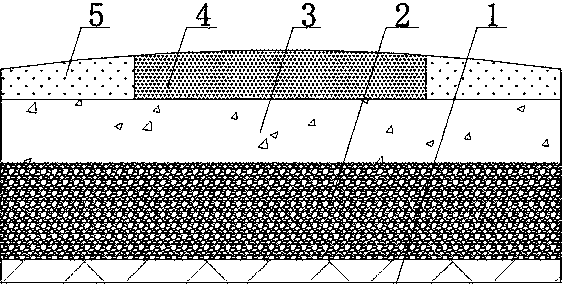

The invention relates to a colored stone and fiber concrete artistic board as well as a manufacturing method and an application thereof. The colored stone and fiber concrete artistic board is formed by at least two layers of structures including a base layer and a surface layer on the base layer, wherein the base layer is a fiber concrete layer and comprises raw materials as follows: macadam, medium sand, alkali-resistant glass fiber, cement, kaolin, a water reducing agent, a defoaming agent, cellulose ether, a retarder and water; the surface layer is a colored stone concrete layer, and comprises raw materials as follows: colored stone, quartz sand, cement, kaolin, a water reducing agent, a retarder, a coloring agent and water. The surface of the colored stone and fiber concrete artistic board has a natural stone effect, and the artistic board can be hung on an external maintenance structure of a building to replace natural stone to form a building decorative surface, and has the characteristics of beauty, economy, environment friendliness and high efficiency.

Owner:高志斌 +1

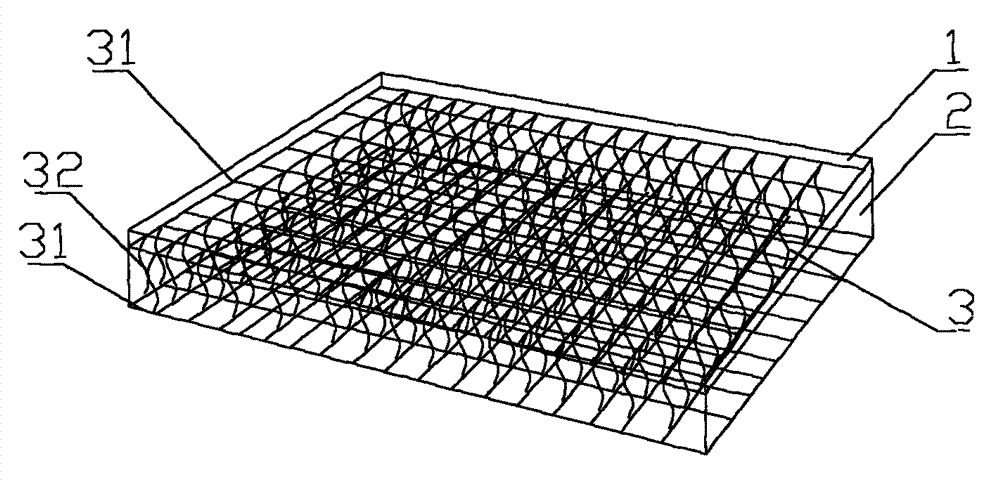

Manufacturing process for external wall decoration hanging plate

InactiveCN103924763ALow priceImprove liquidityCovering/liningsSolid waste managementCement mortarCoal

The invention discloses a manufacturing process for an external wall decoration hanging plate. The manufacturing process comprises the step of manufacturing a structure layer. The main raw material of the structure layer comprises coal ash, industrial wastes such as wear-resisting industrial waste molding sand, broken quarry scraps and colored quarry processing factory corner wastes. The manufactured structure layer is a color stone concrete layer or a color concrete layer or a cement mortar layer. The structure layer is filled with a 3D-structure alkali-resisting glass fiber mesh which comprises net-like alkali-resisting glass fiber cloth of the top face and the bottom face of a heat-preserving layer. Alkali-resisting glass fiber filaments arranged in the structure layer in a penetrating mode are uniformly distributed between the two pieces of the net-like alkali-resisting glass fiber cloth. Utilizing waste resources for producing the external wall decoration hanging plate, the manufacturing process has the advantage of low cost. In addition, the 3D-structure alkali-resisting glass fiber mesh is embedded into the structure layer, the related requirements of traditional external wall cladding can be met, and the strength and the shock-resistant, cracking-resistant and waterproof abilities are improved.

Owner:ANHUI HUAPU ENERGY SAVING MATERIALS

Marble-imitated natural mica paint and preparation method thereof

The invention discloses a marble effect imitating natural mica paint, which is characterized in that the weight proportions of the constituents are that water 30-35 percent, addition agent 5-10 percent, modifying silica sol 30-35 percent, color stone sand 30-35 percent, natural mica sheets 5-10 percent, the summation of all the constituents equals to 100 percent. Cellulose is added into the prescription according to requirement. The preparing method includes that firstly water, cellulose, addition agent are added in a stirring container and are mixed and stirred for 10-15 minutes; secondly, modifying silica sol is added in the container and is stirred for 10-15 minutes, and then color stone sand is added in and is mixed and stirred for 10-15 minutes; finally, natural mica sheets are added in the container, and is mixed and stirred for about 10 to15 minutes after being ball milled and dispersed; and then the product is finished after testing and packaging. The invention has fine performance, is environment-friendly and energy-saving, has moderate price, and has the unique decorative effects of marbles.

Owner:刘春雨

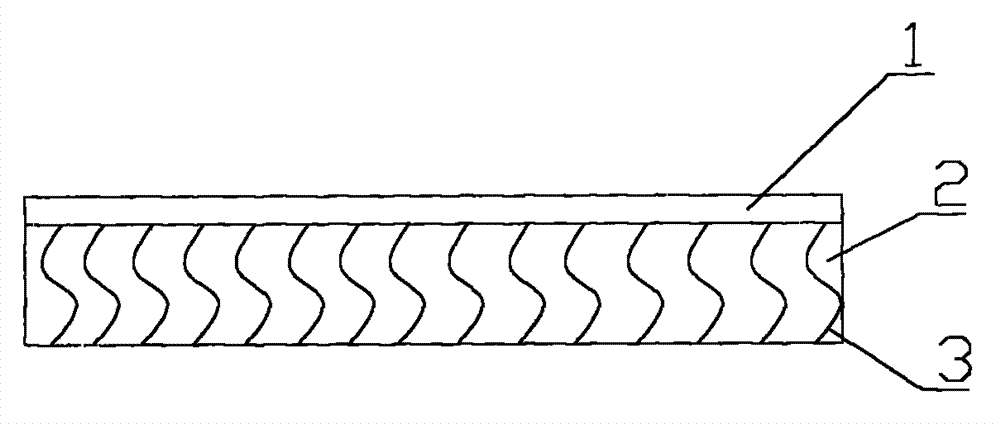

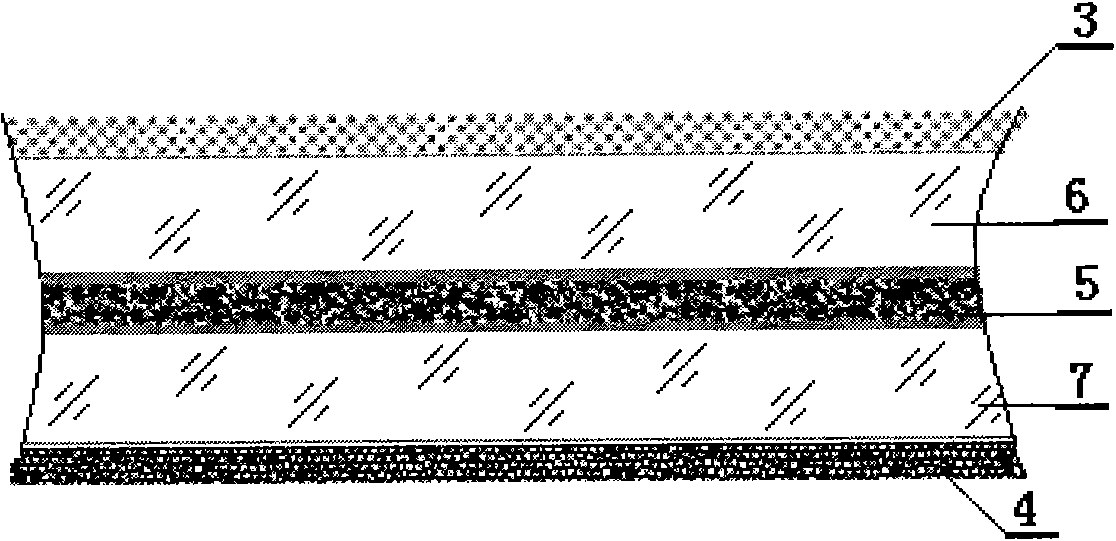

Waterproof heat-preservation composite material with self-adhesive layer

InactiveCN103967222AGood value for moneyEasy constructionRoof covering using slabs/sheetsBituminous material adhesivesSelf-healingPolystyrene

The invention discloses a waterproof heat-preservation composite material with a self-adhesive layer. The waterproof heat-preservation composite material with the self-adhesive layer comprises a metal waterproof layer, a heat preservation layer, a high polymer waterproof layer, a flame retardant layer and a self-adhesive and isolating layer which are arranged from top to bottom. Through the mode, high-viscosity self-healing pressure sensitive adhesive serves as a bottom layer, a polystyrene heat preservation plate or a polyurethane heat preservation plate serves as a middle layer, and colored stone tiles or colored steel tiles capable of lap joint serve as a top layer, so that the waterproof heat-preservation composite material with the self-adhesive layer is easy and convenient to construct, reliable in construction quality and high in the overall cost performance ratio, and has the waterproof, heat preservation and flame retardant effects.

Owner:宿迁金倍尔建筑材料有限公司

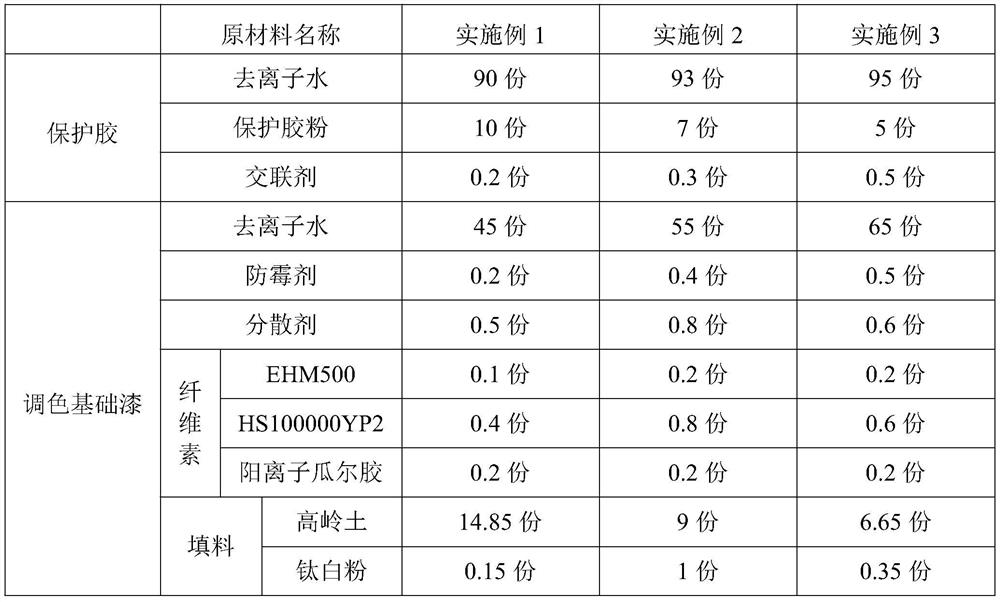

Sand-in-sand multicolor paint and preparation method thereof

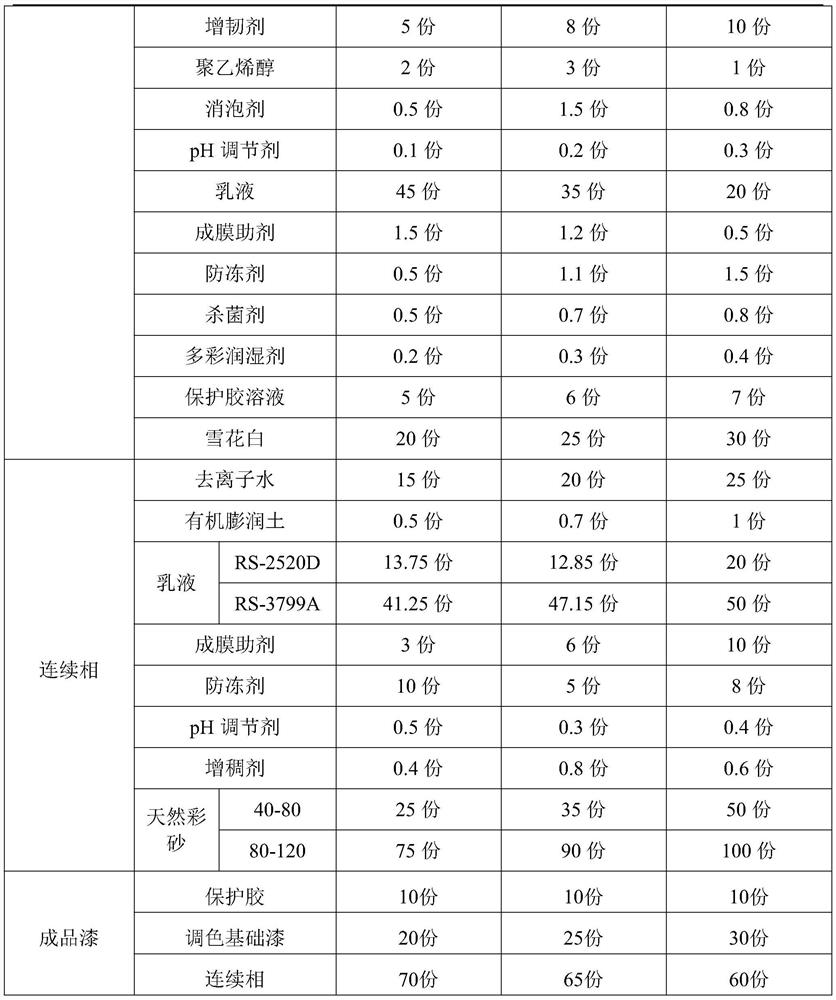

ActiveCN113122099AGuaranteed toughnessGuaranteed StrengthMulticolor effect coatingsColor StoneUltimate tensile strength

The invention relates to a sand-in-sand type multicolor coating which is mainly prepared from protective glue, a color matching base material, a continuous phase, a pH regulator and a thickening agent, wherein the mass ratio of the protective glue to the color matching base material to the continuous phase is 10:(20-30):(60-70); the pH regulator accounts for 0.1% of the total mass of the protective glue, the toning base material and the continuous phase; and the thickening agent accounts for 0.3-0.5% of the total mass of the protective glue, the toning base material and the continuous phase. The color points prepared by the preparation method are high in toughness and strength, so that the color points are not greatly deformed during spraying due to mutual extrusion of muzzles, the sensitivity to spraying air pressure is reduced, and the color points can be directly sprayed under high air pressure; therefore, the spraying efficiency is improved, and moreover, the colored stone is not easy to break, the whole colored stone is clear, and the stone imitation effect is good.

Owner:福建省三棵树新材料有限公司

Thermal-insulation reflective color stone paint and preparation method thereof

The invention discloses a thermal-insulation reflective color stone paint. According to a formula, the thermal-insulation reflective color stone paint comprises the following components in parts by weight: 750-1010 parts of color stone sand, 40-60 parts of quartz powder, 0.3-0.7 part of HPMC (Hydroxy Propyl Methyl Cellulose), 0.8-1.2 parts of starch ether SHE-05K, 70-90 parts of acrylic based emulsion 6021A and 8-12 parts of nanometer vitrified microspheres. The invention discloses a thermal-insulation reflective color stone paint which has the characteristics of waterproofness, acid and alkaline resistance, pollution resistance, no volatile matters, capability of imitating the decorative surface effect of natural stone, strong adhesion and colorfastness.

Owner:南通苏宝建筑节能科技有限公司

High-strength water-resistant putty powder

This invention discloses a high intensity water-proof putty material suitable for metope decoration in the following proportion: double-fly powder: 30-70, ash calcium powder: 30-70, methyl-fibrin: 0.025-1.5 and French blue: 0.02-0.15, in which, white cement, cassava starch and natural free of radioactivity color stone powder are added to produce color putty.

Owner:刘超

Imitation natural stone sheet and making process thereof

The invention discloses an imitation natural stone SMC / BMC sheet and a making process thereof, relating to a thermal insulating decoration material for a wall. Heat-resistant resin is adopted for the imitation natural sheet to increase the resin content, reduces the shrinking agent content, increases the ultraviolet-resistant absorbent and antioxidant, reduces calcium powder, and increases the aluminum hydroxide, natural color stone particles and real stone particles. The components of the raw material comprises resin, low shrinking agent, ultraviolet-resistant absorbent, antioxidant, dispersant, calcium powder, aluminum hydroxide, natural color stone particles, glass fiber, release agent, magnesium oxide and curing agent. The steps of confecting the low shrinking agent, mixing, adding filler, online mixing and thickening are performed to obtain the product. The invention can produce imitation stones and granite products of various colors and patterns and external wall panels of various veined patterns and tones as well as internal wall decoration board. The invention has the characteristics of aging resistance, no color change, great strength, high hardness, good flame retardant effect and the like, and is an excellent product for both indoor and external wall decoration.

Owner:山东中南集团有限公司

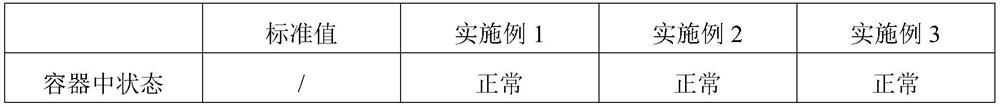

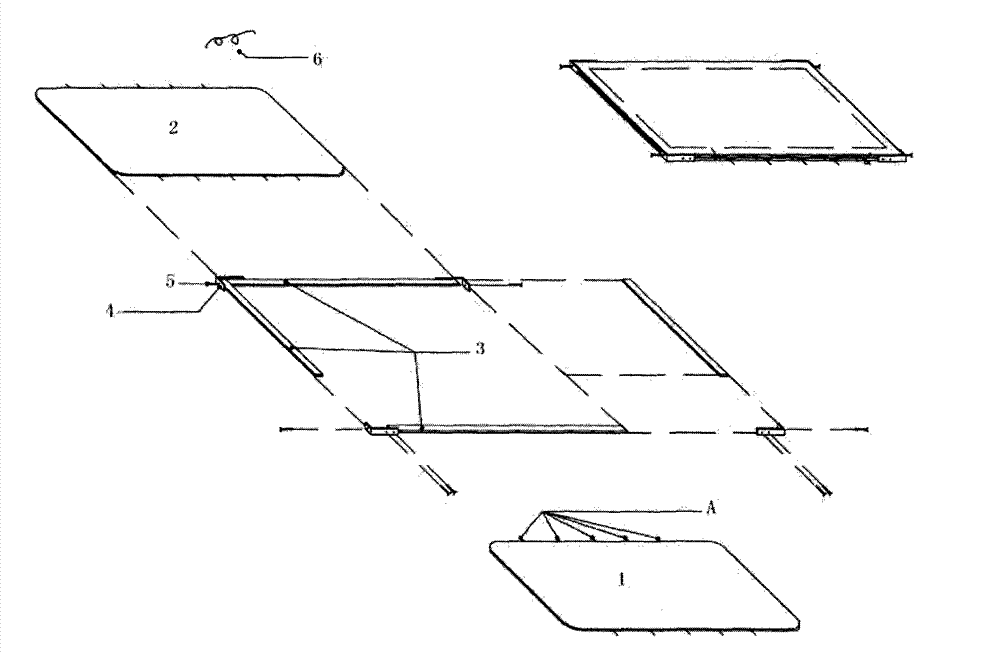

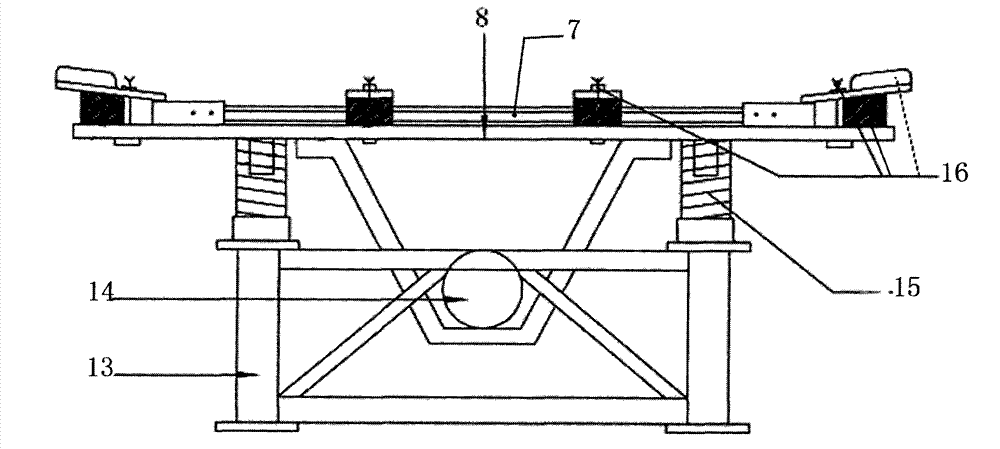

Process for manufacturing preformed color-stone concrete composite veneers

The invention relates to a process for manufacturing preformed color-stone concrete composite veneers, and belongs to the field of production process. The process includes laying a color-stone concrete layer (9), reinforcement meshes (10) and common fine aggregate concrete (11) to complete steps of manufacturing of blanks, patterning of decorative plates, manufacturing of hollow-out patterned plates, finished surface treatment and the like. The process has he advantages of low production cost, and products of the process have the advantages of no pollution or deterioration, capability of being recovered, high controllability in production scale, moderate price and the like.

Owner:李思全

Stone paint for wickerwork

InactiveCN104387855AImprove adhesionInsect resistantAntifouling/underwater paintsPaints with biocidesEmulsionLacquer

The invention relates to stone paint for wickerwork. The stone paint comprises colored stone powder, styrene-acrylic emulsion, a dispersant, titanium dioxide powder, dimethyl sulfoxide and a preservative solution. The stone paint for wickerwork has the advantages of good adhesion property, no toxicity, corrosion resistance, insect resistance and mildew resistance and has a good preservative effect on wood products coated with the stone paint.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

Preparation method for colored-stone foamed thermal-insulation decorative plate and product thereof

The invention relates to a preparation method for a colored-stone foamed thermal-insulation decorative plate. The preparation method comprises the following steps: step 1, preparation of a green body: mixing raw materials consisting of perlite, bentonite, zeolite, kaolin, travertine, black clay, green ceramic silicon powder, fluorite tailings, combustible carbon powder, gangue, short-cut basalt fiber and polypropylene short-cut fiber, then successively carrying out crushing, wet ball milling, uniform ageing, spray drying, granulation and pulverization, carrying out compacting and molding so as to obtain a biscuit and drying the biscuit so as to obtain the green body; step 2, preparation of a glaze and glazing: subjecting the raw materials for the green body, albite and potash feldspar to ball milling so as to obtain the glaze and glazing the green body with the glaze; and step 3, carrying out high-temperature sintering on the glazed green body so as to form the colored-stone foamed thermal-insulation decorative plate with the glaze and with closed pores uniformly and densely distributed in the green body. The colored-stone foamed thermal-insulation decorative plate provided by the invention has the technical effects of lightweight, thermal insulation performance, fire resistance, water resistance, high strength, aging resistance and wearing of a decorative surface.

Owner:浙江孚瓯科技有限公司

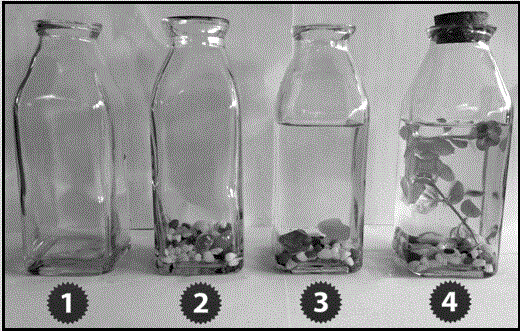

Ecological bottle with aquarium fishes

InactiveCN104521865APhysically strongStrong ability to adapt to the environmentBacteriaPisciculture and aquariaTemperature controlIntelligent lighting

The invention relates to an ecological bottle with aquarium fishes. The ecological bottle contains the aquarium fishes, green plants, a microbial flora, alga larvae, shells, color stones, ornaments, water, an automatic temperature control base and an intelligent lighting system. The ecological bottle is a stable ecological system manufactured based on the ecology principle and contains basic elements of a food chain, and in this way, the ecological bottle almost does not need water changing or feeding. If storage conditions are net and feeding is not performed, the survival time of the organisms in the ecological bottle can reach more than two mouths; if feeding is performed as required and matter cycle materials are supplied, the survival time of the organisms in the ecological bottle can reach more than half a year.

Owner:FUZHOU UNIV

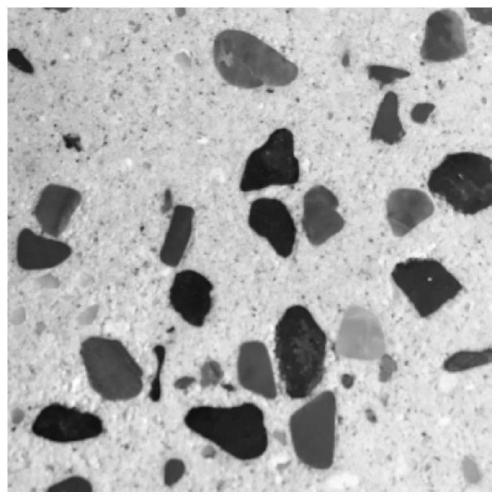

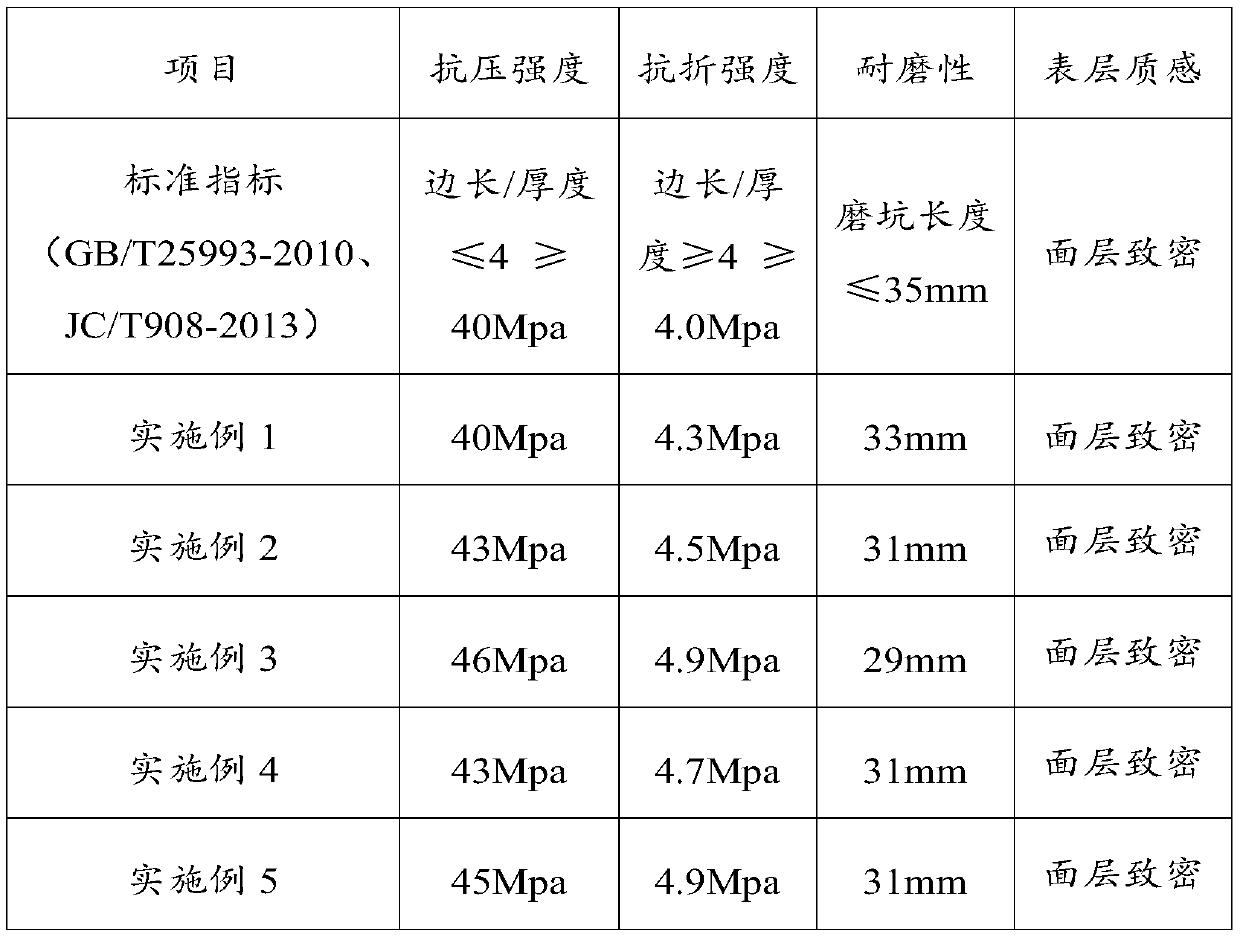

Concrete stone imitation brick and method for preparing same

The invention relates to the field of building materials, particularly relates to a concrete stone imitation brick and a method for preparing the same, and belongs to concrete products. The concrete stone imitation brick comprises base layers and surface layers. The base layers comprise, by weight, 40-80 parts of graded crush stone, 12-28 parts of base layer inorganic cementing materials, 4-8 parts of base layer water and 0.1-0.4 part of base layer water reducing agents; the surface layers comprise, by weight, 35-65 parts of compound fine sand with the particle sizes of 10-120 meshes, 10-40 parts of color stone with the particle size smaller than 5 mm, 15-30 parts of surface layer inorganic cementing materials, 4-8.7 parts of surface layer water and 0.1-0.4 part of surface layer water reducing agents. The concrete stone imitation brick and the method have the advantages that the concrete stone imitation brick prepared by the aid of the method is not constrained by mineral resources; the concrete stone imitation brick is excellent in compactness and weather resistance.

Owner:重庆亲禾生态环境科技有限公司

Moisture-proof mildew-proof color putty for inner walls

InactiveCN110294955APlay a moisture-proof roleGood absorption and decompositionFilling pastesCelluloseDecomposition

The invention discloses moisture-proof mildew-proof color putty for inner walls, and the moisture-proof mildew-proof color putty comprises the following components in parts by weight: 500-600 parts ofwhite cement, 400-500 parts of an inorganic filler, 3-10 parts of calcium lignosulphonate, 4-6 parts of a dry powder mildew preventive, 2-3 parts of a dispersant, 30-50 parts of color stone powder, 10-15 parts of redispersible rubber powder, 1-2 parts of starch ether, 3-5 parts of cellulose ether, 10-15 parts of xanthan gum, 10-20 parts of nano titanium dioxide, 5-10 parts of activated carbon, 5-10 parts of zeolite, 1-2 parts of graphene and 8-12 parts of super absorbent resin. The moisture-proof mildew-proof color putty for the inner walls has moisture-proof and mildew-proof effects and canabsorb harmful gases such as formaldehyde and the like in decomposition rooms.

Owner:四川威斯顿建材有限公司

True color stone art wall poster and preparation method thereof

InactiveCN105952077AAvoid failure problems after long-term storageAvoid failureCovering/liningsCoatingsEngineeringColor Stone

The invention discloses a true color stone art wall poster and a preparation method thereof; the true color stone art wall poster uses non-woven fabrics as the base material, and the surface is made by aqueous paint; the true color stone art wall poster is used for decorating and integrating the outer wall surface, thus providing decoration, beautifying, protection and functional effects in the same time; the method can prevent storage and transport nodes after production manufacturer raw material production, thus liberating unnecessarily used transport power; the aqueous paint long time storage failure problems can be prevented; the true color stone art wall poster and the preparation method thereof cannot cause scurviness influences on environment, can solve the inconsistent problems when workers spray products, and cannot pollute environment and waste materials during the spraying work under the natural environment.

Owner:王英俊

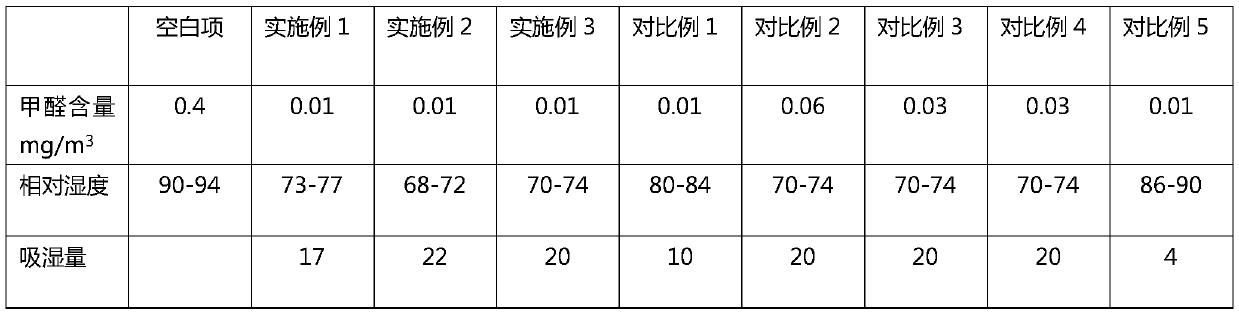

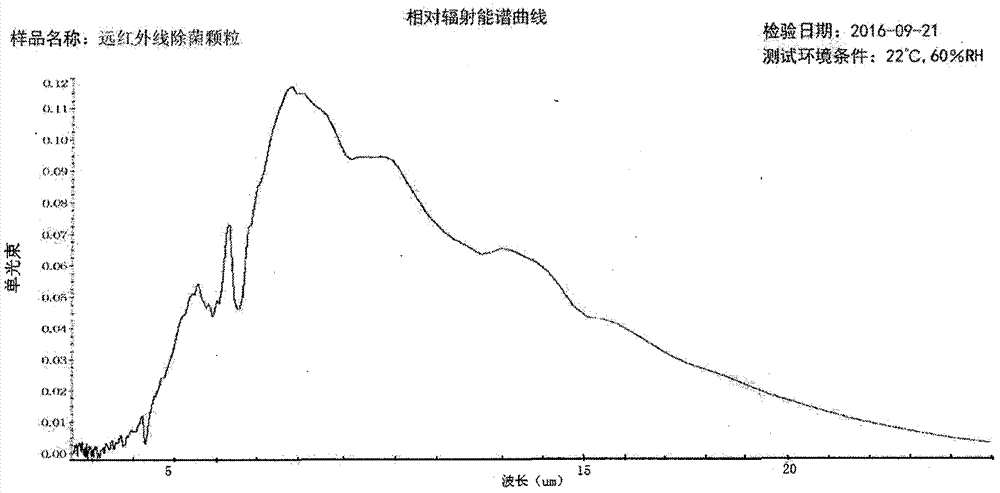

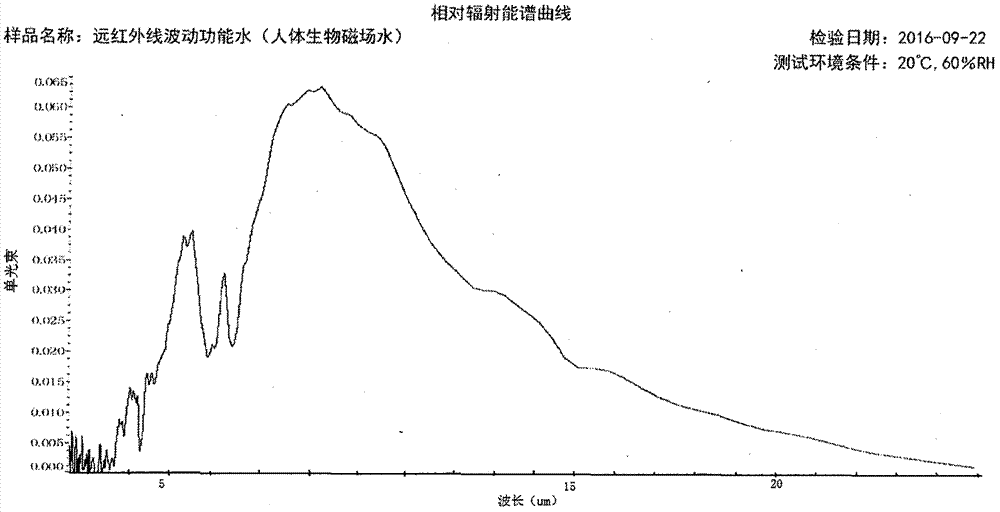

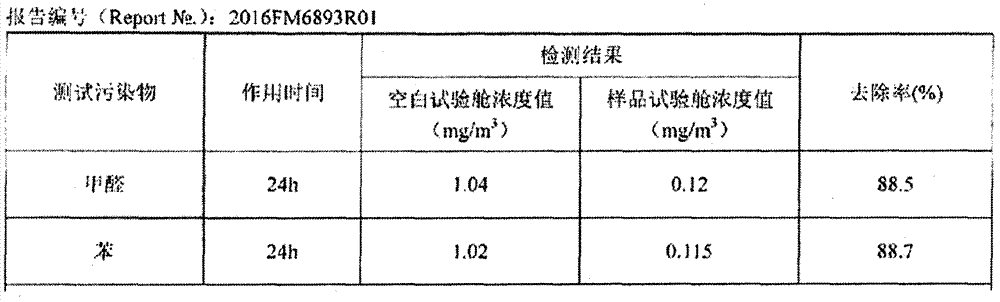

Antibacterial irradiator capable of radiating far infrared ray at normal temperature, immersed product, and preparation method thereof

InactiveCN108002805AHigh infrared emission efficiencyRadiationClaywaresChemical reactionFar infrared

The invention discloses an antibacterial irradiator capable of radiating far infrared ray at normal temperature, an immersed product, and a preparation method thereof. The antibacterial irradiator comprises one kind of or a plurality of kinds of circular particles which are mixed together; the circular particles are prepared via baking of mixed clay with a compound A, wherein the weight amount ofthe component A accounts for 10 to 15% of that of the mixture, and A is one selected from China medical stone, illite, diamond stone, Yingyang seven color stone, Gunma feldspar, and biotite; the immersed product is obtained via immersing the antibacterial irradiator in water for longer than 60min. The preparation method comprises following steps: clay is mixed with component A, water is added forstirring so as to obtain a plurality of circular particles; the circular particles are subjected to air dying, and are baked at 850 to 1200 DEG C. The antibacterial irradiator is excellent in indoor air purifying, bacteria removing, methanol and benzene removing effects. No battery is needed, no heating is needed, no special chemical reaction is needed, the antibacterial irradiator is capable of radiating far infrared ray with a wavelength ranging from 4 to 16mm at 22 DEG C, radiating rate ranges from 80 to 97%, the infrared emission efficiency is high, and the antibacterial irradiator is safe, and is friendly to the environment.

Owner:青岛创恩康生物科技有限公司

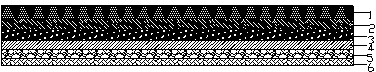

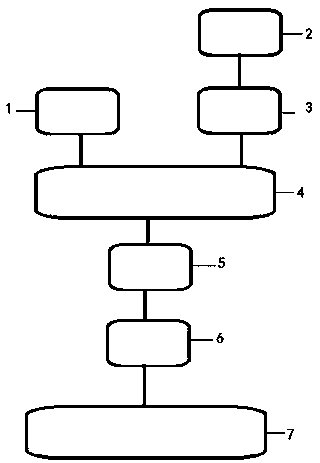

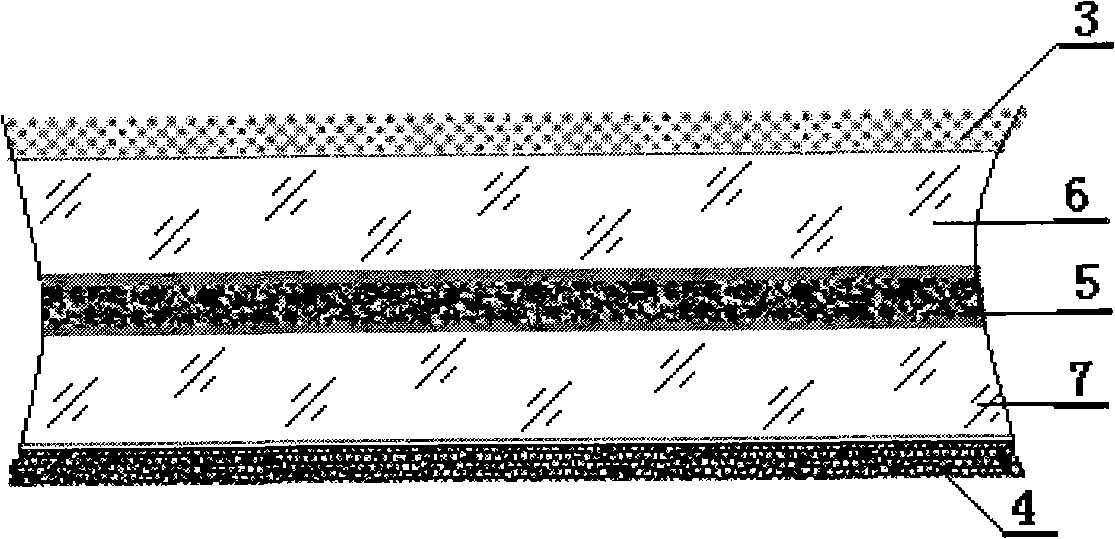

Integrated thermal-insulation energy-saving decorative sheet and manufacturing method thereof

InactiveCN103410287ASimple construction procedureGood quality and stabilityCovering/liningsCoatingsIodideThermal insulation

The invention relates to an integrated thermal-insulation energy-saving decorative sheet and a manufacturing method thereof. The integrated thermal-insulation energy-saving decorative sheet comprises a core material and a surface layer, wherein the core material is provided with gridding cloth; the surface layer is arranged on the core material; the surface layer is prepared from the following materials in parts by weight: base stock: 100 parts of polyamide modified silicone acrylic emulsion; auxiliaries: 12-15 parts of cured adipic acid dihydrazide, 2-3 parts of film-forming dodecanedioic tertiary alcohol, 0.1-0.3 part of defoaming dimethyl silicon oil, 0.5-0.7 part of mildew-proof agent, 0.1-0.3 part of fluorocarbon surface-active perfluor octyl iodide, 0.1-0.4 part of light stabilizer (2-2-6-6 tetramethyl piperidyl) sebacate and 1-2 parts of flame-retardant hexabromocyclododecane; and filler: 300-400 parts of natural colored stone powder. According to a test, the integrated thermal-insulation energy-saving decorative sheet disclosed by the invention is simple and convenient in construction process, good in performance, low in manufacturing cost, unlikely to drop, good in decorative effect, light in weight, environment-friendly and energy-saving, free of radiation and strong in stain resistance.

Owner:HENAN DESHENG ENVIRONMENT ENERGY CONSERVATION TECH LIMITED

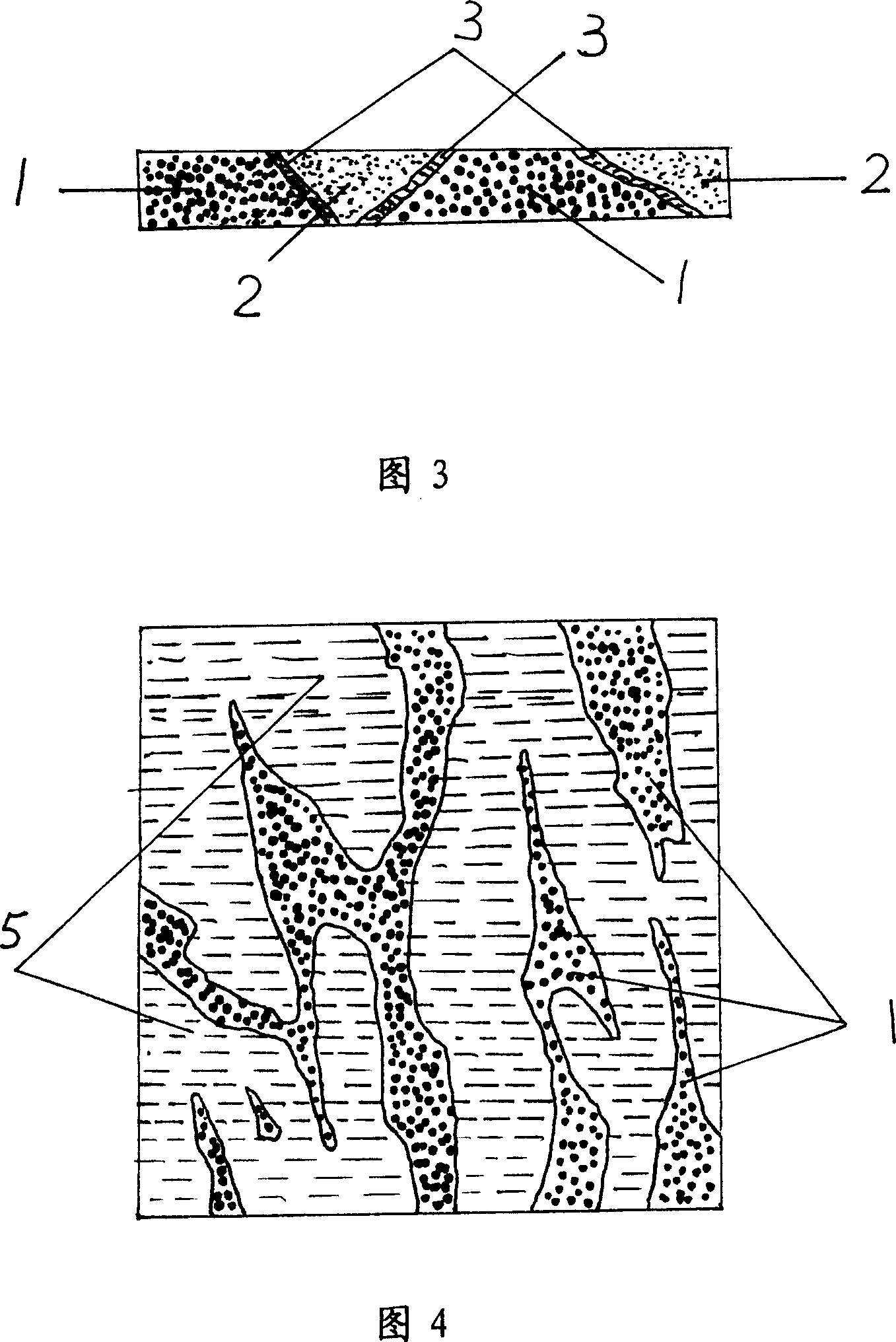

Technology for making pigment pattern edge to form colour stone-imitation seam by pattern die

InactiveCN101024294AFine and realisticFine and realistic pattern features are goodFeeding arrangmentsSurface layering apparatusWork in processEngineering

The invention relates to a technology used pattern die to make colorant pattern edge form color stone imitated steam. It includes the following steps: falling the first color material according to the given pattern edge shape to form slope heap; laying the second color material with 0.1mm-3mm thickness by upper cover board die orifice in covering type; laying the first or third color material with 3mm-100mm thickness; pressurizing, burning or solidifying to gain semi-manufactures; polishing to gain finished product.

Owner:杨德宁

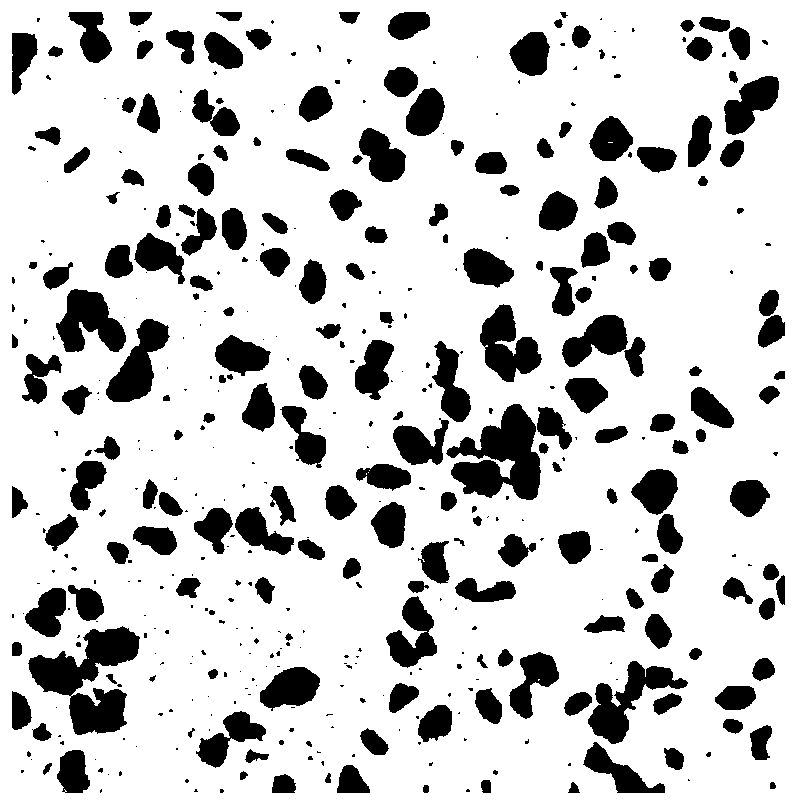

Composite color stone-like product, preparation method and preparation system thereof

ActiveCN108178613ALower firing temperatureReduce adsorptionCeramic materials productionCeramicwareColor StoneAbsorption rate

The invention discloses a composite color stone-like product, a preparation method and a preparation system thereof. The preparation method of the composite color stone-like product comprises the following steps: performing multi-stage screening on ceramic particles and / or polishing mud with a water absorption rate being less than 1%; grinding clay to powder with fineness being at least 350 meshes, and adding 1.5-2.5% of soda ash for modification to form clay powder; forming a first base material and / or a second base material, forming a first surface material / or a second surface material, andforming the composite color stone-like product. The moulding predetermined temperature of a mold is 50-100 DEG C, pressure intensity is greater than 10 Mpa, a base substrate is transported to a sintering furnace for slow sintering at a curve high temperature for 4-8 hours to obtain the composite color stone-like product, and the sintering temperature is 1150-1230 DEG C.

Owner:JIANGXI LVDAO TECH CO LTD

Attractive and practical composite material well cover

The invention relates to an attractive and practical composite material well cover. The well cover has attractive appearance, is convenient to match a ground environment and consists of a base and a cover; both the base and the cover consist of lower surface layers, upper surface layers, middle frameworks, and upper and lower filling layers, wherein the lower surface layers are filled with glass fiber cloths; the upper surface layers are filled with an adhesive formed by mixing colored stone and resin; the middle frameworks are filled with glass fiber racks or glass fiber disks made by bonding glass fiber yarn and resin; the upper and lower filling layers are positioned between the upper and lower surface layers and the middle frameworks and are filled with an adhesive formed by mixing quartz sand and the resin. The upper surfaces are attractive and wearable and the colored stone can be selected as required, so the defects of single surface color, poor appearance and poor environment matching property of the well cover in the prior art are overcome and high practicability is achieved.

Owner:公明文

Hemp colored stone coating with high adhesiveness

The invention relates to the technical field of coatings, and discloses a hemp colored stone coating with high adhesiveness. A basic paint of the hemp colored stone coating comprises the following components in percentage by weight: 17.2 to 20.9 percent of deionized water, 0.1 to 0.2 percent of a dispersing agent, 0.2 to 0.4 percent of a defoaming agent, 0.5 to 1 percent of a coalescing agent, 1 to 2 percent of titanium dioxide, 0.2 to 1 percent of kaolin, 1 to 2 percent of cellulose, 0.1 to 0.3 percent of a neutralizing agent, 20 to 30 percent of silicone acrylic emulsion, 0.2 to 0.5 percent of a preservative, 0.5 to 1 percent of propylene glycol, 0.3 to 0.6 percent of an associate thickener and 30 to 40 percent of 70 to 90-mesh gravel; the base paint comprises the following components in percentage by weight: 5-10% of a 10wt% protective glue water solution and 1-2% of cellulose, the cellulose is a mixture of hydrophobic modified hydroxyethyl cellulose and hydroxyethyl cellulose, and the viscosity (1% of the water solution) of the hydrophobic modified hydroxyethyl cellulose is 0.5-1.5 thousand mPa.s. The base paint prepared by the process disclosed by the invention is applied to the prepared hemp colored stone coating, and the coating has the advantages of high hardness, high wear resistance, high wear resistance and the like. The hemp colored stone coating has high strength, toughness and adhesiveness.

Owner:铁壁金钢(福建)新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com