Manufacturing process for external wall decoration hanging plate

A production process and exterior wall decoration technology, applied in the field of building materials, can solve problems such as the inability to ensure uniform mixing of plant fibers or plant shavings, waste of resources and energy, and dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

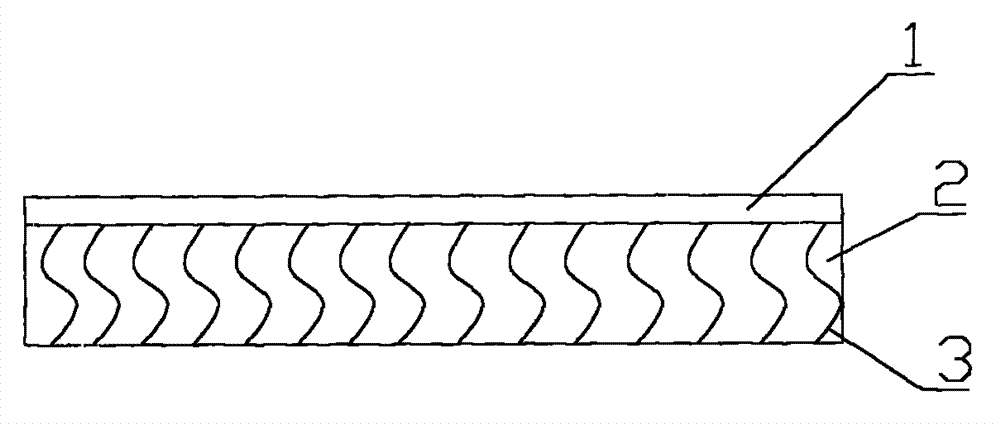

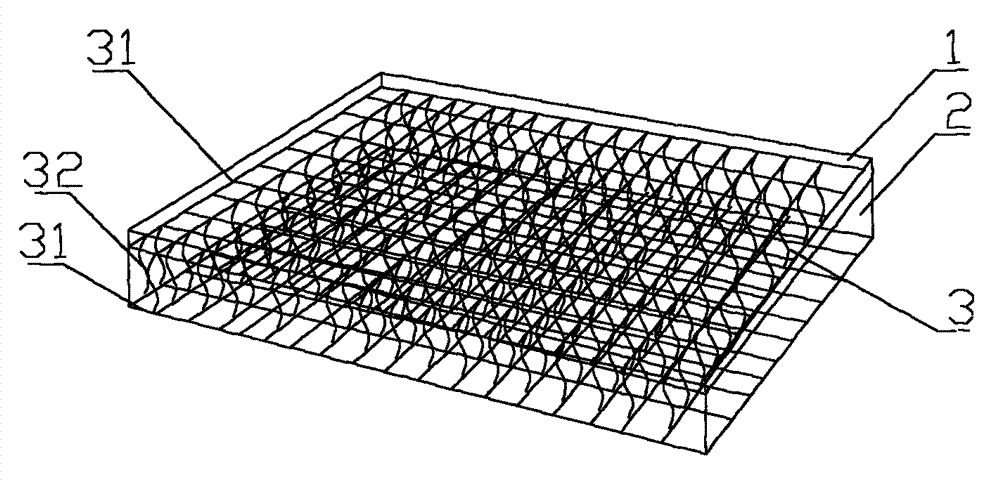

[0030] see figure 1 , an exterior wall decorative hanging board provided by the present invention, comprising a decorative layer 1 and a structural layer 2, the structural layer 2 is a colored stone concrete layer, colored concrete or cement mortar layer, and its interior is filled with a 3D structure alkali-resistant glass fiber mesh 3.

[0031] For the decorative layer 1, in order to better adhere and combine with the structural layer 2 (plate), and to withstand the influence of the external environment, the coating with strong weather resistance and good corrosion resistance should be selected. It is currently used in the market for exterior Fluorocarbon coatings and water-based environmentally friendly elastic coatings have excellent performance in the decorative surface of wall coatings, and before the finishing layer is painted, the surface of the structural layer 2 should be infiltrated with a primer, so that the structural layer 2 (plate) can be compatible with The fi...

Embodiment 2

[0035] Present embodiment is the production process of the present invention:

[0036] (1) Prepare raw materials: cement 25-40kg, river sand 10-30kg, fly ash 5-15kg, waste molding sand 0-20kg, stone scrap 0-25kg, early strength water reducer 0.2-0.5kg, hydrophobic Agent 0.02-0.04kg, alkali inhibitor 0.01-0.03kg;

[0037] Waste molding sand is the solid waste generated in the production process of the wear-resistant casting industry, which is a mixture of granular and powdery, and the sieve residue after passing through a 2.50mm sieve is ≤8%;

[0038] The fineness modulus of river sand is 1.5-2.6, and the mud content is less than 3%;

[0039] Stone leftovers are discarded leftovers after crushing in the quarry and leftovers after the stone is cut into finished products by the stone processing plant. The maximum particle size is ≤5mm. Since the stone includes a variety of colors, colored stone concrete will be produced during processing and manufacturing. layer, colored concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com