Sand-in-sand multicolor paint and preparation method thereof

A technology of colorful coatings and sand molds, applied in the field of coatings, can solve the problems of blurred overall effects, differences in imitation stone effects, increased consumption, etc., and achieve the effects of increasing stone imitation effects, easy mixing and even enhancement of thixotropic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

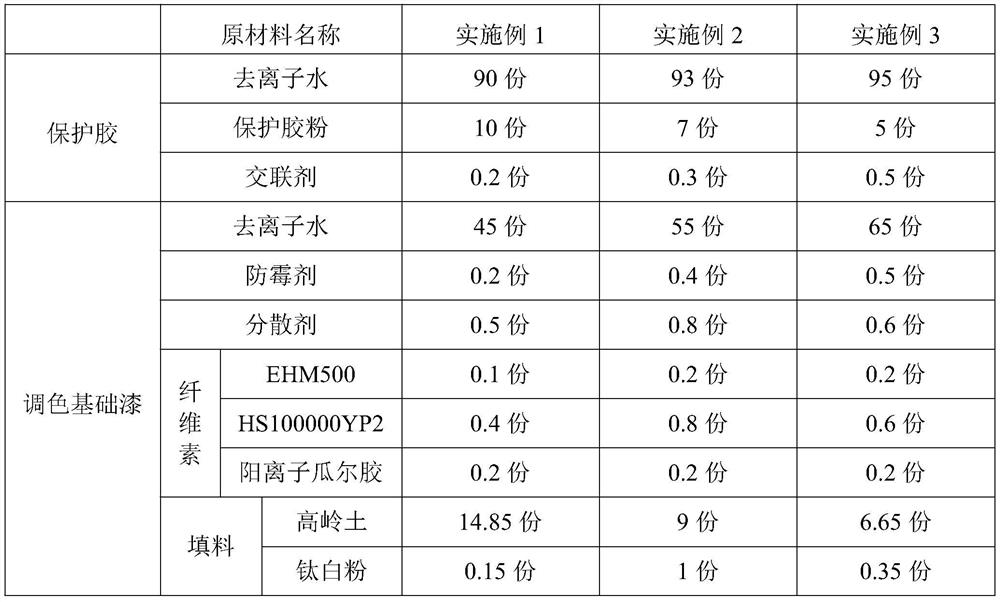

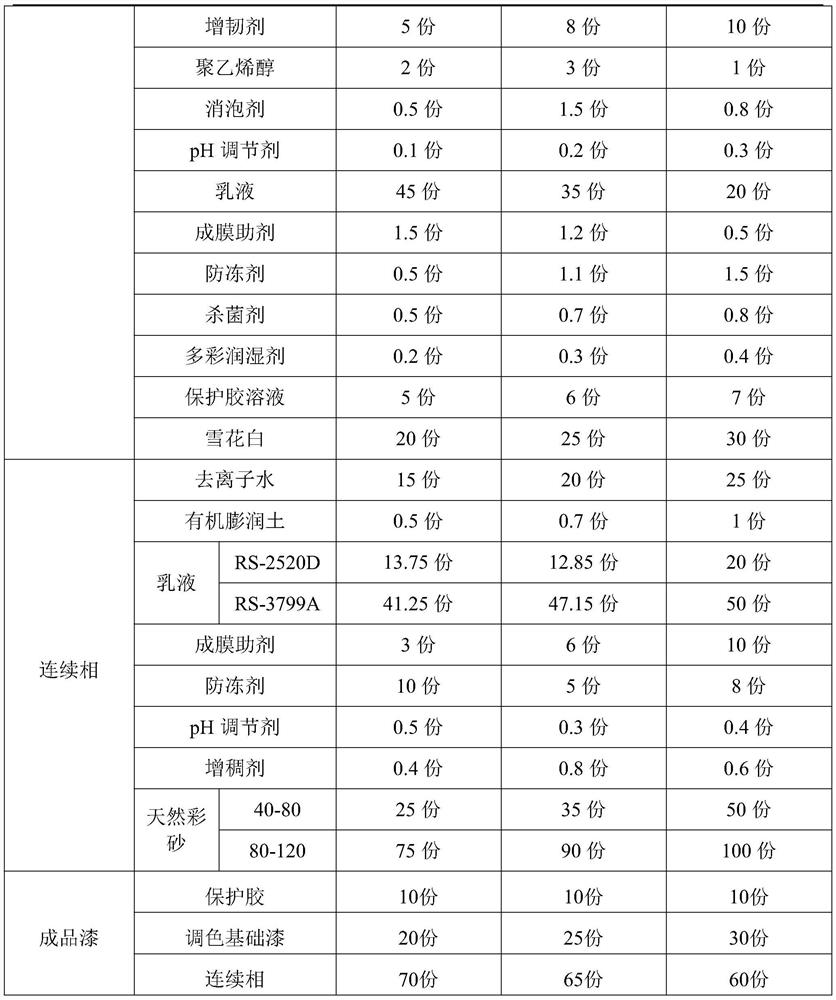

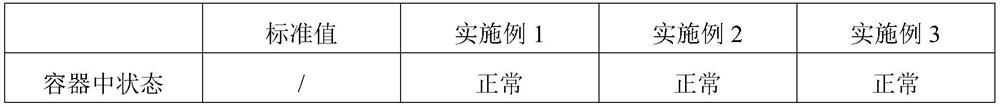

Embodiment 1

[0060] The protective glue is prepared by the following method: add deionized water to container 1, then add protective powder and crosslinking agent at a stirring speed of 1300rpm, and stir for 30 minutes to obtain it;

[0061] Described toning base material is prepared by following method:

[0062] Add deionized water into container two;

[0063] Then, at a stirring rate of 300rpm, add the antifungal agent and dispersant and stir for 1min;

[0064] Then at a stirring rate of 600rpm, add cellulose and stir for 5min;

[0065] Then at a stirring rate of 700rpm, add fillers, toughening agents, polyvinyl alcohol, defoamers and pH regulators, then adjust the rotating speed to 1200rpm and stir for 15min;

[0066] Then at a stirring rate of 1000rpm, add emulsion, film-forming aid, antifreeze, bactericide and colorful wetting agent and stir for 5min;

[0067] Then, at a stirring rate of 1100rpm, add the protective colloid solution and stir for 8min;

[0068] Finally, at a stirrin...

Embodiment 2

[0077] The protective glue is prepared by the following method: add deionized water into container 1, then add protective powder and cross-linking agent at a stirring rate of 1500 rpm, and stir for 40 minutes to obtain it;

[0078] Described toning base material is prepared by following method:

[0079] Add deionized water into container two;

[0080] Then at a stirring rate of 500rpm, add the antifungal agent and dispersant and stir for 2min;

[0081] Then at a stirring rate of 800rpm, add cellulose and stir for 10min;

[0082] Then at a stirring rate of 900rpm, add fillers, toughening agents, polyvinyl alcohol, defoamers and pH regulators, then adjust the rotating speed to 1500rpm and stir for 25min;

[0083] Then at a stirring rate of 1200rpm, add emulsion, film-forming aid, antifreeze, bactericide and colorful wetting agent and stir for 10min;

[0084] Then, at a stirring rate of 1300rpm, add the protective colloid solution and stir for 10min;

[0085] Finally, at a st...

Embodiment 3

[0094] The protective glue is prepared by the following method: add deionized water into container 1, then add protective powder and crosslinking agent at a stirring rate of 1400rpm, and stir for 35 minutes to obtain it;

[0095] Described toning base material is prepared by following method:

[0096] Add deionized water into container two;

[0097] Then at a stirring rate of 400rpm, add the antifungal agent and dispersant and stir for 1.5min;

[0098] Then at a stirring rate of 700rpm, add cellulose and stir for 6min;

[0099] Then at a stirring rate of 800rpm, add fillers, toughening agents, polyvinyl alcohol, defoamers and pH regulators, then adjust the rotating speed to 1400rpm and stir for 20min;

[0100] Then at a stirring rate of 1100rpm, add emulsion, film-forming aid, antifreeze, bactericide and colorful wetting agent and stir for 8min;

[0101] Then, at a stirring rate of 1200rpm, add the protective colloid solution and stir for 9min;

[0102] Finally, at a stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com