Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45 results about "APRICOT JUICE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

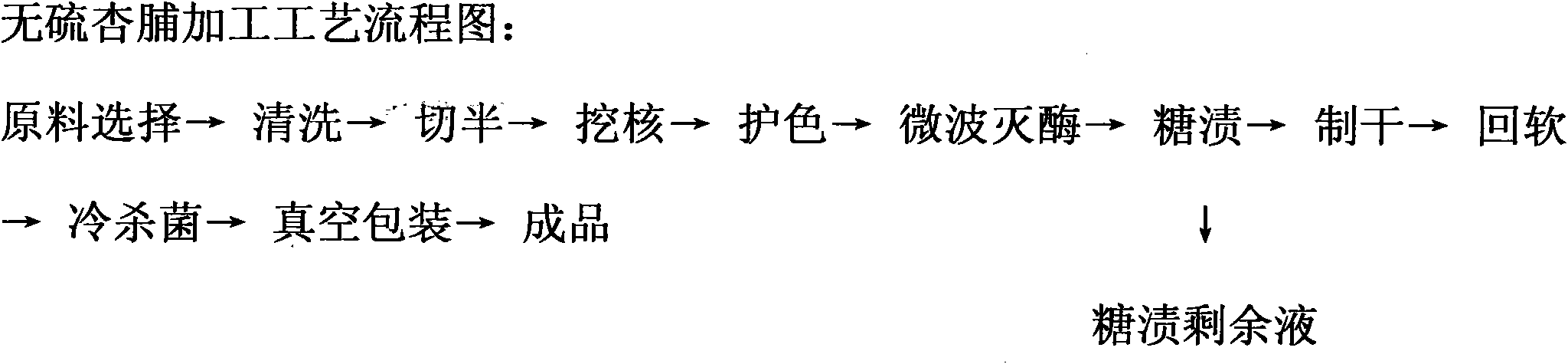

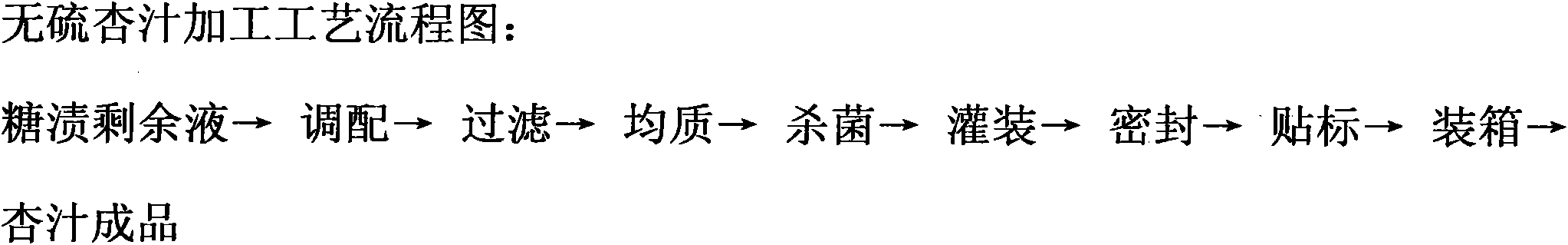

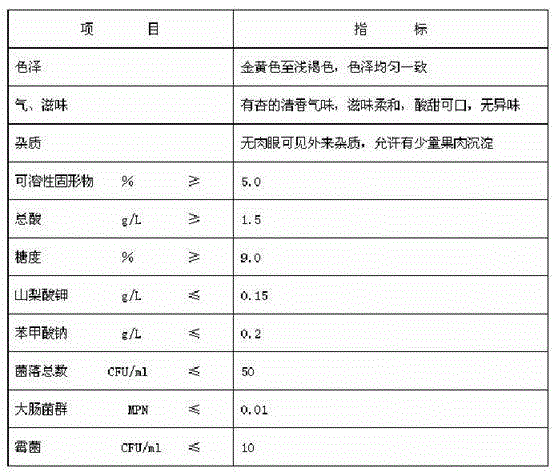

Processing method of sulfur-free preserved apricots and apricot juice

InactiveCN101912024APrevent browningModerate hardnessConfectionerySweetmeatsCarrot juiceAdditive ingredient

The invention belongs to the technical field of food processing of fruits and vegetables. In order to solve the technical problems of high sugar content and high sulfur content of preserved apricots, fresh apricots are taken as raw materials, a sugar-soaking process for multiple times is changed to a sugar-soaking process once, and a process for inactivating enzymes by microwaves is used for replacing the traditional sulfuring process to produce sulfur-free preserved apricots and sulfur-free apricot juice. The technical scheme is characterized in that the process for producing the sulfur-free preserved apricots mainly comprises the steps of color protection by inactivating enzymes by microwaves and preparation of the sulfur-free apricot juice. The optimal process parameters of microwave treatment are as follows: the power is 600w, the weight of the fresh apricots is 45g, and the heating time is 180s. The product of the sulfur-free preserved apricots has golden color, good luster and proper sour and sweet taste. The residual liquid generated after the sugar-soaking process is used for producing the sulfur-free apricot juice, and the product of the sulfur-free apricot juice has yellowy color and strong apricot flavor. The ratio of the residual liquid after the sugar-soaking process to the purified water is 1:5. The adding amounts (g / mL) of additives are as follows: white granulated sugar powder is 1.0%, citric acid is 0.1%, and CMC-Na is 0.1%. The method is mainly used for producing preserved apricots and apricot juice. On the premise of ensuring that the preserved apricots have low sugar content and no sulfur, the method ensures the unique sensory quality of the preserved apricots and has the advantages of short treatment time for apricot fruits, good quality of the preserved apricots and high production efficiency; and the intermediate product residual liquid generated after the sugar-soaking process can also be used for producing the sulfur-free apricot juice.

Owner:XINJIANG UNIVERSITY

Large apricot juice drink

The invention belongs to the field of juice drink manufacture and in particular relates to large apricot juice drink. The large apricot juice drink is prepared from the raw materials including apricot protoplasm, white granulated sugar, sodium cyclamate, AK sugar, juice stabilizer, potassium sorbate, citric acid, large apricot essence and water. According to a novel large apricot juice drink formula provided by the invention, the materials are simple, safe and reasonable, the cost of the drink is low, a market of the large apricot juice drink is developed, and the drink can meet the needs of consumers loving unique flavors of large apricots.

Owner:HENAN YANGSHAO DAIRY IND

Process for producing concentrated clear apricot juice

The invention discloses a process for producing concentrated clear apricot juice. The process comprises the following steps of: smashing ripe apricots, juicing the smashed apricots and adding water into the obtained juice with full stirring to obtain initial cloudy juice; heating the initial cloudy juice, cooling heated initial cloudy juice to the temperature of between 50 and 55 DEG C, adding amylase, pectinase, pear juice complex enzyme and hemicellulose into the cooled initial cloudy juice, preserving heat at the temperature of between 50 and 55 DEG C and clearing up the mixture to obtain primary cloudy juice; centrifugally separating supernatant from the primary cloudy juice to obtain clear apricot juice; and filtering the clear apricot juice with a filter membrane until the clear apricot juice becomes clear and performing vacuum concentration on the clear apricot juice to obtain the concentrated clear apricot juice. In the process, a temperate condition is adopted and pectin and starch which affect the clear juice through the combination of ordered temperature rise and fall and enzymolysis are removed. The condition of an entire technical process keeps nutrition constituents of the apricot possibly and the color and flavor of the juice are kept to the maximum extent.

Owner:合德堂食品工业(泾阳)有限公司

Method for preparing compound juice contg. apricot juice, pumpkin juice and carrot juice

InactiveCN1692833ASolve the problem of low juice yieldOvercome the shortcomings of light taste and not easy to be accepted by peopleFood scienceCarrot juiceAdditive ingredient

A composite fruit-vegetable juice with high output rate and the high stability of color and cloudiness is prepared from the concentrated apricot jam, pumpkin and carrot through respectively pretreating, enzymolyzing, deactivating enzyme and centrifugal separation to obtain their juices, proportionall mixing, adding white sugar and hydrophilic colloid, homogenizing, sterilizing and cooling.

Owner:JIANGNAN UNIV

Method for producing concentrated apricot juice and natural fruit acid

InactiveCN102210447ASolve the problem of coloringSolve the problem of sour tasteFood preparationPectinaseCentrifugation

The invention relates to a method for producing natural fruit acid, concentrated apricot juice and apricot powder. Apricots are taken as a raw material. The invention relates to a process for producing the natural fruit acid, the concentrated apricot juice and the apricot powder. The process is characterized by comprising the following steps of: removing cores of the apricots, homogenating, adding pectinase and performing enzymolysis, extracting residue obtained after enzymolysis and centrifugation for the second time according to the conditions, removing the residue, mixing two supernatants and concentrating, allowing the concentrated supernatant to pass through a resin column, eluting by using water, concentrating solution obtained after elution to obtain the concentrated apricot juice, eluting by using 50 percent ethanol in which a small amount of ammonia water is added, concentrating eluent under reduced pressure at the temperature of between 60 and 70 DEG C, and drying to obtain the solid natural fruit acid.

Owner:JIANGNAN UNIV

Pumpkin beverage

InactiveCN101862003AAbundant resourcesSimple preparation processFood preparationFood additiveAdditive ingredient

The invention discloses a pumpkin beverage, which comprises the following main ingredients: pumpkin juice, apple juice, wild apricot juice, crystal sugar and an appropriate amount of purified water. The pumpkin beverage has the advantages of abundant raw material resources, simple preparation process, rich nutrition, increasing importance to people, high edible value, very important food therapy effect, no need of food additive, suitability for children and adults, biological health-care function, and capability of meeting the requirements of vast consumers.

Owner:周洁

Compound fruit juice

The invention relates to compound fruit juice which comprises 10-15 parts of apple juice, 10-15 parts of kiwi-fruit juice, 10-40 parts of apricot juice, 15-30 parts of peach juice, 2-8 parts of wolfberry juice, 10-20 parts of lemon juice, 30-35 parts of pear juice, 10-20 parts of coconut milk, 3-5 parts of pumpkin juice, 5-10 parts of honey, 0.2-0.6 part of sodium carboxymethylcellulose, 0.2-0.6 part of carrageenan and 10-15 parts of purified water. The compound fruit juice provided by the invention has very good mouthfeel and rich and comprehensive nutrition and is delicious with sourness and sweetness; and the technical problem that the apricot, lemon and pumpkin are sour and astringent with bad mouthfeel and thus are not accepted by people is solved.

Owner:张红军

Composite juice of hawthorn and oleaster and preparation method thereof

The invention relates to a composite juice of hawthorn and oleaster and a preparation method thereof. The composite juice is prepared from hawthorn juice, oleaster juice, apricot juice and auxiliary materials. The invention is characterized in that the mass ratio of hawthorn juice to oleaster juice to apricot juice is (10-15): (8-12): (6-10); the auxiliary materials comprise the following materials by mass ratio: 8-12% of white granulated sugar, 0.1-0.2% of citric acid and 0.01-0.1% of potassium sorbate. The preparation method comprises the following steps of: 1) mixing and blending; 2) homogenizing; 3) degassing; and 4) sterilizing and cooling. According to the invention, the sense indexes are as follows: the color is red-yellow and uniform; the fragrance mixed with strong hawthorn juice, oleaster juice and apricot juice is formed; and the composite juice is sweet without odor. The physiochemical indexes are as follows: the content of vitamin C is more than or equal to 100mg / 100ml; the content of the original juice is more than or equal to 40%; the content of the soluble solid matter is 10%-13%; and all the indexes conform to the specifications of GB11671 and GB2760-1996.

Owner:吴肖慧

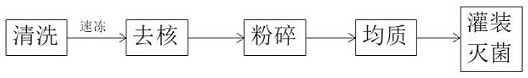

Apricot juice processing method

The invention relates to an apricot juice processing method. The apricot juice processing method comprises the steps of selecting apricots which have high acidity and orange fruit flesh color, and is fully mature and fresh without mildew and moth bite; cleaning up with clear water, cutting in half, and removing cores; adding pulp and the clear water into a stainless steel kettle, adding a little vitamin C, citric acid and table salt, cooking for 20 minutes, fishing out, adding a little water for pulping, and sieving through a 80-mesh sieve; and putting an apricot juice into the stainless steel kettle, quickly rising the temperature of the apricot juice to be 80 DEG C with quick fire, cooling to room temperature after 3 minutes, homogenizing through a homogenizer, and canning and sterilizing the homogenized apricot juice at high temperature.

Owner:董德华

Fresh apricot probiotic fermented drink and production method

InactiveCN101632476ADeliciousIncrease health functionBacteriaFood preparationBifidobacteriumAPRICOT JUICE

A fresh apricot probiotic fermented drink is characterized by using fresh apricot juice to produce a culture medium, fermenting and culturing such probiotics as bifidobacterium, lactobacillus bulgaricus, streptococcus thermophilus and lactobacillus under certain temperature and time, and then inactivating the fermented probiotic liquid to produce the drink. The residues produced in the process of producing the fresh apricot probiotic fermented drink can be used for producing fresh apricot probiotic jams. The invention greatly expands the application range of the culture medium materials of the probiotics such as bifidobacterium, provides a novel probiotic inactivated fermented drink for the consumers and enjoys rich raw material sources, low cost, stable production process, small investment on production equipment, simple operation and easy popularization.

Owner:赵敏

Handmade soap capable of preventing ageing and beautifying skin

The invention discloses handmade soap capable of preventing ageing and beautifying skin. The handmade soap comprises the following raw materials in parts by weight: 5-9 parts of camellia oil, 2-3 parts of holly juice, 2-3 parts of grape juice, 5-6 parts of gleditsia sinensis lam powder, 2-3 parts of papaya juice, 1-3 parts of yellow apricot juice and 5-7 parts of water. The handmade soap with whitening, anti-ageing and anti-oxidation effects on the skin of a human body is prepared from natural biological raw materials and the camellia oil, and has the effects of delaying skin ageing and improving skin environment; moreover, the used materials are natural, nontoxic and harmless, and a preparation process is also simple and feasible.

Owner:TIANE COUNTY PINGCHANG ECOLOGICAL AGRI

Making method of apricot vinegar

InactiveCN107779383ARetain nutritional valuePreserve the flavorVinegar preparationPectinaseFruit juice

Owner:尤玉民

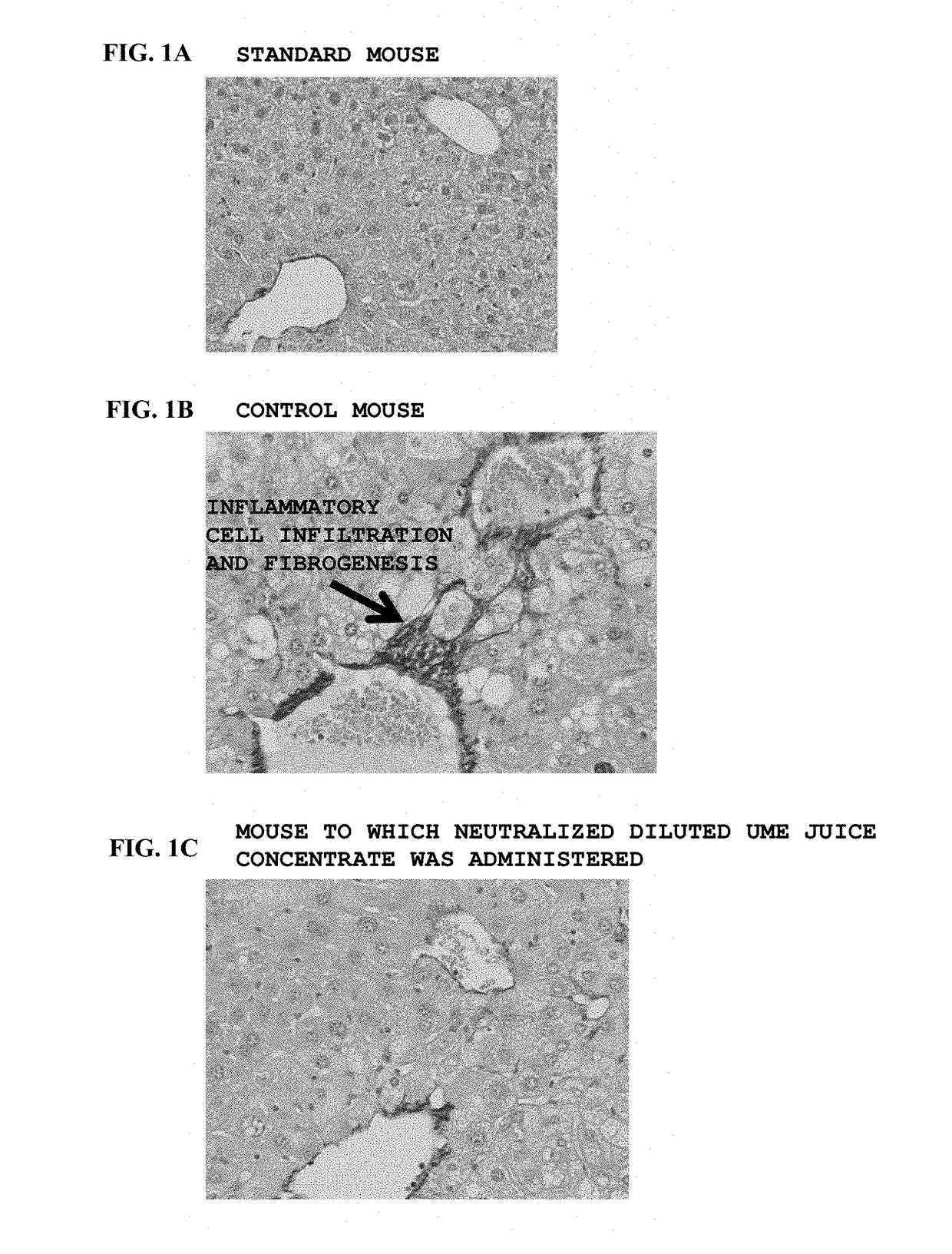

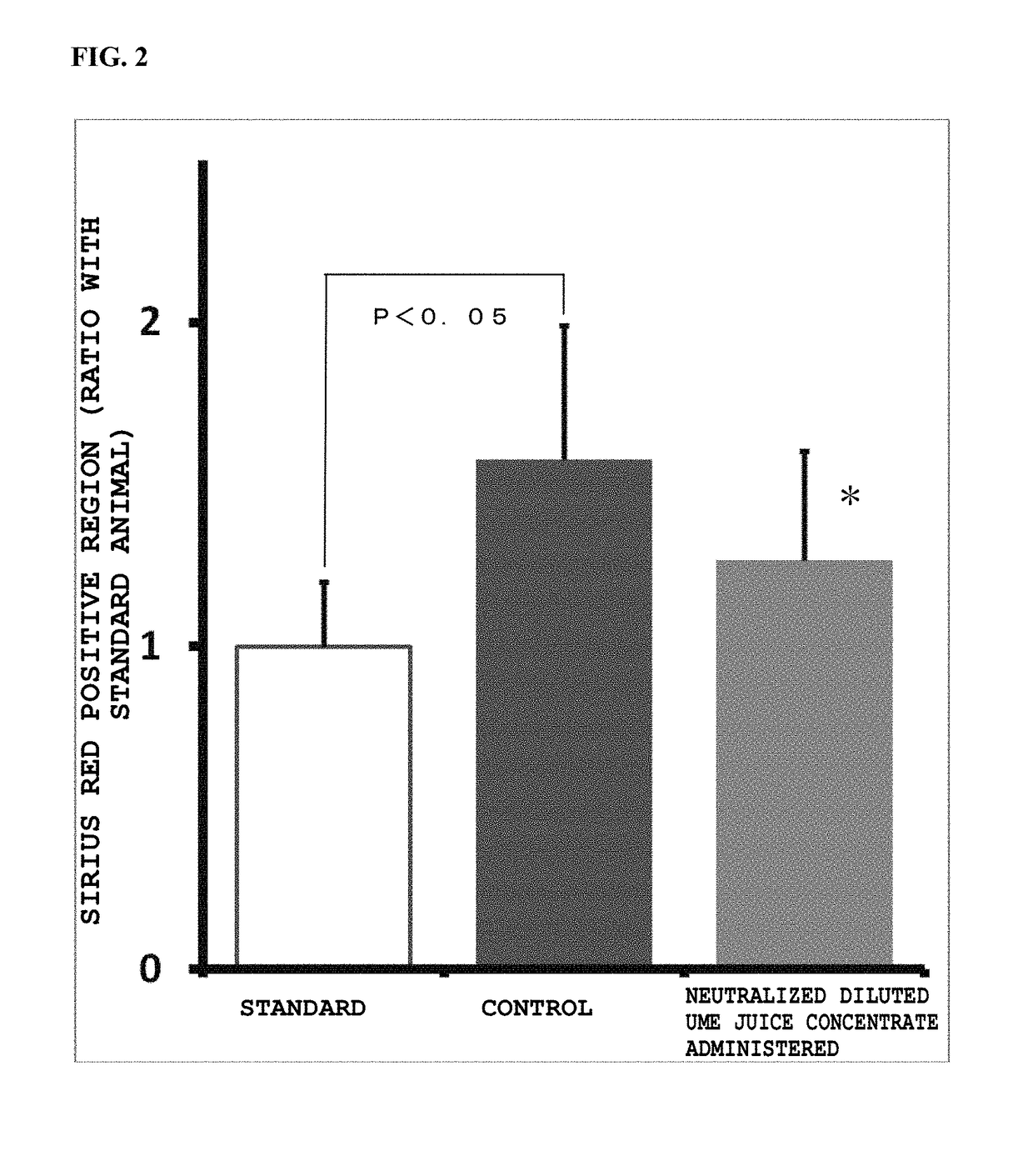

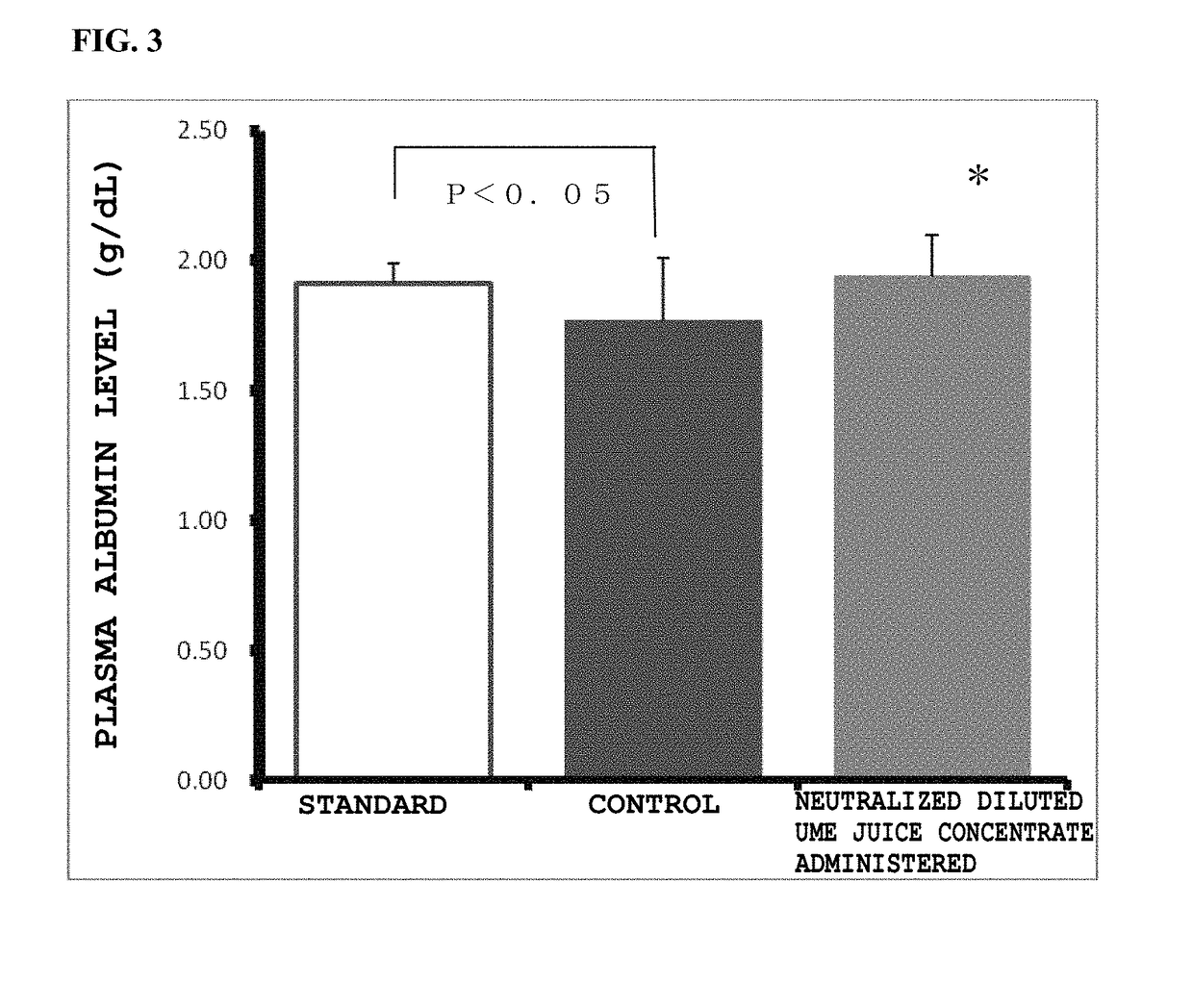

Prophylactic and/or therapeutic agent for nafld/nash

ActiveUS20180325975A1Reduce incidenceNASH can be preventedDigestive systemFood ingredient functionsNash modelFruit juice

The present invention provides a prophylactic and / or therapeutic agent for non-alcoholic fatty liver disease (NAFLD), and particularly non-alcoholic steatohepatitis (NASH) comprising an ume (Japanese apricot) juice concentrate or a processed product thereof. The prophylactic and / or therapeutic agent is obtained by utilizing a component contained in a plant or a processed product thereof, and hence is safe and easily taken. It has been confirmed that when the ume juice concentrate or the processed product thereof is orally administered to a streptozocin (STZ)-induced NAFLD model mouse or an STZ-induced NASH model mouse, liver fibrogenesis can be reduced.

Owner:ADABIO +1

Nutritional fruit tea

The invention provides nutritional fruit tea, which consists of the following components by weight: 250 of apple juice; 100 of carrot juice; 200 of watermelon juice; 100 of sweet orange juice; 0.5 of xanthan gum; 0.05 of citric acid; 0.7 of glutamic acid; 0.1 of potassium sorbate; 1.5 of aspartic acid; 650 of vitamin B; 500 of glucose; 0.5 of vitamin c; and 800 of water. The fruit tea can be prepared by the processes of blending, high pressure homogenization, sterilization and filling. The invention aims to provide nutritional fruit tea of a new flavor. The fruit tea of the invention is rich in amino acid necessary for the human body, so that fruit juice beverages are in a healthy and nutritional trend.

Owner:广东华馨香料有限公司

Red apricot drink containing calcium

InactiveCN101467784APromote absorptionWide adaptabilityFood preparationAPRICOT JUICEAqueous solution

This invention provides a calcic red apricot drink, containing red apricot juice, water and plaster aqueous solution; and the weight percentages thereof are: more than 75 of red apricot juice, less than 1% of plaster aqueous solution, and the other is water. This drink contains calcium ion which can be easily absorbed by the human body under the acid condition. This drink having function of enriching the calcium is suitable for all ages, with wide crowd suitability and good palatability, and is especially suitable for drinking in long time.

Owner:TIANJIN ZHONGYING HEALTH FOOD

Fruit and vegetable compound juice containing apple

The invention relates to fruit and vegetable compound juice. The formula of the fruit and vegetable compound juice comprises the following components: 10-40 parts of apple juice, 10-40 parts of kiwi-fruit juice, 10-40 parts of apricot juice, 15-40 parts of peach juice, 10-20 parts of snow pear juice, 10-20 parts of white radish juice, 40-50 parts of tomato juice, 10-20 parts of eggplant juice, 5-10 parts of rock candies, 0.2-0.6 part of sodium carboxymethylcellulose, and 0.2-0.6 part of carrageenan. The fruit and vegetable compound juice provided by the invention is diverse in ingredients, comprehensive in function, extremely good in mouthfeel, rich and comprehensive in nutrition, sweet, sour and tasty, and can prolong life if being drunk frequently. Preferably, the formula comprises 0.3 part of carrageenan.

Owner:张红军

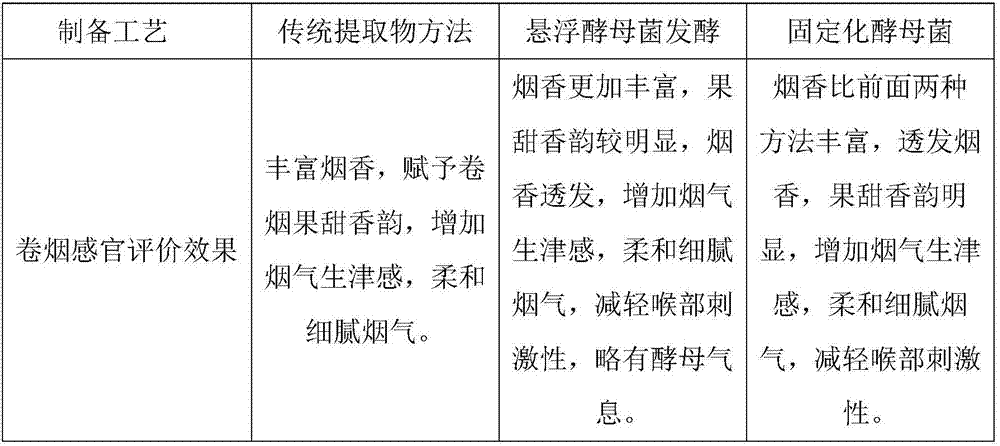

Method for preparing apricot extract for cigarette by immobilized saccharomycetes

InactiveCN106957865AImprove qualityRich aromaTobacco preparationTobacco treatmentThroat irritationAlcohol

The invention provides a method for preparing an apricot extract for cigarette by immobilized saccharomycetes. The method comprises the following steps: (1) juicing fresh apricot; (2) preparing a saccharomycetes bacterial suspension; (3) immobilizing saccharomycetes with sodium alginate-CaCl2; (4) performing fermenting reaction on the immobilized saccharomycetes and the apricot juice; (5) filtering fermentation liquor, thereby acquiring clear fermentation liquor, and then performing alcohol precipitation and vacuum concentration, thereby acquiring the apricot extract. According to the invention, the apricot is taken as a raw material and the immobilized saccharomycetes are utilized to ferment the apricot juice, so that the high-quality apricot extract for cigarette can be acquired. The extract in cigarette has the functions of enriching cigarette flavor, inducing cigarette fragrance, increasing fruity sweet and fragrance, enhancing smoke saliva-generating feel, softening and fining smoke, relieving throat irritation, and the like.

Owner:WUHAN HUANGHELOU FLAVOR & SPICES

Vinegar mainly made of apricot juice and making method of vinegar

The invention discloses vinegar mainly made of apricot juice and a making method of the vinegar. According to the method, millet is soaked with warm water for 12 hours and fished out to be mixed with malt to be steamed for 2-3 hours, then the mixture is aired to about 50 DEG C and placed into a fermentation tank, saccharifying enzyme is added, meanwhile radix angelicae, fructus tsaoko, bark of Japanese cinnamon, anise, fennel and flos caryophylli are added to the mixture at the same time, fermentation is conducted at the room temperature of 25-30 DEG C, stirring is conducted twice each day, when vinous flavour is emitted out of wine with dregs four days later, apricot juice is added to the mixture, meanwhile vinegar koji is added, stirring is conducted continuously, when vinegar smell is emitted out of the wine with dregs three days later, the fermentation tank is covered and sealed, the mixture stands still at the room temperature of 15-25 DEG C and is fermented for one month, then filtering and bottling are conducted, sterilization is conducted, and a finished product is obtained. The product is rich in nutrition, unique in flavor, the research blank on the aspect in China is made up for, and development of vinegar production in China is promoted.

Owner:史占彪

Production process of apricot-tasted coffee

The invention discloses a production process of apricot-tasted coffee. The production process includes the following steps that first, 100-200 parts of apricot fruits are selected, and raw materials are detected and screened according to the national food hygiene standards; second, the detected and screened raw materials are classified and put into a cleaning tank and cleaned quickly for total 4 times by using a cleaning machine, the cleaning time is totally 6-10 min, and then the raw materials are subjected to centrifuge dripping under the condition of 2300-2400 r / min; and third, the drippedapricot fruits are put in a juicer to extract apricot juice, then the apricot juice is directly blended into produced coffee at the high concentration ratio being 5% or 8% or 10% per bottle of coffee,finally, a finished product is obtained after sterilization and packaging, and in this way, a bottle of apricot-tasted coffee is prepared. Apricot is one of common fruits, has extremely rich nutrition, contains multiple sugar, proteins and mineral substances such as calcium and phosphorus, and additionally contains vitamins A, vitamins C and B group vitamins.

Owner:高国鹏

Preparation method of apricot soy sauce

The invention relates to a preparation method of apricot soybean sauce. The method comprises the following steps that glutinous millet is soaked for 12 hours by warm water, and is then fished out for use; wheat is soaked for 12 hours by warm water and is then spread on a plastic film for sprouting at the room temperature being 25 to 30 DEG C; after 3 to 6 days, when the wheat sprout grows to 1 to 1.5 cm, the wheat sprout is mixed with the soaked glutinous millet to be steamed for 2 to 3 hours in a food steamer; then, the materials are dried to be about 40 DEG C and are put into a fermentation tank; compound enzyme is added; the fermentation is performed at the room temperature being 25 DEG C to 30 DEG C; after the four days, apricot juice is poured into the fermentation tank; the fermentation is continuously performed for 6 days; common salt is added when a great amount of wine aroma is given out from undecanted wine; continuous stirring is performed; after the common salt is completely dissolved, the stirring is stopped; the fermentation tank is covered and sealed; the still standing fermentation is performed for three months at the normal temperature; then, filtering, bottle charging and sterilization are performed; finished products are obtained. The apricot soybean sauce provided by the invention has the advantages that the flavor is unique; the nutrition is rich; the manufacturing method is simple and can be easily learned.

Owner:史占彪

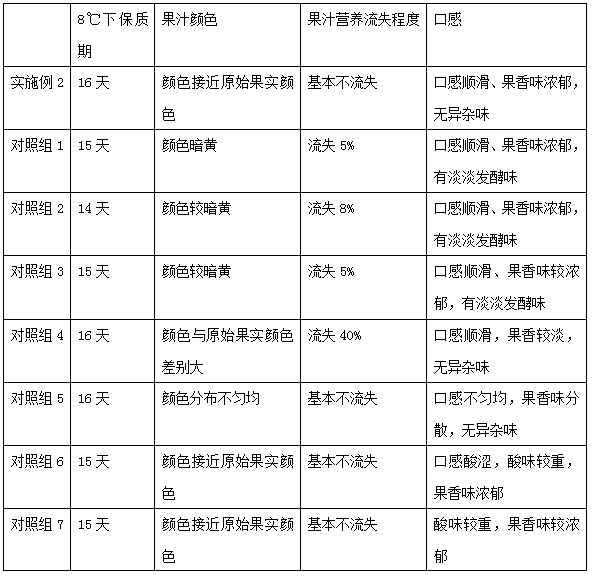

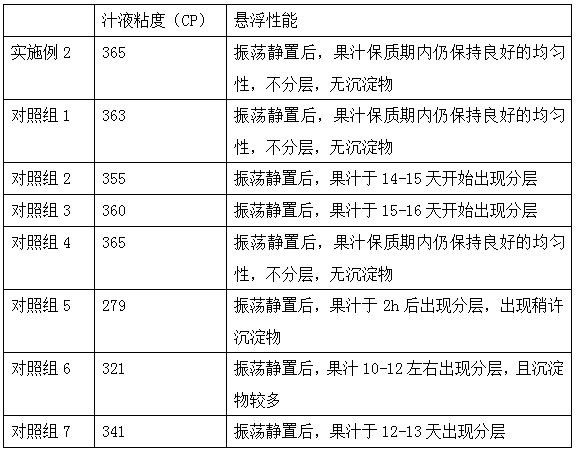

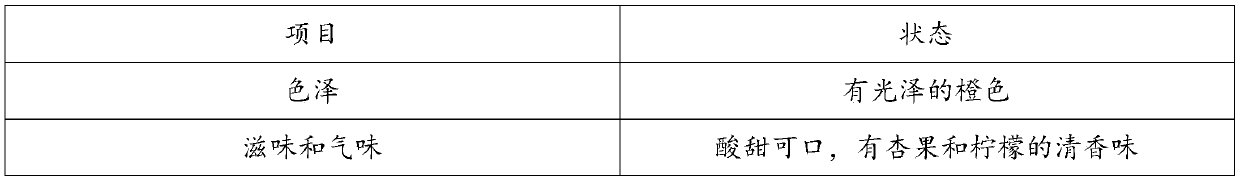

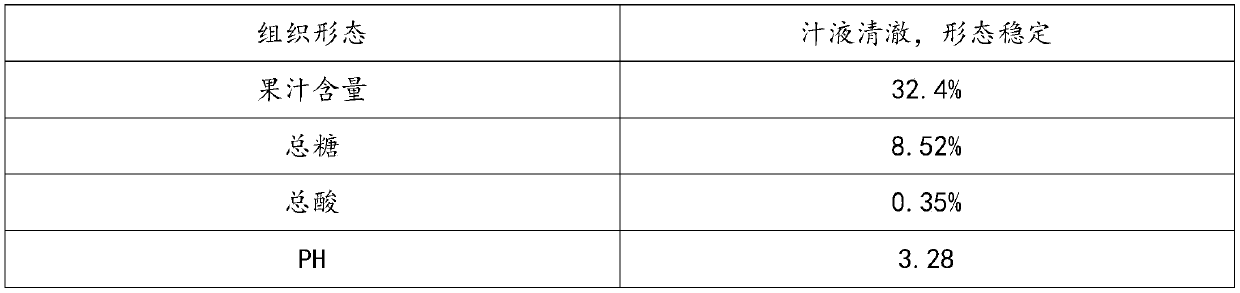

Preparation method of pearl oil apricot juice with pearl oil apricot peel

ActiveCN110973419AGreat tasteIncrease the way of deep processingFood ingredient as mouthfeel improving agentFruit juiceAPRICOT JUICE

The invention belongs to the technical field of food development, and particularly relates to a preparation method of pearl oil apricot juice with pearl oil apricot peel. The method comprises the following steps: firstly, preparing pearl oil apricot peel powder; preparing pulp from pearl oil apricot pulp, carrying out centrifugal filtration and taking a filtrate; and blending the filtrate and thepeel powder, performing homogenizing, adding a nisin solution, carrying out plasma cold treatment, and carrying out supercritical carbon dioxide treatment. The method can enrich the taste of the juice, has high commercial promotion value, and is of important practical significance to widening the deep processing ways of the pearl oil apricots and enriching the juice market. Under the synergistic effect of the above steps, the suspension stability of the juice is good, the storage life of the juice can be prolonged to 15 days (below 8 DEG C), bioactive compounds, colors and sensory quality of the juice are reserved, and the original quality of the pearl oil apricots is kept.

Owner:UNIV OF JINAN

Apricot juice capable of being sucked

PendingCN112568345AKeep the tasteKeep the flavorFood homogenisationUltra high pressure food processesBiotechnologyFruit juice

The invention discloses apricot juice capable of being sucked. The apricot juice is characterized in that the apricot juice is a mobile pulp juice obtained by crushing fresh apricot pulp and performing ultrahigh pressure sterilization, the water content is greater than 80%, the total sugar content is greater than 18%, and the fruit grain size can pass through a 150-200-mesh sieve. According to theapricot juice, the special taste and flavor of apricots (especially apricots purchased in color) can be better maintained, the nutritional ingredients of the apricots are retained, the apricots are convenient to store and transport, and the deep processing way of apricot products is expanded.

Owner:英吉沙德源农林科技有限公司

Flavored fish with black tea flavor and preparation method of flavored fish

InactiveCN104473232AClearing lung and relieving coughElasticFood preparationMonosodium glutamateBlack tea

The invention discloses flavored fish with black tea flavor and a preparation method of the flavored fish. The flavored fish is prepared from the following raw materials in parts by weight: 300-310 parts of wild small fish dices, 30-40 parts of table salt, 15-18 parts of zanthoxylum, 3-5 parts of cooking wine, 6-9 parts of white sugar, 1-2 parts of monosodium glutamate, 15-17 parts of ginger, 13-15 parts of green onions, 15-17 parts of minced garlic, 8-10 parts of beef rolls, 12-13 parts of apricot juice, 7-8 parts of raisin tree fruit powder, 3-5 parts of carrot leaves, 4-6 parts of tender sweet potato leaves, 1-2 parts of olive oil, 3-4 parts of egg rolls, 20-22 parts of black tea juice, 4-5 parts of maca powder, 1-2 parts of lemon root, 1-2 parts of radix adenophora, 1-2 parts of poria cocos, 0.5-1 part of astragalus smicus, 1-2 parts of pawpaw peel, a proper amount of water and 100-150 parts of nutrition additives. By adding the black tea, the flavored fish can be used for stimulating gastrointestinal digestion, promoting an appetite, inducing diuresis, eliminating edema and strengthening cardiac function; and by adding the traditional Chinese medicines, the flavored fish has the functions of nourishing, dispelling chills and fever, and clearing lung and relieving cough.

Owner:HUAINAN JIAOGANGHU ZHONGHUI FOOD

Toxin expelling cocktail making method

InactiveCN103789158AEasy to operateDetoxifyingAlcoholic beverage preparationAPRICOT JUICESkin tender

The invention discloses a toxin expelling cocktail making method. The making method comprises the following steps: 1, selecting raw materials comprising tequila, a lemon juice, an apricot juice, brine and hot water; 2, blending tequila with the lemon juice, the apricot juice, brine and hot water according to a ratio of 2:3:3:1:1; and 3, uniformly shaking the above obtained mixed liquid for 5-8min. A toxin expelling cocktail obtained in the invention is simple to operate, is suitable for women loving beauty, and has the efficacies of toxin expelling, face nourishing, whitening and skin tendering.

Owner:曹平

Raw juice of apricot meat

InactiveCN101327026AMeet the urgent needs of health and longevityFood preparationCarrot juiceAdditive ingredient

The invention relates to an apricot juice preparation method which comprises the following steps: the apricot which falls off, is broken and going to go bad in batches in rainy days in summer is purchased at low cost, cleaned, denucleated, ground, sterilized at high temperature and put into a jar together with all edible ingredients to be sealed; the product can be packaged in jars to be drunk by customers as apricot juice, and mixed into other food as ingredient.

Owner:刘波

Process for producing concentrated clear apricot juice

Owner:合德堂食品工业(泾阳)有限公司

Lemon-fruit apricot-peel tea and preparation method thereof

The invention discloses lemon-fruit apricot-peel tea and a preparation method thereof, and relates to the technical field of food processing; and the invention solves the problems of few types and lowadded values of existing deep-processed apricot fruit products. The lemon-fruit apricot-peel tea disclosed by the invention is prepared from the following active ingredients: 30-60 parts of dried apricot peel, 8-20 parts of lemon slices, 2-6 parts of dried hawthorn fruits, 60-100 parts of white granulated sugar, 1-5 parts of a citric acid concentrated, 0.01-0.2 part of a thickening agent, 0.01-0.3 parts of tian-wei-bao (sodium saccharin), 1.0-1.8 parts of citric acid, 0.01-0.6 part of malic acid, 0.01-0.5 part of sodium citrate, 0.01-0.3 part of vitamin C, 0.05-0.3 part of an apricot essence,0.01-0.3 part of preservatives, and the balance of softened sterile water. According to the preparation method of the lemon-fruit apricot-peel tea, a high-temperature instantaneous sterilization technology is adopted for a sterilizing process; and sterile cold canning is adopted for a filling process. The lemon-fruit apricot-peel tea and the preparation method thereof have the advantages of beingcapable of enriching types of deep-processed apricot fruit products and increasing nutritional values of single apricot fruit juice.

Owner:临泽县祁连红枣业开发有限公司

Preparation method of soybean milk, apricot juice and grape juice foliage fertilizer

InactiveCN105693337AHigh hardnessHigh activityBio-organic fraction processingOrganic fertiliser preparationAmyrisCarrot juice

The invention discloses soybean milk, apricot juice and grape juice foliage fertilizer and a preparation method thereof. The preparation method includes: pouring soybean milk, apricot juice and grape juice after being mixed into a fermentation tank, adding amylase for fermentation at room temperature of 25-30 DEG C, and stirring twice each day to increase oxygen in the fermentation tank; when strong wine aroma is emitted in the fermentation tank after 6 days, stopping stirring, then transferring a mixture of the soybean milk, the apricot juice and the grape juice after being fermented into a container, boiling, adding urea, continuously stirring, maintaining for 20 min after urea is completely dissolved, extincting for cooling, then adding sodium hydroxide to regulate ph value to 6-7, and cooling before filtering and bottling to obtain a finished product.

Owner:史占彪

Production process of apricot-flavor pure milk

InactiveCN110477114AAccurate quantityMeet the standardsMilk preparationOther dairy technologyHigh concentrationVitamin C

The invention discloses a production process of apricot-flavor pure milk. The production process comprises steps as follows: step 1, selecting 100-200 parts of pulp of apricots, and detecting and screening raw materials according to national food hygiene standard; step 2, classifying and placing the detected and screened raw materials in a cleaning tank, quickly cleaning the raw materials by a cleaning machine for 4 times in total for 6-10 min, then, performing centrifugal dripping at 2300-2400 r / min; step 3, placing the dripped apricot pulp in a juicer to juice apricot juice, then, directly blending the apricot juice in produced yogurt in the high-concentration proportion of 5%, 8% or 10% for each bottle of yogurt, and finally, performing sterilization and packaging to obtain a finished product. Thus, the apricot-flavor yogurt (one bottle) is completed. The apricots are one of common fruits, have very rich nutrients and contain more sugar, protein, calcium, phosphorus and other minerals and also contain vitamins A, b and C.

Owner:高国鹏

Apricot brandy and preparation method thereof

InactiveCN108004084AImprove resource utilizationLow costAlcoholic beverage preparationCarrot juiceAPRICOT JUICE

The invention belongs to the technical field of brandy and in particular relates to apricot brandy and a preparation method thereof. The apricot brandy is prepared by fermenting apricot crisp chips puffed by microwaves. The preparation method comprises the following preparation steps: pre-treating, slicing or crushing, drying, puffing, fermenting, distilling and storing. According to the apricot brandy and the preparation method thereof, the problem that apricot juice and fresh apricot pulp easily go bad is solved through the method of puffing apricot pulp and fruits by the microwaves and fermenting to obtain the brandy; meanwhile, the content of fusel oil in the apricot brandy also can be reduced through puffing treatment and an obtained finished product has a good taste and high quality.

Owner:平度市职业中等专业学校

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com