Processing method of sulfur-free preserved apricots and apricot juice

A technology of preserved apricot and apricot fruit, applied in the confectionery industry, confectionery, food science and other directions, can solve the problems of consumer health hazards, industrial processing rate reduction, benefit decline, etc., and achieves reduction of melanin production, short processing time, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] 5.1 Materials: Commercially available fresh apricots.

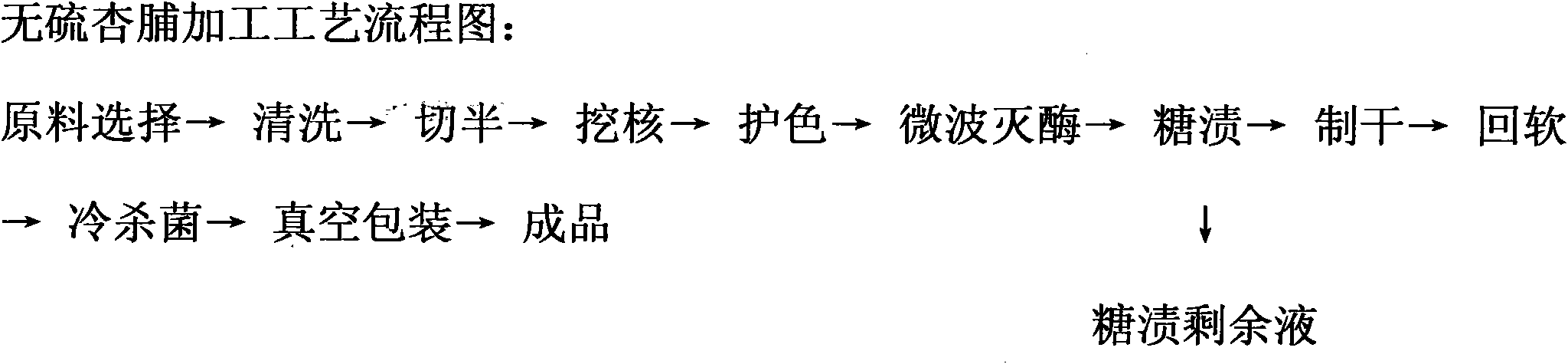

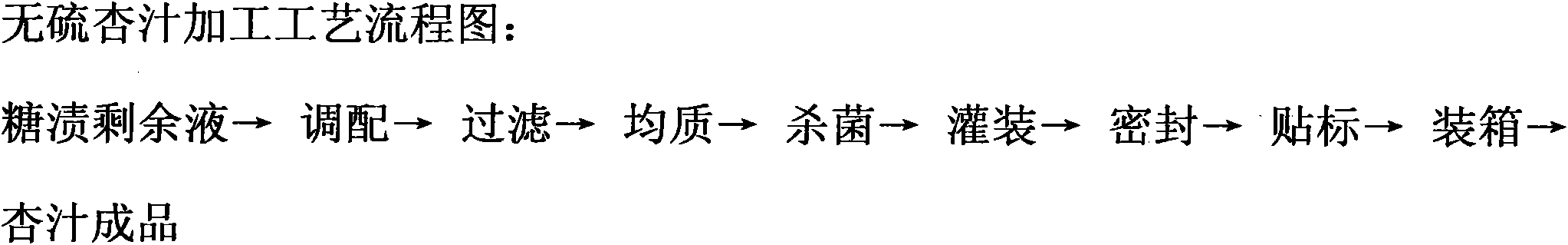

[0008] 5.2 Production of sulfur-free preserved apricot

[0009] Preparation of color-protecting agent: prepare compound color-protecting solution in proportion with food additives and purified water: 0.01% sodium erythorbate (VC), 0.25% citric acid (CA) and 0.15% table salt (NaCl).

[0010] Raw material selection: choose Saimaiti fresh apricots that are yellow in color, have not yet softened in texture, have thick fresh flesh, no bruises, no spots, and are as consistent in size as possible. Eliminate the apricots with pests, rot, cyan and softened apricots fruit.

[0011] Color protection: wash the apricot with water. Separate the apricots along the suture by machine or by hand, and remove the apricot core. After the apricots are cored and cut in half, the apricot bowls are soaked in a compound color-protecting solution for 3 hours. The purpose is to protect the color of the apricot bowls and inhibit the activit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com