Large apricot juice drink

A fruit juice and apricot technology, applied in the field of apricot juice beverages, can solve problems such as incomplete development, and achieve the effect of low cost, safe and reasonable, and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] According to percentage by weight, take apricot puree 10%, white granulated sugar 5%, cyclamate 0.02%, AK sugar 0.01%, fruit juice stabilizer 0.2%, potassium sorbate 0.01%, citric acid 0.1%, apricot essence 0.01%, Water 84%, add water to apricot puree, pass through a colloid mill, and grind to 300 mesh; mix white sugar and stabilizer, pass through a colloid mill, and grind to 300 mesh; take cyclamate, AK sugar and potassium sorbate, mix Add water to dissolve; mix the above-mentioned processed raw materials, add citric acid to acidify until the acidity of the mixture is ≥ 1.5, add water and add apricot essence to flavor at 60°C-90°C, homogenize after blending, and heat at 127°C After high temperature sterilization for 3-6 seconds, hot filling is carried out at 90°C. After filling, it is sterilized in warm water at 95°C for 15-20 minutes. After sterilization, it is cooled to 10°C-40°C to obtain the finished product. Apricot juice drink.

Embodiment 2

[0033] According to percentage by weight, take apricot puree 30%, white granulated sugar 6%, cyclamate 0.05%, AK sugar 0.015%, fruit juice stabilizer 0.25%, potassium sorbate 0.05%, citric acid 0.15%, apricot flavor 0.05%, Water 64%, add water to apricot puree, pass through a colloid mill, and grind to 300 mesh; mix white sugar and stabilizer, pass through a colloid mill, and grind to 300 mesh; take cyclamate, AK sugar and potassium sorbate, mix Add water to dissolve; mix the above-mentioned processed raw materials, add citric acid to acidify until the acidity of the mixture is ≥ 1.5, add water and add apricot essence to flavor at 60°C-90°C, homogenize after blending, and heat at 127°C After high temperature sterilization for 3-6 seconds, hot filling is carried out at 90°C. After filling, it is sterilized in warm water at 95°C for 15-20 minutes. After sterilization, it is cooled to 10°C-40°C to obtain the finished product. Apricot juice drink.

Embodiment 3

[0035] According to weight percentage, take 20% apricot puree, 6% white sugar, 0.05% cyclamate, 0.012% AK sugar, 0.25% fruit juice stabilizer, 0.02% potassium sorbate, 0.1% citric acid, 0.03% apricot essence, Water 73.538%, add water to apricot puree, pass through a colloid mill, and grind to 300 mesh; mix white sugar and stabilizer, pass through a colloid mill, and grind to 300 mesh; take cyclamate, AK sugar and potassium sorbate, mix Add water to dissolve; mix the above-mentioned processed raw materials, add citric acid to acidify until the acidity of the mixture is ≥ 1.5, add water and add apricot essence to flavor at 60°C-90°C, homogenize after blending, and heat at 127°C After high temperature sterilization for 3-6 seconds, hot filling is carried out at 90°C. After filling, it is sterilized in warm water at 95°C for 15-20 minutes. After sterilization, it is cooled to 10°C-40°C to obtain the finished product. Apricot juice drink.

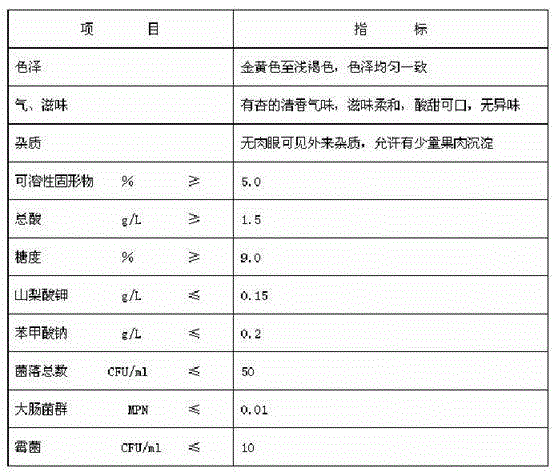

[0036] The following are the physi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com