Preparation method of pearl oil apricot juice with pearl oil apricot peel

A pearl oil and juice technology, applied in the functions of food ingredients, food ingredients as taste improvers, food science and other directions, can solve the problems of processing technology and product quality gap, uneven processing methods, prone to stratification and other problems, To achieve the effect of broadening the way of deep processing, enriching the taste and reducing the sour taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Production of peel powder: wash the pearl oil apricot with clean water, separate the pulp from the peel, beat the peel, then add peach gum accounting for 1 / 40 of the mass of the peel pulp, freeze it in the refrigerator, and dry it with a freeze dryer. The final pericarp is pulverized with a low-temperature ultrafine pulverizer, and the pulverization time is 10min;

[0032] (2) Pulp pulverization: cut the peeled pulp into pieces, add cod peptide, the mass ratio of pulp to cod peptide is 1000:1, and then pulverize with a low-temperature ultrafine pulverizer, and the pulverization time is 20 minutes;

[0033] (3) centrifugation plus filtration: the pulp obtained in step 2 is centrifuged at 4° C. at 4800 r / min for 20 min with a filter refrigerated centrifuge, and the filtrate is taken after centrifugation;

[0034] (4) Deployment: Add crushed fruit peel powder, isomaltooligosaccharide, citric acid, tea polyphenols, and brown algae cellulose nanofibers to the filtrate co...

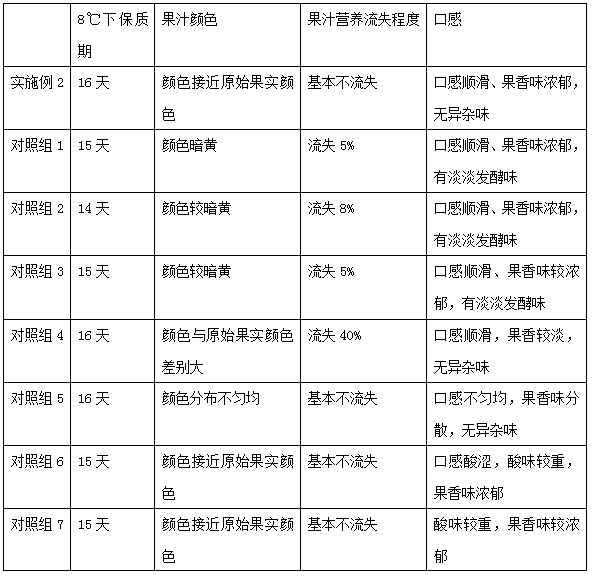

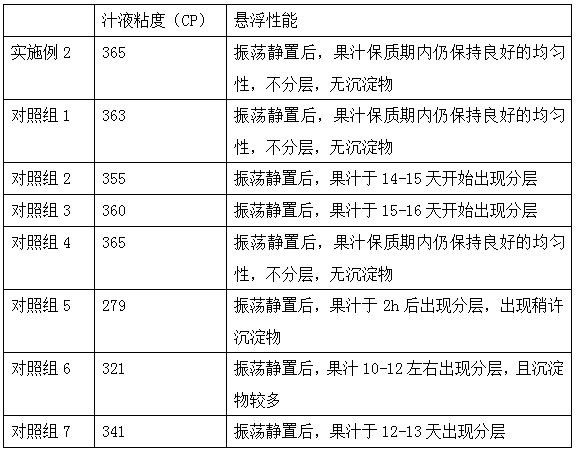

Embodiment 2

[0040] (1) Production of peel powder: wash the pearl oil apricot with clean water, separate the pulp from the peel, beat the peel, then add peach gum accounting for 1 / 40 of the peel pulp mass, freeze it in a refrigerator, and dry it with a freeze dryer. The dried pericarp is pulverized with a low-temperature ultrafine pulverizer, and the pulverization time is 20 minutes;

[0041] (2) Pulp pulverization: cut the peeled pulp into pieces, add cod peptide, the mass ratio of pulp to cod peptide is 1000:2, and then pulverize with a low-temperature ultrafine pulverizer, and the pulverization time is 30 minutes;

[0042] (3) centrifugation plus filtration: the pulp obtained in step 2 is centrifuged at 4° C. at 4800 r / min for 30 min with a filter refrigerated centrifuge, and the filtrate is taken after centrifugation;

[0043] (4) Deployment: Add crushed fruit peel powder, isomaltose oligosaccharide, citric acid, tea polyphenols, and brown algae cellulose nanofibers to the filtrate col...

Embodiment 3

[0049] (1) Production of peel powder: wash the pearl oil apricot with clean water, separate the pulp from the peel, beat the peel, then add peach gum accounting for 1 / 40 of the peel pulp mass, freeze it in a refrigerator, and dry it with a freeze dryer. The dried pericarp is pulverized with a low-temperature ultrafine pulverizer, and the pulverization time is 30 minutes;

[0050] (2) Pulp pulverization: cut the peeled pulp into pieces, add cod peptide, the mass ratio of pulp to cod peptide is 1000:3, and then pulverize with a low-temperature ultrafine pulverizer, and the pulverization time is 40 minutes;

[0051] (3) centrifugation plus filtration: the pulp obtained in step 2 is centrifuged at 4° C. at 4800 r / min for 40 min with a filter refrigerated centrifuge, and the filtrate is taken after centrifugation;

[0052] (4) Deployment: Add crushed fruit peel powder, isomaltose oligosaccharide, citric acid, tea polyphenols, and brown algae cellulose nanofibers to the filtrate col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com