Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Anhydrous magnesium carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing anhydrous magnesium carbonate powder

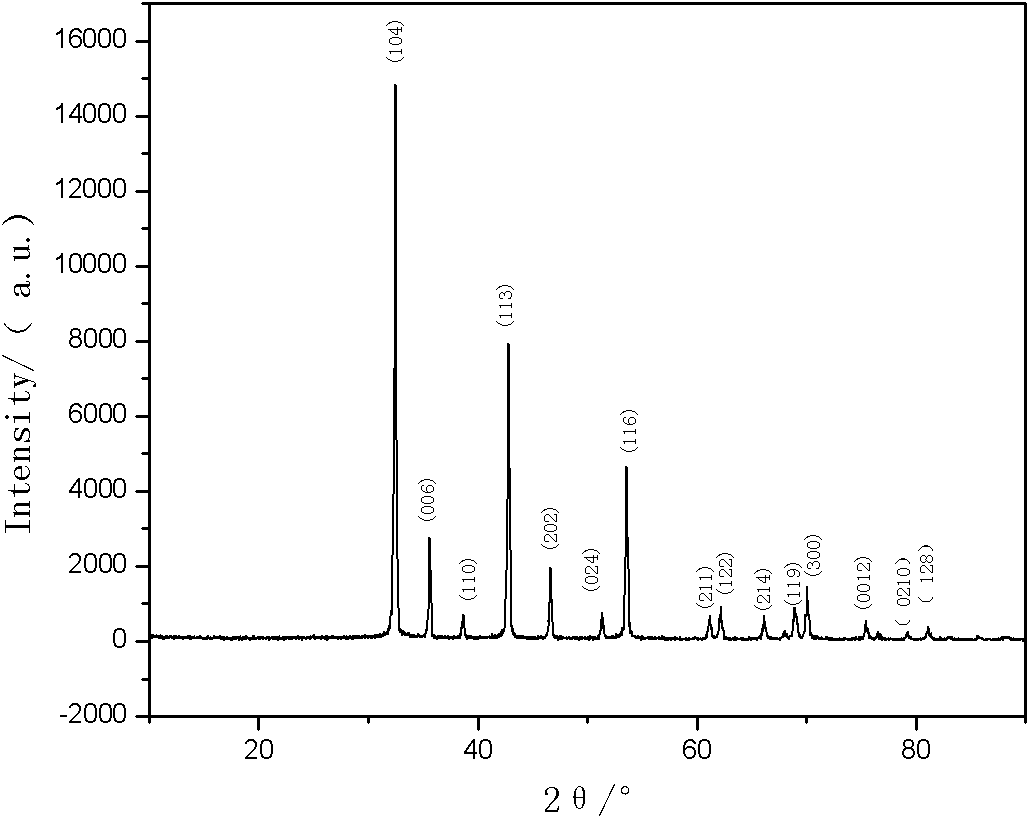

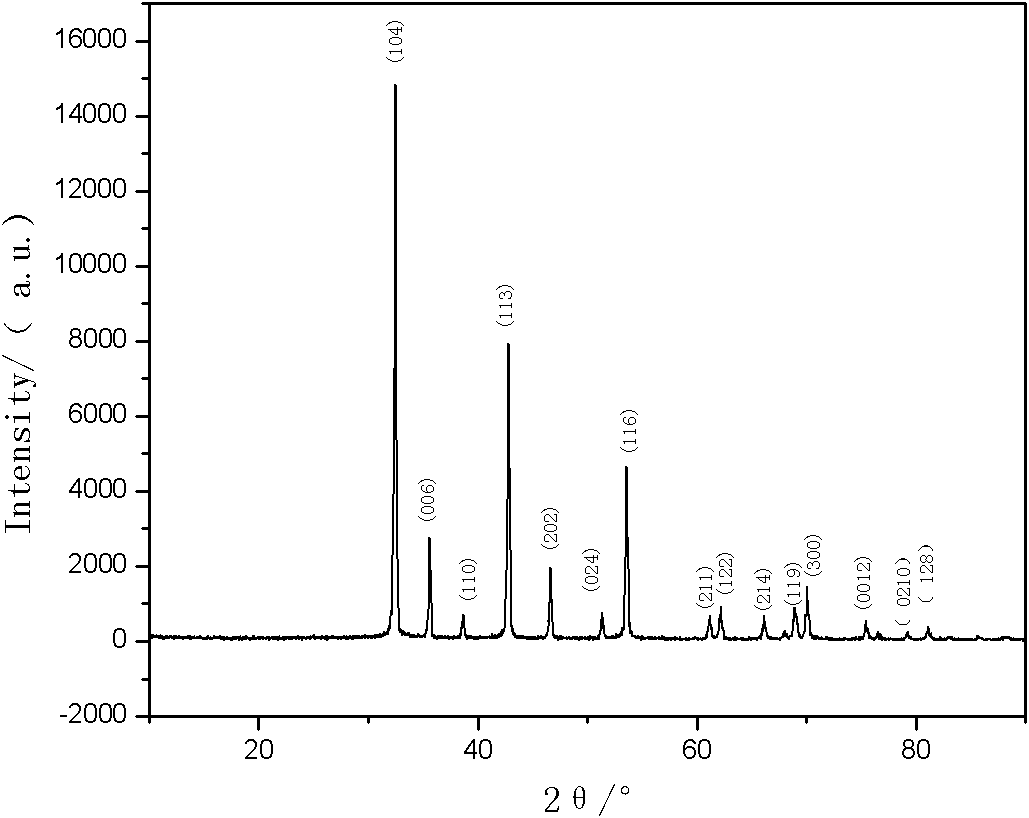

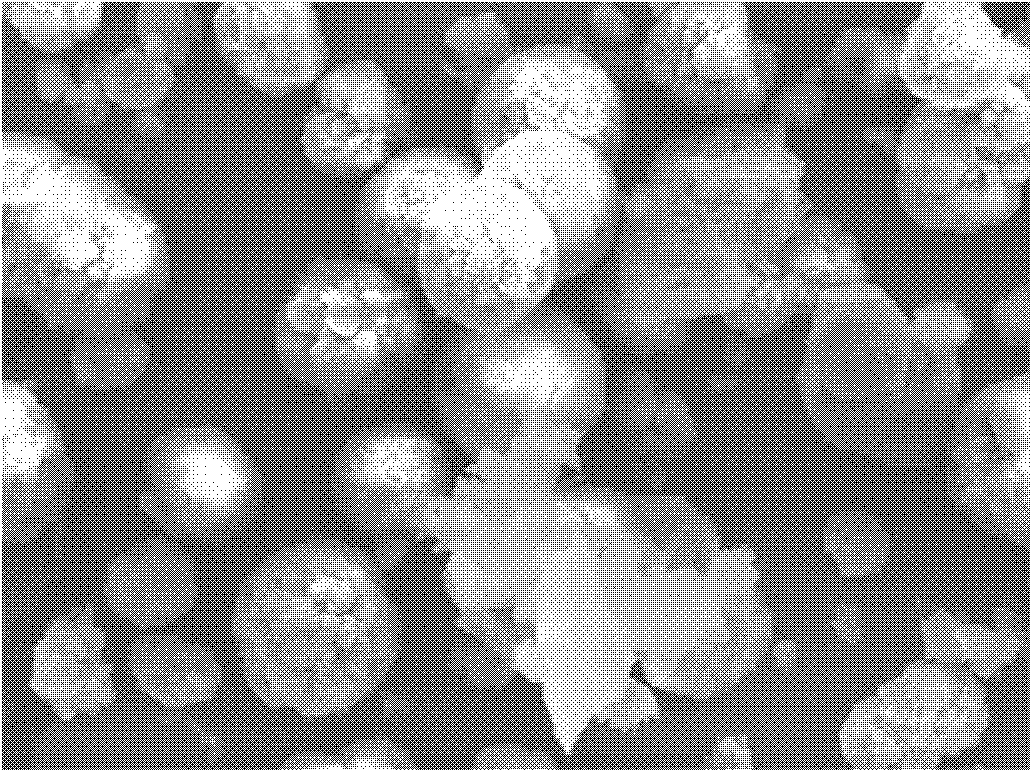

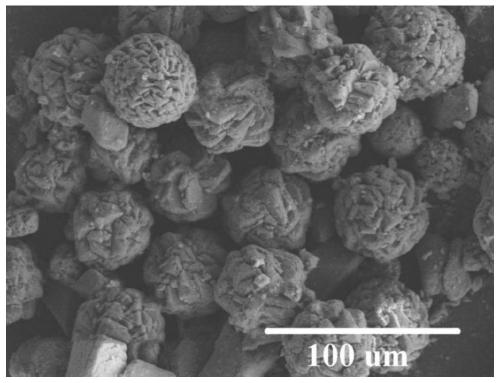

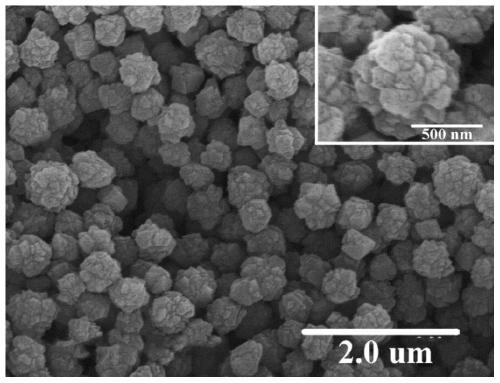

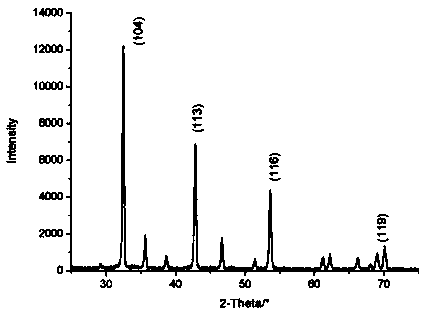

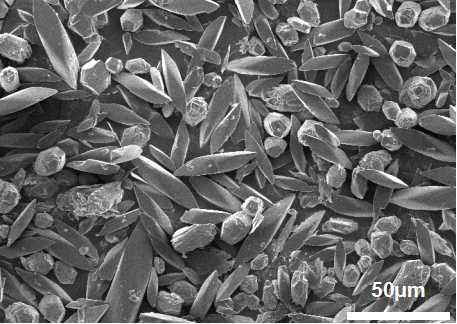

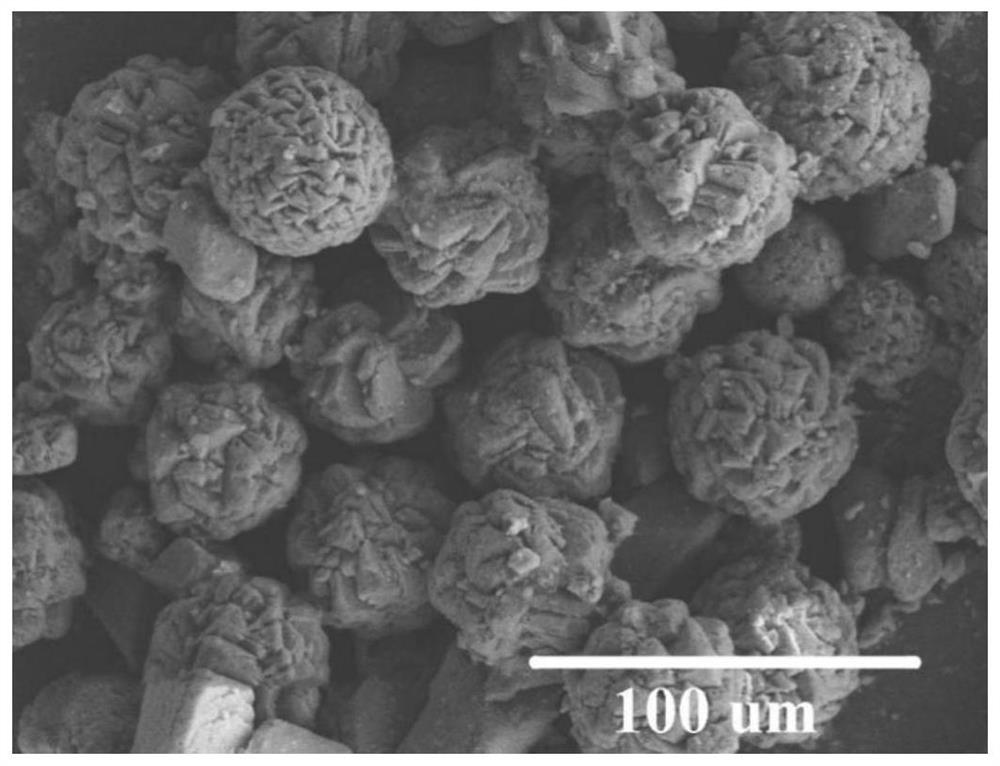

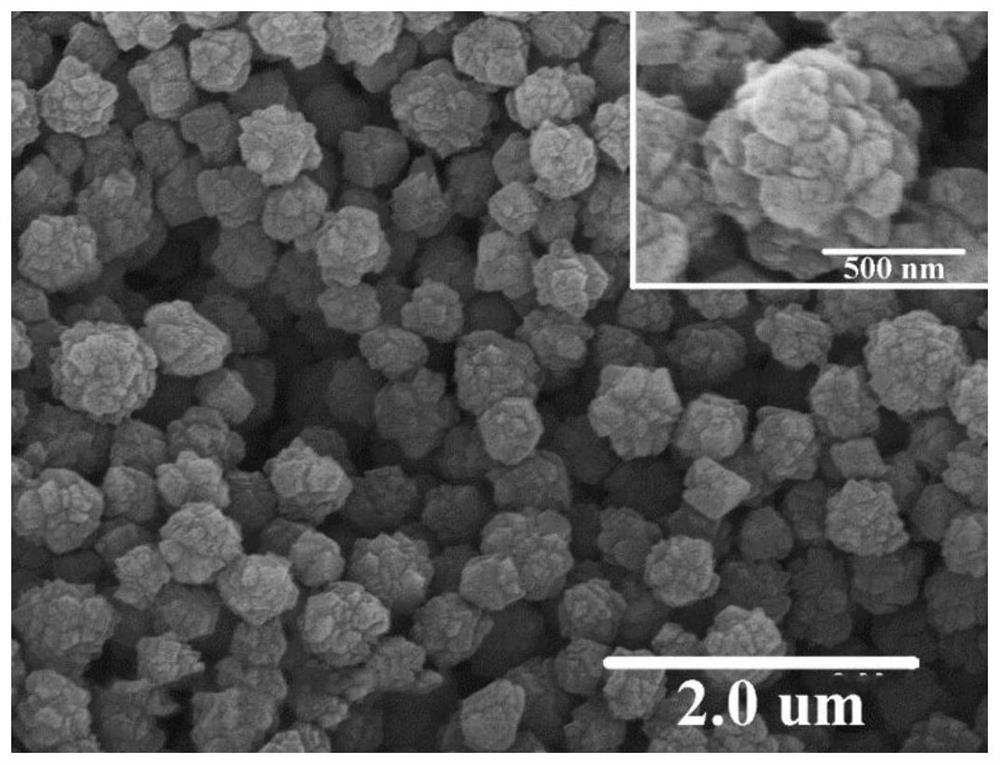

The invention discloses a method for preparing anhydrous magnesium carbonate (MgCO3) powder. In the method, magnesium chloride (MgCl2) is adopted as a magnesium source, carbamide (NH2)2CO is adopted as a precipitant, and chelant sodium citrate (C6H5O7Na3 2H2O) is added under the condition of hydrothermal reaction and different reaction time of 6-24 hours under the temperature of 100-200 DEG C to prepare the anhydrous magnesium carbonate powder. With the method, the anhydrous magnesium carbonate powder with single-phase composition and unique flowery and spherical shapes can be prepared. At present, except for magnesite magnesium carbonate, other magnesium carbonate products are all hydrate basic magnesium carbonate in the market. Compared with the prior art, the method fully realizes the single-phase composition of the anhydrous magnesium carbonate powder and besides fire retardant, the anhydrous magnesium carbonate powder can be used for various respects. The method is simple in technology and lower in production cost, and fills a gap in the production of the single-phase anhydrous magnesium carbonate powder.

Owner:DALIAN JIAOTONG UNIVERSITY

Fireproof aluminum-plastic panel core material

The invention discloses a fireproof aluminum-plastic panel core material comprising the following components: low-density polyethylene, an ethylene-octene copolymer, aluminum hydroxide, anhydrous magnesium carbonate, calcium stearate, silicon dioxide, a coupling agent, a smoke suppressant, a reinforcing toughener and titanium dioxide. The fireproof aluminum-plastic panel core material prepared by the formula has the advantages of being halogen-free, low-smoke, flame-retardant, and drop-resistant; the panel has flexible rolling property; the fireproof aluminum-plastic panel core material is strong in toughness, easy to mold and good in processability and play roles in thermal insulation, oxygen isolation and smoke suppression; a relatively good flame retardant effect is reached; and continuous automatic production can also be achieved.

Owner:RUGAO BINJIANG URBAN CONSTR INVESTMENT

Method for preparing anhydrous magnesium carbonate powder

The invention discloses a method for preparing anhydrous magnesium carbonate (MgCO3) powder. In the method, magnesium chloride (MgCl2) is adopted as a magnesium source, carbamide (NH2)2CO is adopted as a precipitant, and chelant sodium citrate (C6H5O7Na3 2H2O) is added under the condition of hydrothermal reaction and different reaction time of 6-24 hours under the temperature of 100-200 DEG C to prepare the anhydrous magnesium carbonate powder. With the method, the anhydrous magnesium carbonate powder with single-phase composition and unique flowery and spherical shapes can be prepared. At present, except for magnesite magnesium carbonate, other magnesium carbonate products are all hydrate basic magnesium carbonate in the market. Compared with the prior art, the method fully realizes the single-phase composition of the anhydrous magnesium carbonate powder and besides fire retardant, the anhydrous magnesium carbonate powder can be used for various respects. The method is simple in technology and lower in production cost, and fills a gap in the production of the single-phase anhydrous magnesium carbonate powder.

Owner:DALIAN JIAOTONG UNIVERSITY

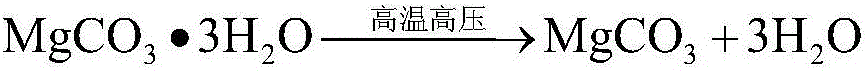

Method for preparing anhydrous magnesium carbonate through magnesium-containing mother solution

ActiveCN105540625AAvoid generatingStable in natureAmmonium nitratesMagnesium carbonatesPhysical chemistryCarbonization

A method for preparing anhydrous magnesium carbonate through a magnesium-containing mother solution includes the following steps of firstly, adjusting the pH value, wherein ammonia gas is introduced into the magnesium-containing mother solution till the pH value is 10.0-12.0 to obtain Mg(OH)2 slurry; secondly, conducting CO2 carbonizing, wherein CO2 is introduced till the pH value is 7.5-8.0 to obtain a carbonized mother solution; thirdly, conducting pyrolysis separation, wherein the carbonized mother solution is heated and decomposed to separate solid and liquid and obtain MgCO3.3H2O solid salt and a pyrolysis separation mother solution; fourthly, conducting calcining, wherein MgCO3.3H2O is calcined to obtain anhydrous magnesium carbonate. Calcining is further conducted to obtain magnesium oxide. The MgCO3.3H2O obtained through pyrolysis separation is large in granularity, the filter separation performance is good, the carrying amount of the mother solution is small, the MgO content reaches up to 47.3%, and the total yield of magnesium ions reaches up to 92.8%; the purity of the MgO product is high, and inorganic ammonium salt type by-products can be co-produced; the method is simple in process, beneficial to industrial production, low in cost, green and environmentally friendly.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

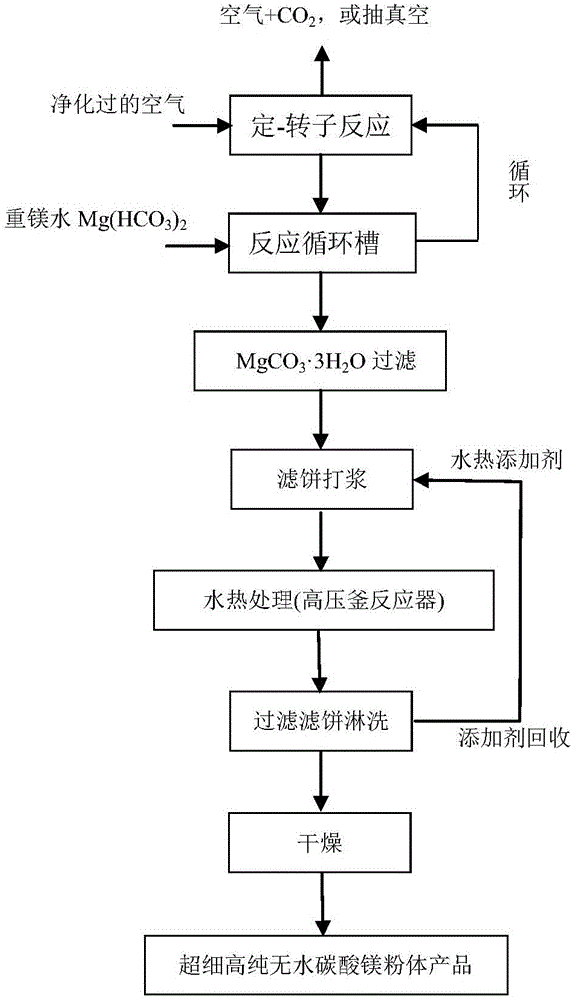

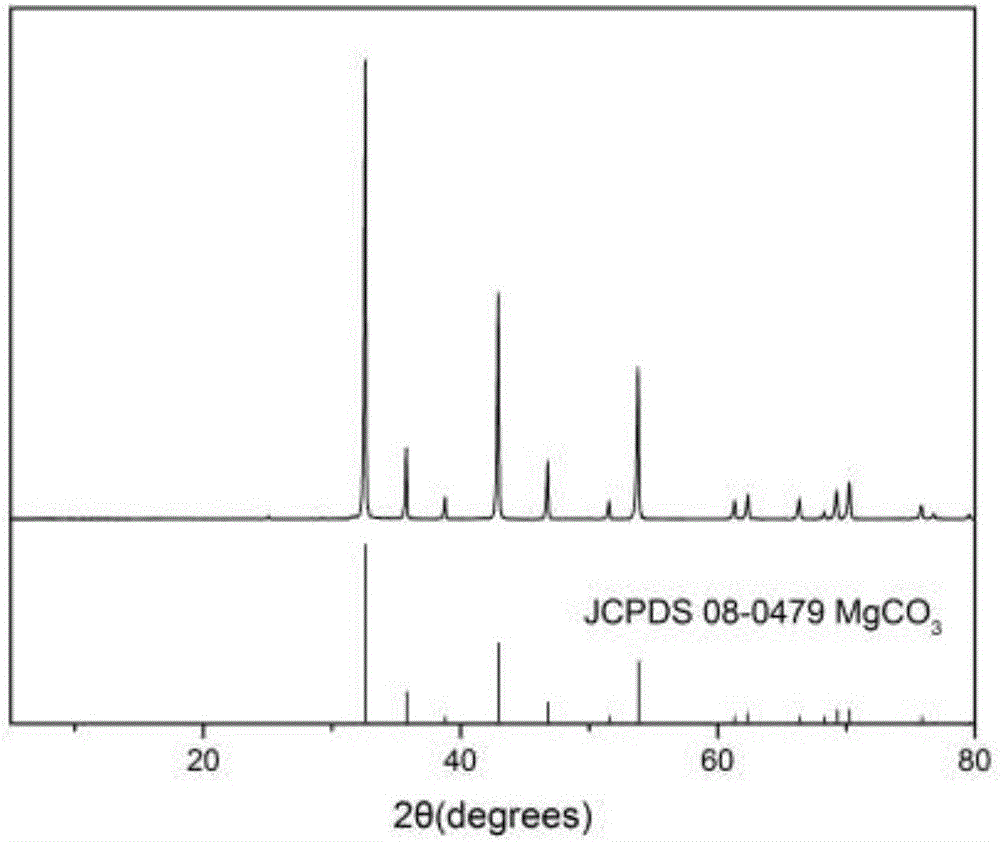

Environment-friendly preparation process of high-purity and superfine anhydrous magnesium carbonate

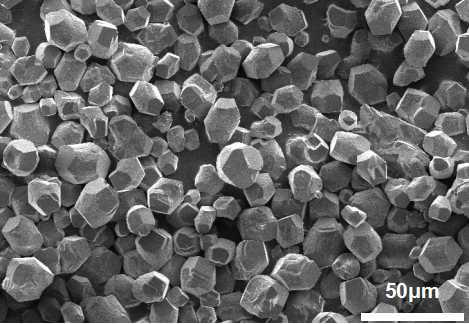

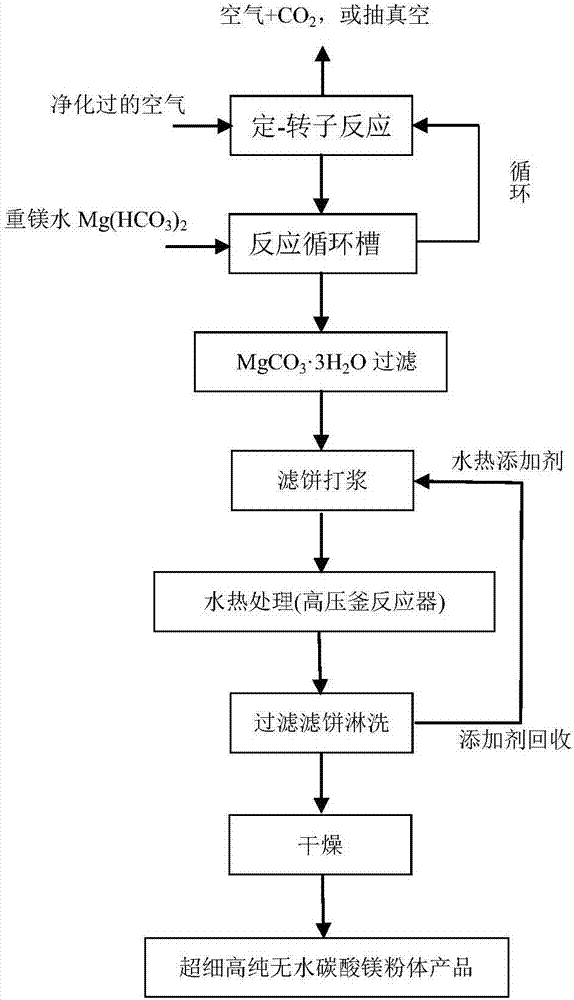

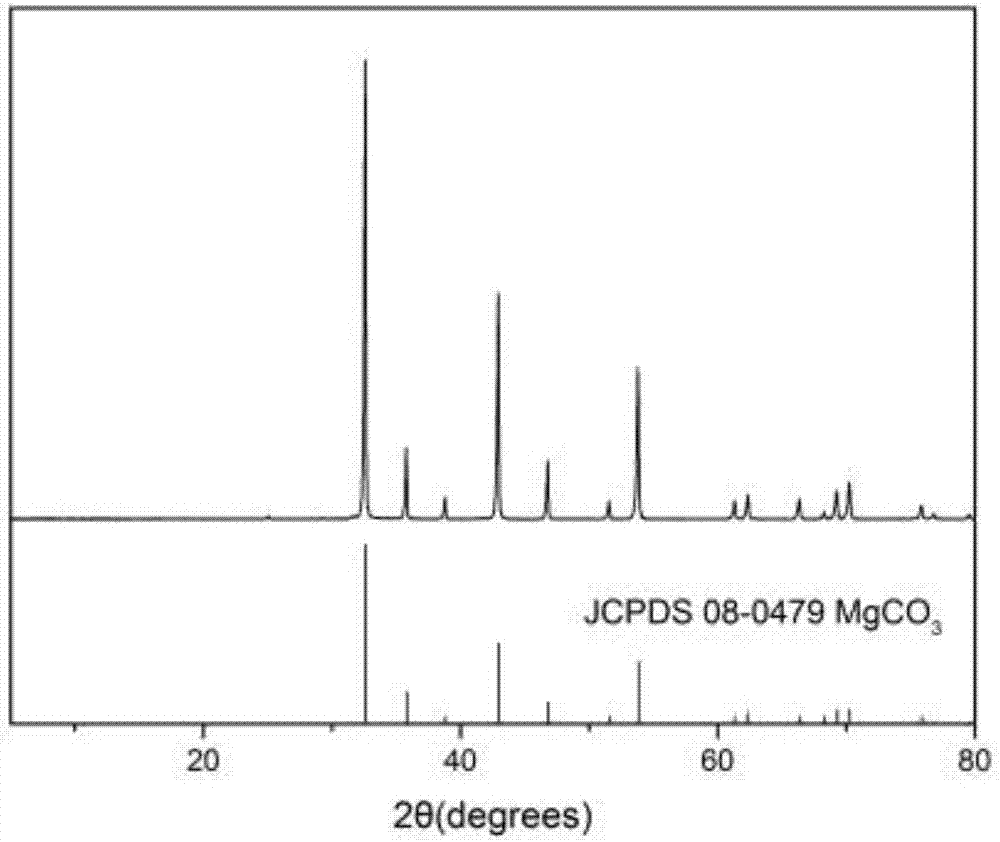

The invention discloses an environment-friendly preparation process of high-purity and superfine anhydrous magnesium carbonate and belongs to the field of inorganic chemical synthesis and inorganic materials. Light calcined powder or magnesium hydroxide is taken as a raw material, heavy magnesium water reversely contacts with purified air in a supergravity stator-rotor reactor after a carbonization reaction and removal of iron ions and heavy metal impurities (or heavy magnesium water is vacuumized), interphase transfer is reinforced, liquid-phase carbon dioxide is rapidly diffused to a gas phase, the magnesium bicarbonate is accelerated to be decomposed to generate magnesium carbonate trihydrate and carbon dioxide, magnesium carbonate trihydrate and carbon dioxide are mixed with an ammonium hydrogen carbonate solution with certain concentration after precipitation and filtration, a uniform sizing agent is prepared, a hydrothermal reaction is performed in a reactor, and loose single-phase high-purity and superfine anhydrous magnesium carbonate powder is obtained. The preparation process is environment-friendly, the raw materials are cheap, no organic additive is required in the production process, and high-purity and superfine anhydrous magnesium carbonate has wide application fields, has remarkable price and performance advantages and high market competitiveness and has remarkable innovativeness, economical efficiency and practicability.

Owner:BEIJING UNIV OF CHEM TECH

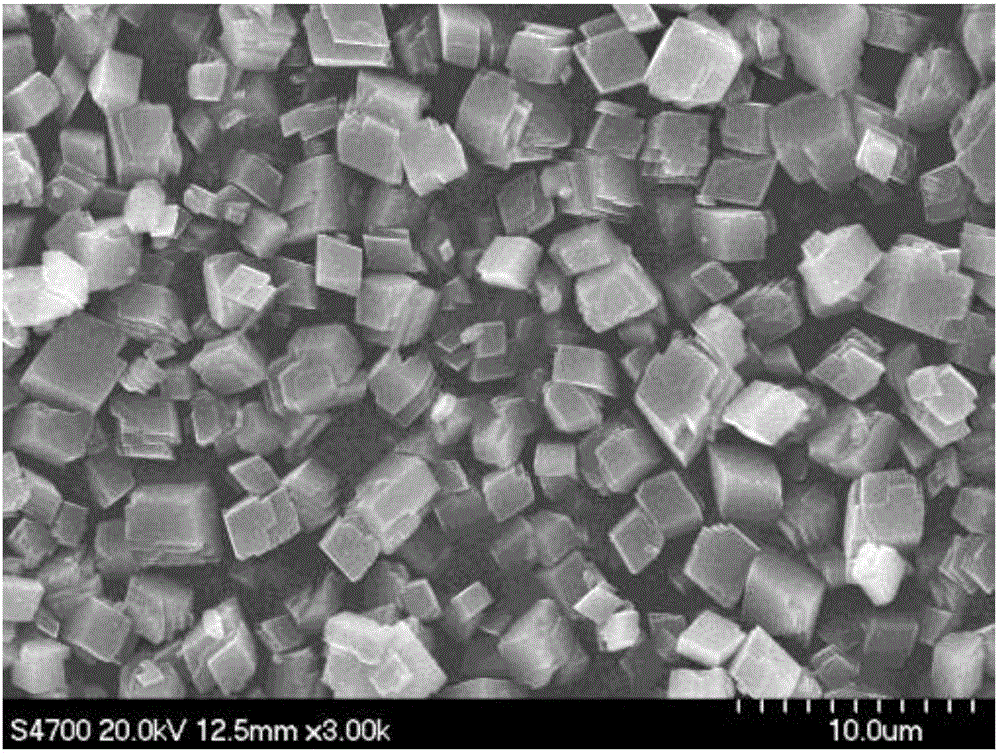

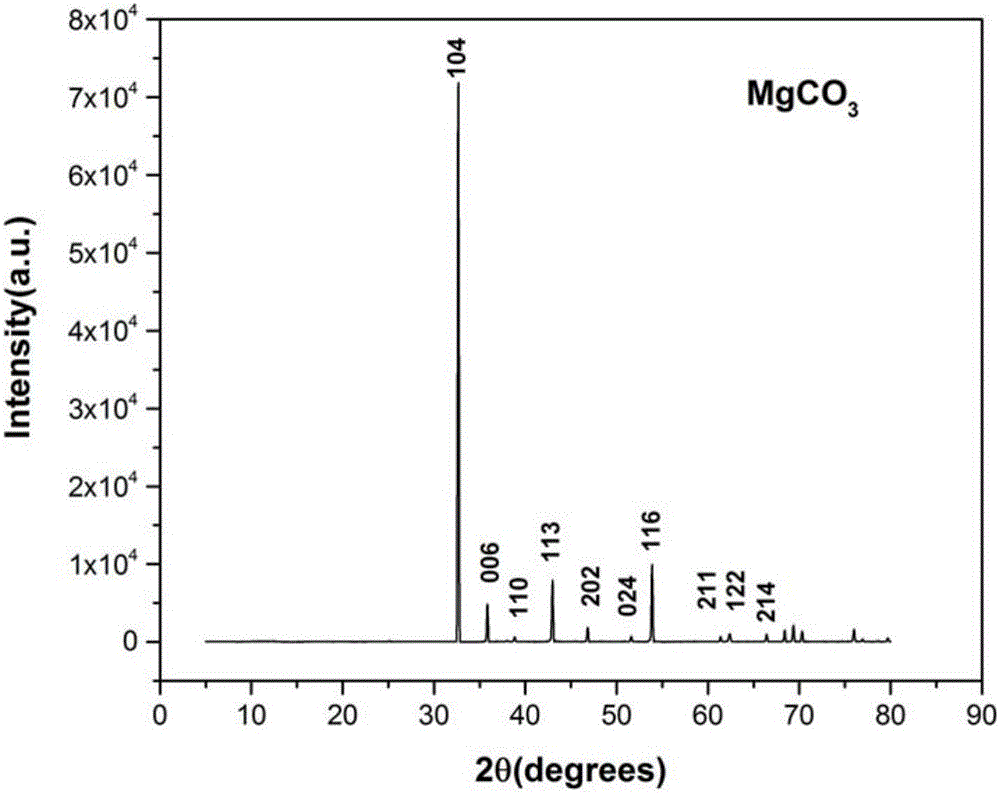

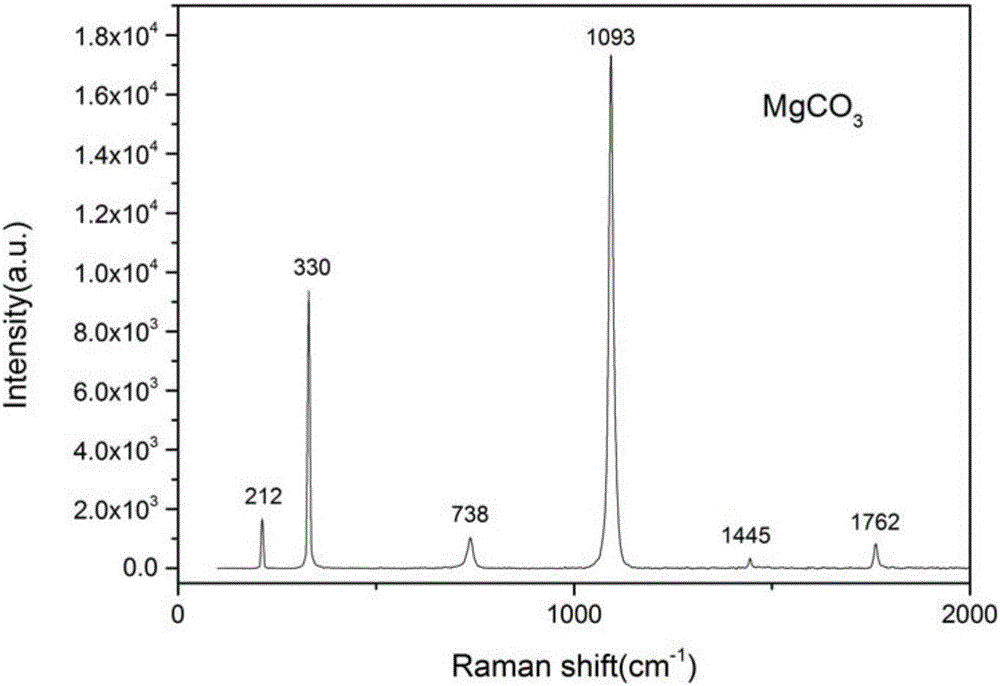

Method for preparing anhydrous magnesium carbonate under high temperature and high pressure

The invention discloses a method for preparing anhydrous magnesium carbonate under high temperature and high pressure. The method includes: using analytically-pure nesquehonite powder as the initial raw material; using a tablet press to press the nesquehonite powder into a cylinder, and using silver foil to wrap the cylinder to obtain a sample; grinding sodium chloride into powder above 200 meshes, and drying in a drying oven under 150 DEG C for 2 hours; using the dried sodium chloride powder to prepare a sodium chloride cylinder sample containing the sample obtained in the second step; assembling the sodium chloride cylinder sample into a high pressure synthesis assembling block, and placing into a cubic press for high-temperature and high-pressure reaction; taking out the sample after the reaction, and removing the silver foil on the surface of the sample to obtain the anhydrous magnesium carbonate. By the method, the technical problems that the prior art which uses a hydrothermal method, CO2 atmosphere protection and annealing to prepare the anhydrous magnesium carbonate is complex in operation process and long in reaction time, and the prepared anhydrous magnesium carbonate is low in purity, poor in chemical stability and prone to water absorption are solved.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Synthetic method for mint benzoate

InactiveCN103588642AHigh yieldThe synthesis process is simpleOrganic compound preparationCarboxylic acid esters preparationRefluxBenzoic acid

The invention discloses a synthetic method for mint benzoate. The method comprises the following steps: adding menthol and benzoic acid according to a mol ratio of 1: 0.8-1.6 and adding the catalyst para-toluenesulfonic acid accounting for 1 to 4% of the weight of menthol and benzoic acid; carrying out heating reflux at a temperature of 95 to 102 DEG C, beginning timing when reflux appears and allowing a reaction to last for 2 to 10 h; after completion of the reaction, successively subjecting a cooled solution to washing with deionized water, washing with a sodium carbonate solution and liquid separation; carrying out drying by using anhydrous magnesium carbonate and removing magnesium sulfate through filtration after drying so as to obtain a clear light-yellow solution; and subjecting the solution to normal pressure distillation, removing cyclohexane through steaming at a temperature of 81 DEG C, subjecting a crude mint benzoate product to reduced pressure distillation and collecting a fraction obtained at 263 to 271 DEG C (5.8 kPa) as a product. According to the invention, para-toluenesulfonic acid is a good catalyst for synthesis of mint benzoate, and the synthetic method has the advantages of a high practical application value, high yield of mint benzoate and simple synthesis process.

Owner:太仓市运通化工厂

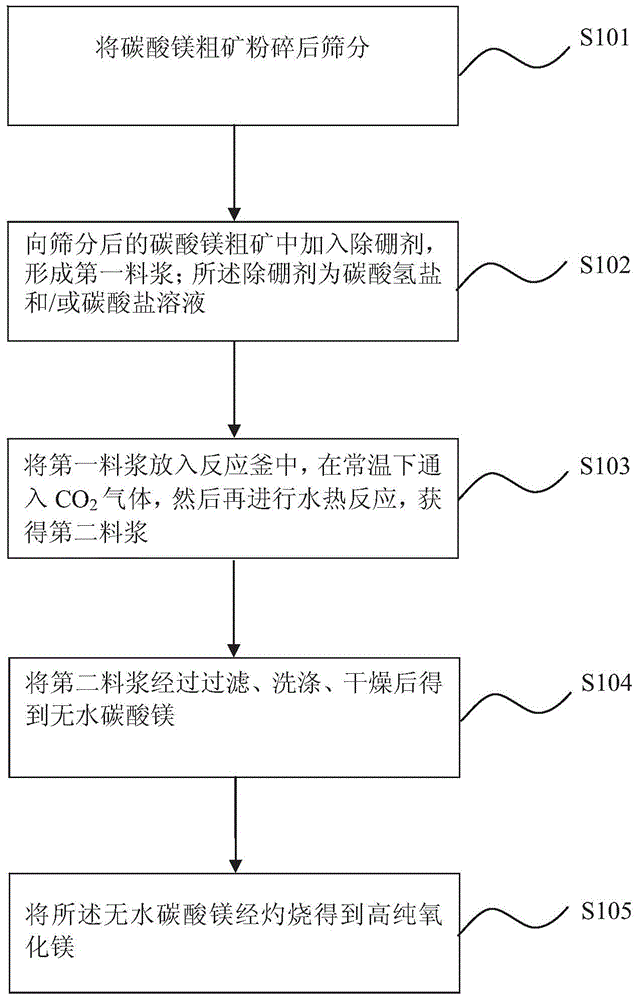

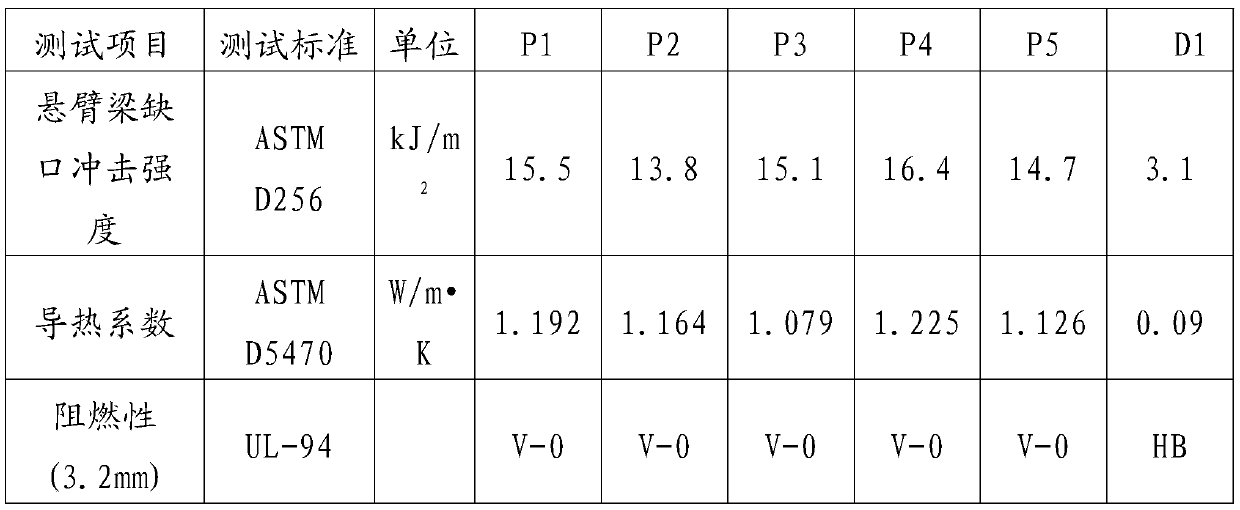

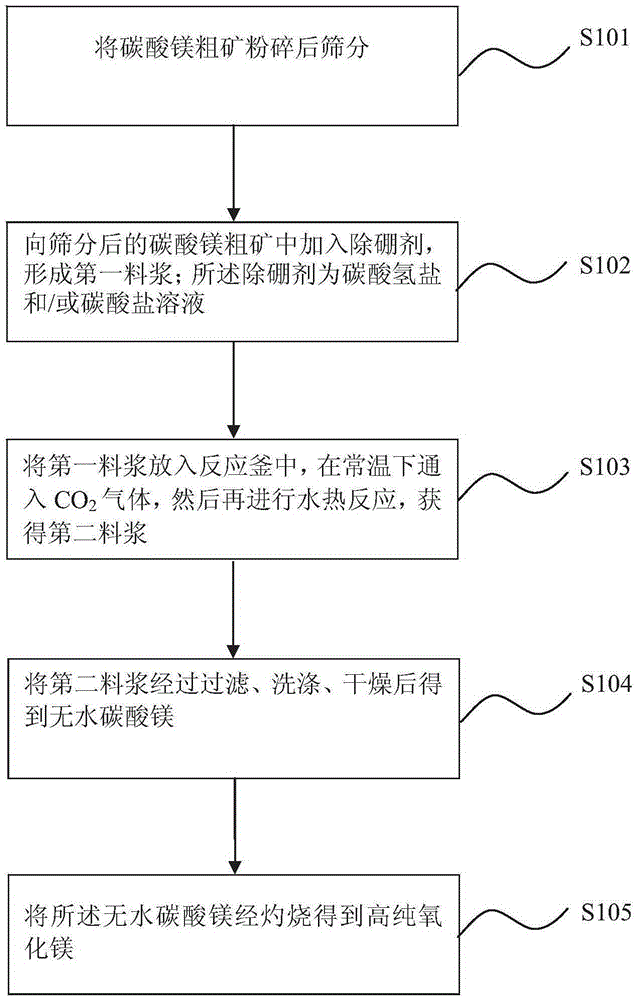

Method for preparing high-purity magnesium oxide from coarse magnesium carbonate ore

The invention discloses a method for preparing high-purity magnesium oxide from coarse magnesium carbonate ore. The method comprises steps as follows: (1) crushing and then screening the coarse magnesium carbonate ore; (2) adding a boron removing agent to the screened coarse magnesium carbonate ore to obtain first slurry, wherein the boron removing agent is a bicarbonate and / or carbonate solution; (3) placing the first slurry into a reaction kettle, feeding CO2 at the normal temperature, and then conducting a hydrothermal reaction to obtain second slurry; (4) filtering, washing and drying the second slurry to obtain anhydrous magnesium carbonate; (5) burning the anhydrous magnesium carbonate to obtain the high-purity magnesium oxide. According to the method, bicarbonate is formed through feeding the CO2 into the mixed slurry, the hydrothermal reaction is conducted in the presence of the bicarbonate to convert boron compounds among magnesium carbonate crystals into soluble substances, then boron impurities are removed through washing, and the purity of the finally prepared magnesium oxide is higher than 98%.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

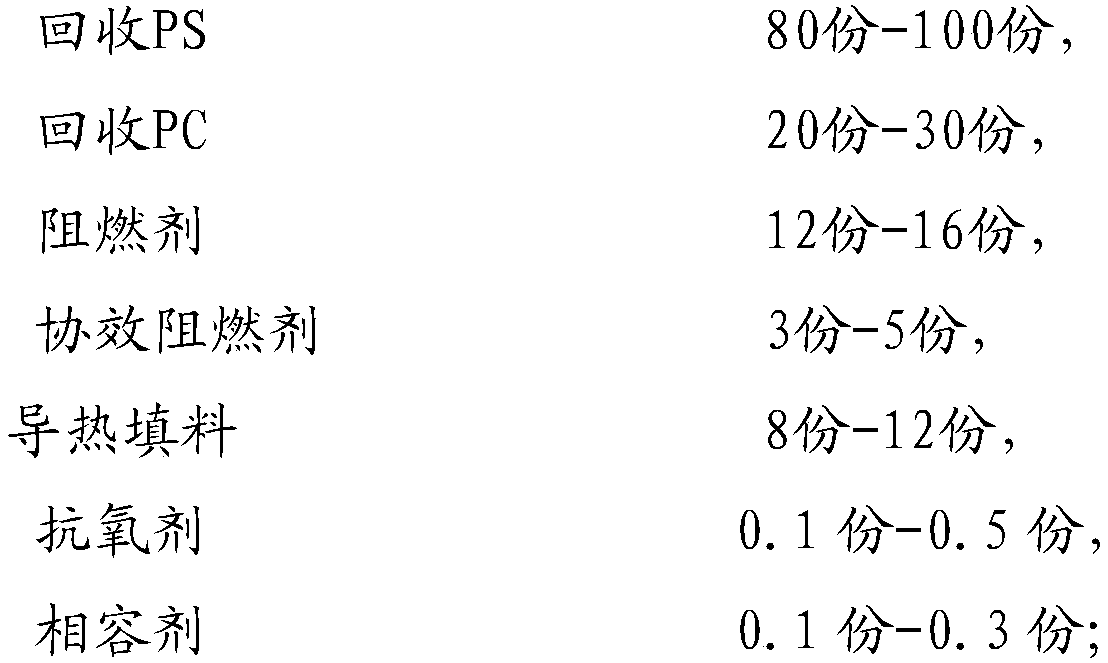

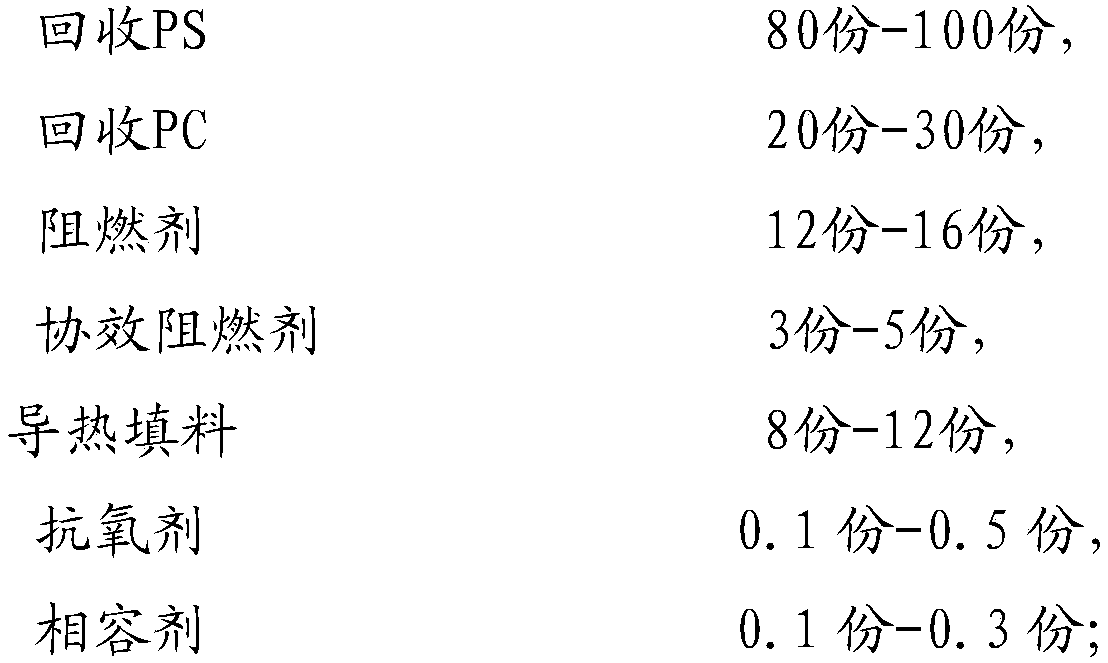

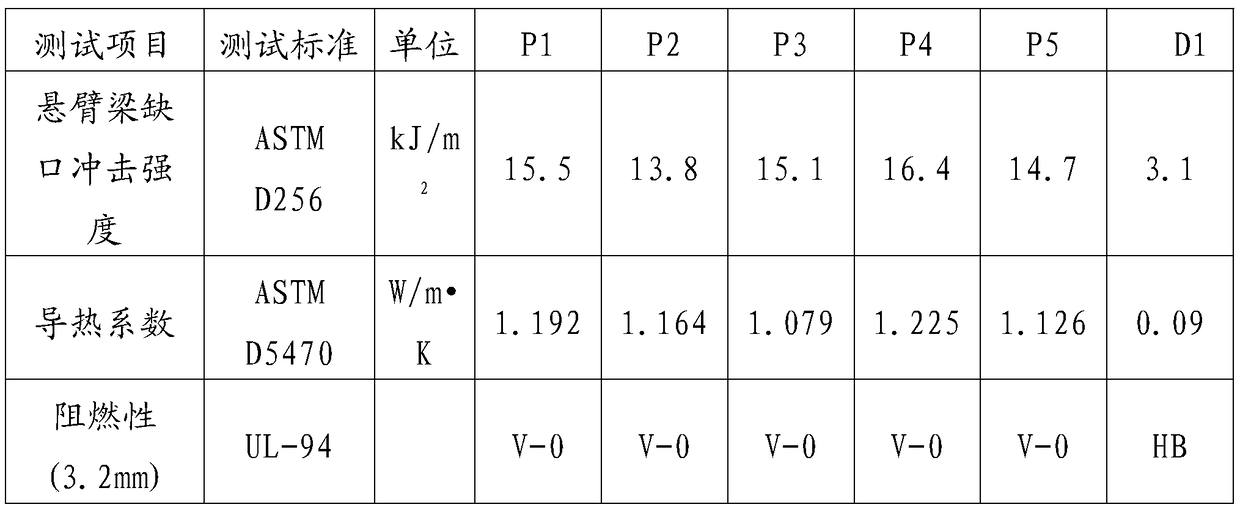

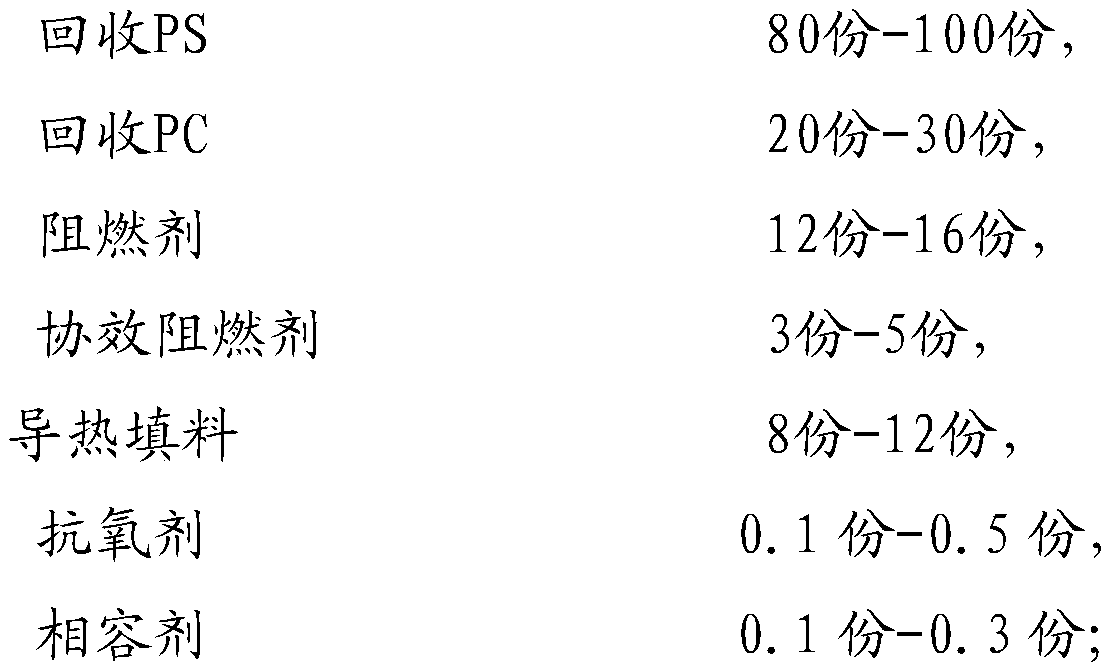

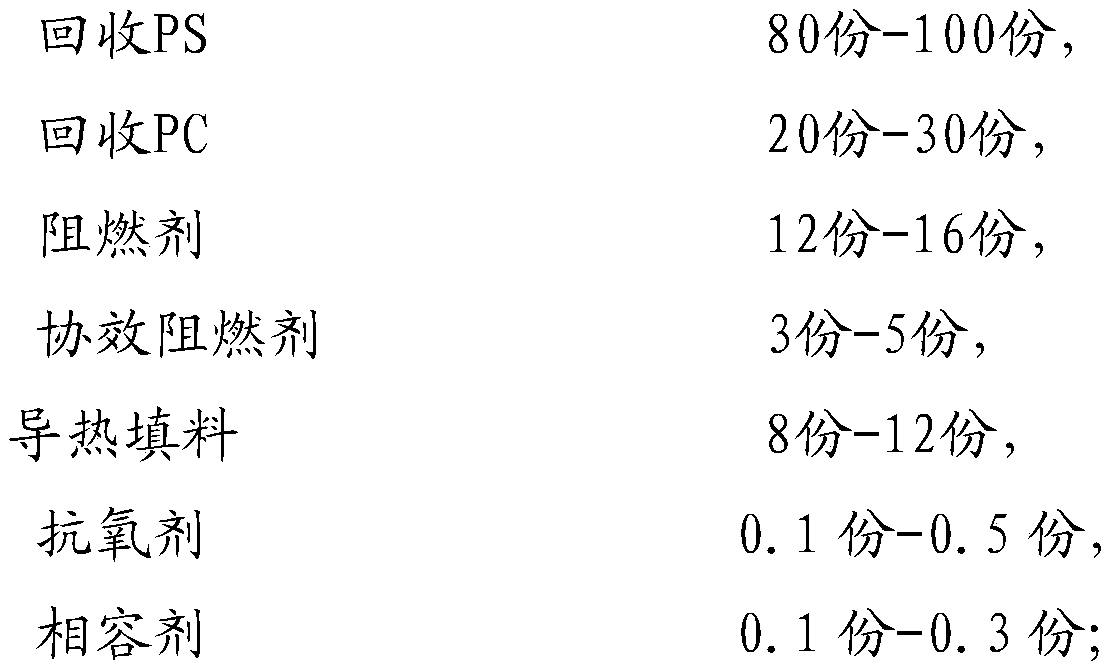

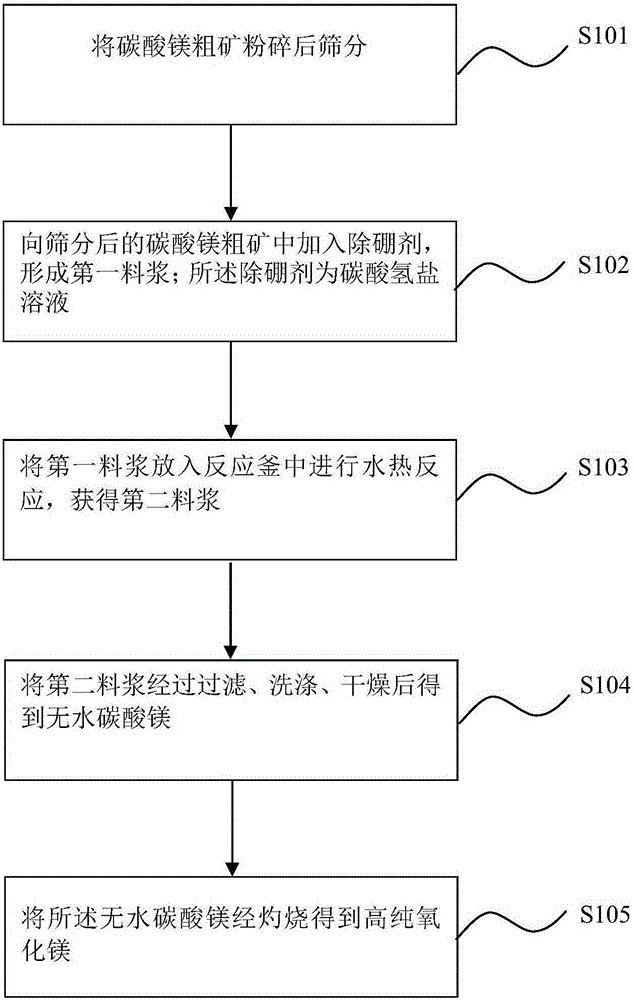

Flame-retardant heat-conduction recycled PS (polystyrene) composite material and preparation method thereof

ActiveCN108752775AImprove flame retardant performanceHigh thermal conductivityCalcium silicateAntioxidant

The invention relates to a flame-retardant heat-conduction recycled PS (polystyrene) composite material and a preparation method thereof. The preparation method includes weighing 80-100 parts of recycled PS, 20-30 parts of recycled PC (polycarbonate), 12-16 parts of flame retardants, 3-5 parts of calcium silicate whiskers, 8-12 parts of Bi2O3, 0.1-0.5 part of antioxidants, 0.1-0.3 part of-g-MAH SEBS and mixing with stirring uniformly to obtain a mixture; extruding the mixture to granulate through a double-screw extruder to obtain the PS composite material. Since tetrabromobisphenol S bis-(2,3-dibromopropyl ether) and anhydrous magnesium carbonate are compounded as the main flame retardant creatively and calcium silicate whiskers serve as an auxiliary flame retardant, flame retardance of the PS composite material is improved; calcium silicate whiskers, serving as the auxiliary flame retardant, have classical porous structures and can be expanded into carbon under catalysis, and thus, the flame redardance of the PS composite material is improved further.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Method for preparing special-shaped anhydrous magnesium carbonate based on hydrothermal carbonization reaction

The invention discloses a method for preparing special-shaped anhydrous magnesium carbonate based on a hydrothermal carbonization reaction. According to the method, with ascorbic acid as a carbon source, the ascorbic acid is dissolved in deionized water, the initial pH of an ascorbic acid aqueous solution is adjusted to be 5.5-14.0, then magnesium salt is added, and under the condition that the temperature of a hydrothermal reaction is 120-250 DEG C and the time of the hydrothermal reaction is 1-12 hours, anhydrous magnesium carbonate powder which is good in dispersity, diverse in shape and even in size is prepared. The magnesium salt is one of magnesium sulfate and magnesium chloride and magnesium hydroxide and magnesium oxide and magnesium acetate. The preparation method is easy and convenient to implement, easy to control, efficient and capable of saving energy, CO2 does not need to be introduced as the carbon source, by easily changing the concentration of the magnesium salt or regulating the initial pH value of the ascorbic acid solution, the shape and size of the anhydrous magnesium carbonate can be regulated, and the obtained product is pure-phase anhydrous magnesium carbonate.

Owner:EAST CHINA UNIV OF SCI & TECH

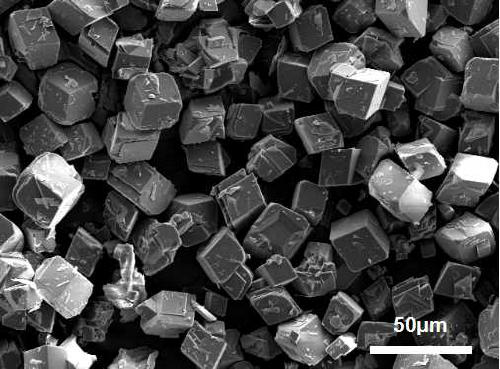

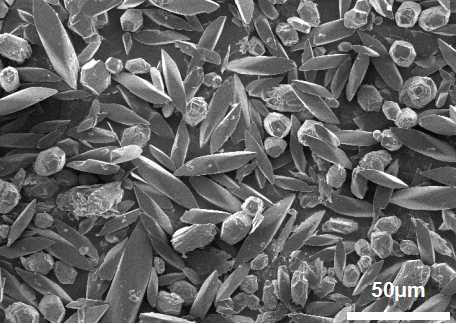

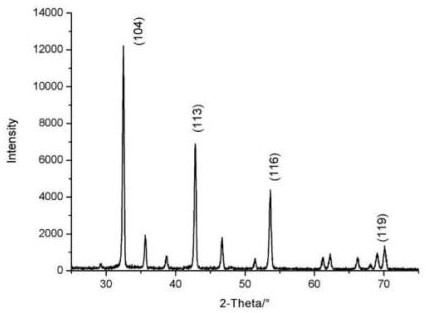

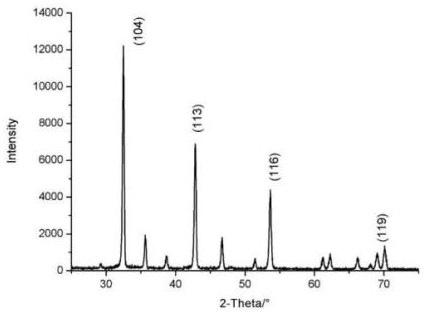

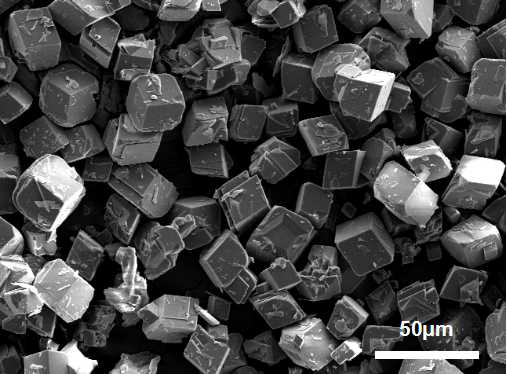

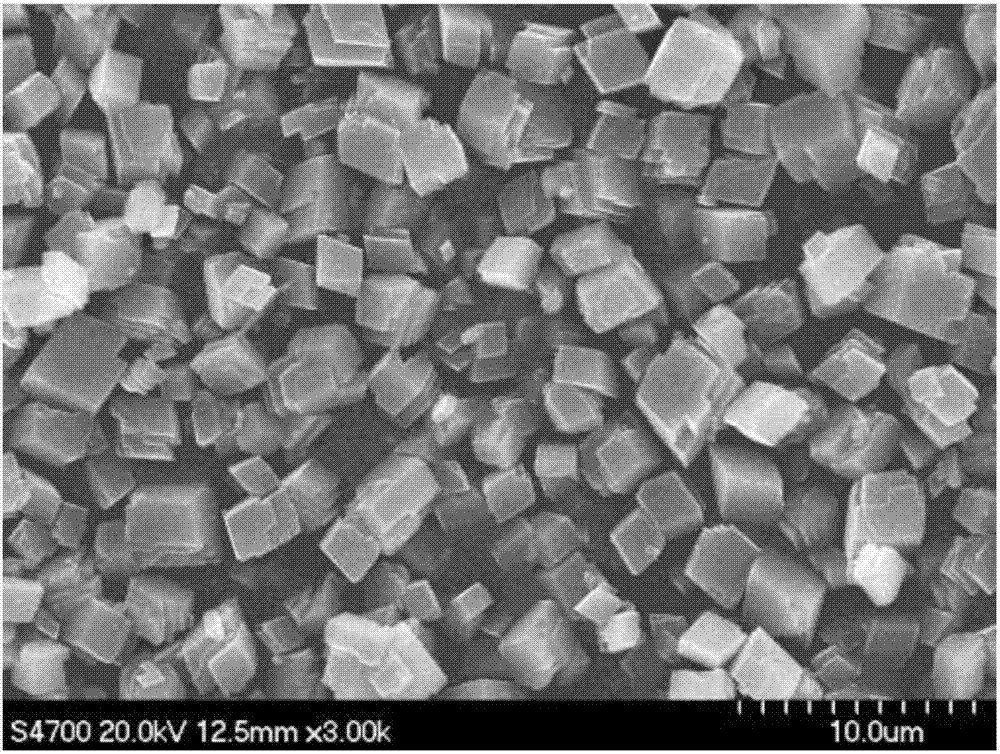

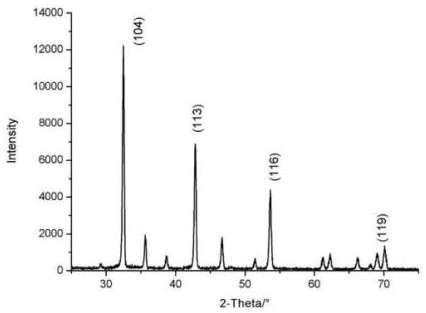

Preparation method of rhombohedral anhydrous magnesium carbonate

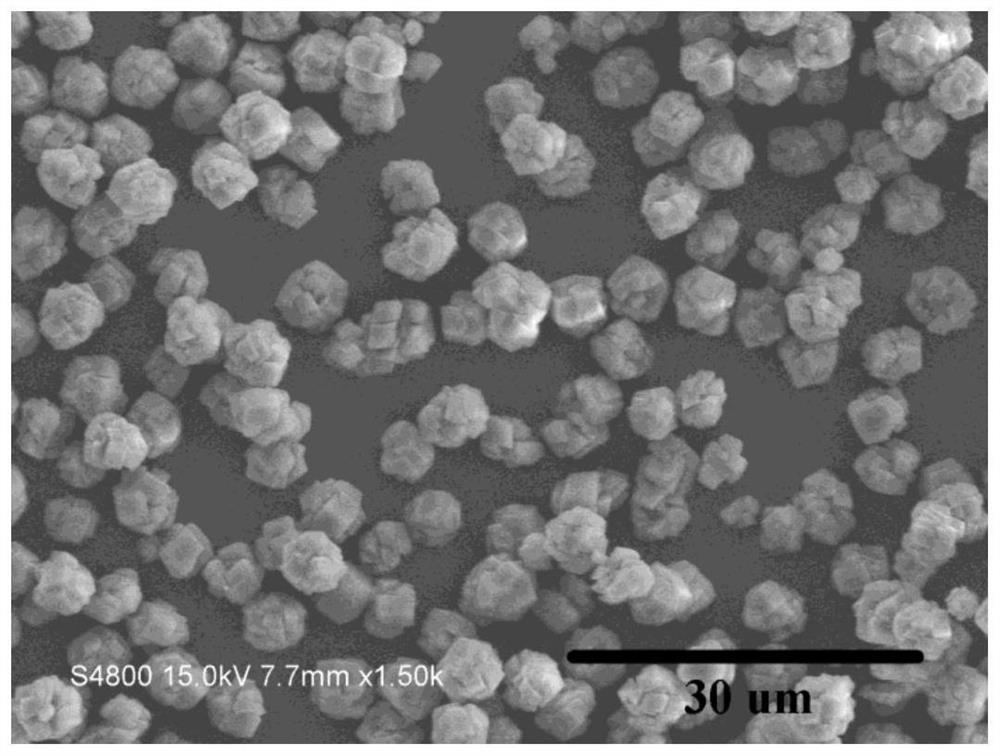

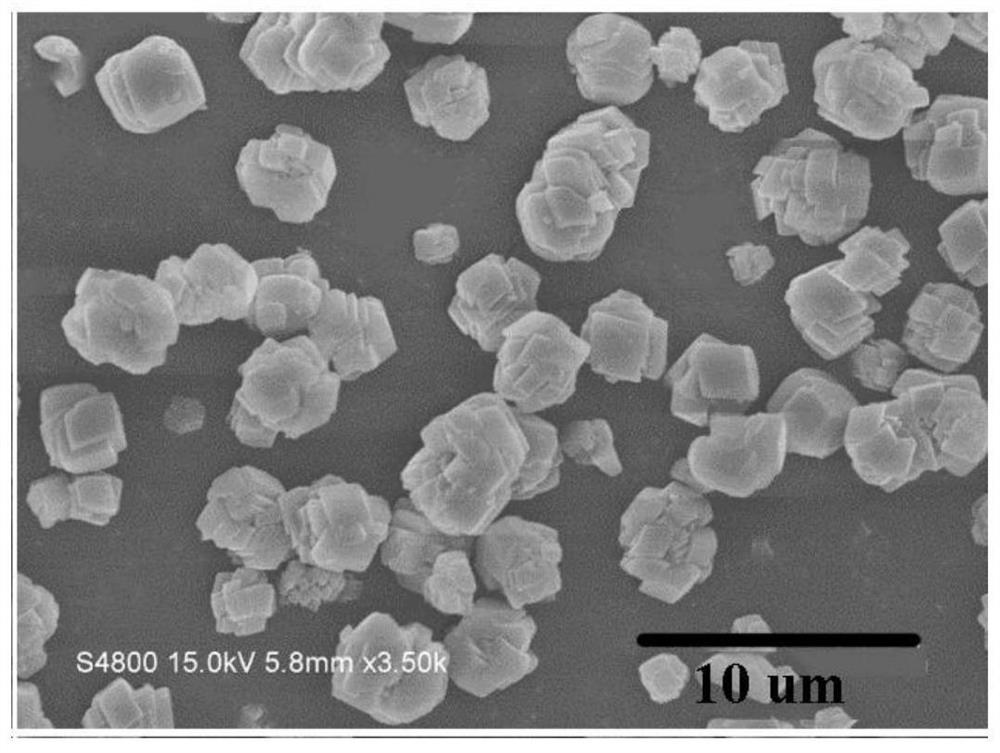

The invention provides a preparation method of rhombohedral anhydrous magnesium carbonate, and belongs to the technical field of inorganic chemical new materials. The preparation method comprises thefollowing steps: adding MgCl2.6H2O to distilled water to prepare a solution with a certain concentration, adding CH4N2O according to a certain mass molar ratio, and performing stirring to obtain a transparent solution; heating the prepared solution to carry out a pre-synthesis reaction at 80-95 DEG C for 1-2 h; transferring a mixed solution obtained after the pre-synthesis reaction into a stainless steel reactor with a polytetrafluoroethylene lining, and carrying out a hydrothermal reaction at 140-150 DEG C for 2-4 h; and carrying out negative pressure filtration, washing and drying on a product obtained after the hydrothermal reaction is completed in order to obtain the rhombohedral anhydrous magnesium carbonate. The rhombohedral anhydrous magnesium carbonate prepared in the present invention belongs to a trigonal system, the side length of every rhombus is 20-25 [mu]m, and the size of every rhombohedral particle is 25-30 [mu]m.

Owner:SHANDONG UNIV OF TECH

Preparation method of heavy anhydrous magnesium carbonate and magnesium oxide

InactiveCN106276990AEfficient use ofSimple technologyMagnesium carbonatesMagnesiaMagnesium saltReaction temperature

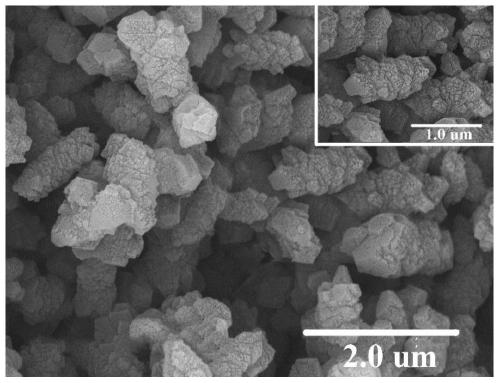

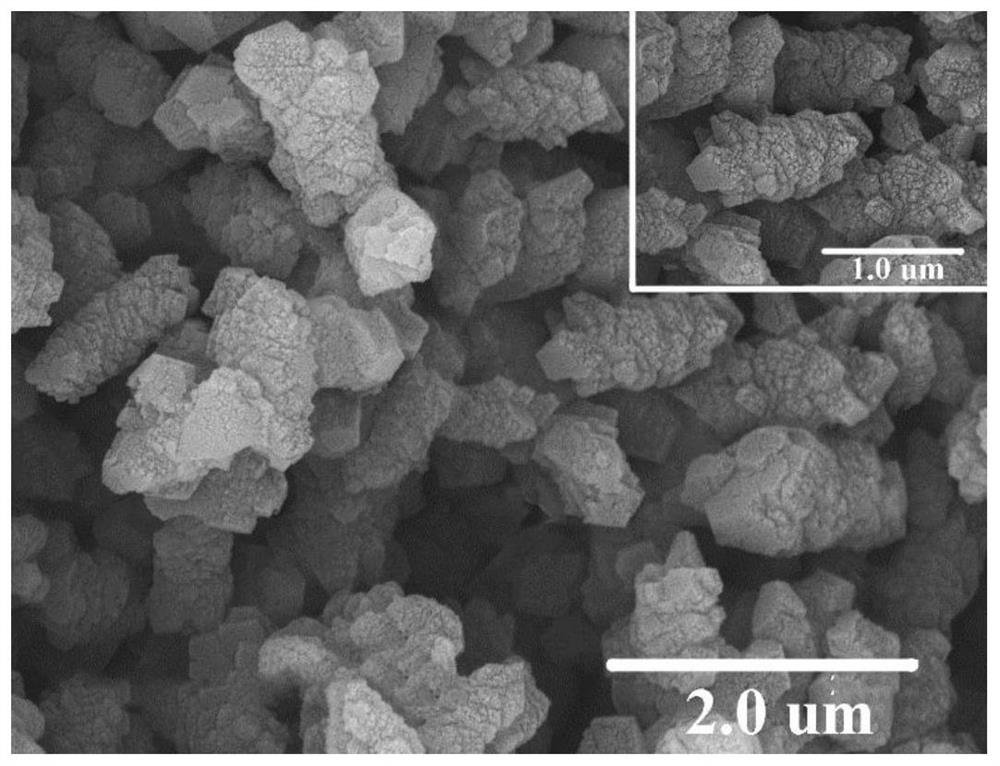

The invention discloses a preparation method of anhydrous magnesium carbonate MgCO3 and magnesium oxide MgO. According to the preparation method, a water soluble magnesium salt is taken as a magnesium source, ammonium carbonate (NH4)2CO3 is taken as a precipitating agent, and ammonium magnesium carbonate (NH4)2Mg(CO3)2 is prepared at a reaction temperature ranging from 30 to 90 DEG C under hydrothermal reaction conditions; and ammonium magnesium carbonate is conversed into heavy anhydrous magnesium carbonate and magnesium oxide via high temperature pyrolyzing at different temperatures. The commercial magnesium carbonate products are all hydrated basic magnesium carbonate with apparent density of 0.15g / ml except magnesite magnesium carbonate. Compared with the prior art, the preparation method possesses following advantages: heavy anhydrous magnesium carbonate and magnesium oxide powder single phase composition is realized, apparent density is 0.6g / ml; the obtained product can be taken as a fire retardant, and can be applied to a plurality of fields; the preparation method is simple; production cost is relatively low; and production of single phase heavy anhydrous magnesium carbonate and magnesium oxide powder is disclosed for the first time.

Owner:徐强

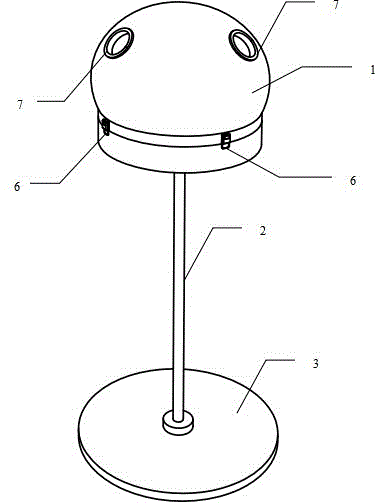

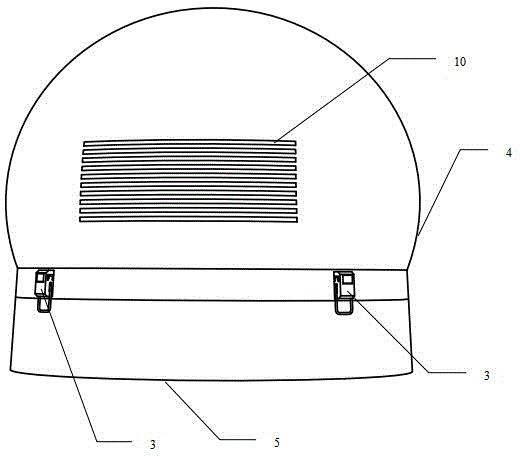

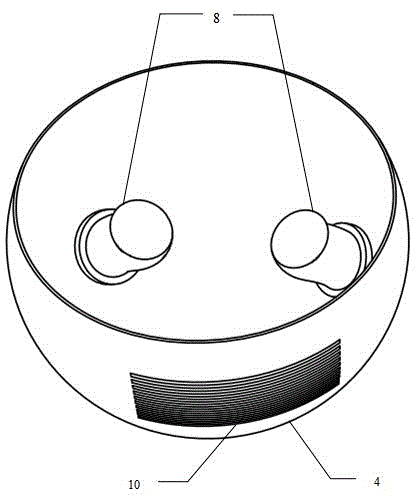

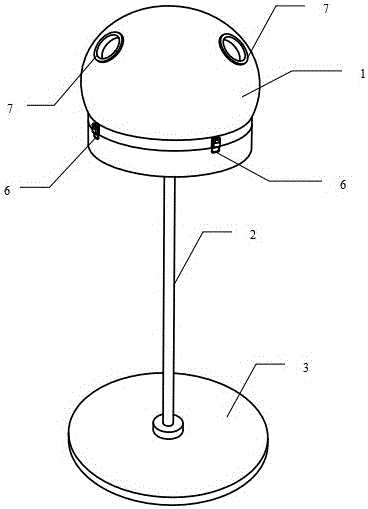

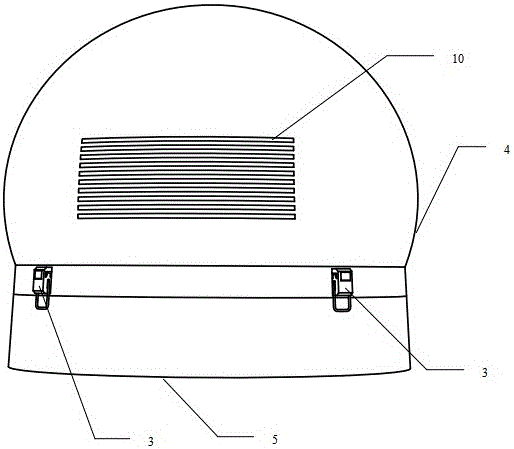

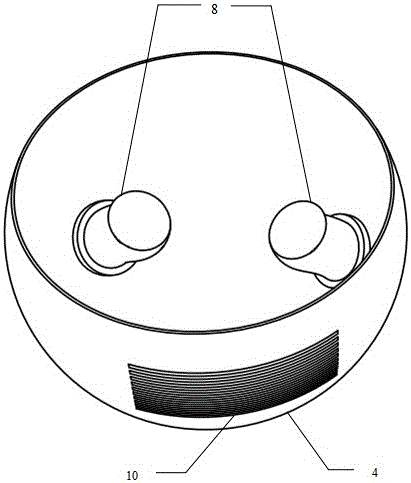

Multifunctional safe magnesium powder frame

ActiveCN104368142AReduce wasteStop the fireSport apparatusFire - disastersAnhydrous magnesium carbonate

The invention provides a multifunctional safe magnesium powder frame. The multifunctional safe magnesium powder frame is characterized by comprising a magnesium powder storage box, a vertical frame rod and a base, wherein the magnesium powder storage box is provided with a upper spherical magnesium powder box body and a lower spherical magnesium powder box body which are connected through a buckle, the front face of the upper magnesium powder storage box body is provided with two extending-in holes, the inner end of each extending-in hole is provided with a jacket, the lower magnesium powder storage box body is provided with a hole groove which is connected with the vertical frame rod in a sliding mode, the back face of the upper magnesium powder storage box body is evenly provided with screening holes, and the overall magnesium powder frame is made of fireproof materials. By the adoption of the multifunctional safe magnesium powder frame, besides the hand powder taking function of an ordinary magnesium powder frame, the multifunctional safe magnesium powder frame can also slide to the base to achieve the foot powder taking function; the semi-closed type upper magnesium powder storage box body with the jacket can reduce the waste of magnesium powder; when a fire disaster occurs, through the length of the vertical frame rod, the upper magnesium powder storage box body is close to a fire source, anhydrous magnesium carbonate in the upper magnesium powder storage box body is evenly sprayed out through the screening holes, a fire behavior is retarded, and on-site fire fighting is facilitated.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

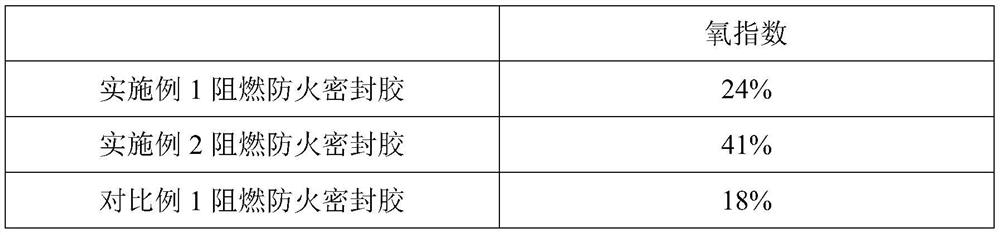

Flame-retardant and fireproof sealant and preparation method thereof

ActiveCN113881394ARealize the effect of fire prevention and flame retardantNon-macromolecular adhesive additivesPolymer sciencePtru catalyst

The invention relates to the technical field of sealant preparation, and particularly discloses a flame-retardant and fireproof sealant and a preparation method thereof. The flame-retardant and fireproof sealant is prepared from the following raw material components in parts by weight: 80-100 parts of polydimethylsiloxane; 5-10 parts of a cross-linking agent; 0.5-2 parts of a catalyst; 3-6 parts of a dispersant; 1-10 parts of a plasticizer; and 1-5 parts of a flame retardant. The flame retardant is composed of zinc borate and anhydrous magnesium carbonate. Research shows that in the process of preparing the flame-retardant and fireproof sealant by taking polydimethylsiloxane as a raw material, the flame retardant composed of zinc borate and anhydrous magnesium carbonate is added, and a certain fireproof and flame-retardant effect can be achieved under the condition that only a small amount of flame retardant is added.

Owner:东莞市山力高分子材料科研有限公司

Flame-retardant silicon core pipe

InactiveCN109849468AImprove flame retardant performanceReduce the impactSynthetic resin layered productsWater vaporMoisture absorption

The invention relates to a flame-retardant silicon core pipe. An outer layer of the flame-retardant silicon core pipe comprises the ingredients in parts by mass: 100 parts of high-density polyethylene, 15-35 parts of polyarylate, 1-10 parts of aluminum sulfate octadecahydrate, 1-10 parts of anhydrous magnesium carbonate, 1-5 parts of basic copper carbonate, 0.5-5 parts of dispersant and 1-6 partsof antioxidant; and an inner layer of the flame-retardant silicon core pipe comprises the ingredients in parts by mass: 100 parts of high-density polyethylene, 1-8 parts of silica-gel master batch and1-6 parts of aluminum sulfate octadecahydrate. According to the silicon core pipe disclosed by the invention, by adding the aluminum sulfate octadecahydrate, the substance has a large volume of crystalline water and meanwhile has very high moisture absorption capacity; in case of combustion, the aluminum sulfate octadecahydrate can release a large volume of water vapor and play roles in extinguishing a fire and retarding flame; the anhydrous magnesium carbonate is also added and will be decomposed to absorb heat and release a large volume of water vapor and carbon dioxide during combustion, thereby playing a role in retarding flame; and the polyarylate and the basic copper carbonate exert a synergistic action and endow the silicon core pipe with good inflaming retarding capacity, and thesilicon core pipe is relatively light in environmental pollution due to no halogen.

Owner:JIANGSU NOBEL PLASTICS CO LTD

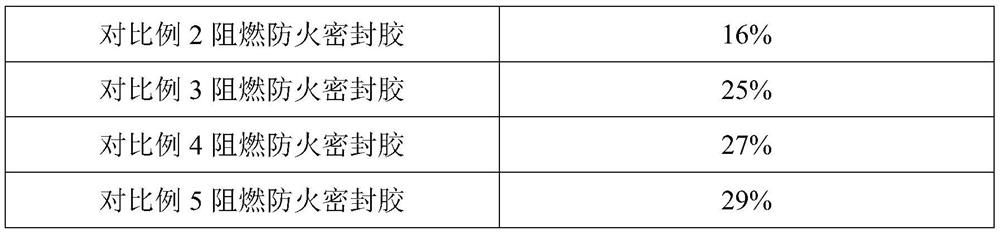

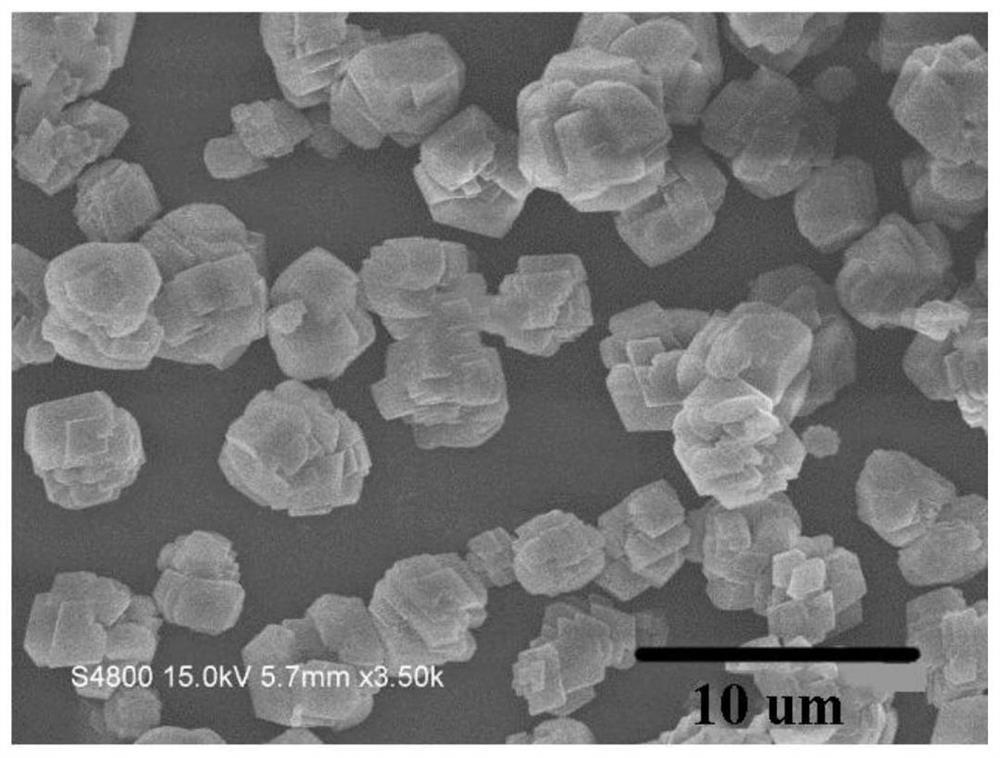

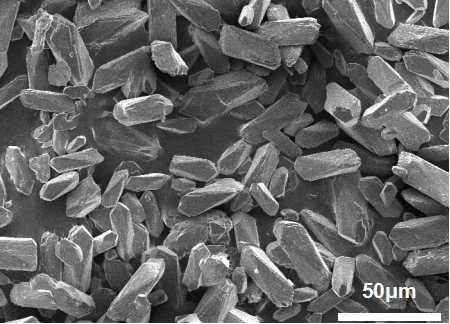

Method for preparing long-rhombohedron and short-column rhombohedron anhydrous magnesium carbonate mixture

ActiveCN110217808AConsistent shapeUniform sizeMagnesium carbonatesReaction temperatureDistilled water

The invention provides a method for preparing a long-rhombohedron and short-column rhombohedron anhydrous magnesium carbonate mixture. The method is characterized by employing the following steps: adding MgCl2.6H2O and CH4N2O into distilled water according to a certain mass-mole ratio, so as to prepare a clear solution of a certain concentration; heating up the solution, and carrying out a pre-synthesis reaction for 1 to 2 hours at a reaction temperature of 80 DEG C to 95 DEG C; slowly adding NaOH into a pre-synthesis reacted mixed solution, and adjusting a pH value of the mixed solution to be11; transferring the mixed solution into a Teflon-lined stainless-steel reactor, and carrying out a hydrothermal reaction for 4 to 6 hours at a temperature of 140 DEG C to 150 DEG C; and subjecting aproduct to negative-pressure filtering, washing and baking after the hydrothermal reaction is completed, thereby obtaining anhydrous magnesium carbonate, wherein the anhydrous magnesium carbonate isformed through mixing two kinds of crystals of different morphologies, one kind of crystals are long rhombohedra, the other kind of crystals are short column rhombohedra, and both kinds belong to a trigonal crystal system, the long-rhombohedron anhydrous magnesium carbonate crystals have the diameter of 10 to 20 microns and the length of 25 to 50 microns, and the short-column-rhombohedron anhydrous magnesium carbonate crystals have the diameter of 15 to 20 microns and the length of 20 to 25 microns.

Owner:SHANDONG UNIV OF TECH

A kind of method of producing anhydrous magnesium carbonate with magnesium-containing mother liquor

ActiveCN105540625BAvoid generatingStable in natureAmmonium nitratesMagnesium carbonatesGranularitySlurry

A method for preparing anhydrous magnesium carbonate through a magnesium-containing mother solution includes the following steps of firstly, adjusting the pH value, wherein ammonia gas is introduced into the magnesium-containing mother solution till the pH value is 10.0-12.0 to obtain Mg(OH)2 slurry; secondly, conducting CO2 carbonizing, wherein CO2 is introduced till the pH value is 7.5-8.0 to obtain a carbonized mother solution; thirdly, conducting pyrolysis separation, wherein the carbonized mother solution is heated and decomposed to separate solid and liquid and obtain MgCO3.3H2O solid salt and a pyrolysis separation mother solution; fourthly, conducting calcining, wherein MgCO3.3H2O is calcined to obtain anhydrous magnesium carbonate. Calcining is further conducted to obtain magnesium oxide. The MgCO3.3H2O obtained through pyrolysis separation is large in granularity, the filter separation performance is good, the carrying amount of the mother solution is small, the MgO content reaches up to 47.3%, and the total yield of magnesium ions reaches up to 92.8%; the purity of the MgO product is high, and inorganic ammonium salt type by-products can be co-produced; the method is simple in process, beneficial to industrial production, low in cost, green and environmentally friendly.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

A kind of preparation method of rhombohedral and short rhombohedral anhydrous magnesium carbonate mixture

ActiveCN110217808BConsistent shapeUniform sizeMagnesium carbonatesCrystal systemReaction temperature

The invention provides a method for preparing a mixture of rhombohedral and rhombohedral anhydrous magnesium carbonate, which belongs to the technical field of new inorganic chemical materials, and is characterized in that the following steps are adopted: MgCl 2 ·6H 2 Add O into distilled water to prepare a transparent solution with a certain concentration, and add CH at a certain molar ratio 4 N 2 O, stir to obtain a mixed solution; heat the mixed solution to carry out a pre-synthesis reaction, the reaction temperature is 80-95°C, and the reaction time is 1-2h; NaOH is slowly added to the mixed solution of the pre-synthesis reaction, and the pH value of the mixed solution is adjusted to 11 ; The mixed solution is moved to a stainless steel reaction kettle with polytetrafluoroethylene lining for hydrothermal reaction, the temperature of the hydrothermal reaction is 140-150°C, and the reaction time is 4-6h; after the hydrothermal reaction is completed, the product is negatively Press filtration and washing to obtain anhydrous magnesium carbonate; anhydrous magnesium carbonate is composed of two crystals with different shapes; one of them is rhombohedral and the other is short columnar rhombohedral, both of which belong to the trigonal crystal system The rhombohedral anhydrous magnesium carbonate crystal has a diameter of 10-20 μm and a length of 25-50 μm; the rhombohedral anhydrous magnesium carbonate crystal has a diameter of 15-20 μm and a length of 20-25 μm.

Owner:SHANDONG UNIV OF TECH

Method for preparing anhydrous magnesium carbonate by directly utilizing salt lake brine

PendingCN112479237ASimple processMild conditionsMagnesium carbonatesPotassium magnesium sulfateSalt lake brine

The invention relates to a method for preparing anhydrous magnesium carbonate by directly utilizing salt lake brine, and the method comprises the following steps: extracting potash magnesium sulphatefertilizer from the salt lake brine, then extracting potassium chloride, and then extracting boron to finally obtain sulfate type brine; adding urea into the brine, adjusting the pH value of the mixedsolution to 7.0-14.0, uniformly stirring, putting into a reaction kettle, controlling the reaction temperature to be 120-250 DEG C and the reaction time to be 1-12 hours, and naturally cooling to room temperature to obtain a reaction solution; carrying out suction filtration on the reaction solution, performing washing until the pH value is 7.0, and drying at 40-200 DEG C for 4-48 hours to obtainthe anhydrous magnesium carbonate. The preparation method provided by the invention is simple to operate, efficient and energy-saving, the used raw materials are low in price, large-scale industrialproduction of the anhydrous magnesium carbonate powder can be realized, and the prepared anhydrous magnesium carbonate is used as a novel inorganic flame retardant and can be used as an inorganic flame retardant additive of products such as plastics, rubber and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

A flame-retardant heat-conducting recycled PS composite material and its preparation method

ActiveCN108752775BImprove flame retardant performanceTypical porous structureCalcium silicateAntioxidant

The invention relates to a flame-retardant heat-conduction recycled PS (polystyrene) composite material and a preparation method thereof. The preparation method includes weighing 80-100 parts of recycled PS, 20-30 parts of recycled PC (polycarbonate), 12-16 parts of flame retardants, 3-5 parts of calcium silicate whiskers, 8-12 parts of Bi2O3, 0.1-0.5 part of antioxidants, 0.1-0.3 part of-g-MAH SEBS and mixing with stirring uniformly to obtain a mixture; extruding the mixture to granulate through a double-screw extruder to obtain the PS composite material. Since tetrabromobisphenol S bis-(2,3-dibromopropyl ether) and anhydrous magnesium carbonate are compounded as the main flame retardant creatively and calcium silicate whiskers serve as an auxiliary flame retardant, flame retardance of the PS composite material is improved; calcium silicate whiskers, serving as the auxiliary flame retardant, have classical porous structures and can be expanded into carbon under catalysis, and thus, the flame redardance of the PS composite material is improved further.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Preparation method of nylon material with flame retardance

The invention relates to a preparation method of a nylon material with flame retardance. The preparation method comprises the following steps (1) weighing nylon, microcapsule mannitol, anhydrous magnesium carbonate and calcium chloride, mixing and weighing glass fibers, (2) heating and kneading the mixture, (3) carrying out melt extrusion on the kneaded mixture and the glass fibers, and (4) cooling the blank to obtain a finished product. According to the method, microcapsule mannitol and anhydrous magnesium carbonate which do not contain phosphorus and halogen are introduced, so that the nylonmaterial has flame retardance, the microcapsule mannitol can reduce the temperature around the nylon through phase change heat absorption to hinder combustion, the anhydrous magnesium carbonate can absorb heat during combustion and is decomposed to generate carbon dioxide, and the oxygen concentration around the nylon material is reduced, so that a flame-retardant effect is achieved.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

A method for preparing high-purity magnesium oxide by utilizing magnesium carbonate coarse ore

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

A kind of preparation method of rhombohedral anhydrous magnesium carbonate

The invention provides a preparation method of rhombohedral anhydrous magnesium carbonate, which belongs to the technical field of new inorganic chemical materials, and is characterized in that the following steps are adopted: MgCl 2 ·6H 2 Add O into distilled water to prepare a solution with a certain concentration, and add CH at a certain molar ratio 4 N 2 O, stir to obtain a mixed solution; heat the configured mixed solution to carry out a pre-synthesis reaction, the reaction temperature is 80-95°C, and the reaction time is 1-2h; the mixed solution after the pre-synthesis reaction is moved to a tank with polytetrafluoroethylene Hydrothermal reaction in a lined stainless steel reactor, the temperature of the hydrothermal reaction is 140-150°C, and the reaction time is 2-4h; after the hydrothermal reaction is completed, the product is filtered and washed under negative pressure to obtain rhombohedral anhydrous magnesium carbonate; Anhydrous magnesium carbonate The rhombohedral anhydrous magnesium carbonate prepared in the present invention belongs to the trigonal crystal system, the side length of each rhomboid is 20-25 μm, and the rhombohedral particle size is 25-30 μm.

Owner:SHANDONG UNIV OF TECH

A method for preparing high-purity magnesium oxide by utilizing magnesium carbonate coarse ore

The invention discloses a method for preparing high-purity magnesium oxide from coarse magnesium carbonate ore. The method comprises steps as follows: (1) crushing and then screening the coarse magnesium carbonate ore; (2) adding a boron removing agent to the screened coarse magnesium carbonate ore to obtain first slurry, wherein the boron removing agent is a bicarbonate and / or carbonate solution; (3) placing the first slurry into a reaction kettle, feeding CO2 at the normal temperature, and then conducting a hydrothermal reaction to obtain second slurry; (4) filtering, washing and drying the second slurry to obtain anhydrous magnesium carbonate; (5) burning the anhydrous magnesium carbonate to obtain the high-purity magnesium oxide. According to the method, bicarbonate is formed through feeding the CO2 into the mixed slurry, the hydrothermal reaction is conducted in the presence of the bicarbonate to convert boron compounds among magnesium carbonate crystals into soluble substances, then boron impurities are removed through washing, and the purity of the finally prepared magnesium oxide is higher than 98%.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Preparation method of rhombohedra short-column anhydrous magnesium carbonate

The invention provides a preparation method of a rhombohedra short-column anhydrous magnesium carbonate, and belongs to the technical field of inorganic chemical engineering materials. The preparationmethod is characterized by comprising the following steps: adding MgCl2.6H2O into distilled water to prepare a transparent solution with a certain concentration, adding CH4N2O according to a certainmass molar ratio, and carrying out stirring to obtain a transparent solution; heating the solution, and carrying out a pre-synthesis reaction, wherein the reaction temperature is 80-95 DEG C, and thereaction time is 1-2 hours; slowly dropwise adding NH3.H2O into a mixed solution of the pre-synthesis reaction, and adjusting the pH value of the mixed solution to be 13; transferring the mixed solution into a stainless-steel reaction kettle with a polytetrafluoroethylene lining for a hydrothermal reaction, wherein the hydrothermal reaction temperature is 140-150 DEG C, and the reaction time is 3-4 hours; and after the hydrothermal reaction is completed, carrying out negative-pressure filtration and washing on the product to obtain the rhombohedra short-column anhydrous magnesium carbonate. The anhydrous magnesium carbonate belongs to a trigonal crystal system and is formed by polymerizing a circular column and a rhombohedra, the cross section of the short column is circular, and each of two ends of the column are provided with three near-quadrilateral flat crystal surfaces, wherein the diameter of the circular column is 15-20 microns, and the length of the short column is 25-30 microns.

Owner:SHANDONG UNIV OF TECH

A kind of high-purity ultrafine anhydrous magnesium carbonate environment-friendly preparation process

The invention discloses an environment-friendly preparation process of high-purity and superfine anhydrous magnesium carbonate and belongs to the field of inorganic chemical synthesis and inorganic materials. Light calcined powder or magnesium hydroxide is taken as a raw material, heavy magnesium water reversely contacts with purified air in a supergravity stator-rotor reactor after a carbonization reaction and removal of iron ions and heavy metal impurities (or heavy magnesium water is vacuumized), interphase transfer is reinforced, liquid-phase carbon dioxide is rapidly diffused to a gas phase, the magnesium bicarbonate is accelerated to be decomposed to generate magnesium carbonate trihydrate and carbon dioxide, magnesium carbonate trihydrate and carbon dioxide are mixed with an ammonium hydrogen carbonate solution with certain concentration after precipitation and filtration, a uniform sizing agent is prepared, a hydrothermal reaction is performed in a reactor, and loose single-phase high-purity and superfine anhydrous magnesium carbonate powder is obtained. The preparation process is environment-friendly, the raw materials are cheap, no organic additive is required in the production process, and high-purity and superfine anhydrous magnesium carbonate has wide application fields, has remarkable price and performance advantages and high market competitiveness and has remarkable innovativeness, economical efficiency and practicability.

Owner:BEIJING UNIV OF CHEM TECH

A multifunctional safe magnesium powder rack

ActiveCN104368142BReduce wasteStop the fireSport apparatusFire - disastersAnhydrous magnesium carbonate

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Method for preparing anhydrous magnesium carbonate based on hydrothermal carbonization reaction

The invention discloses a method for preparing anhydrous magnesium carbonate based on hydrothermal carbonization reaction. The method uses ascorbic acid as a carbon source, dissolves it in deionized water, adjusts the initial pH of the ascorbic acid aqueous solution to 5.5-14.0, and then adds magnesium salt, Under the condition that the hydrothermal reaction temperature is 120-250° C. and the hydrothermal reaction time is 1-12 hours, anhydrous magnesium carbonate powder with good dispersibility, various shapes and uniform size is prepared. Above-mentioned magnesium salt is any one in magnesium sulfate, magnesium chloride, magnesium hydroxide, magnesium oxide or magnesium acetate. The preparation method of the present invention is simple and easy to control, highly efficient and energy-saving, and does not need to introduce CO 2 As a carbon source, the shape and size of anhydrous magnesium carbonate can be adjusted by simply changing the concentration of magnesium salt or adjusting the initial pH value of ascorbic acid solution, and the obtained product is pure phase anhydrous magnesium carbonate.

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of preparation method of dirhombohedral anhydrous magnesium carbonate

ActiveCN110127734BConsistent shapeUniform sizeMagnesium carbonatesCrystal systemReaction temperature

The invention provides a preparation method of double rhombohedral anhydrous magnesium carbonate, which belongs to the technical field of new inorganic chemical materials, and is characterized in that the following steps are adopted: 2 ·6H 2 O is added to distilled water to prepare a transparent solution with a certain concentration, and CH is added according to a certain molar ratio. 4 N 2 O, stir to obtain a mixed solution; heat the mixed solution to carry out a pre-synthesis reaction, the reaction temperature is 80-95 ℃, and the reaction time is 1-2h; slowly add NaOH to the mixed solution of the pre-synthesis reaction, and adjust the pH of the mixed solution to 13 ; Move the mixed solution to a stainless steel reactor with a polytetrafluoroethylene lining for hydrothermal reaction, the temperature of the hydrothermal reaction is 150-160 ° C, and the reaction time is 4-6 h; After the hydrothermal reaction is completed, the product is negatively charged. Press filtering and washing to obtain double rhombohedral anhydrous magnesium carbonate; the double rhombohedral anhydrous magnesium carbonate belongs to the trigonal crystal system, and the crystal is formed by the polymerization of two rhombohedrons, and the crystal diameter is 10-20 μm and the length is 20-35 μm.

Owner:SHANDONG UNIV OF TECH

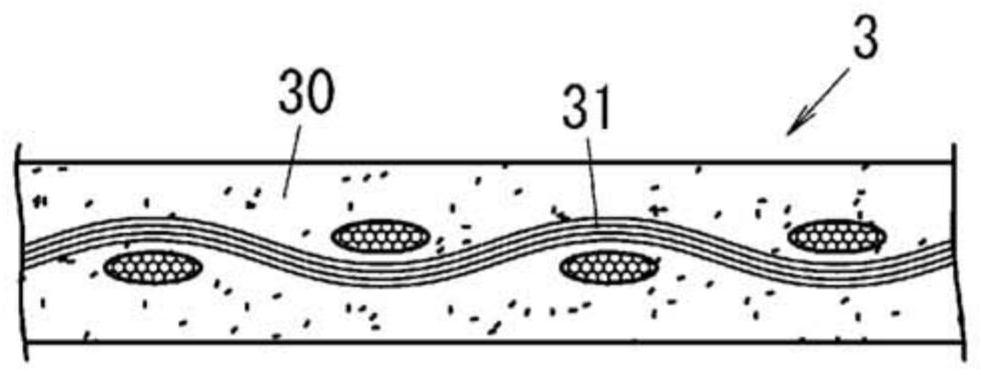

Resin composition, resin film, metal foil with resin, prepreg, metal-clad laminate and printed wiring board

PendingCN112004888ASemiconductor/solid-state device detailsPrinted circuit aspectsMetallic foilPolymer science

A resin composition according to the present invention contains (A) a resin and (B) an inorganic filler. The component (B) contains (b1) anhydrous magnesium carbonate and (b2) aluminum oxide. The content of the component (b1) is within the range of from 35% by volume to 65% by volume (inclusive) relative to 100% by volume of the total of the component (b1) and the component (b2). The content of the component (B) is within the range of from 60% by volume to 75% by volume (inclusive) relative to 100% by volume of the resin composition.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com