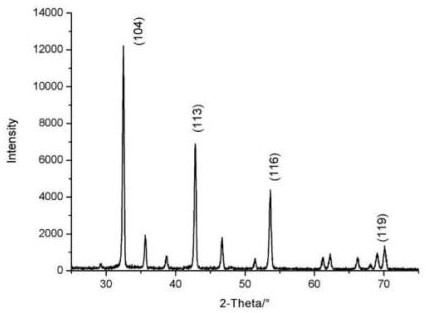

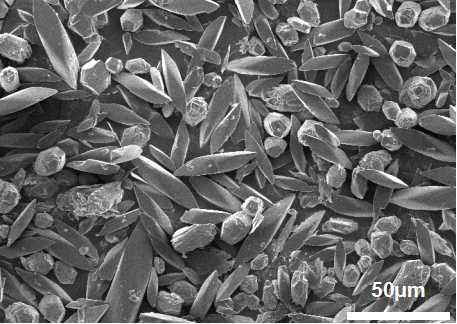

A kind of preparation method of rhombohedral and short rhombohedral anhydrous magnesium carbonate mixture

An anhydrous magnesium carbonate, rhombohedral technology, applied in the direction of magnesium carbonate, etc., can solve the problems of affecting the processing performance and product performance, affecting product purity, increasing production costs, etc., and achieving easy control of production conditions and complete crystal morphology. , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) MgCl 2 ·6H 2 Add O into distilled water to prepare a transparent solution with a concentration of 0.1 mol / L, and use MgCl 2 ·6H 2 O and CH 4 N 2 The molar ratio of O is 1:8 by adding CH 4 N 2 O, stirred to obtain a mixed solution;

[0023] (2) MgCl 2 ·6H 2 O and CH 4 N 2 The mixed solution prepared by O is heated to carry out the pre-synthesis reaction, the reaction temperature is 95°C, and the reaction time is 1h;

[0024] (3) Slowly add NaOH to the mixed solution of the pre-synthesis reaction, adjust the pH value of the mixed solution to 11; then move the mixed solution to a stainless steel reactor with a polytetrafluoroethylene liner for hydrothermal reaction, and the hydrothermal reaction The temperature is 150°C, and the reaction time is 4h;

[0025] (4) After the hydrothermal reaction is completed, the product is filtered and washed under negative pressure to obtain anhydrous magnesium carbonate; anhydrous magnesium carbonate is composed of two cry...

Embodiment 2

[0027] (1) MgCl 2 ·6H 2 Add O into distilled water to prepare a transparent solution with a concentration of 0.3 mol / L, and use MgCl 2 ·6H 2 O and CH 4 N 2 The molar ratio of O is 1:8 by adding CH 4 N 2 O, stirred to obtain a mixed solution;

[0028](2) MgCl 2 ·6H 2 O and CH 4 N 2 The mixed solution prepared by O is heated to carry out the pre-synthesis reaction, the reaction temperature is 90°C, and the reaction time is 1.5h;

[0029] (3) Slowly add NaOH to the mixed solution of the pre-synthesis reaction, adjust the pH value of the mixed solution to 11; then move the mixed solution to a stainless steel reactor with a polytetrafluoroethylene liner for hydrothermal reaction, and the hydrothermal reaction The temperature is 140°C, and the reaction time is 6h;

[0030] (4) After the hydrothermal reaction is completed, the product is filtered and washed under negative pressure to obtain anhydrous magnesium carbonate; anhydrous magnesium carbonate is composed of two cr...

Embodiment 3

[0032] (1) MgCl 2 ·6H 2 Add O into distilled water to prepare a transparent solution with a concentration of 0.2 mol / L, and use MgCl 2 ·6H 2 O and CH 4 N 2 The molar ratio of O is 1:8 by adding CH 4 N 2 O, stirred to obtain a mixed solution;

[0033] (2) MgCl 2 ·6H 2 O and CH 4 N 2 The mixed solution prepared by O is heated to carry out the pre-synthesis reaction, the reaction temperature is 80°C, and the reaction time is 2h;

[0034] (3) Slowly add NaOH to the mixed solution of the pre-synthesis reaction, adjust the pH value of the mixed solution to 11; then move the mixed solution to a stainless steel reactor with a polytetrafluoroethylene liner for hydrothermal reaction, and the hydrothermal reaction The temperature is 145°C, and the reaction time is 5h;

[0035] (4) After the hydrothermal reaction is completed, the product is filtered and washed under negative pressure to obtain anhydrous magnesium carbonate; anhydrous magnesium carbonate is composed of two cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com