Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132 results about "3d drawing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

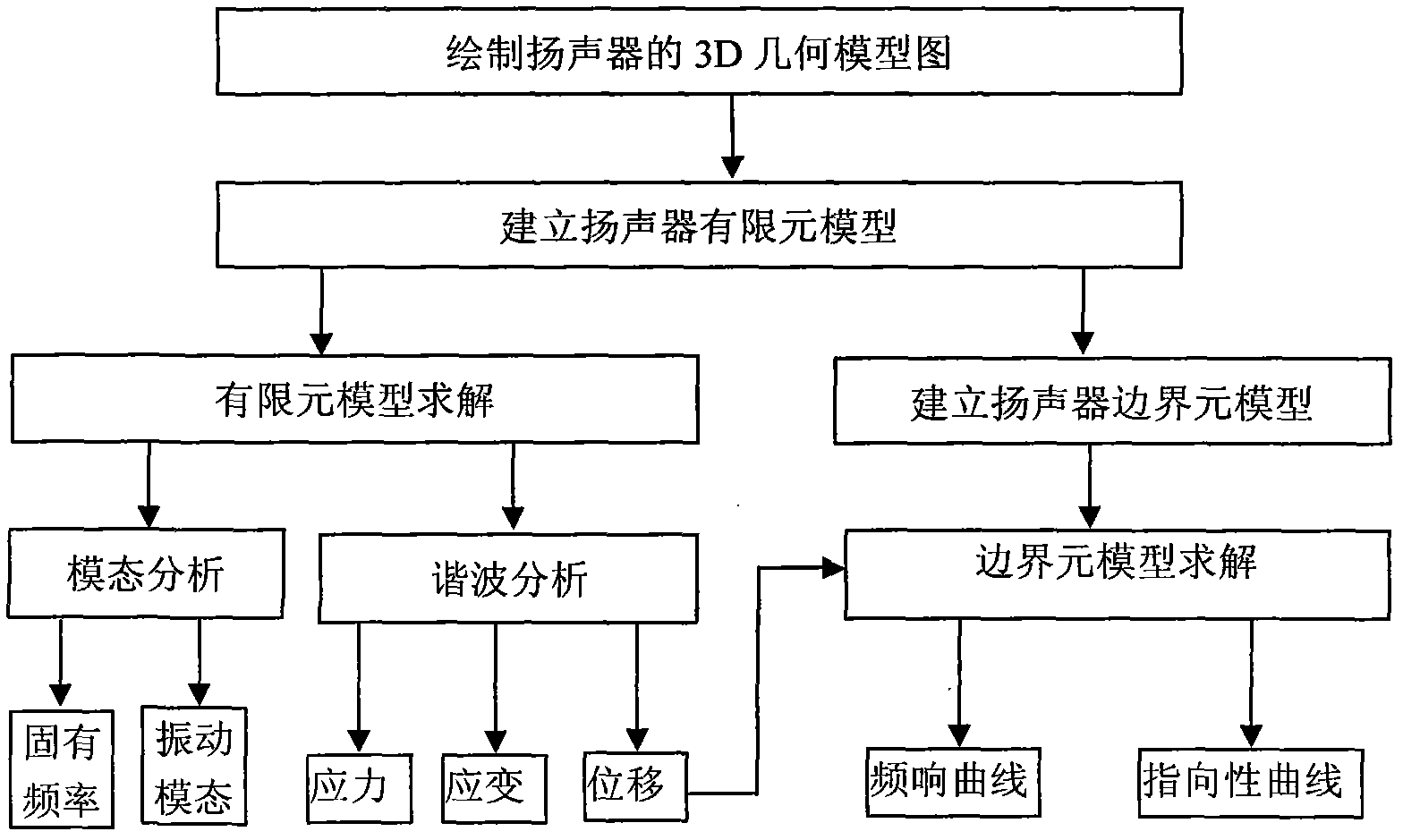

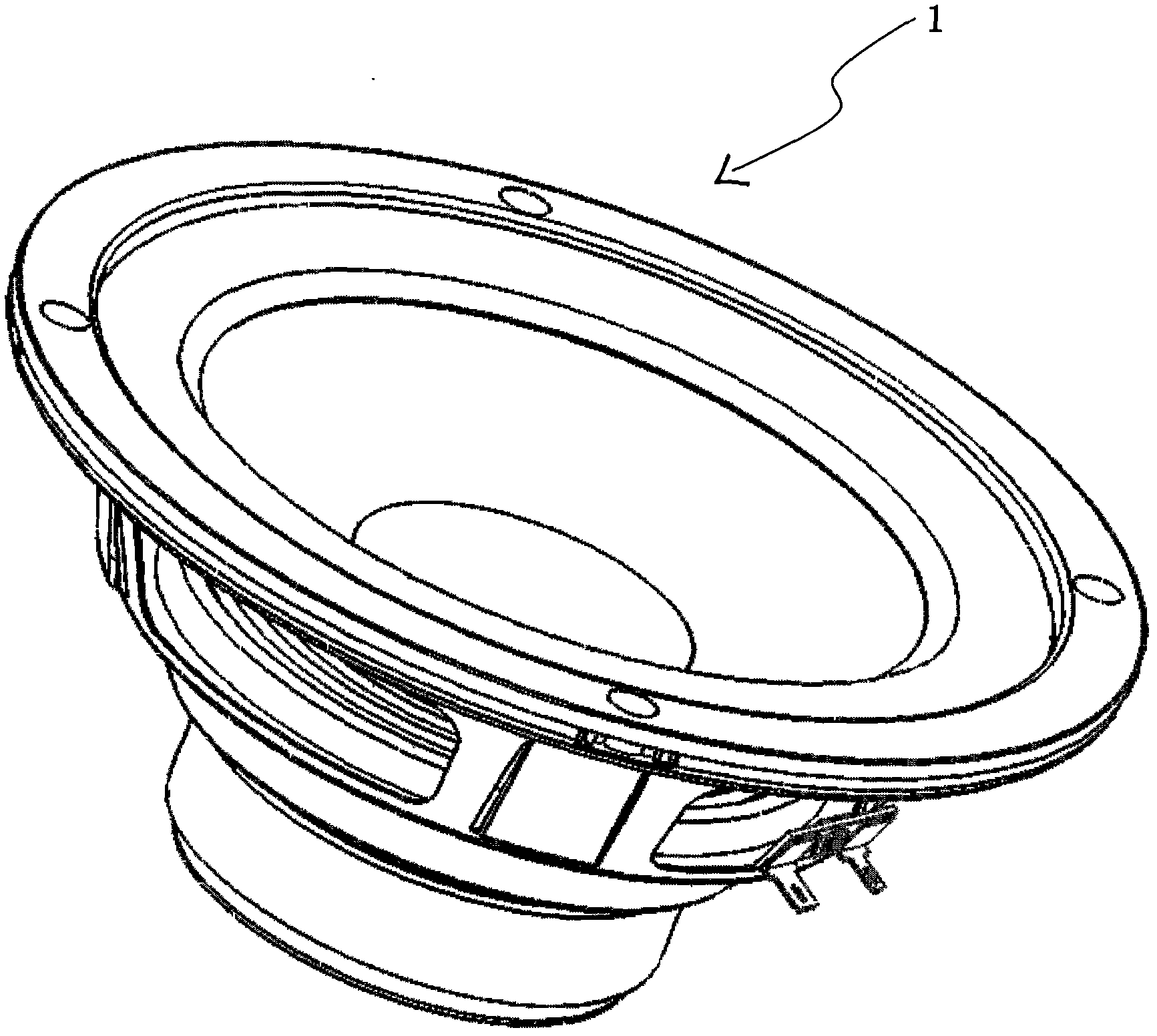

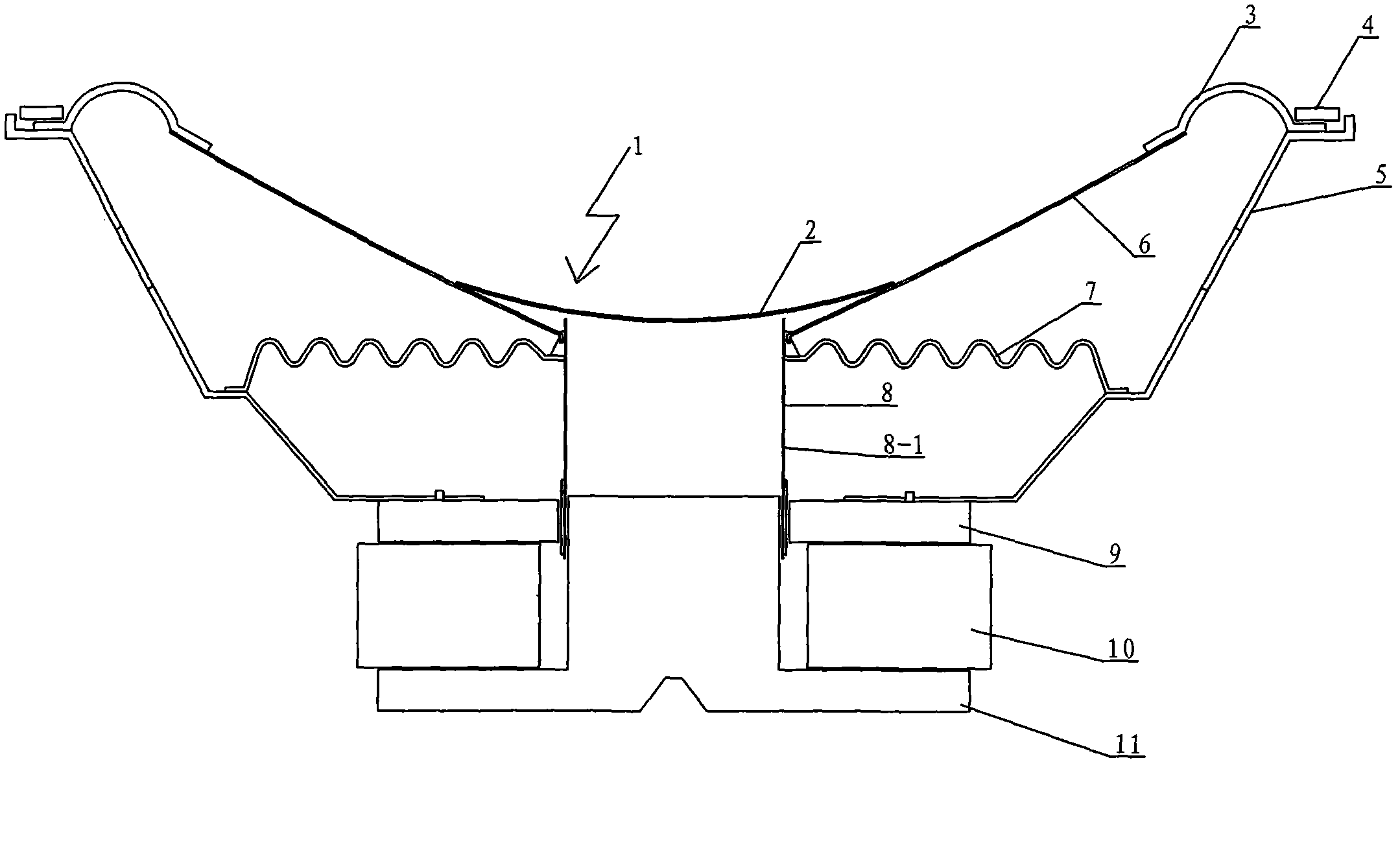

Numerical value simulation method of vibration and acoustic characteristics of speaker

ActiveCN102004823ASpeed up the design processOvercome the disadvantage of being limited to low frequenciesSpecial data processing applicationsElement modelGeometric modeling

The invention provides a numerical value simulation method of the vibration and acoustic characteristics of a speaker. The method comprises the following steps of: firstly, drawing a 3D (Three-Dimensional) geometric model diagram of the speaker by using 3D drawing software; then, adding the 3D geometric model diagram of the speaker to meshing software to mesh the 3D geometric model diagram into body elements, defining element types, materials and boundary conditions and applying a load to acquire a finite element model; establishing a boundary element model matched with the finite element model; and finally, solving the finite element model with a finite element solver to acquire the vibration characteristics of the speaker, and solving the boundary element model with a boundary element solver to acquire the acoustic characteristics of the speaker, wherein the vibration characteristics include the natural frequency, the vibration mode (vibration type), the displacement, the strain and the stress, and the acoustic characteristics include a frequency response curve and a directivity curve.

Owner:ZHEJIANG ELECTRO ACOUSTIC R&D CENT CAS +1

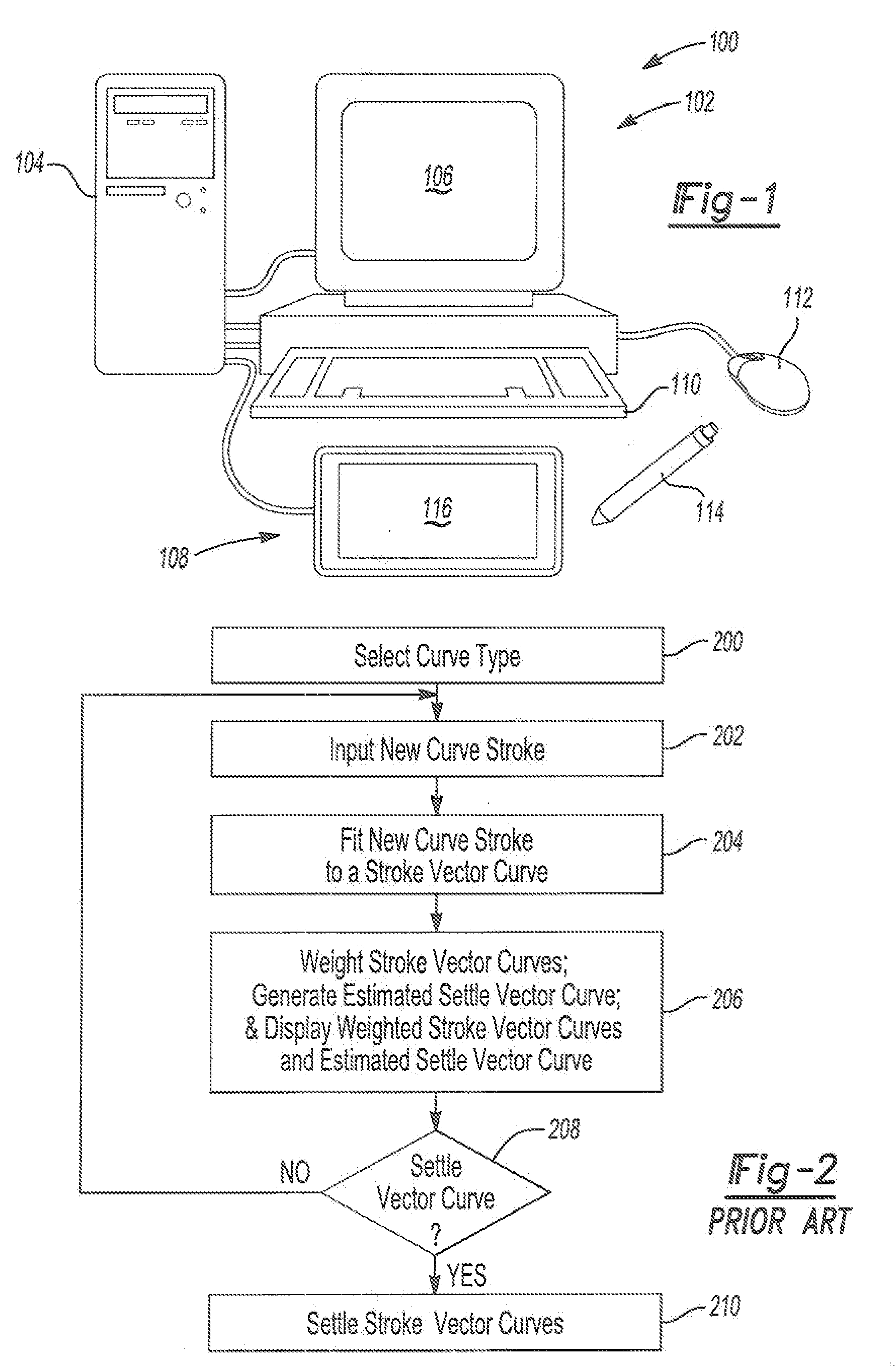

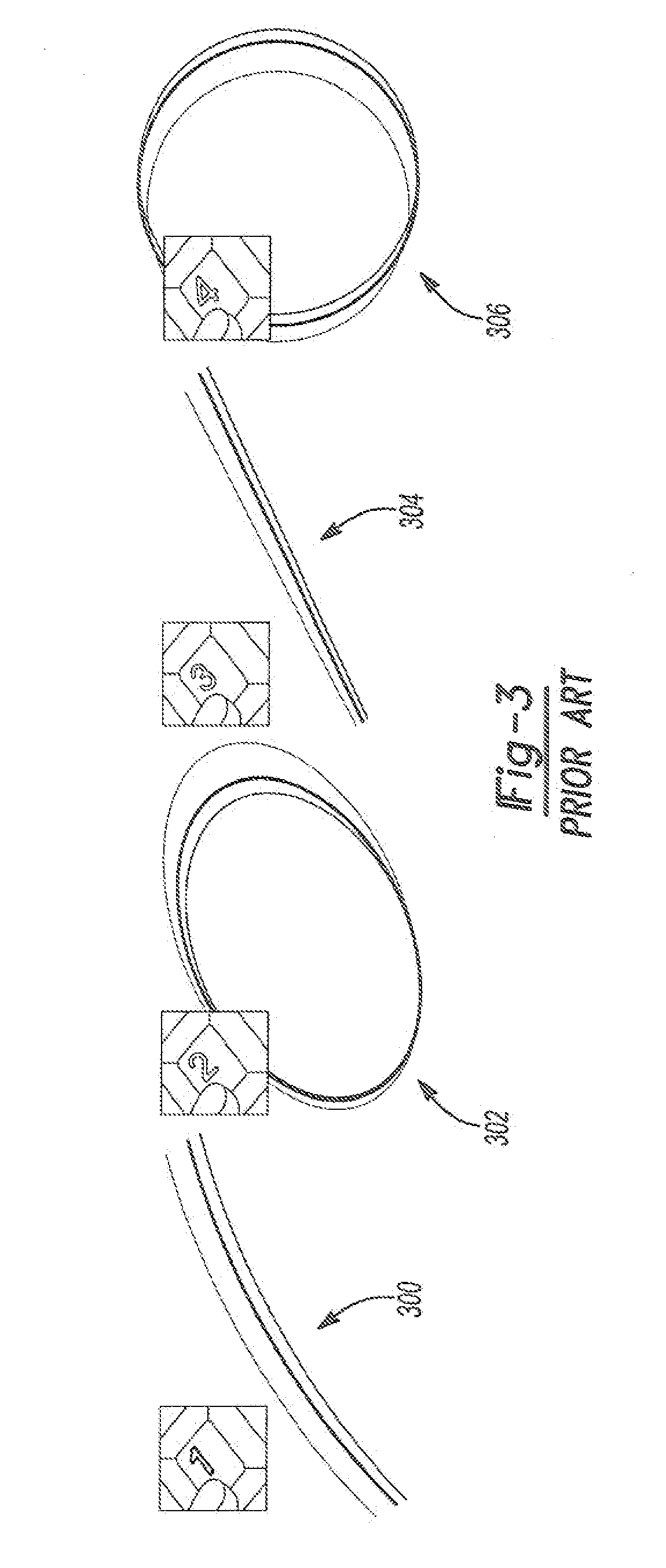

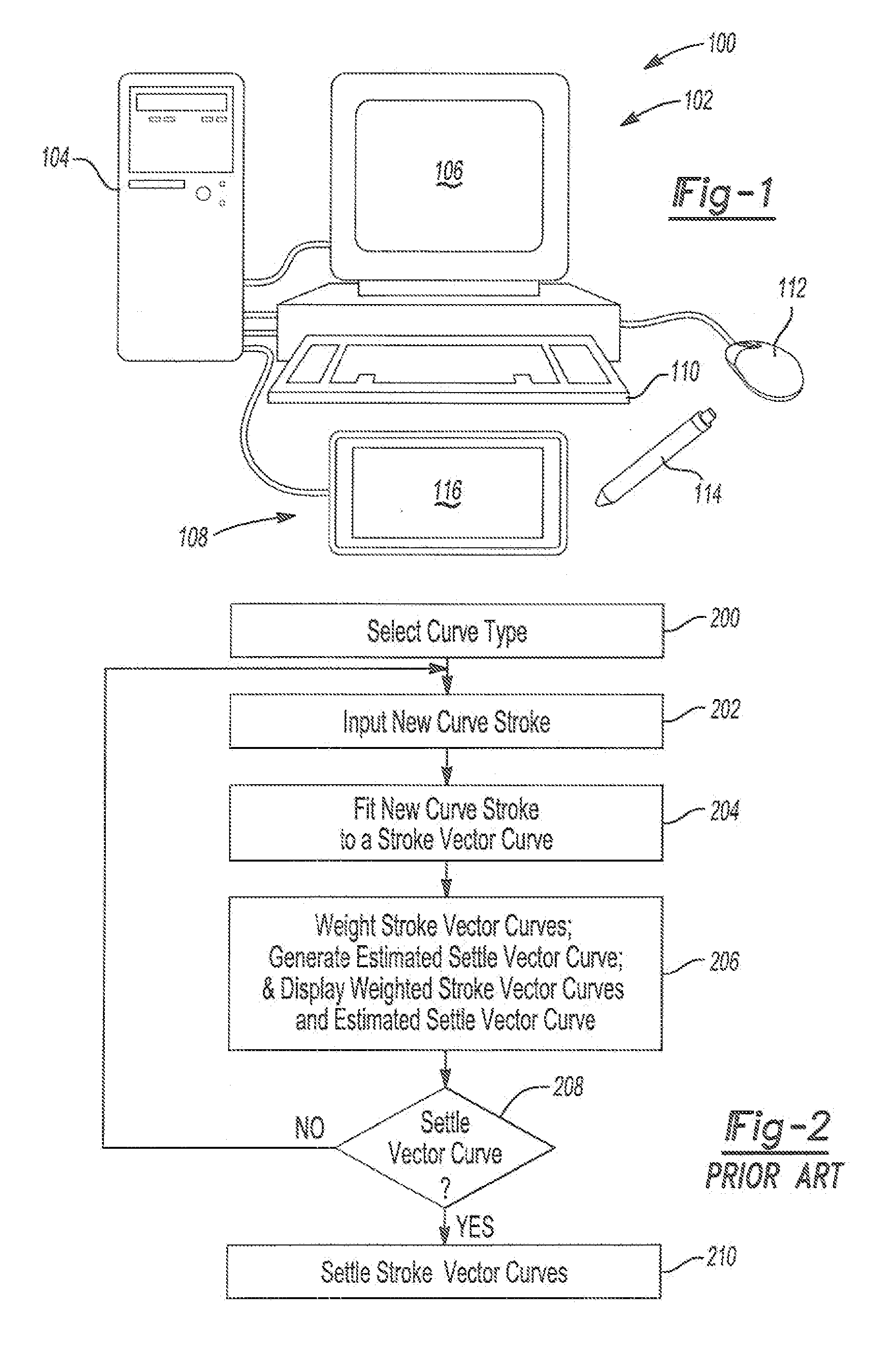

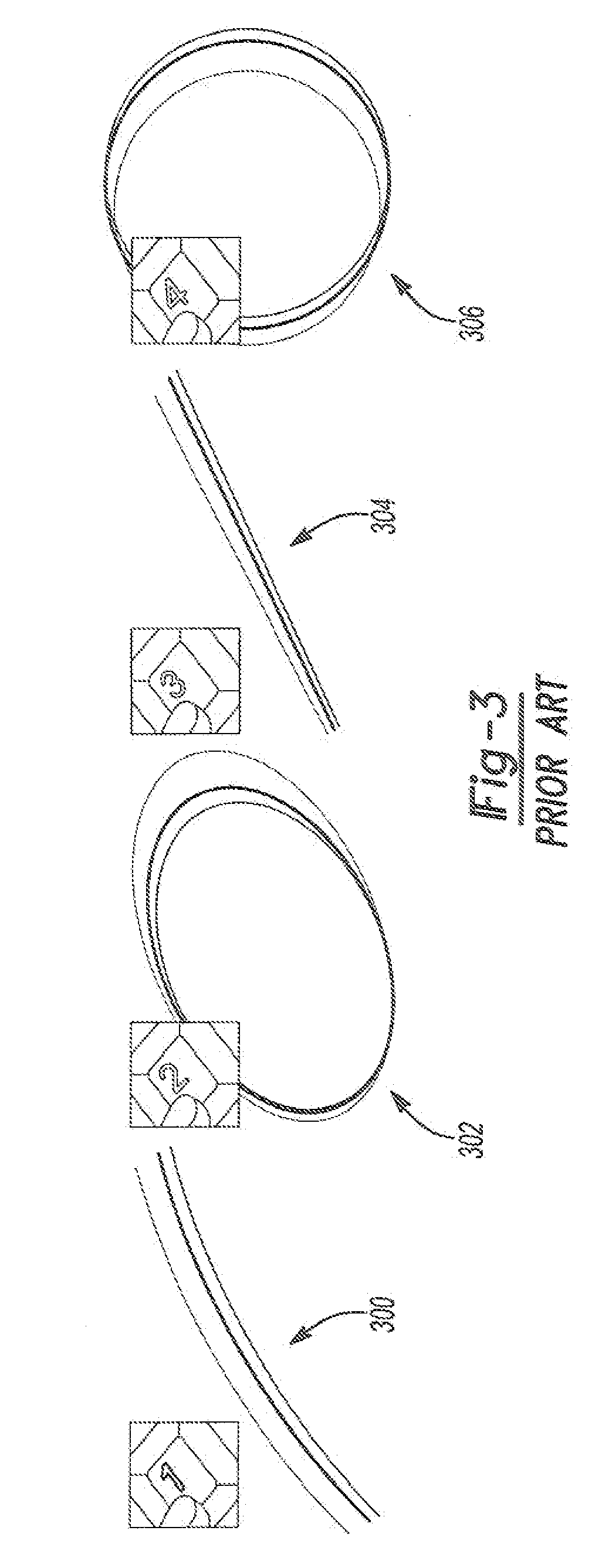

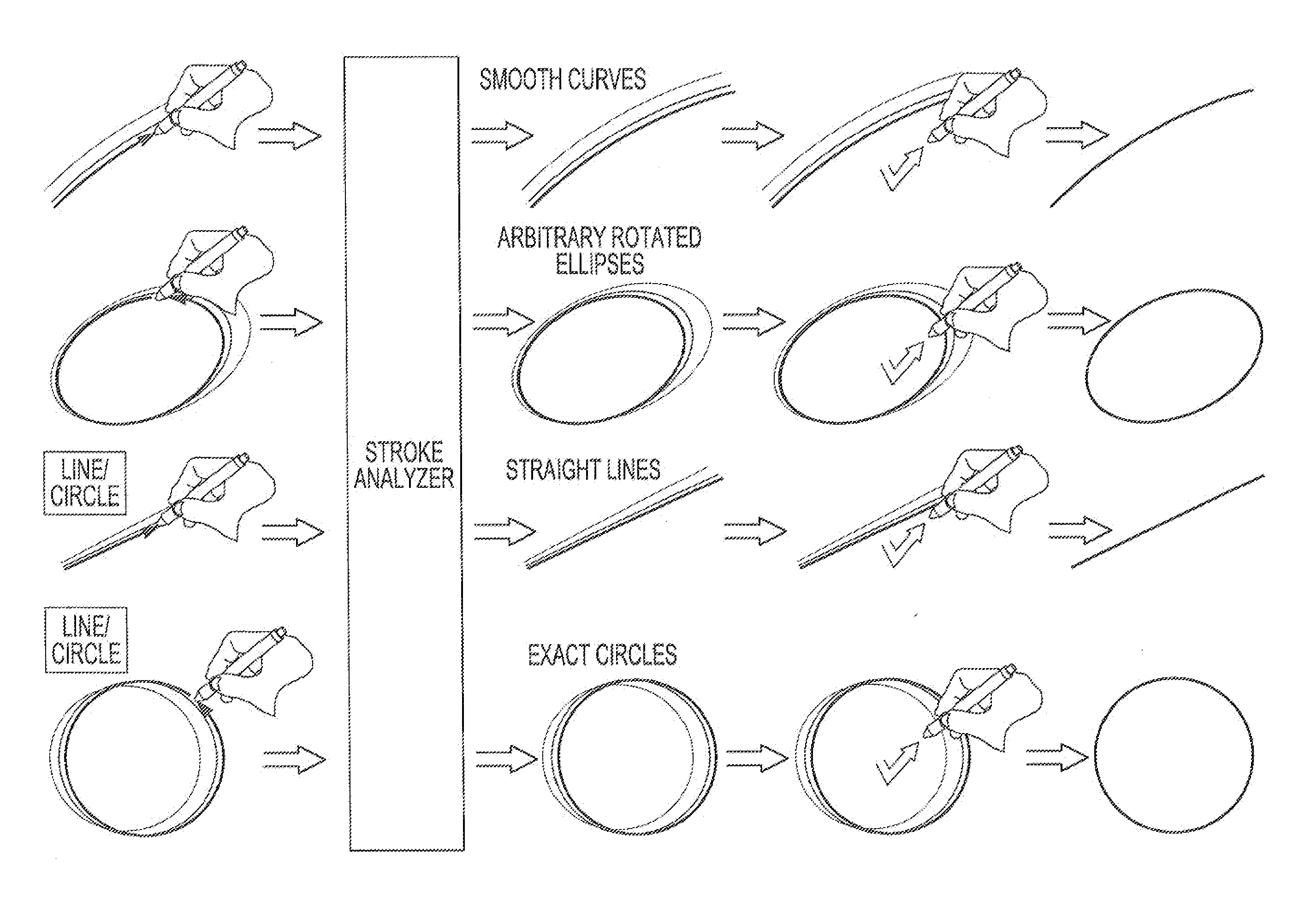

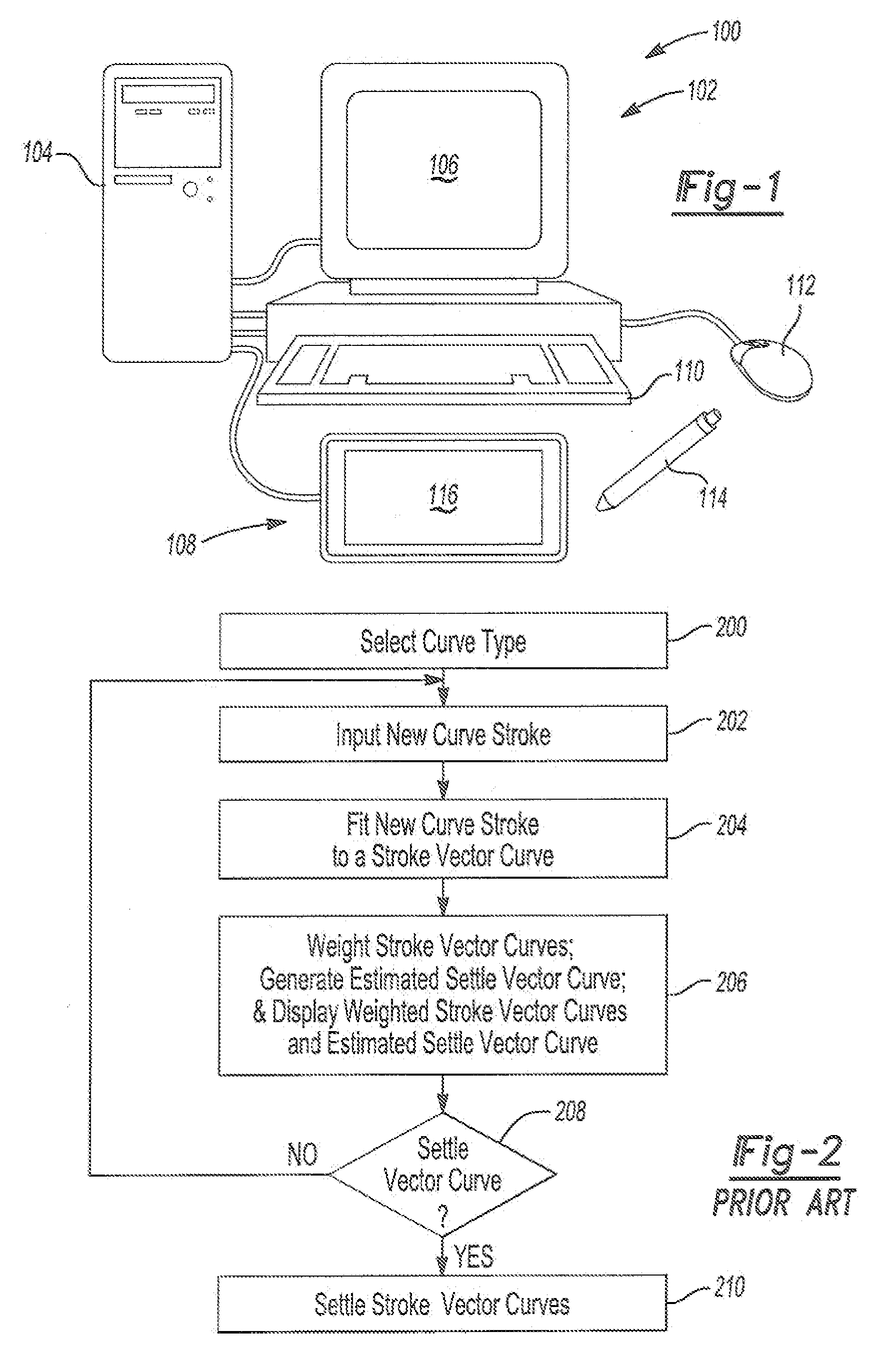

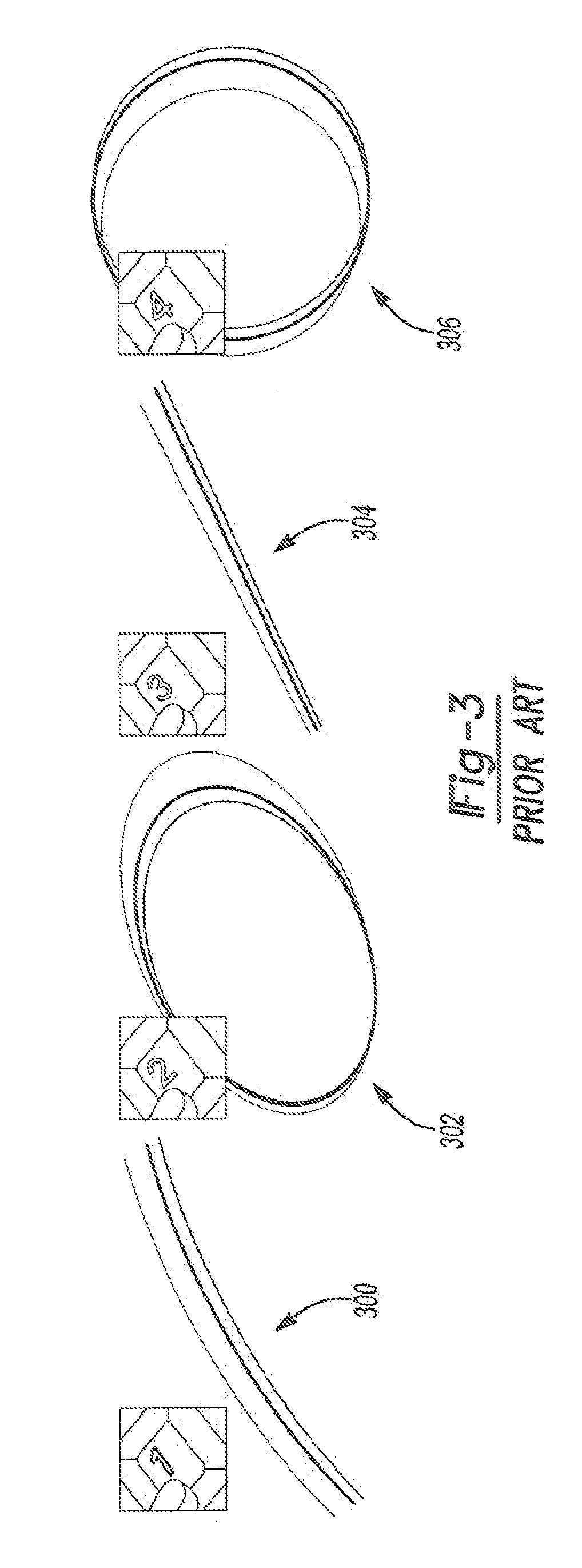

Pen-based 3D drawing system with 3D orthographic plane or orthrographic ruled surface drawing

A pen-based system allow users, such as artists, graphic designers sand illustrators, and the like, to create accurate curve models by sketching. A tool set implemented in software that runs on a computer system combines paper sketch metaphors and a minimalist gesture set. This tool set provides an environment where the artists can focus on the creative task at hand rather than the details of operating software. A pen-based drawing method and system allows users to create and edit three dimensional (“3D”) objects by sketching.

Owner:FCA US

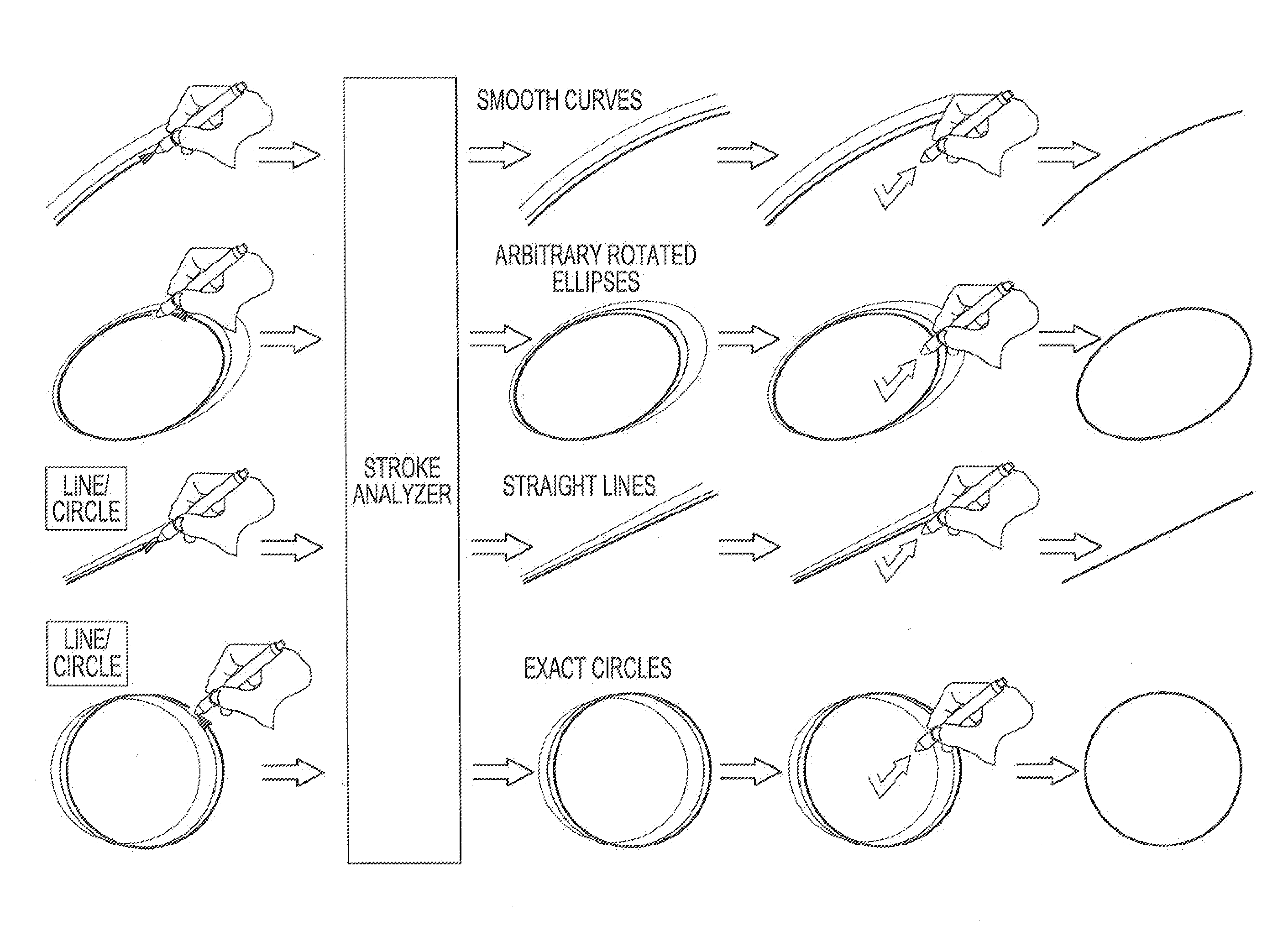

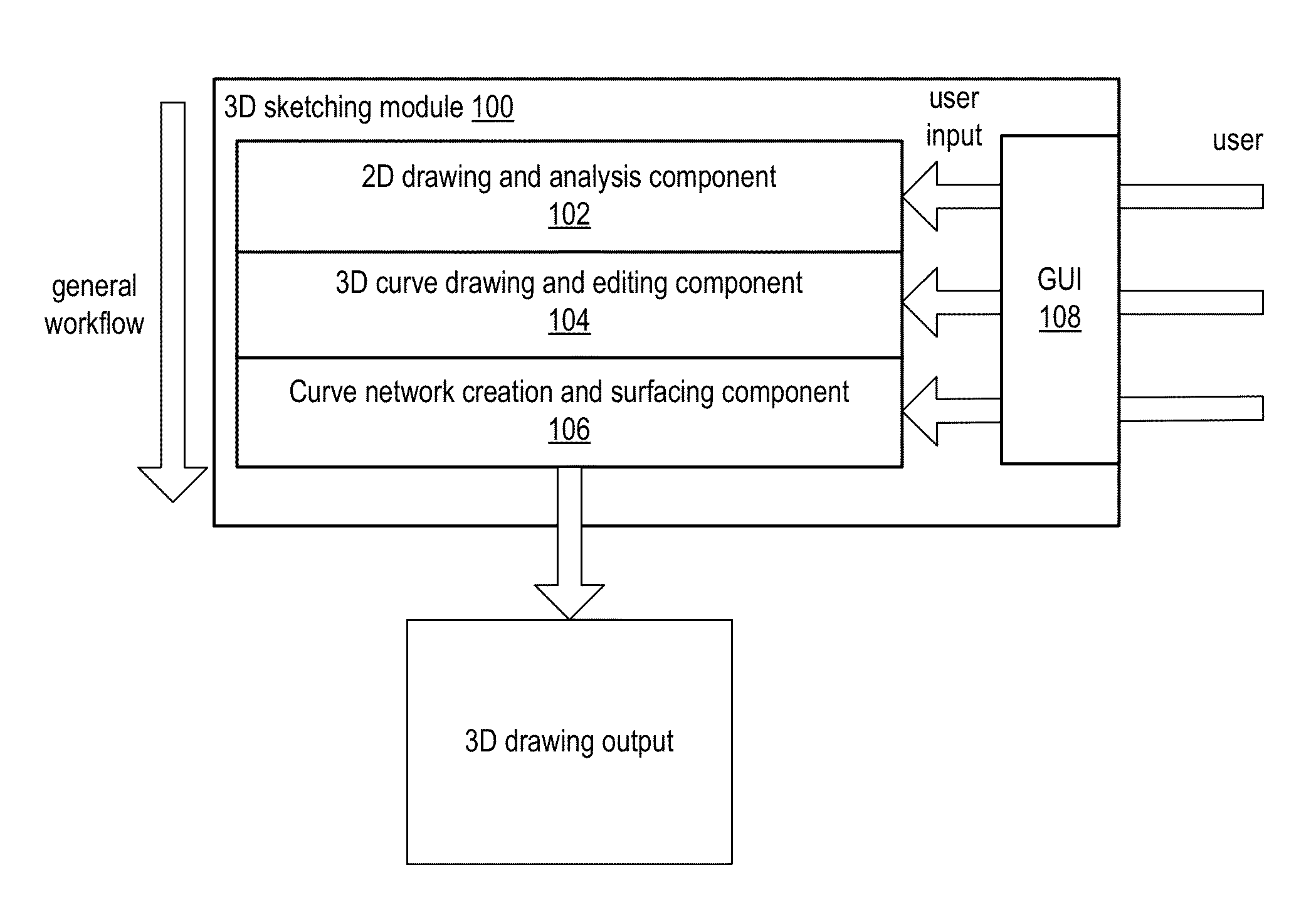

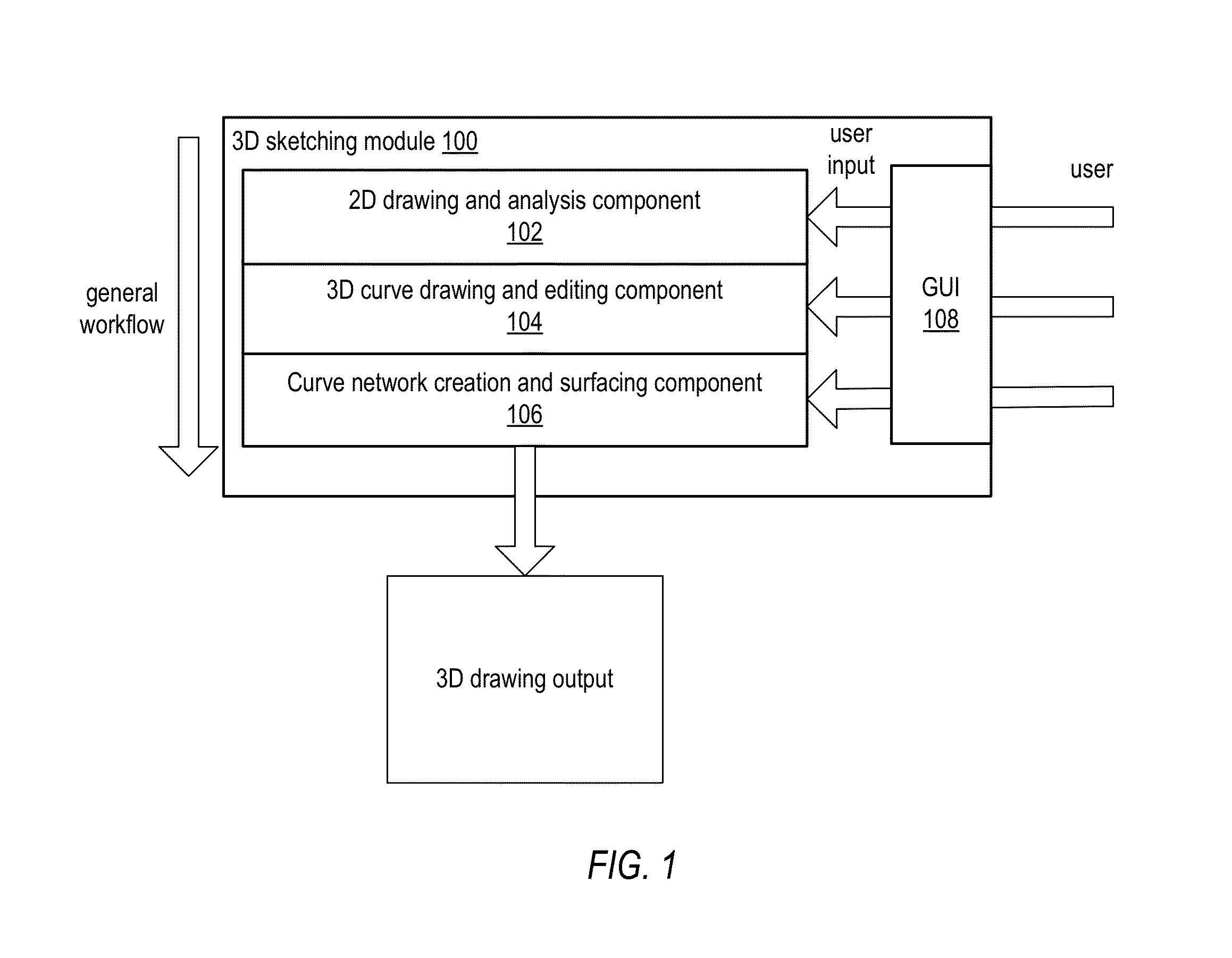

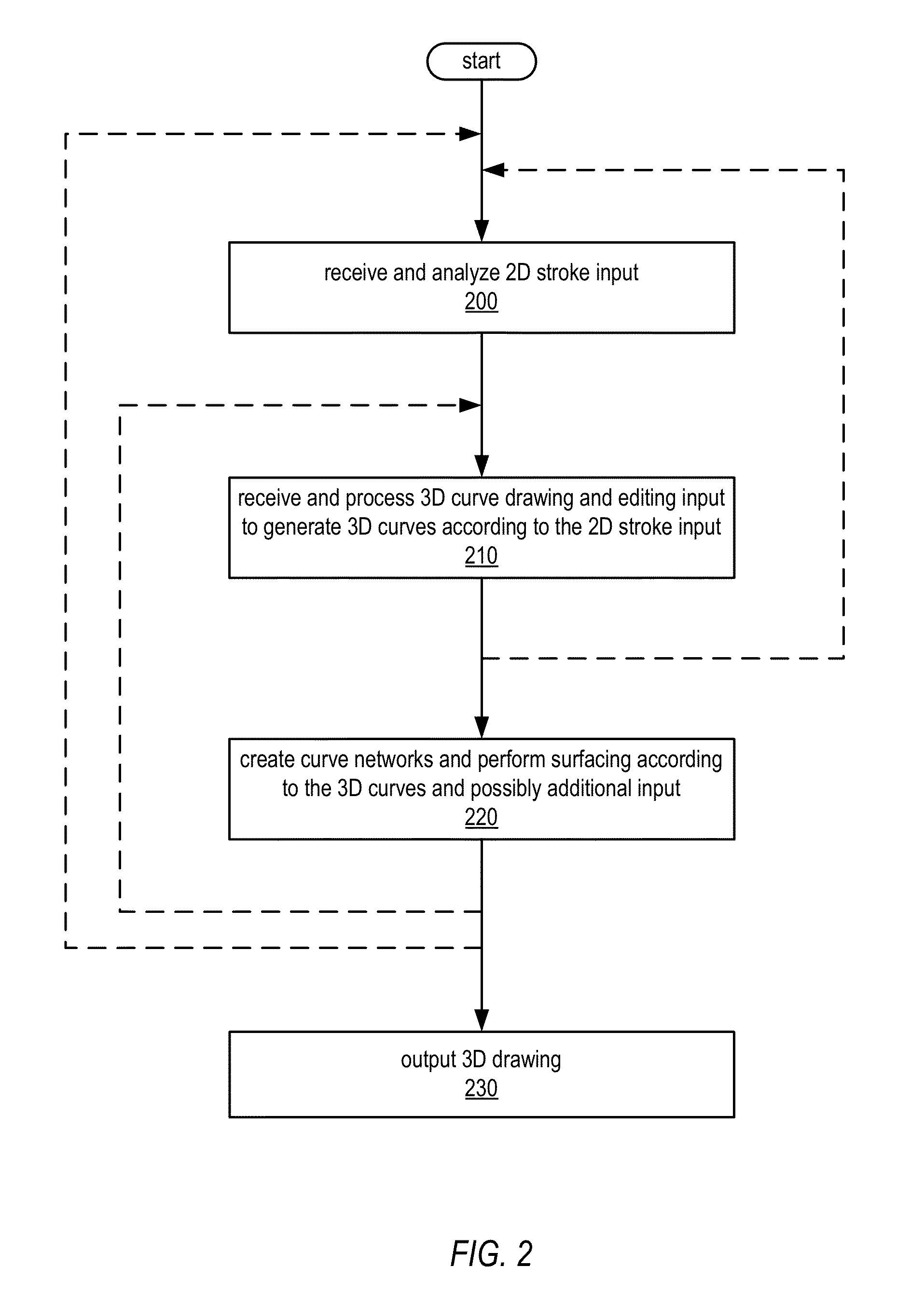

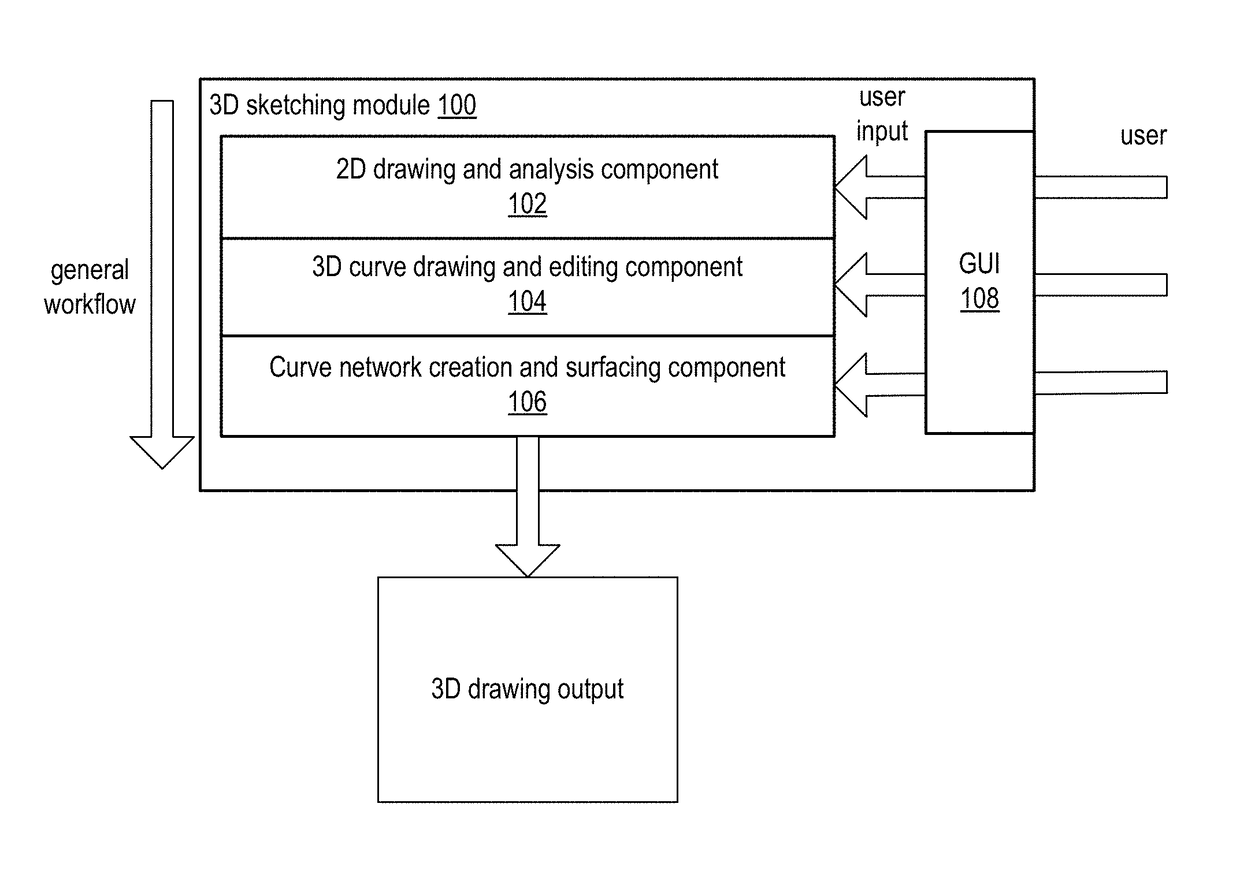

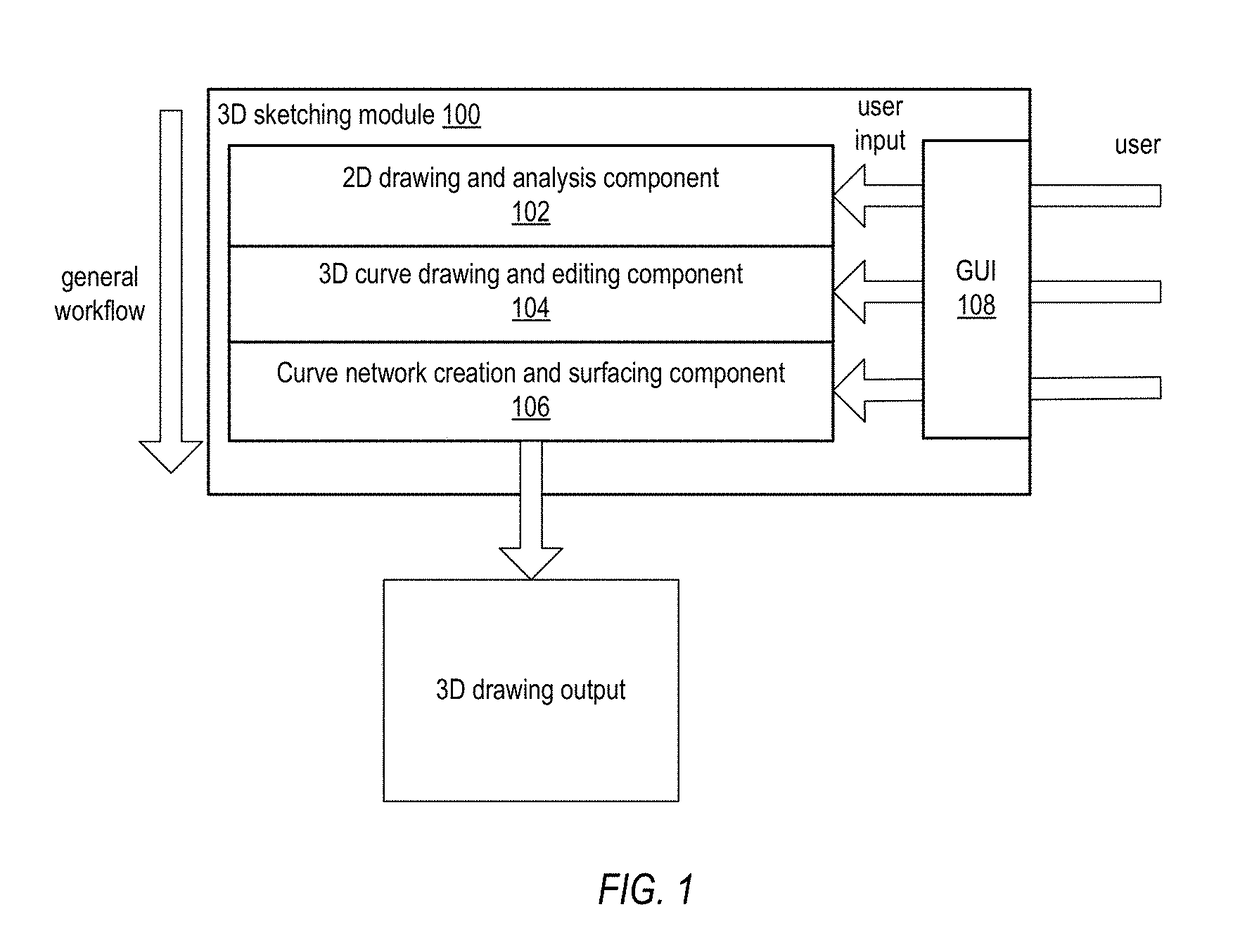

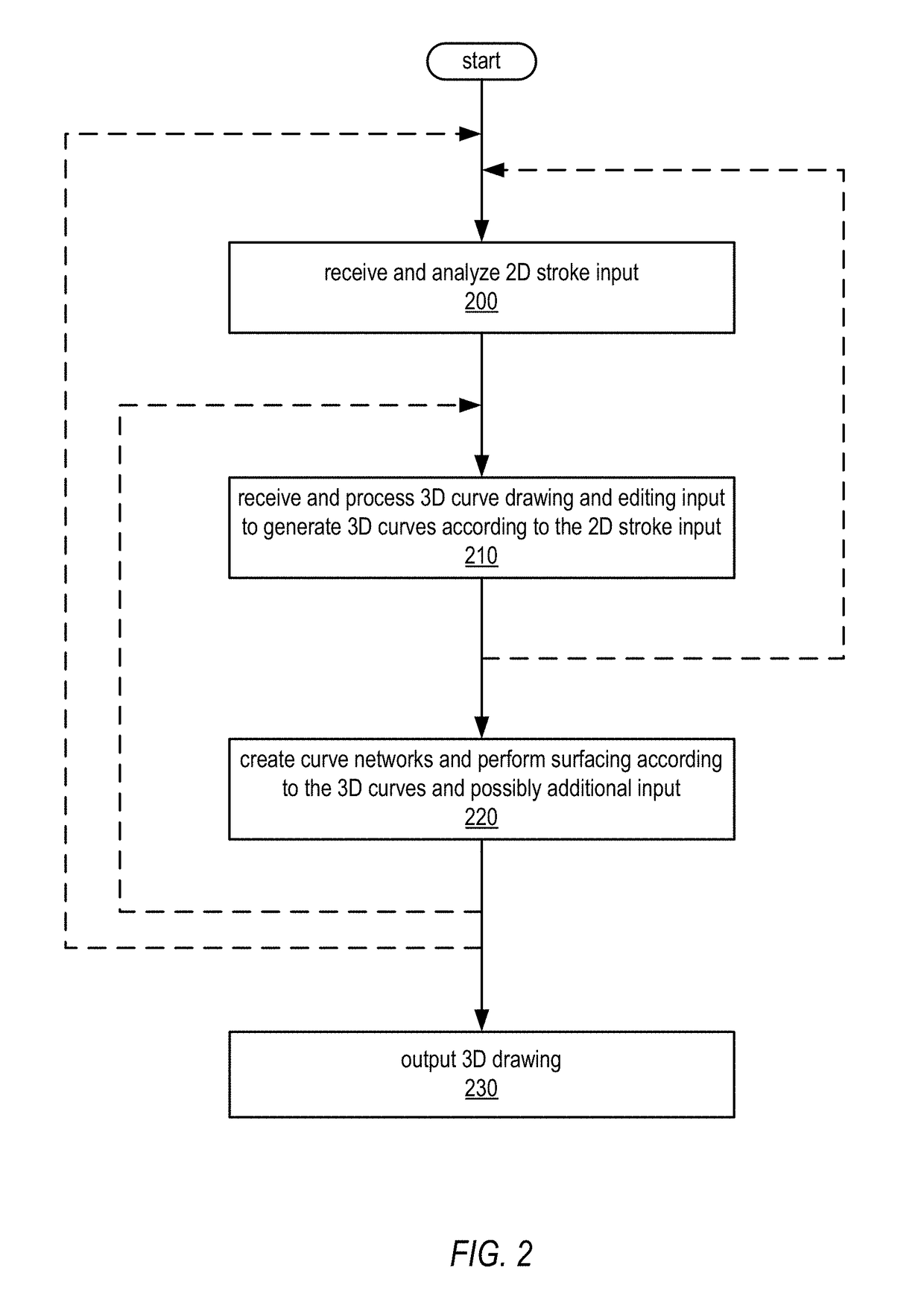

Methods and Apparatus for Three-Dimensional (3D) Sketching

ActiveUS20130127836A1Facilitates task2D-image generationSpecial data processing applicationsComputer graphics (images)User interface

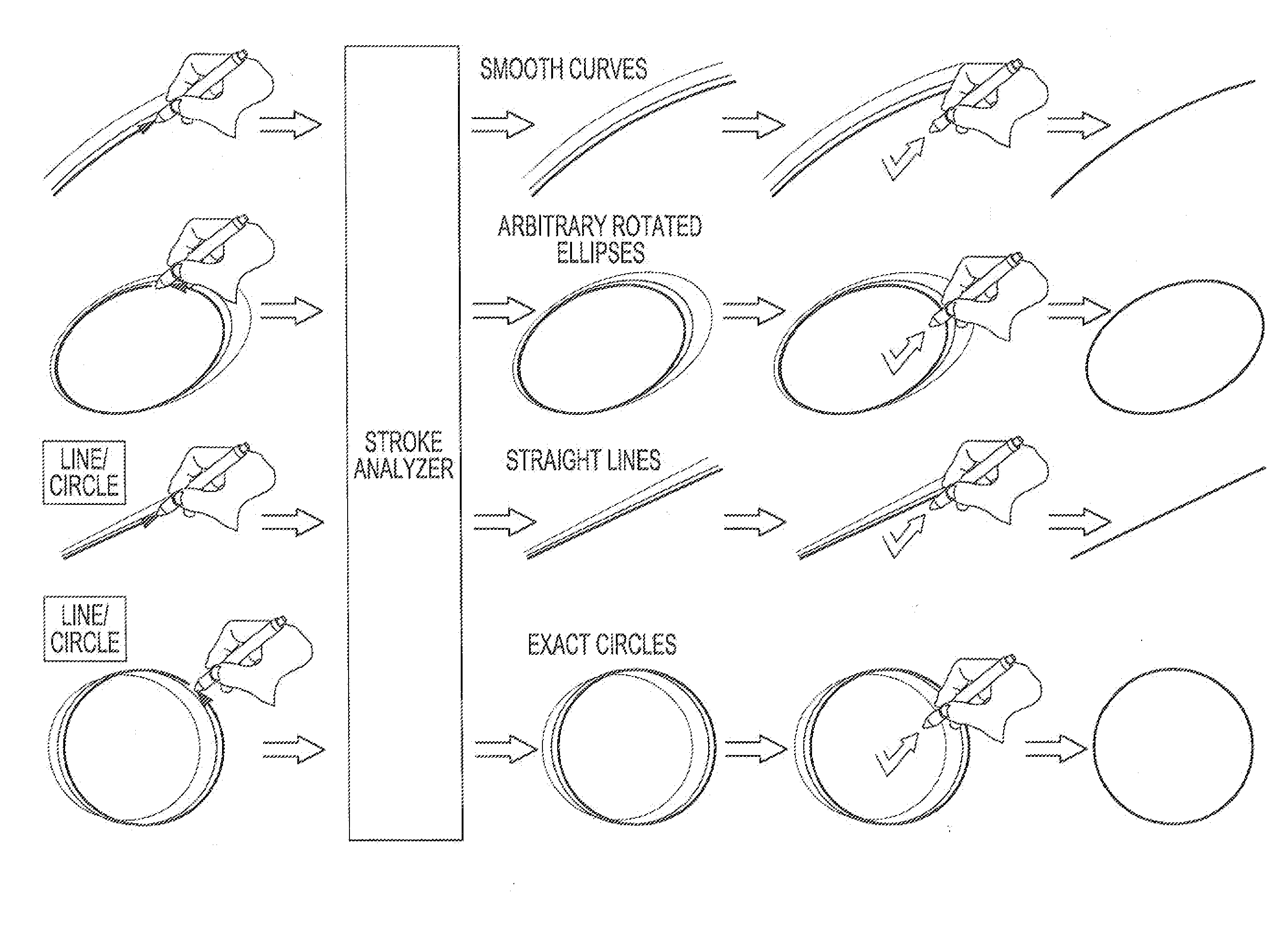

Methods and apparatus for 3D sketching may provide an interface for creating 3D drawings from 2D and 3D input, and for creating 3D curve networks. The technique may provide tools for 2D sketching that enable 2D sketching in 3D space, and for creating a network of intersecting 3D curves. The technique may provide user interface elements and techniques that facilitate the curve drawing tasks. For 2D sketching, the technique may provide methods for interpreting imprecise user 2D strokes as continuous, high-quality 3D curves. The technique may provide the ability to edit existing 3D curves using sketched 2D strokes. The technique may enable sketching of 3D curves by rotating a drawing plane and / or by creating drawing surfaces on which curves may be added. The technique may provide user interface elements for converting curves in 3D space into a curve network.

Owner:ADOBE SYST INC

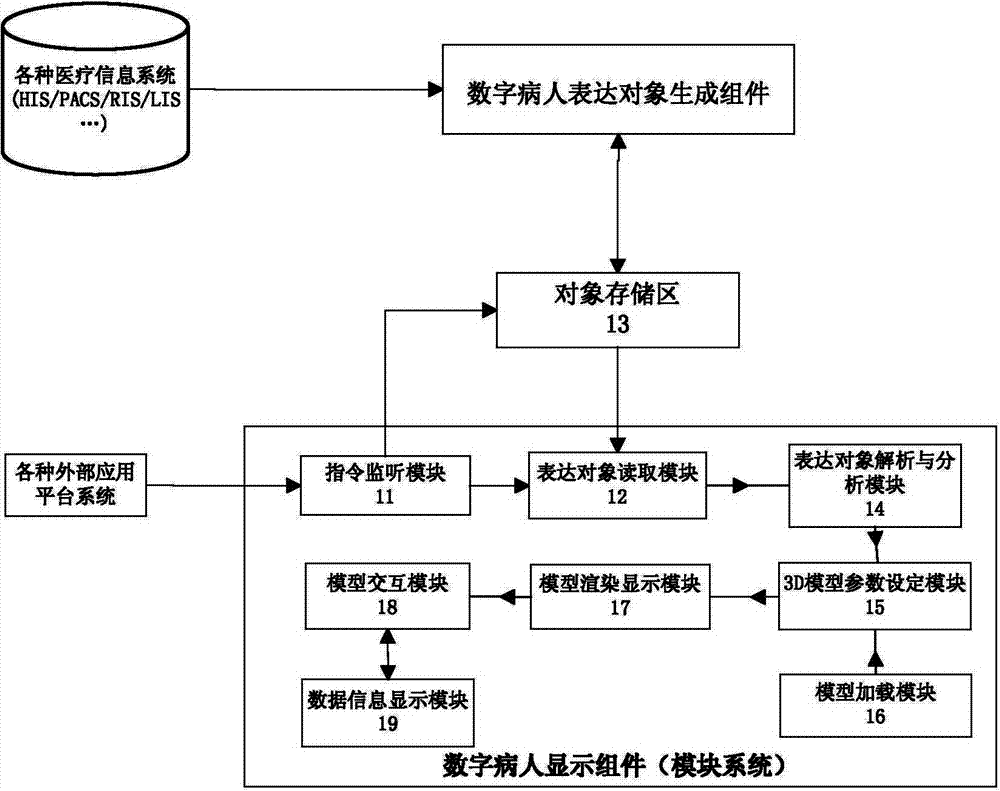

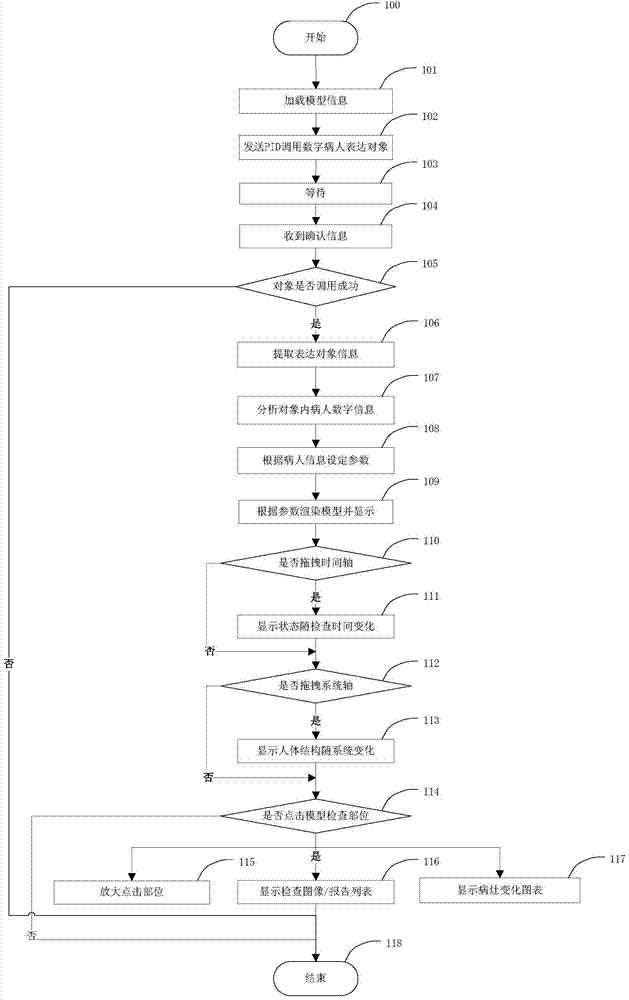

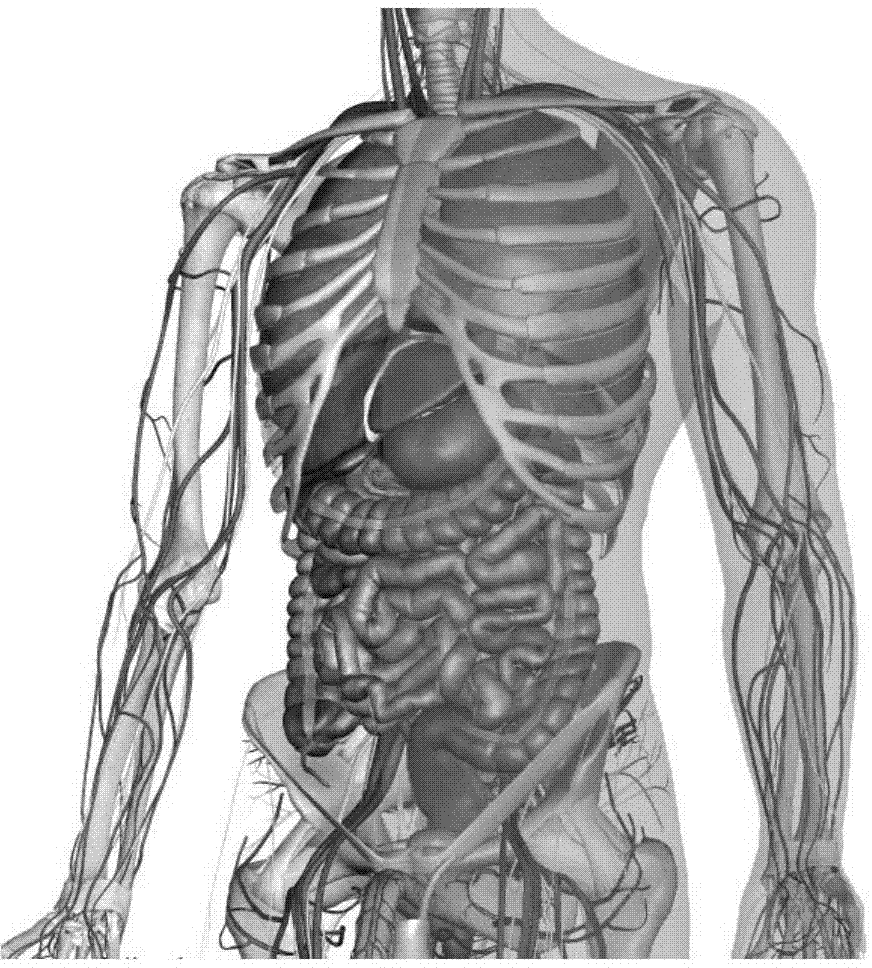

Medical information visualization method and device

ActiveCN103793611AEasy accessObtain intuitivelySpecial data processing applicationsPersonalizationUsability

The invention relates to a medical information visualization method and device. The method includes the steps of loading a human model through 3D drawing software, converting patient information stored in a medical information system to structured medical information, and finally loading the medical information onto the human model. The medical information visualization device receives an instruction of a user and selects a displayed organ, a subclinical organ and / or the corresponding medical information according to the instruction of the user so that integration expression and visualized display of various types of digital medical information of patients can be achieved. The medical information visualization device can be integrated with various types of medical application platform systems. According to the medical information visualization method and device, materials such as clinical medical data, images and medical examination reports of the patients can be fully utilized; because of the visualization function, the recognition degree of non-medical staff on the health conditions of the patients can be improved, the intellectualization and personalization of user interfaces can be improved, the usability of the medical information of the patients can be improved, and the value chain and use efficiency of the medical information can be prolonged.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

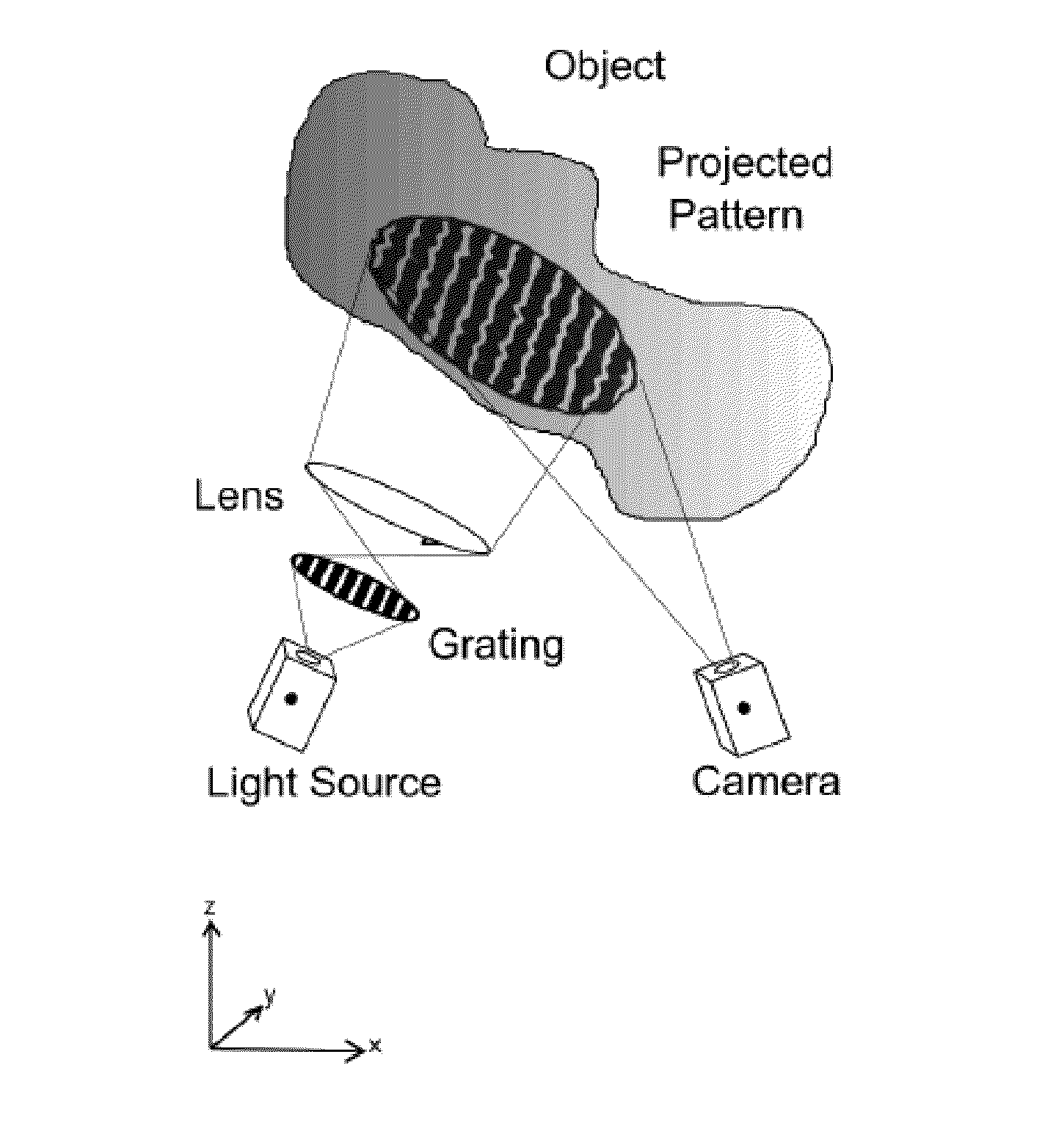

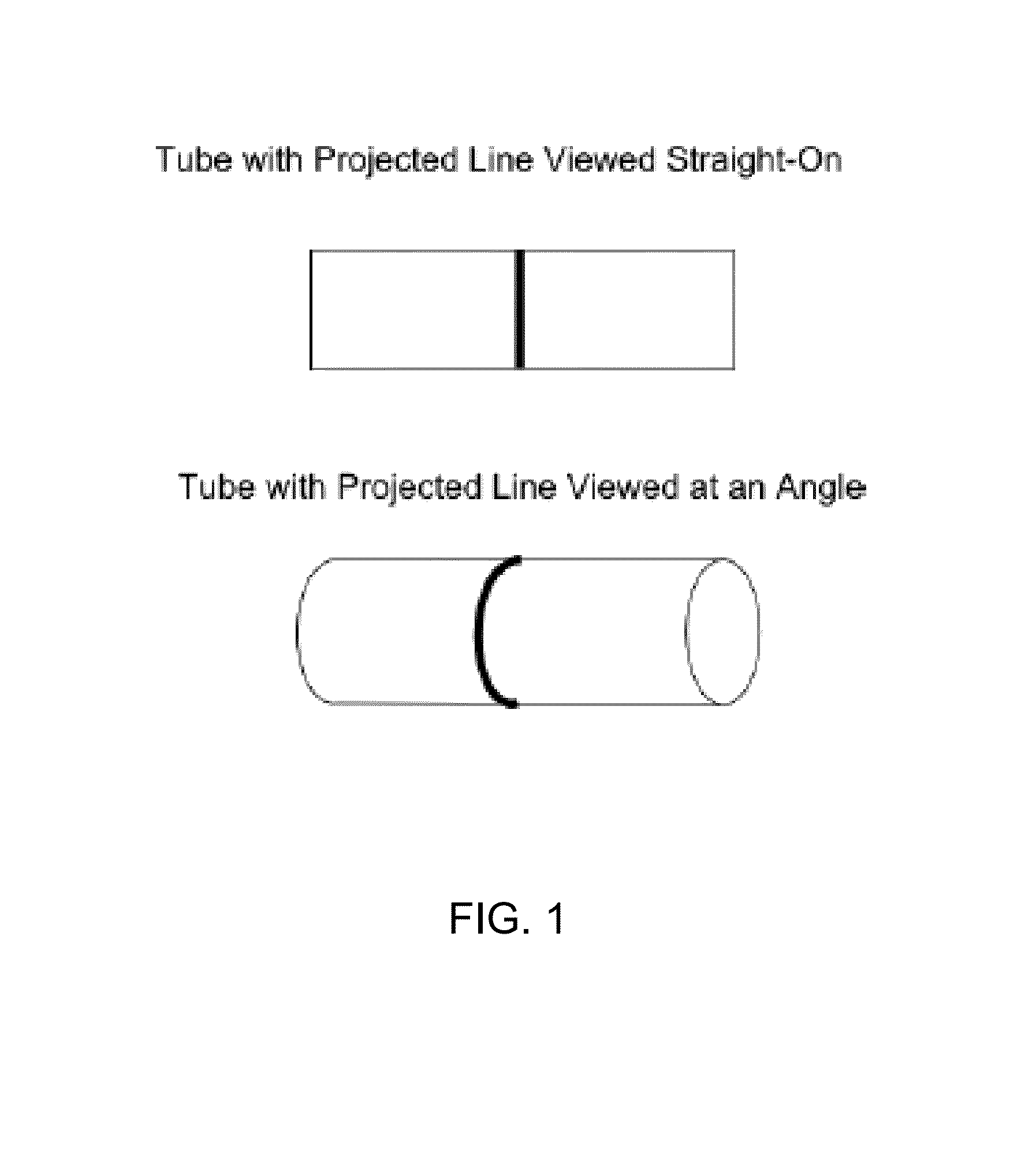

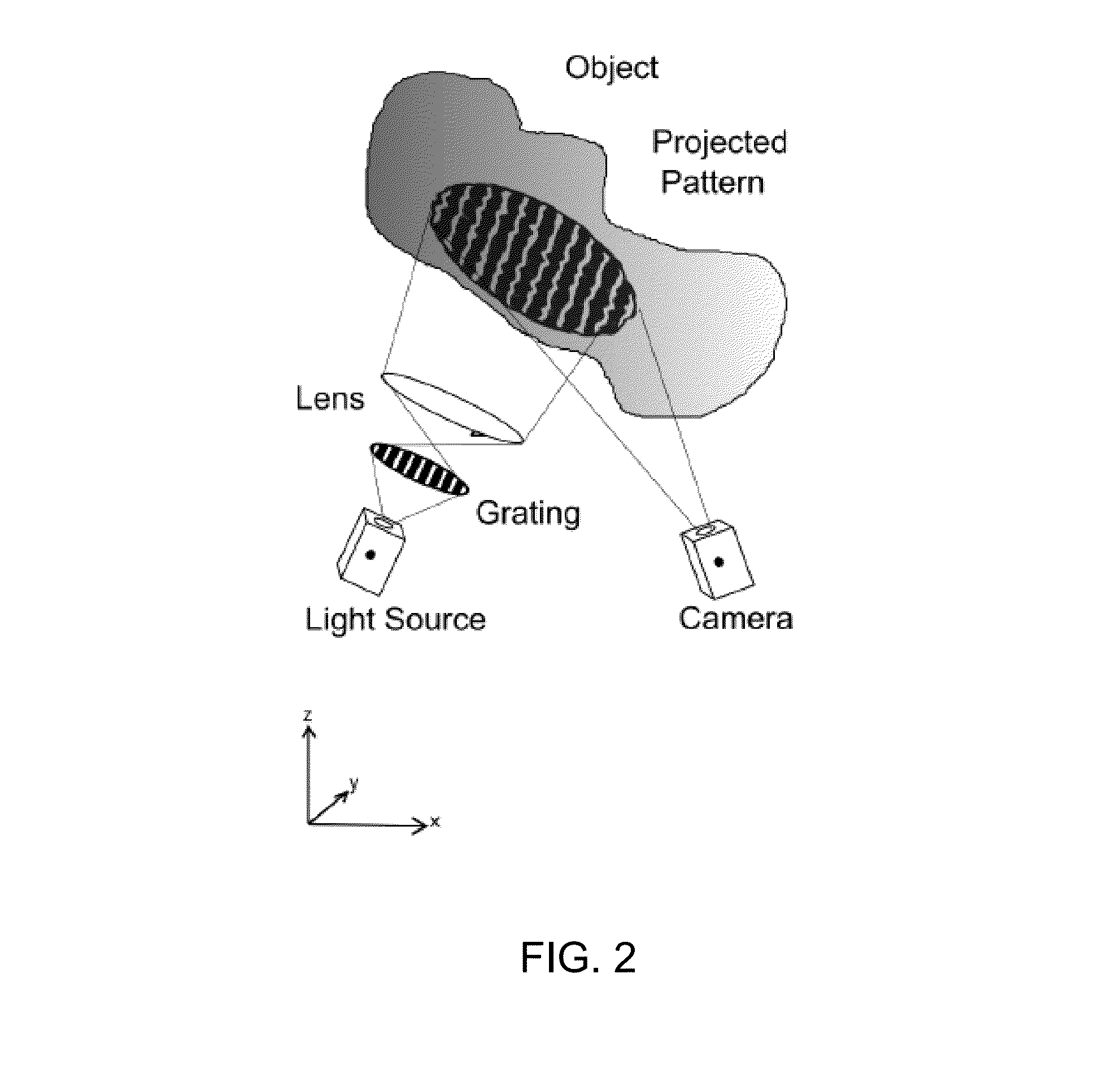

3D mapping using structured light and formation of custom surface contours

A 3D mapping apparatus is provided that includes a light source, a projector, and a portable device. The projector is constructed to project a structured light pattern onto a target object. The projector includes an interface enabled to collects light from the light source, a grating that corresponds to the structured light pattern, and a lens interposed between the light source and the target object. The portable device includes an integrated camera for capturing light reflected from the target object and generating an image therefrom. Also included is a storage medium enabled to store the image. The camera and the lens of the projector are located at a predetermined distance from each other. Also provided are multicomponent items having a desired surface contour and method for producing such items.

Owner:JOSEPH BENJAMIN E

Pen-based 3D drawing system with geometric-constraint based 3D cross curve drawing

InactiveUS20080024500A1Drawing from basic elementsCharacter and pattern recognitionGraphicsGraphic designer

A pen-based system allows users, such as artists, graphic designers and illustrators, and the like, to create accurate curve models by sketching. A tool set implemented in software that runs on a computer system combines paper sketch metaphors and a minimalist gesture set. This tool set provides an environment where the artists can focus on the creative task at hand rather than the details of operating software. A pen-based drawing method and system allows users to create and edit three dimensional (“3D”) objects by sketching.

Owner:FCA US

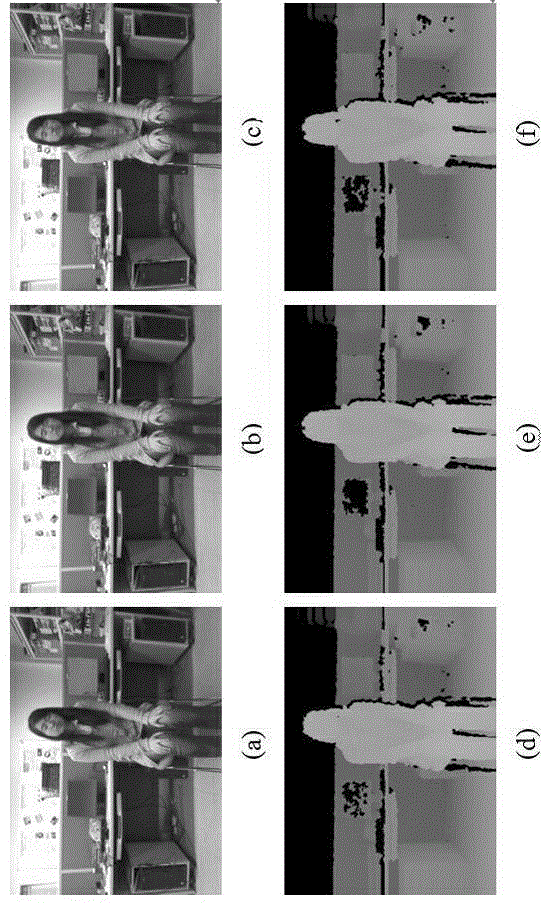

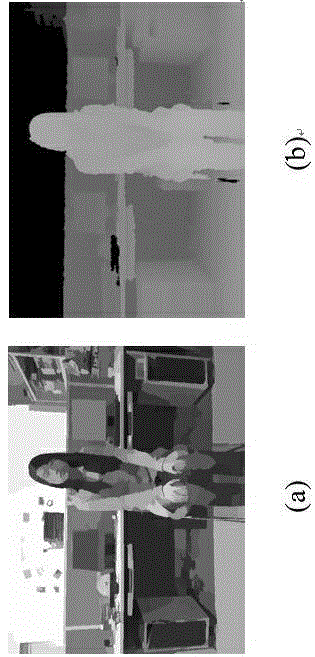

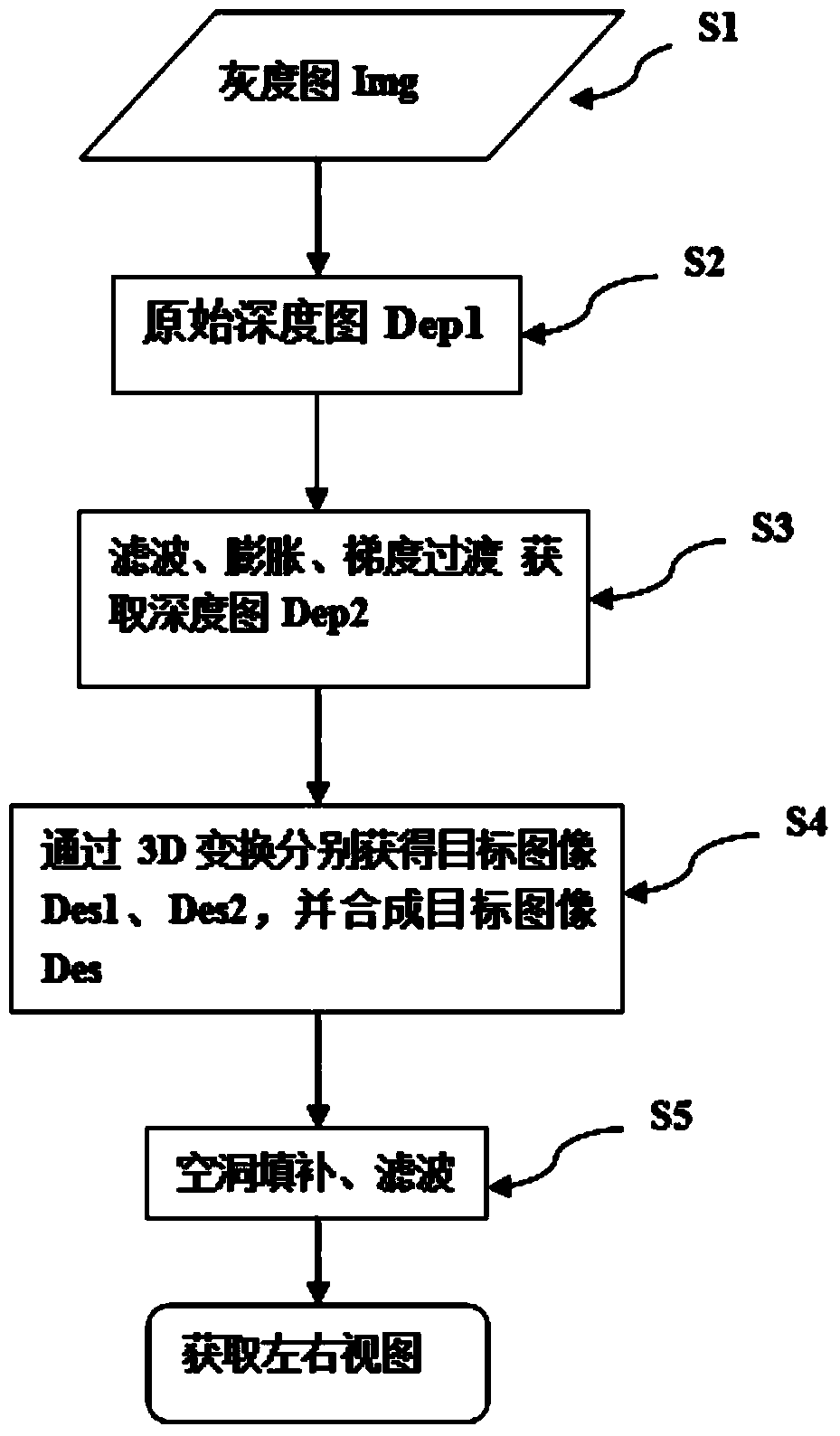

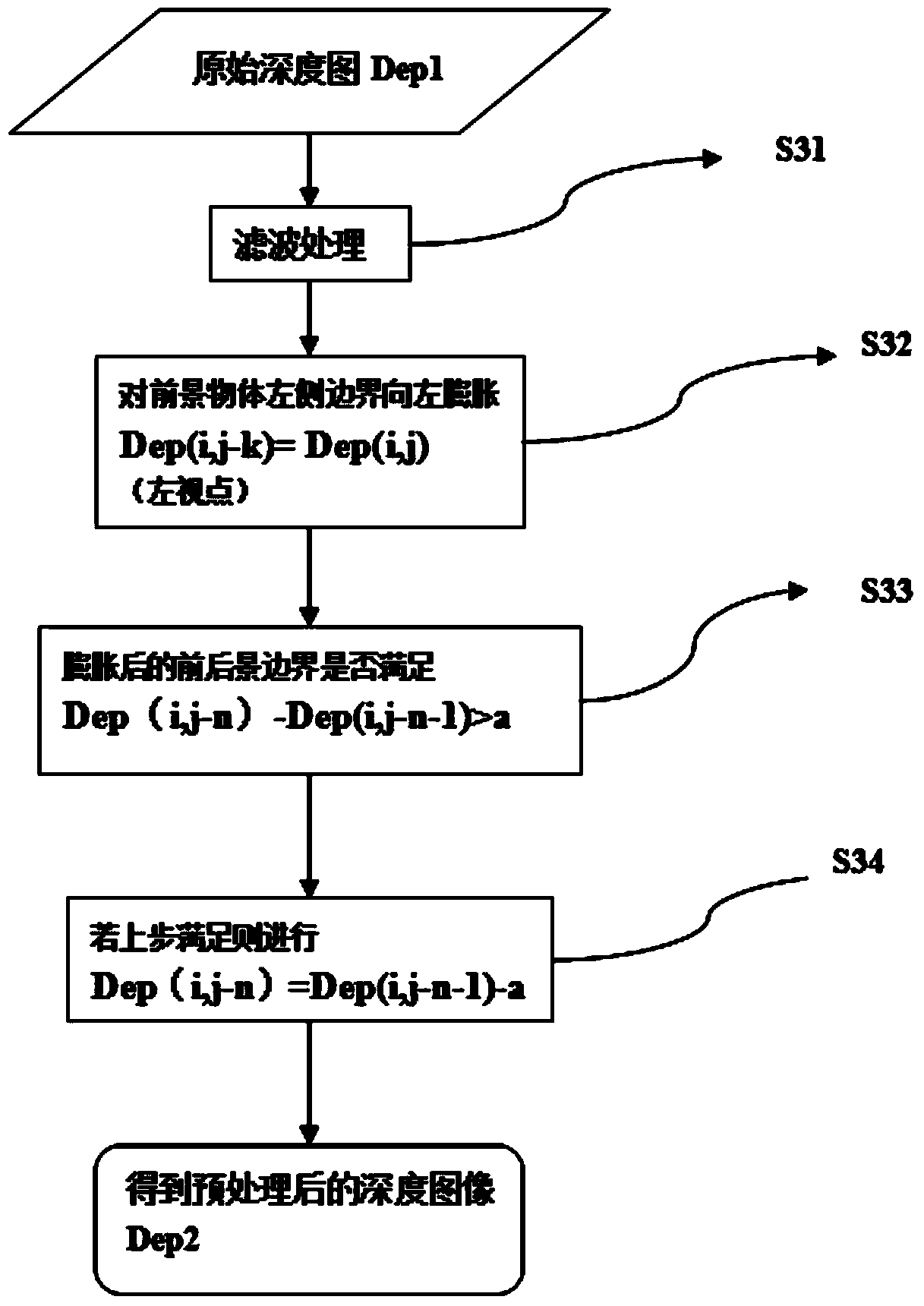

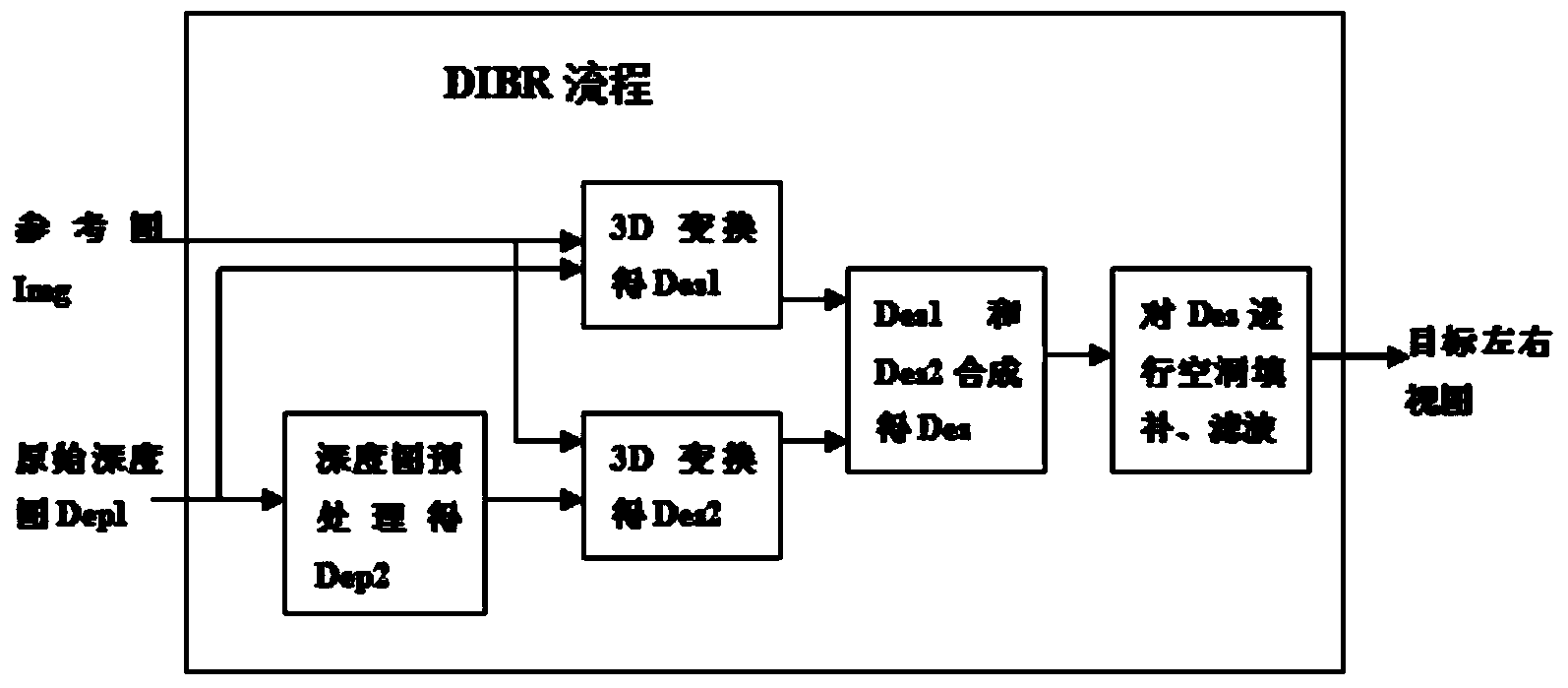

Kinect depth video spatio-temporal union restoration method

Provided is a Kinect depth video spatio-temporal union restoration method. According to the Kinect depth video spatio-temporal union restoration method, on the basis of the hypothesis that neighborhood pixels with similar colors should have similar depth values, a color segment image which corresponds to color images is used for guiding depth filling carried out on motion areas extracted from a first depth image and motion areas extracted from all the follow-up depth images; in consideration that some areas with darker colors and without effective depth values can cause failure of the Kinect depth video spatio-temporal union restoration method, the areas with the darker colors are detected firstly, and effective depth values of the same areas with the darker colors are used for repairing empty areas; according to static areas in depth video shot by a Kinect, if a current depth image is provided with empty pixels, filling is carried out by using depth values of positions, corresponding to the positions of the empty pixels, of a previous depth image. Due to the fact that the drawing technology based on the depth images is used for drawing a virtual viewpoint, the image quality of a virtual right view which is correspondingly obtained through the Kinect depth video spatio-temporal union restoration method is obviously better than that of an original virtual right view, and the Kinect depth video spatio-temporal union restoration method can be applied to 3D drawing.

Owner:TONGJI UNIV

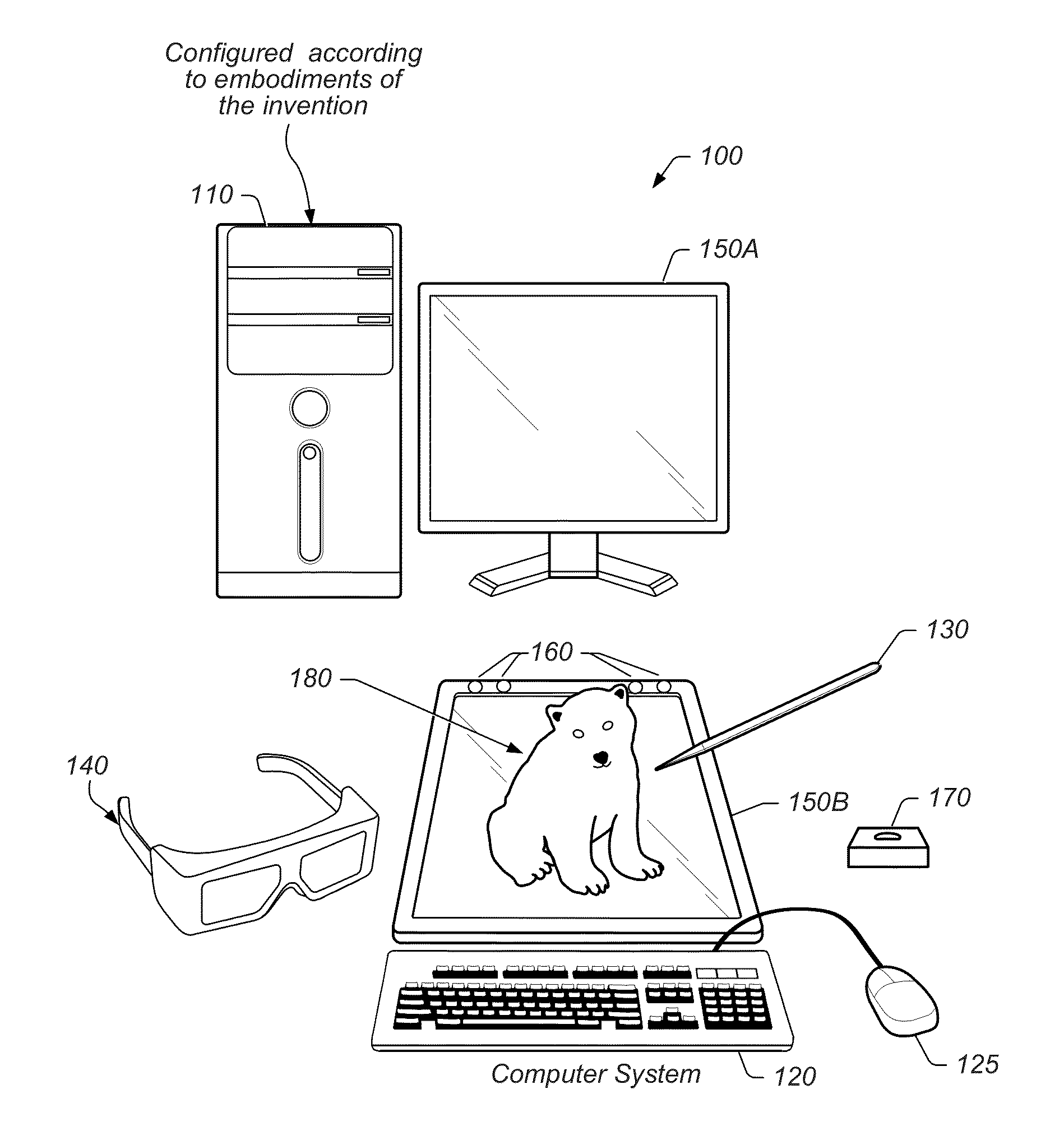

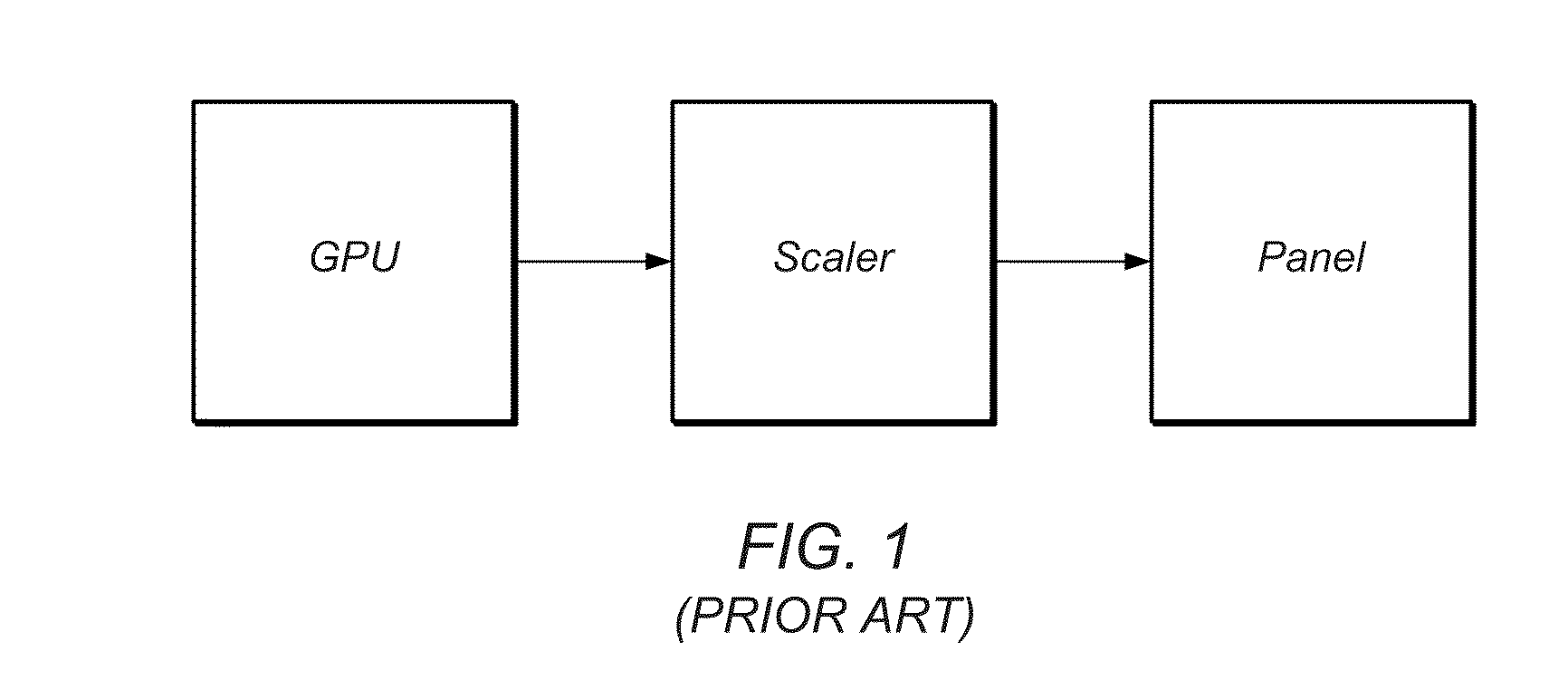

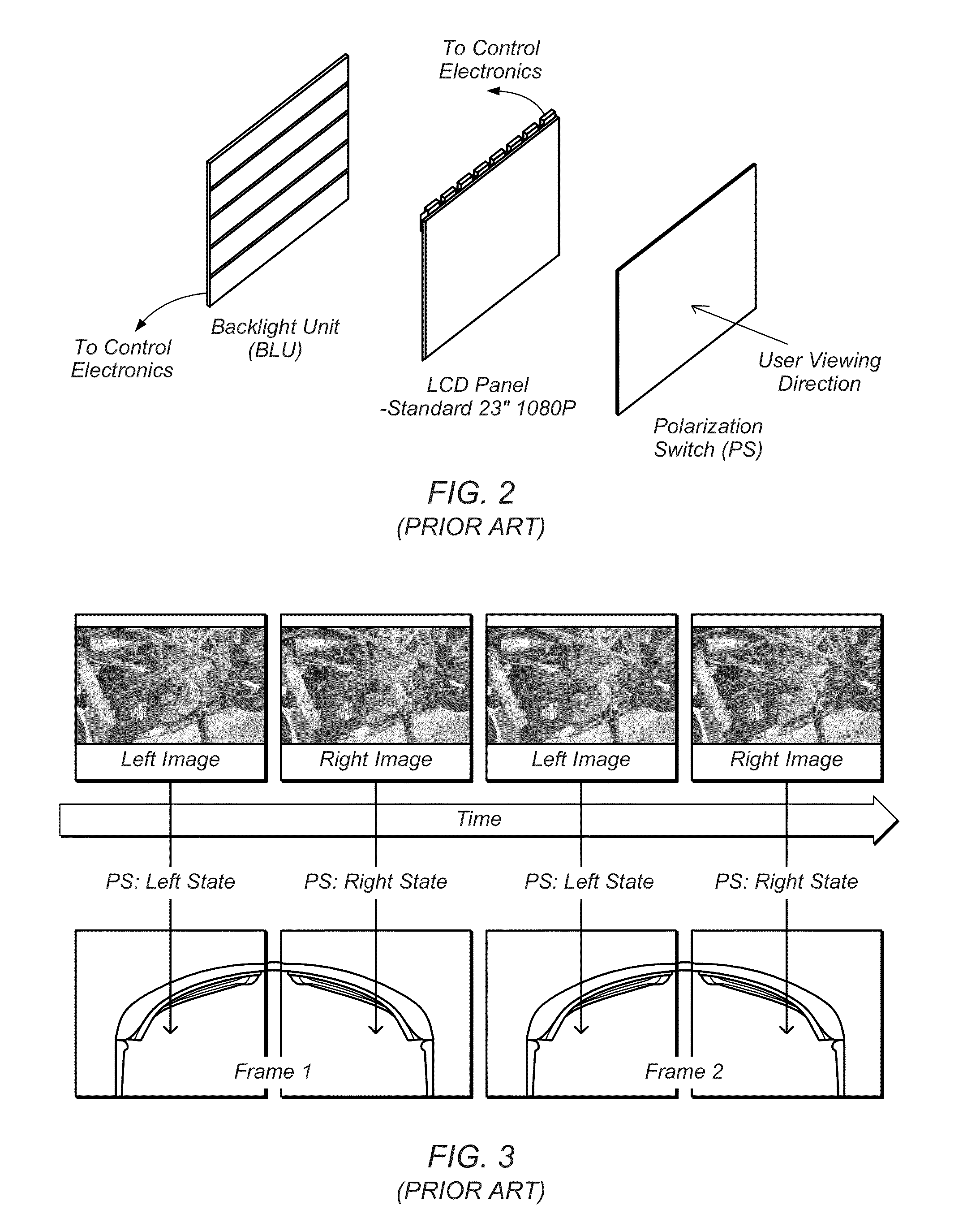

Zero Parallax Drawing within a Three Dimensional Display

ActiveUS20140317575A1Steroscopic systemsInput/output processes for data processingParallaxUser input

Systems and methods for digitally drawing on virtual 3D object surfaces using a 3D display system. A 3D drawing mode may be enabled and a display screen of the system may correspond to a zero parallax plane of a 3D scene that may present a plurality of surfaces at non-zero parallax planes. User input may be received at a location on the display screen, and in response, a surface may be specified, rendered, and displayed at the zero parallax plane. Further, additional user input on the display screen may be received specifying drawing motion across the rendered and displayed surface. The drawing motion may start at the location and continue across a boundary between the surface and another contiguous surface. Accordingly, in response to the drawing motion crossing the boundary, the contiguous surface may be rendered and displayed at the zero parallax plane along with results of the drawing motion.

Owner:INFINITE Z

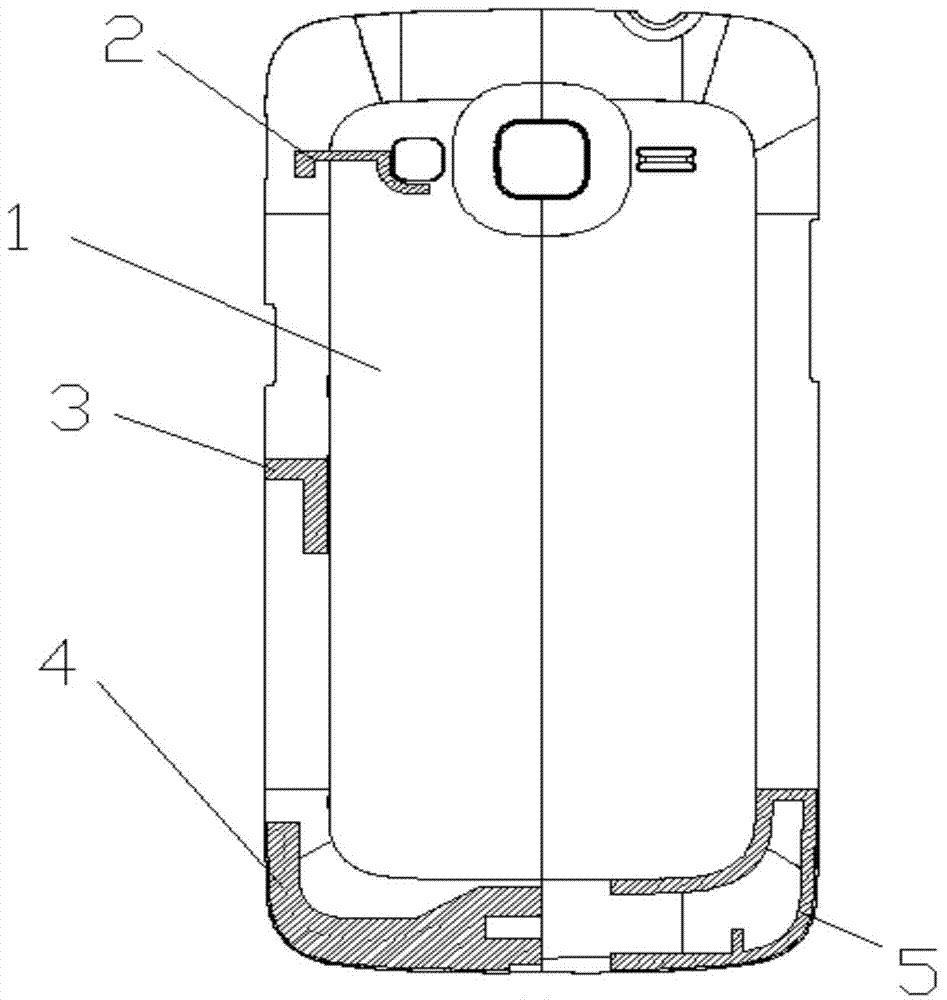

Method for manufacturing shell of electronic product

ActiveCN103702529ASimilar or consistent flatnessAvoid problems that affect appearanceElectrical apparatus casings/cabinets/drawersManufacturing cost reductionFile design

The invention discloses a method for manufacturing a shell of an electronic product. The method comprises the following steps of A, generating of 3D (Three-Dimensional) drawing file design of an injection mold: reserving an antenna groove by the injection mold when a mold opening 3D drawing file design is generated; B, injection mold processing: carrying out shape processing on the antenna groove when a mold core is processed so as to ensure the integrated forming of an antenna and the shell of the product when the antenna is subsequently processed, and enabling the shell of the product not to be subjected to poor appearance when surface processing is carried out; C, injection molding machine molding: completing the injection molding of the product by utilizing the injection mold, which is already designed and processed in a mold, of the antenna groove; D, mobile phone antenna processing: directly processing a mobile phone antenna in the antenna groove on the surface or the inner wall of a mobile phone plastic piece; E, mobile phone surface processing and coating. According to the method disclosed by the invention, the bottlenecks of a surface decoration technology that the surface of the product is rugged when the mobile phone antenna is assembled or printed on the surface of the product, and the surface of the product needs to be sanded when the mobile phone antenna is produced can be broken through, highly-textured appearance on the surface of the product can be generated, the manufacturing cost can be reduced, and the yield of the product can be increased.

Owner:KUNSHAN RUIXIANG XUNTONG COMM TECHCO

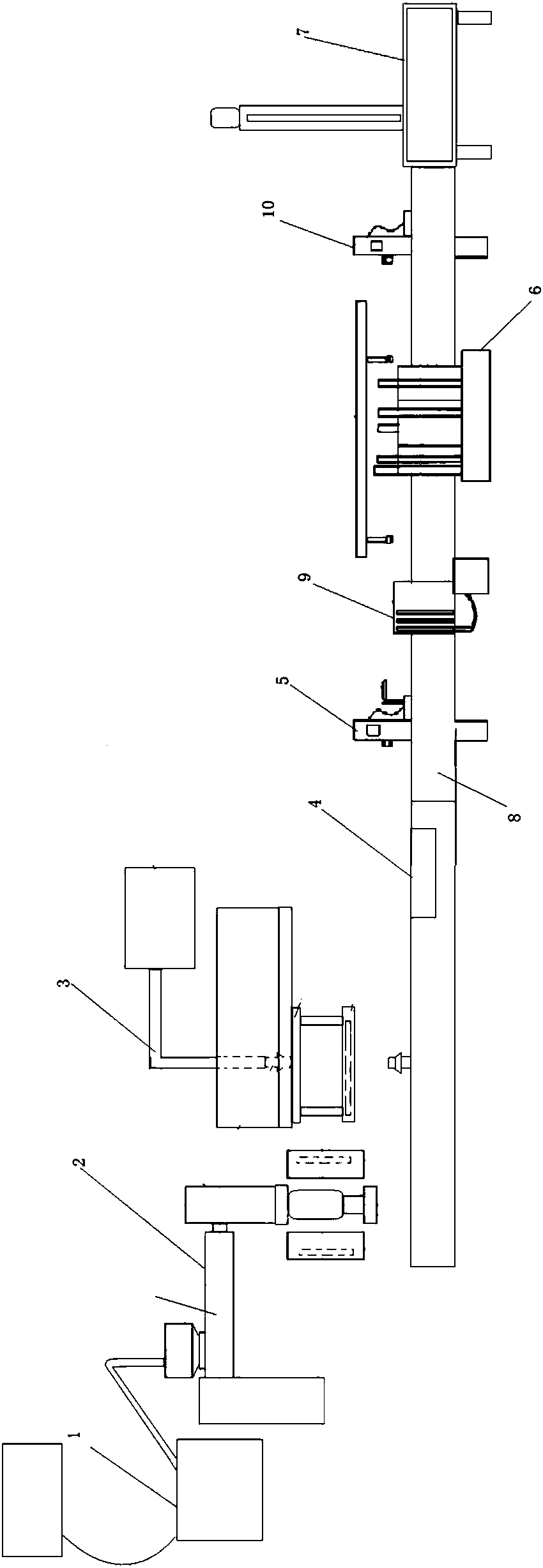

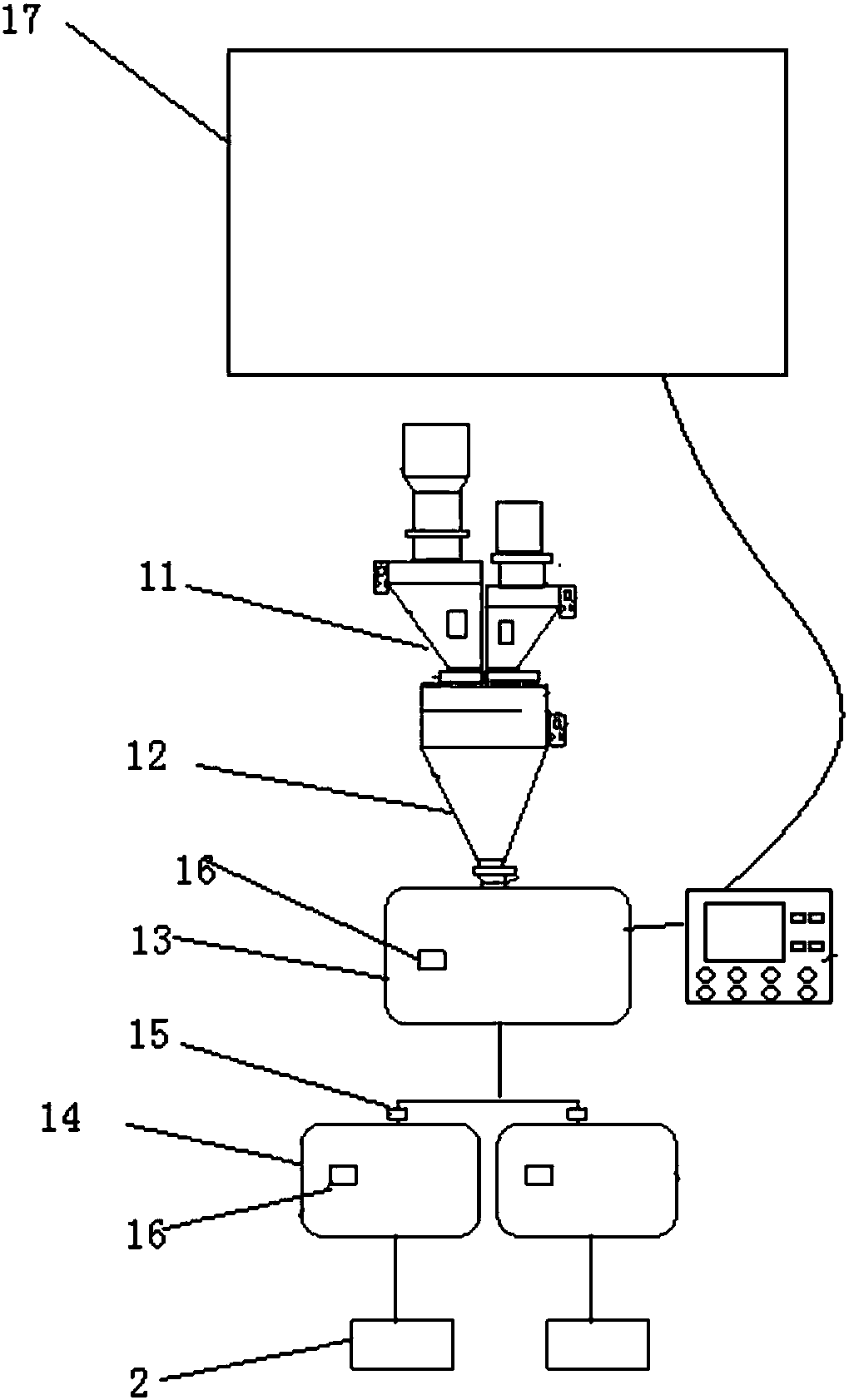

Human-computer interaction intelligent closed-loop control method of full-automatic blow-molding production line and process thereof

InactiveCN107775946ASolving Dispersion ProblemsSolve the problem of energy consumptionClosed loop feedbackClosed loop

The invention belongs to the field of blow-molding production and particularly relates to a human-computer interaction intelligent closed-loop control method of a full-automatic blow-molding production line and a process thereof. The method successively comprises the following steps: scanning and inputting a 3D bottle shape or a 3D drawing; selecting a suitable flow glue head and determining a flow glue curve; automatically mixing materials, checking and feeding color difference on line and automatically adjusting a color masterbatch ratio; carrying out electromagnetic induction heating, flexibly adjusting the thickness of the radial wall and the axial wall of an extrusion blank, monitoring and feeding the wall thickness of the blank, and enabling the wall thickness of the products to be more uniformly distributed; carrying out a blow molding process by checking and feeding the appearance and the cutting quality on line; automatically removing burrs, measuring the size of bottle openings and bottle bodies on line, testing leakage on line, labeling on line, shooting video on line and finally automatically stacking and packing through a packing machine. The method has the beneficialeffects that the operation is based on lasting and automatic process adjustment; the manual intervention is not needed; hollow container raw materials are accurately distributed; the products are monitored in real time and are measured and fed back; the process is automatically adjusted; the products are in dynamic and continuous adjustment state and continuously tend to be standard samples; the quality of hollow containers is improved; the production of waste products is reduced or avoided; the passive situation of established fact caused by post detection can be completely changed; the method is capable of achieving online detection and closed-loop feedback and adjusting at first time; the ideal state with early prediction, process control and high-quality production can be really achieved.

Owner:岱纳包装(天津)有限公司

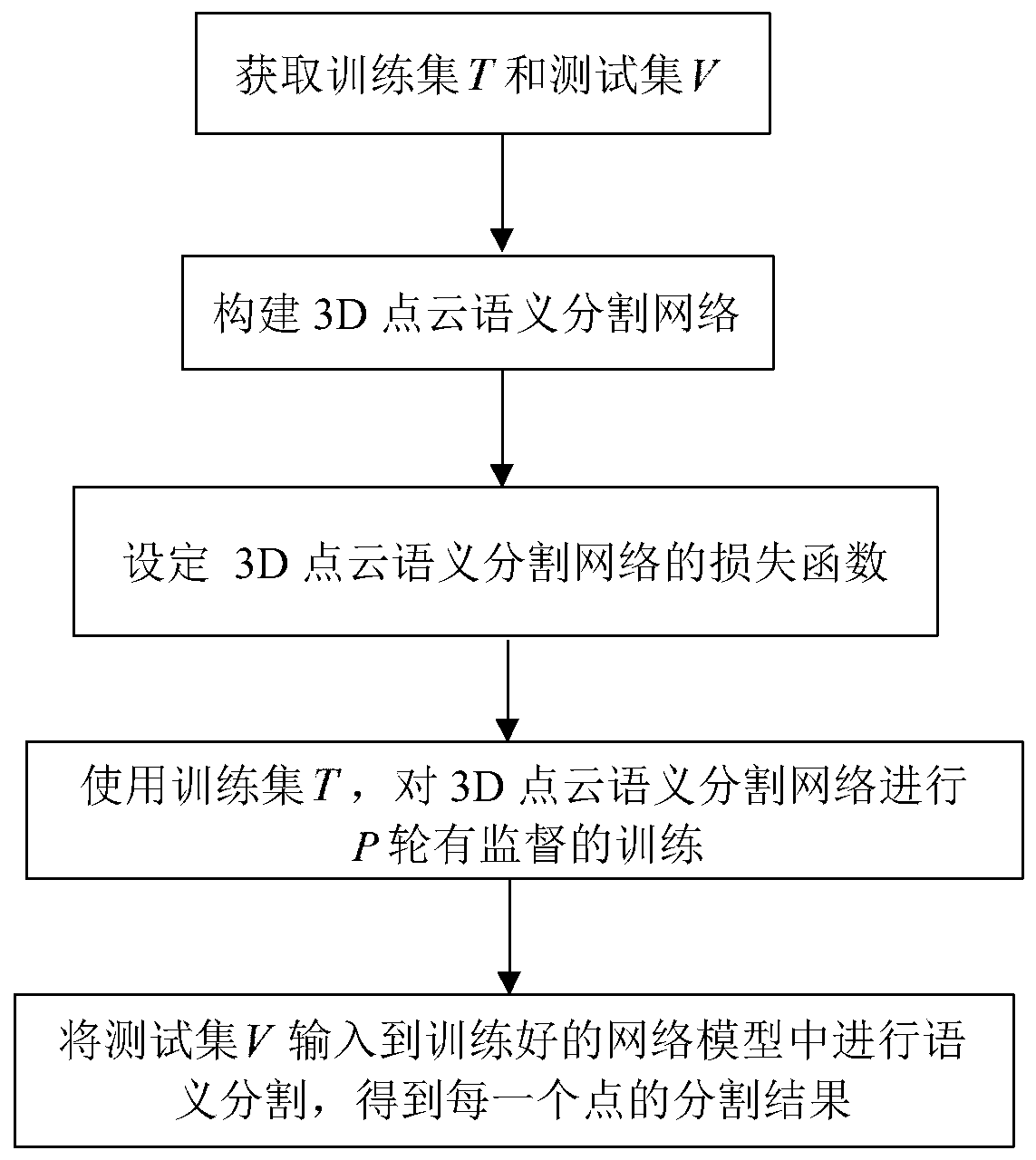

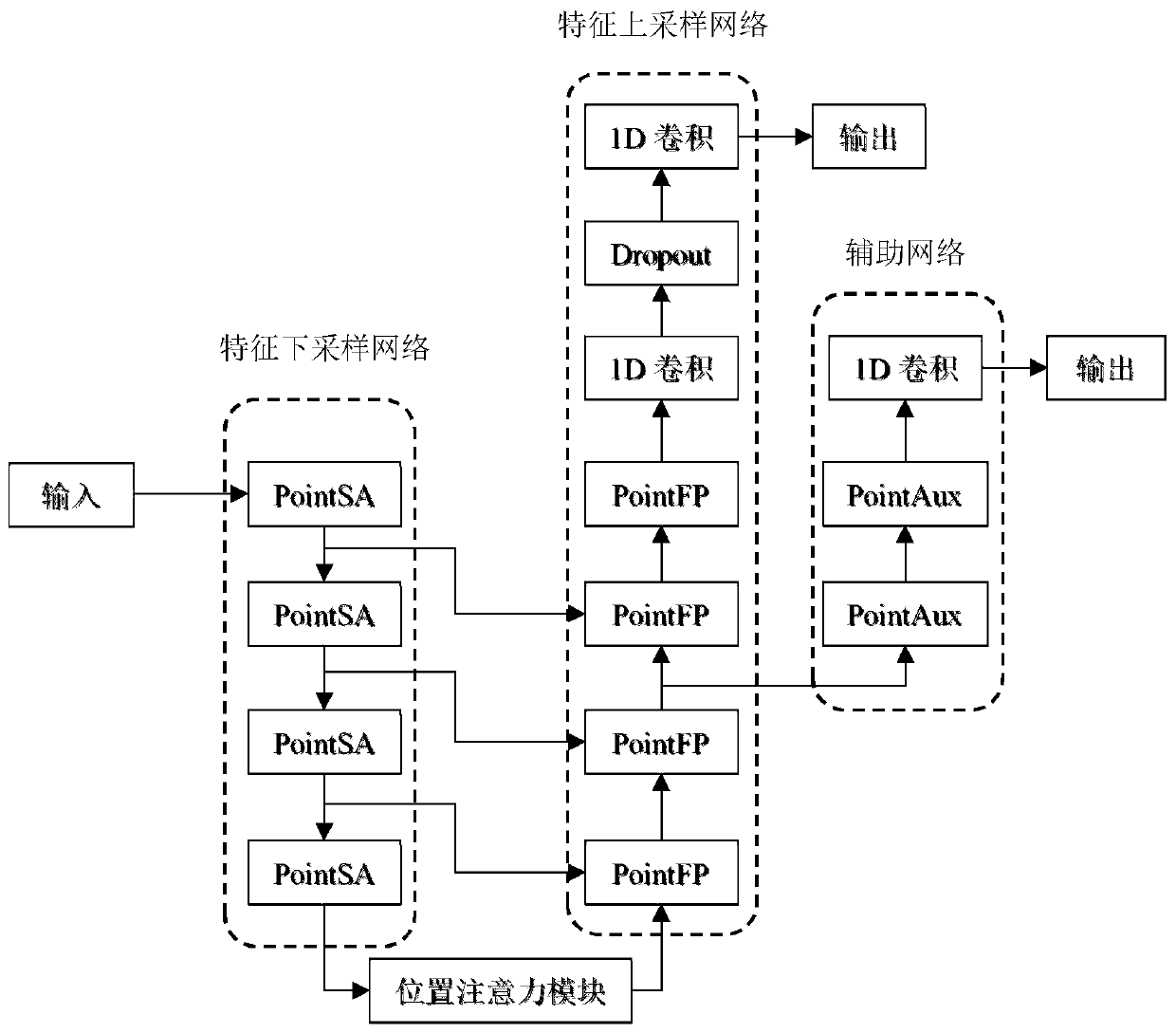

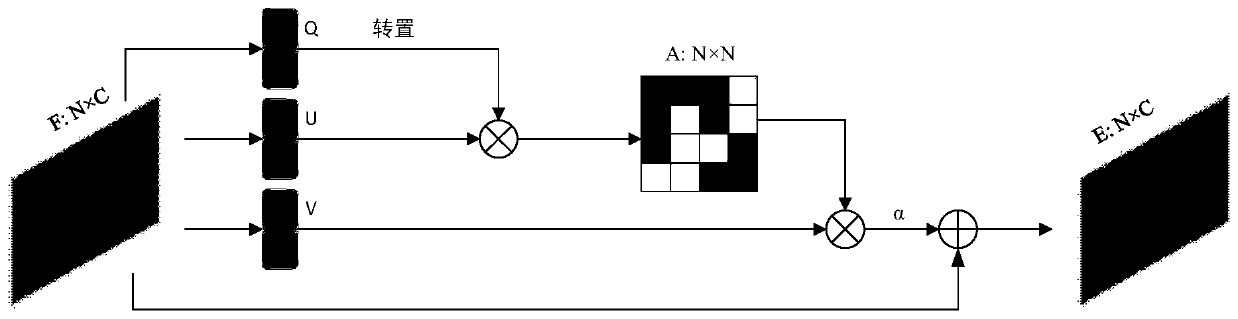

3D point cloud semantic segmentation method based on position attention and auxiliary network

ActiveCN110322453AImprove Segmentation AccuracyImage enhancementImage analysisPoint cloudNetwork model

The invention provides a 3D point cloud semantic segmentation method based on position attention and an auxiliary network, mainly solves the problem of low segmentation precision in the prior art, andadopts the implementation scheme which comprises the following steps of acquiring a training set T and a test set V; constructing a 3D point cloud semantic segmentation network, setting a loss function of the network wherein the network comprises a feature down-sampling network, a position attention module, a feature up-sampling network and an auxiliary network which are cascaded in sequence; performing P rounds of supervised training on the segmentation network by using the training set T: in each round of training process, adjusting network parameters according to a loss function, and afterthe P rounds of training are completed, taking the network model with the highest segmentation precision as a trained network model; and inputting the test set V into a trained network model for semantic segmentation to obtain a segmentation result of each point. The 3D point cloud semantic segmentation precision is improved, and the method can be used for automatic driving, robots, 3D scene reconstruction, quality detection, 3D drawing and smart city construction.

Owner:XIDIAN UNIV

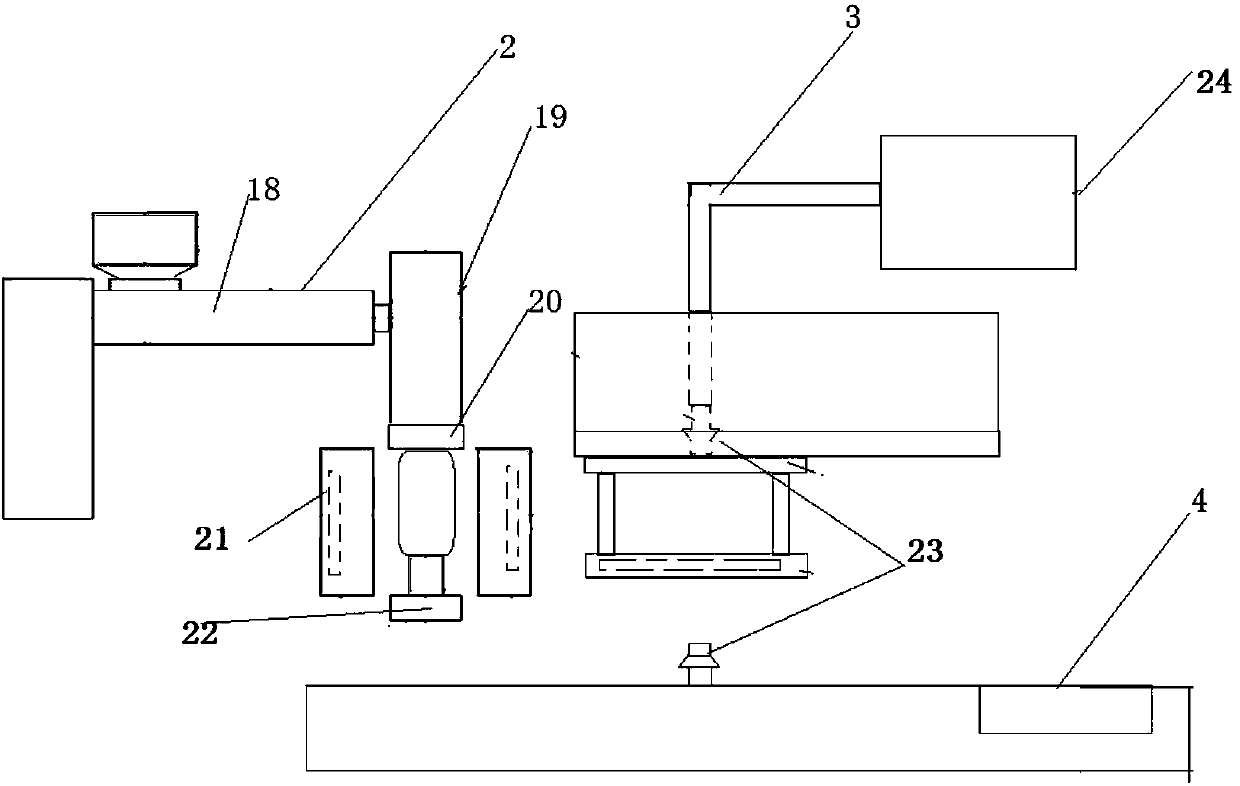

Automatic workpiece polishing method based on off-line programming

ActiveCN109571152AGuaranteed uniformityQuality assuranceGrinding feed controlGrinding work supportsPoint cloudStandard form

The invention relates to the techncial field of machining and particularly relates to an automatic workpiece polishing method based on off-line programming. The automatic workpiece polishing method comprises the following steps of: (S1) generating a reference polishing track in off-line programming software according to 3D drawing document data of to-be-machined workpieces; (S2) scanning a real standard part of each workpiece so as to extract a 3D point cloud model of the real standard part and store the 3D point cloud model as a standard form model; (S3) moving the real standard part according to the reference polishing track so as to correct the reference polishing track by virtue of the acquired track deviation data, thereby generating a standard polishing track which is in accordancewith the real standard part; and (S4) polishing the to-be-machined workpieces one by one according to the standard polishing track. By adopting a robot for clamping the workpieces, the automatic workpiece polishing method provided by the invention can implement precise surface treatment operation of each workpiece (especially a small-size workpiece) by steps such as scanning comparison and track difference compensation, can effectively guarantee the uniformity and quality of each workpiece product and also reduces the programming difficulty of automatic surface treatment operation.

Owner:FENGTAI INTELLIGENT CONTROL SHENZHEN CO LTD

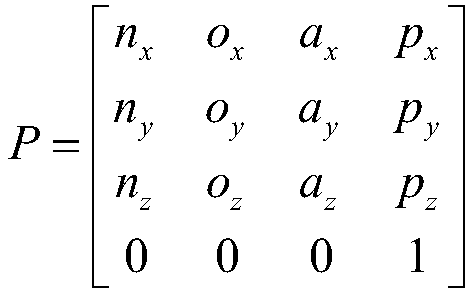

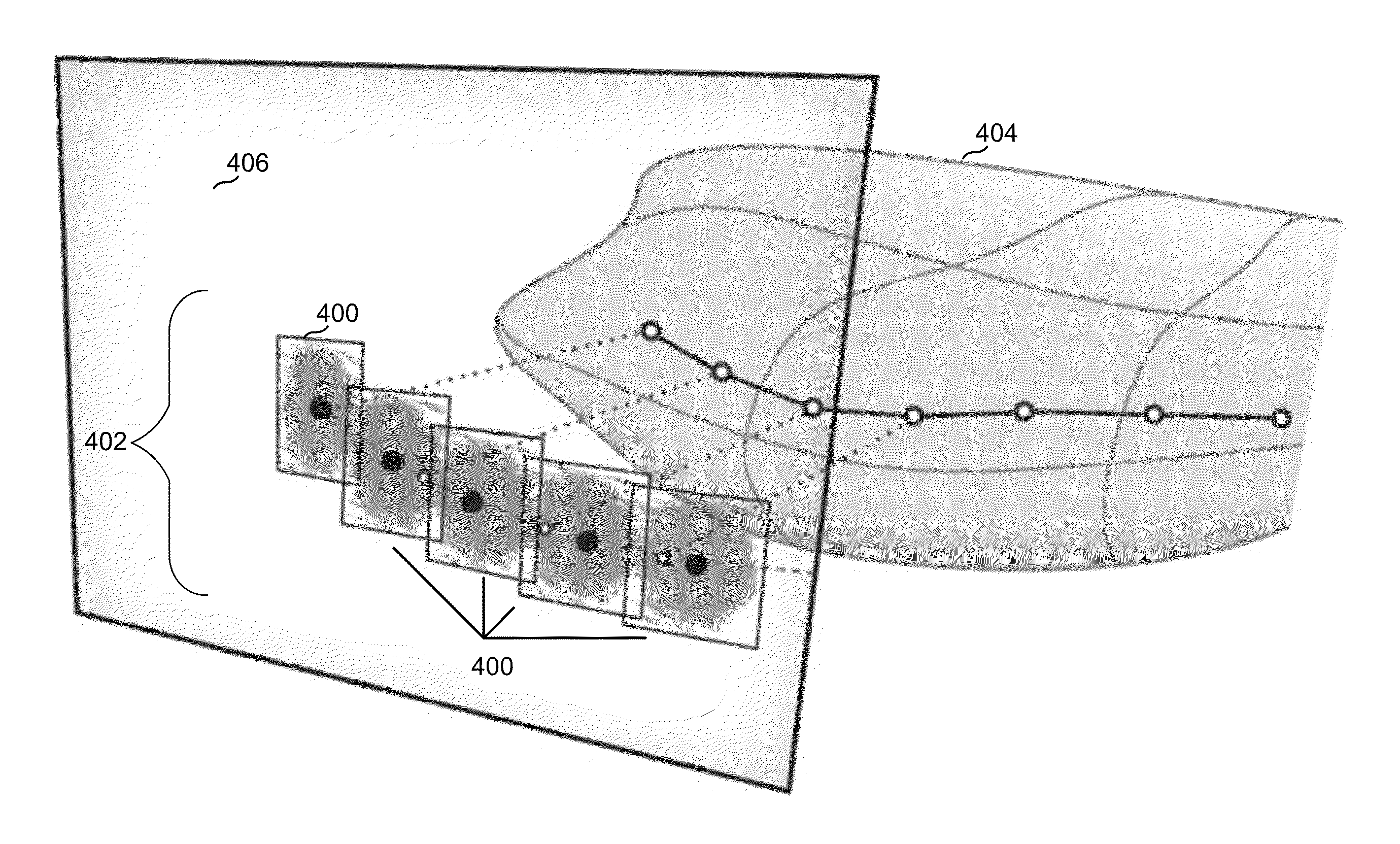

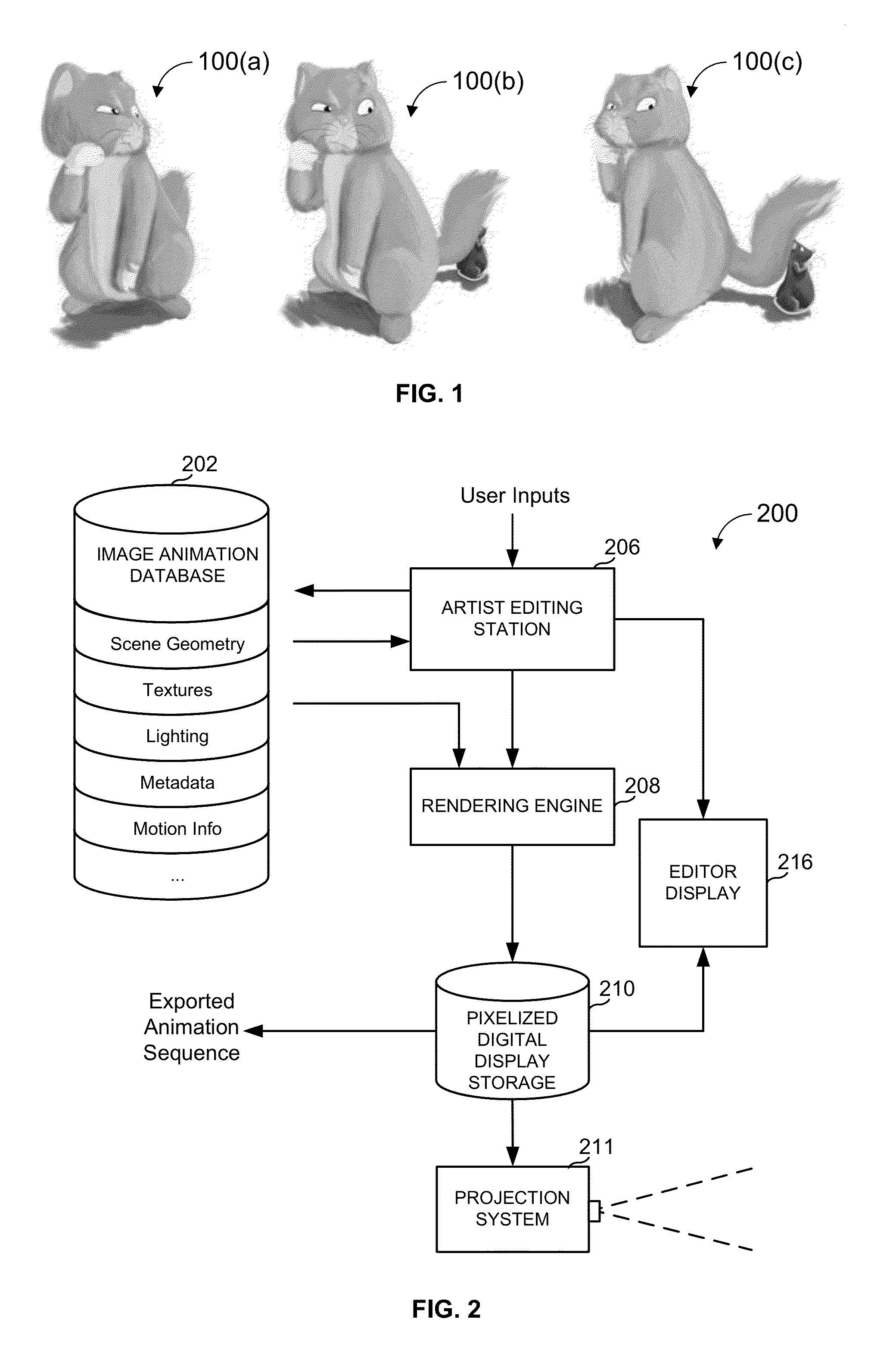

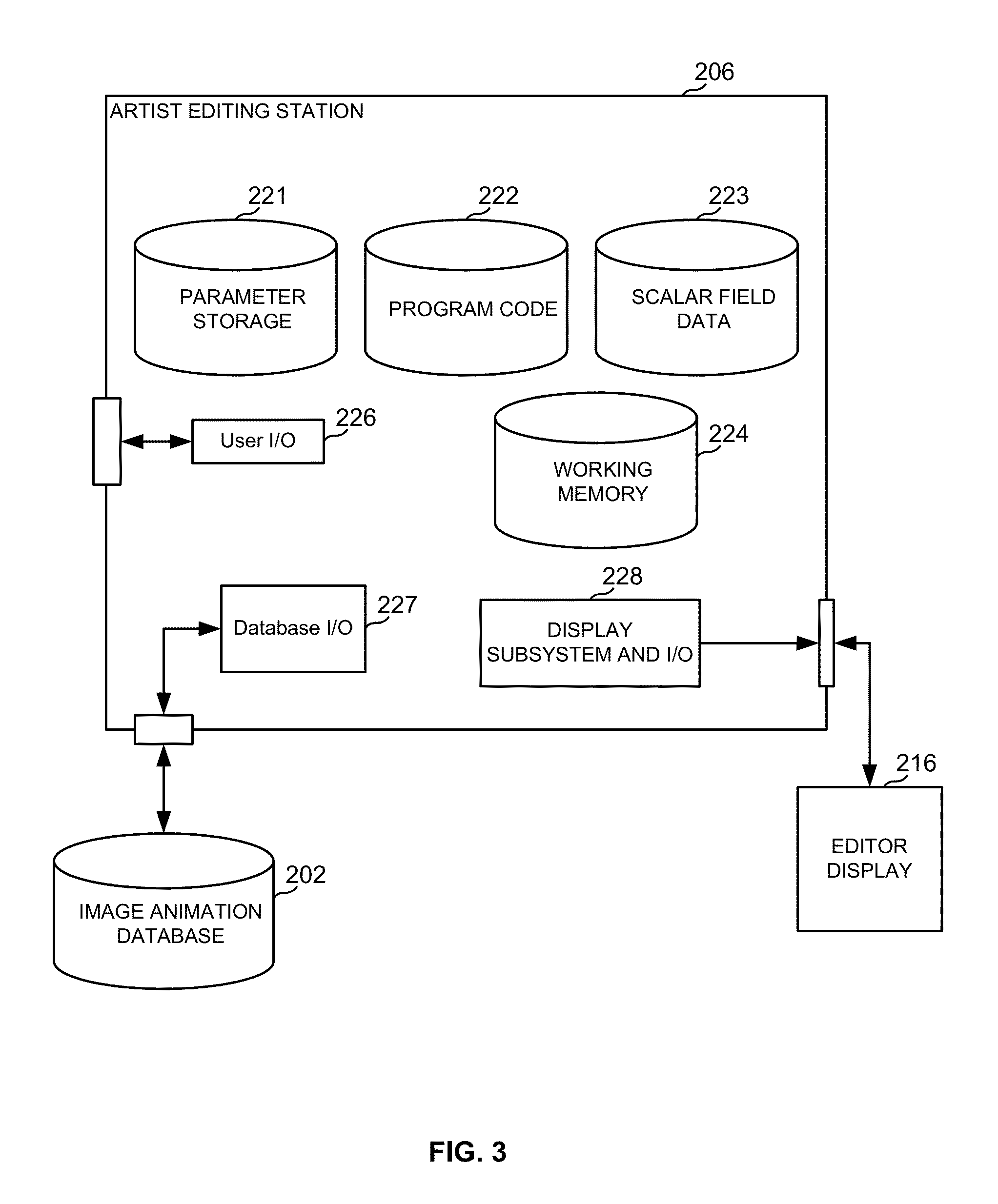

3D drawing and painting system with a 3D scalar field

ActiveUS8988461B1Acceptable level of controllabilityTexturing/coloringCathode-ray tube indicatorsAlgorithmEngineering

Rendering 3D paintings can be done by compositing strokes embedded in space. Users input strokes and other image elements using an input device that specifies a 2D view of the element, and the system provides the 3D position of the element based on rules and processes, some of which allow for user input of high level parameters, thereby allowing for intuitive and quick entry of 3D elements, and a 3D scalar field. The artist can treat the full 3D space as a canvas. Strokes painted in a 2D viewport window are embedded in 3D space in a way that gives creative freedom to the artist while maintaining an acceptable level of controllability. The canvas need not be tied to any particular object already in a scene, but the canvas can be dependent on, or a function of, another object. An implicit canvas can be defined by the 3D scalar field.

Owner:ETH ZURICH EIDGENOESSISCHE TECHN HOCHSCHULE ZURICH +1

Pen-based 3D drawing system with 3D mirror symmetric curve drawing

InactiveUS20080036772A1Drawing from basic elementsCharacter and pattern recognitionGraphicsGraphic designer

A pen-based system allows users, such as artists, graphic designers and illustrators, and the like, to create accurate curve models by sketching. A tool set implemented in software that runs on a computer system combines paper sketch metaphors and a minimalist gesture set. This tool set provides an environment where the artists can focus on the creative task at hand rather than the details of operating software. A pen-based drawing method and system allows users to create and edit three dimensional (“3D”) objects by sketching.

Owner:FCA US

Three-dimensional game interaction system based on monocular video

InactiveCN102622509AImplement interactive functionsInput/output for user-computer interactionGraph readingInteraction systemsComputer module

The invention relates to the technical field of motion capture based on a video, and discloses a three-dimensional game interaction system based on a monocular video. The three-dimensional game interaction system comprises a motion capture module and a three-dimensional engine module, wherein the motion capture module is used for processing video input data of a camera head and outputting motion data of a three-dimensional model; a main game system extracts the motion data and drives a player model according to the motion data; and the three-dimensional engine module as a main module of the system is used for processing a 3D drawing and providing an interface related with an Ogre engine. Compared with the traditional method, the system has the advantages as follows: the key interaction function is realized by software; general computers are equipped with camera heads; and equipment is simple and easily accessible. In this way, players can enjoy the interactive electronic games without buying special equipment when wanting to play games.

Owner:TIANJIN UNIV

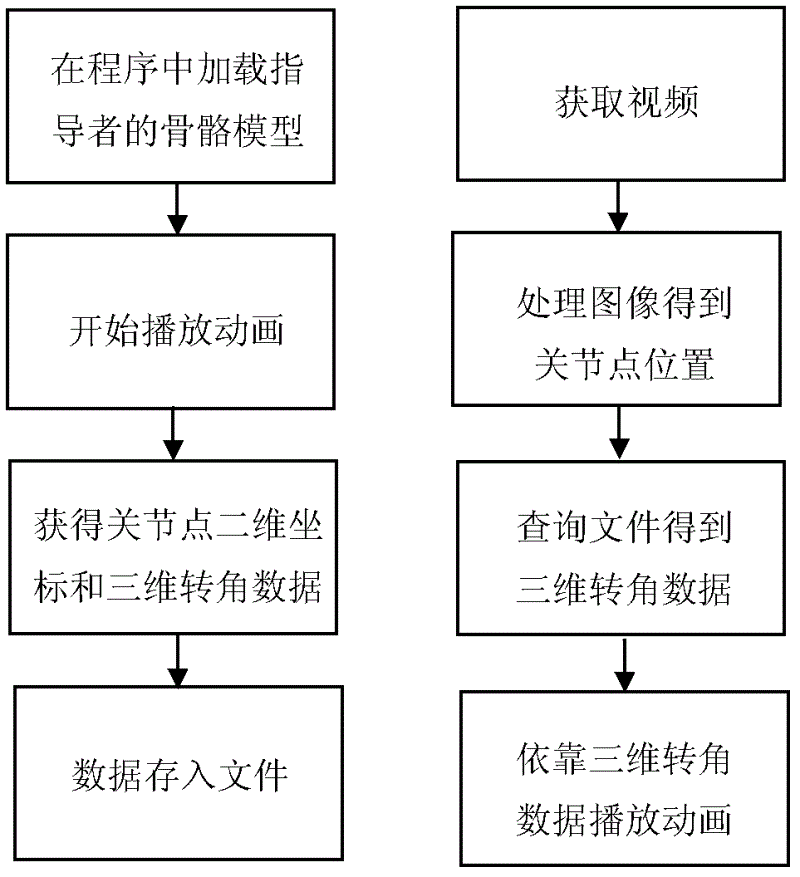

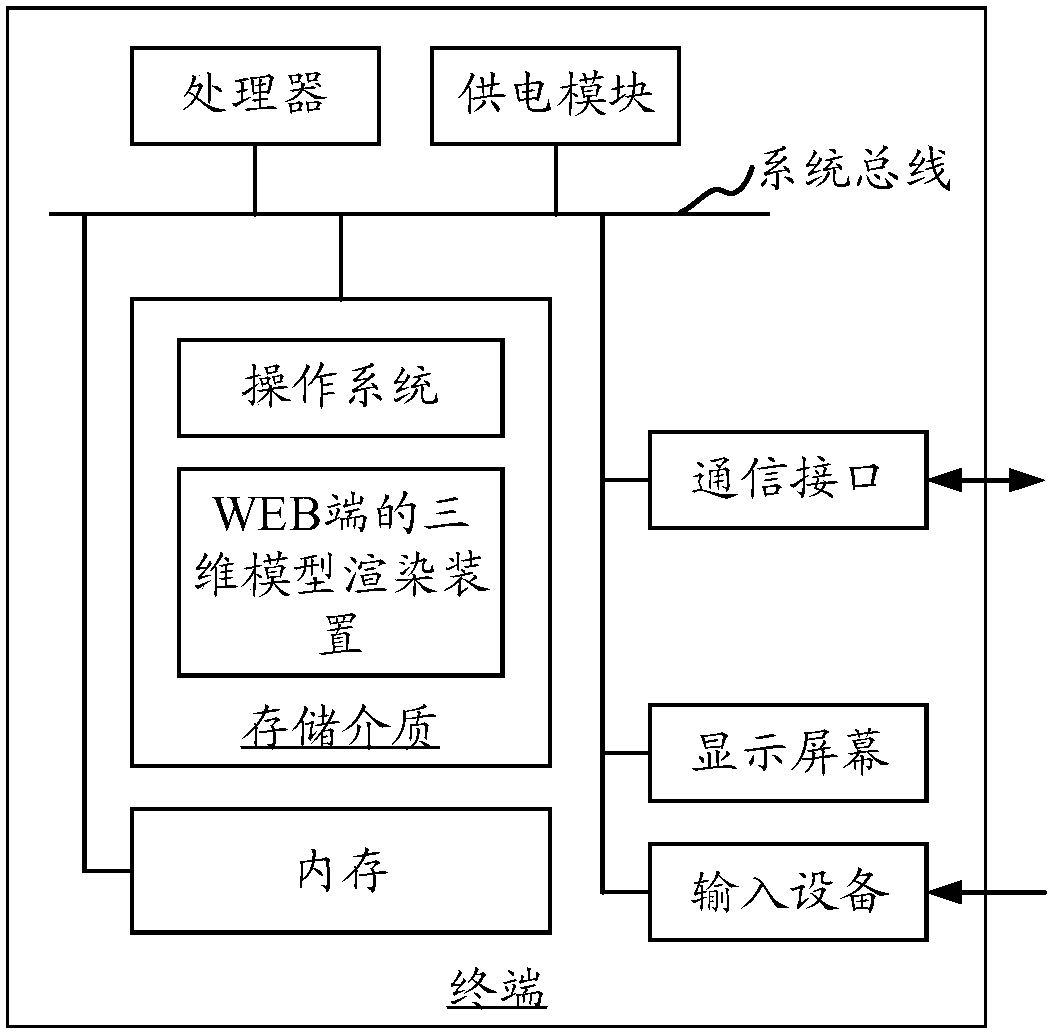

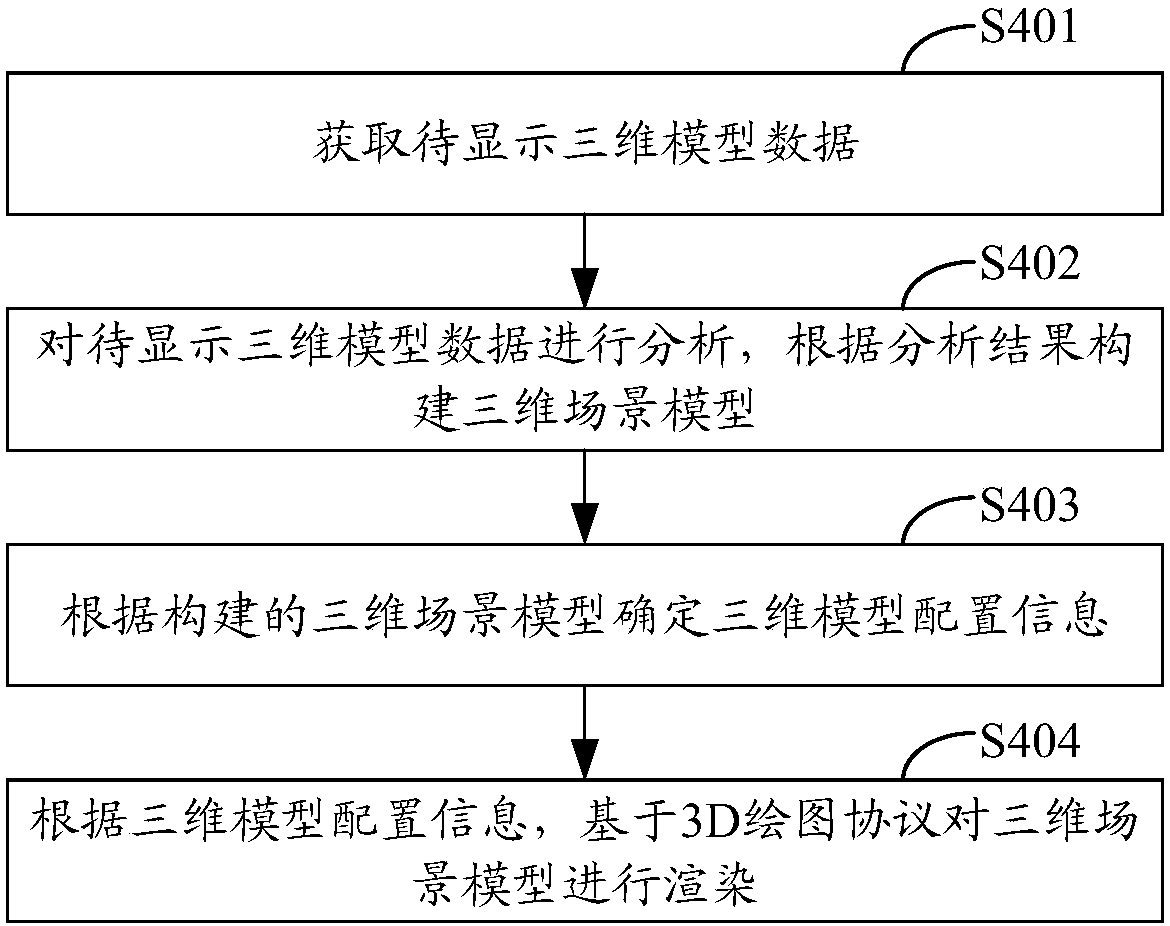

Three-dimensional model rendering method and device of WEB terminal, computer device and computer storage medium

ActiveCN107890671AImprove efficiencyReduce memory consumptionVideo games3D-image renderingThird partyComputer graphics (images)

The invention relates to a three-dimensional model rendering method and a three-dimensional model rendering device of a WEB terminal, a computer storage medium and a computer device. The method comprises the following steps: acquiring three-dimensional model data to be displayed; analyzing the three-dimensional model data to be displayed, and constructing a three-dimensional scene model accordingto the analysis result; determining three-dimensional model configuration information according to the constructed three-dimensional scene model; and rendering the three-dimensional scene model basedon the 3D drawing protocol according to the three-dimensional model configuration information. According to the technical scheme provided by the invention, the three-dimensional scene model is constructed according to the acquired three-dimensional model data to be displayed, the three-dimensional model configuration information is further determined, then the three-dimensional scene model is rendered according to the three-dimensional model configuration information and directly based on the 3D drawing protocol, the introduction of a third-party 3D model rendering plug-in is avoided, thus thememory consumption is low, the operation is convenient, and the rendering efficiency of the three-dimensional model of the WEB terminal is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

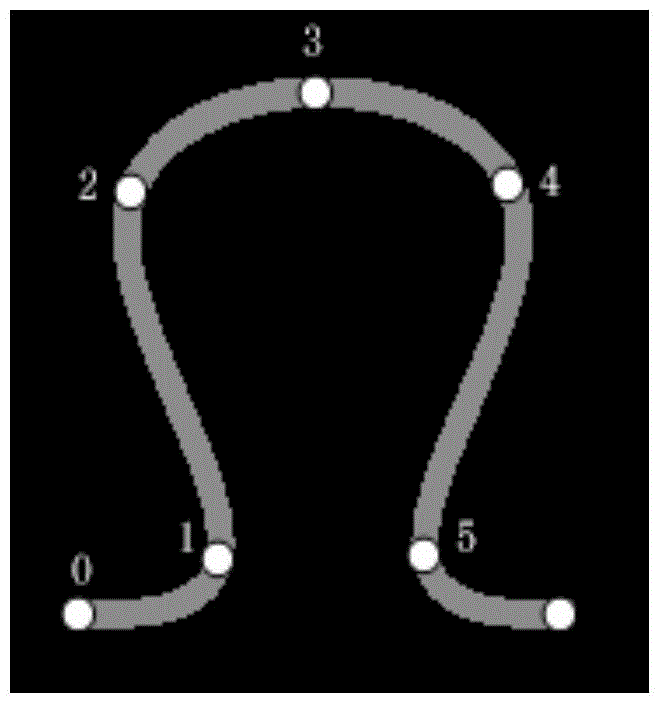

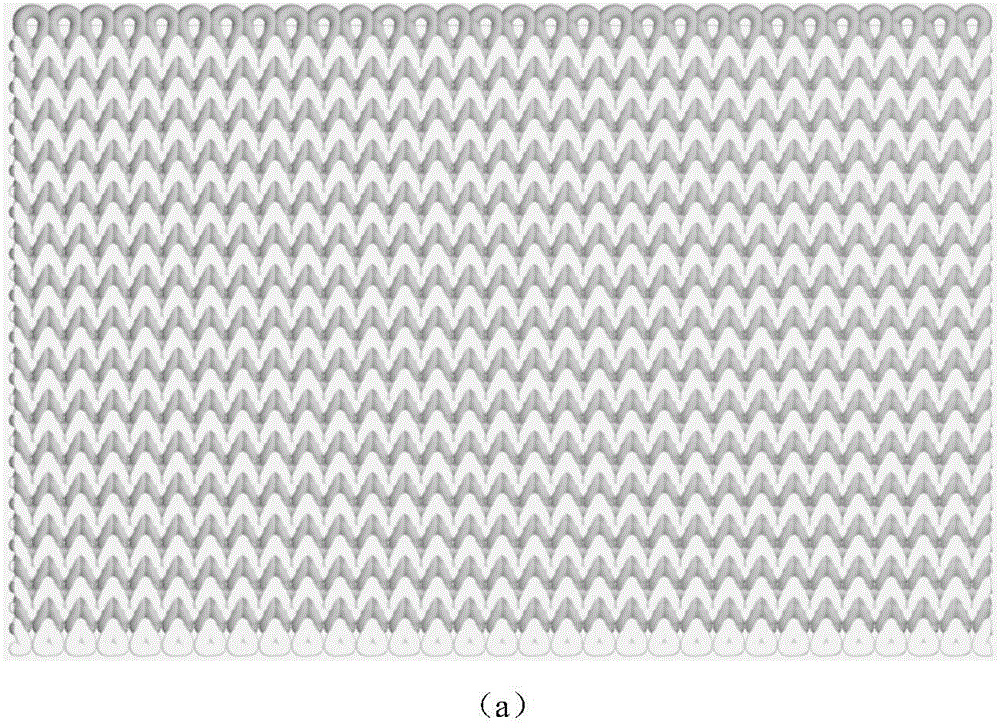

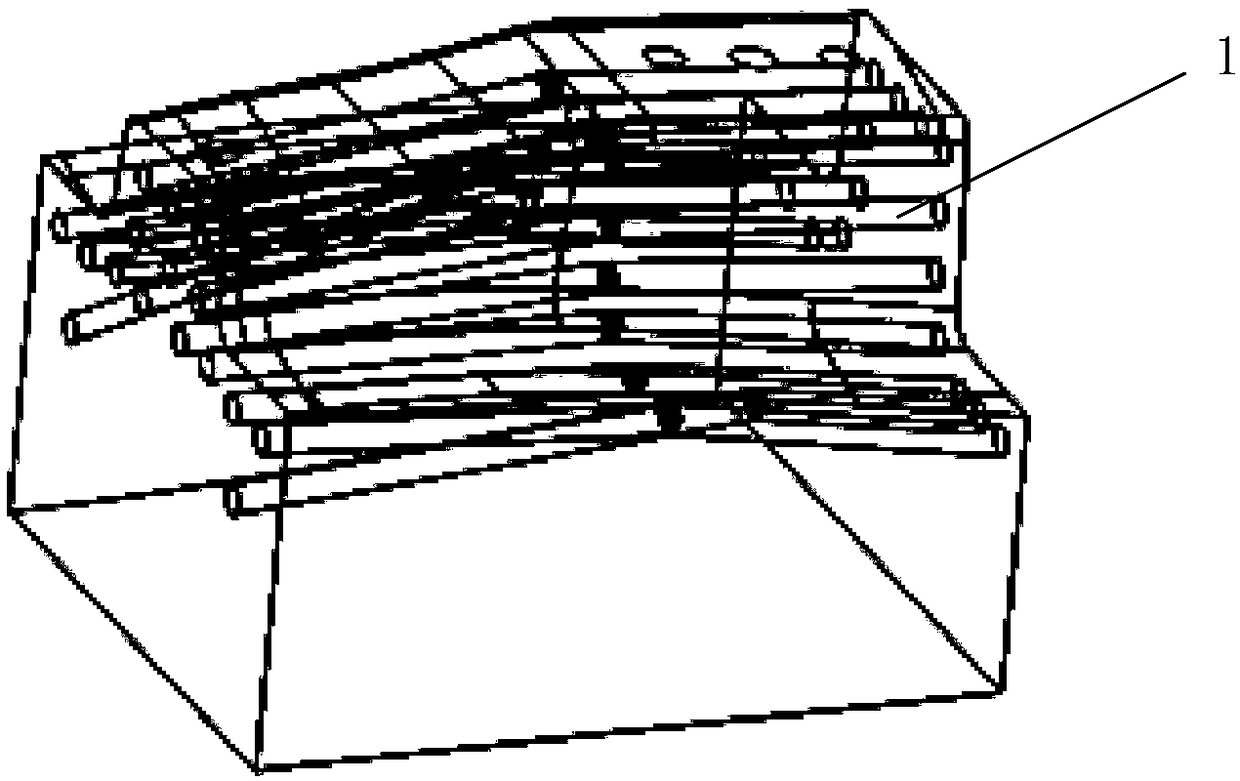

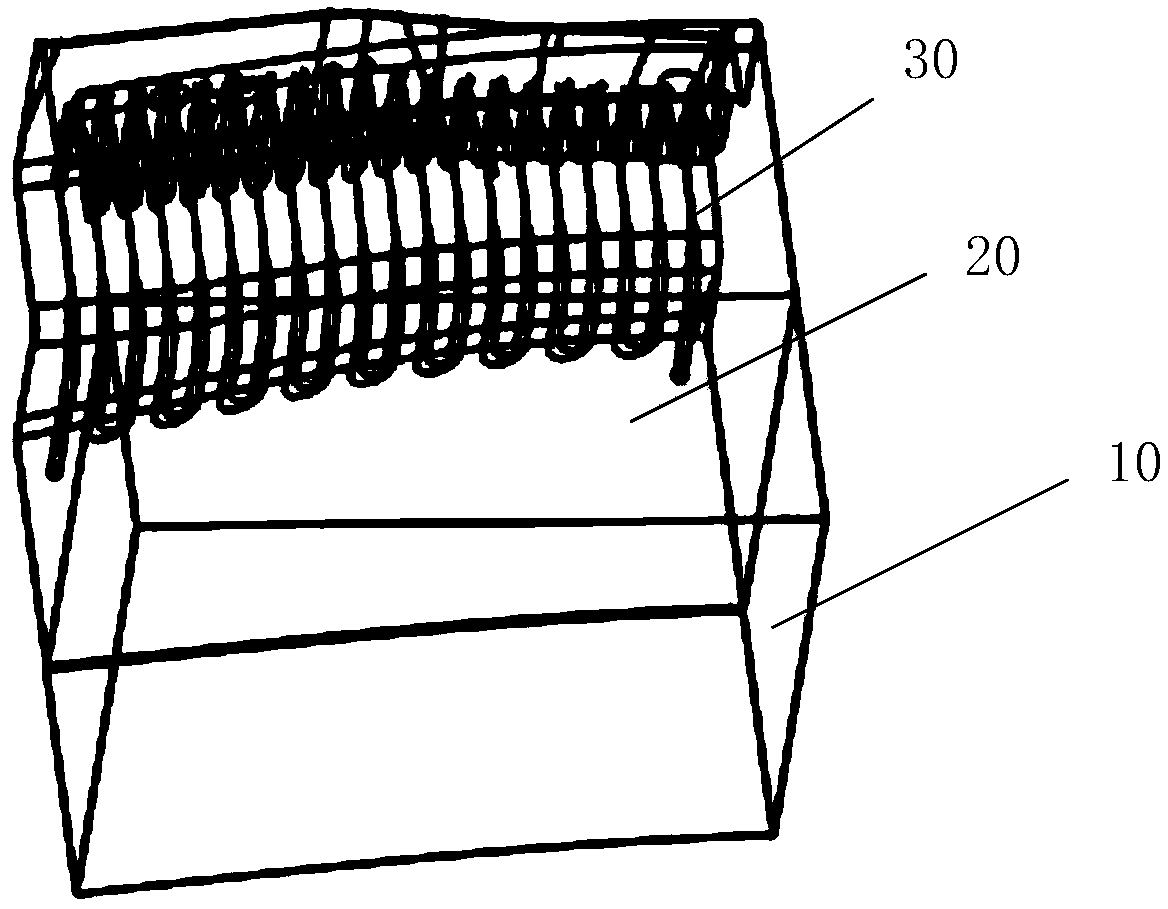

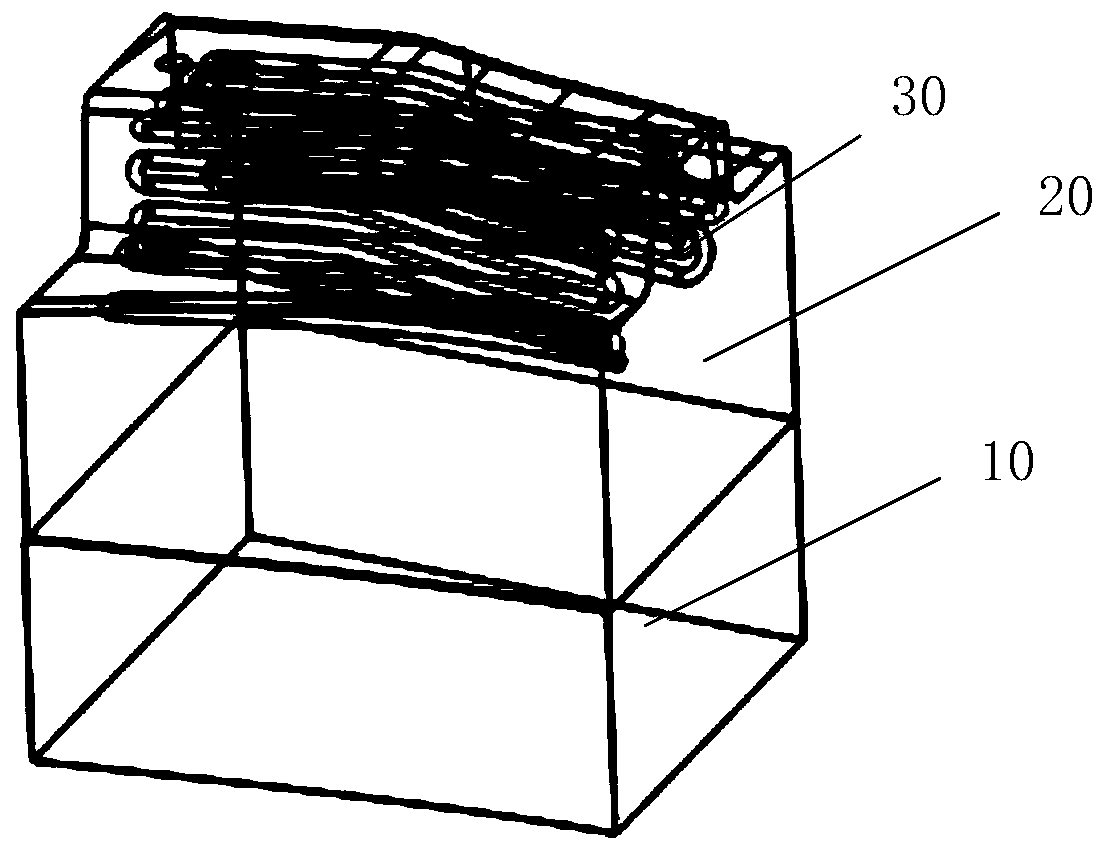

Simulation method of ball B-spline-based weft knitted fabric model

InactiveCN104933216AFlexible operationFlexible deformationSpecial data processing applicationsCad system3d drawing

The present invention discloses a simulation method of ball B-spline-based weft knitted fabric model. According to the present invention, the ball B-spline-based constructed knitted fabric model is simulated. By defining a series of control points, a control radius of the control points and a B-spline curve associated with the control points, the ball B-spline reflects a 2D drawing and a 3D drawing. During the operations, by virtue of different construction manners of the coils, an effect diagram of any row and column of the weft knitted fabric can be obtained through computer simulation. By changing the colors at the different positions of the coil, the weft knitted fabrics having different patterns can be obtained. The present invention has the advantages that a 3D model can be conveniently and flexibly processed and deformed such that the storage and transmission efficiency is higher, the computer can practically simulate 3D models of weft knitted fabrics having different styles and patterns, such that the knitted fabric has a sense of reality and thus a good simulation effect is achieved, thereby providing a new concept and method for deformation simulation of the fabric in a CAD system.

Owner:BEIJING NORMAL UNIVERSITY

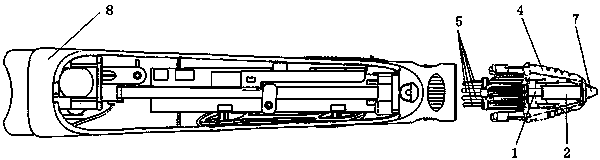

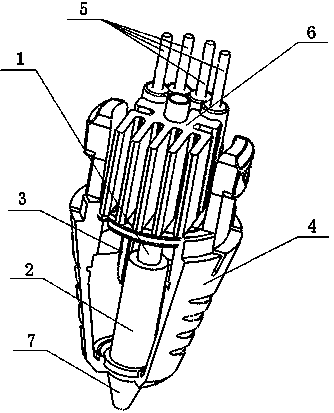

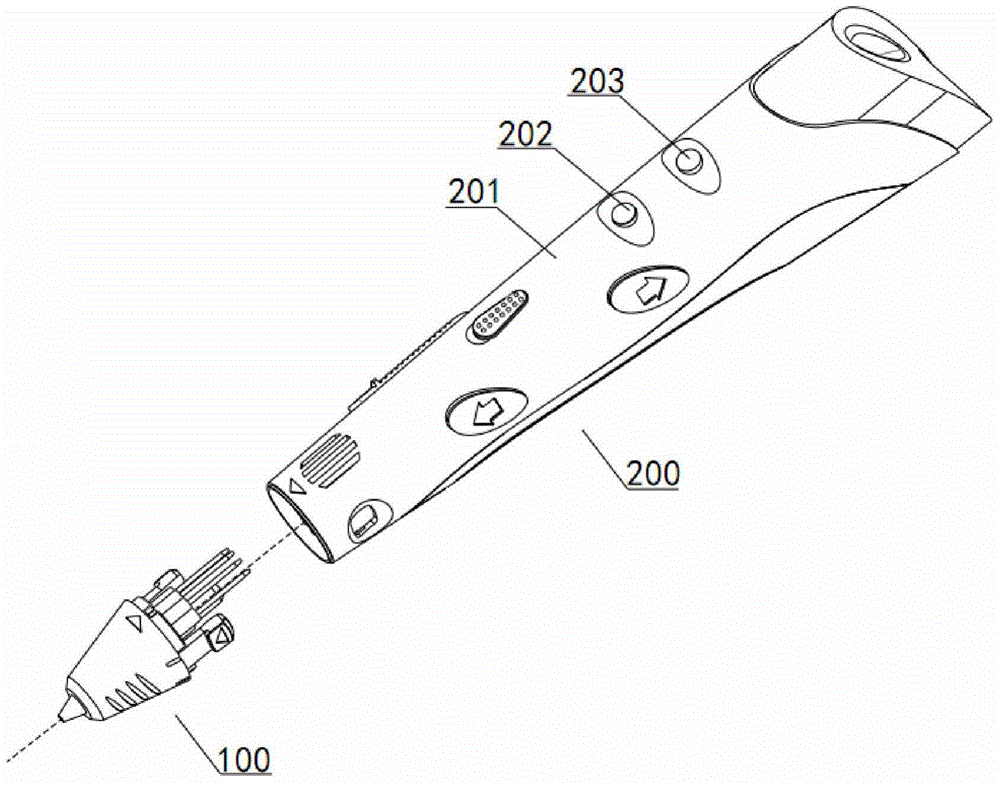

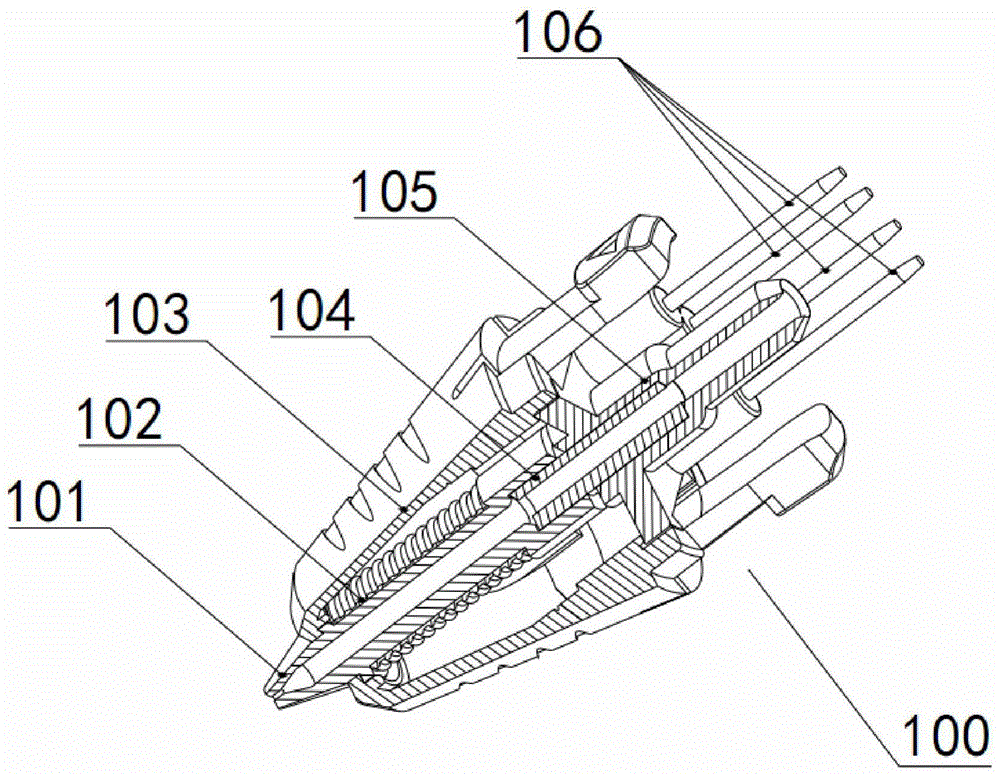

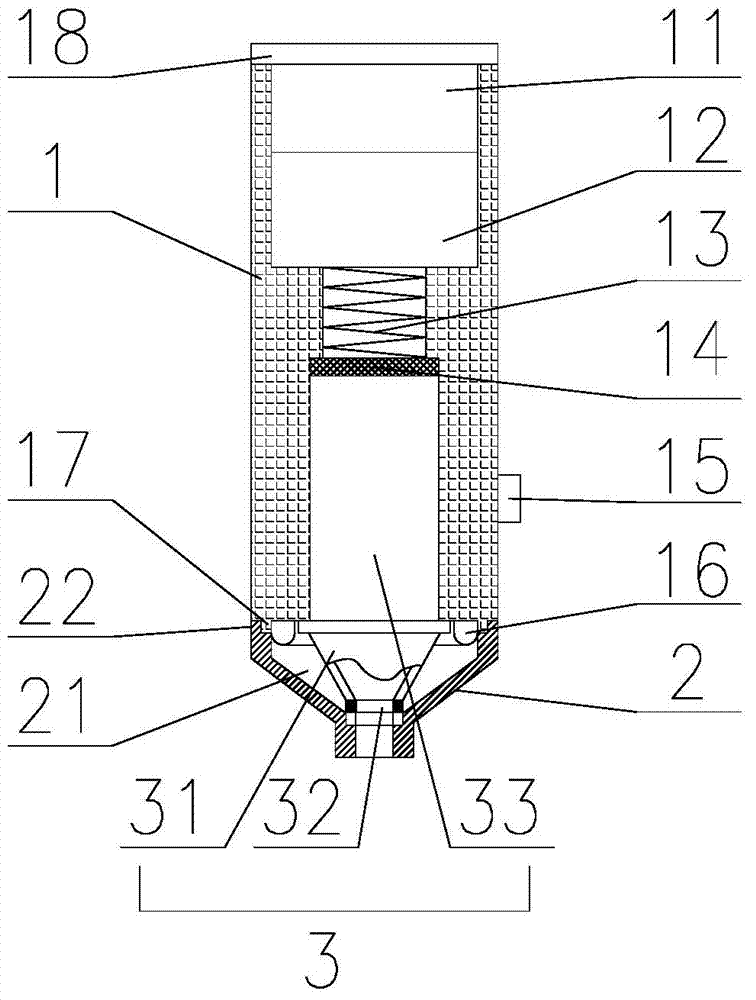

3D (three-dimensional) drawing pen

The invention discloses a 3D (three-dimensional) drawing pen which is composed of a nib and a shell thereof, wherein a bracket is fixed on the inner wall of the shell of the nib, and the bracket is hollow and has a through hole through which drawing materials are outputted, an annular electric heating device is fixed on the outer wall of the bracket, a connector for a power supply of the annular electric heating device is fixed at the upper end of the bracket, and the annular electric heating device is in circuit connection with the nib through the connector. The 3D drawing pen disclosed by the invention has the beneficial effects that because a pen body and the nib are formed into a split structure, if part of the pen is damaged, damaged parts can be replaced, and integral replacement is not required, therefore, the cost of users can be reduced. When a heating structure is damaged, a user directly unplugs the nib, and disconnects the connector of the nib, so that the nib can be replaced, and the user maintenance is facilitated, thereby achieving the purpose of the invention.

Owner:句容利威尔电器有限公司

Rapid and efficient hole filling algorithm based on foreground and background gradient transition

InactiveCN104378619AEasy to understandThe result is accurateImage analysisSteroscopic systemsAlgorithmReal time display

Owner:HEFEI UNIV OF TECH

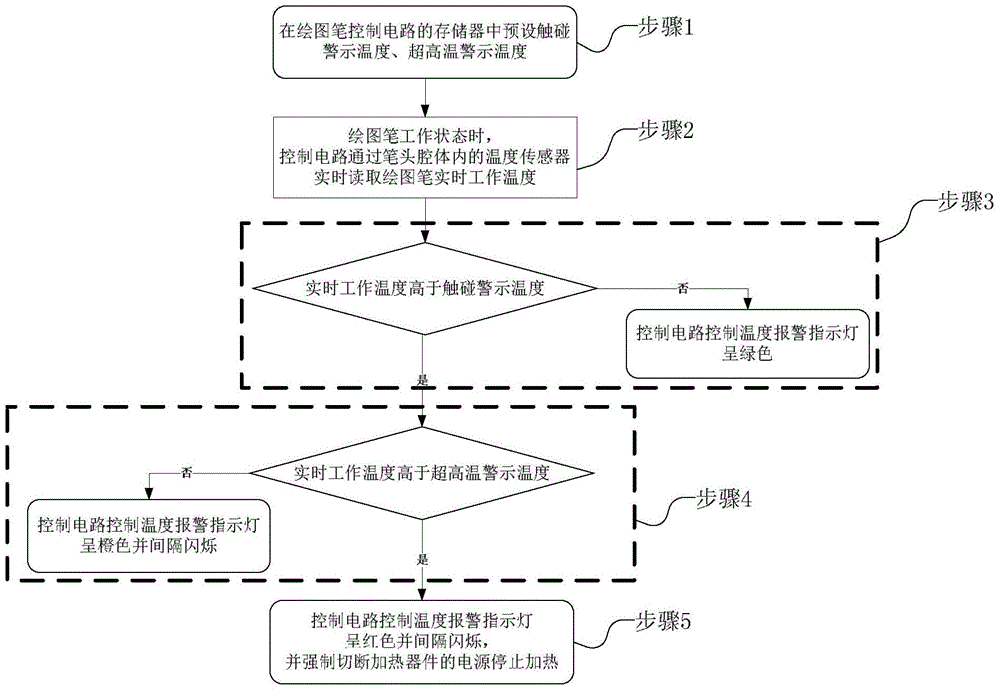

3D drawing pen

The invention discloses a 3D drawing pen and a high temperature warning method. As both a temperature warning indicator and a temperature sensor which is arranged in a pen head cavity are connected with a control circuit, trigger warning temperature and ultra-high temperature warning temperature can be configured accordingly; once the real-time work temperature of the drawing pen is higher than the trigger warning temperature and is lower than the ultra-high temperature warning temperature, the control circuit controls the temperature warning indicator to turn from green to orange and flash at interval, so as to warn an operation user; once the real-time work temperature of the drawing pen is greater than the ultra-high warning temperature, the control circuit controls the temperature warning indicator to turn red and flash at shorter interval, and controls a heating part to stop heating, so that the use safety of the drawing pen is improved. Furthermore, the consumables of the 3D drawing pen are led in through a high temperature resistant plastic pipe the melting point of which is higher than that of the consumables, thus the problem that an expansion pipe is blocked due to thermal energy transmission in a lead-in through hole before the consumable enters a nozzle to be heated and melted is solved and the selection scope of 3D printing consumable is enlarged.

Owner:句容利威尔电器有限公司

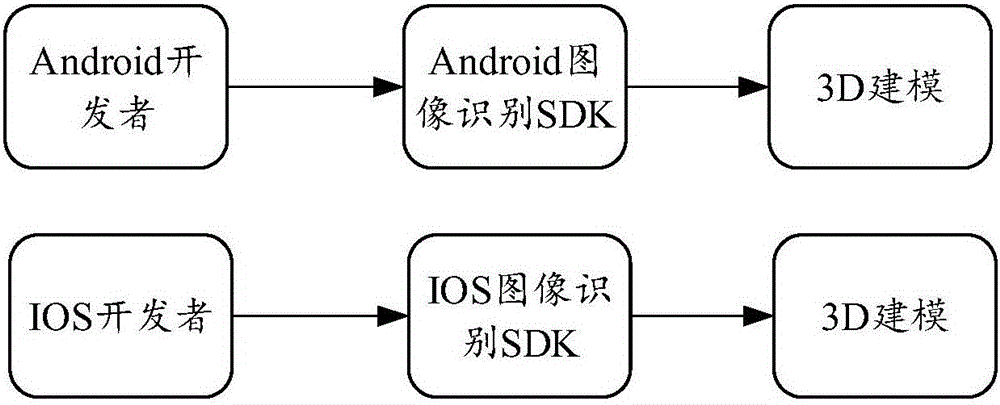

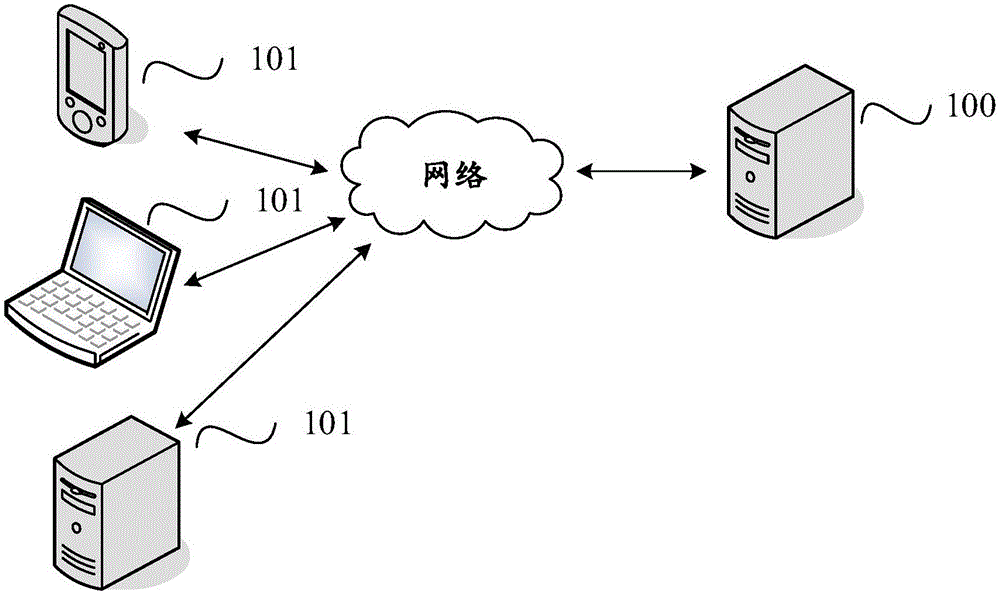

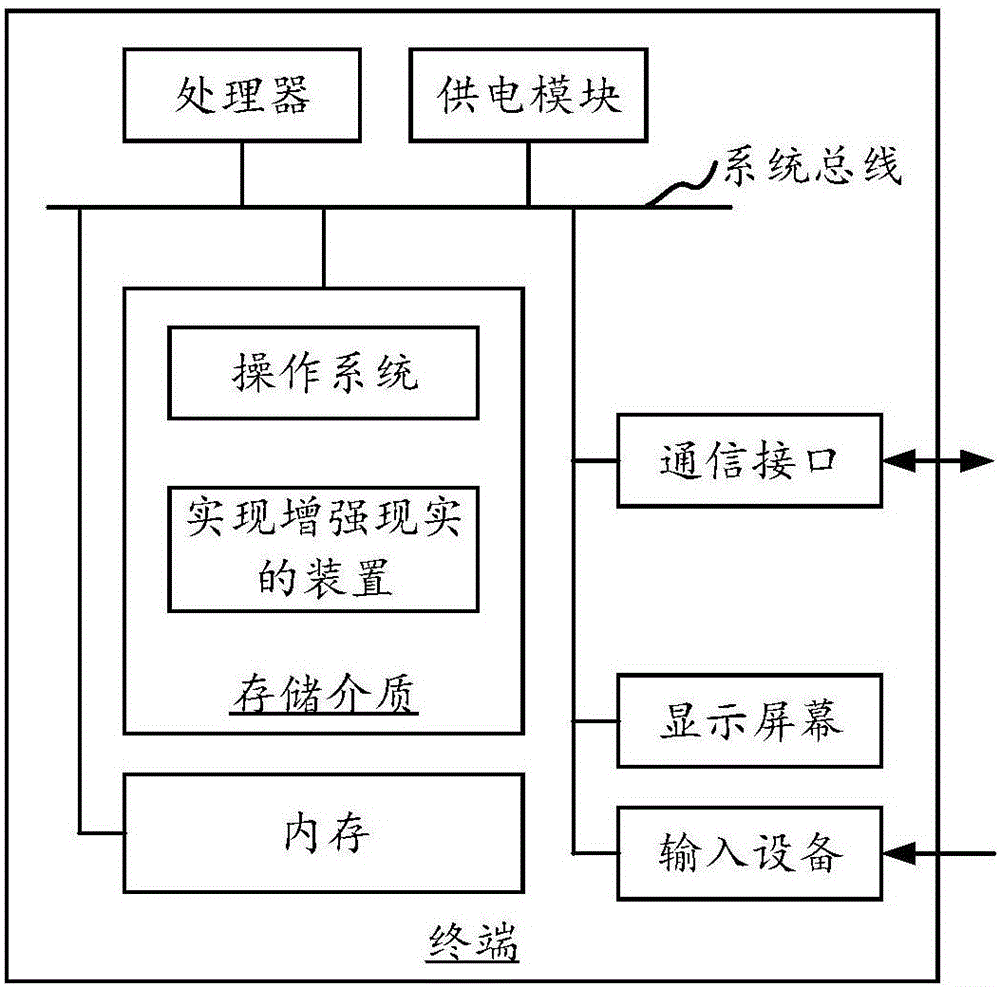

Method and device for implementing augmented reality

ActiveCN106846495AReduce development costsLow costWebsite content managementImage data processingImaging processingOperational system

The invention relates to a method and a device for implementing augmented reality. In one embodiment, the method comprises the steps of: sending a page access request to a WEB server, wherein the page access request comprises a page identifier; receiving a page access response returned by the WEB server according to the page access request, wherein the page access response comprises a WEB page corresponding to the page identifier, and a device for augmented reality is embedded into the WEB page; and by the device for augmented reality, acquiring video stream of image pickup equipment of a terminal where the device for augmented reality is arranged, carrying out image processing on video frames of the video stream, identifying out a preset identifier from the image subjected to image processing, carrying out 3D drawing on the identified preset identifier to obtain a drawn 3D image, and displaying the drawn 3D image in an image picked up by the image pickup equipment so as to form an augmented reality display image. According to the scheme of the embodiment, development cost is low, and the method and the device can be applied to the terminal with a random operation system, can be used in a cross-platform mode, are convenient to maintain and are low in maintenance cost.

Owner:TENCENT TECH (SHENZHEN) CO LTD

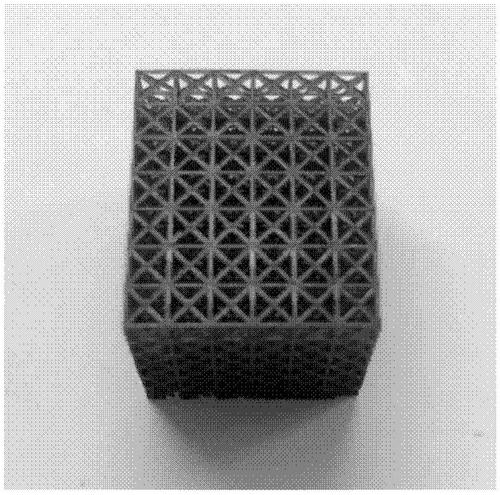

Loading structure for adsorbing heavy metal pollutants and preparation method and application thereof

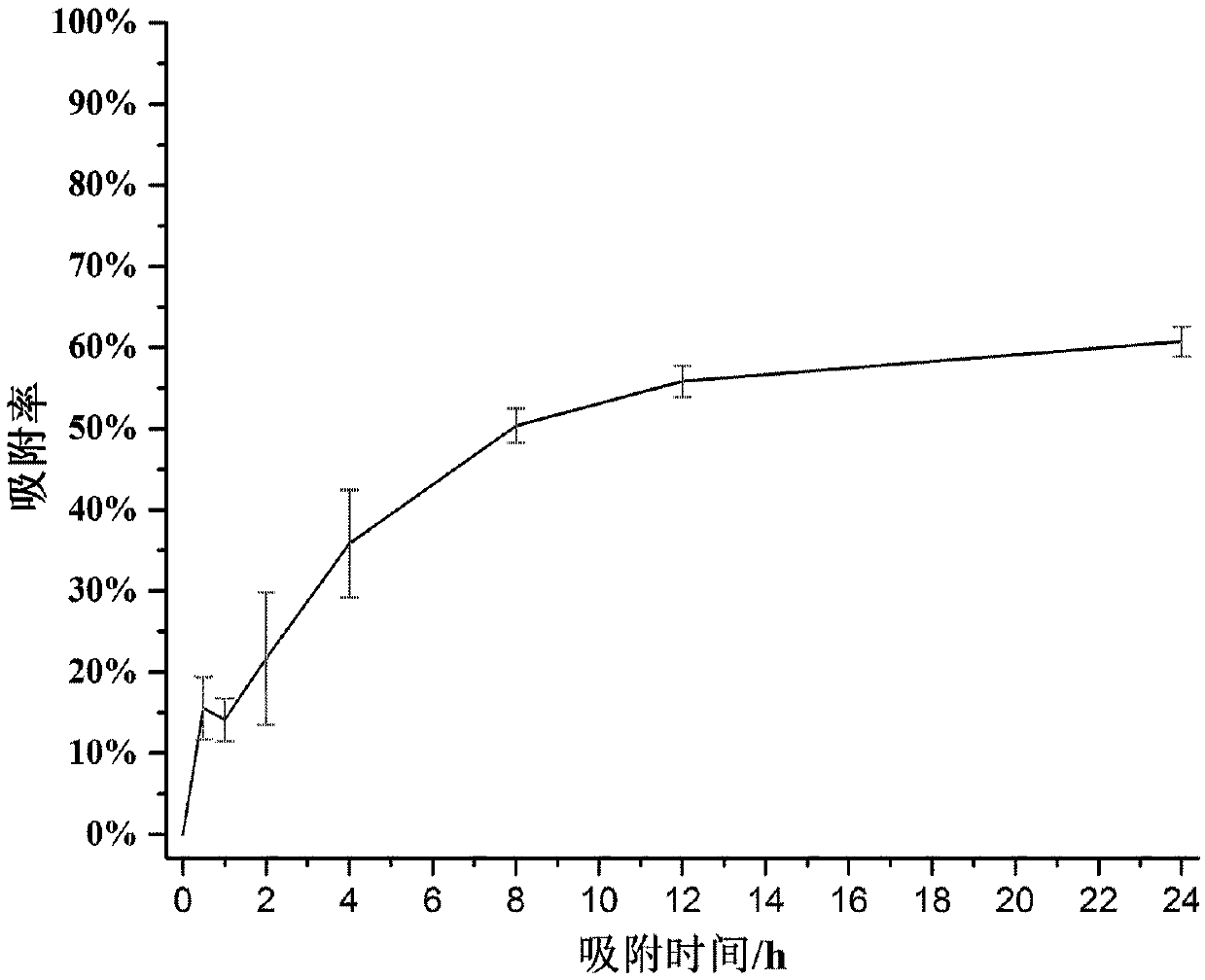

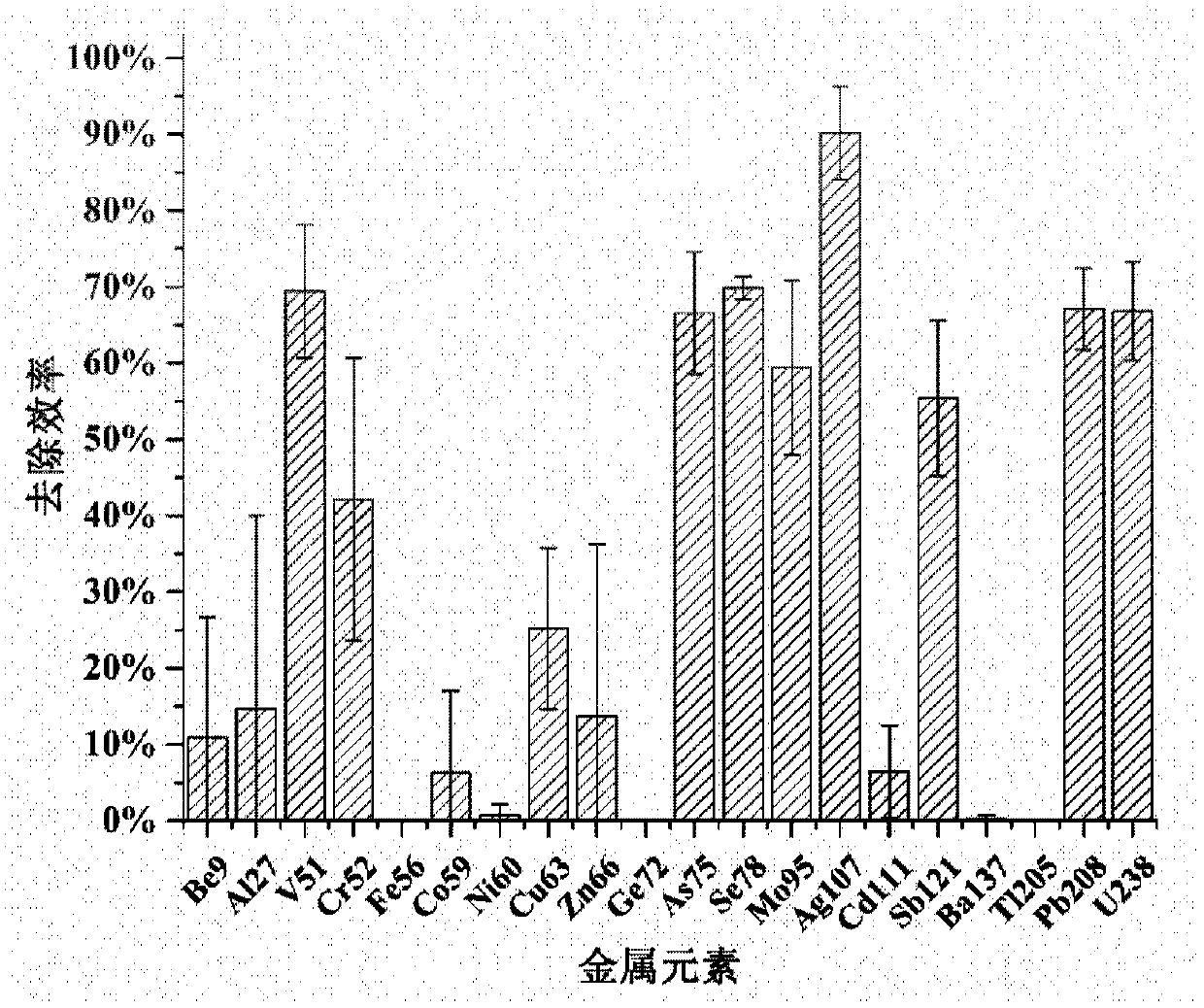

InactiveCN109603746AImprove adsorption capacityHigh adsorption selectivityAdditive manufacturing apparatusOther chemical processesSorbentWastewater

A loading structure for adsorbing heavy metal pollutants and a preparation method and application thereof are disclosed. The loading structure is a hollow structure obtained through 3D printing by using a 3D printing nanocomposite material which is formed by mixing a heavy metal adsorbing nano material and a 3D printing material. Devices or components of a particular shape and size are specifically designed using three-dimensional drawing software, the heavy metal adsorbing nano material is uniformly doped into that 3D printing material, a 3D printing technique is used to manufacture the device or component designed by the 3D drawing software by using the synthetic 3D printing nano composite material, and then the wastewater containing the target heavy metal pollutant is absorbed by the printed device or component. The invention avoids the agglomeration of the heavy metal adsorption material, improves the adsorption selectivity and the adsorption efficiency, is simple to use, does notcause the residue of the adsorbent after use, avoids potential secondary pollution, is easy to recover and reuse, and reduces the cost.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

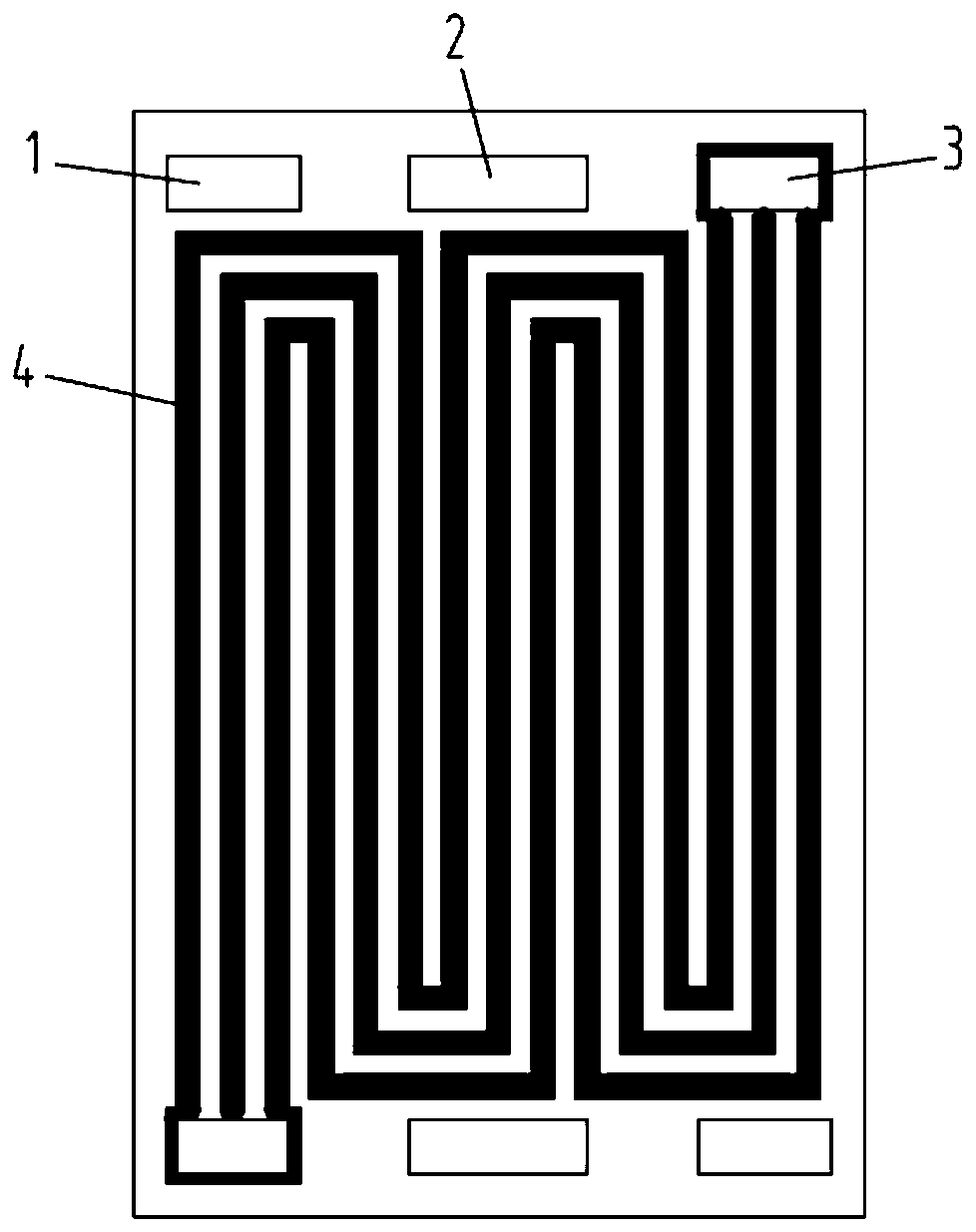

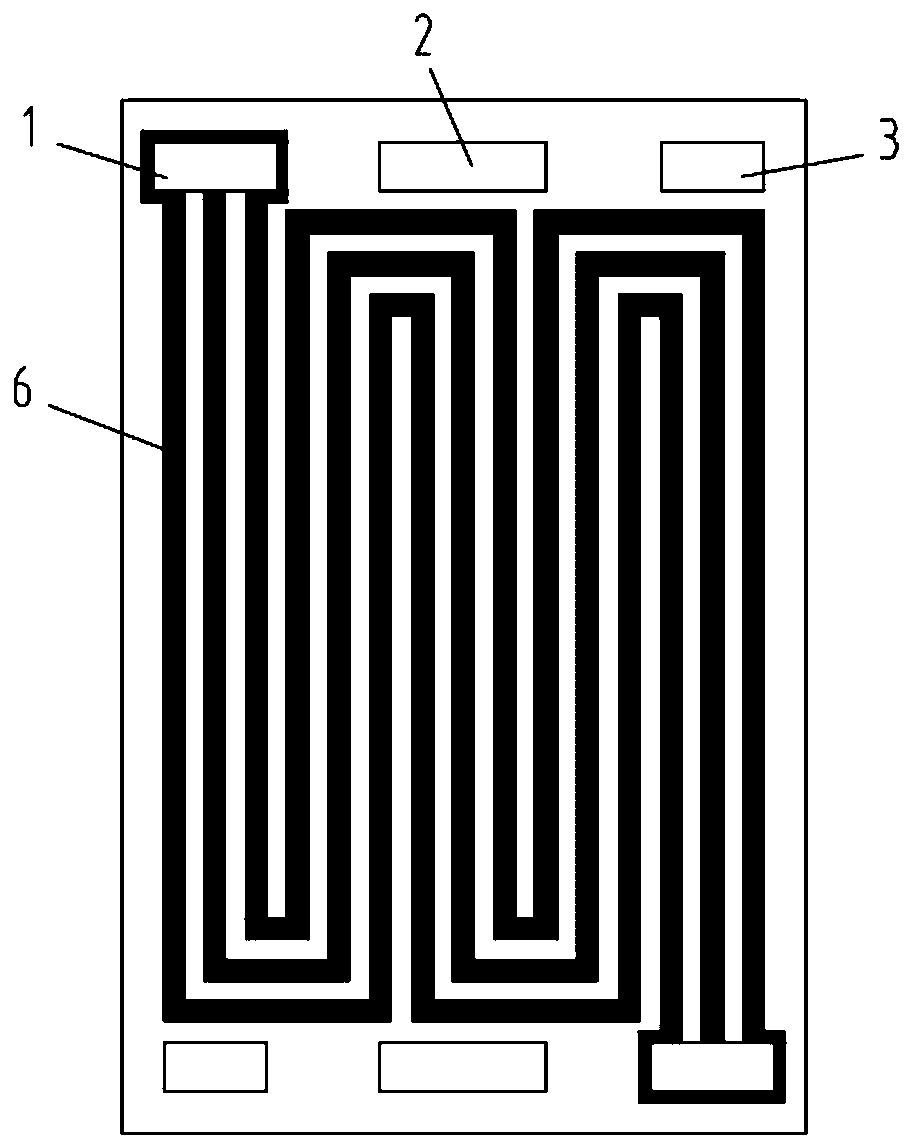

Preparation method of fuel cell bipolar plate with flow channel

ActiveCN110336053AReduce thicknessImprove corrosion resistanceFinal product manufactureCollectors/separatorsConductive pasteFuel cells

The invention discloses a preparation method of a fuel cell bipolar plate with a flow channel, which includes the following steps: drawing an anode flow field pattern, a cathode flow field pattern anda coolant flow field pattern through 3D drawing; applying conductive paste to a surface of one metal plate through 3D printing or injection molding to form an anode (or cathode) flow field, and applying conductive paste to the two surfaces of the other metal plate through 3D printing or injection molding to form a cathode (or anode) flow field and a coolant flow field; and aligning and fitting the smooth surface of the metal plate with the anode (or cathode) flow field formed thereon with the surface of the metal plate with the coolant flow field formed thereon, and carrying out welding and sealing to form a bipolar plate with a flow channel. The method combines the processing advantages of a metal bipolar plate and a molded composite graphite plate, reduces the cost of mold opening and the difficulty of processing, and has the advantages of short construction period and low cost especially for frequent modification of the design of the flow channel.

Owner:CENT SOUTH UNIV

Thermoforming profile-followed waterway mold and machining method thereof

InactiveCN108723208ALow costReduce dosageShaping toolsAdditive manufacturing apparatusThermoformingMachining

The invention discloses a thermoforming profile-followed waterway mold and a machining method thereof. The machining method comprises the steps that 1, a mold model of the thermoforming profile-followed waterway mold is designed through 3D drawing software, the molded surface of the mold is adjusted, and the thermoforming profile-followed waterway mold comprises a base body insert and a cooling insert mounted on the base body insert and provided with a profile-followed waterway; 2, the base body insert is pre-heated and subjected to surface oil removing and dust removing treatment; 3, the cooling insert provided with the profile-followed waterway is printed on the base body insert through 3D printing equipment; and 4, the printed cooling insert is subjected to finish machining treatment. According to the thermoforming profile-followed waterway mold and the machining method thereof, only the cooling insert is formed through a 3D printing technology, in this way, the using amount of printing powder can be decreased in quantity, meanwhile, the thermoforming profile-followed waterway mold after 3D printing forming does not need to be subjected to heat treatment, the mold cost is saved,the 3D printing time is reduced, and the production efficiency is improved; and the thermoforming profile-followed waterway mold and the machining method thereof have the advantages of high cooling efficiency and good uniformity of the mold surface temperature.

Owner:SUZHOU PRESSLER ADVANCED FORMING TECHNOLOGIES CO LTD

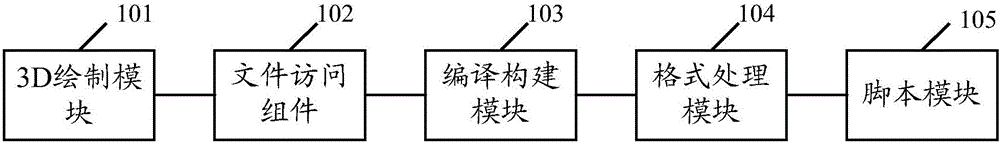

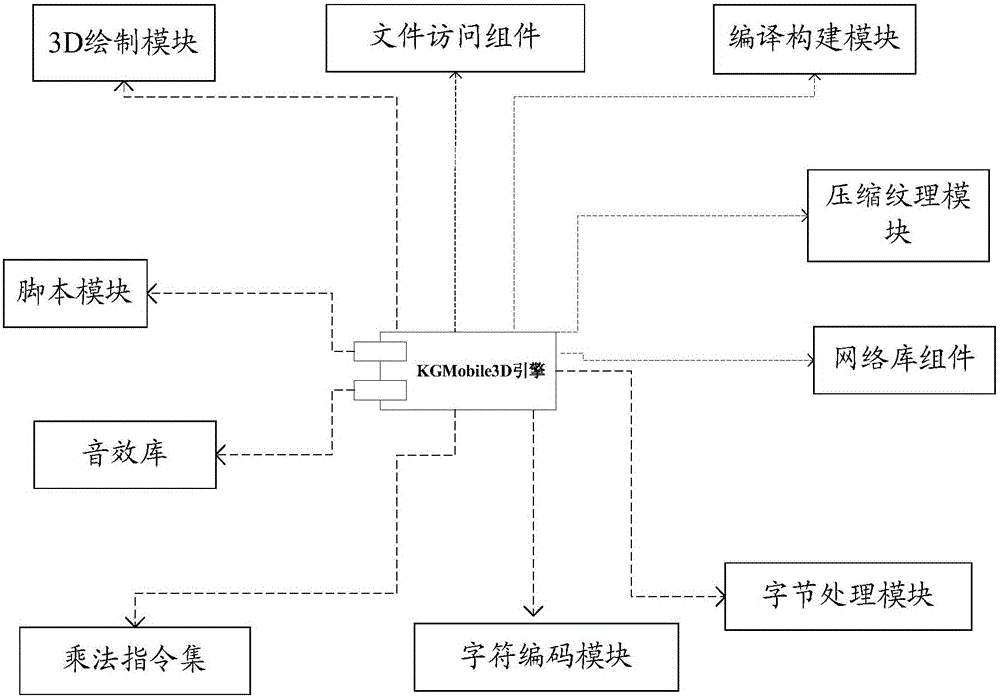

Game engine

An embodiment of the invention discloses a game engine, comprising a 3D drawing module for using an Opengl ES driver layer to adaptively rewrite codes, reducing vertex shader and pixel shader instructions of a glsl shader and using a 0-multiplication or 1-multiplication mode to remove conditional branch structures, a file access component for packaging file reading methods of KGFOpen and KGFRead and referring to interface parameters and use methods of fopen and fread, a compiling construction module for using vc for compiling in a Windows environment, using Eclipse and gcc for compiling in an Android environment and using xcode llvm-gcc for compiling in an ios environment, a format processing module for using a premade tool to automatically transform, publish and export texture formats required for a Windows platform, an Android platform or an ios platform in an editor, and a script module for using a script to export an interface mode and using a lua virtual machine to perform access. With the adoption of the embodiment of the invention, cross-platform transplantation of the game engine can be realized.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD

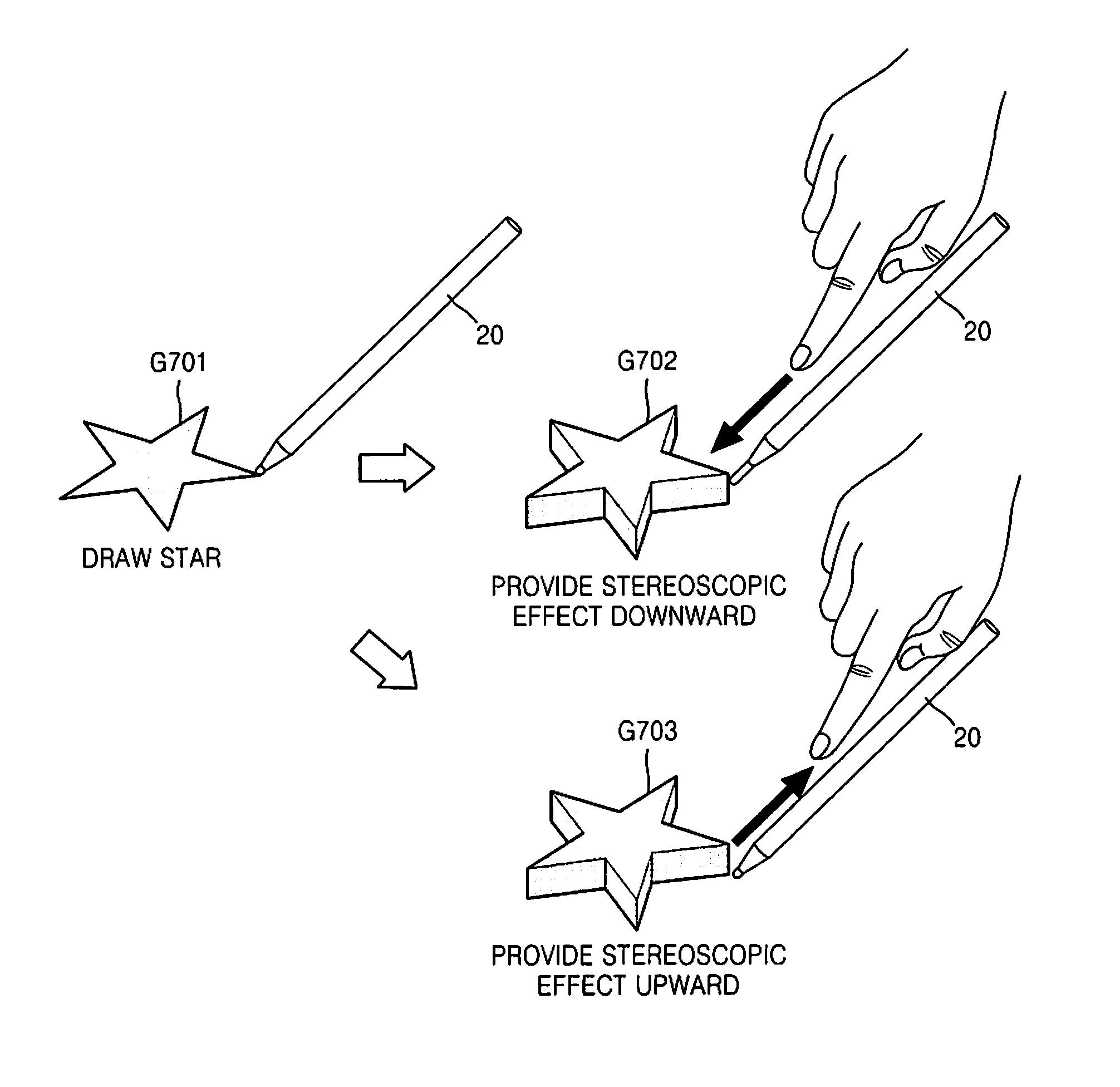

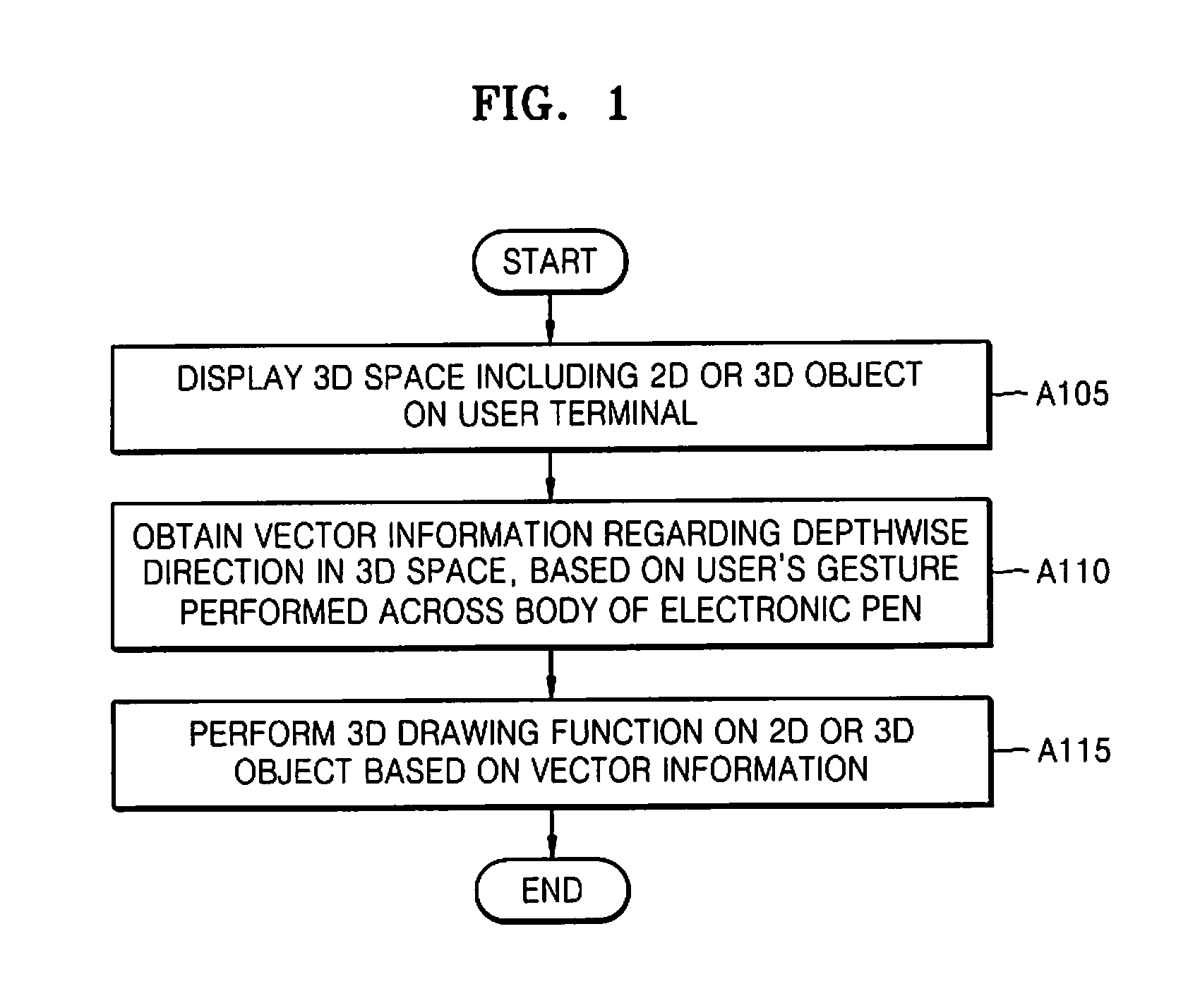

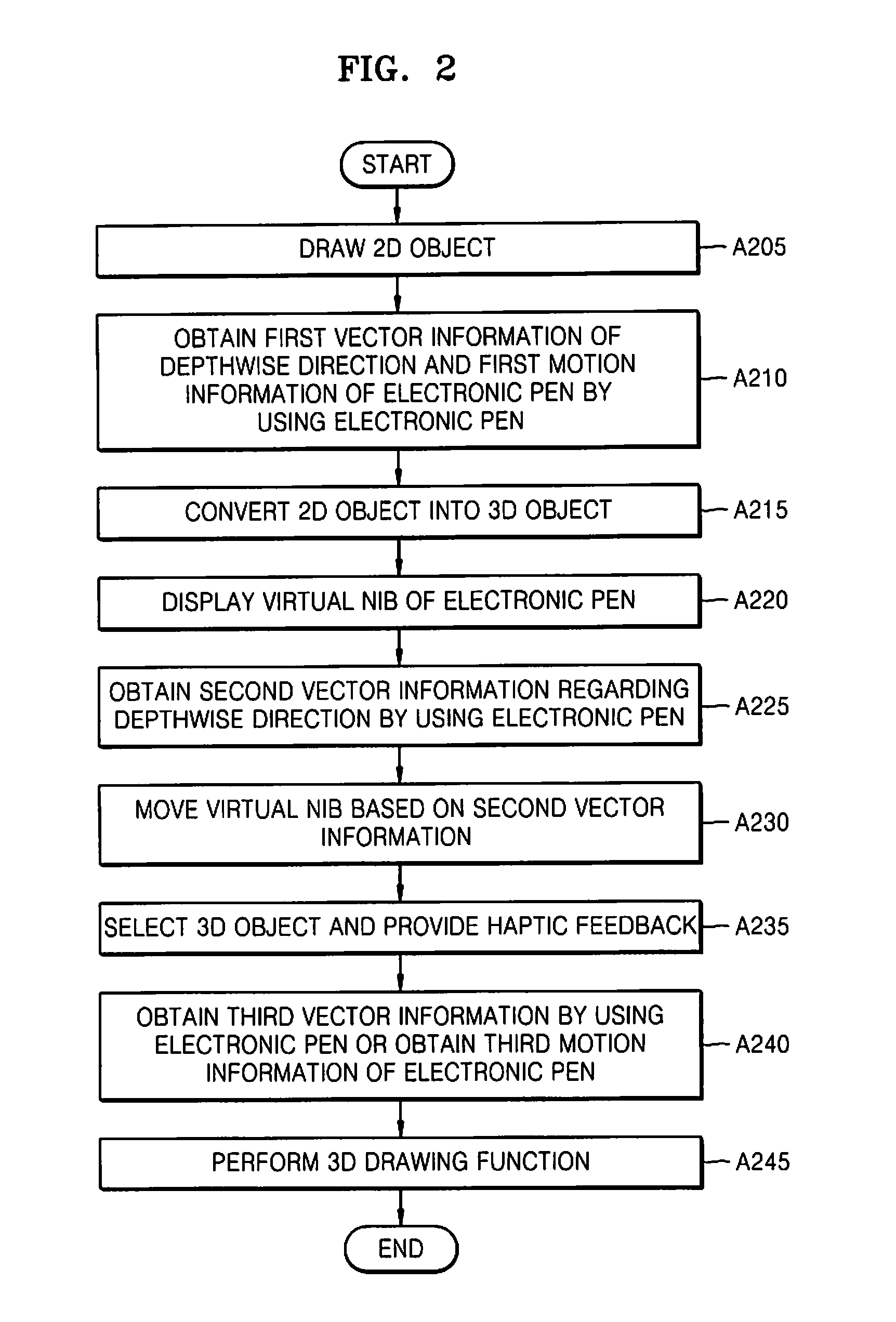

Method and apparatus for drawing three-dimensional object

InactiveUS20150084936A1Convenient to drawInput/output for user-computer interactionImage data processingComputer graphics (images)Computer terminal

Owner:SAMSUNG ELECTRONICS CO LTD

3D drawing pen

The invention discloses a 3D drawing pen comprising a pen holder, a pen head and a pen core; the pen holder is internally provided with a battery box, a driving mechanism and a pen core cavity; the surface of the pen holder is provided with a switch; one end, close to the pen core cavity, of the pen holder is provided with a light source; the pen core comprises a light curing material storing chamber surrounded by a soft material and a discharging mouth made of a hard material; the discharging mouth is provided with a window; the storing chamber of the pen core is located in the pen core cavity; the discharging mouth is located in the pen head; the pen head is mounted at one end, close to the pen core cavity, of the pen holder through a connecting structure. The 3D drawing pen provided by the invention is simple in structure, realizes 3D printing in a manner that a battery allows a threaded rod to drive a light curing material to be subjected to extrusion feeding, is safe and convenient in use, at the same time, can change different-color pen cores and pen heads with different-shape discharge mouths according to the needs, and is more flexible in use process.

Owner:内蒙古梦像科技有限公司

Production process of household appliance glass

InactiveCN109551644AEasy to useImprove aestheticsGlass reforming apparatusGlass severing apparatusCustomer requirementsScreen printing

The invention discloses a production process of household appliance glass. The production process comprises the following steps that (1) product design is conducted, specifically, product design is conducted through cartographic software such as CAD and PROE according to customer requirements, and a drawing is output and externally sent to manufacture a mould; (2) a plane drawing is drawn, specifically, the product plane drawing is drawn, and the periphery and the inner circle of a product are corrected through the CAD or 3D-drawing drawing software according to a product official drawing; (3)ink preparation is conducted, specifically, ink resistant to the temperature of 740-780 DEG C is externally purchased; and (4) a screen printing plate is manufactured, specifically, design is conducted through CAD and COREIDRAW software, pattern output and film manufacturing are conducted, the screen printing plate is subjected to screen pulling according to 14-16 N, the screen printing plate subjected to screen pulling is pulled to the dark light position, the front and reverse faces of the screen printing plate are evenly and fully coated with photosensitive glue, and after the photosensitive glue is air-dried, development is conducted on the screen printing plate through exposure equipment and film patterns. The production process has the beneficial effects that through the scientificdesign and planning and strict control of multiple processes, it is guaranteed that the household appliance glass has excellent using performance, the attractive degree is greatly increased, strengthis greatly improved, and a good material is provided for household appliance production.

Owner:徐元庆

Methods and apparatus for three-dimensional (3D) sketching

ActiveUS10019440B2Facilitates taskDrawing from basic elementsDigital data information retrievalComputer graphics (images)3d space

Methods and apparatus for 3D sketching may provide an interface for creating 3D drawings from 2D and 3D input, and for creating 3D curve networks. The technique may provide tools for 2D sketching that enable 2D sketching in 3D space, and for creating a network of intersecting 3D curves. The technique may provide user interface elements and techniques that facilitate the curve drawing tasks. For 2D sketching, the technique may provide methods for interpreting imprecise user 2D strokes as continuous, high-quality 3D curves. The technique may provide the ability to edit existing 3D curves using sketched 2D strokes. The technique may enable sketching of 3D curves by rotating a drawing plane and / or by creating drawing surfaces on which curves may be added. The technique may provide user interface elements for converting curves in 3D space into a curve network.

Owner:ADOBE SYST INC

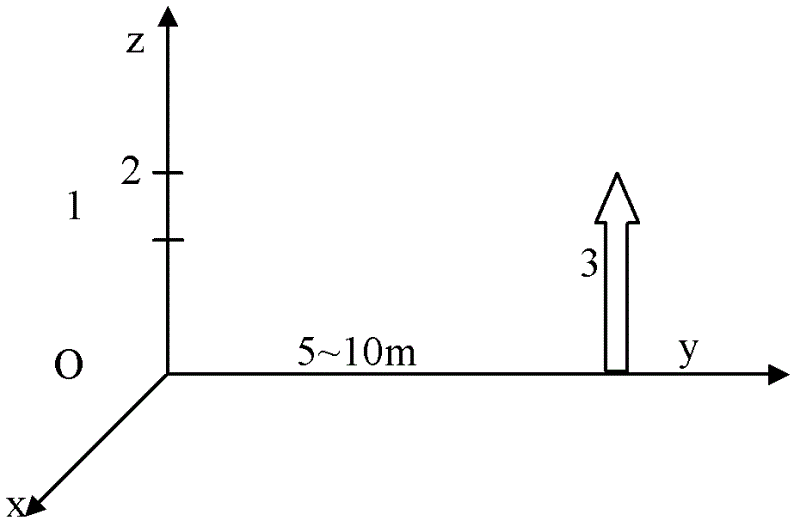

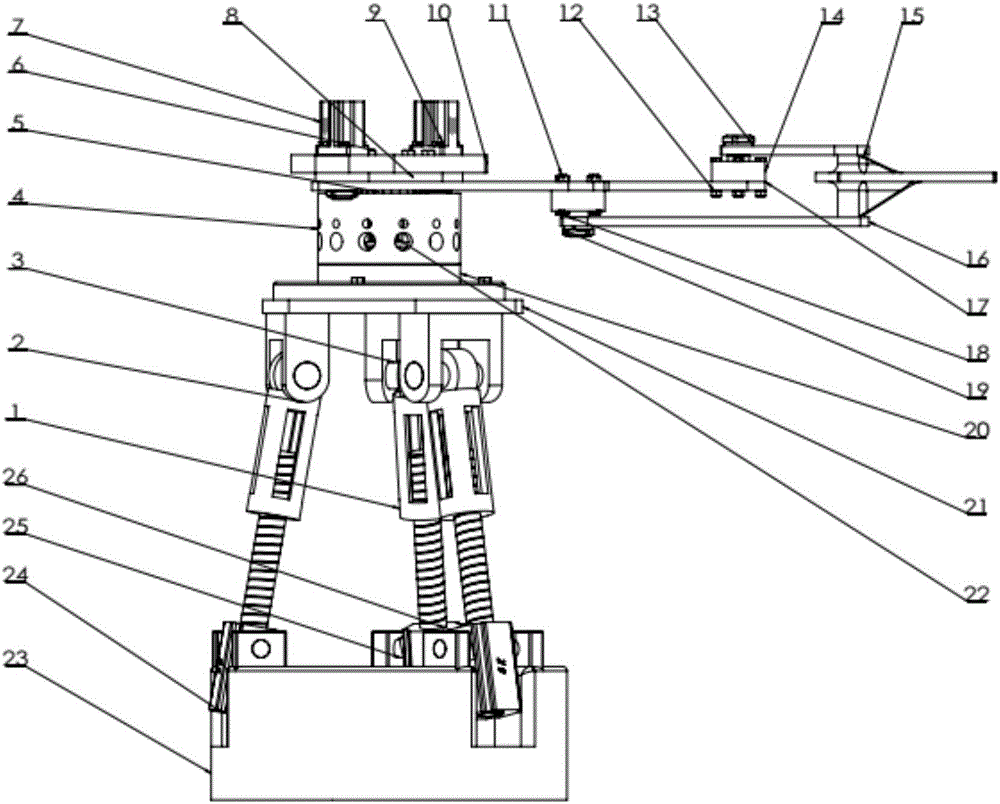

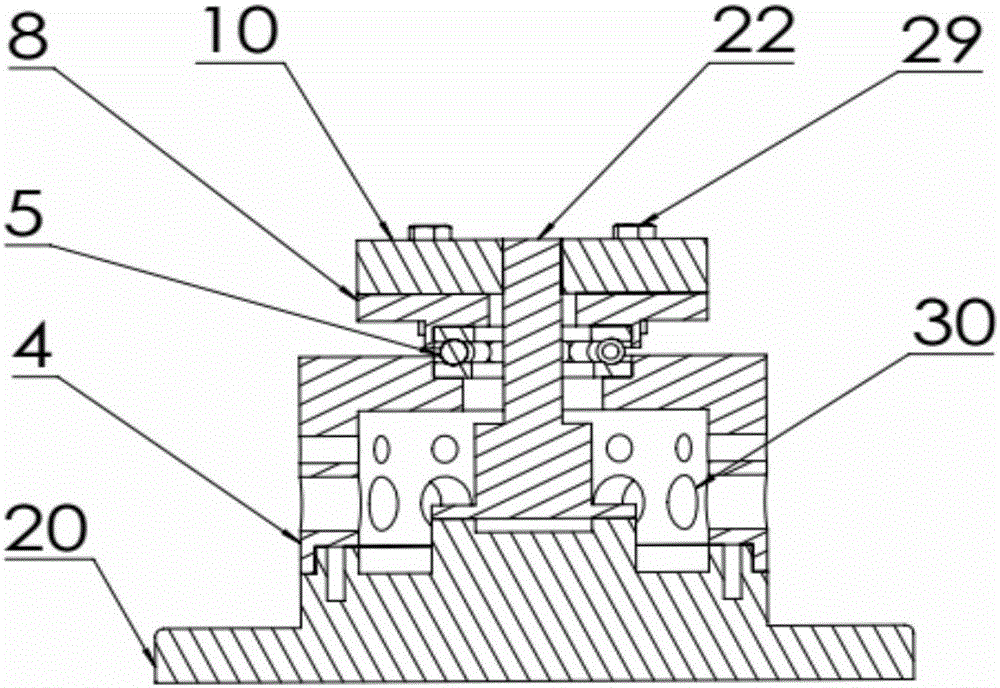

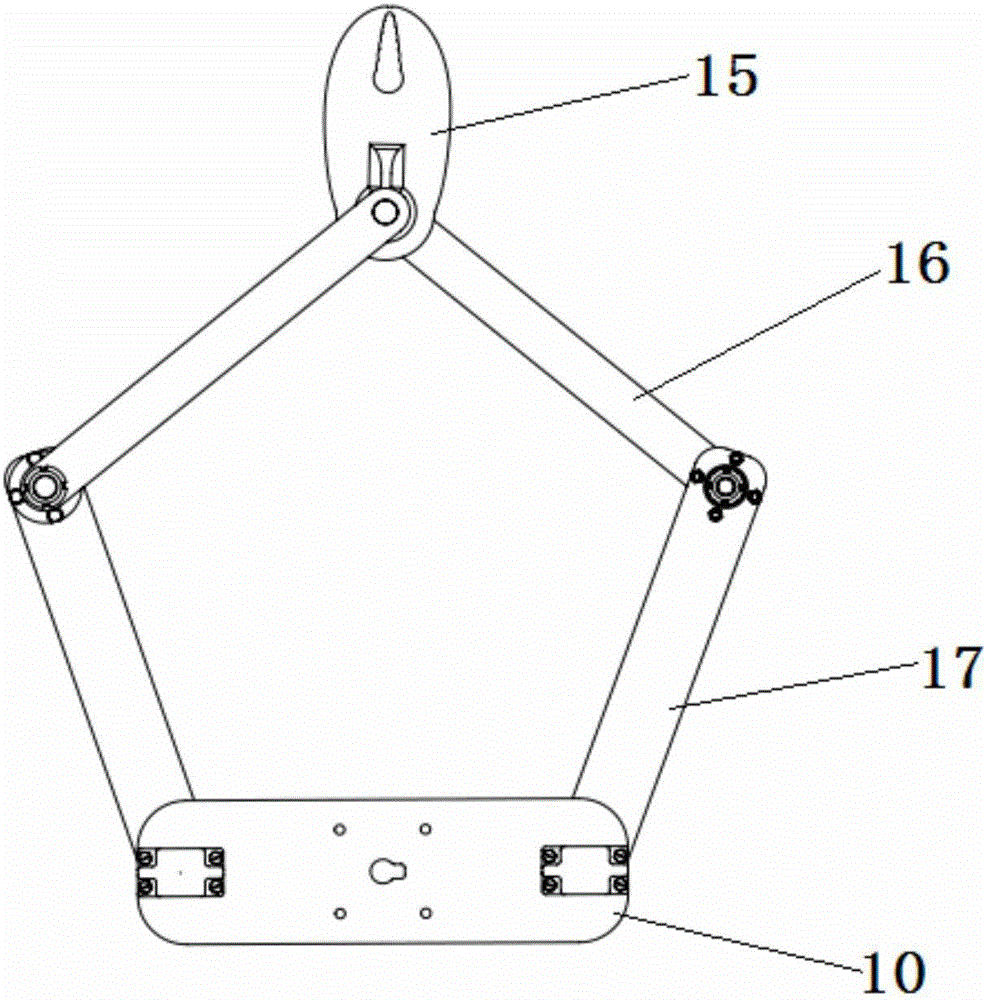

Servo-controlled 3D drawing robot

InactiveCN106346461AReduce cumulative errorLarge working spaceProgramme-controlled manipulatorInterference fitHuman body

The invention relates to a servo-controlled 3D drawing robot composed of a 3-DOF parallel base, a waist auxiliary device and a five-rod robot actuator. The servo-controlled 3D drawing robot can realize plane and space drawing operation with a small driving moment during actual work. The five-rod robot actuator realizes drawing of a two-dimensional plane complex curve through a five-rod structure, and proper interference fit is utilized in the five-rod structure to lower the transmission error, so that the drawing process is convenient to control precisely and stably; an embedded structure is adopted in the waist auxiliary device, and a servo motor is utilized for enlarging working space for actuation; the 3-DOF parallel base imitating movement of the shoulder of a human body enables the drawing robot to realize space drawing operation at three degrees of freedom. The product has the advantages of being flexible in structure, small in occupied space, good in compatibility and stability, low in weight and cost, good in locating precision and the like.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com