Human-computer interaction intelligent closed-loop control method of full-automatic blow-molding production line and process thereof

A closed-loop control and human-computer interaction technology, applied in the field of blow molding production, can solve problems such as poor distribution of raw materials, affecting process quality, production line shutdown, etc., to achieve the effect of shortening the molding cycle, reducing costs and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

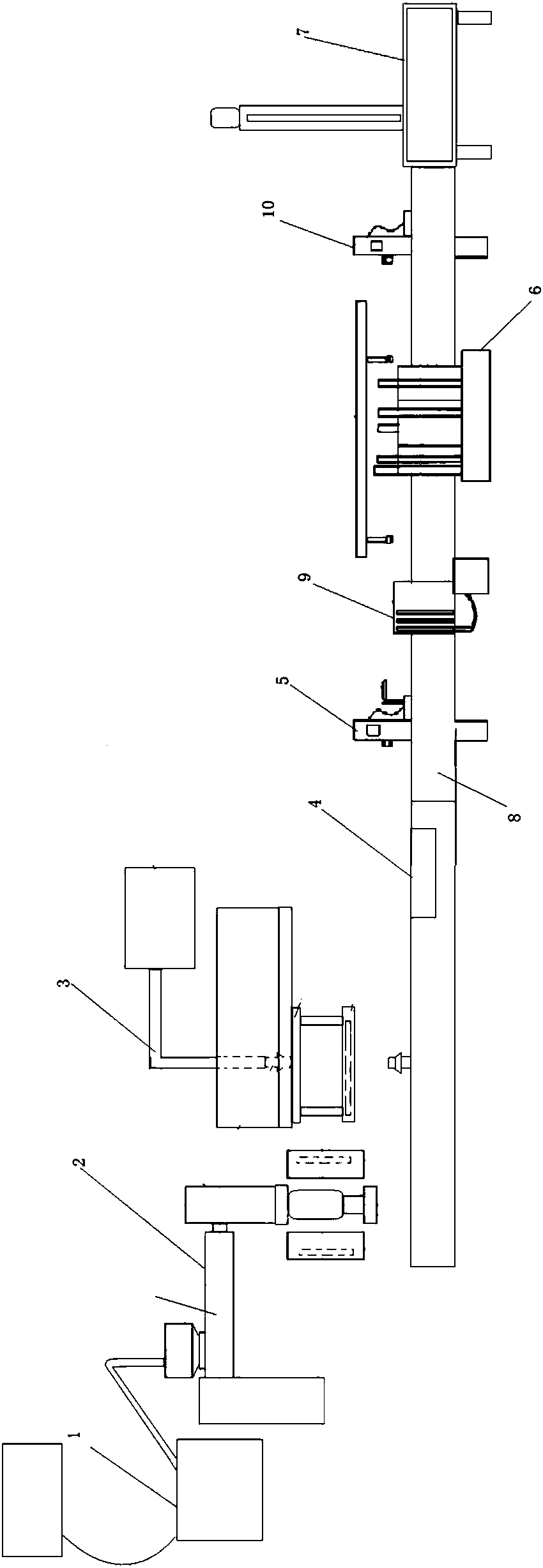

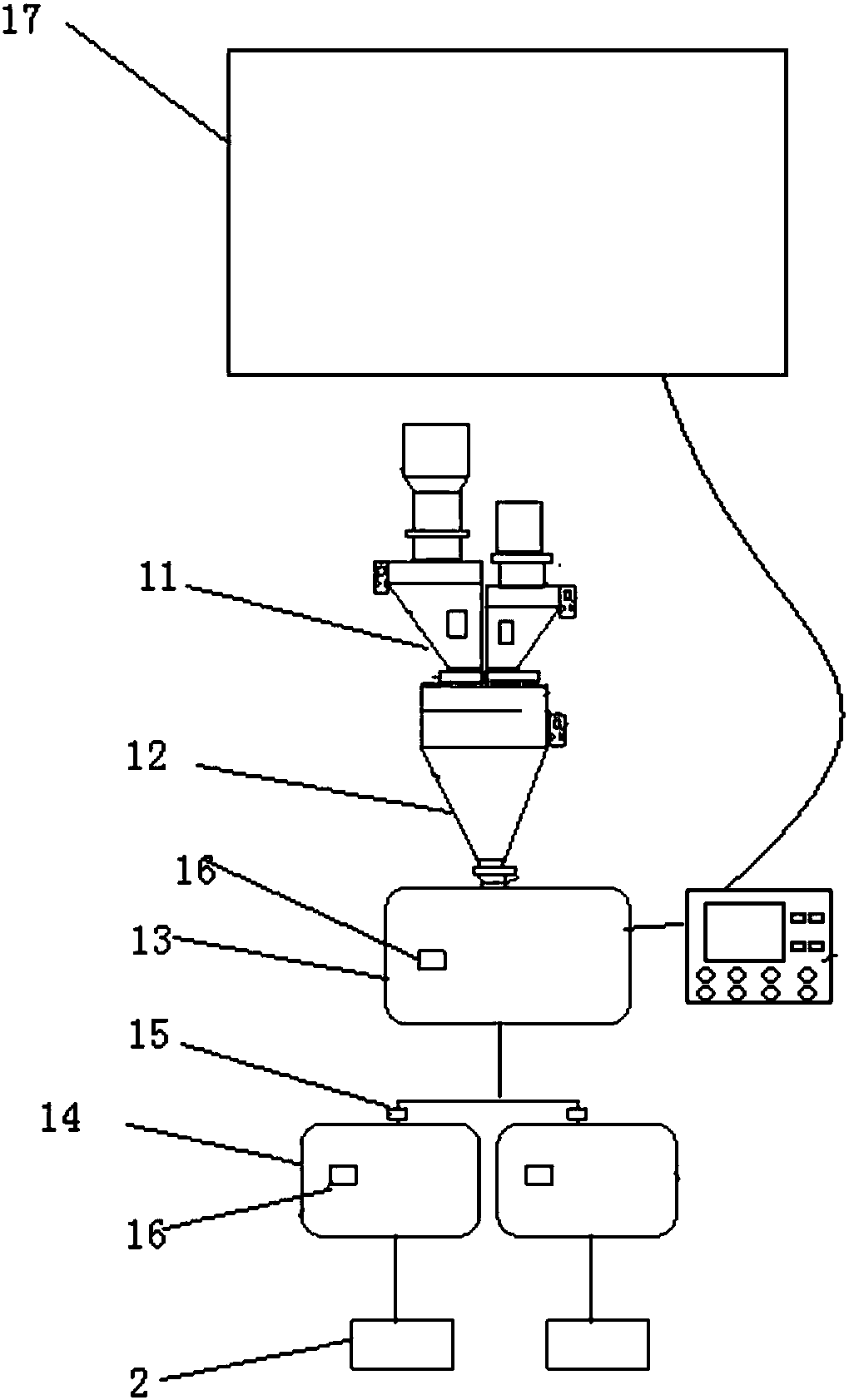

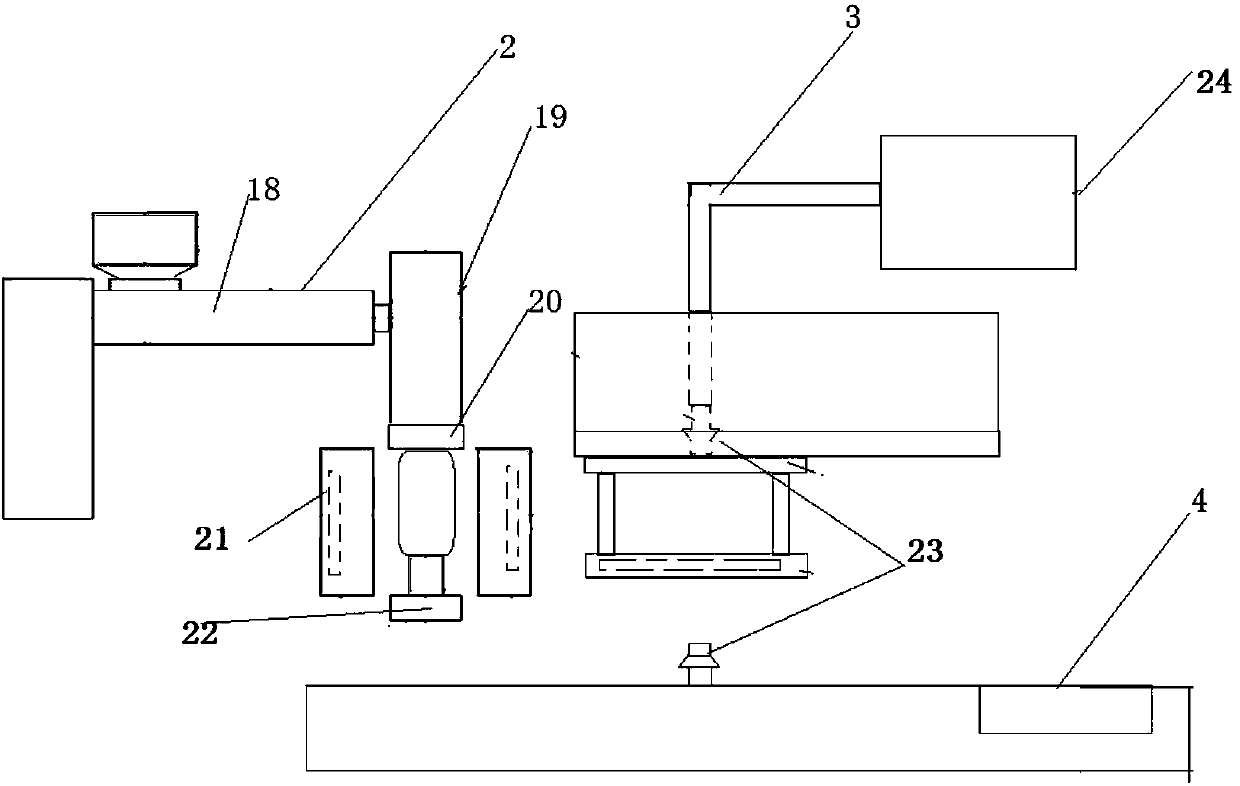

[0030] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0031] In the drawings, 1. Automatic feeding system, 2. Blow molding machine, 3. Secondary cooling mechanism, 4. Edge material removal mechanism, 5. Online leak tester, 6. Online labeling machine, 7. Stacking packaging Machine, 8. Conveying mechanism, 9. Flame pretreatment device, 10. Secondary leak detection device, 11. Feeding system, 12. Mixer, 13. Main storage tank, 14. Sub-storage tank, 15. Solenoid valve , 16. Material level sensor, 17. Automatic control display board, 18. Extruder, 19. Stocker, 20. Head, 21. Mold cooling device, 22. Air intake rod structure, 23. Cooling duckbill, 24. Compressed cold air supply mechanism, 25. Blower, 26. Air inlet hood, 27. Air-cooled heat exchanger, 28. Outlet air hood, 29 Dehumidifier. 30. First solenoid valve, 31. First gas Flow meter, 32. dry air device, 33. dust collector, 34. threaded connection section.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com