Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "The result is accurate and effective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

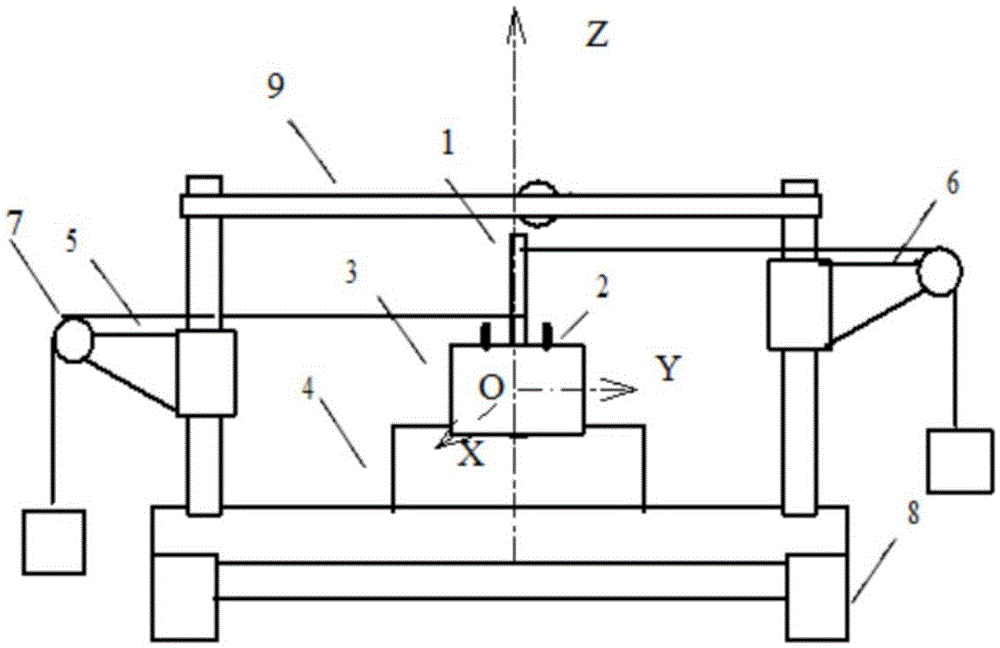

Automobile crane hoisting simulation method on basis of virtual reality

InactiveCN102663196AImprove formulation efficiencyHigh feasibilitySpecial data processing applicationsSimulationVirtual reality

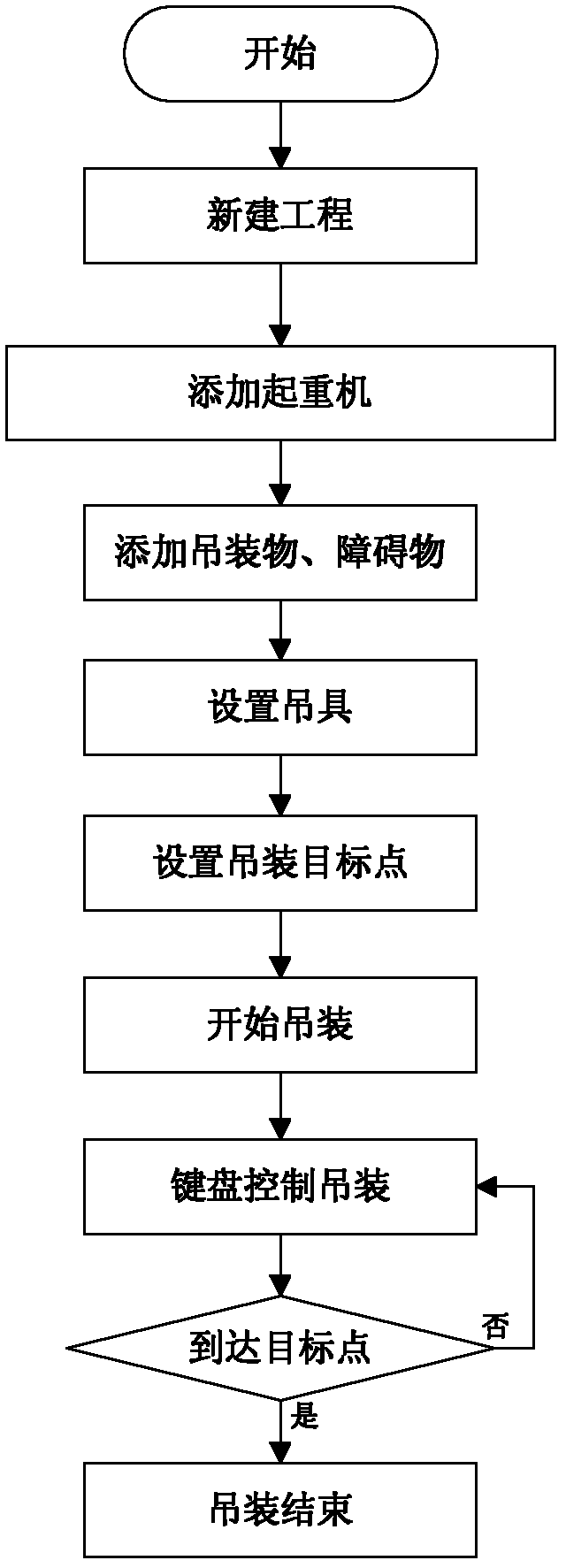

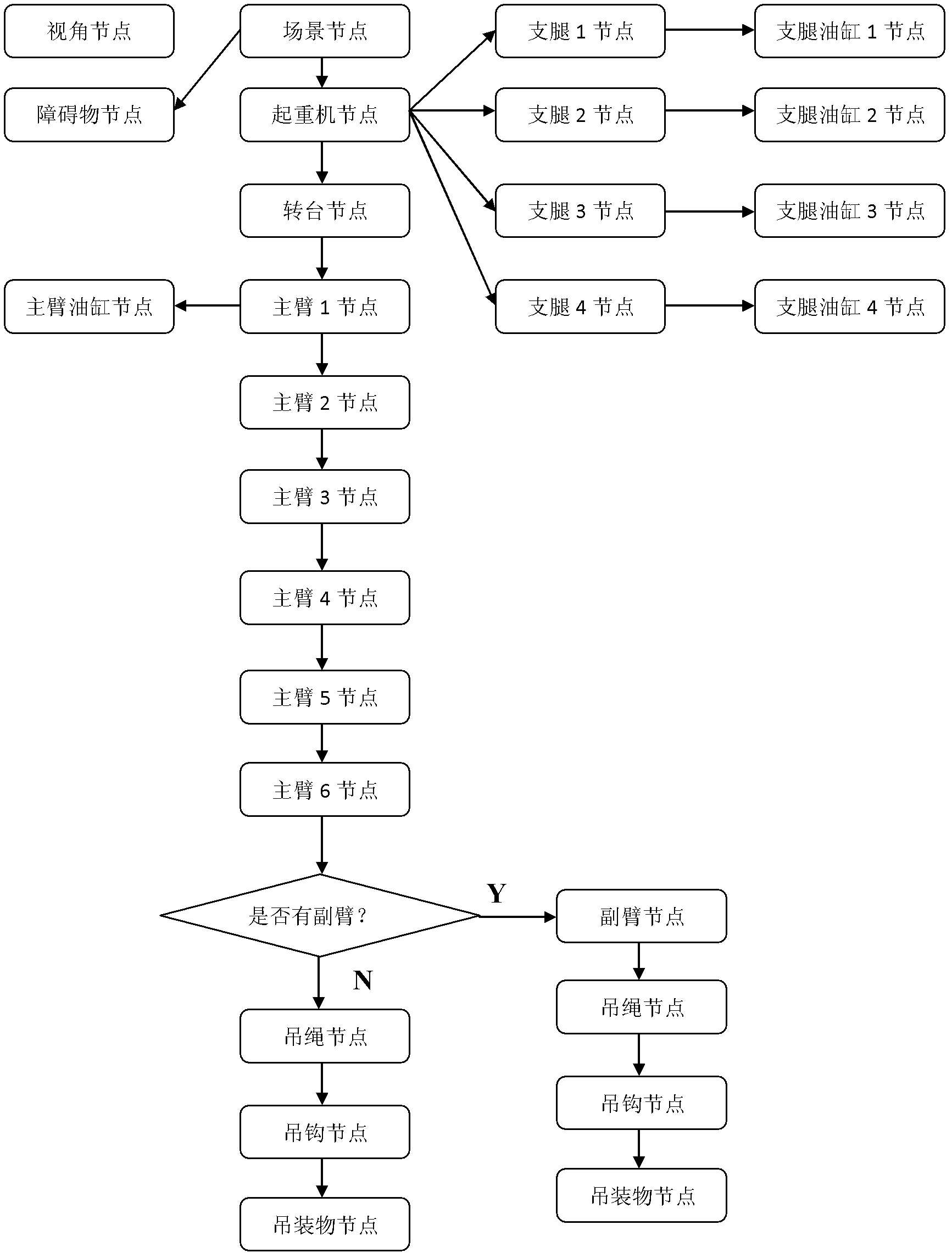

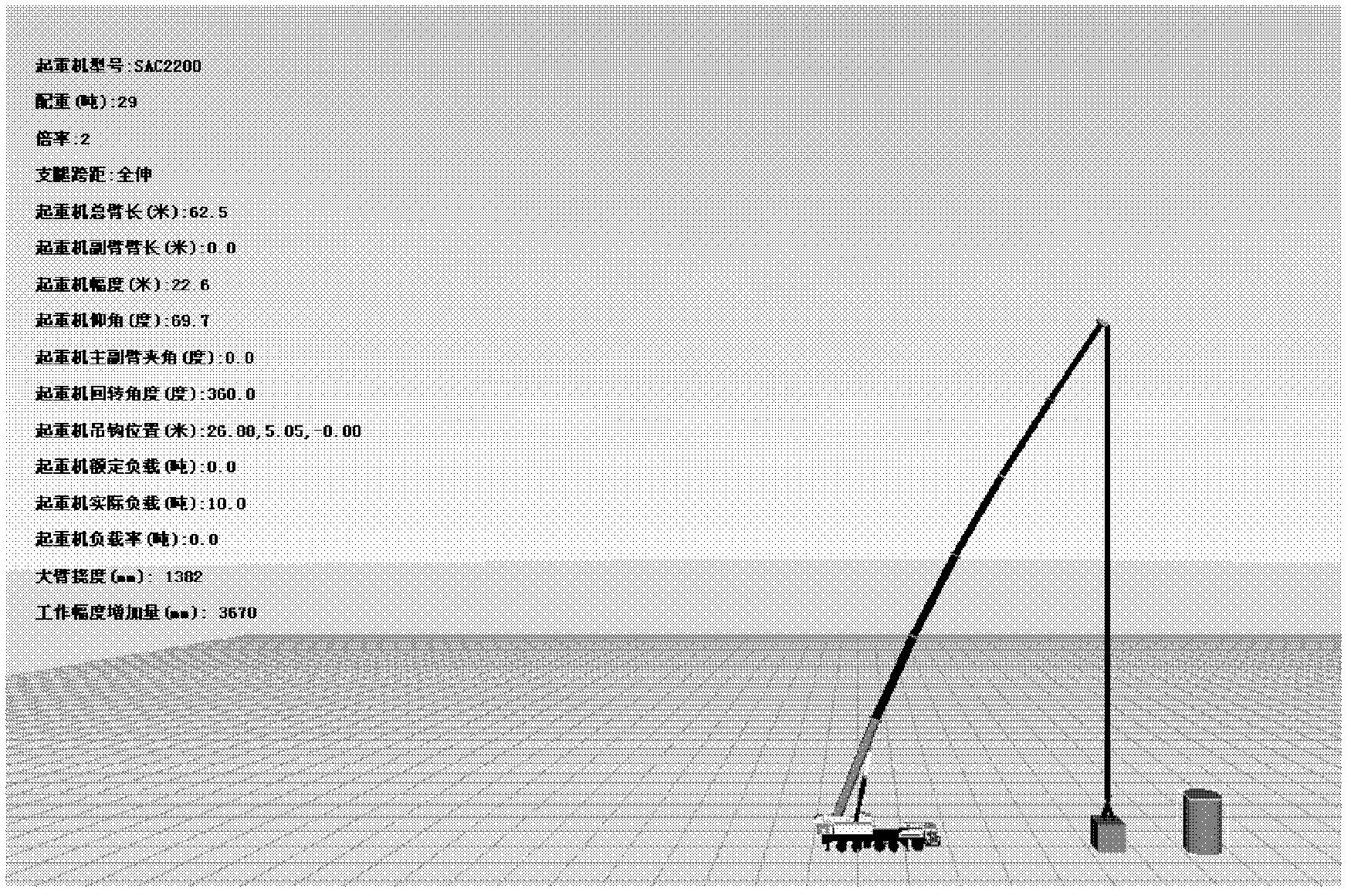

The invention discloses an automobile crane hoisting simulation method on the basis of the virtual reality, which is characterized by comprising the following steps of: a first step of newly constructing a project and setting a project name for the new project; a second step of constructing a crane mode; a third step of adding hoisted objects and barriers; a fourth step of setting a hoisting target point; and a fifth step of implementing the hoisting simulation operation by keyboard operation until the hoisted objects reach the hoisting target point, completing hoisting and storing the operation process from a hoisting initial point to the hoisting target point. The construction of the hoisting model adopts a custom configuration mode or a mode of inquiring and adding on the basis of the working condition. The automobile crane hoisting simulation method on the basis of the virtual reality is easy to implement and can accurately simulate the hoisting operation process of a crane.

Owner:CENT SOUTH UNIV

Temperature sensor self-testing device and method

ActiveCN109186813AEfficient discoveryDirect discoveryThermometer testing/calibrationStatistical analysisAnomaly detection

The invention provides a temperature sensor self-testing device and method. The method comprises the following steps: performing differential processing on a temperature data sequence of a train undernormal conditions to obtain a segmented standard deviation sequence, and performing statistical analysis on the standard deviation sequence to obtain an abnormality detection threshold; performing differential processing on a real-time input temperature data sequence to obtain segmented standard deviation sequence; judging whether the segmented standard deviation sequence is abnormal based on thethreshold and the standard deviation sequence; if a certain segment of segmented standard deviation sequence is greater than or equal to the threshold, judging that the segment of temperature deviation sequence is abnormal, and entering the next step, otherwise, indicating that the sensor is normal; judging the distribution consistency between the abnormal certain segment of temperature deviationsequence, a normal reference sequence and the previous adjacent time period of temperature deviation sequence; if the consistency is present, judging that the sensor is normal, otherwise, judging that the sensor is abnormal. By adoption of the temperature sensor self-testing device and method provided by the invention, the technical problems that fast and effect self-testing cannot be performedon the temperature sensor in the prior art, and the safe and efficient running of the train cannot be guaranteed are solved.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

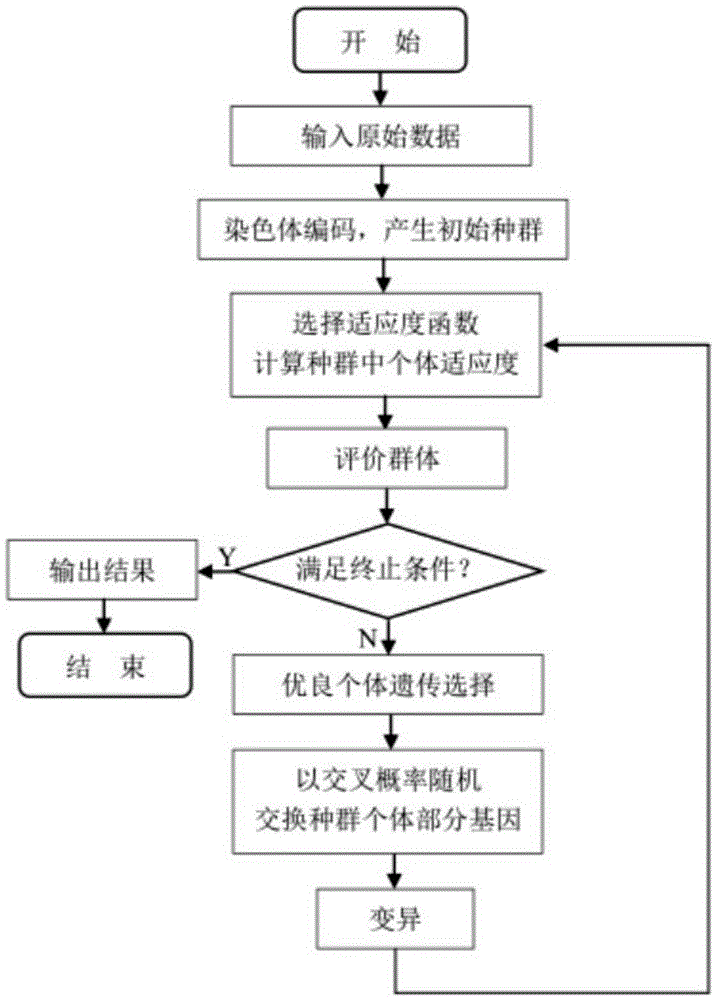

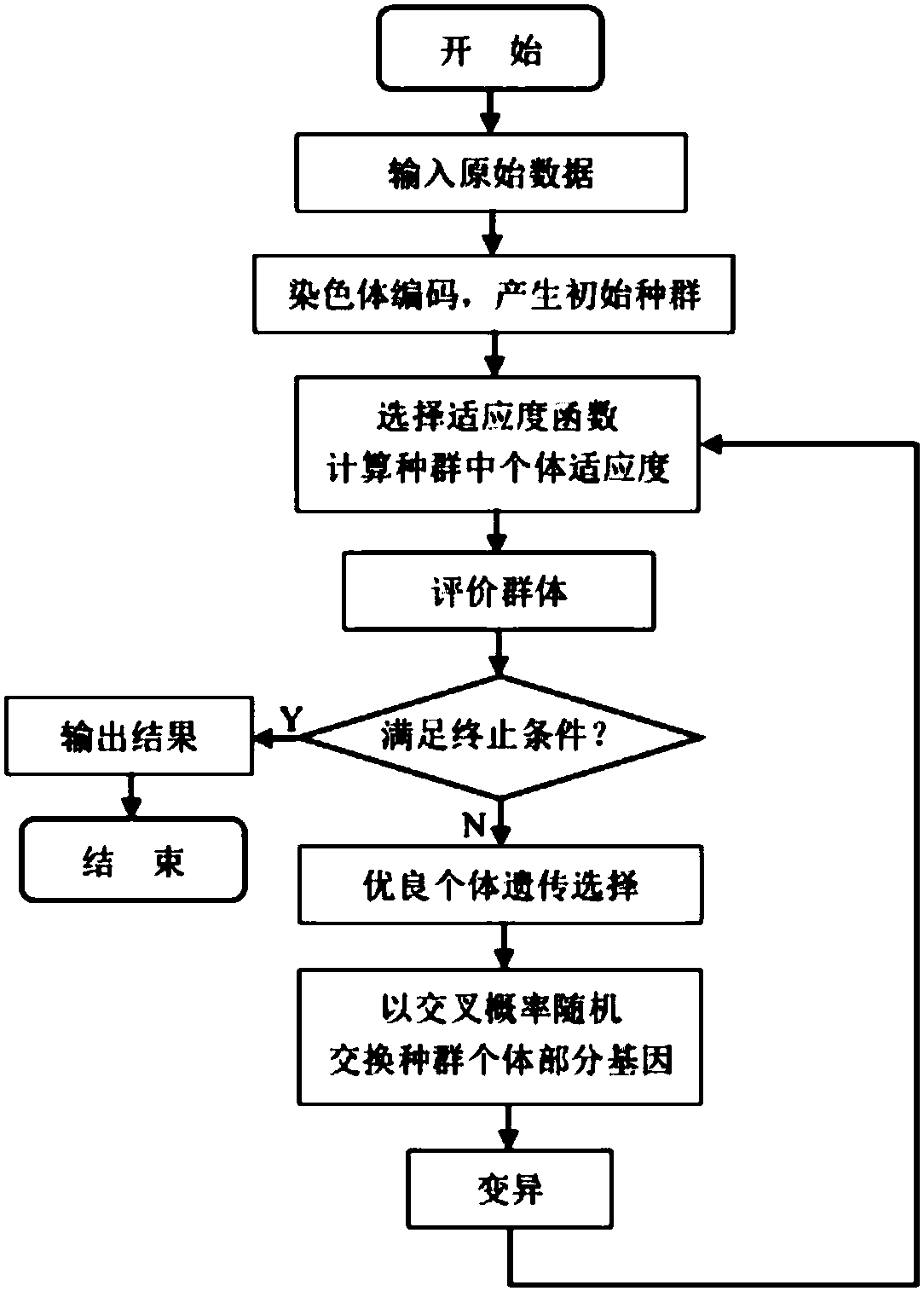

Multi-dimensional force sensor calibration experiment data fitting method based on genetic algorithm

ActiveCN105651457AThe algorithm is simple and reliableThe result is accurate and effectiveGenetic modelsForce/torque/work measurement apparatus calibration/testingGlobal optimumVoltage

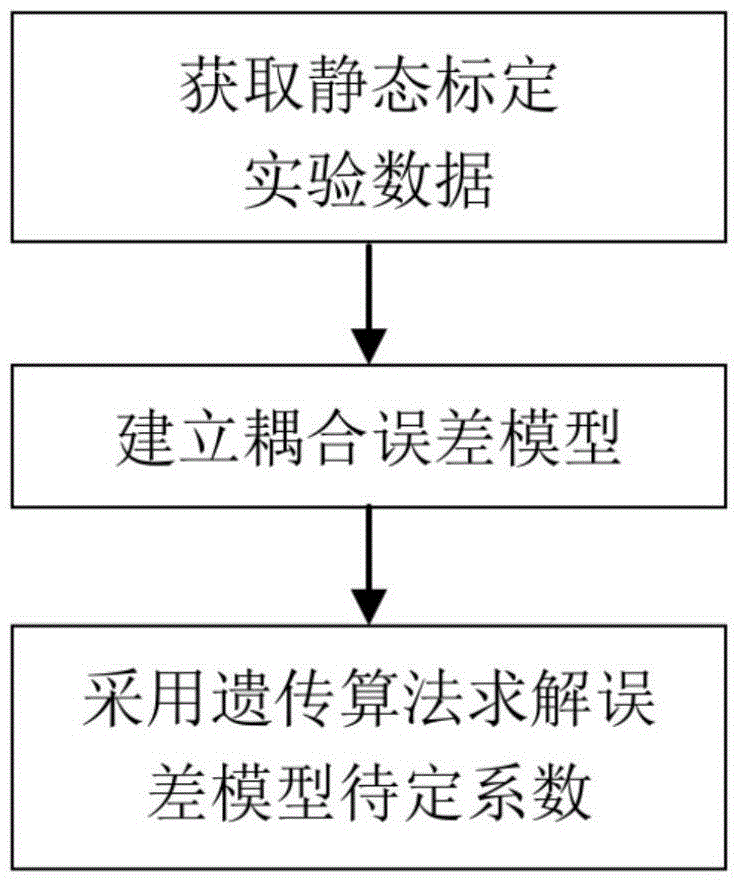

The invention discloses a multi-dimensional force sensor calibration experiment data fitting method based on a genetic algorithm. The method comprises the following steps: (1) carrying out a multi-dimensional force sensor static calibration experiment, and recording each dimension of input force / torque value of a multi-dimensional force sensor and each path of output voltage value under the action of the input force / torque value respectively; (2) deducing a coefficient solution formula of a sensor coupling error theoretical model; and (3) solving the error coefficient solution formula in the step (2) based on the genetic algorithm by using MATLAB (Matrix Laboratory) software, and outputting an undetermined coefficient solution of global optimum. According to the multi-dimensional force sensor calibration experiment data fitting method based on the genetic algorithm, random global search and optimization of the genetic algorithm can be used for data fitting of the multi-dimensional force sensor calibration experiment; the algorithm is simple and reliable and a result is accurate and effective; and a self-adaptive searching process of an optimal fitting curve of the experiment data is finished, so that the precision of a decoupling algorithm is improved.

Owner:SOUTHEAST UNIV

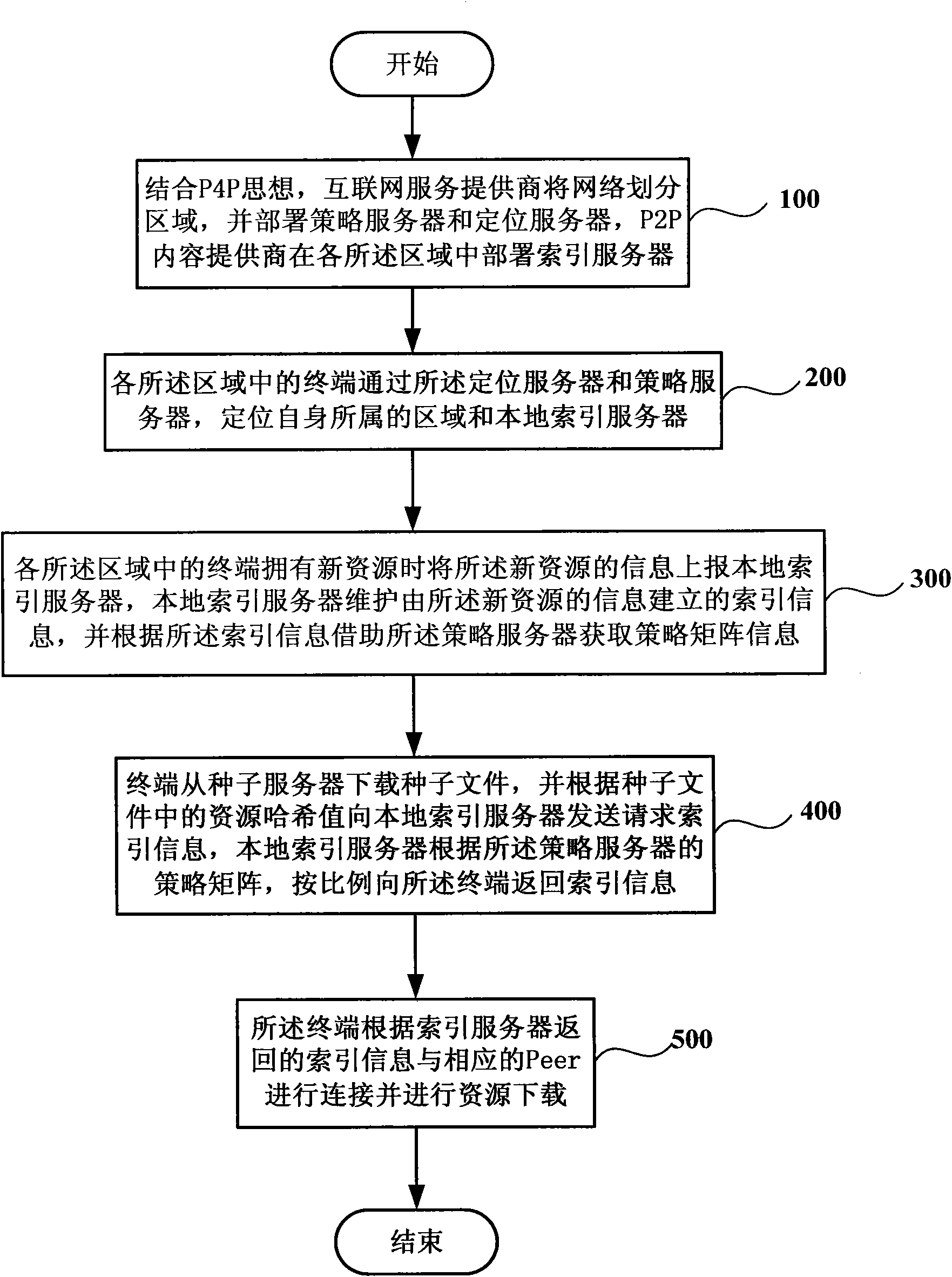

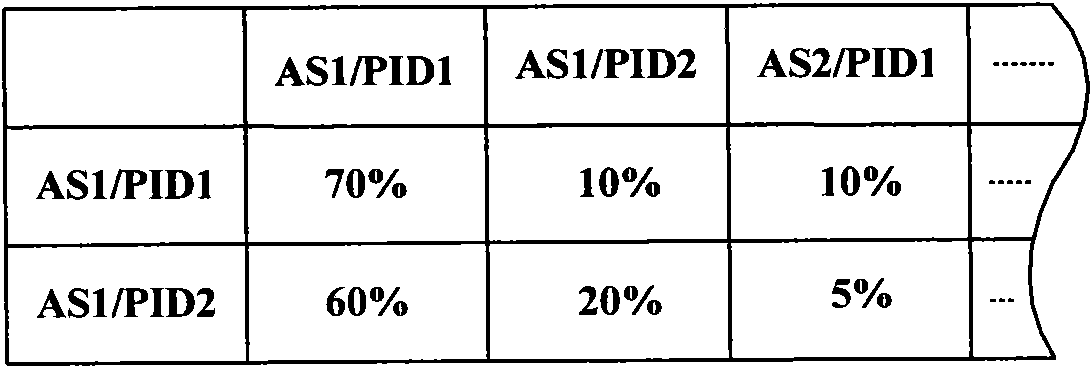

P2P flow optimization method and system based on distributed index server architecture

InactiveCN101854387AEffective Regional ManagementAvoid overheadData switching networksComputer networkDistributed index

The invention discloses P2P flow optimization method and system based on a distributed index server architecture. The method comprises the following steps of: on the basis of the P4P concept, partitioning the network into regions and deploying policy servers and positioning servers by an Internet service provider, and deploying index servers in each region by a P2P content provider; positioning the affiliated region and the local index server by a terminal in each region; when possessing new resources, reporting information of the new resources to the local index server by the terminal in each region, and maintaining index information established by the information of the new resources by the index server and acquiring policy matrix information by the aid of the policy server; downloadinga seed file from a seed server by the terminal and transmitting request index information to the local index server according to the hash value in the seed file, and proportionally returning the index information to the terminal by the local index server according to the policy matrix; and getting connection with the corresponding terminal by the terminal according to the returned index information and downloading the resources.

Owner:深圳算力快车科技有限公司

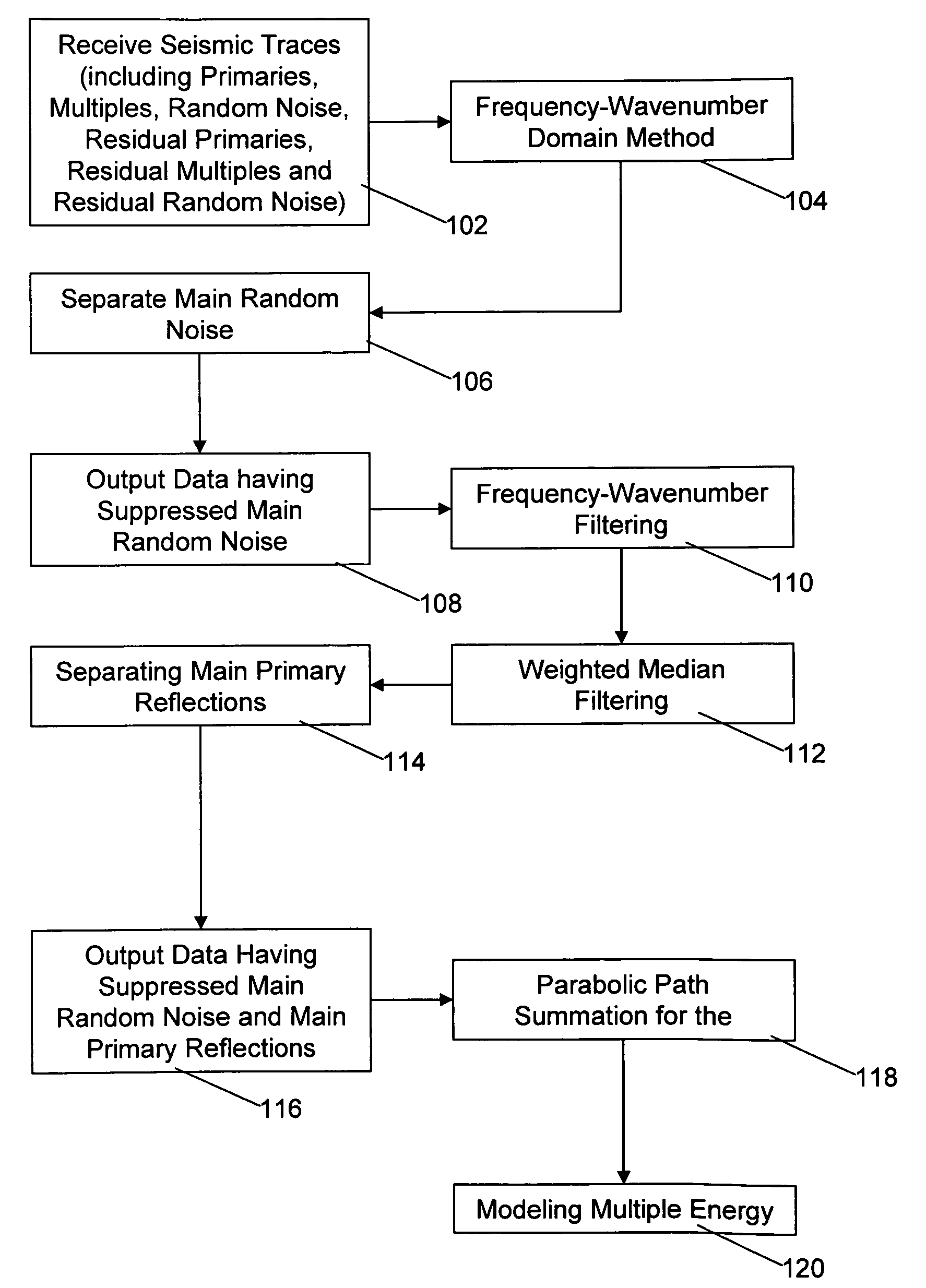

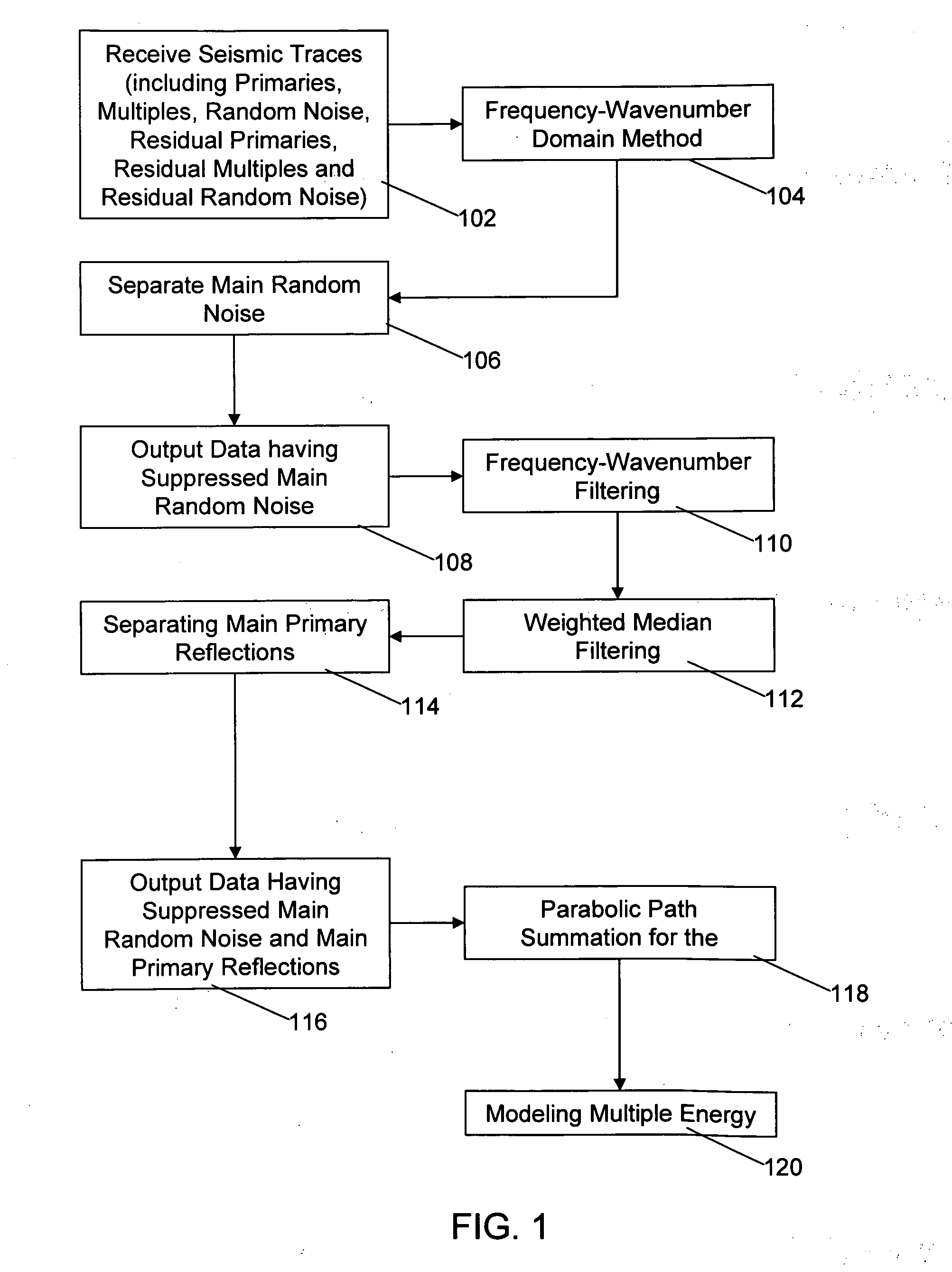

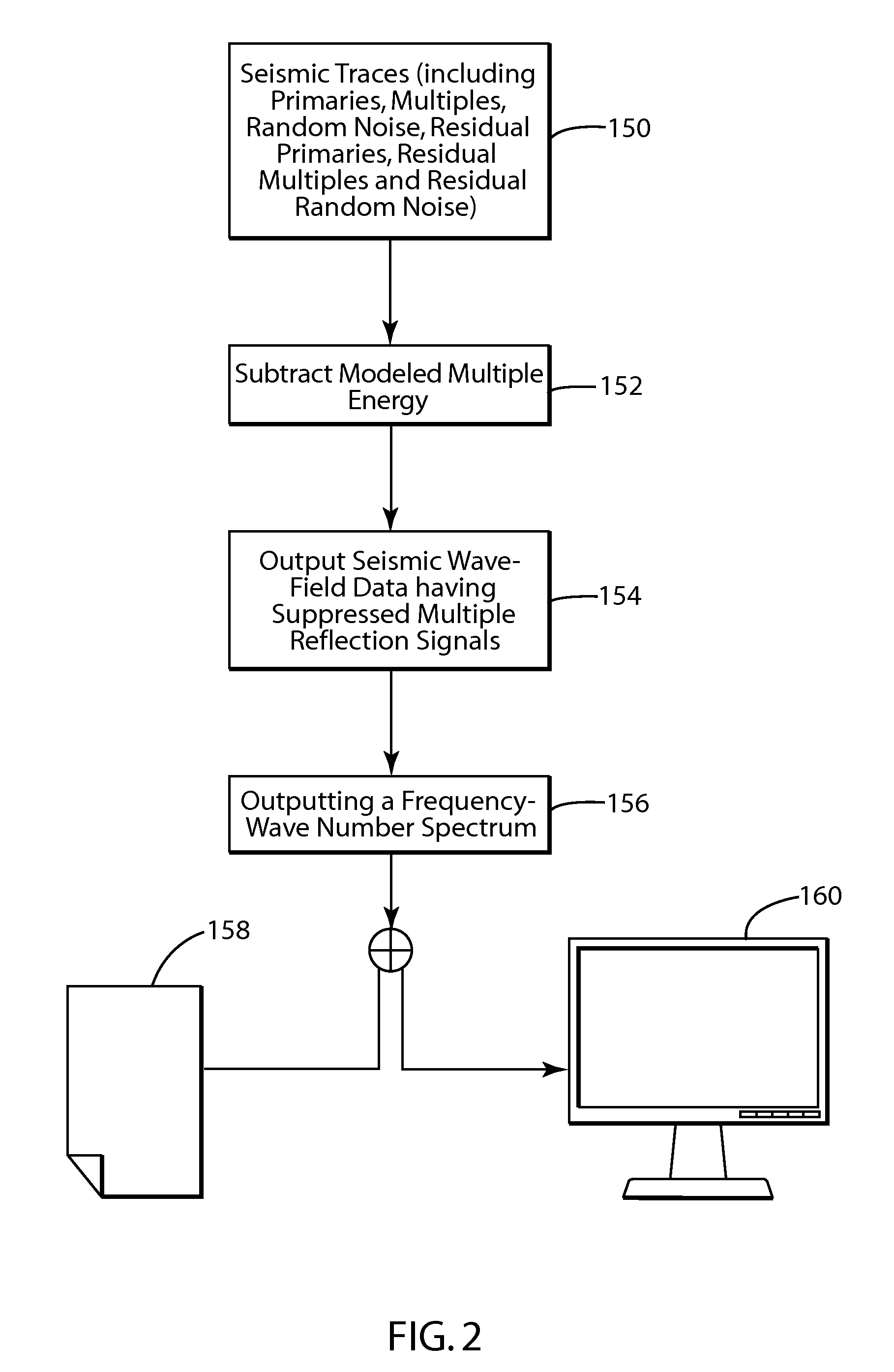

System and method for suppression of seismic multiple reflection signals

ActiveUS8315124B2The result is accurate and effectiveSeismic signal processingSpecial data processing applicationsData modelingWave field

A method of modeling seismic wave-field data in order to suppress near-surface and sub-surface related multiple reflection signals is provided. The reflection signals include main primary reflection signals, main random noise signals, main multiple reflection signals, residual primary reflection signals, residual random noise signals, and residual multiple reflection signals. Main random noise signals are separated from the reflection signals using a frequency-wavenumber domain method to provide data having suppressed main random noise. Main primary reflection signals are separated from the data having suppressed main random noise using frequency-wavenumber filtering and weighted median filtering to provide data having suppressed main random noise and main primary reflections. Multiple reflection signals are modeled using parabolic path summation on the data having suppressed main random noise and main primary reflections.

Owner:SAUDI ARABIAN OIL CO

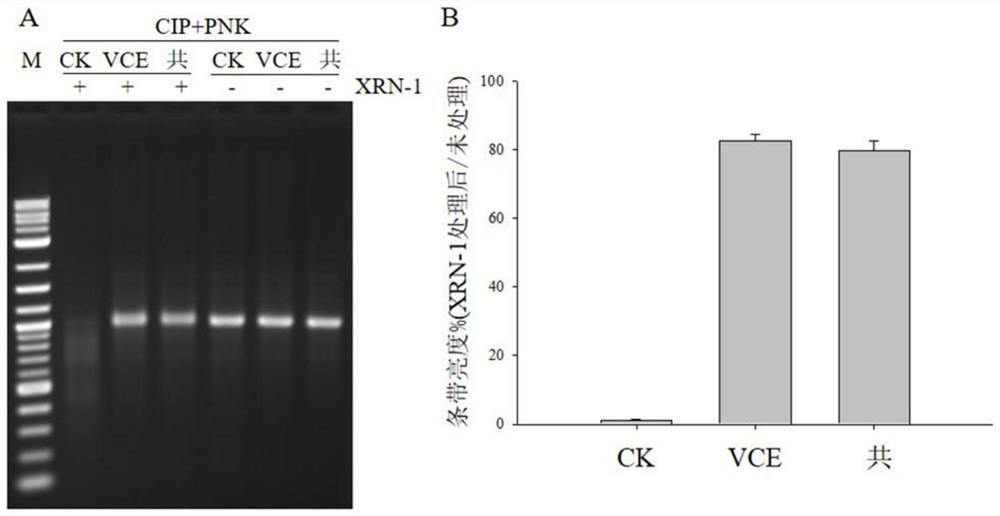

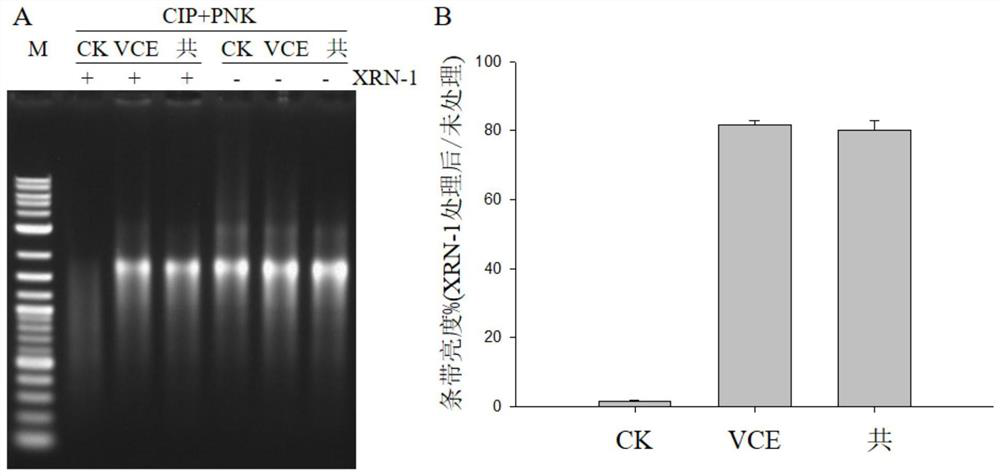

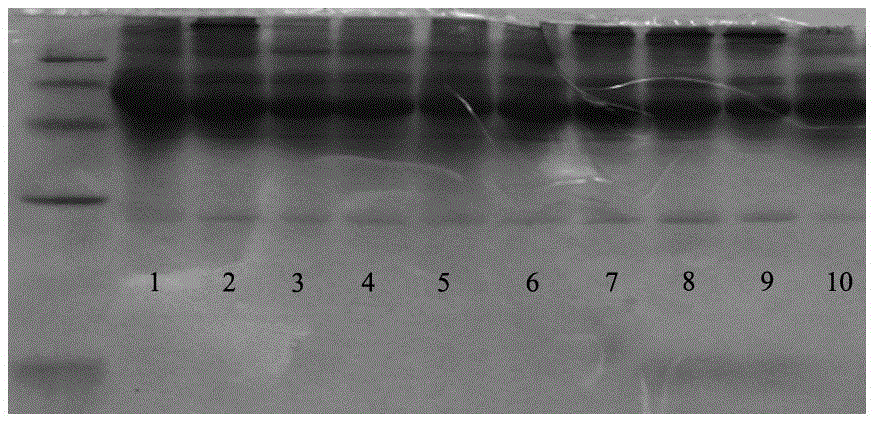

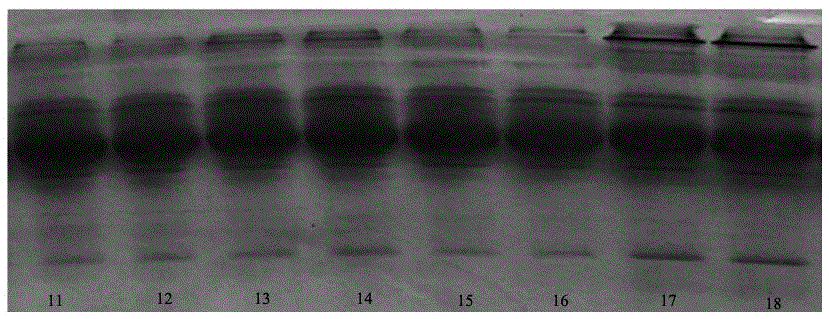

Method for rapidly and quantitatively detecting capping efficiency of RNA

PendingCN112626177ADetection of capping efficiencyEasy to operateMicrobiological testing/measurementPhosphorylationKinase

The invention discloses a method for rapidly and quantitatively detecting the capping efficiency of RNA. The method comprises the following steps: S1, performing in-vitro transcription to synthesize uncapped RNA and removing template DNA; S2, carrying out capping treatment on the RNA; S3, performing mono-phosphorylation treatment on the RNA obtained in the steps S1 and S2: firstly, performing dephosphorylation by using alkaline phosphatase, purifying the RNA, and then adding monophosphate to the 5' end of the RNA by using polynucleotide kinase; S4, removing the RNA subjected to the monophosphorylation treatment by using monophosphatase, and setting a control group not treated with the monophosphatase; and S5, performing glue leaking detection: quantitatively determining the strip brightness (denoted as n) of the RNA treated by the monophosphatase and the strip brightness (denoted as N) of the RNA of the control group, and calculating the capping efficiency of the RNA: (n / N)*100%. The method has the beneficial effects that (1) the capping efficiency of the RNA can be rapidly and quantitatively detected, the operation is simple and rapid, and the result is effective and accurate; and (2) the method has less demand on samples, has no special requirements on RNA types, lengths and the like, and has a wide application range.

Owner:HUAZHONG UNIV OF SCI & TECH +1

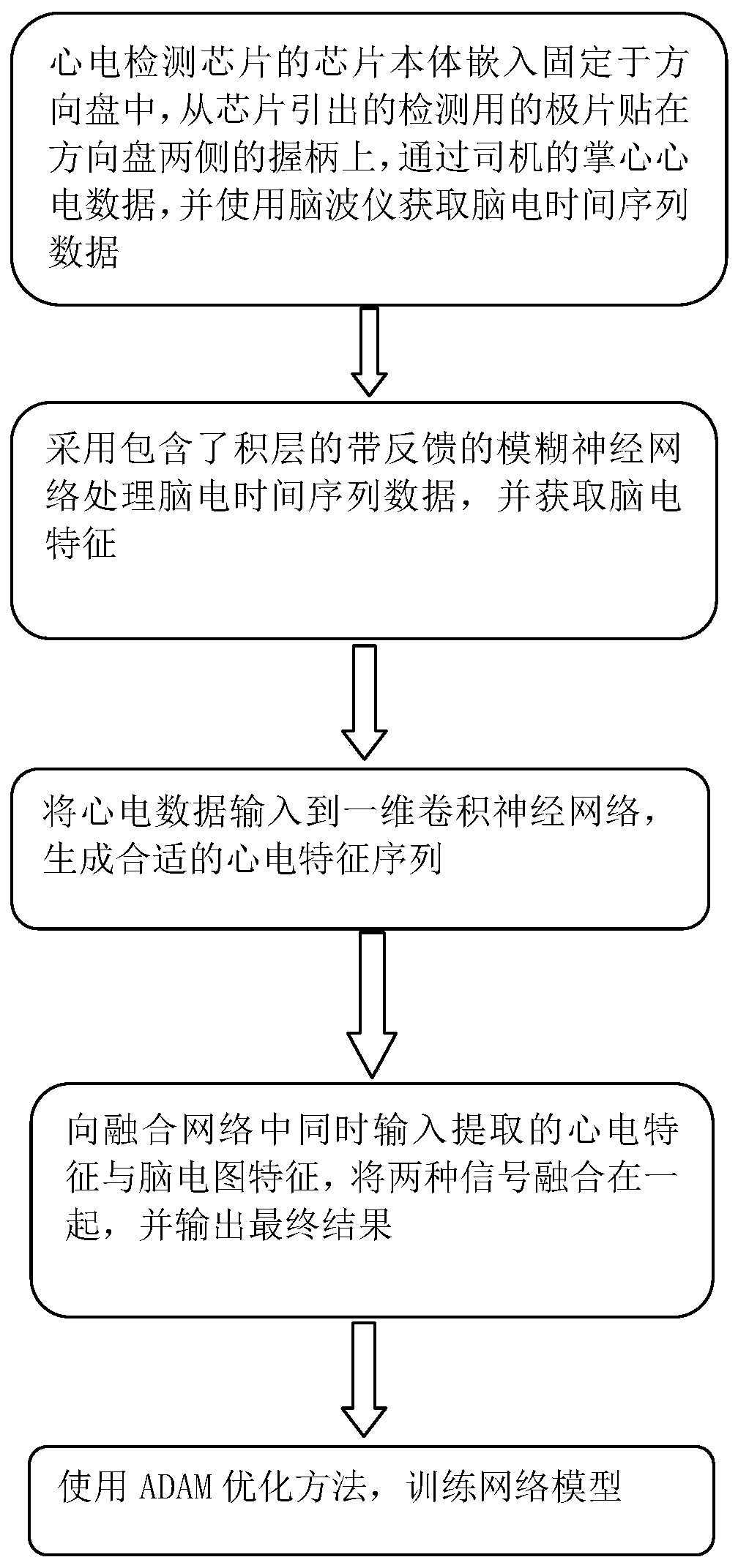

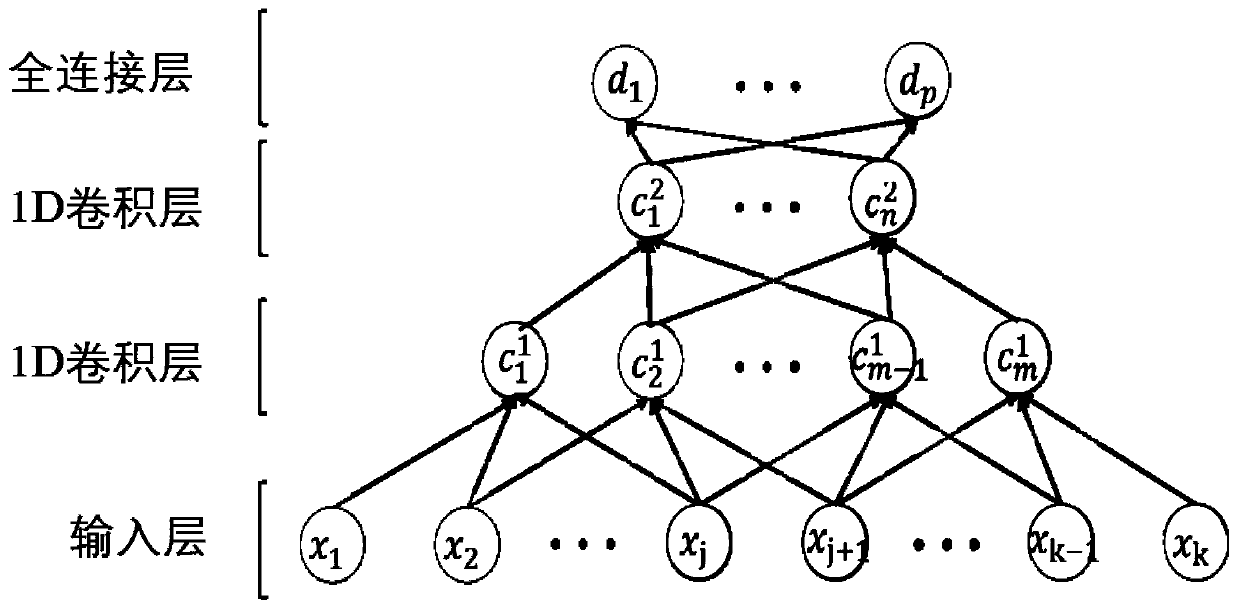

Electroencephalogram and electrocardiogram-based fatigue detection method of electrocardiogram sensor embedded into steering wheel

ActiveCN111407260AHigh precisionThe result is accurate and effectiveCharacter and pattern recognitionSensorsElectroencephalogram featureFeature Dimension

The invention discloses an electroencephalogram and electrocardiogram-based fatigue detection method of an electrocardiogram sensor embedded into a steering wheel. The method performs fatigue detection by constructing a product fuzzy convolutional network. The method specifically comprises the following steps: S1, acquiring electrocardiogram data through an electrocardiogram detection chip, and acquiring electroencephalogram time series data by using an electroencephalograph; S2, processing the electroencephalogram time series data by adopting a fuzzy neural network which contains a laminationand has feedback, and acquiring electroencephalogram characteristic; S3, establishing a depth feature extraction network based on a one-dimensional convolutional neural network framework to extract fatigue features of the electrocardiogram data, and generating an electrocardiogram feature sequence; S4, designing a fusion network, inputting the electrocardiogram characteristic sequence and the electroencephalogram characteristic at the same time, fusing the two signals together, and giving a prediction value; and S5, performing optimizing by using an adaptive moment estimation algorithm, and training a network model. The method can reduce the noise and improve the detection precision, the limitation of the fuzzy neural network on the feature dimension of the input data is reduced by introducing the lamination, and the accuracy of the classification result is improved.

Owner:SOUTH CHINA UNIV OF TECH

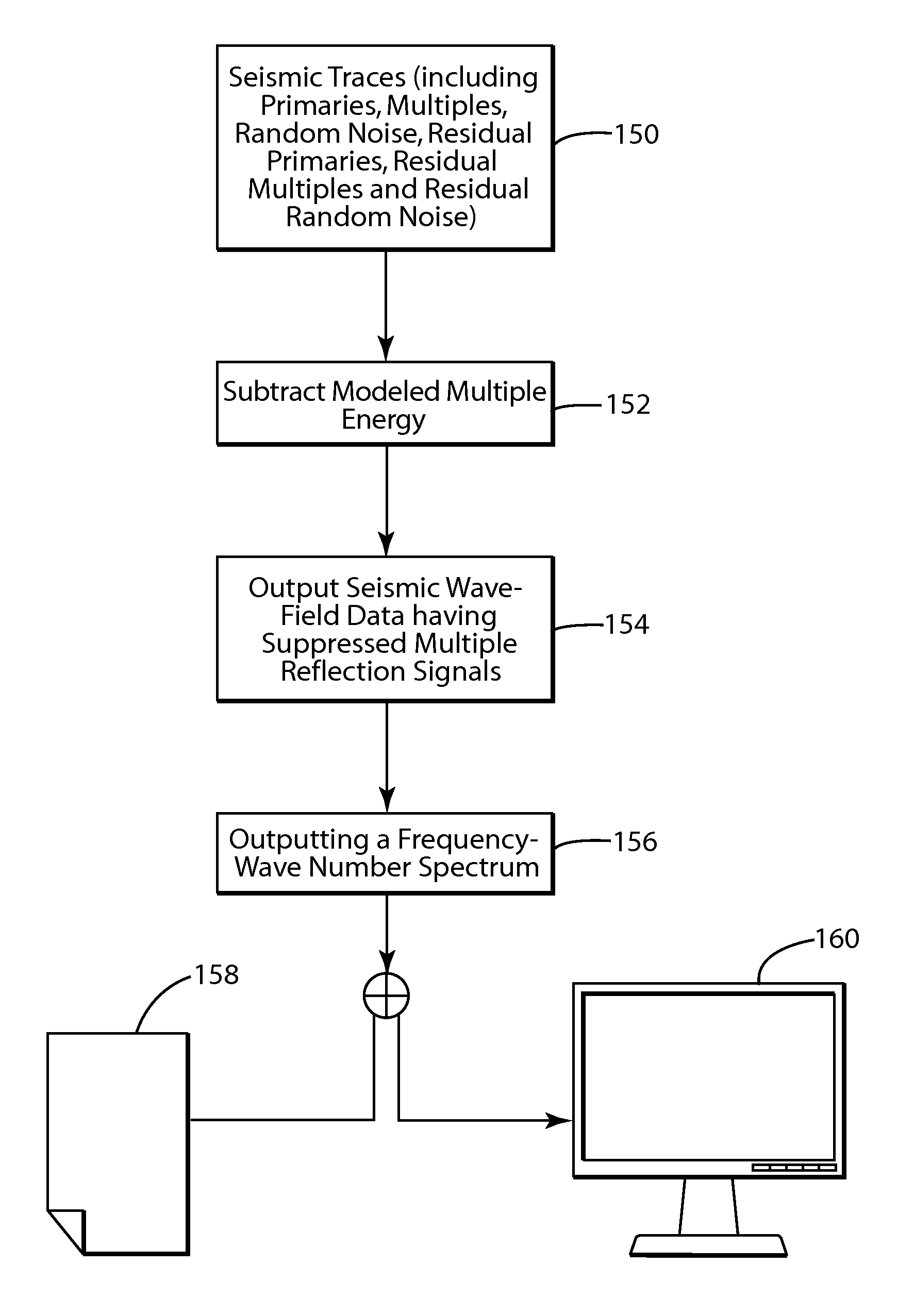

System and method for suppression of seismic multiple reflection signals

ActiveUS20110013483A1Accurate and reliable modelingThe result is accurate and effectiveSeismic signal processingSpecial data processing applicationsWavenumberWave field

A method of modeling seismic wave-field data in order to suppress near-surface and sub-surface related multiple reflection signals is provided. The reflection signals include main primary reflection signals, main random noise signals, main multiple reflection signals, residual primary reflection signals, residual random noise signals, and residual multiple reflection signals. Main random noise signals are separated from the reflection signals using a frequency-wavenumber domain method to provide data having suppressed main random noise. Main primary reflection signals are separated from the data having suppressed main random noise using frequency-wavenumber filtering and weighted median filtering to provide data having suppressed main random noise and main primary reflections. Multiple reflection signals are modeled using parabolic path summation on the data having suppressed main random noise and main primary reflections.

Owner:SAUDI ARABIAN OIL CO

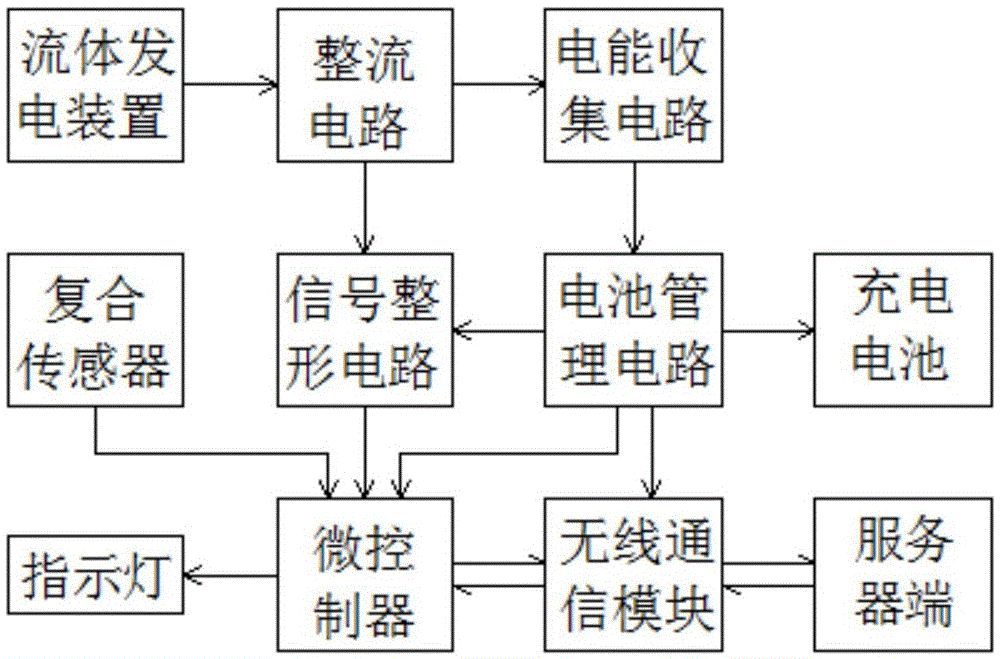

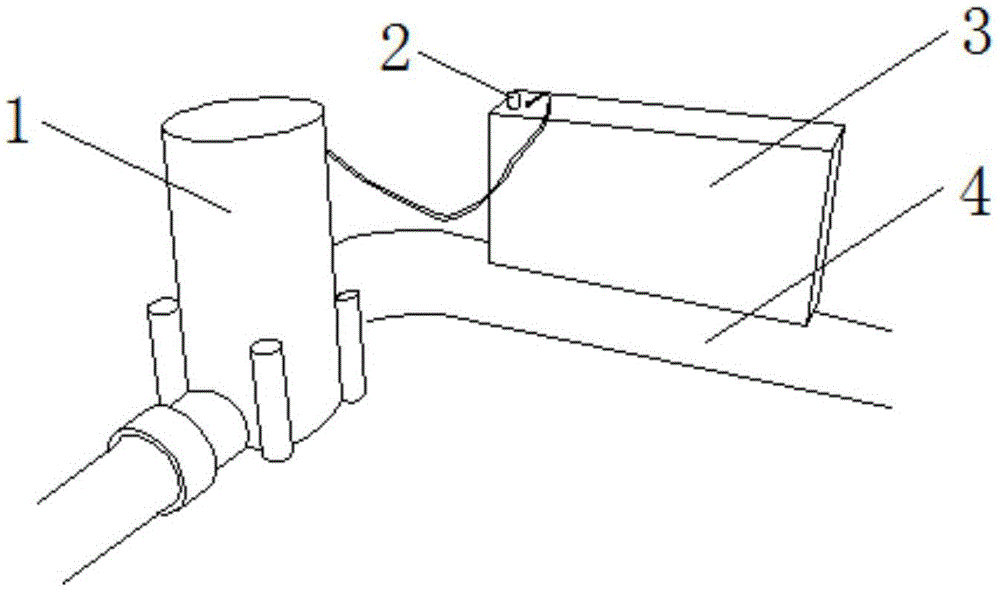

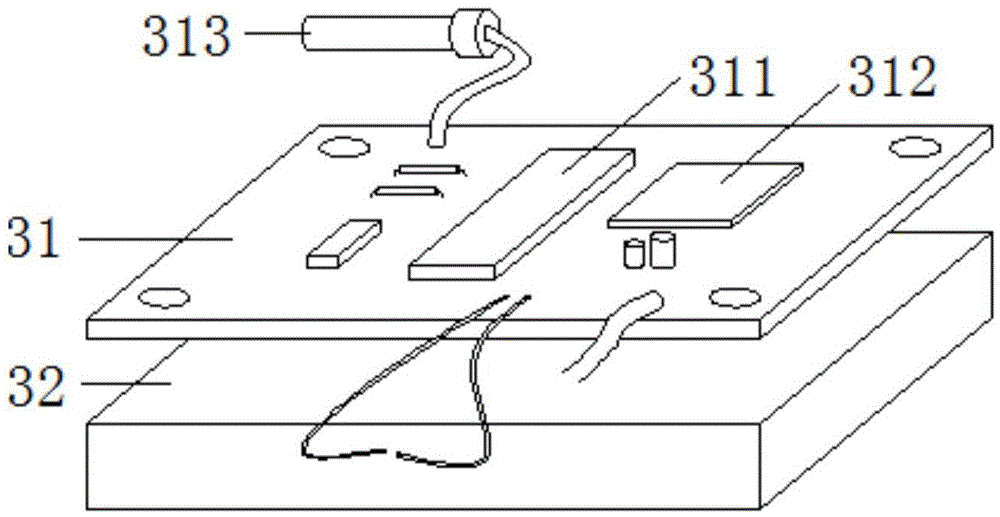

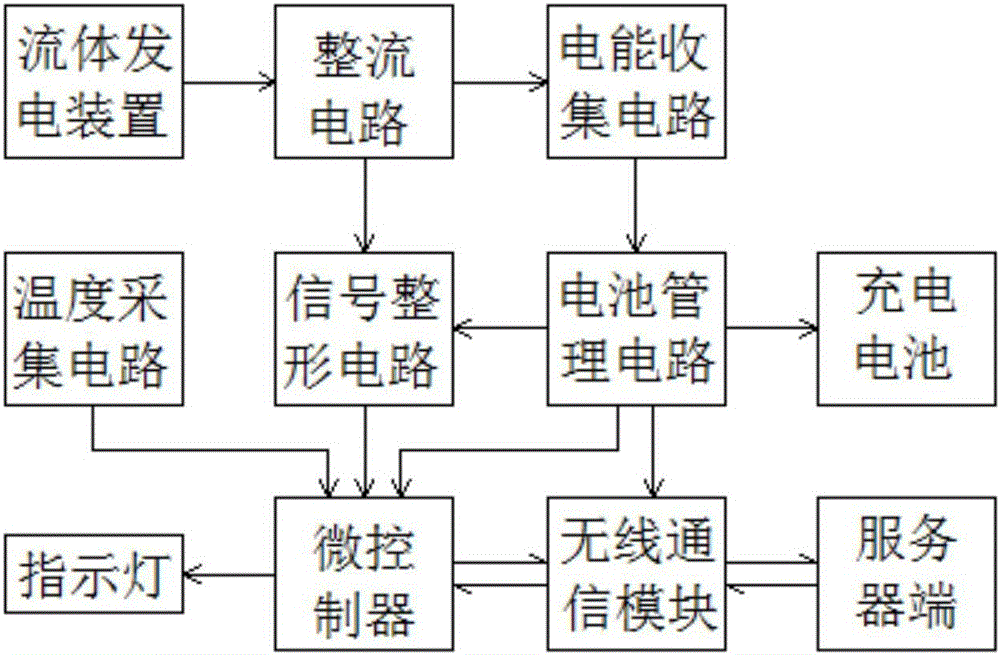

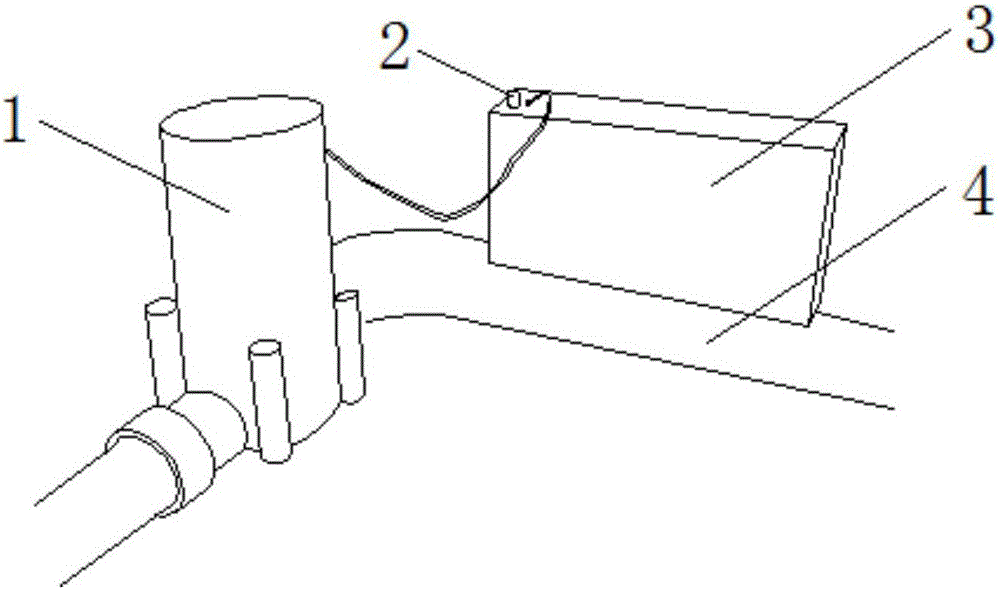

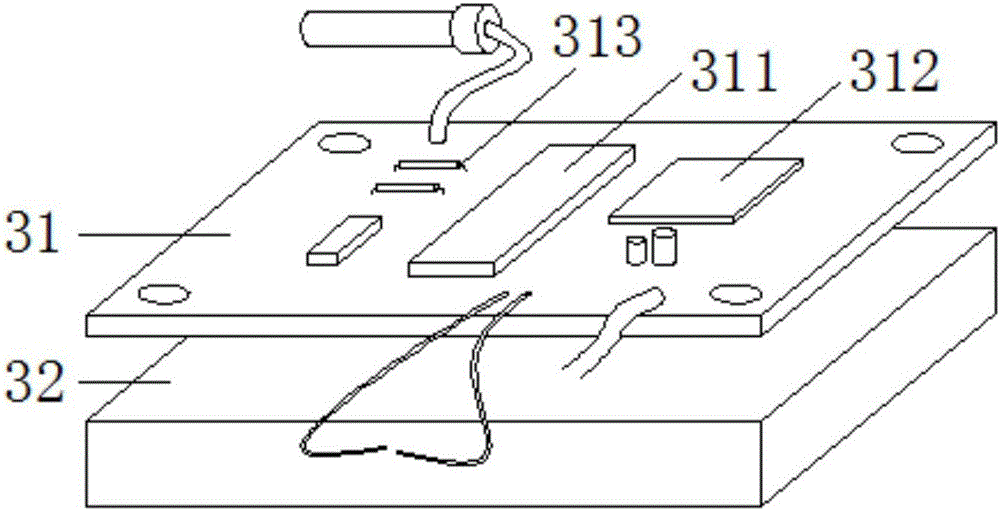

Remote self-powered pipe fluid parameter monitoring terminal

InactiveCN105548605ATimely detection of leaksLeakage is fastBatteries circuit arrangementsMeasurement of fluid loss/gain rateMicrocontrollerControl engineering

The invention discloses a remote self-powered pipe fluid parameter monitoring terminal, and the terminal comprises a fluid power generation device and an energy storage monitoring device. The energy storage monitoring device comprises an intelligent control panel and a rechargeable battery. The intelligent control panel comprises a microcontroller, a wireless communication module, and a composite sensor. The terminal converts fluid energy into electric energy through the fluid power generation device, stores the electric energy in the rechargeable battery, and achieves the technical effects of self-power and energy storage. Through a WIFI module or a GPRS module, the terminal achieves a technical effect of wireless remote transmission. The terminal analyzes the flowing speed of fluid through the microcontroller, collects the temperature and pressure information of the fluid through the composite sensor, achieves a technical effect of monitoring the parameters of pipe fluid, saves a fluid monitoring module, enables the structure to be more simple, is low in cost, and is smaller in size.

Owner:SUZHOU CHUANGBICHENG ELECTRONICS TECH CO LTD

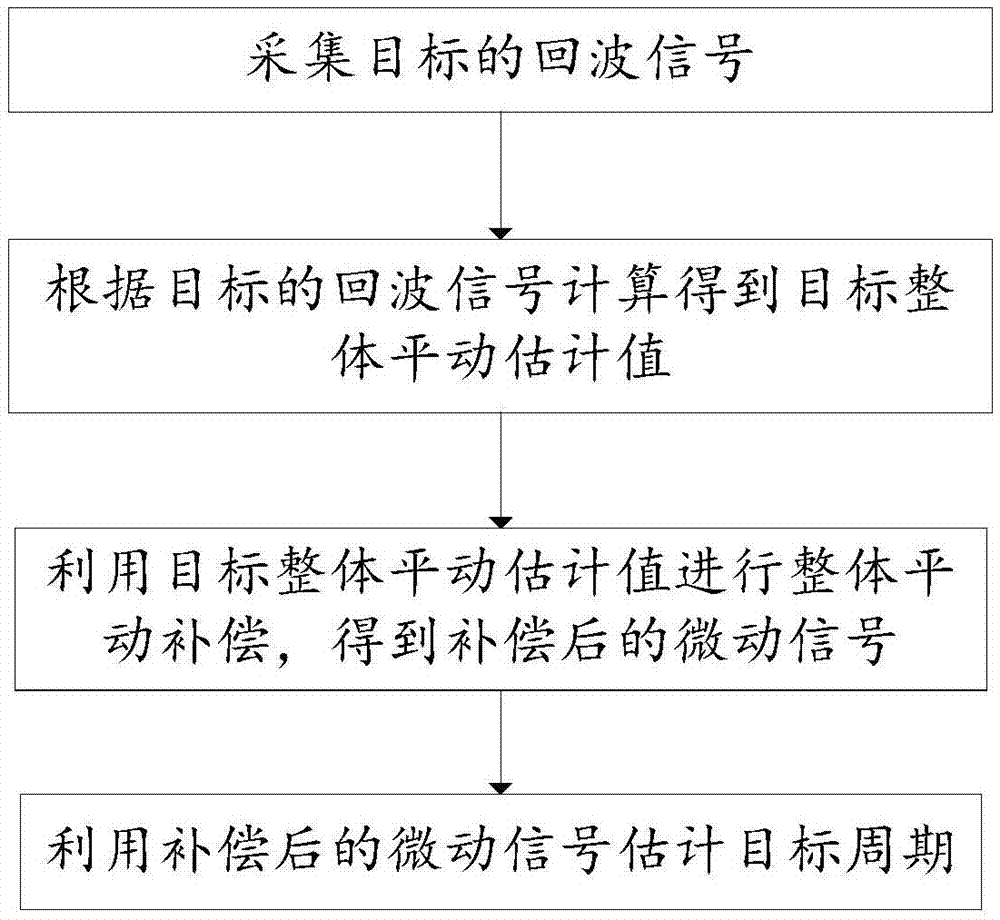

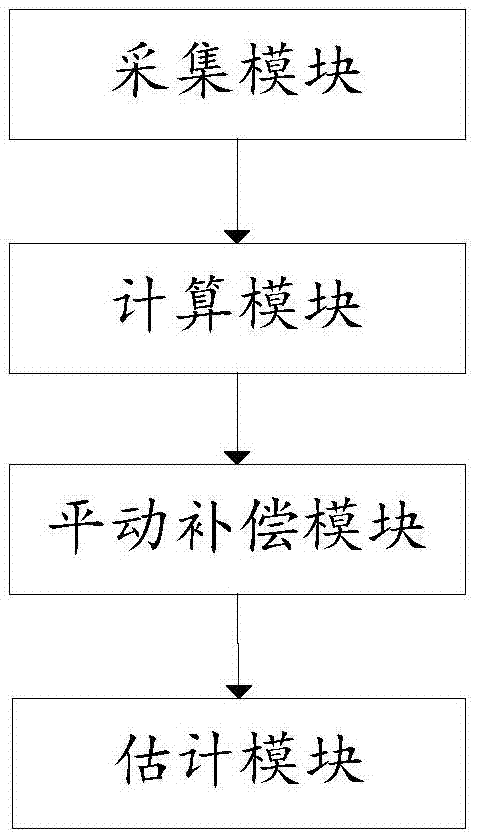

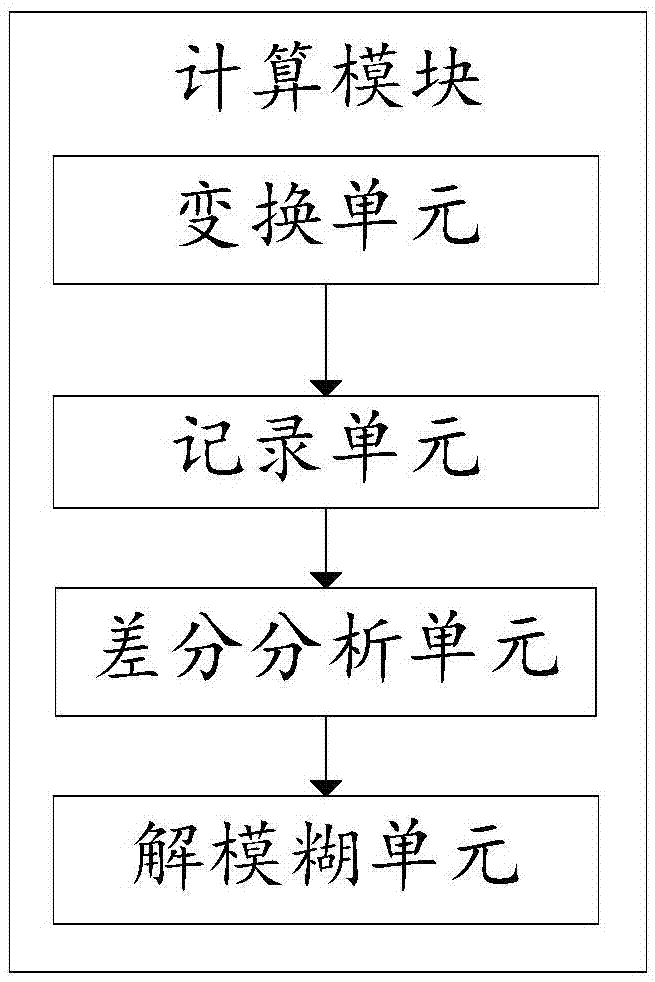

Highly-maneuvering target micro cycle calculation method and highly-maneuvering target micro cycle calculation system

ActiveCN105445713AAccurate and effective target fretting periodAvoid missingWave based measurement systemsAmbiguityComputer science

The invention relates to a highly-maneuvering target micro cycle calculation method and a highly-maneuvering target micro cycle calculation system. The method comprises the following steps: step 1, acquiring an echo signal x of a target, wherein x={x1, x2,..., xi,..., xN}, i=1, 2,..., N, N is the number of pulses accumulated, and xi is the value of the echo signal at the ith point; step 2, calculating the overall translation estimated value of the target according to the echo signal of the target; step 3, using the overall translation estimated value of the target to compensate overall translation to obtain a micro signal after compensation; and step 4, estimating the cycle of the target according to the micro signal after compensation. According to the method of the invention, by processing Doppler ambiguity of the target and compensating the overall translation of the target, the estimated micro cycle of the target is more accurate and effective.

Owner:BEIJING INST OF RADIO MEASUREMENT

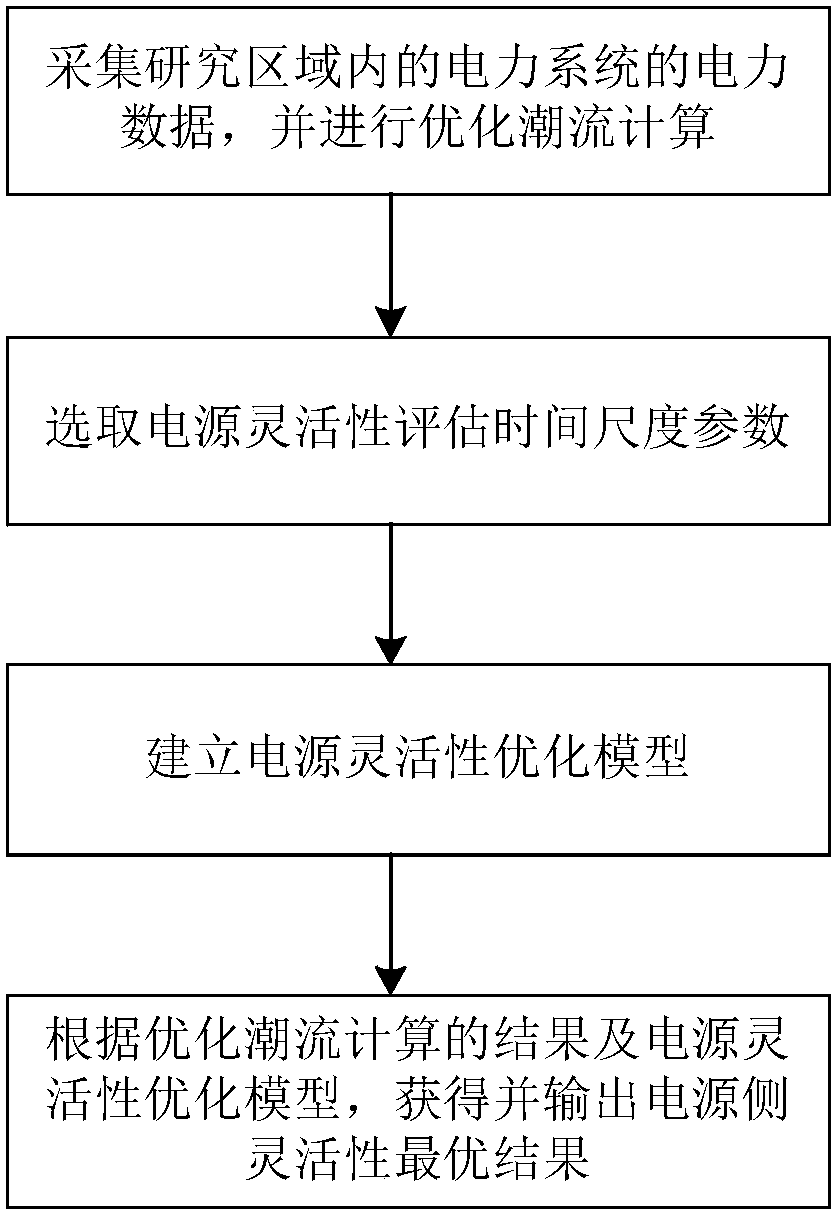

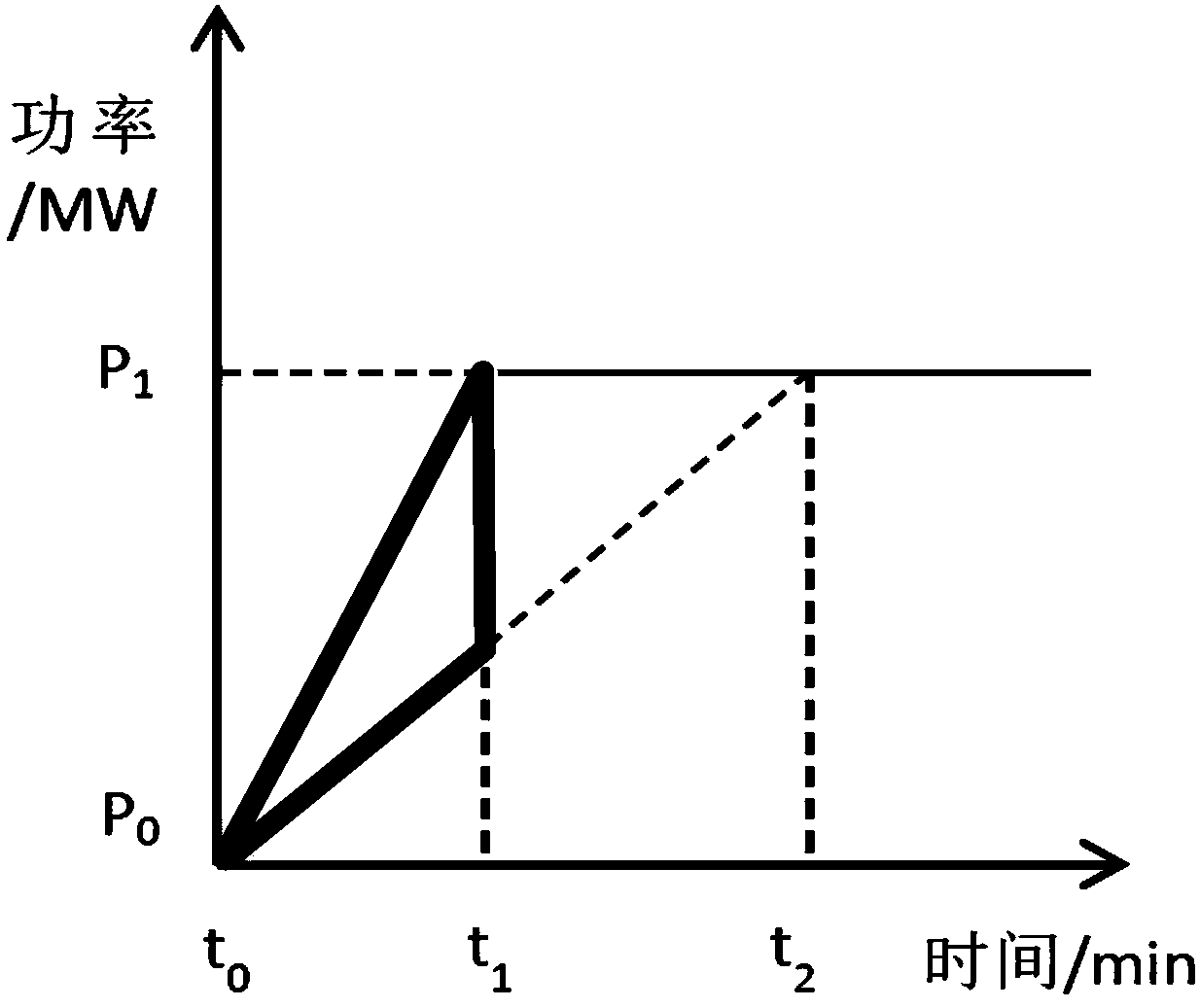

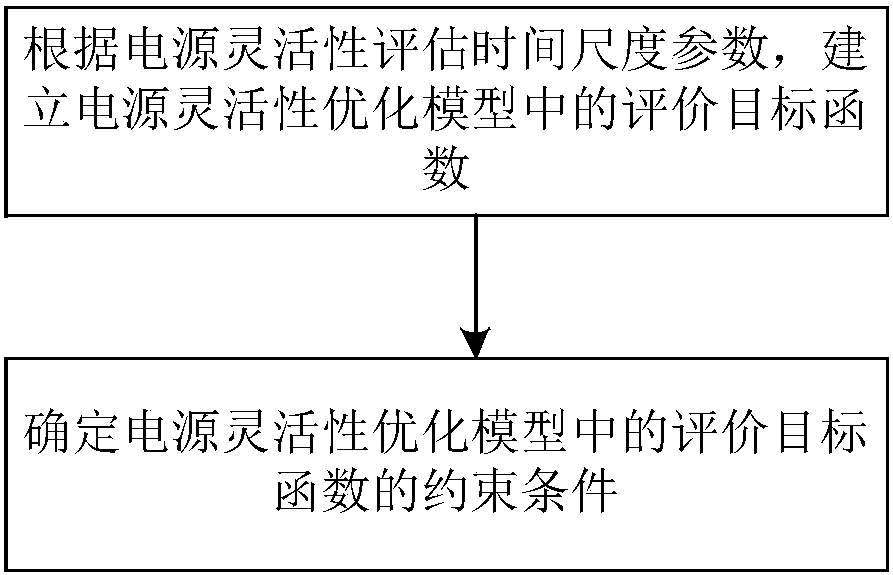

Optimal scheduling method for power system to which renewable energy is accessed

InactiveCN105790301AImprove stabilitySimple methodSingle network parallel feeding arrangementsWind energy generationRenewable energyProcess engineering

The invention provides an optimal scheduling method for a power system to which renewable energy is accessed. Power data of the power system in a research area are acquired, and optimal power flow calculation is carried out; power supply flexibility evaluation time scale parameters are selected; a power supply flexibility optimal model is built; and according to the result of the optimal power flow calculation and the power supply flexibility optimal model, the power supply-side flexibility optimal result is acquired and outputted. According to the method of the invention, acquisition of the optimal combination of the power system power supply flexibility and the operation cost in various conditions is realized, the optimal process is simple and reliable, the optimal result is accurate and effective, an effective theoretical basis is provided for power system operation and scheduling, and the operation stability of the power system is thus improved.

Owner:CHINA ELECTRIC POWER RES INST +3

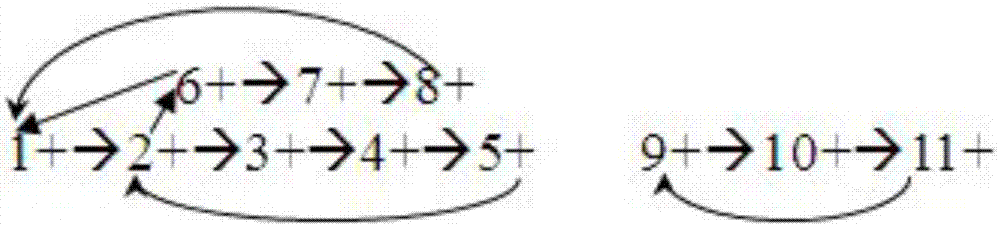

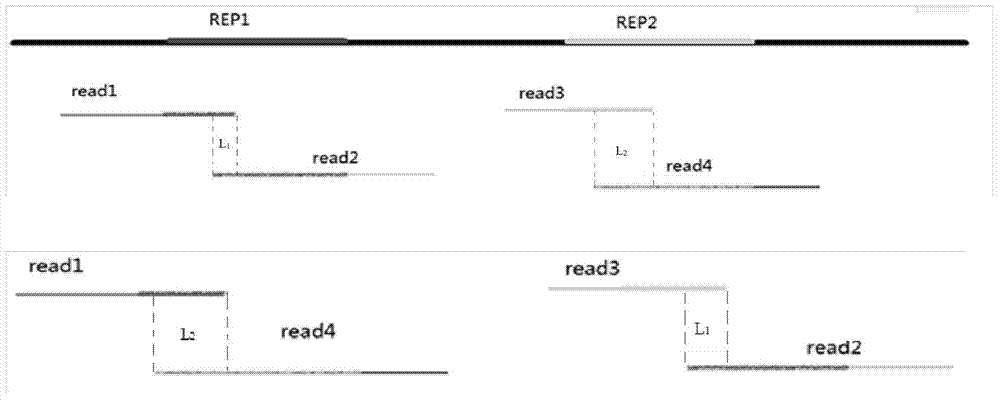

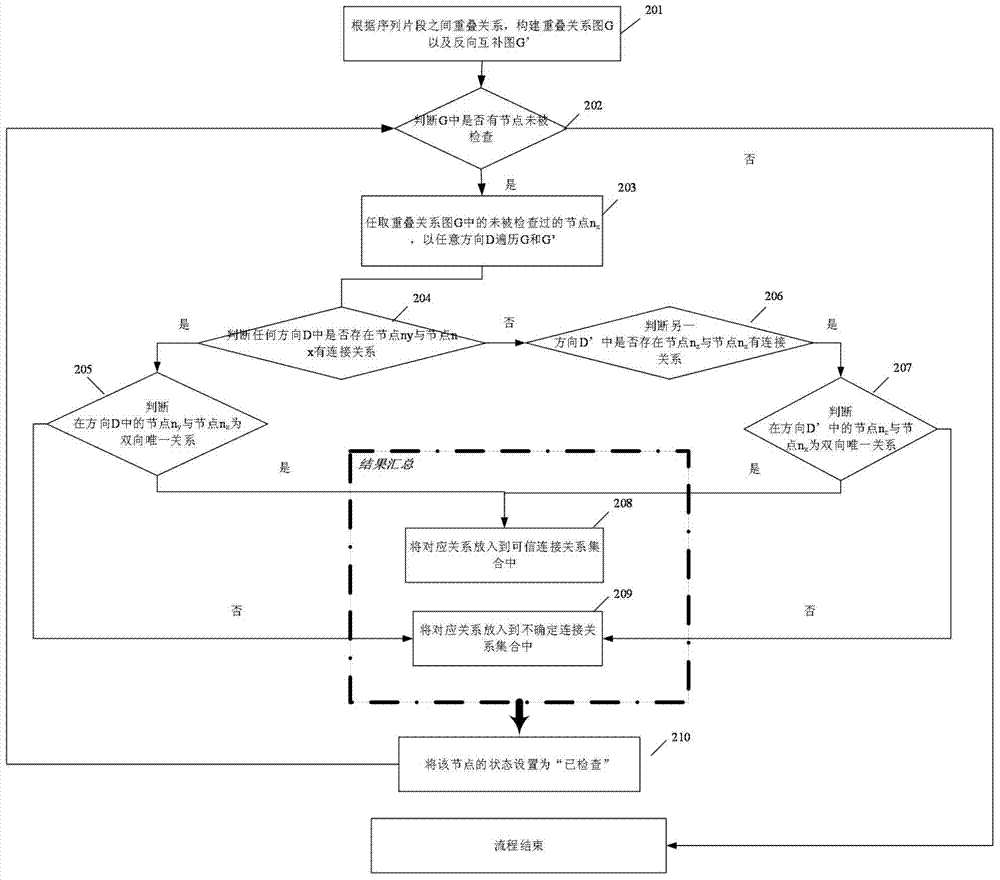

Genome sequencing data sequence assembling method

ActiveCN104750765AThe result is accurate and effectiveSpecial data processing applicationsGenomic sequencingGenetics

The embodiment of the invention provides a genome sequencing data sequence assembling method. By means of the method, the advantages of denovo sequencing and the advantages of re-sequencing can be integrated, and genome sequencing data sequences are effectively assembled. A drafted sequence traversal path of the genome sequencing sequences obtained based on a reference sequence and generated after sequencing data are mapped to the reference sequence in a comparing mode and an overlapping relation set of the genome sequencing data are known. The set comprises a determined relation subset and an undetermined relation subset. The method includes the steps that after the sequencing data sequences are mapped to an affinis reference genome in a comparing mode, the drafted data traversal path of the genome sequencing sequences is obtained based on the reference sequence, all nodes in the drafted sequence traversal path are checked one by one; iterated revision is conducted on the drafted sequence traversal path according to the connection relation of the determined relation subset and / or the undetermined relation subset in the overlapping relation set, and the overlapping relation set is updated; the next node is checked based on the updated drafted sequence traversal path and the updated overlapping relation set till the last node is checked.

Owner:天工生物科技(天津)有限公司

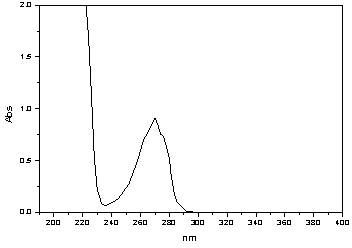

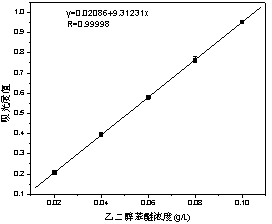

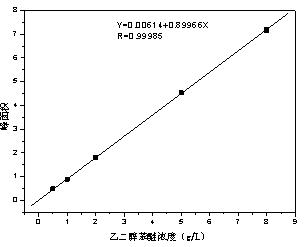

Method for testing content of glycol phenylate

InactiveCN104048932AShort measurement timeThe result is accurate and effectiveColor/spectral properties measurementsUltraviolet spectrophotometryStandard curve

The invention discloses a method for testing the content of glycol phenylate. The method comprises the following steps: preparing glycol phenylate standard solutions of different concentrations, with water as blank control, testing the absorbance values of the standard solutions at the wavelength of 270nm, establishing a coordinate system with the absorbance values and standard concentration as coordinates, drawing a standard curve, testing the absorbance values of the glycol phenylate standard solutions at the wavelength of 270nm, and performing linear regression on the absorbance values by virtue of the standard curve so as to obtain the concentration of the solution to be tested. In such a mode, the method for testing the content of glycol phenylate is to rapidly test the content of glycol phenylate in a solution by an ultraviolet spectrophotometry method. The method is short in testing time, accurate and effective in result, easy to perform, free of expensive experiment instruments or reagents, relatively low in cost and easy to popularize and used in middle and small laboratories.

Owner:SUZHOU COMING CHENGYE MEDICAL TECH

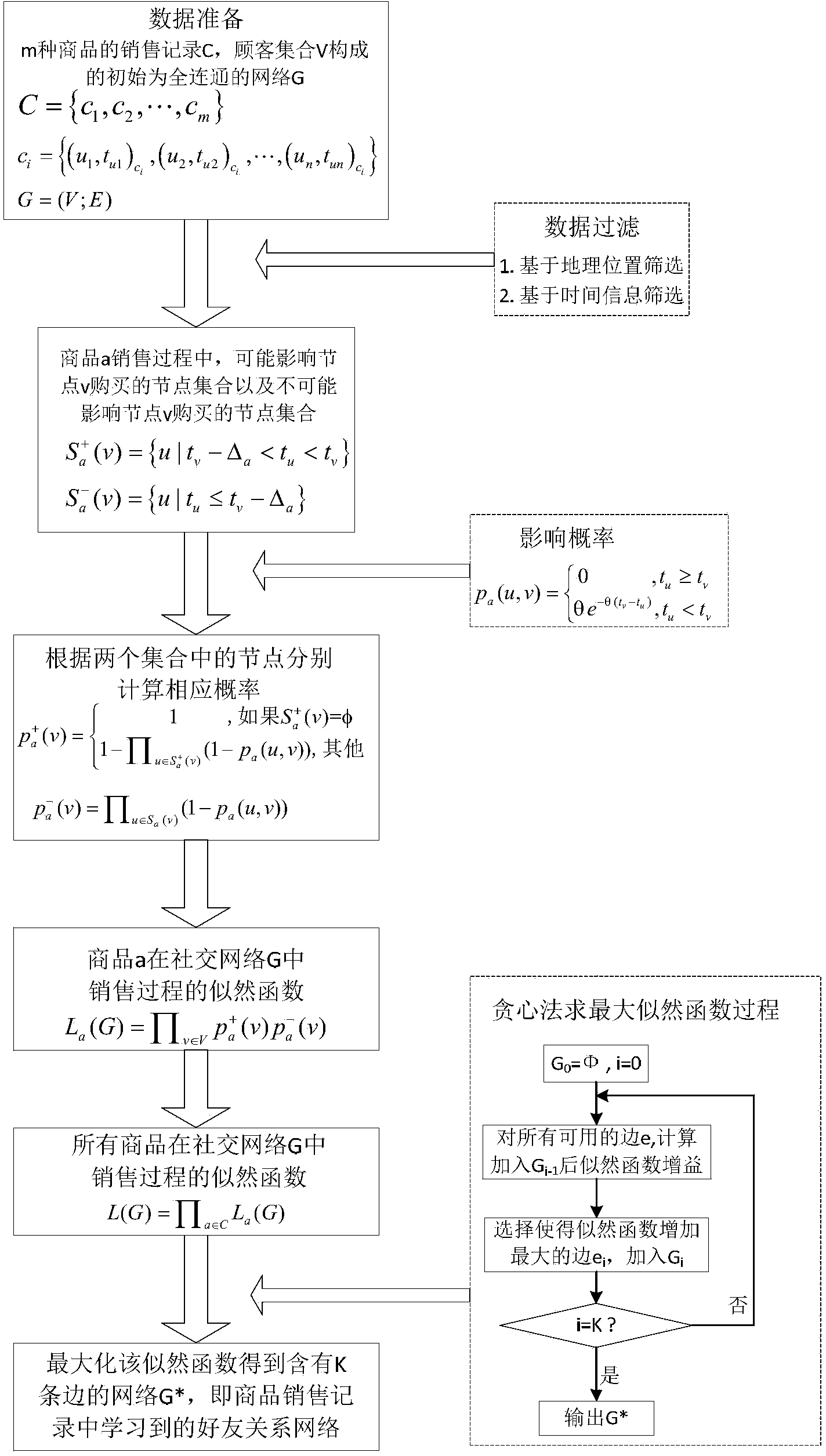

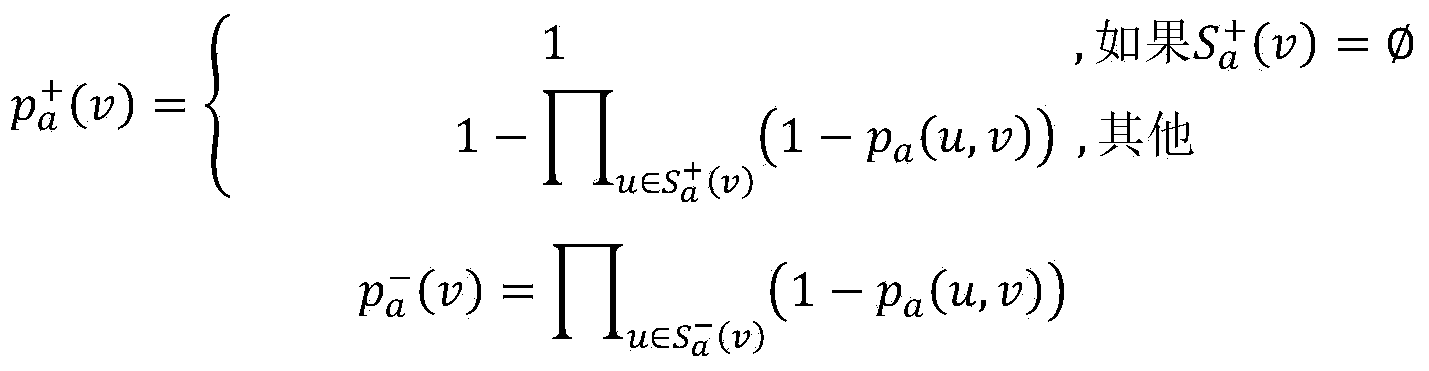

Method for mining friend relationship network of customer in E-commerce website

ActiveCN103761665ASolve the problem of passivityTake advantage ofMarketingSpecial data processing applicationsE-commerceComputer science

The invention discloses a method for mining a friend relationship network of a customer in an E-commerce website. Offline friend relationships of the customer are speculated according to historical sales records of commodities. According to the method for mining the friend relationship network of the customer in the E-commerce website, the offline friend relationship network is mined according to online consumption records of a user, the customer does not need to actively manage friend relationships, and the offline friend relationships are obtained in a mining mode through a system.

Owner:SOUTHEAST UNIV

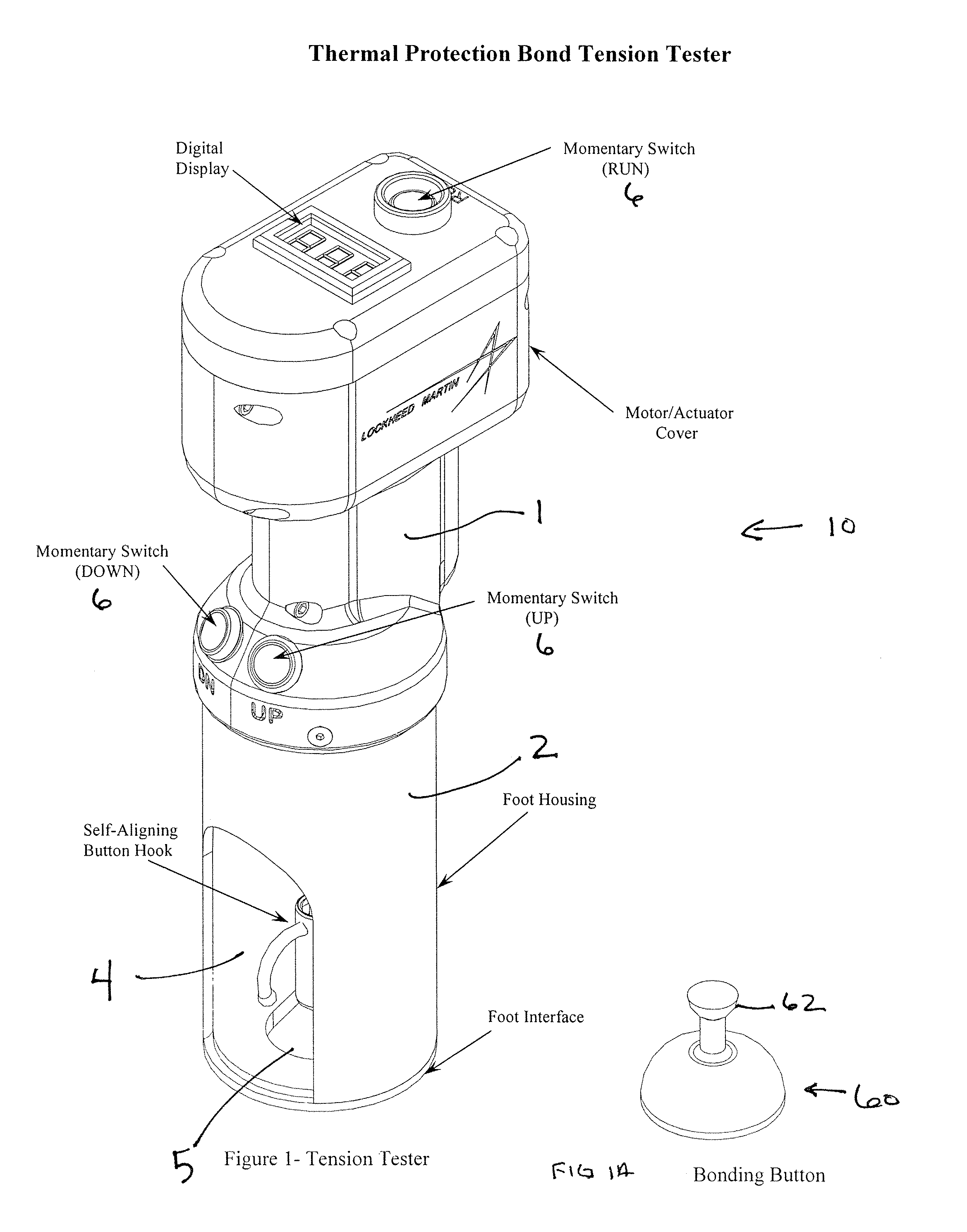

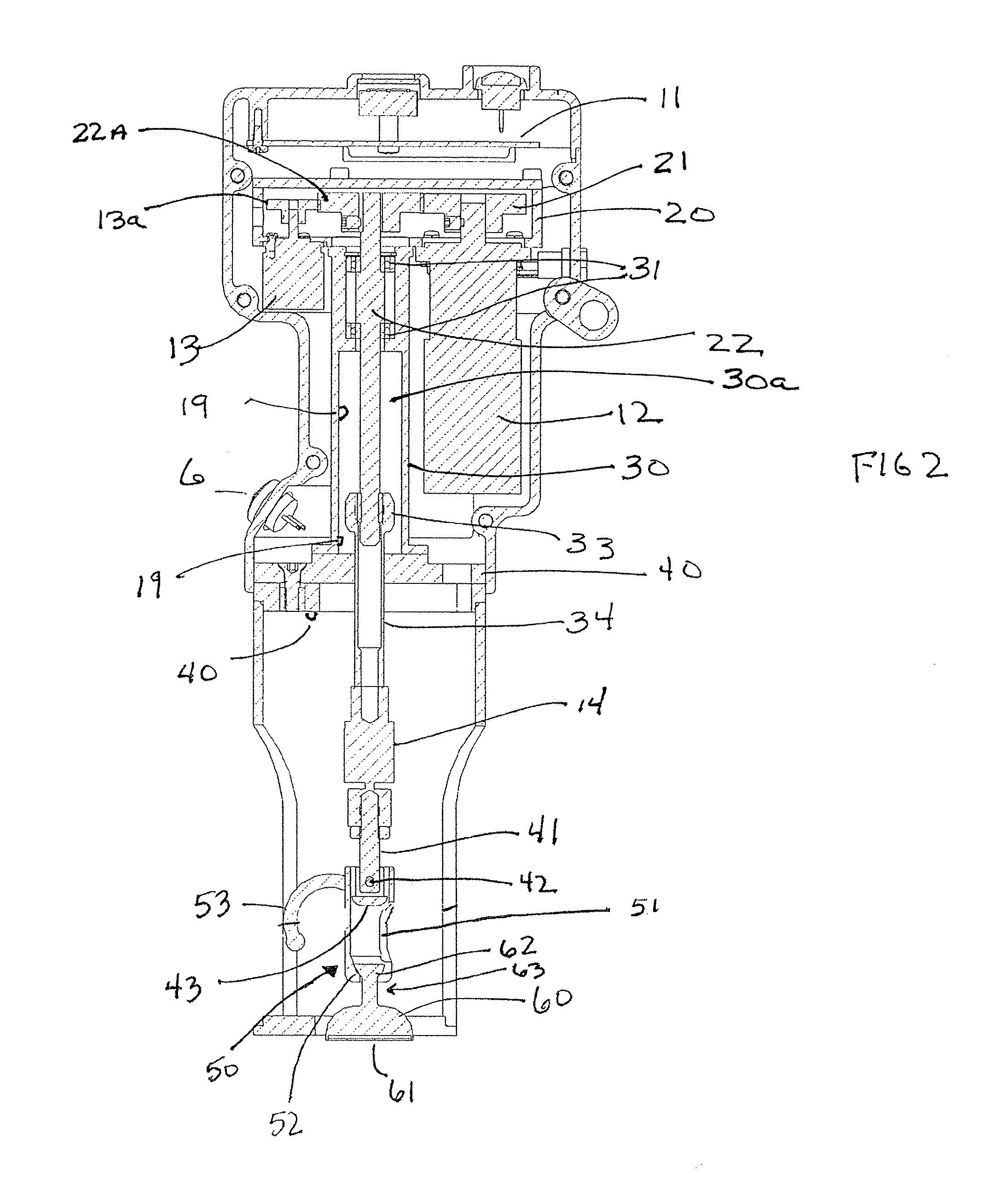

Adhesion testing device

InactiveUS7739918B1Cheap manufacturingEconomical to useMaterial strength using tensile/compressive forcesUsing mechanical meansTest fixtureControl theory

The present invention provides a testing apparatus and method for testing the adhesion of a coating to a surface. The invention also includes an improved testing button or dolly for use with the testing apparatus and a self aligning button hook or dolly interface on the testing apparatus. According to preferred forms, the apparatus and method of the present invention are simple, portable, battery operated rugged, and inexpensive to manufacture and use, are readily adaptable to a wide variety of uses, and provide effective and accurate testing results. The device includes a linear actuator driven by an electric motor coupled to the actuator through a gearbox and a rotatable shaft. The electronics for the device are contained in the head section of the device. At the contact end of the device, is positioned a self aligning button hook, attached below the load cell located on the actuator shaft.

Owner:LOCKHEED MARTIN CORP

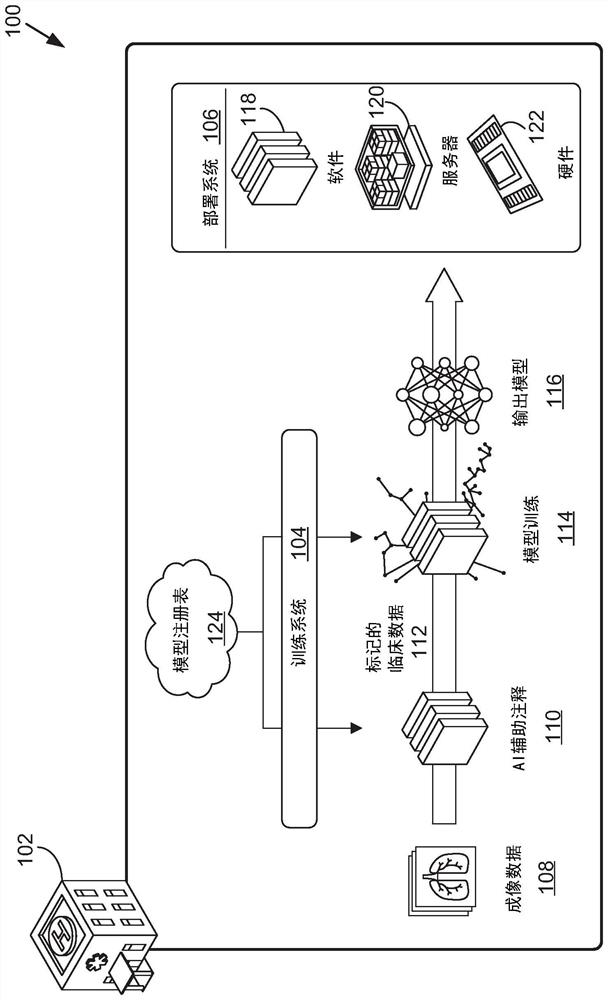

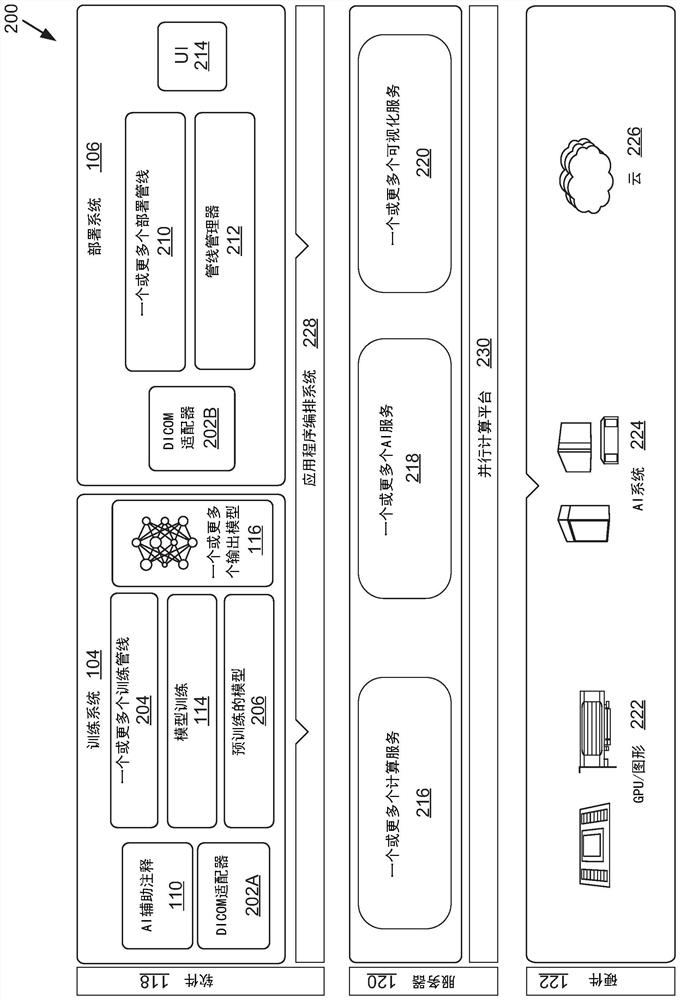

Virtualized computing platform for inferencing, advanced processing, and machine learning applications

PendingCN112771622AIncreased complexityImprove Patient CareImage enhancementImage analysisVirtualizationVisualization

In various examples, a virtualized computing platform for advanced computing operations including image reconstruction, segmentation, processing, analysis, visualization, and deep learning may be provided. The platform may allow for inference pipeline customization by selecting, organizing, and adapting constructs of task containers for local, on-premises implementation. Within the task containers, machine learning models generated off-premises may be leveraged and updated for location specific implementation to perform image processing operations. As a result, and by using the virtualized computing platform, facilities such as hospitals and clinics may more seamlessly train, deploy, and integrate machine learning models within a production environment for providing informative and actionable medical information to practitioners.

Owner:NVIDIA CORP

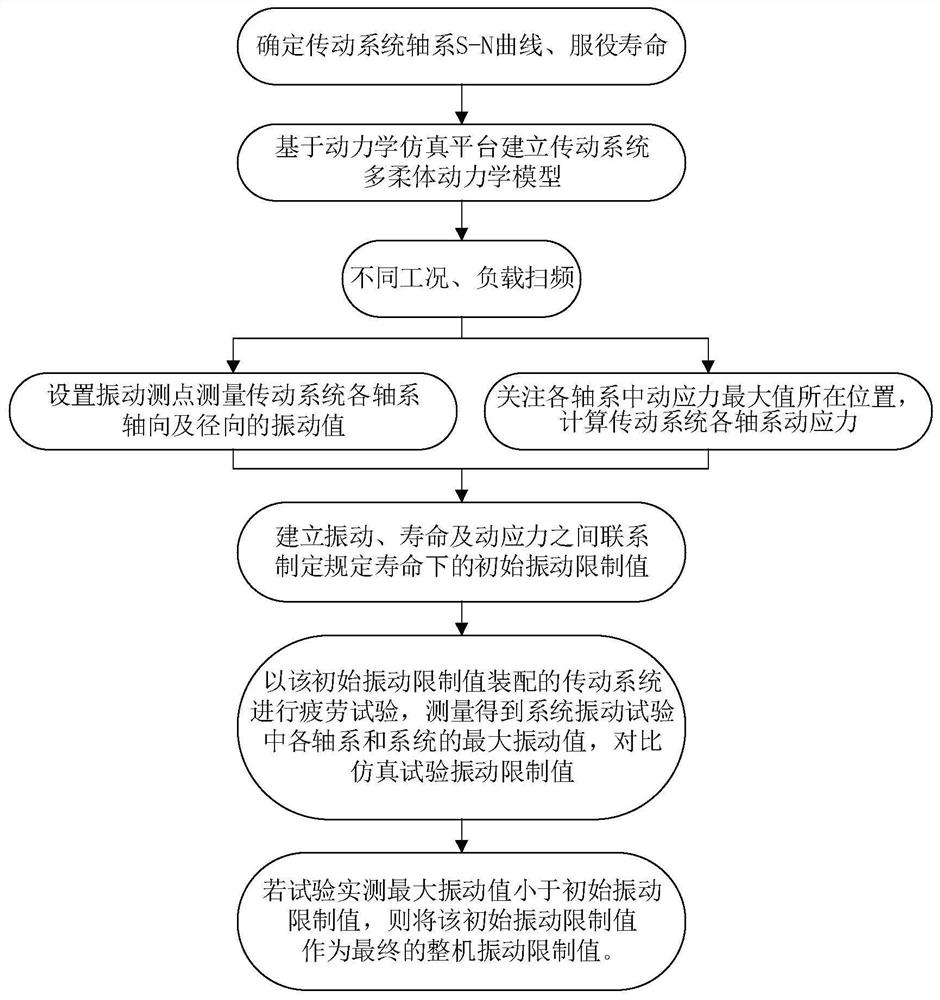

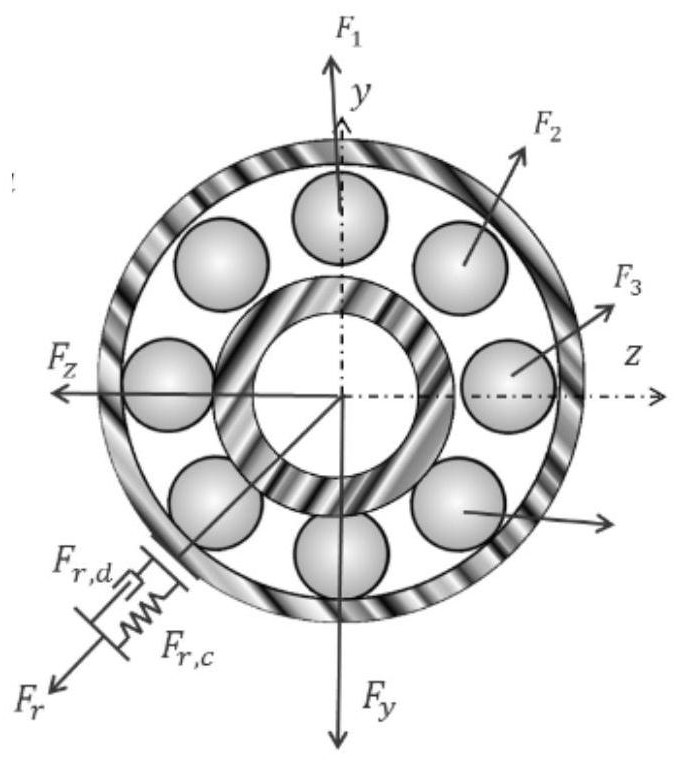

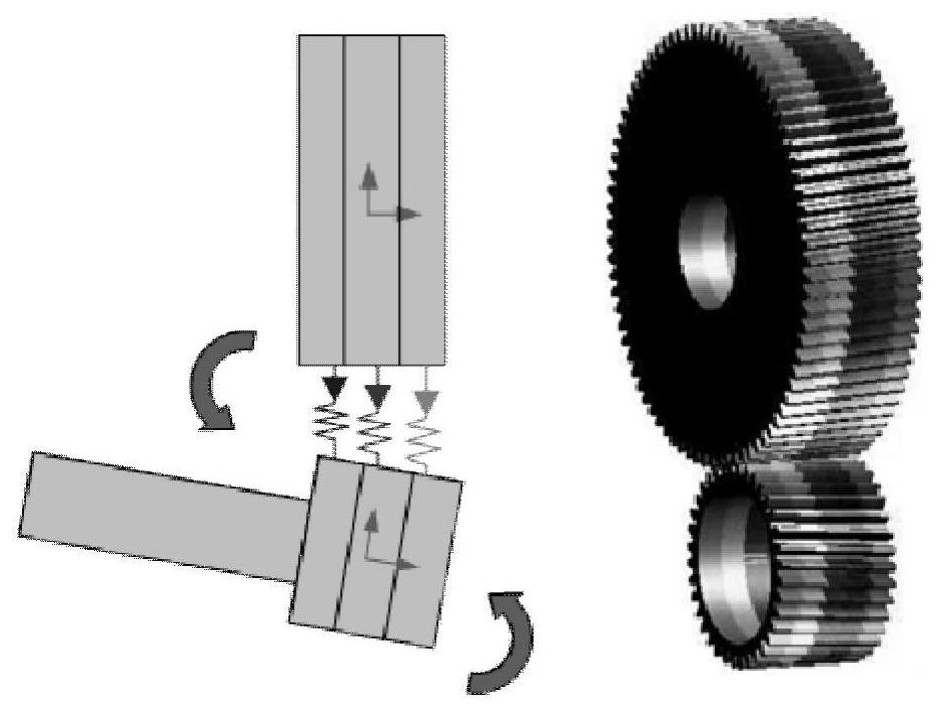

Method for formulating vibration limit value of aeronautical transmission system

ActiveCN113221261AThe result is accurateIn line with the actual operating conditionsGeometric CADSustainable transportationAviationDynamic models

The invention discloses a method for formulating a vibration limit value of an aeronautical transmission system. The method comprises the following steps: 1) determining a life value of the aeronautical transmission system and an S-N curve of a material; 2) establishing a multi-flexible dynamic model of the aeronautical transmission system; 3) measuring vibration values of each shafting of the aeronautical transmission system under different working conditions and load conditions, and calculating dynamic stress and load of each shafting of the aeronautical transmission system along with time history; 4) compiling a load spectrum based on the load of each shafting of the aeronautical transmission system along with the time history; 5) calculating the service life of each shafting of the aeronautical transmission system under different working conditions and load conditions; 6) establishing a coupling relation between the vibration values and the service life of each shafting of the aeronautical transmission system under different working conditions and load conditions. According to the method for formulating the limit value through combination of simulation and tests, a large number of tests are avoided, and the cost of time, manpower, material resources and the like is saved.

Owner:CHONGQING UNIV +1

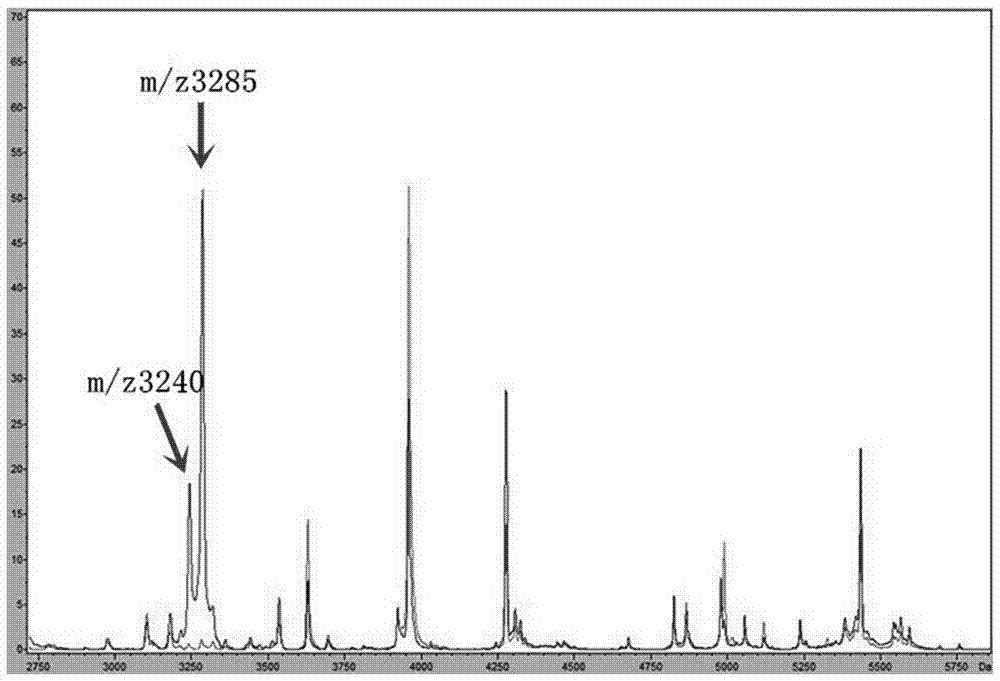

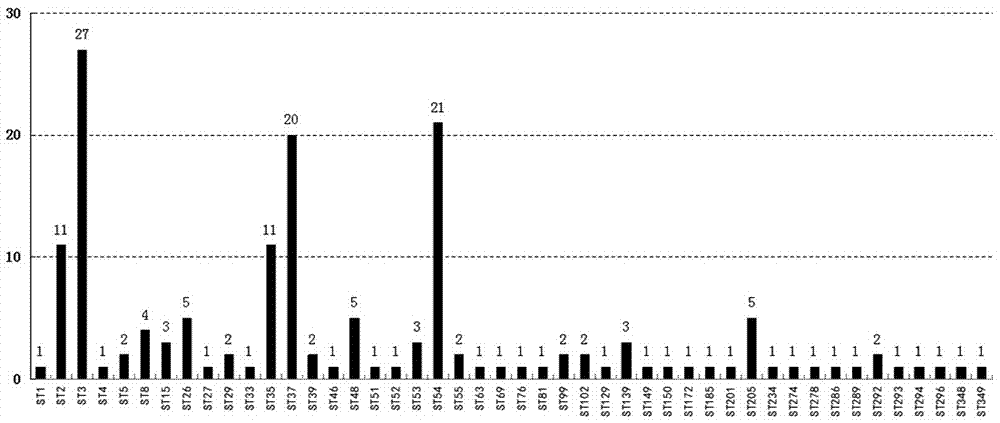

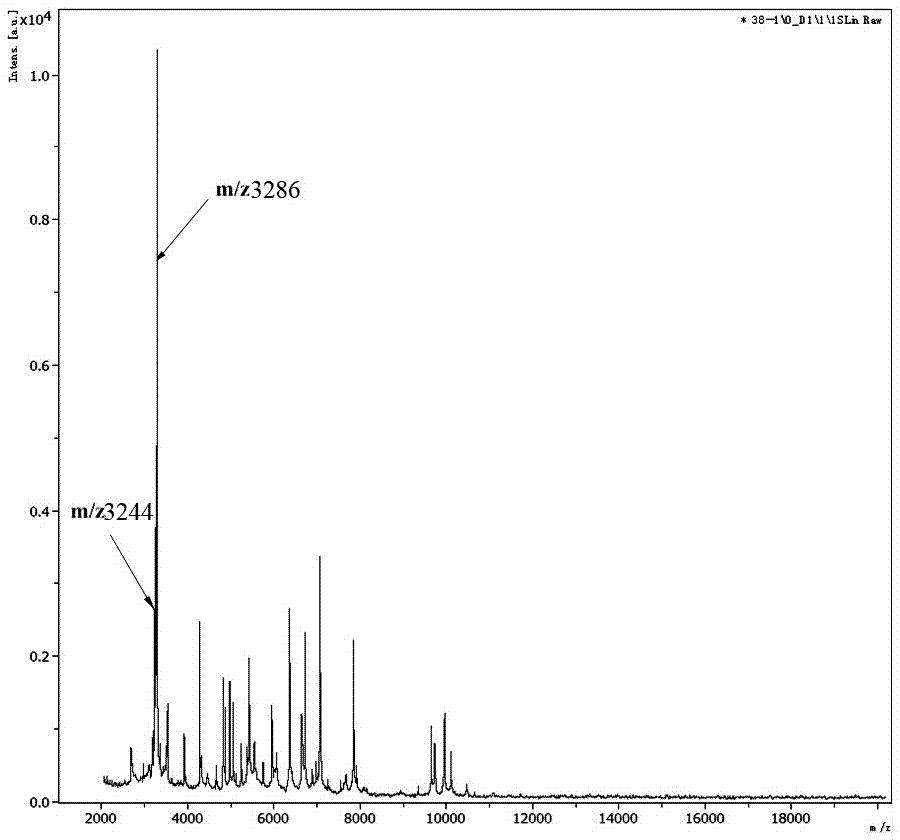

Identification method of ST37 type clostridium difficile and unit point variation type ST81 thereof

InactiveCN107202834ARapid diagnosisTimely clinical medication guidanceMaterial analysis by electric/magnetic meansDiseaseClostridium difficile toxin B

The invention provides an identification method of ST37 type clostridium difficile and unit point variation type ST81 thereof. The identification method comprises the following steps: protein in a clostridium difficile strain to be identified is extracted to obtain a mass spectrometric text sample; and mass spectrometric detection equipment is utilized to detect the sample, and strains with specific protein peaks at m / z 3235-3245 and m / z 3280-3290 in an obtained mass spectrogram are the ST37 type clostridium difficile or the unit point variation type ST81 thereof. The invention establishes an MALDI-TOF MS-based rapid identification method of the ST37 type clostridium difficile and the unit point variation type ST81 thereof for the first time. The method has the characteristics of real time and rapidness, can screen the ST37 type clostridium difficile and the unit point variation type ST81 thereof in real time while identifying the strains, only needs to add 1min for the detection process of ST37 or ST81 type on the basis of strain identification without other special instruments or equipment or additional operation steps and has important significance on rapidly diagnosing diseases and timely providing clinical medication guidance.

Owner:THE SECOND HOSPITAL OF HEBEI MEDICAL UNIV

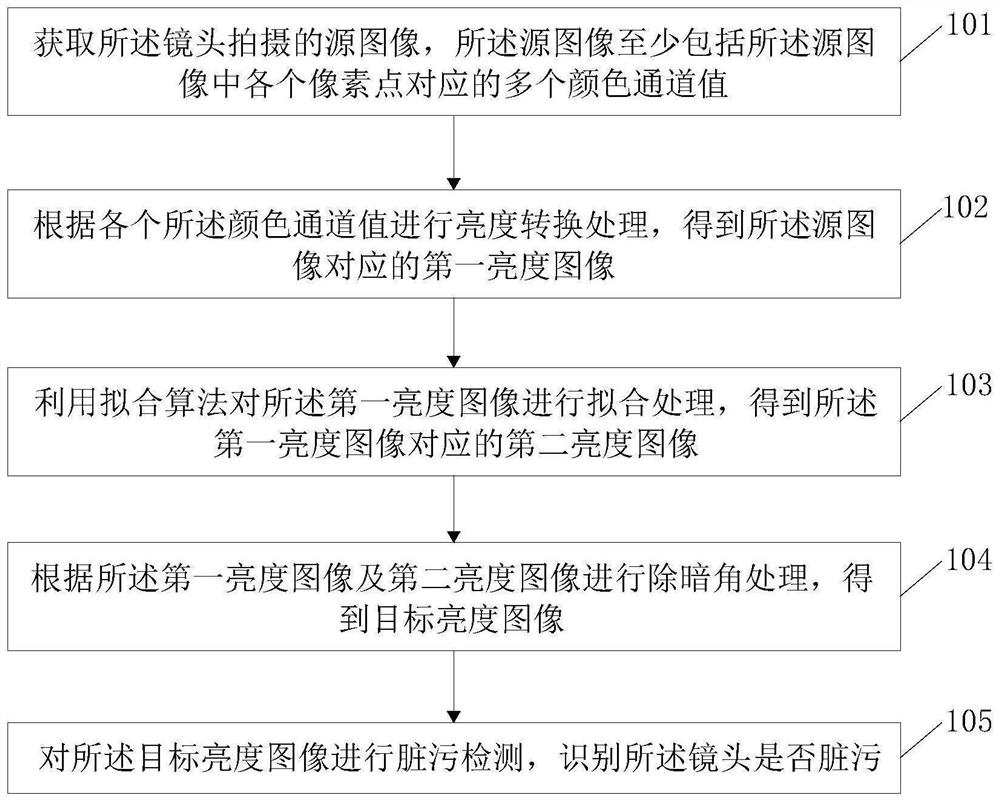

Lens dirt identification method and device, computer equipment and storage medium

PendingCN114359414AThe result is accurate and effectiveImage enhancementImage analysisVignettingRadiology

The embodiment of the invention discloses a lens smudginess identification method and device, computer equipment and a storage medium, and the method comprises the steps: obtaining a source image shot by a lens, the source image at least comprising a plurality of color channel values corresponding to each pixel point in the source image; performing brightness conversion processing according to each color channel value to obtain a first brightness image corresponding to the source image; performing fitting processing on the first brightness image by using a fitting algorithm to obtain a second brightness image corresponding to the first brightness image; performing dark corner removal processing according to the first brightness image and the second brightness image to obtain a target brightness image; and carrying out smudginess detection on the target brightness image, and identifying whether the lens is smudginess. According to the method, the target brightness image without the vignetting is obtained by using the first brightness image subjected to brightness conversion and the second brightness image subjected to fitting, and whether the lens is dirty or not is identified on the premise of removing the vignetting, so that the result is more accurate and effective.

Owner:AAC OPTICS(NANNING)TECH LTD

Synthetic method of test object for determining astragaloside content in radix astragali medicinal material

InactiveCN104458363AReduce contentThe result is accurate and effectivePreparing sample for investigationMedicinal herbsAstragaloside

A synthetic method of a test object for determining astragaloside content in a radix astragali medicinal material belongs to the technical field of traditional Chinese medicine component determination, and in particular, the invention relates to a synthetic method of a test object for determining astragaloside content in a radix astragali medicinal material. The invention provides a preparation method of a control solution for determining stilbene content in chinaroot greenbrier. The method of the invention comprises: taking about 1 g of radix astragali medicinal material medium powder, weighing precisely, putting the medium powder in a conical flask with a plug, adding 5-10 mL of an ammonia test solution, shaking for complete wetting, adding 50-100 mL of n-butanol, sealing with the plug, performing ultrasonic treatment at a power of 600 W and a frequency of 33 kHz for 15 min, allowing the solution to stand for layering, pouring out the n-butanol liquid in the upper layer, adding 50 mL of n-butanol into the lower layer, treating the solution once in the same manner, combining the two n-butanol liquids, filtering, washing the filtrate with water twice, 30 mL of water each time, discarding the water, evaporating the n-butanol liquid, dissolving the residue with methanol, and adding methanol to obtain a volume of 10 mL, so as to obtain the test object solution.

Owner:李月梅

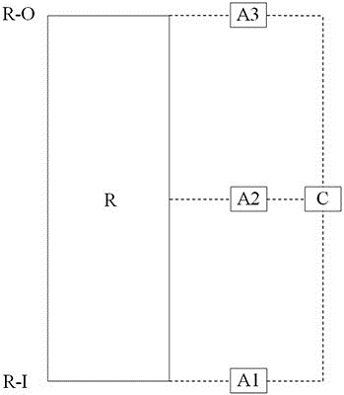

Non-contact medical partition access control system and method

ActiveCN112381986AGuarantee the safety of useReduce infectionClosed circuit television systemsIndividual entry/exit registersComputer hardwareIdentity recognition

The invention relates to a non-contact medical partition access control system, which comprises a temporary storage channel, wherein a first identification module is arranged at the inlet position ofthe temporary storage channel, a second identification module is arranged in the temporary storage channel, a third identification module is arranged at the outlet position of the temporary storage channel, and the first identification module, the second identification module and the third identification module are respectively connected with a main controller. The invention provides a non-contactmedical partition access control system and method, wherein on the premise that no physical contact with a user exists, identity recognition and confirmation are conducted on the user, the user is disinfected after air showering, and then the user is allowed to enter, so that in a non-contact environment, even if the user wears the protective clothing, identity recognition and people number confirmation and disinfection can be realized, the infection possibility is effectively reduced, the use safety of the user is ensured, and recognition is convenient and accurate.

Owner:NANJING GENERAL HOSPITAL NANJING MILLITARY COMMAND P L A

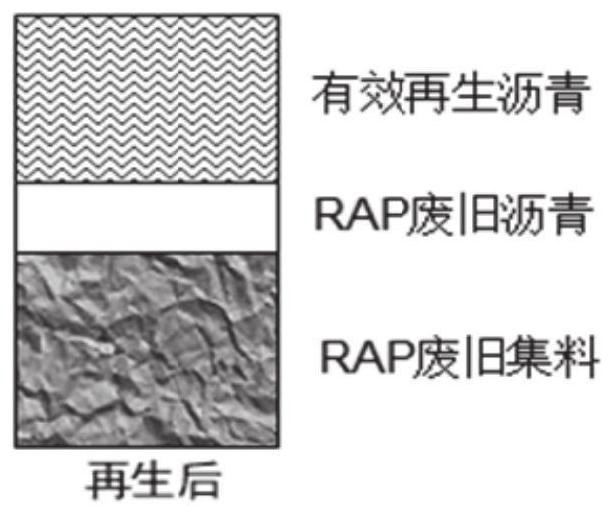

Method for quantifying new-old asphalt interface fusion degree based on performance of asphalt mixture

ActiveCN111739592AEffective control of construction qualityControl construction qualityChemical property predictionIn situ pavingsStructural engineeringAsphalt

The invention discloses a method for quantifying the new-old asphalt interface fusion degree based on the performance of an asphalt mixture. The method comprises the steps of pretreating RAP, and determining synthesis design gradation and the optimal asphalt consumption; screening conventional performance indexes capable of being used for quantitatively calculating the new-old asphalt interface fusion degree DOB, and determining the change relationship of the performance indexes along with the asphalt consumption; determining performance index test results P1, P2 and P3 of the concrete sampleand effective asphalt contents x1, x2 and x3 in a black stone state, an actual regeneration state and a 100% complete fusion state of a new-old asphalt interface; and calculating to obtain the new-oldasphalt interface fusion degree in the actual regeneration state according to the effective asphalt content proportion relationship in different states. According to the method, high-end instrumentsand equipment are not needed, the new-old asphalt interface fusion degree DOB of the recycled mixture can be obtained through a mix proportion design process in a simple and crude engineering field laboratory, and engineering field construction personnel can conveniently judge the RAP regeneration performance in time.

Owner:SHANDONG JIAOTONG UNIV

Method of identifying neonatal calf serum quality

ActiveCN105572208AReduce the amount of introductionQuality assuranceMaterial analysis by electric/magnetic meansColor/spectral properties measurementsElectrophoresisLipid content

The invention provides a method of identifying neonatal calf serum quality, comprising the following steps: full inspecting qualification of a sample to be identified, dependent on the methods in Chinese Pharmacopeia III appendix; detecting total protein content of the sample to be identified, dependent on 'Lowry process' in 'protein determination' from Chinese Pharmacopeia III appendix; subjecting the sample to be identified to non-reducing electrophoretic detection dependent on 'SDS-polyacrylamide gel electrophoresis' in 'electrophoresis' from Chinese Pharmacopeia III appendix, quantitatively scanning and analyzing electrophoresis results, and calculating albumin content of the sample to be identified; measuring lipid content of the sample to be identified by using vanillin development process, wherein the measured total protein content is 4.0-4.5 g / 100ml, the result for quantitative scanning of albumin is 1.0-1., and the sample to be identified, having a lipid content of 5.5-6.5 mg / ml is qualified neonatal calf serum. The invention enables quick and effective screening of high-quality neonatal calf serum and solves the problem that an existing screening method is time consuming and labor consuming.

Owner:华北制药金坦生物技术股份有限公司

Cluster type electrical potential safety hazard pre-judgment method based on artificial neural network

InactiveCN110097259ARealize the early warning effectProtect life and property safetyNeural architecturesResourcesNerve networkCalculation error

The invention relates to a cluster type electrical potential safety hazard pre-judgment method based on an artificial neural network. The method comprises steps of collecting monitoring data of the electrical safety monitoring points as training data; preprocessing to obtain sample training data, using electrical safety monitoring points as neurons of the artificial neural network; inputting the preprocessed sample training data into an artificial neural network to obtain an expected output vector and the actual output of the current artificial neural network, calculating the partial derivative of an error function to each neuron of an output layer, correcting a connection weight and a threshold value by using the partial derivative and the output of the neuron of an input layer, and judging whether to continue iteration or not by using a global error; and after training is completed, judging whether electrical potential safety hazards exist or not according to real-time acquired data.On the basis of relevance of an existing power grid, the electrical safety early warning effect under a cluster type monitoring mode is achieved, along with increase of the sample size and the self-learning time, the pre-judgment result and early warning are more accurate and effective, electrical safety hidden dangers are found out as soon as possible, and the life and property safety of peopleis effectively protected.

Owner:杭州拓深科技有限公司

Short-range self-powered monitor for pipe fluid information

InactiveCN105674064ATimely detection of leaksLeakage is fastBatteries circuit arrangementsHydro energy generationMicrocontrollerControl engineering

The invention discloses a short-range self-powered monitor for pipe fluid information. The short-range self-powered monitor comprises a fluid power generation device and an energy storage monitoring device. The energy storage monitoring device comprises an intelligent control panel and a rechargeable battery. The intelligent control panel comprises a microcontroller, a wireless communication module and a temperature collecting circuit. Fluid energy is converted into electric energy through the fluid power generation device to be stored in the rechargeable battery, and the technical effects of self powering and energy storage are achieved. The technical effect of wireless short-range transmission is achieved through a ZigBee module or an NRF module or a Bluetooth module or an infrared module. The fluid information is analyzed through the microcontroller, fluid temperature information is collected through a temperature sensor, and therefore the technical effect of monitoring the pipe fluid information is achieved. A fluid monitoring module is omitted, so that the structure is simpler, cost is low, and the size is smaller.

Owner:SUZHOU CHUANGBICHENG ELECTRONICS TECH CO LTD

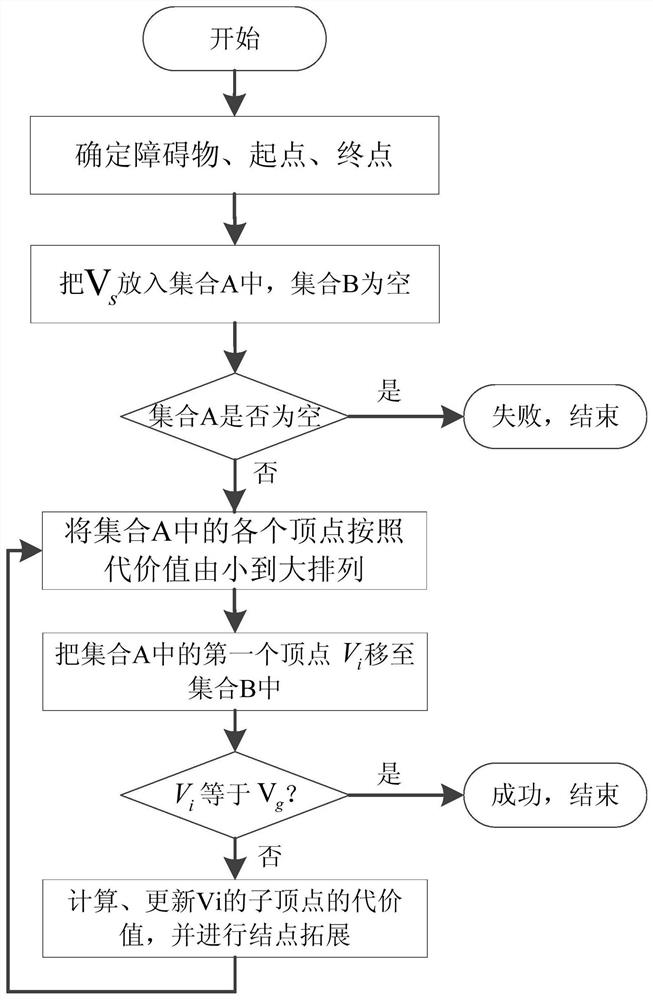

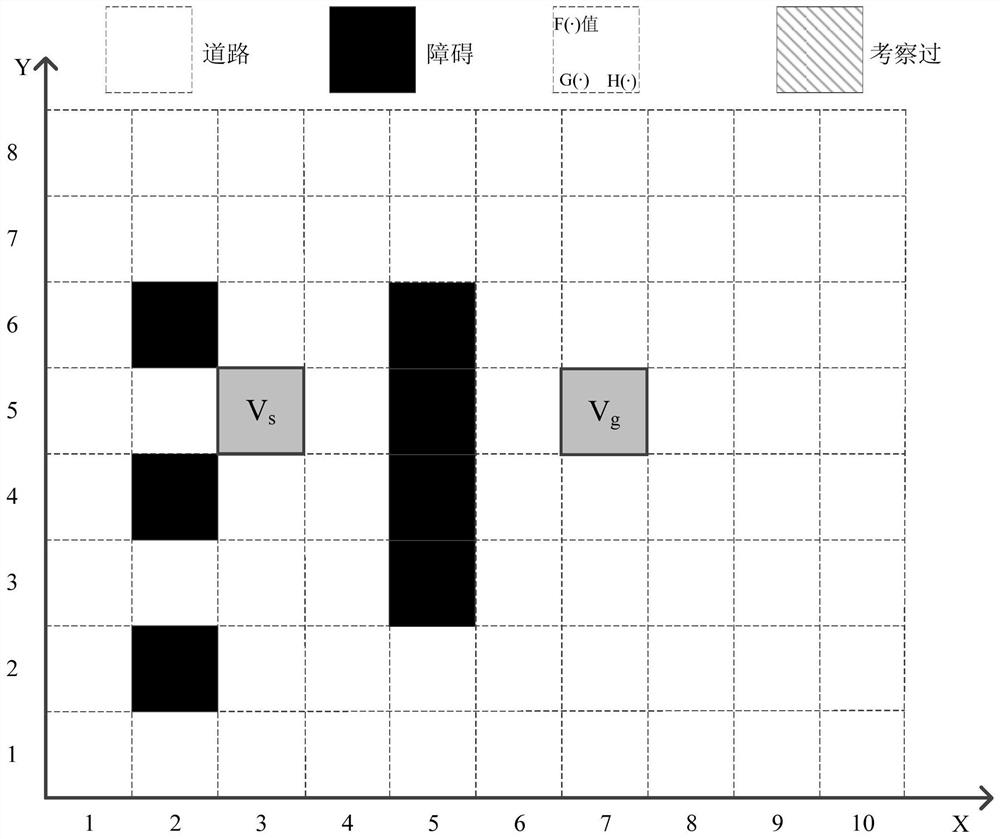

Parking Space Navigation Method Based on A-Star Algorithm

ActiveCN109859525BReduce computational complexityQuick navigationNavigational calculation instrumentsIndication of parksing free spacesAlgorithmParking space

The invention provides a parking space navigation method based on an A star algorithm, and belongs to the technical field of management of parking spaces. The parking space navigation method providedby the invention comprises the steps of: dividing a parking lot into grids, and regarding each grid as one vertex; placing an origin into a set A, and emptying a set B; then carrying out ascending sorting on each vertex in the set A according to cost values, and placing a first vertex Vi into the set B; judging whether the first vertex Vi is an end point, and if yes, ending navigation; if no, expanding a son vertex Vj of the first vertex Vi; if the son vertex Vj does not exist in both the sets A and B, placing the son vertex Vj into the set A and enabling a pointer to point to a parent vertexVi of the son vertex Vj; if the son vertex Vj exists in the set A, updating a cost value of the son vertex Vj in the set A, and enabling the pointer to point to the parent vertex Vi; if the son vertexVj exists in the set B, not considering the vertex; and repeating the operation until the navigation is ended. The invention solves a problem that by an existing parking space navigation method, theshortest path cannot be rapidly and effectively found. The parking space navigation method provided by the invention can be used for management of the parking spaces.

Owner:HARBIN INST OF TECH +1

Data Fitting Method of Multidimensional Force Sensor Calibration Experiment Based on Genetic Algorithm

ActiveCN105651457BOvercome the defect that fitting is easy to fall into local optimumOvercome the defect that it is easy to fall into local optimumGenetic modelsForce/torque/work measurement apparatus calibration/testingMATLABMulti dimensional

Owner:SOUTHEAST UNIV

A kind of method that utilizes vulcanizer to detect heat stabilizer

ActiveCN110160969BValid Stability TestThe result is accurate and effectivePreparing sample for investigationTransmissivity measurementsThermodynamicsMetal sheet

The invention relates to a method for detecting a heat stabilizer by using a vulcanizer. Cut a hollow groove with the same shape and size on the metal sheet to obtain a mold, take two metal splints, turn on the flat vulcanizer to preheat; weigh the PVC resin powder, heat stabilizer and auxiliary materials according to the formula requirements of the tested product, and mix at high speed. Stir in the machine to get the premix, then put the premix in the two-roller machine, take out and cool to get the PVC sheet; lay the mold flat on the metal splint, cut the PVC sheet and put it into the cavity of the mold, and put it in the mold. Put another metal plate on top, and then put them together in the vulcanizing machine. After the time is reached, take out the mold, cool the PVC sheet naturally, and observe the color change, surface condition and transparency; compare and test 1-10 heat stabilizers at different times thermal stability, surface condition and transparency. The invention provides a method for detecting a heat stabilizer by using a vulcanizer, which has the advantages of accurate and effective results, low cost, simple operation and wide application.

Owner:台州联成新材料有限公司

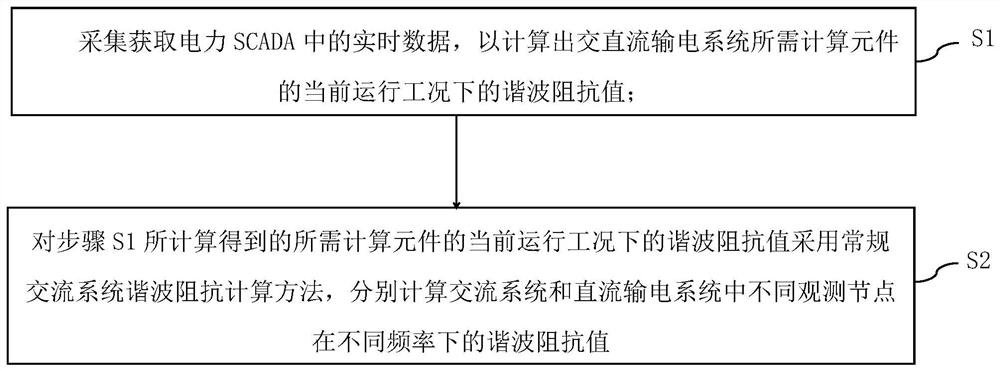

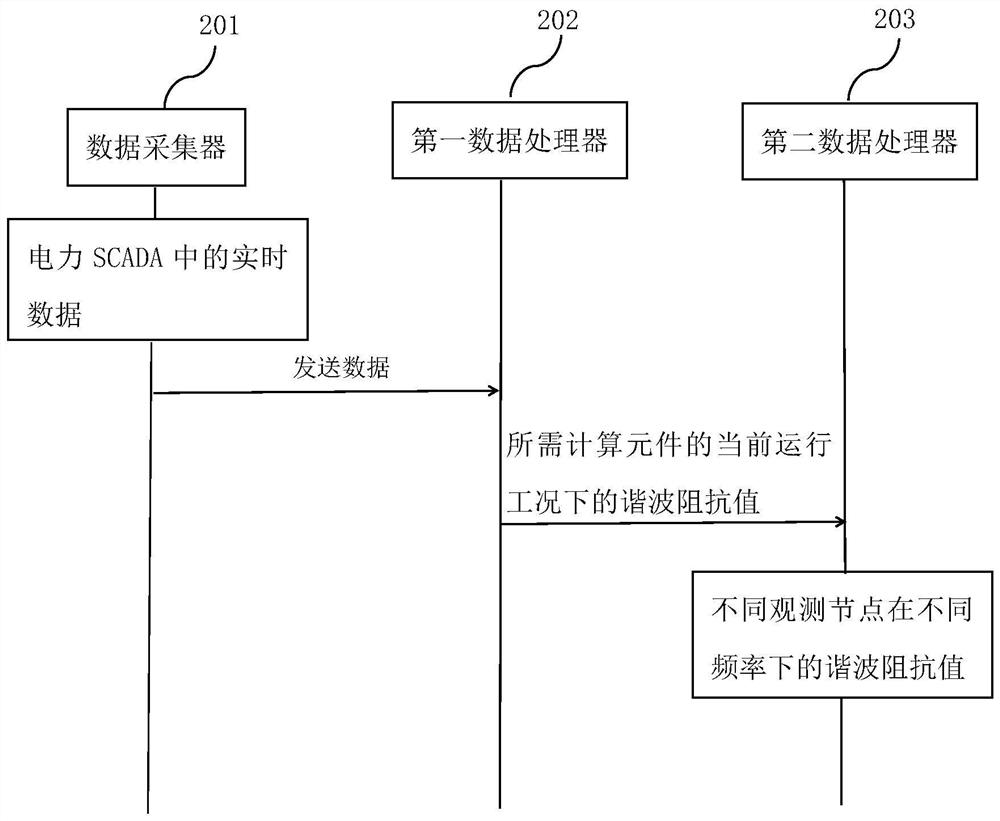

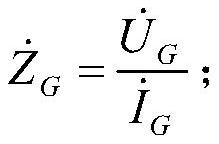

Method and system for measuring harmonic impedance of AC-DC transmission system

ActiveCN111077372BGuaranteed uptimeThe result is accurate and effectiveResistance/reactance/impedenceReal-time dataAC - Alternating current

The invention discloses an AC-DC power transmission system harmonic impedance measurement method and system. The method comprises the steps: S1, collecting and obtaining real-time data in an electricpower SCADA so as to calculate a harmonic impedance value of an element needing to be calculated of an AC-DC power transmission system under a current operation condition; and S2, calculating the harmonic impedance values of different observation nodes in an AC system and a DC power transmission system at different frequencies by adopting a conventional AC system harmonic impedance calculation method according to the harmonic impedance values, calculated in the step S1, of the element needing to be calculated under the current operation condition. According to the method and the system, the harmonic impedance value of each element under the current operation condition is calculated by using the field real-time data, and then the harmonic impedance values of the different observation nodesunder the different frequencies can be obtained by using the conventional alternating current system harmonic impedance calculation method, and a result is accurate and effective so that normal operation of the power transmission system is ensured.

Owner:EXAMING & EXPERIMENTAL CENT OF ULTRAHIGH VOLTAGE POWER TRANSMISSION COMPANY CHINA SOUTHEN POWER GRID

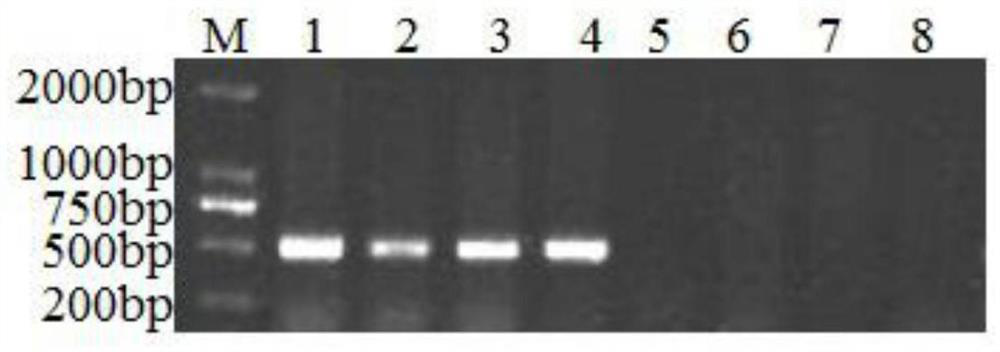

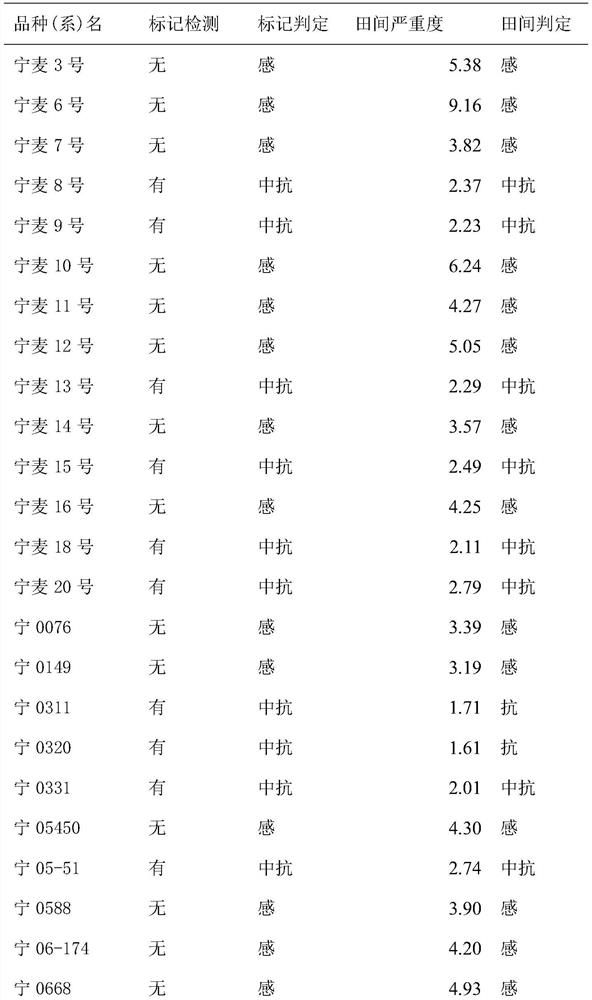

A molecular marker linked to wheat head blight resistance qtl and its application

ActiveCN109355425BGuaranteed specificityGuaranteed accuracyMicrobiological testing/measurementDNA/RNA fragmentationBiotechnologyElectrophoreses

The invention discloses a molecular marker linked with wheat head blight resistance QTL and its application. The molecular marker is based on the DNA of wheat variety Sumai No. 3 as a template, and the nucleotide sequences are respectively as SEQ ID NO.1 and The primer pair shown in SEQ ID NO.2 is electrophoresed after PCR amplification, and the obtained DNA fragment is a 500bp DNA fragment; the molecular marker can be applied to the screening of wheat scab-resistant materials and molecular marker-assisted selection breeding, that is, through detection Whether the molecular marker exists in wheat can determine the resistance of wheat to head blight, its amplification efficiency is high, the amplification result is specific, and the breeding time can be shortened, which is suitable for popularization and application.

Owner:JIANGSU ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com