Data Fitting Method of Multidimensional Force Sensor Calibration Experiment Based on Genetic Algorithm

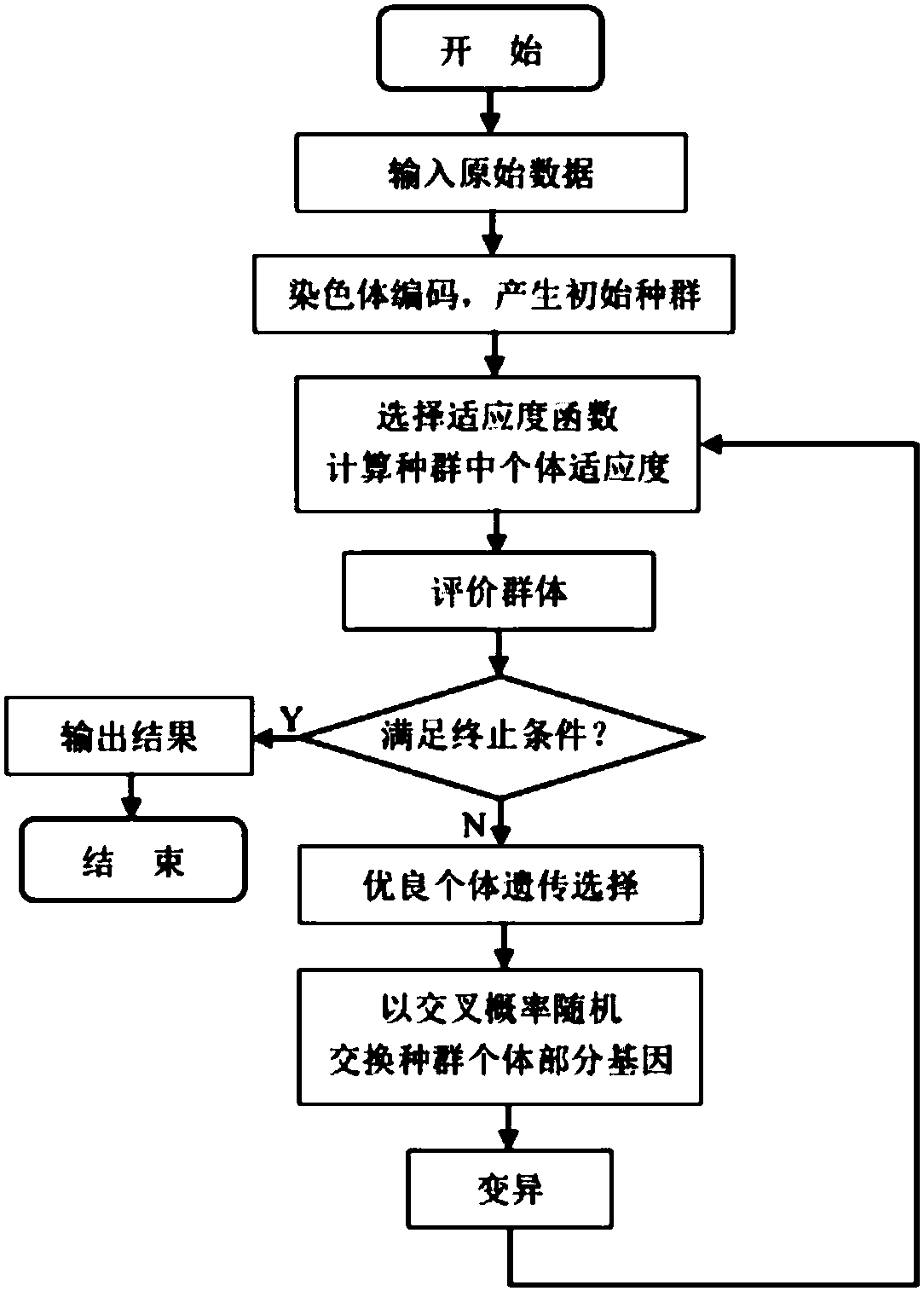

A multi-dimensional force sensor and genetic algorithm technology, applied in the field of multi-dimensional force sensor calibration experiment data fitting, can solve problems such as optimal solution offset and limited numerical accuracy, and achieve the effects of fast algorithm, increased probability, and accurate and effective results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Taking the cross-beam type six-dimensional force sensor developed by Jiangsu Key Laboratory of Remote Measurement and Control Technology of Southeast University as an example, the data fitting problem in the coupling error modeling of sensor decoupling calculation is studied.

[0093] The elastic body of the multi-dimensional force sensor adopts an integral spoke-type cross beam structure, and a full-bridge circuit is formed by strain gauges attached to the front, back and side of the cross beam, and the strain generated when the elastic body is subjected to force / torque is converted into a differential output voltage value .

[0094] Such as image 3 As shown, it is a static calibration experimental device of the present invention, which consists of a force transmission shaft 1, a force column 2, a sensor 3, a dial 4, a left sliding rod 5, a right sliding rod 6, a pulley 7, a test bench base 8, an additional Pulley bar 9 forms.

[0095] The sensor 3 is fixed on a sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com