Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Sufficient deformability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

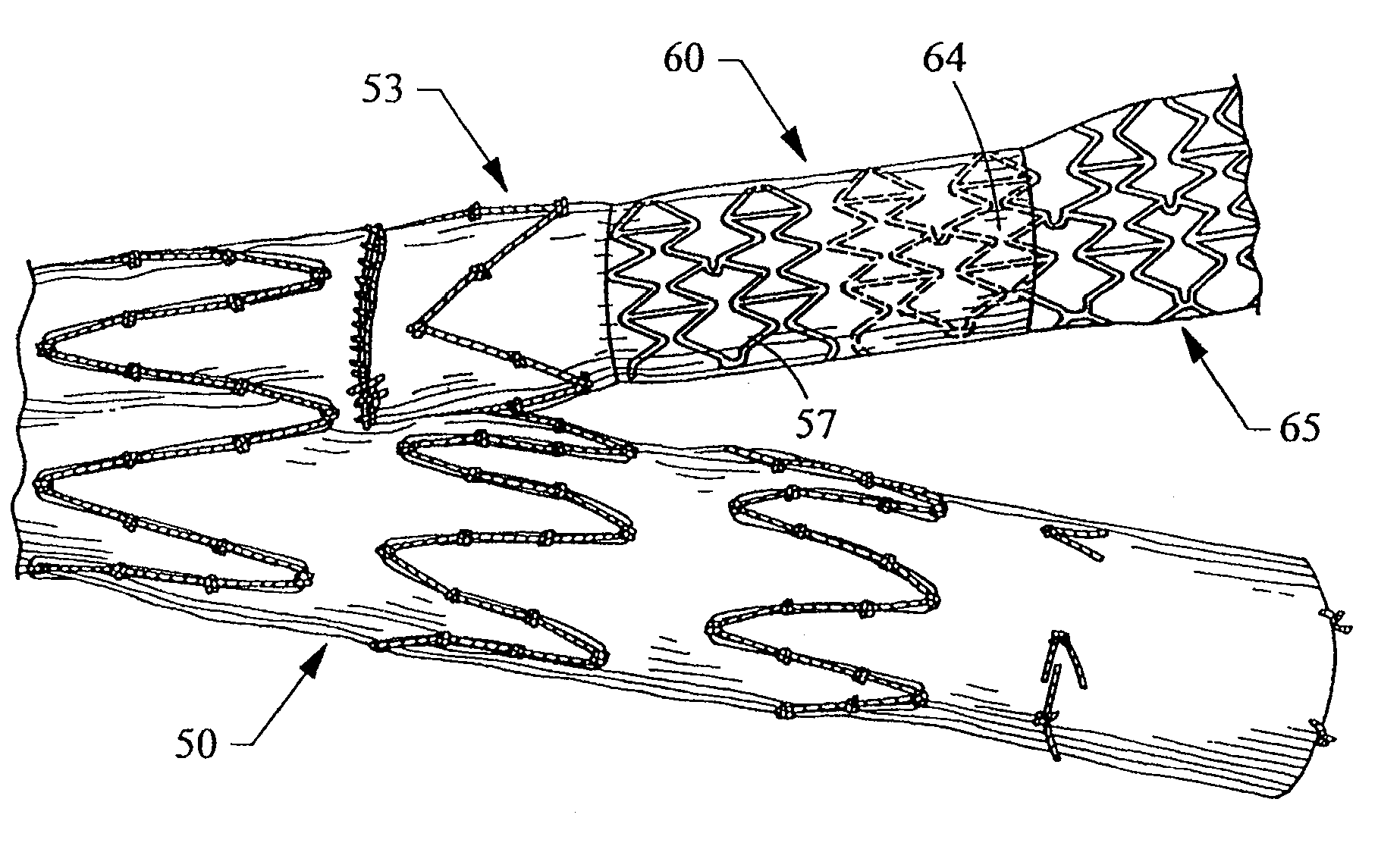

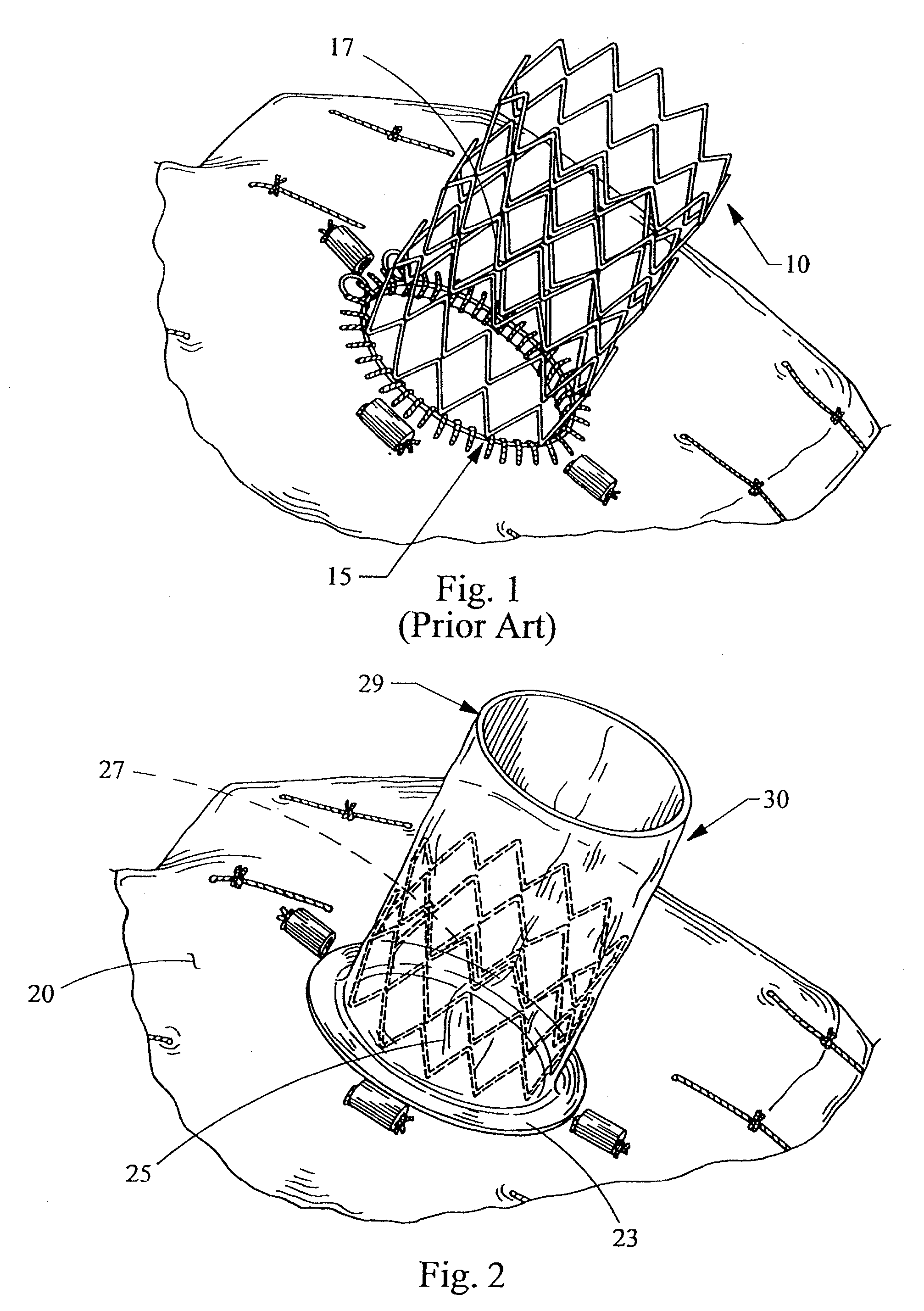

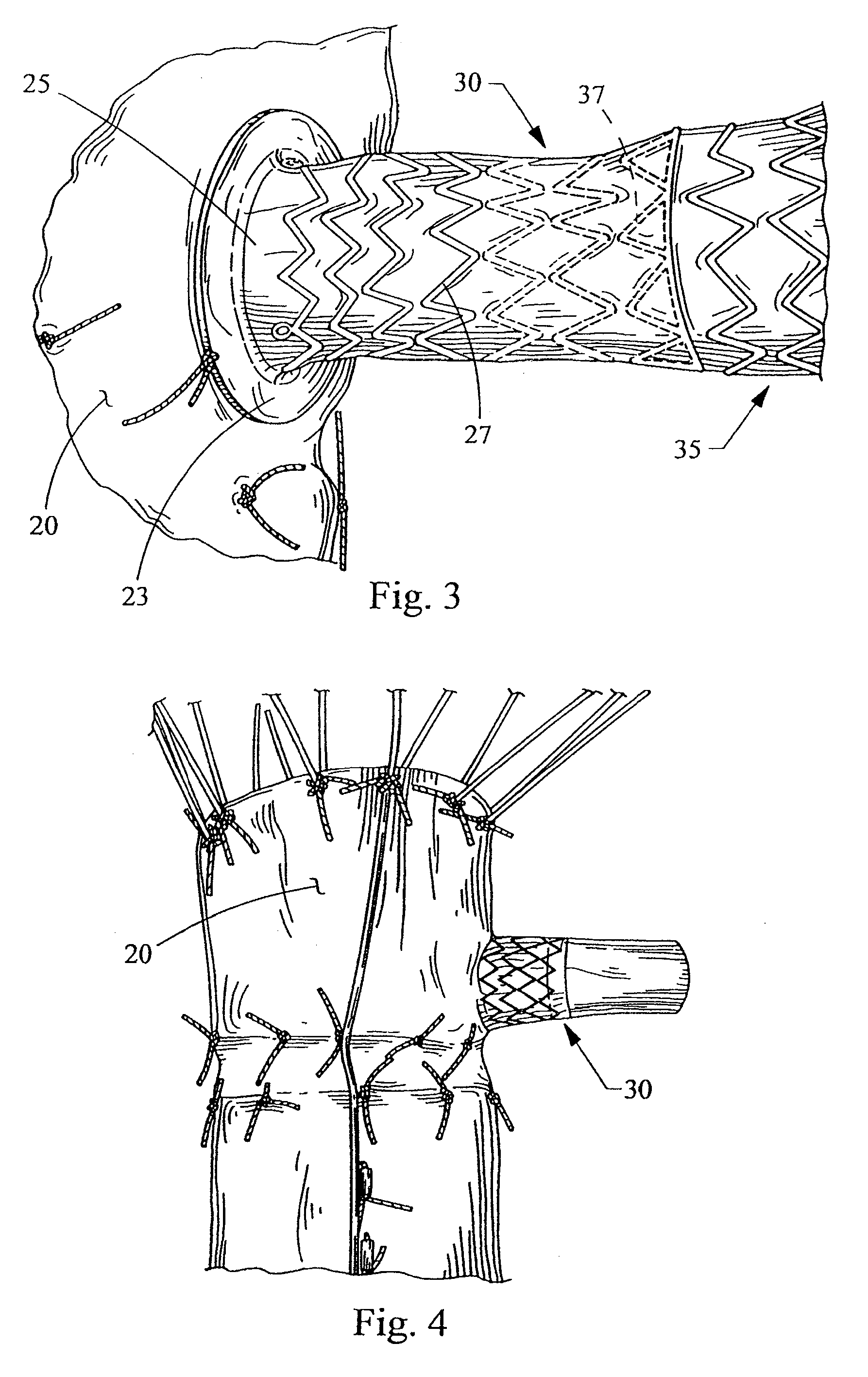

Socket For Fenestrated Tubular Prosthesis

InactiveUS20090164001A1Sufficient elasticity , deformability and biocompatibilityAdjust radial and longitudinal stiffnessStentsBlood vesselsProsthesisAnterior Cerebral Artery Aneurysm

Owner:COOK INC +1

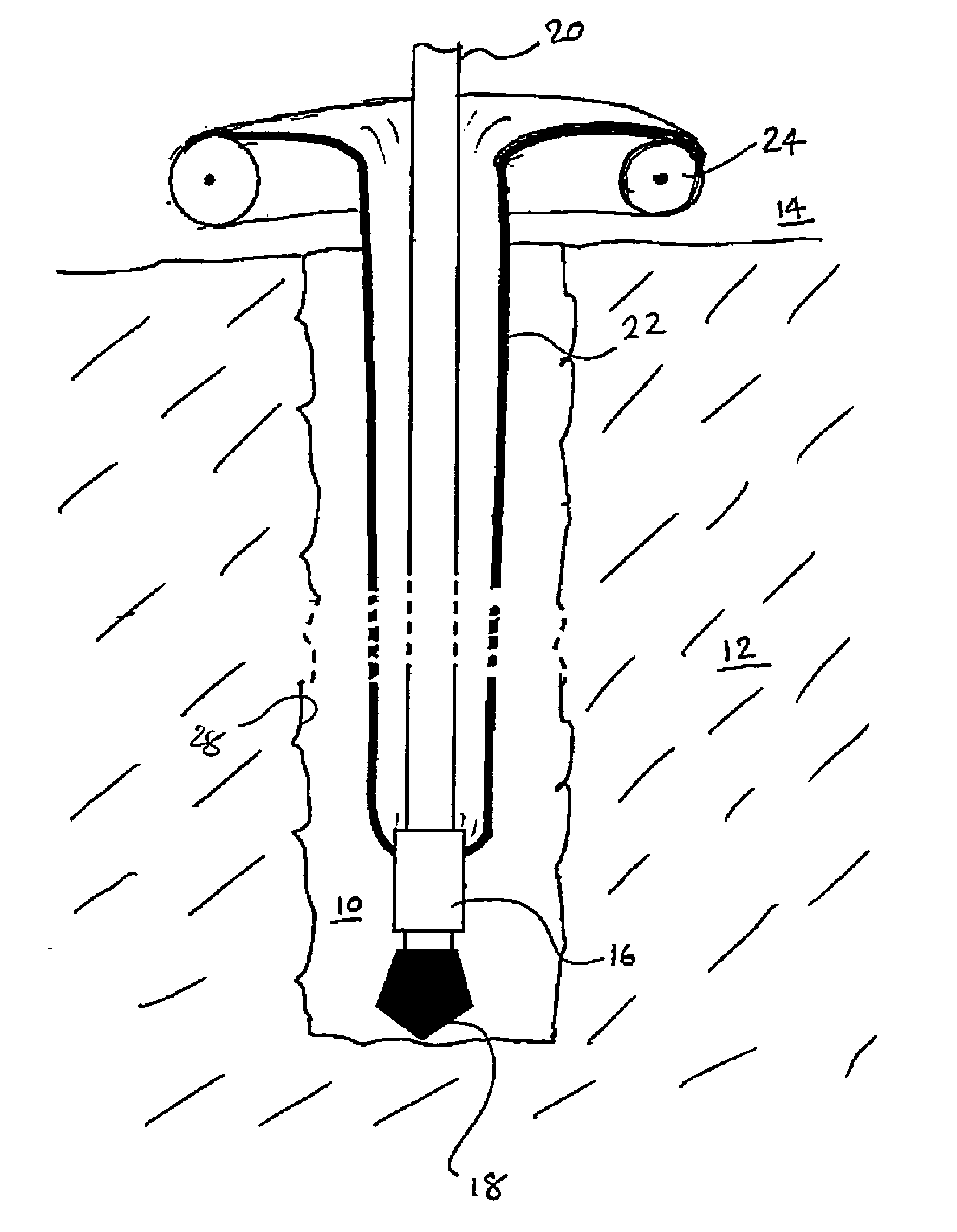

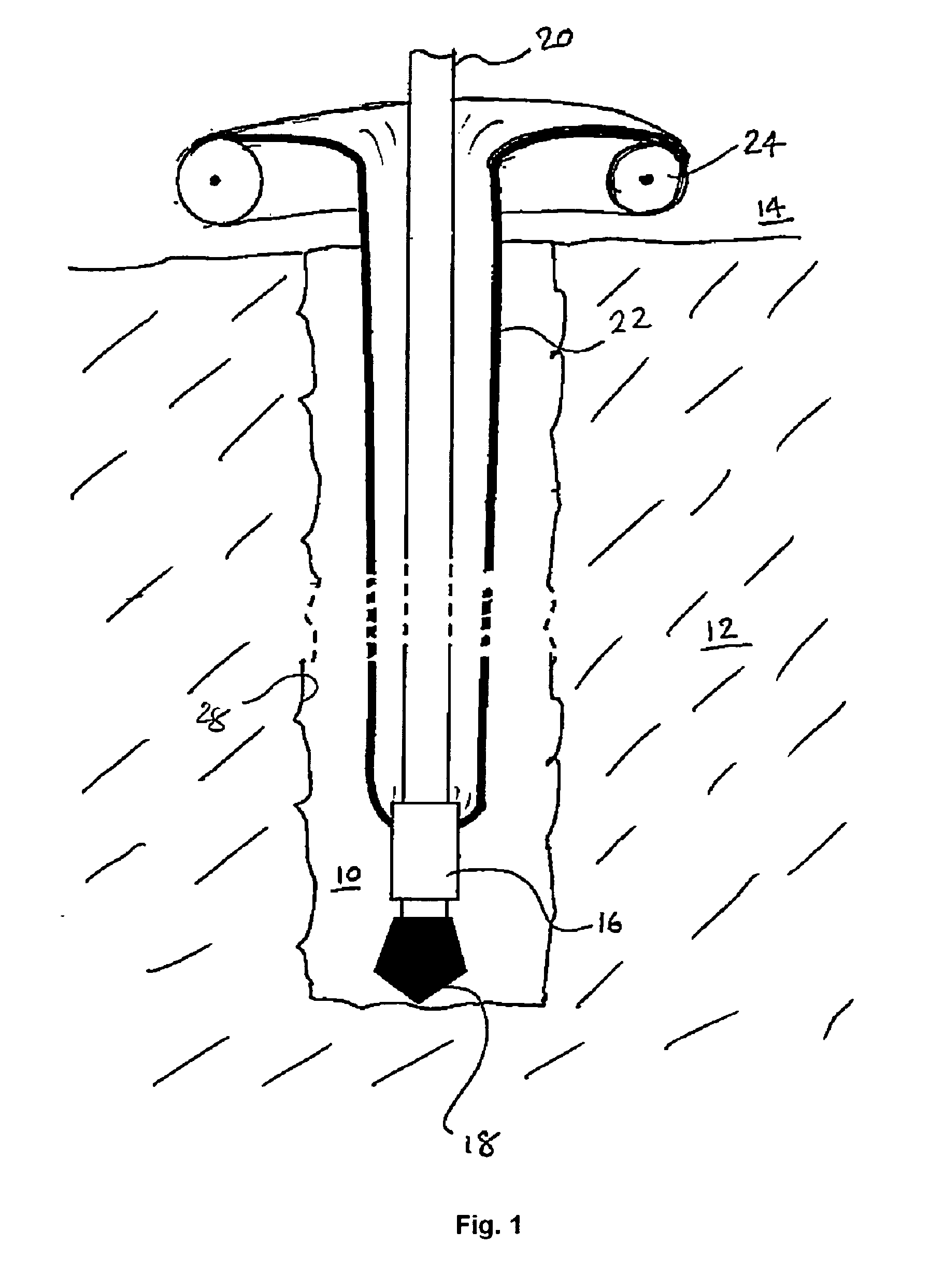

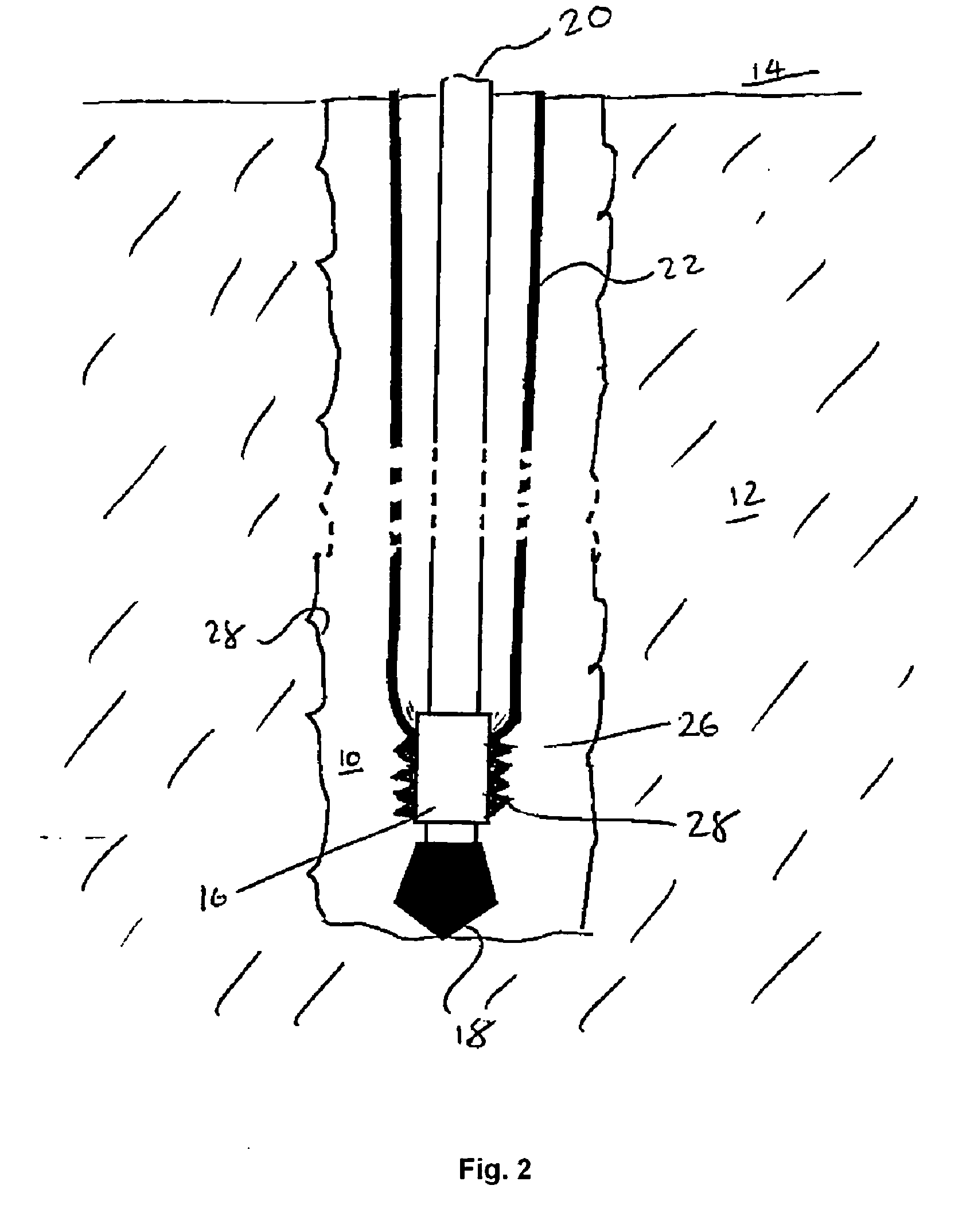

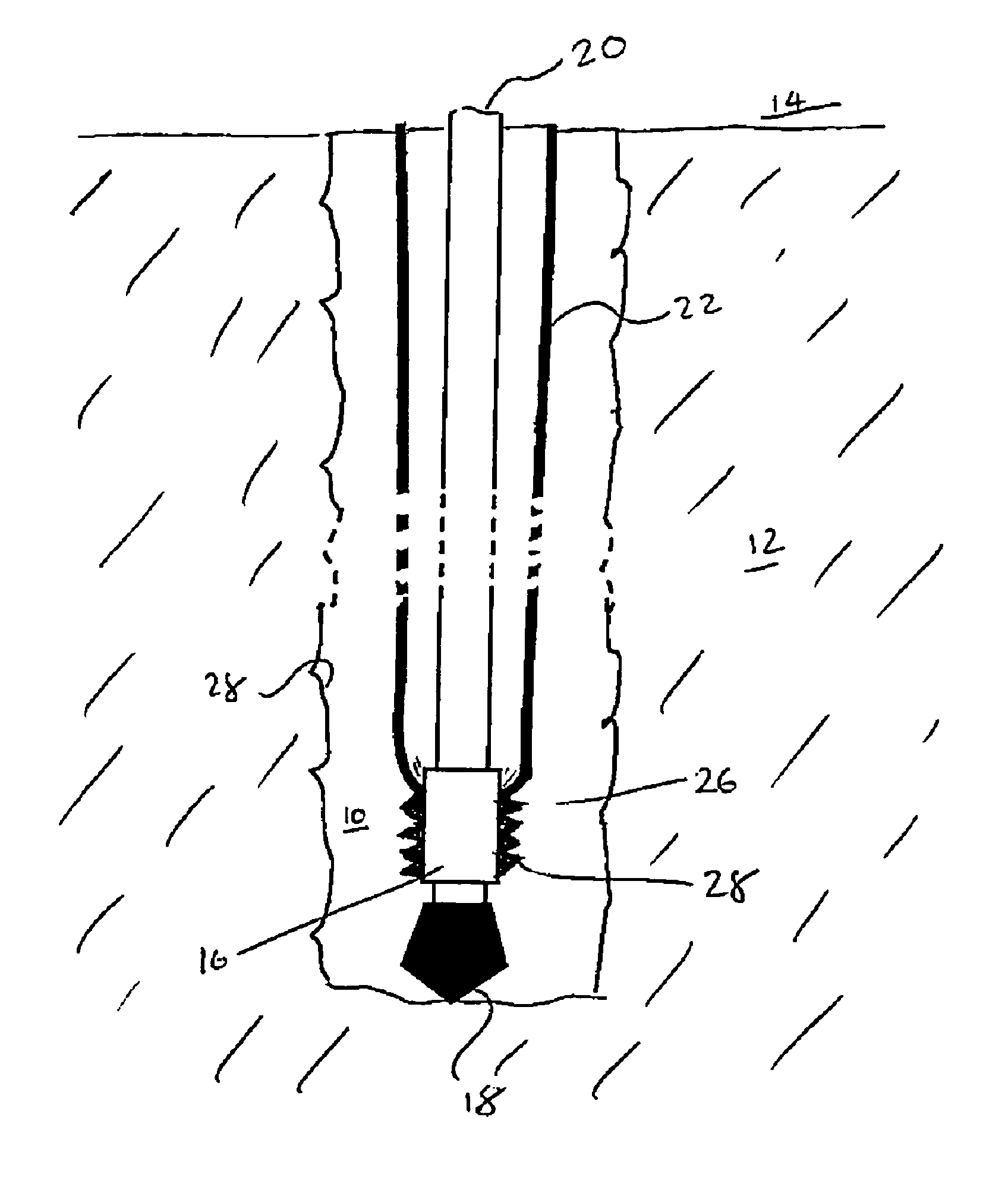

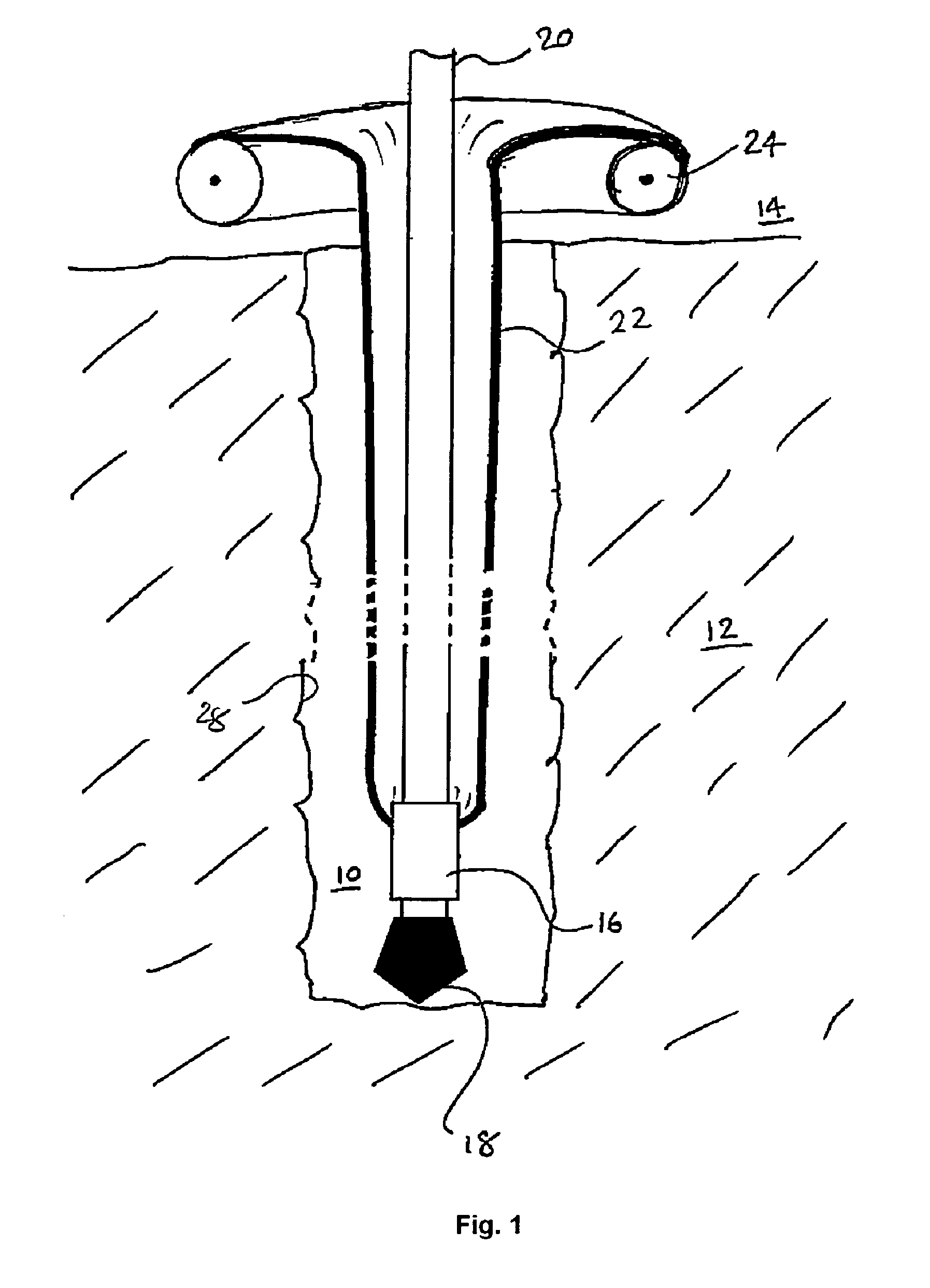

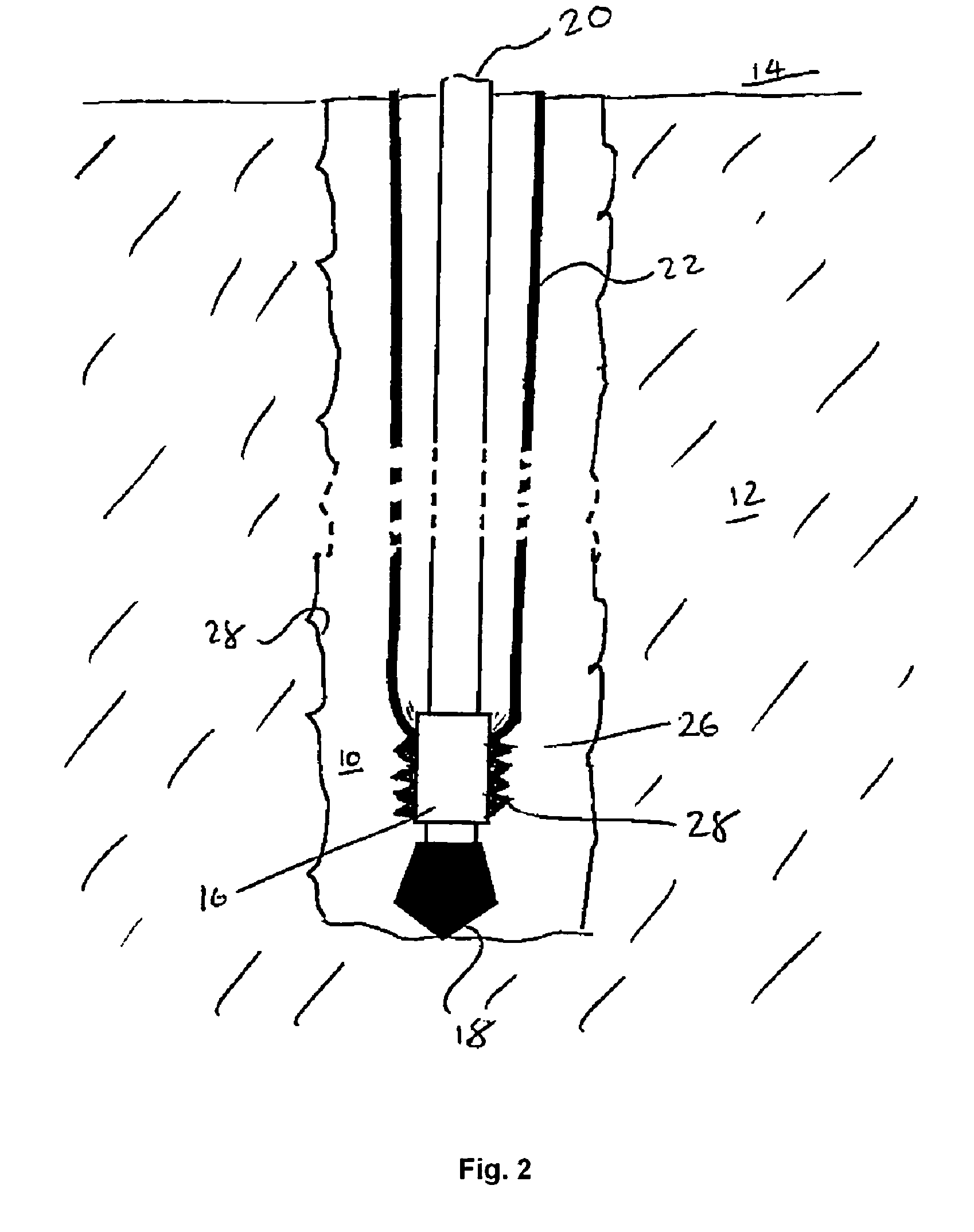

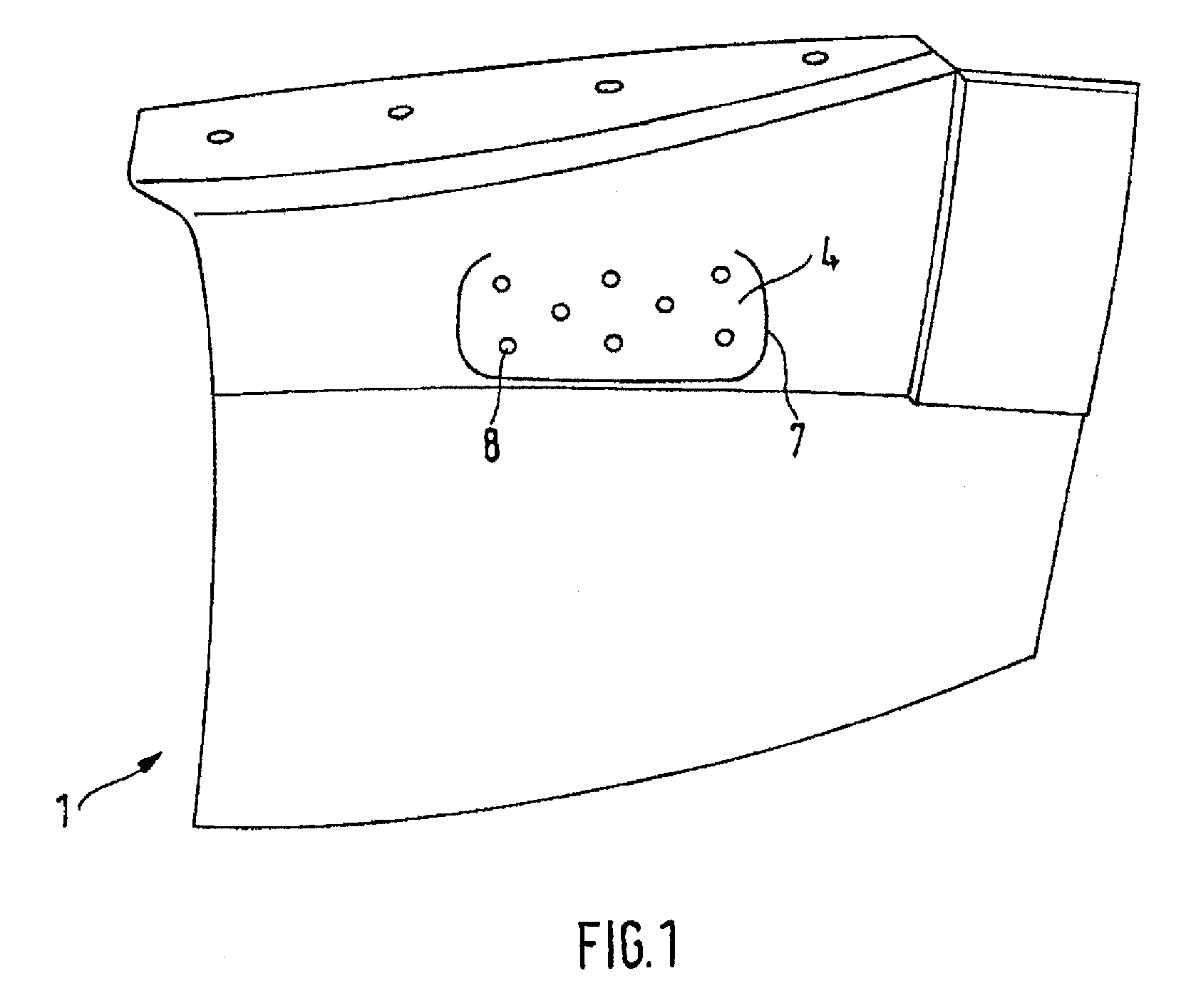

Methods and Apparatus for Well Construction

InactiveUS20090178809A1Increase flexibilitySufficient deformabilityDrilling rodsInsulationDrill holeEnvironmental geology

A method of constructing a borehole drilled with a drilling apparatus (16), the method comprises: connecting a flexible tubular liner sleeve (22) around the outside of the drilling apparatus and connecting the sleeve around an upper opening of the borehole so as to pass into the borehole; progressively extending the sleeve into the borehole as drilling progresses while maintaining connection to the drilling apparatus and borehole opening; at a predetermined point in the drilling, expanding the sleeve so as to contact the borehole wall; and setting the sleeve so as to be fixed to the borehole wall after expansion. Apparatus for use in such a method comprises: a flexible, expandable sleeve (22); a first connector for connecting the sleeve around the outside of a drilling assembly; and a second connector for connecting the sleeve around the opening of the borehole; wherein the sleeve is arranged to extend through the borehole between the connectors as drilling progresses.

Owner:SCHLUMBERGER TECH CORP

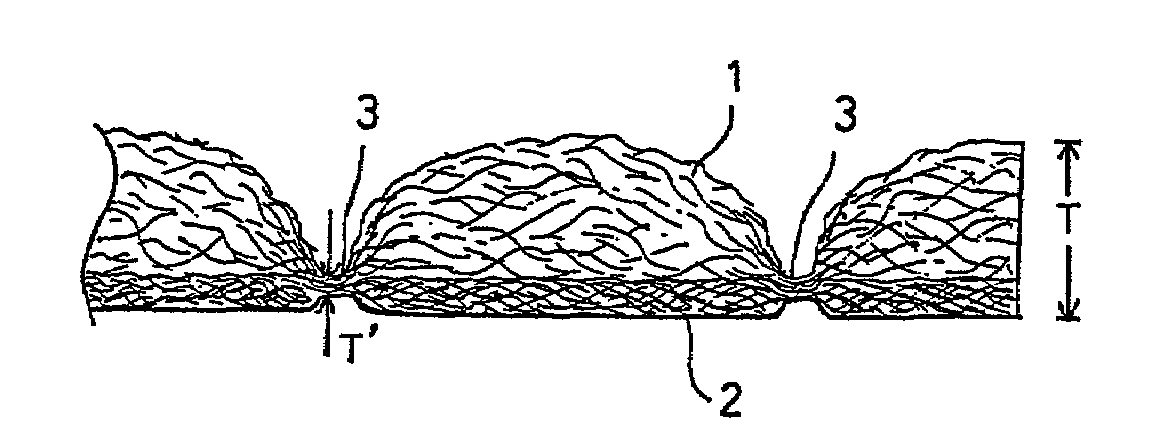

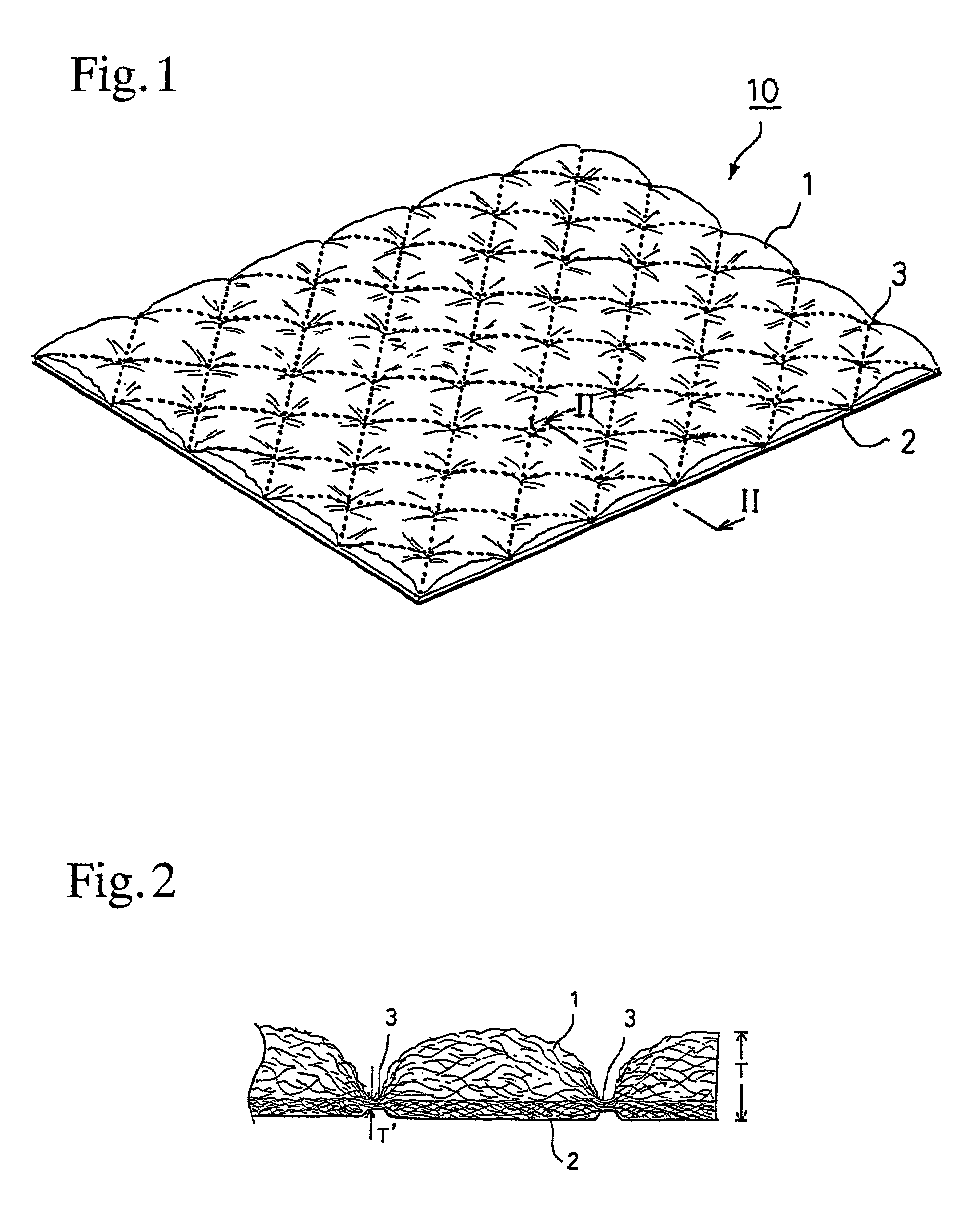

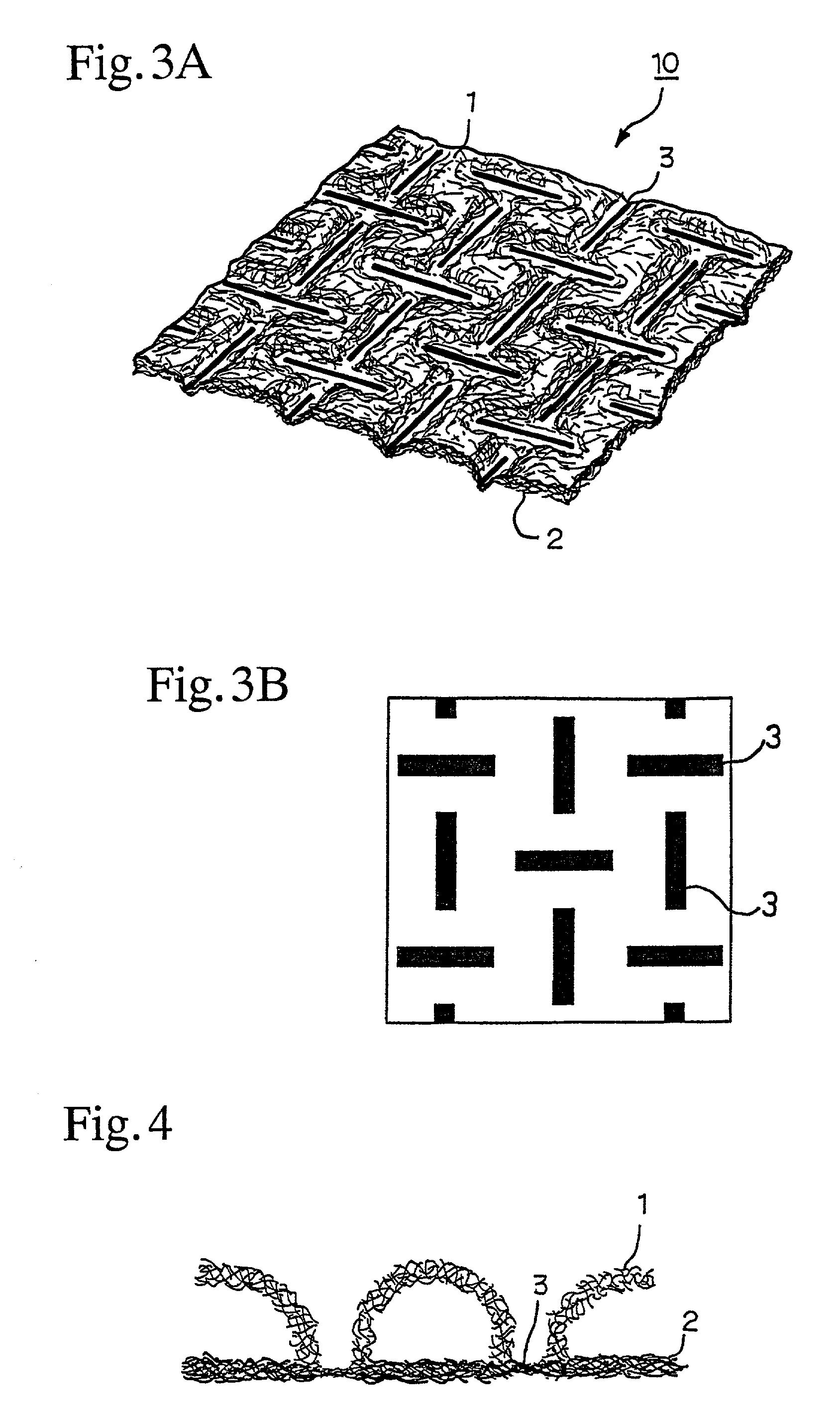

Bulky sheet material having three-dimensional protrusions

InactiveUS7303808B2Relative density is smallFull recoverySynthetic resin layered productsHeating/cooling textile fabricsBiomedical engineeringSecondary layer

A bulky sheet material having three-dimensional protrusions 10 is disclosed. The sheet material comprises a first layer 1 and a second layer 2 adjacent to the first layer 1. The first layer 1 and the second layer 2 is partly joined together at joints 3 in a prescribed pattern. The first layer 1 has a number of raised portions which are located among the joints 3. The second layer 2 comprises a material which exhibits elastomeric behavior. The bulky sheet material 10 exhibits elastomeric behavior as a whole and breathability.

Owner:KAO CORP

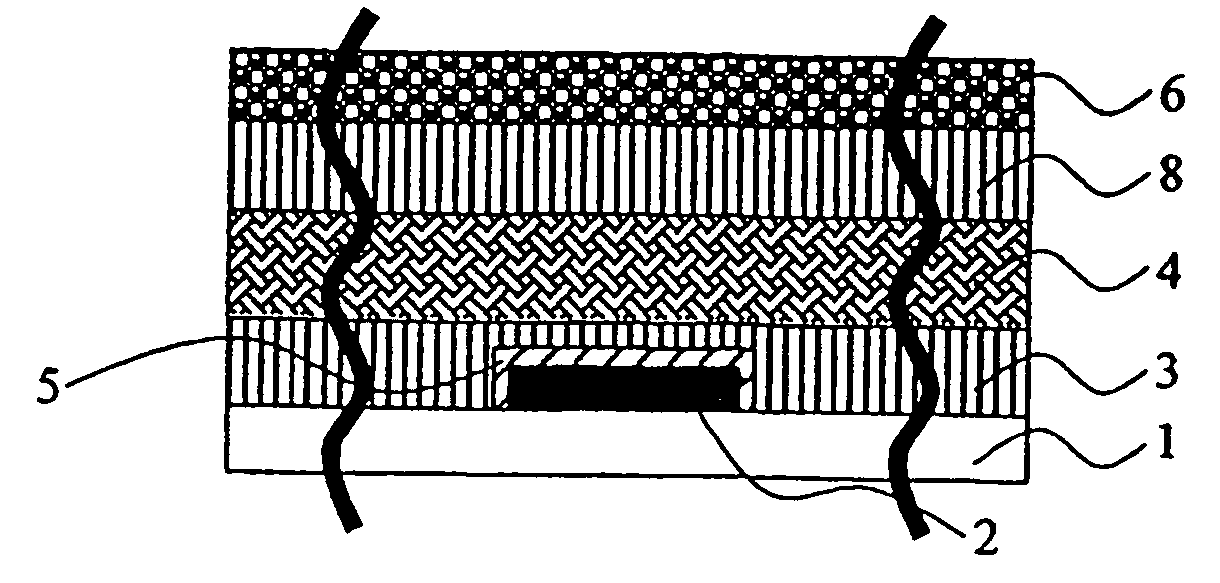

Enzyme electrode and process for manufacturing the same

InactiveUS20040106166A1Improve adhesionHigh yieldMicrobiological testing/measurementVolume/mass flow measurementSilane compoundsSilanes

The present invention provides an enzyme electrode exhibiting good measurement performance under wide ranges of the application conditions, being excellent in durability during long-term use and further being producible with a higher yield, as well as a process for manufacturing the enzyme electrode employing a wafer process particularly suitable to mass production. An enzyme electrode according to the present invention comprises an electrode 2 formed on an insulating substrate 1, an immobilized enzyme layer 4 formed over the electrode 2, and a permeation-limiting layer 6 placed on the uppermost surface and over the immobilized enzyme layer 4, wherein on the immobilized enzyme layer 4 is optionally formed an adhesion layer 8 comprising a silane-containing compound, on whose upper surface is formed the permeation-limiting layer 6; or the permeation-limiting layer 6 may be a film mainly comprising a fluorine-containing polymer in which a number of grooves are built on its surface, or alternatively the film has an irregular surface having a surface roughness of 0.0001 or more and 1 or less fold to its average thickness being selected within a range of 0.01 to 1 mum.

Owner:TANITA CORP

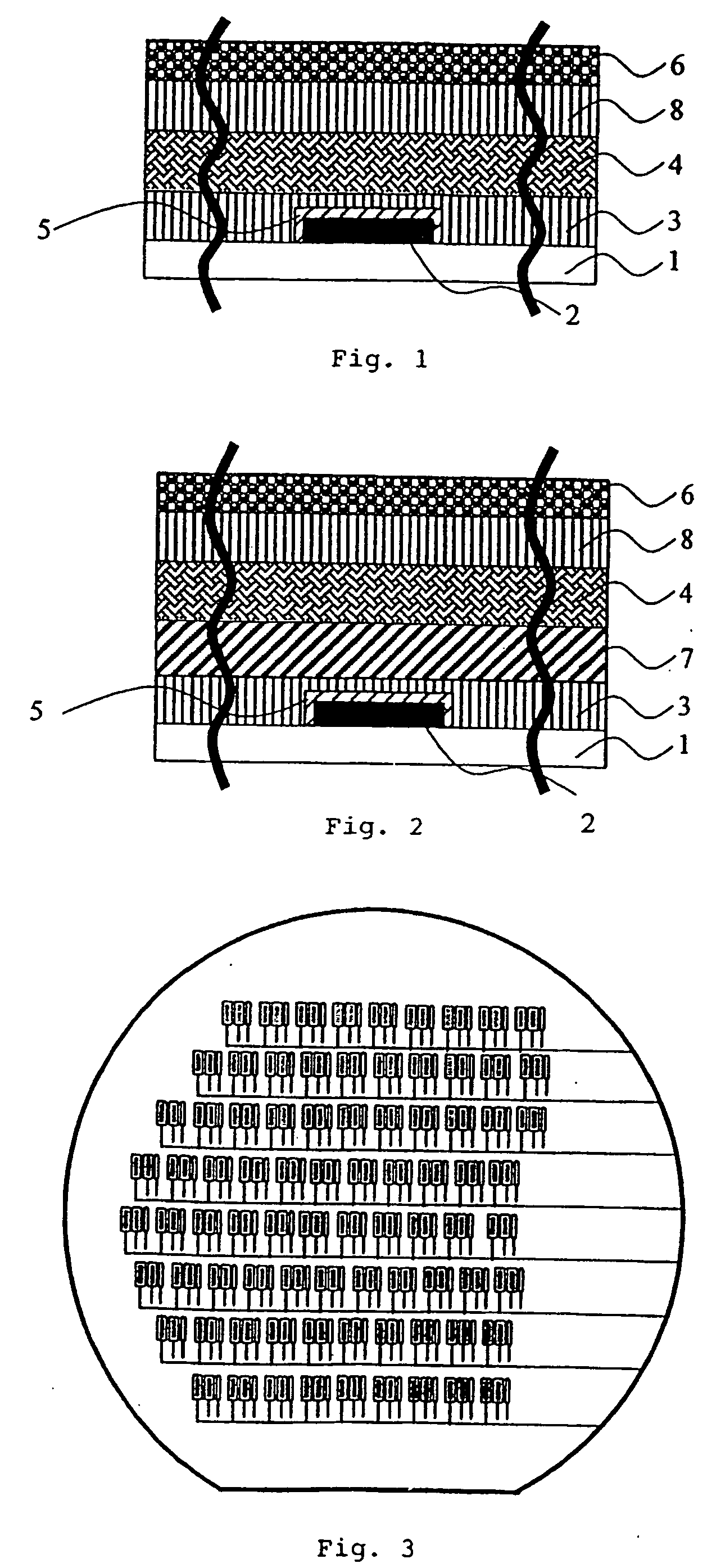

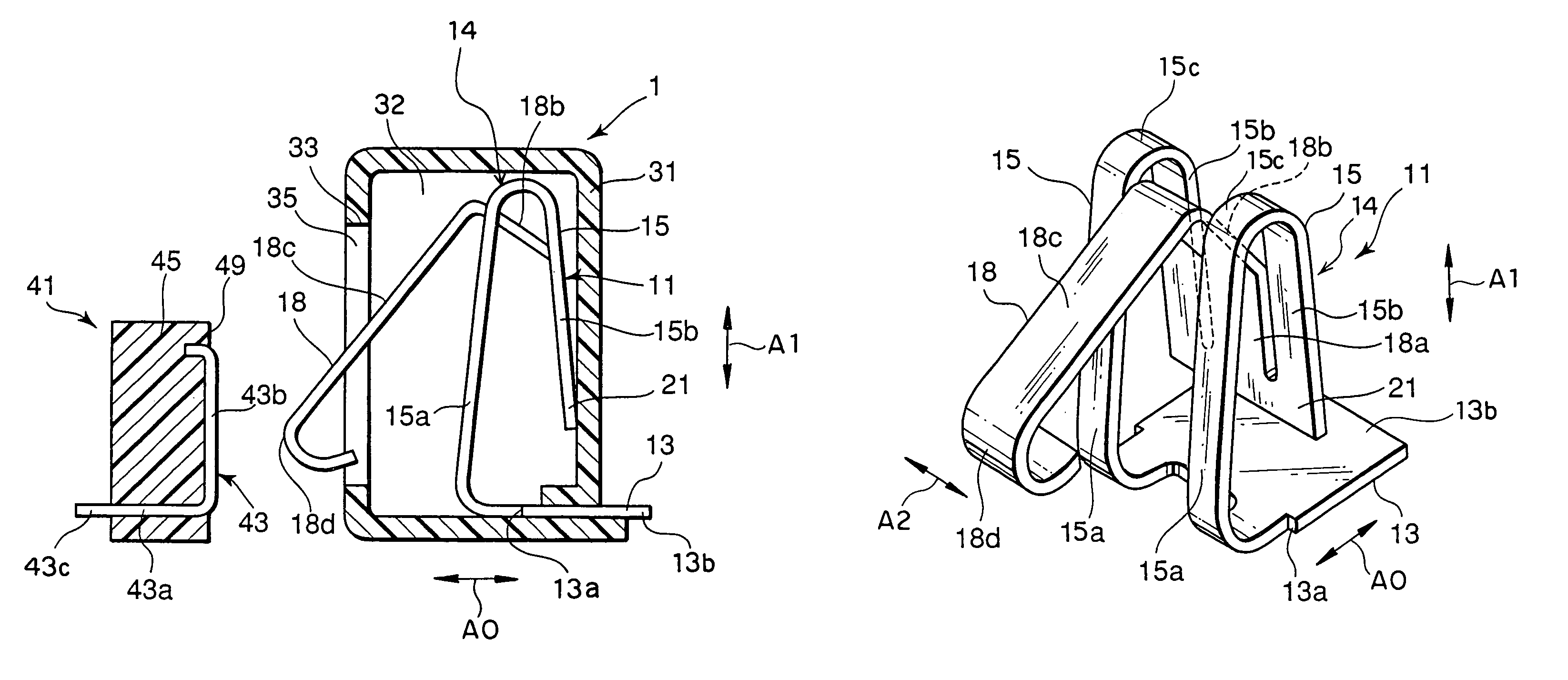

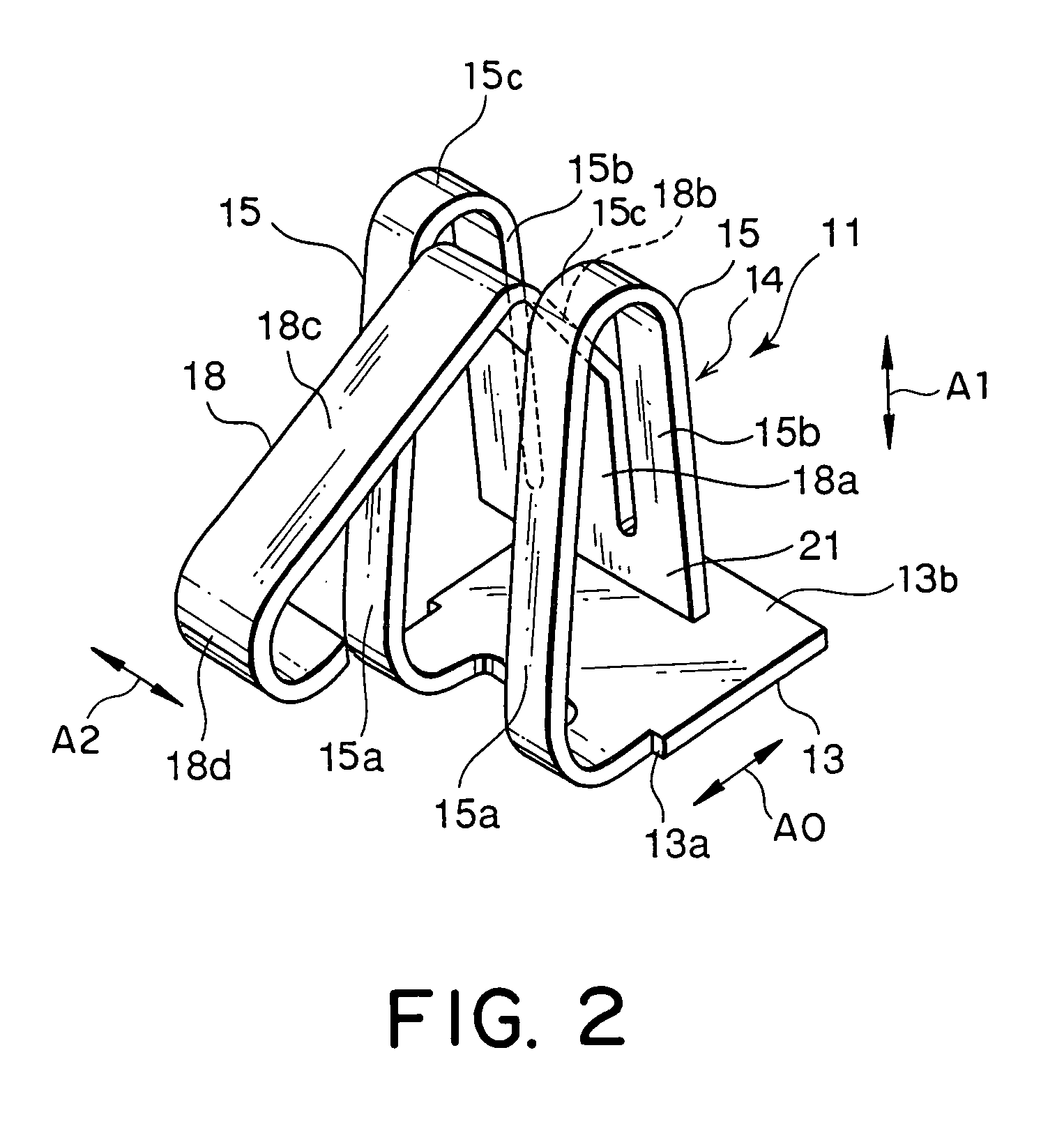

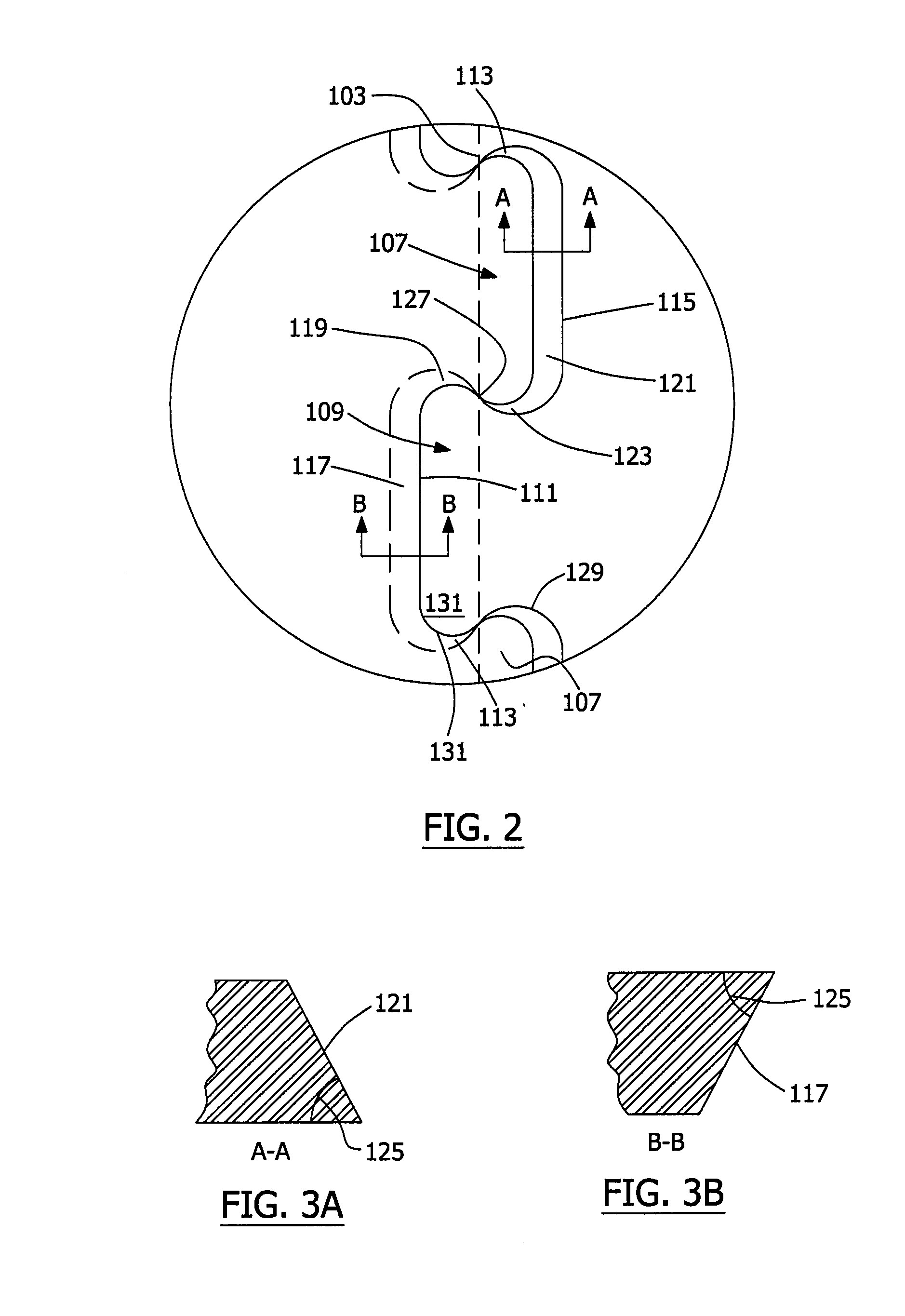

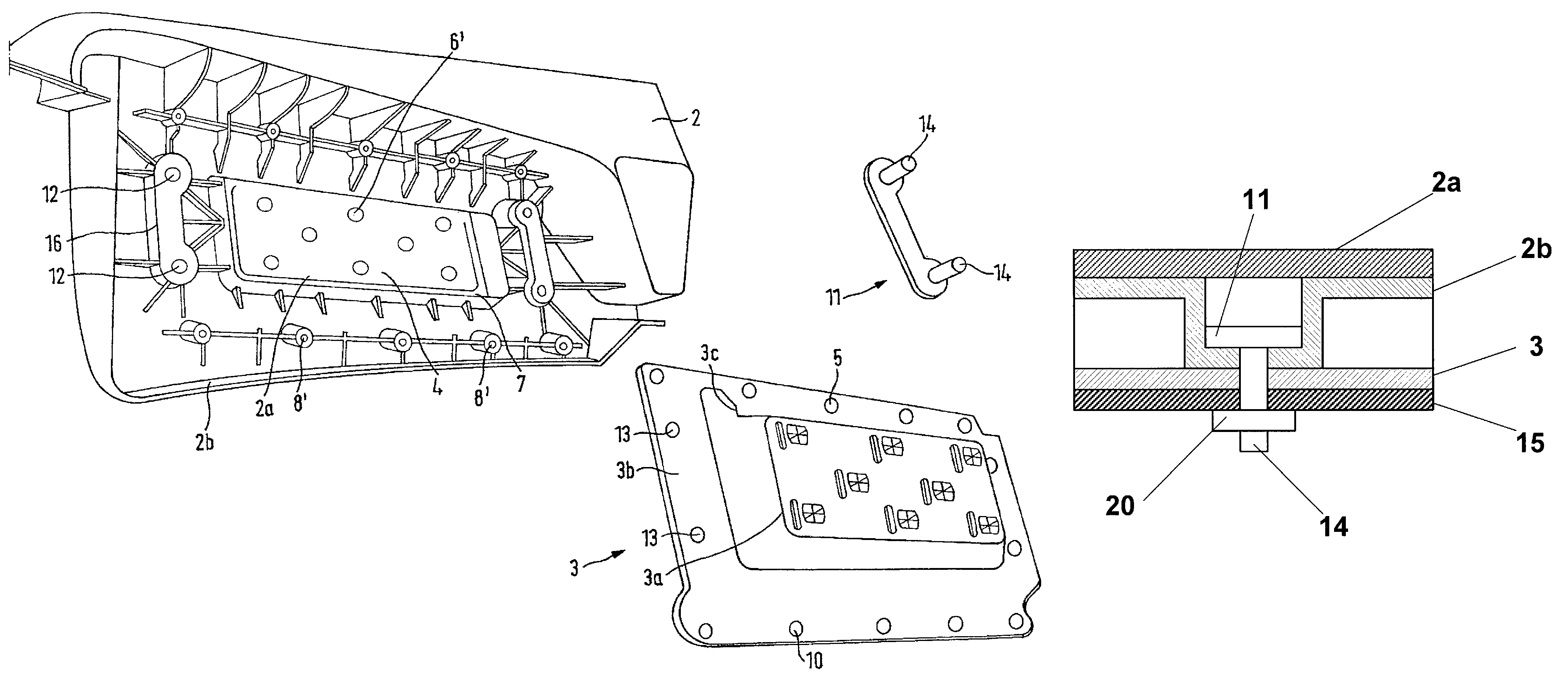

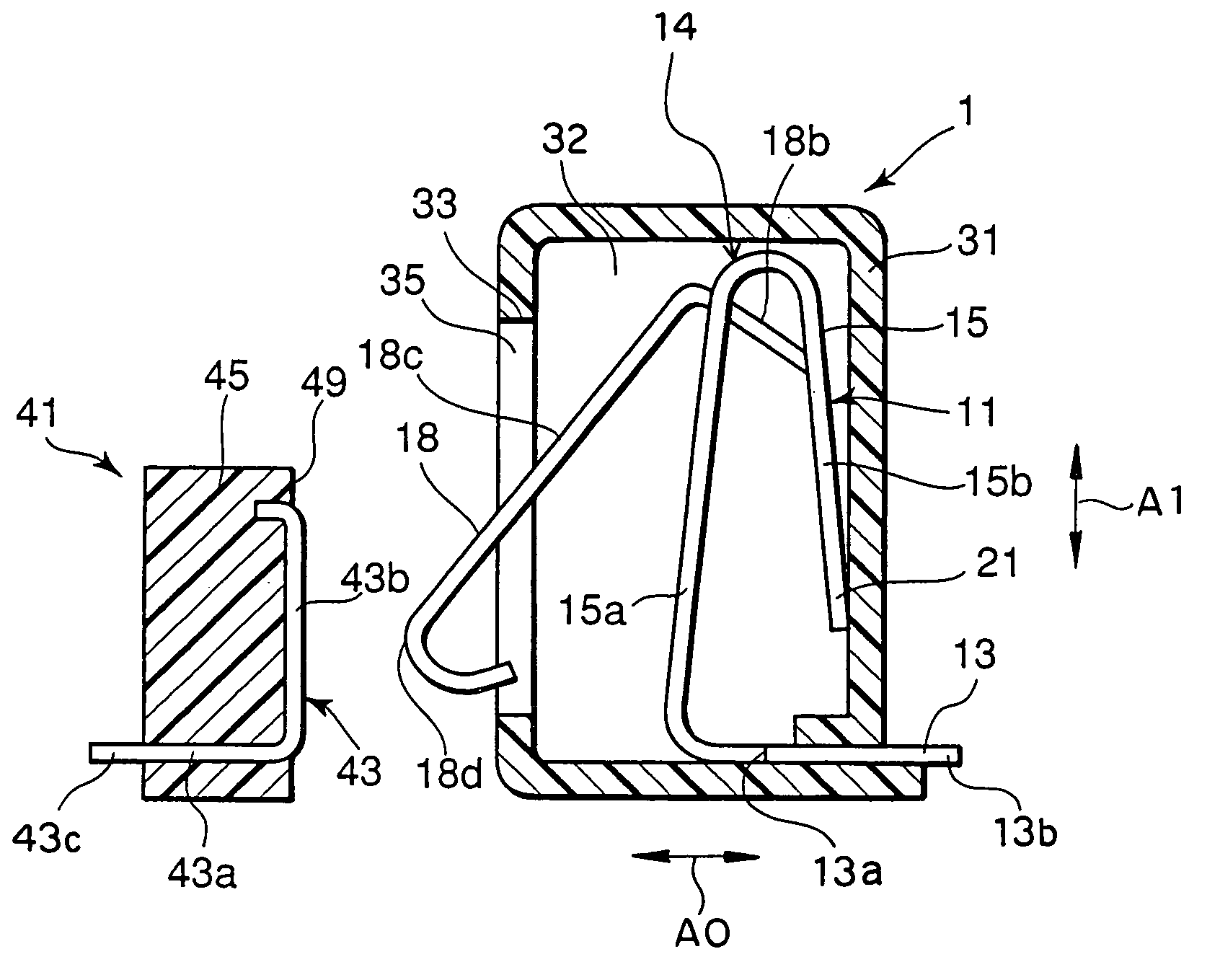

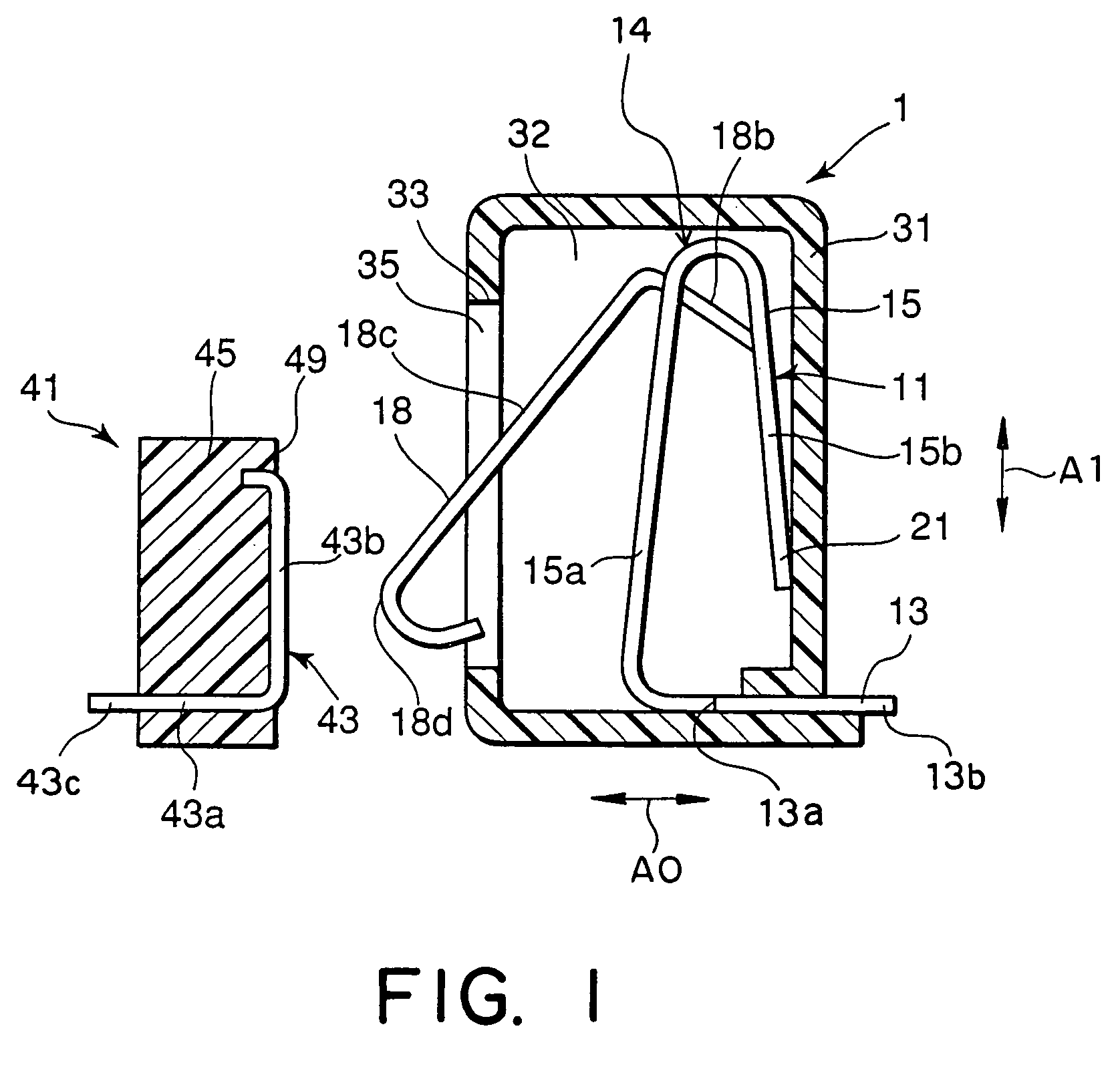

Electrical connector in which a wiping action is carried out in a narrow area

ActiveUS7029287B2Sufficient deformabilityAddressing Insufficient ControlEngagement/disengagement of coupling partsElectric discharge tubesMating connectionEngineering

In an electrical connector to be connected to a mating connector in a predetermined direction, an insulator defines an accommodating space and an opening communicating the accommodating space in the predetermined direction. A contact as a base portion held by the insulator and a spring portion connected to the base portion. The spring portion has a first portion extending from the base portion in the accommodating space to intersect with the predetermined direction, a second portion turned opposite to the opening from the first portion and extending in the accommodating space to intersect with the predetermined direction, and a third portion extending from the second portion to pass through the opening. The third portion has a contact portion located outside the accommodating space to be elastically contacted with the mating connector.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

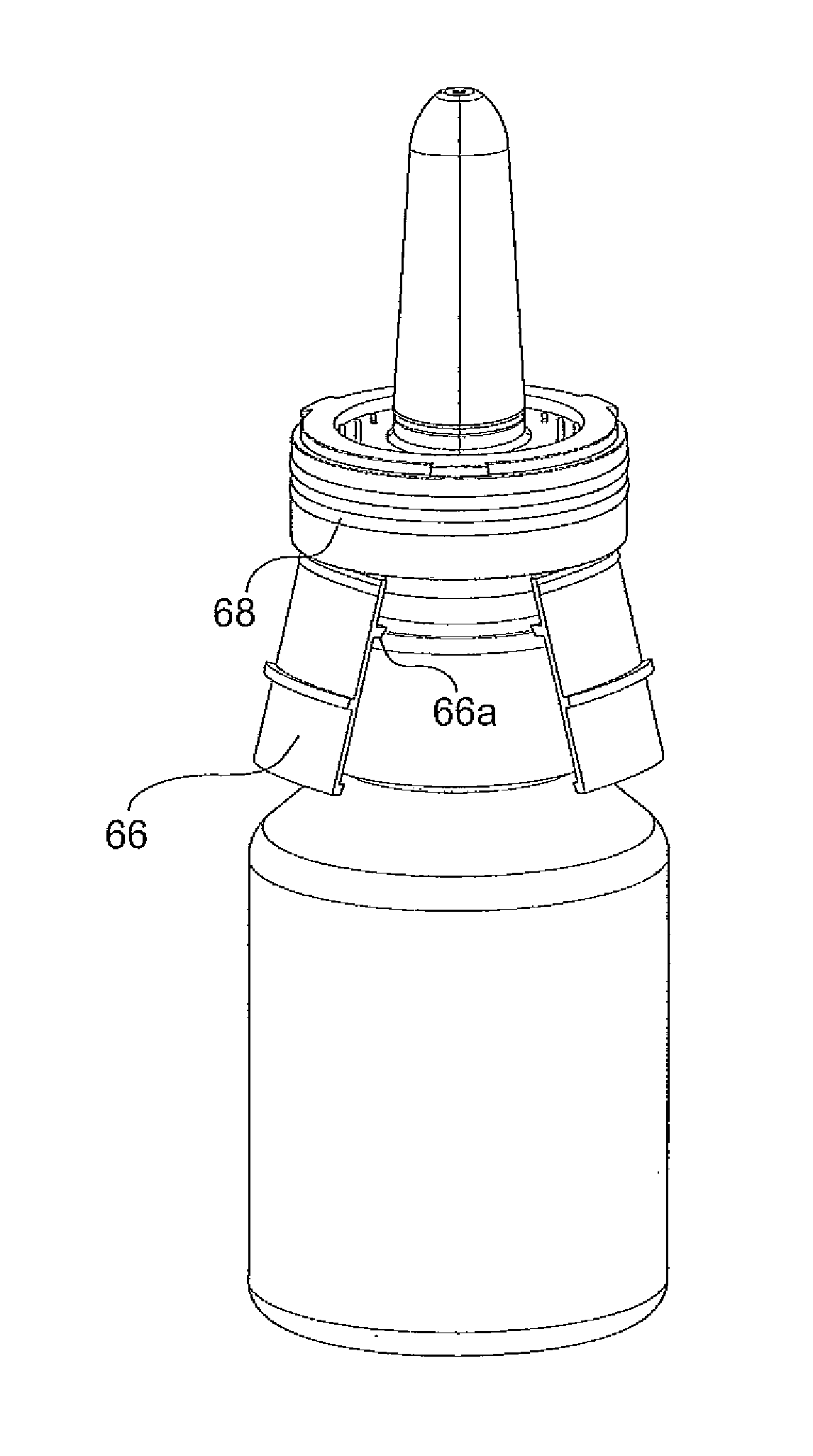

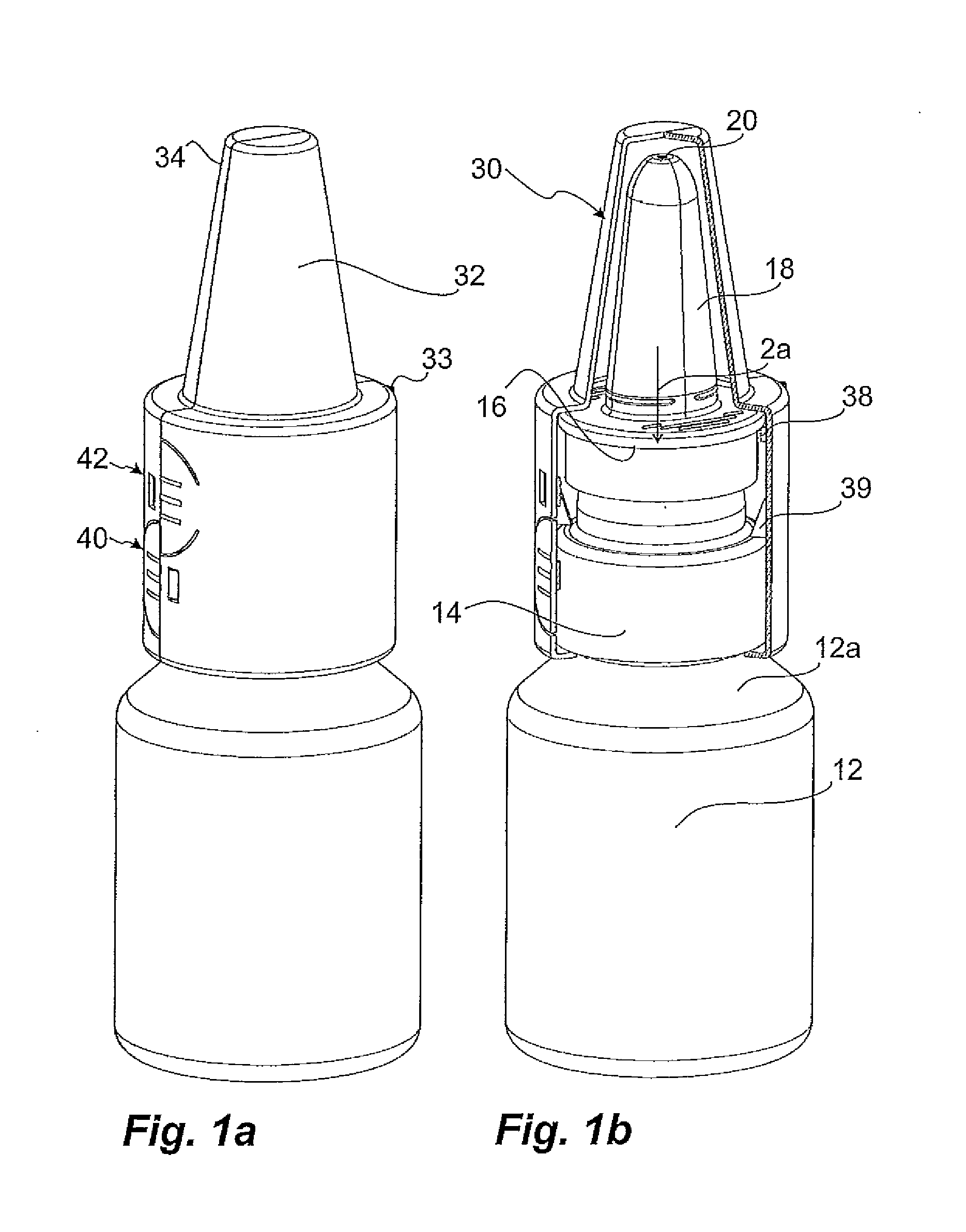

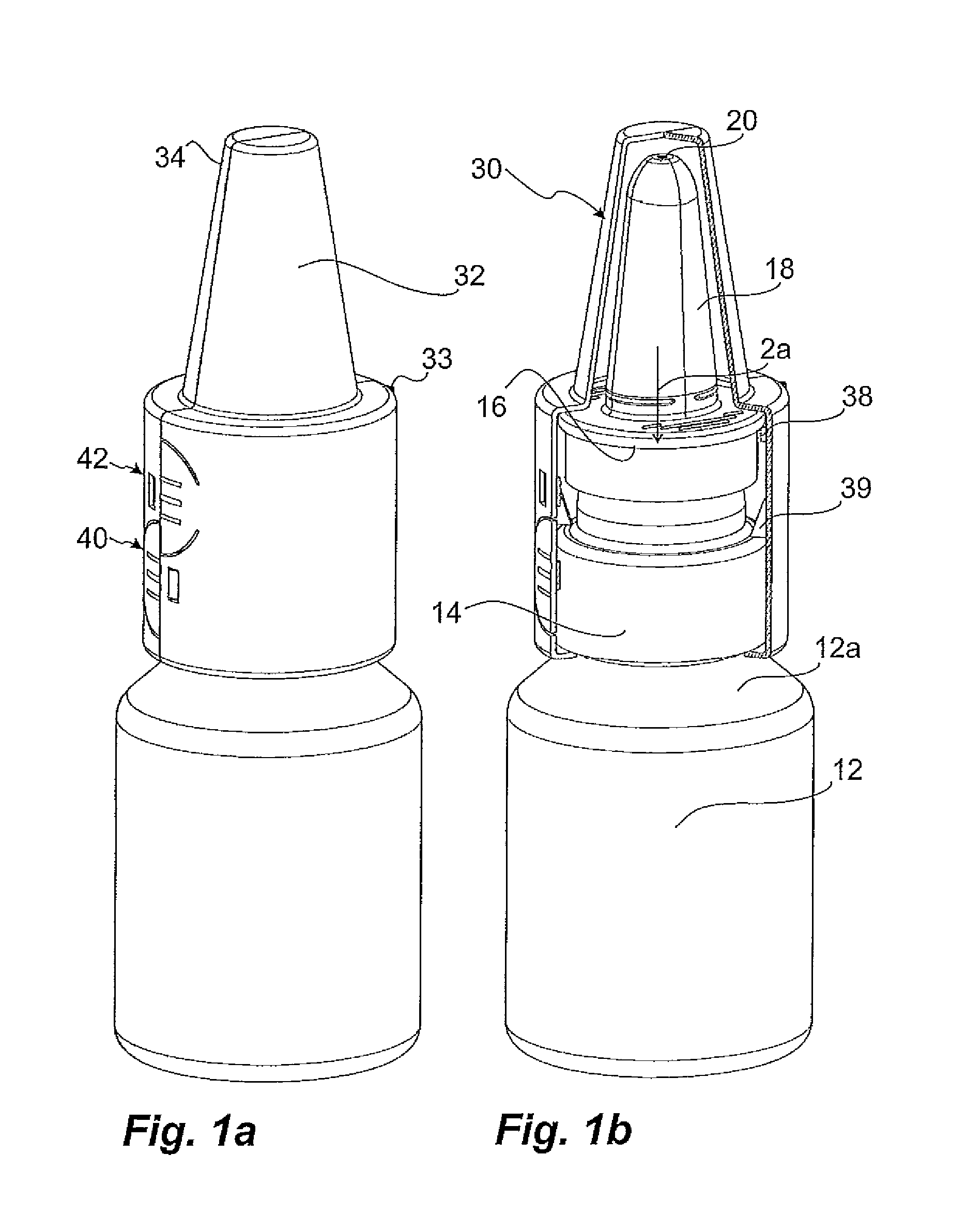

Dispenser with child-proof lock

ActiveUS20140097207A1Sufficient deformabilityAccessibility preventedClosure using stoppersMedical devicesCouplingEngineering

A dispenser including a medium reservoir, a discharge opening, and a feeding device for feeding medium from the medium reservoir to the discharge opening, wherein an actuating handle is displaceable relative to the medium reservoir in an actuation direction to discharge medium.The dispenser includes a protective device with two partial shells interconnected in a protective condition by a coupling device for repeated decoupling and coupling wherein the protective device is attachable to the feeding device in a protective position such that in the protective condition the accessibility and / or maneuverability of the actuating handle is prevented, and upon releasing the coupling device an enable condition of the protective device is achievable in which the partial shells are displaceable relative to another so that the protective device is removable from the feeding device, and thus accessibility or maneuverability of the actuating handle is obtainable thereby.

Owner:APTAR RADOLFZELL

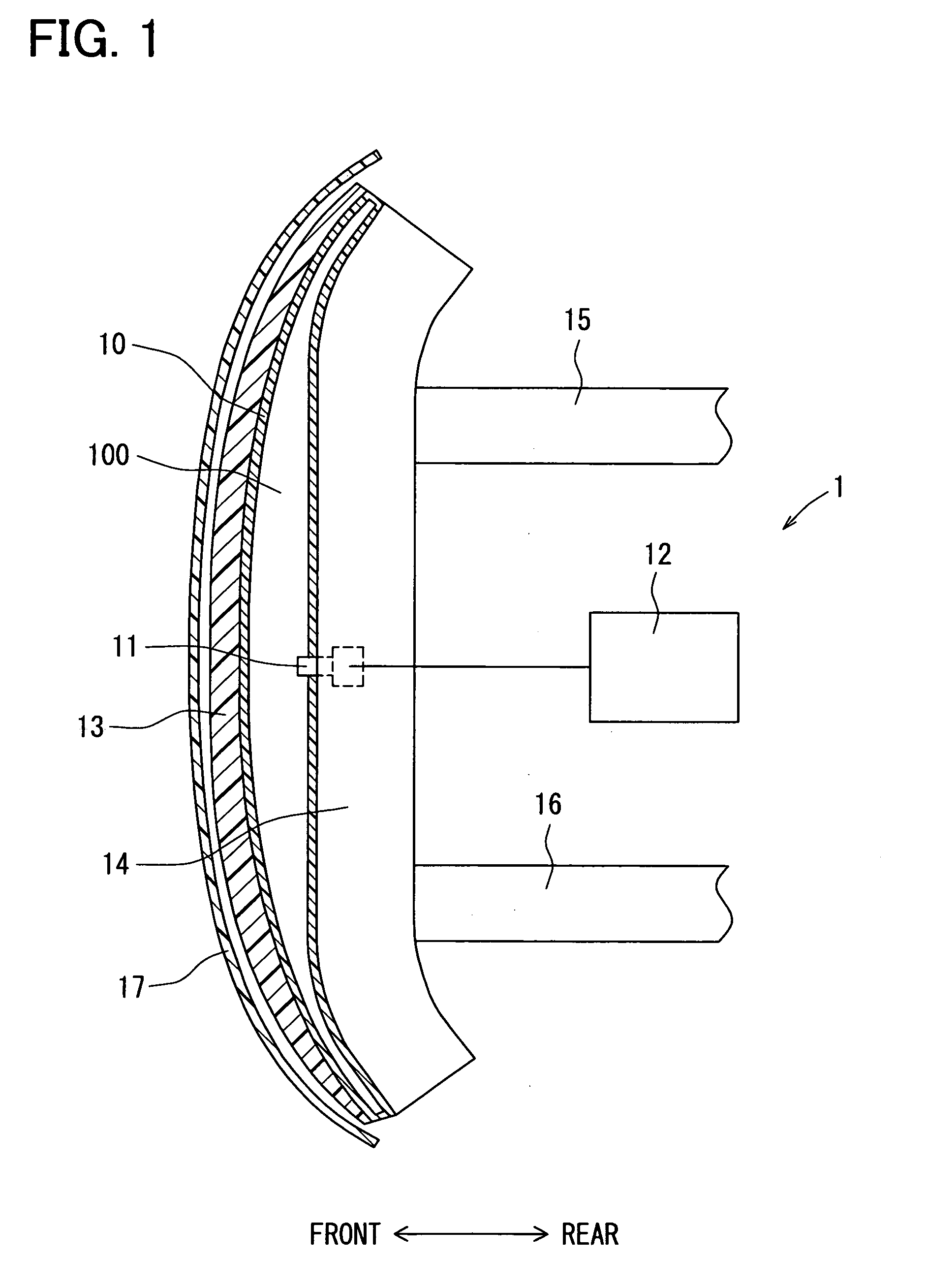

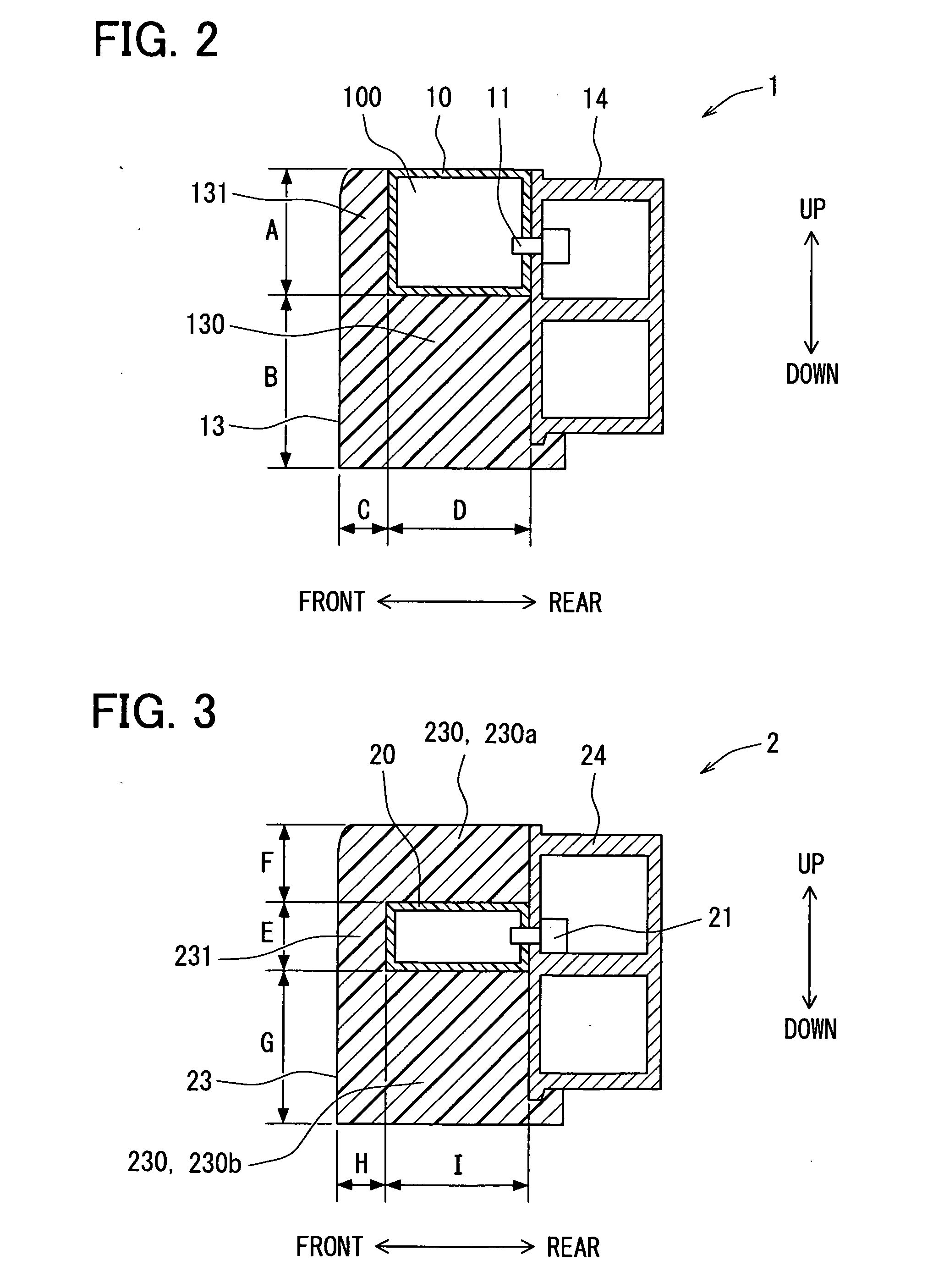

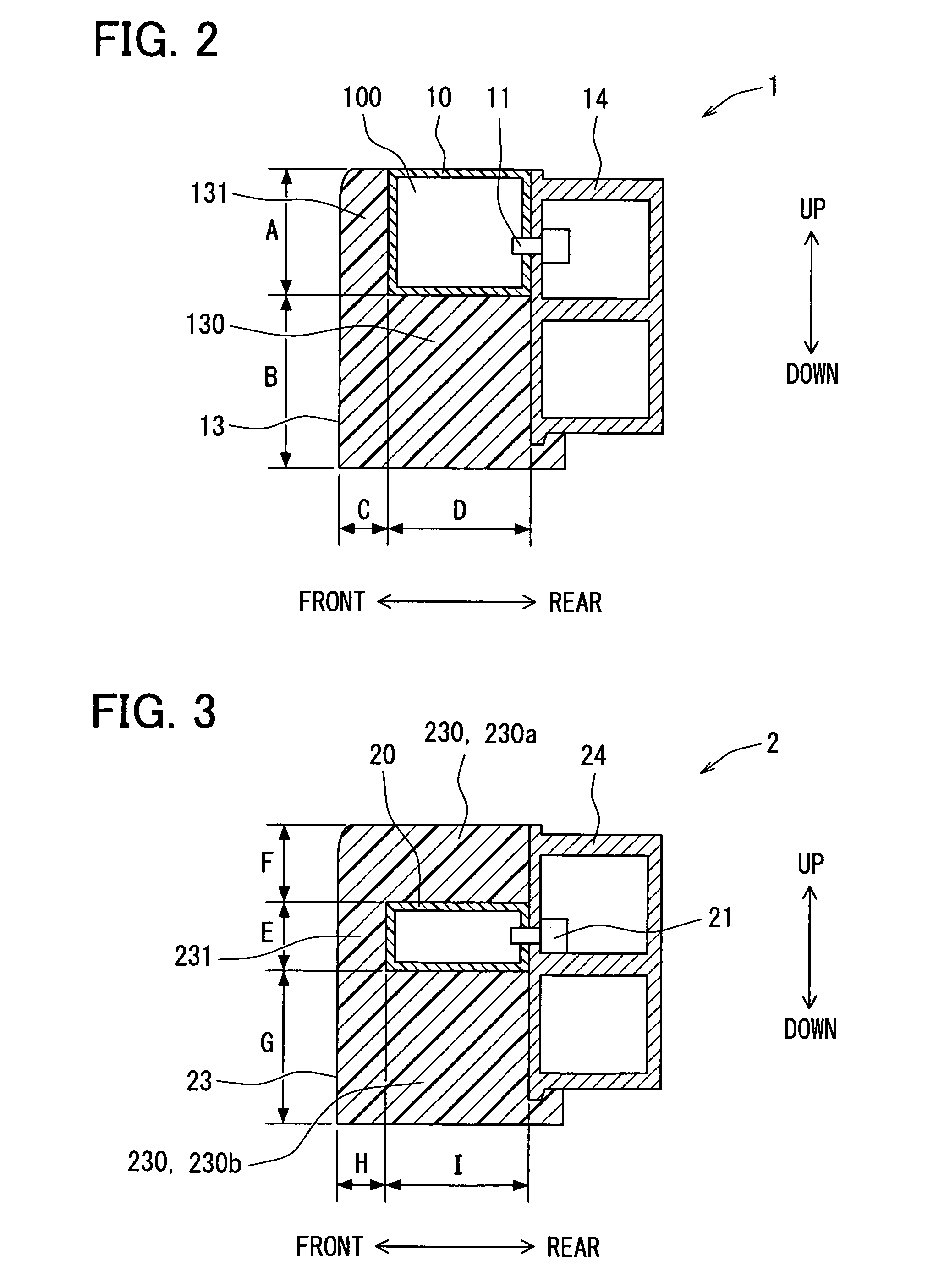

Collision detecting device

InactiveUS20090024323A1Sufficient rigiditySufficient deformabilityDigital data processing detailsAnti-collision systemsPressure sensorElectrical and Electronics engineering

A collision detecting device includes a chamber member providing a chamber, a pressure sensor connected to the chamber member, and a bumper absorber absorbing an impact generated by collision of an object with the vehicle. The bumper absorber has a region, which has a thickness in a front-rear direction of the vehicle. The thickness of the region is equal to or smaller than a predetermined thickness. The region is in contact with at least a portion of the chamber member. The collision is detected based on the pressure of the chamber detected by the pressure sensor. Hereby, a collision detecting device in which the bumper absorber has sufficient rigidity, and the chamber has sufficient deformability in case of collision can be obtained.

Owner:DENSO CORP

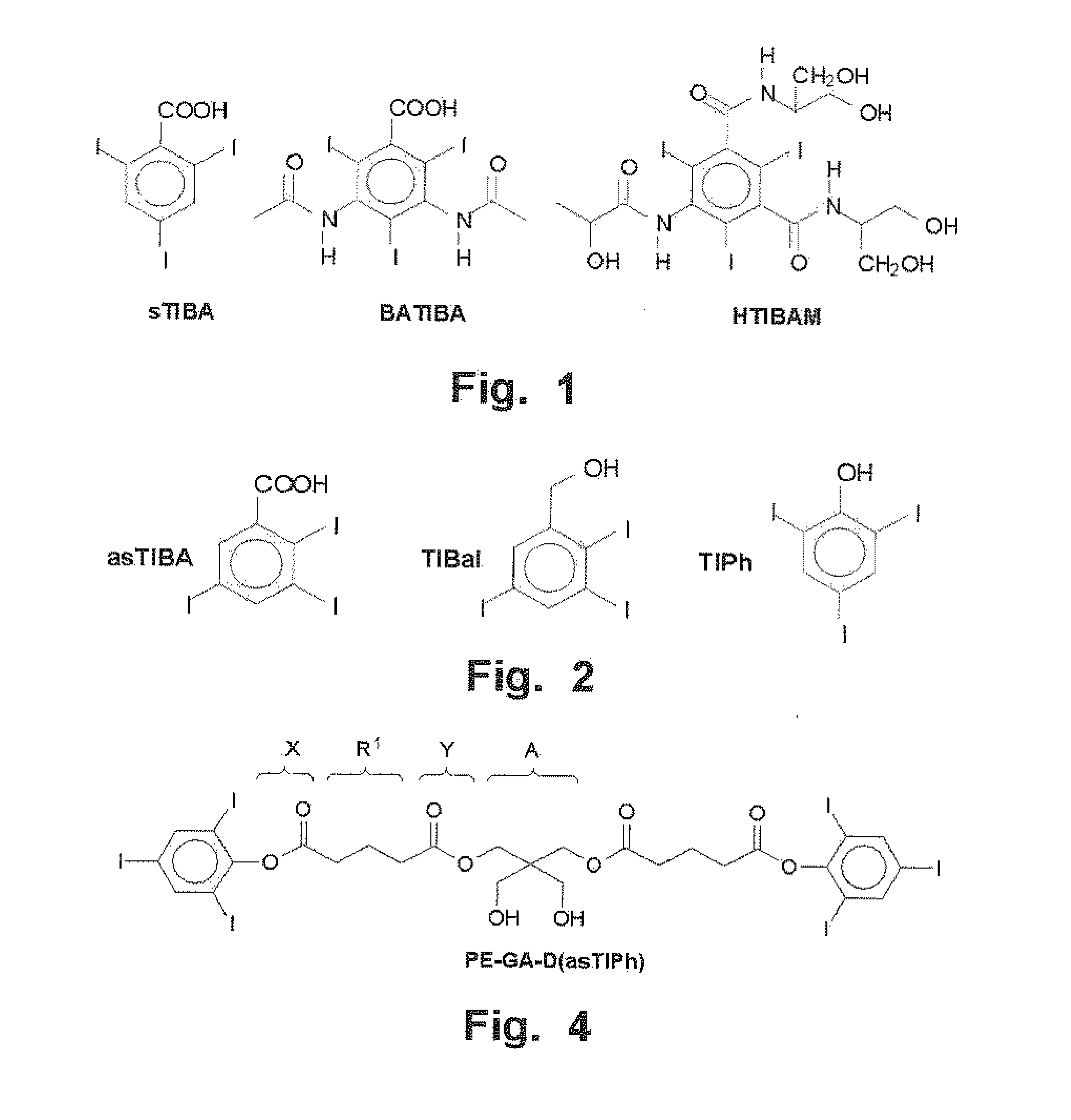

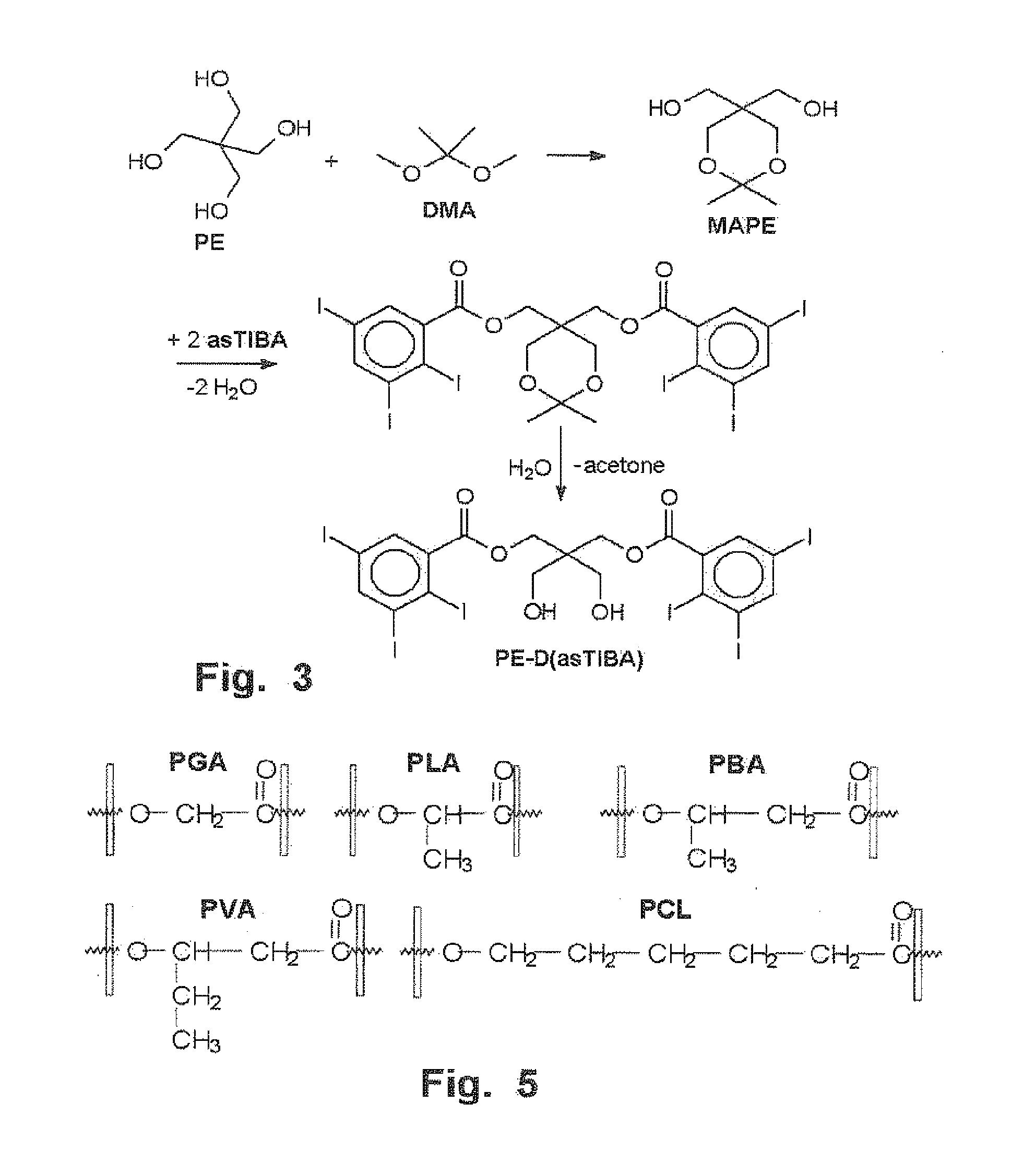

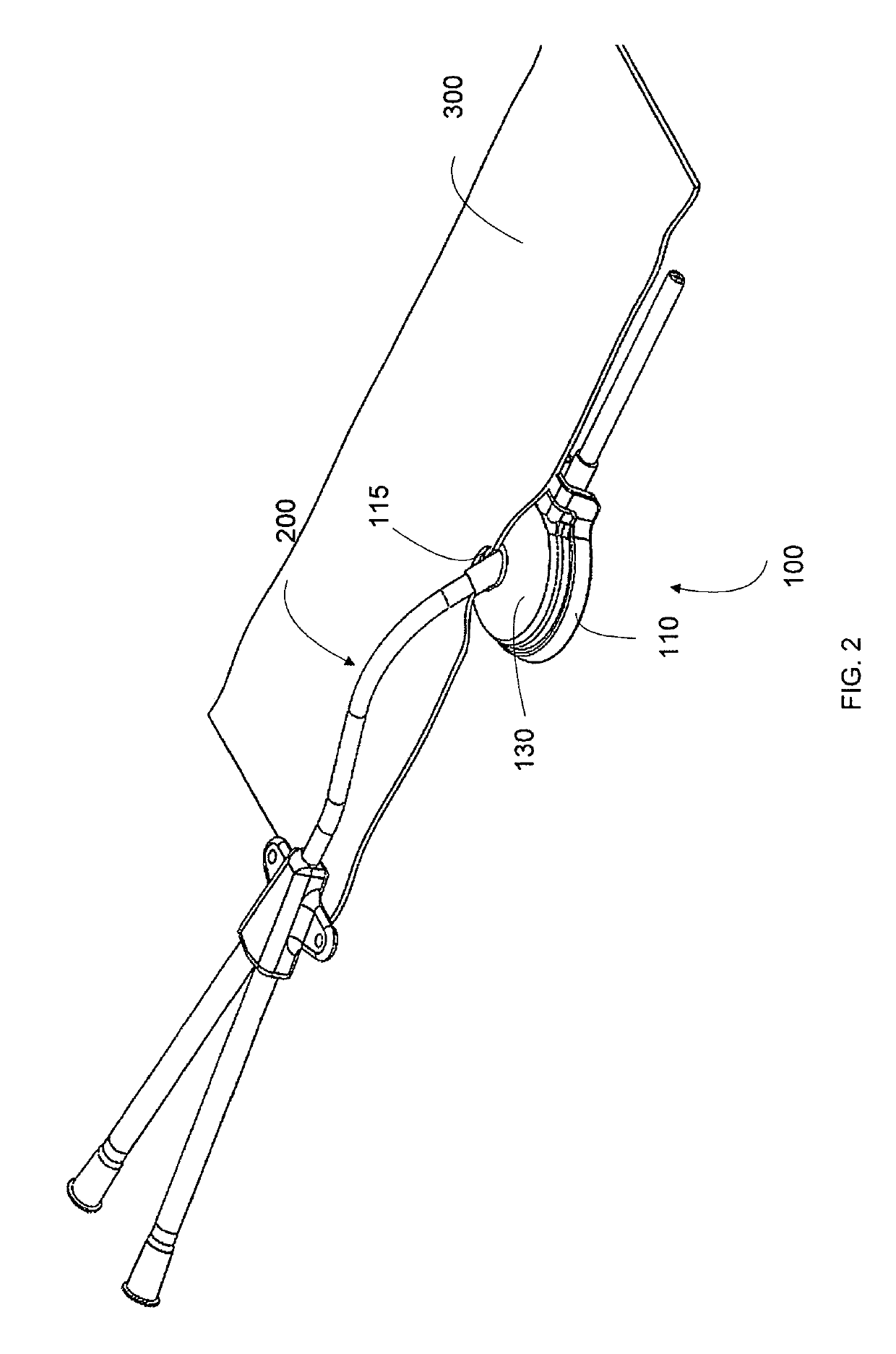

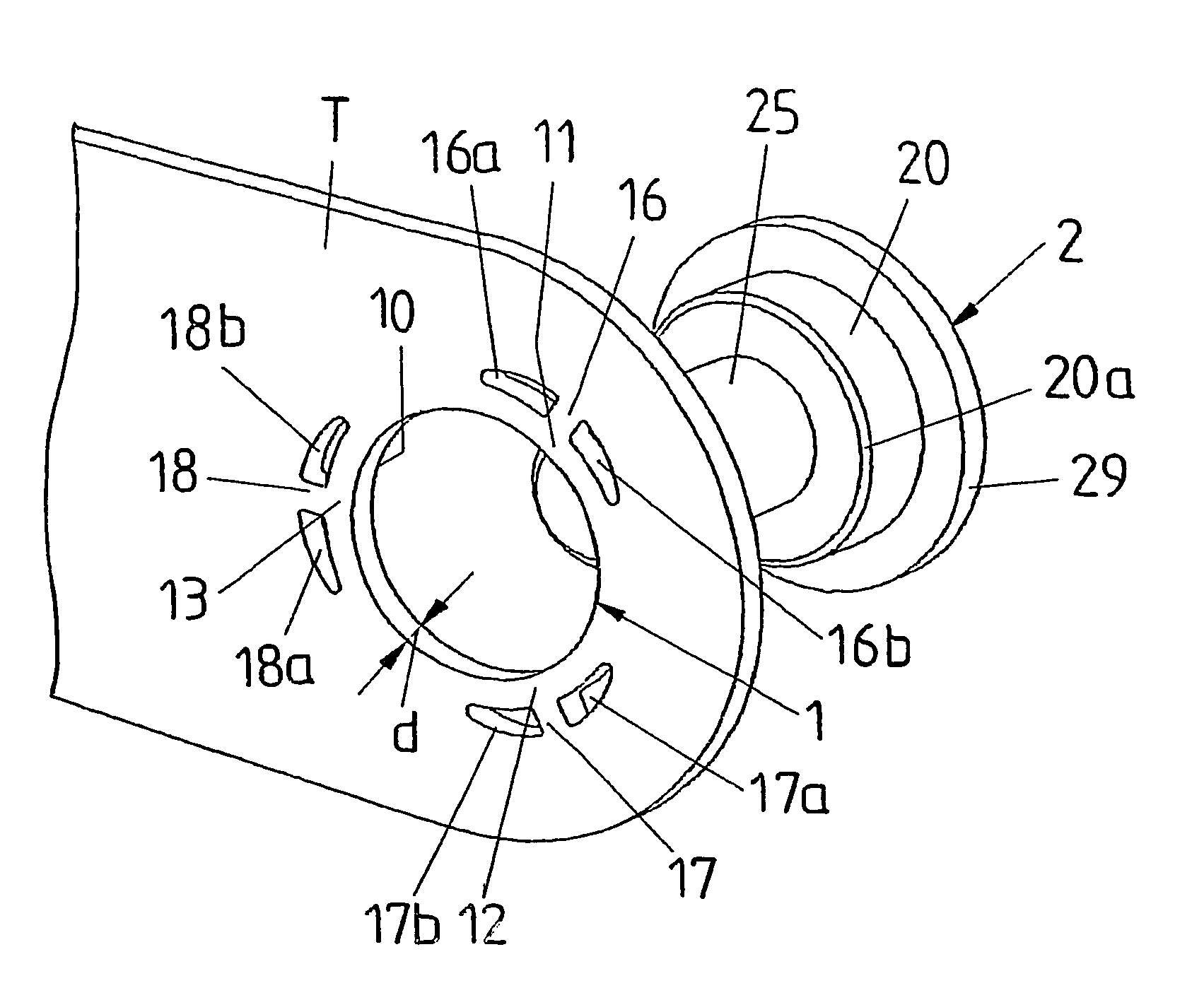

Occlusion Instruments Comprising Bioresorbable Radiopaque Polymeric Materials, As Well As Related Products, Methods And Uses

InactiveUS20100262182A1Appropriate strengthSufficient deformabilityPowder deliveryNanomedicineVisibilityNanoparticle

Described are occlusion instruments (1, 2, 3, 4) comprising bioresorbable and thermoplastically deformable polymers with or without shape memory characteristics, which contain radiopaque building groups in the repeat units of the polymer chains and / or are modified with bioresorbable, radiopaque nanoparticles. The polymers display sufficient strength and deformability, good bioresorbability and sufficient visibility in radiance and are particularly useful for producing metal-free occlusion instruments for closing defects of the septum in the heart, the positioning of which being monitorable using routine diagnostic methods.

Owner:OCCLUTECH GMBH

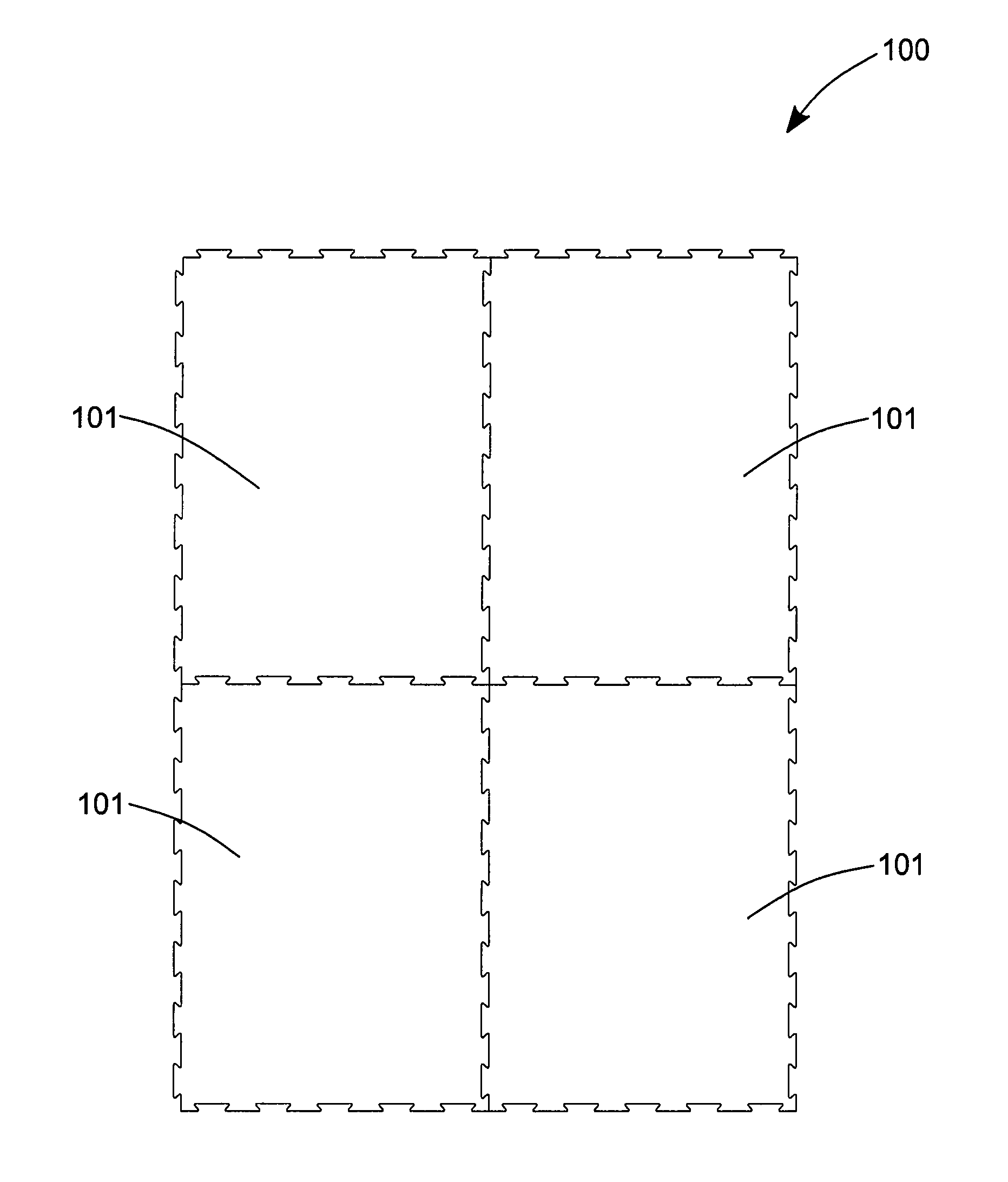

Interlocking modular flooring assembly with bevelled connectors

InactiveUS20100162642A1Rigid enoughSufficient deformabilityTreadsSingle unit pavingsEngineeringHeavy duty

A modular flooring assembly for heavy-duty applications is presented. It is made of a plurality of interlockable mat units, each mat having a plurality of edges with at least one edge having a connector in the plane of the mat unit. Each connector is made of a plurality of alternating teeth and grooves respectively adapted to engage the grooves and the teeth of another mat unit. Each groove has a first bevel with respect to the plane extending along its back wall and a rear portion of its corresponding side walls. Each tooth has a second bevel with respect to the plane extending along its front wall and a front portion of its corresponding side walls. The first and the second bevels are complementary and each side wall form a twist transition between the first and second bevels.

Owner:ANI MAT

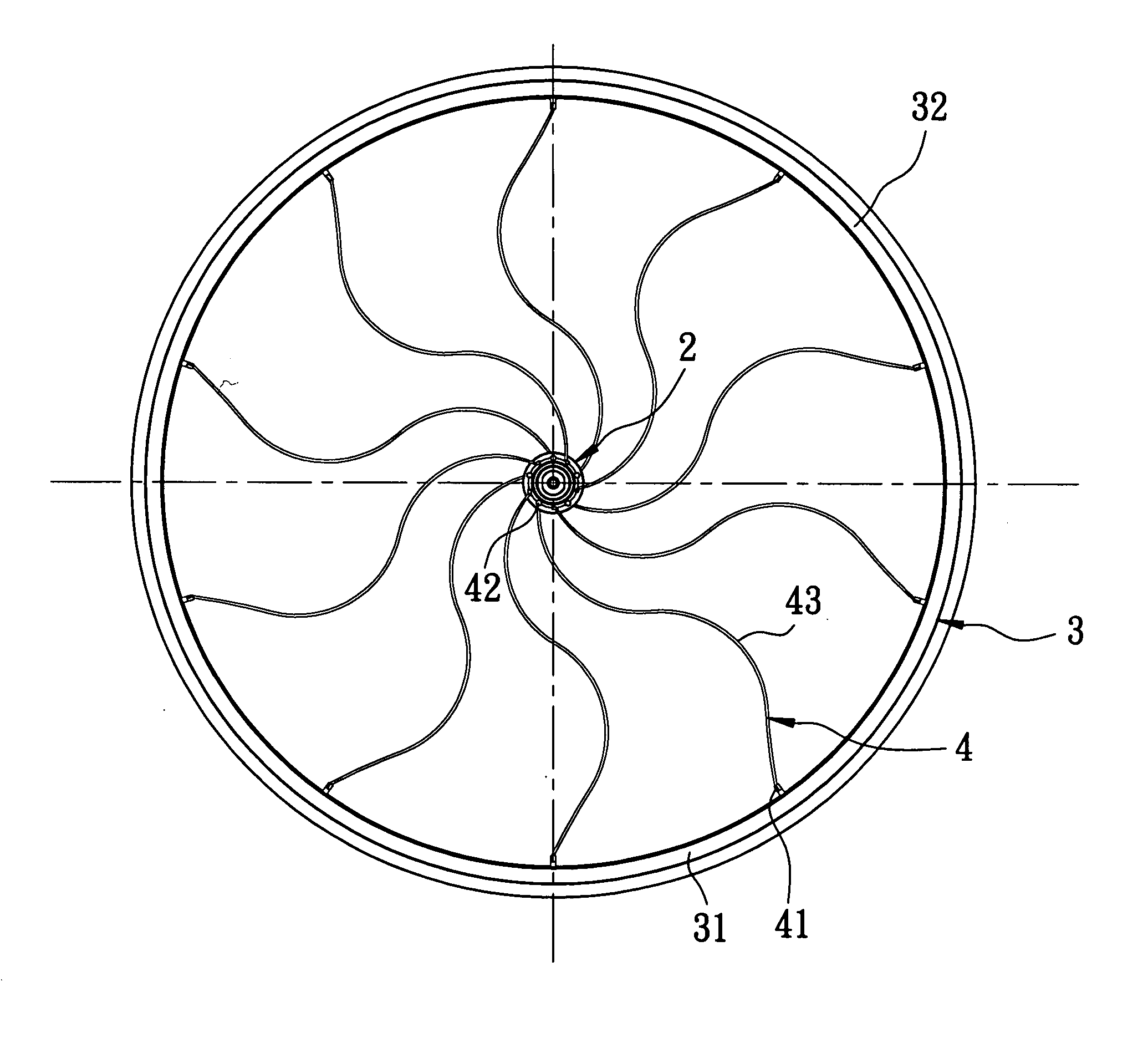

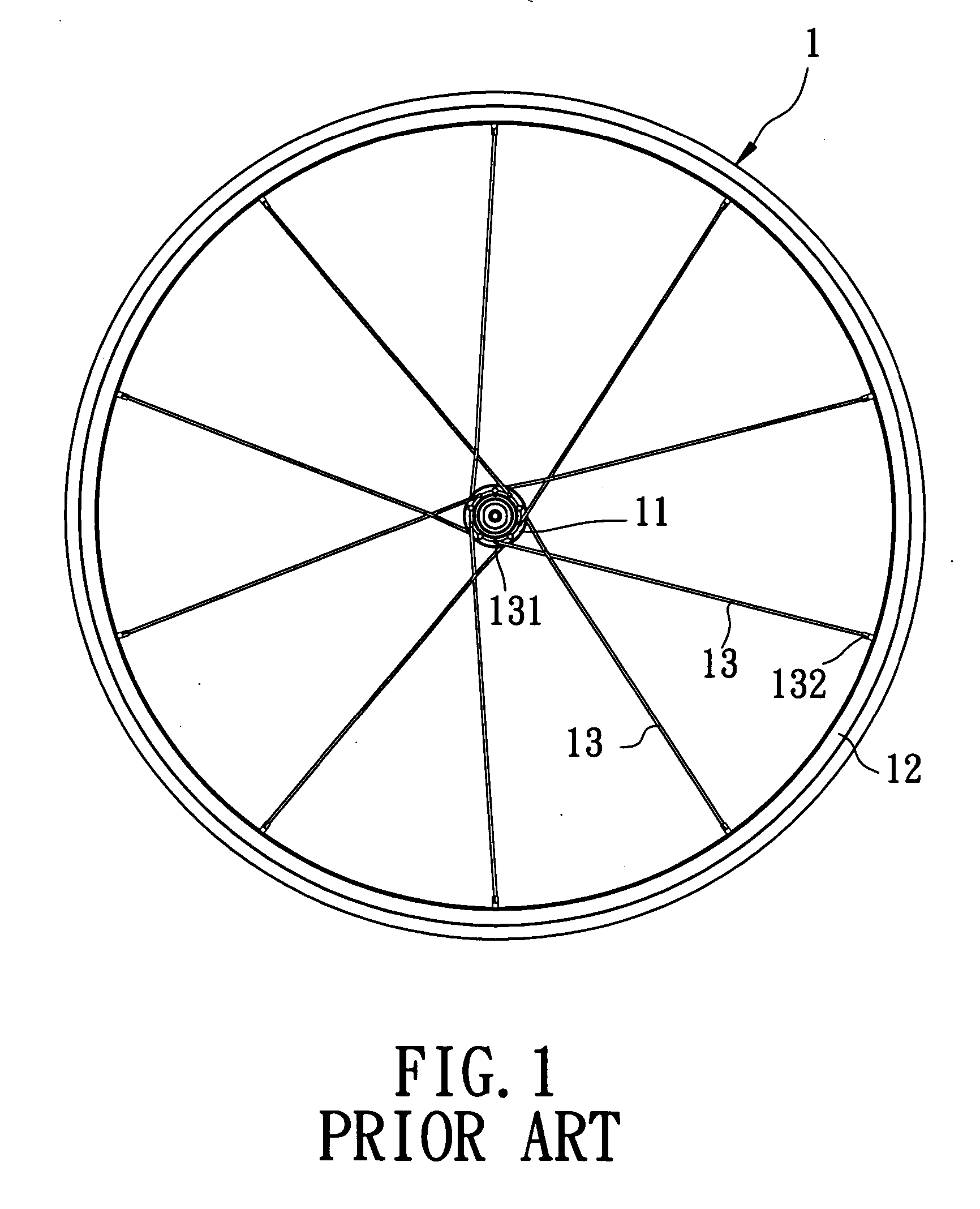

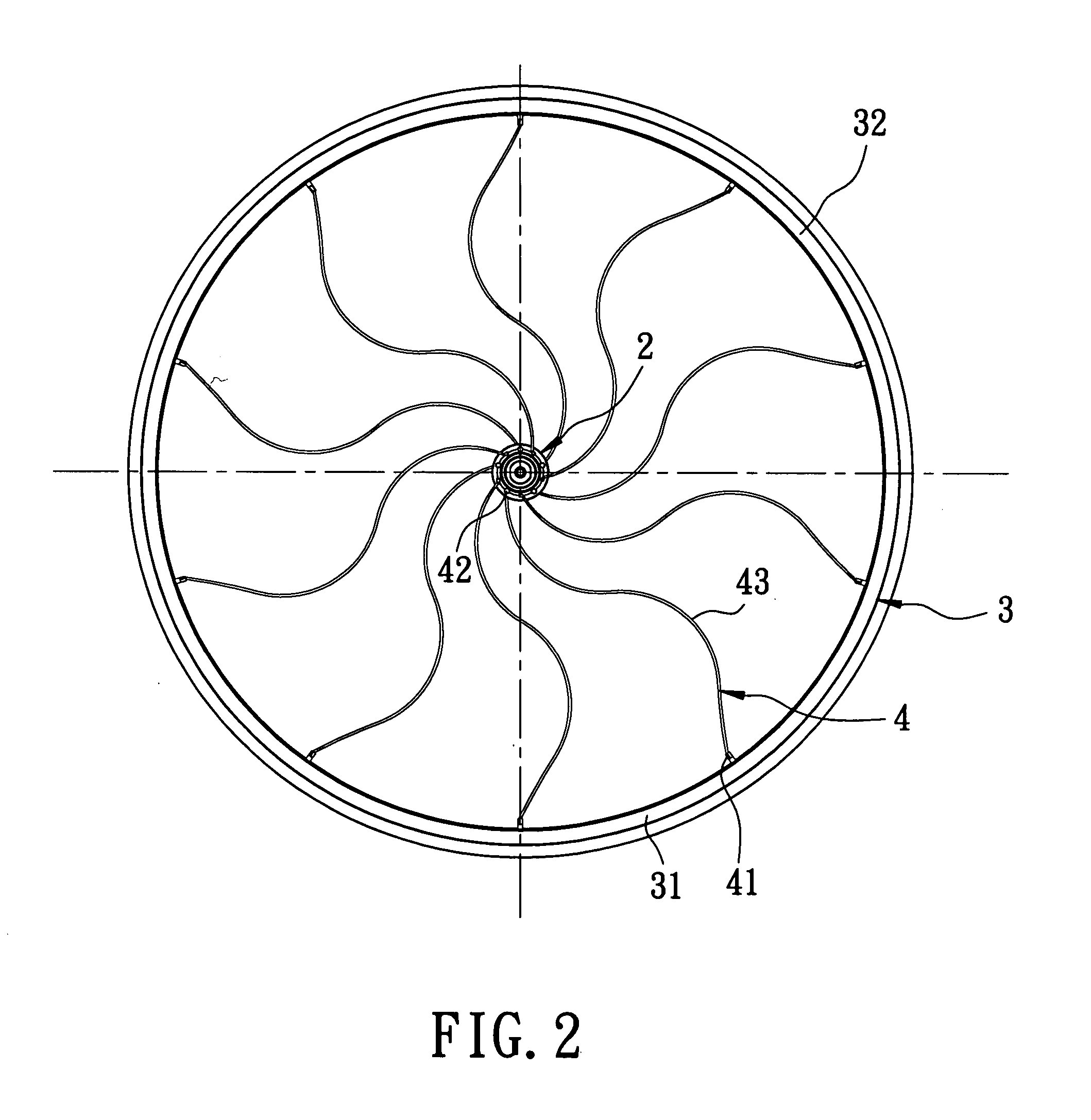

Wheel frame assembly

InactiveUS20070090683A1Sufficient elastic deformabilitySufficient deformabilityNon-metallic wheel bodySpoked wheelsMechanical engineering

A wheel frame assembly includes a hub, a rim surrounding the hub, and a plurality of spokes. Each of the spokes extends between the hub and the rim, and has at least one bent section that is compressible and deformable elastically. Therefore, sufficient elastic deformability and shock absorbability can be provided by the wheel frame assembly.

Owner:LUO CHIN KUANG

Collision detecting device

InactiveUS8350685B2Rigid enoughSufficient deformabilityDigital data processing detailsAnti-collision systemsPressure sensorElectrical and Electronics engineering

A collision detecting device includes a chamber member providing a chamber, a pressure sensor connected to the chamber member, and a bumper absorber absorbing an impact generated by collision of an object with the vehicle. The bumper absorber has a region, which has a thickness in a front-rear direction of the vehicle. The thickness of the region is equal to or smaller than a predetermined thickness. The region is in contact with at least a portion of the chamber member. The collision is detected based on the pressure of the chamber detected by the pressure sensor. Hereby, a collision detecting device in which the bumper absorber has sufficient rigidity, and the chamber has sufficient deformability in case of collision can be obtained.

Owner:DENSO CORP

Instrument of novel circuit board module structure

The invention discloses an instrument of a novel circuit board module structure. The instrument comprises a shell and a circuit board module arranged in the shell and is characterized in that the circuit board module comprises four circuit boards which are assembled to form a square frame structure in the upper direction, the lower direction, the front direction and the back direction, and abutting connection portions of the adjacent circuit boards are in circuit connection through plug-in connectors and provided with bayonets and bayonet flanges, wherein the bayonets and bayonet flanges are used for steady connection and are clamped with each other. According to the circuit board module structure, circuit connection and structural fixation between the circuit boards are achieved by means of the fixing effect of the plug-in connectors, it is ensured that the circuit board module is steadily and fixedly installed in the shell through the plug-in connectors in cooperation with a clamping structure, limiting reinforcing flange bodies and the like, no clamping grooves or other structures need to be formed in the shell of the instrument, no screws or other parts are needed, disassembly and assembly are convenient, the processing technology of the instrument is simplified, the product cost is reduced, the structure of the instrument has the good radiating effect, and the instrument is safe and reliable.

Owner:南京深科博业电气股份有限公司

Methods and apparatus for well construction

InactiveUS7946359B2Increase flexibilitySufficient deformabilityDrilling rodsFluid removalDrill holeBuilding construction

A method of constructing a borehole drilled with a drilling apparatus (16), the method comprises: connecting a flexible tubular liner sleeve (22) around the outside of the drilling apparatus and connecting the sleeve around an upper opening of the borehole so as to pass into the borehole; progressively extending the sleeve into the borehole as drilling progresses while maintaining connection to the drilling apparatus and borehole opening; at a predetermined point in the drilling, expanding the sleeve so as to contact the borehole wall; and setting the sleeve so as to be fixed to the borehole wall after expansion. Apparatus for use in such a method comprises: a flexible, expandable sleeve (22); a first connector for connecting the sleeve around the outside of a drilling assembly; and a second connector for connecting the sleeve around the opening of the borehole; wherein the sleeve is arranged to extend through the borehole between the connectors as drilling progresses.

Owner:SCHLUMBERGER TECH CORP

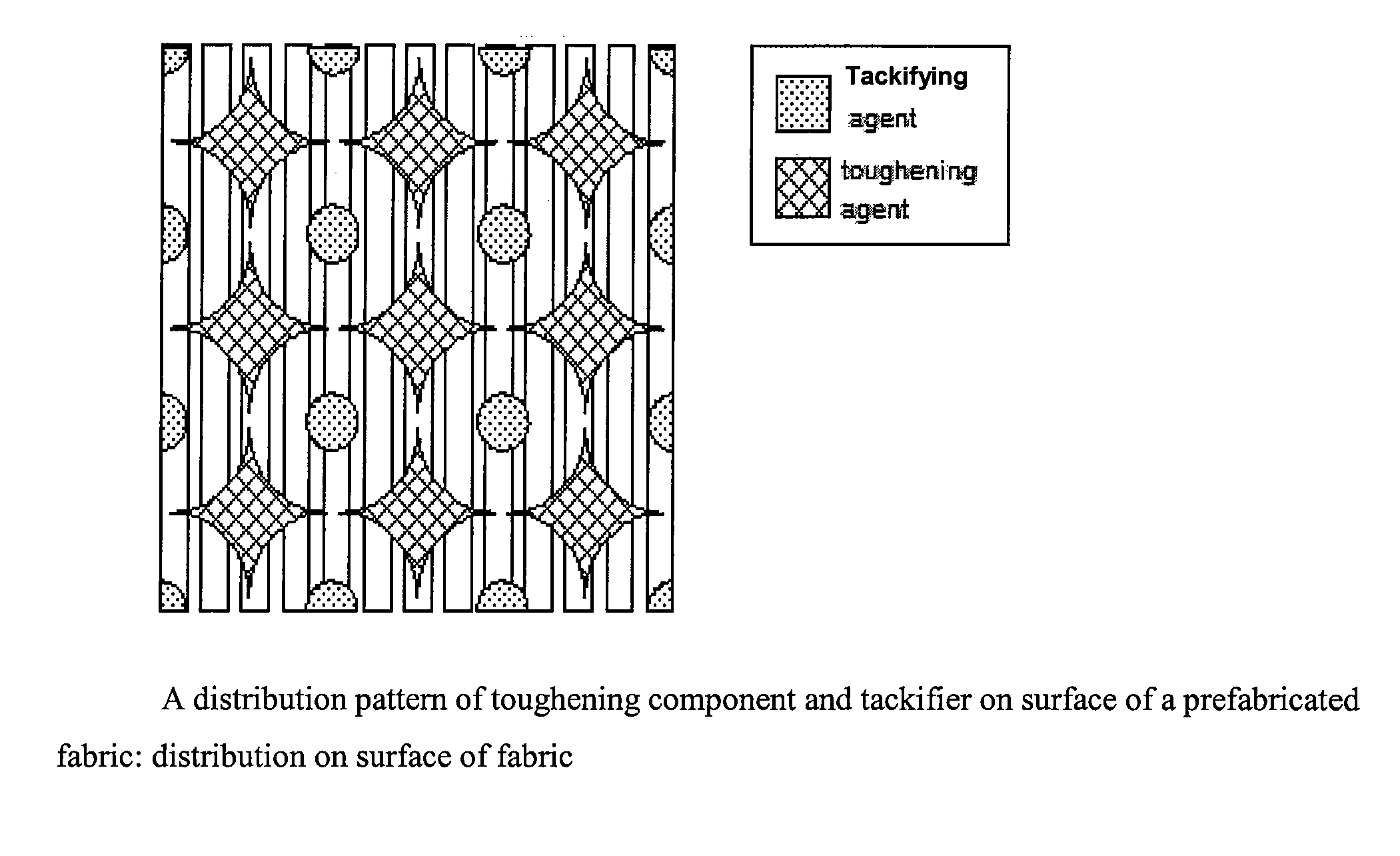

Prefabricated Fabric for Liquid Molding Composite Material and Preparation Method Thereof

InactiveUS20110014834A1Improve toughnessImprove performanceFibre treatmentSynthetic resin layered productsFiberManufacturing technology

The present invention is in the field of composite material manufacturing technology, and relates to a prefabricated fabric for liquid molding composite material and a preparation method thereof. The prefabricated fabric comprises a basal fiber fabric, which is characterized in that one or two surface(s) of the basal fiber fabric is(are) conglutinated with a toughening layer. The method for preparing the prefabricated fabric comprises the steps of conglutination of toughening layer, and conglutination of tackifying layer. The prefabricated fabric has both the interlaminar selective toughening and tackifying functions, and realizes the high toughness modification of the composite material while keeping the composite material liquid molding processibility and the good tackifying performance.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

Dispenser with child-proof lock

ActiveUS9352348B2Accessibility preventedManeuverability preventedMedical devicesSingle-unit apparatusCouplingElectrical and Electronics engineering

A dispenser including a medium reservoir, a discharge opening, and a feeding device for feeding medium from the medium reservoir to the discharge opening, wherein an actuating handle is displaceable relative to the medium reservoir in an actuation direction to discharge medium.The dispenser includes a protective device with two partial shells interconnected in a protective condition by a coupling device for repeated decoupling and coupling wherein the protective device is attachable to the feeding device in a protective position such that in the protective condition the accessibility and / or maneuverability of the actuating handle is prevented, and upon releasing the coupling device an enable condition of the protective device is achievable in which the partial shells are displaceable relative to another so that the protective device is removable from the feeding device, and thus accessibility or maneuverability of the actuating handle is obtainable thereby.

Owner:APTAR RADOLFZELL

Interior trimming piece

InactiveUS7841617B2Eliminate archingSimplify workPedestrian/occupant safety arrangementMobile vehicleFixed frame

Described is an interior trimming piece (e.g., for a motor vehicle) which includes (a) a plastic substrate; (b) a metal reinforcing piece connected to the substrate and (c) at least one bridge. The metal reinforcing piece includes (i) a hinge sheet for bridging a channel for passage of an airbag in at least one region and (ii) a fastening frame for an airbag module which is connected in one piece with the hinge sheet via a hinge web. The at least one bridge engages behind the substrate in the at least one region. The bridge fixes the fastening frame to the substrate. The hinge sheet is mounted on a side of the substrate which faces away from an interior.

Owner:FAURECIA INNENRAUM SYST

Deformable medical implant

InactiveUS10272236B2Maximize of installationMaximize of stabilitySurgeryMedical devicesReduced sizeBiomedical engineering

Owner:MARVAO MEDICAL DEVICES

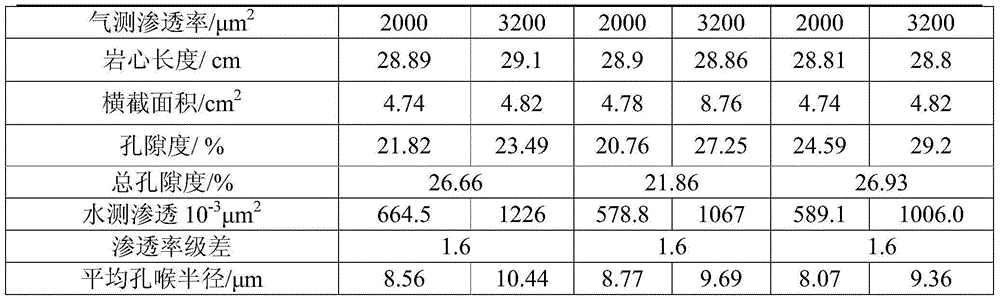

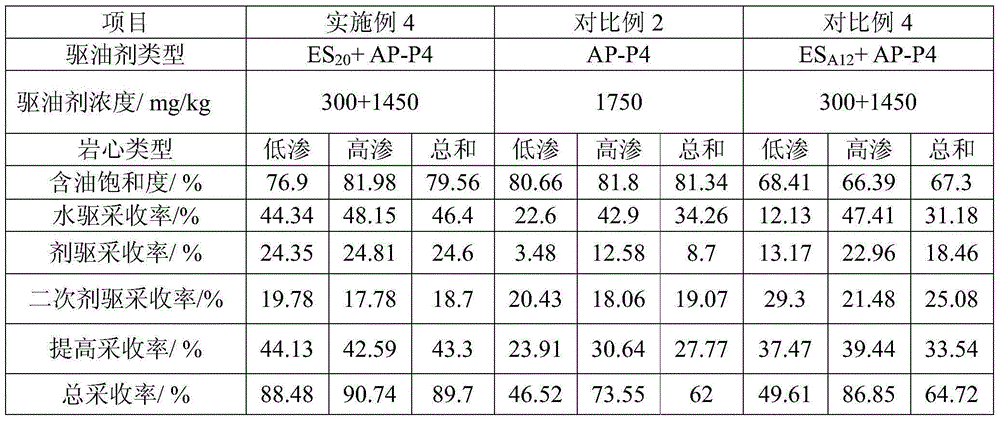

Amphoteric cross-linked polymer microsphere-hydrophobic associative polymer profiling/flooding agent and application thereof

ActiveCN106467733AHigh mechanical strengthSufficient deformabilityDrilling compositionCross-linkPolymer science

The invention relates to an amphoteric cross-linked polymer microsphere-hydrophobic associative polymer profiling / flooding agent and an application thereof. The profiling / flooding agent comprises 0.01-0.5% of amphoteric cross-linked polymer microspheres, 0.01-0.5% of water-soluble hydrophobic associative polymer and balance of water. The amphoteric cross-linked polymer microspheres are prepared through a polymerization reaction in an inert environment. In the reaction system of the polymerization reaction, polymerization monomers account for 1.0-40% of the reaction system by mass; cross-linking monomer accounts for 0.001-3% of the reaction system by mass; the polymerization monomers are anionic monomer, cationic monomer and nonionic monomer, wherein a molar ratio of the anionic monomer to the cationic monomer to the nonionic monomer to the cross-linking monomer is 2.5-25: 2.5-25: 50.0-95: 0.1-6. With the composite deep profiling / flooding agent provided by the invention, water injected reservoir recovery rate can be substantially improved. The profiling / flooding agent is more suitable for waterflooding reservoirs with nonuniform porous media.

Owner:CHINA NAT OFFSHORE OIL CORP +1

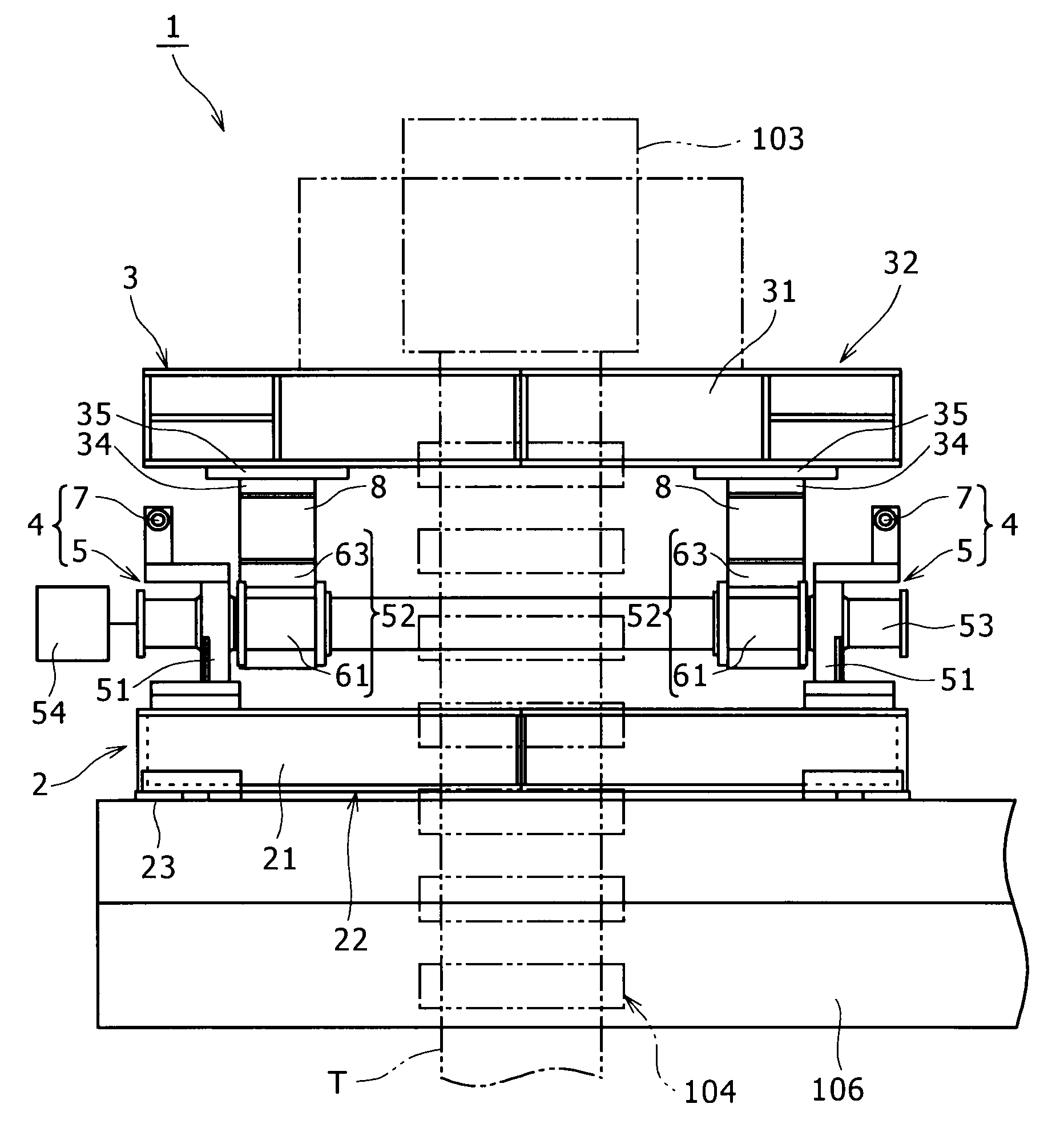

Mold oscillating apparatus

ActiveUS20080196857A1Sufficient deformabilityEliminate deformationConfectioneryCeramic shaping apparatusTorsional deformationMechanical engineering

In a mold oscillating apparatus according to the present invention, a connecting plate for interconnecting a moving bearing housing rotated by eccentric rotation of an eccentric shaft and a mold table oscillated by rotation of the moving bearing housing is supported by the mold table from one end of an upper end part thereof to the other end, and supported by the moving bearing housing from one end of a lower end part thereof to the other end. By such a configuration, torsional deformation of the connecting plate is prevented and a stress generated in the connecting plate is eased.

Owner:KOBE STEEL LTD

Suspension tunnel connecting component

ActiveCN112878374AMeet VibrationMeet the relative displacement deformationArtificial islandsUnderwater structuresRadial stressButt joint

The invention discloses a suspension tunnel connecting component. The suspension tunnel connecting component comprises a connector head and a connector tail which are in butt joint with a front pipe section and a rear pipe section; the head and the tail of the connector are connected through three stress components, namely a radial stress component for bearing radial load and generated displacement of the suspension tunnel, an axial stress component for bearing axial load and displacement and an annular stress component for bearing annular load and rotation; and the stress components are connected to spherical hinge springs through connecting shafts, so that the shock-absorbing and buffering performance is ensured, and the relative degree of freedom of the head and the tail of the connector is met. Compared with a traditional immersed tube connection tunnel connector, the suspension tunnel connecting component is provided with the components which are stressed in the axial direction, the radial direction and the annular direction, the freedom degree in the six directions is met, and the suspension tunnel connecting component can adapt to vibration and deformation generated by a suspension tunnel in the complex marine environment.

Owner:CHONGQING JIAOTONG UNIVERSITY

Energy consumption damper based on tension compression and yield of trepanning steel plate

ActiveCN110629899ASufficient deformabilityNo torsional bucklingBridge structural detailsProtective buildings/sheltersTension compressionEnergy consumption

Theinvention relates to an energy consumption damper based on the tension compression and yield of a trepanning steel plate, and belongs to the field of buildings. The energy consumption damper basedon the tension compression and yield of the trepanning steel plate comprises a trepanningcore plate, external constraint plates and cone-shaped connecting pieces; a first connecting hole and a secondconnecting hole which are used for connecting the cone-shaped connecting pieces are formed in the trepanning core plate, and a third connecting hole used for connecting the externalconstrain plates isformed in the trepanning core plate; the cone-shaped connecting pieces are located at the upper and lower ends of the trepanning core plate, and the inner ends of the cone-shaped connecting piece canslide relatively on the trepanning core plate through a second fastener located in the secondconnecting hole under the action of external force; and the external constrain plates arelocated on the twosides of the middle of the trepanning core plate, and are connected with the trepanning core plate through a third fastener located in the third connecting hole. The invention provides a novel energyconsumption device for structure seismic of props, piers and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Bearing arrangement for a motor vehicle

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

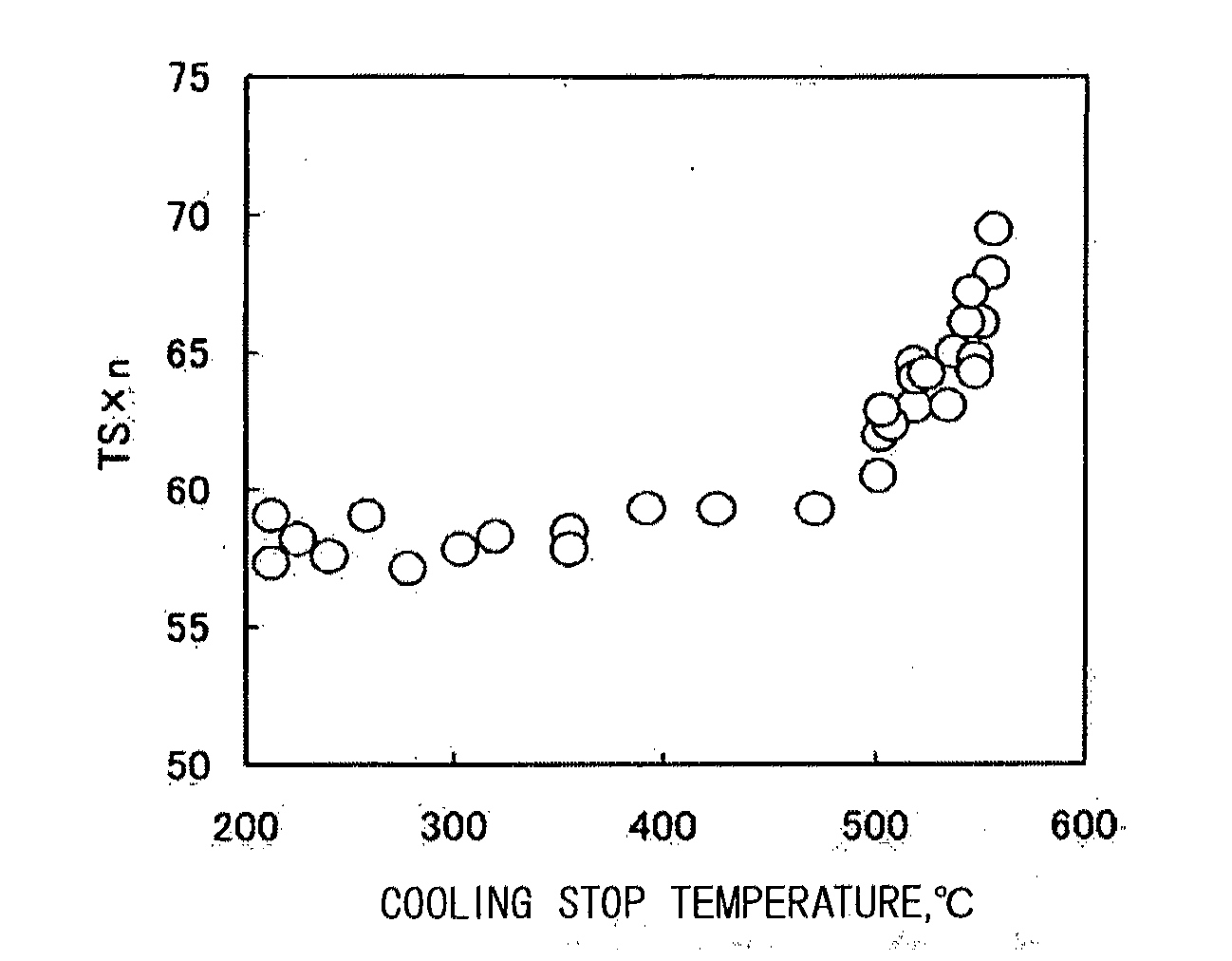

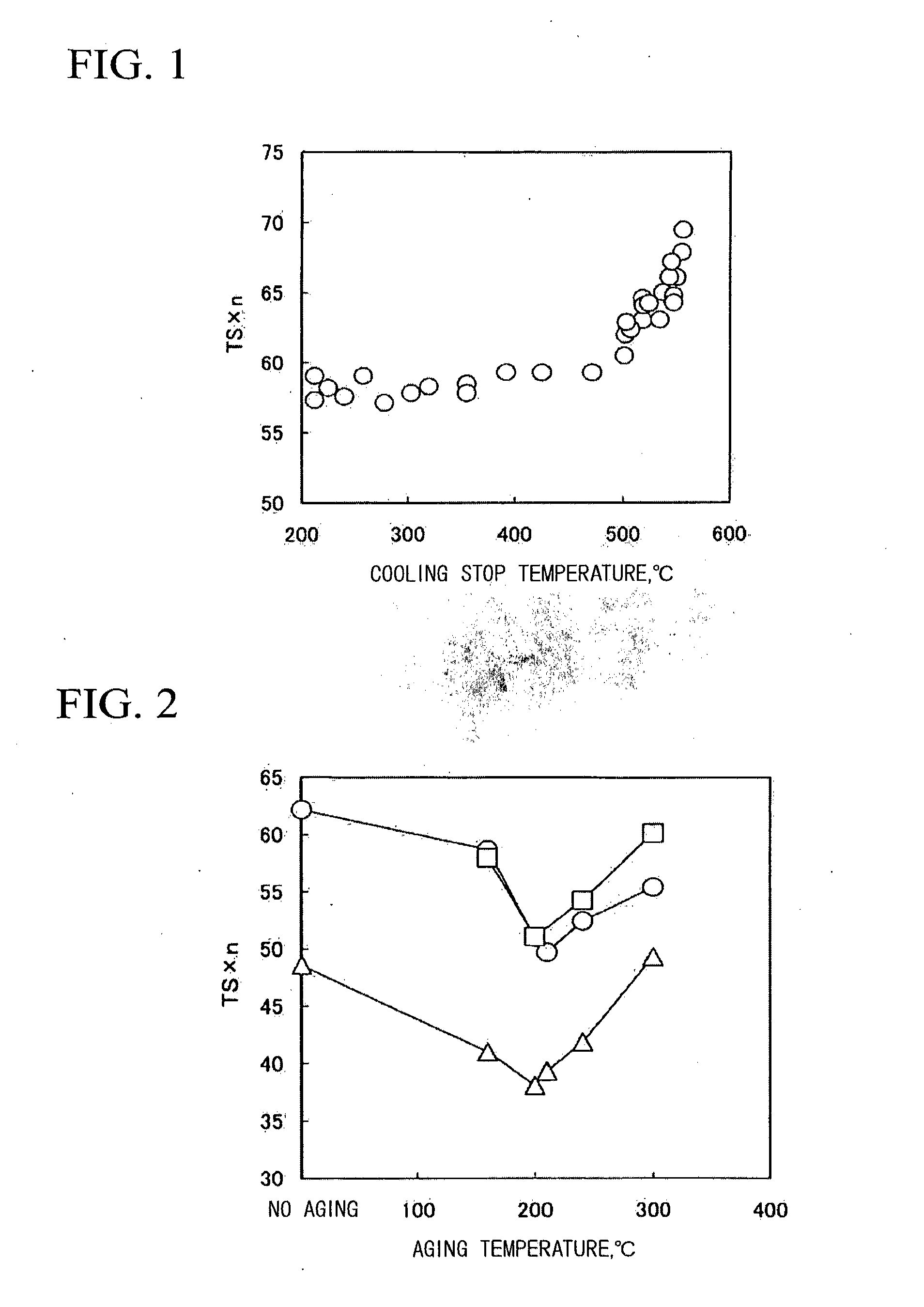

Method for manufacturing bainite high-strength seamless steel tube, and bainite high-strength seamless steel tube

ActiveUS20180282833A1Low cost productionHigh strengthTemperature control deviceFurnace typesAlloyQuenching

A method for manufacturing a bainite high-strength seamless steel tube, comprising the following steps: smelting, manufacturing a billet, heating, perforating, rolling, stretch reducing or sizing to obtain tube, and cooling. In the cooling step, the quenching starting temperature is controlled to be at least 20° C. higher than the Ar3 temperature of the steel grade; the finish cooling temperature is controlled to be within a range between T1 and T2, where T1=519−423C−30.4Mn, T2=780−270C−90Mn, and the units of the T1 and the T2 are ° C.; in the formulas, C and Mn respectively represent the mass percents of element C and element Mn of the steel grade, the content of the element C is 0.06-0.2%, and the content of the element Mn is 1-2.5%; the cooling rate is controlled to be 15-80° C. / s; and the finished product of the bainite high-strength seamless steel tube is directly obtained after the cooling step. The manufacturing of a bainite high-strength seamless steel tube using the method requires neither the addition of precious alloying elements nor the subsequent heat treatment. Therefore the production costs are low.

Owner:BAOSHAN IRON & STEEL CO LTD

Electrical connector in which a wiping action is carried out in a narrow area

ActiveUS20050277338A1Sufficient deformabilityAddressing Insufficient ControlEngagement/disengagement of coupling partsElectric discharge tubesElectrical connectorMechanical engineering

In an electrical connector to be connected to a mating connector in a predetermined direction, an insulator defines an accommodating space and an opening communicating the accommodating space in the predetermined direction. A contact as a base portion held by the insulator and a spring portion connected to the base portion. The spring portion has a first portion extending from the base portion in the accommodating space to intersect with the predetermined direction, a second portion turned opposite to the opening from the first portion and extending in the accommodating space to intersect with the predetermined direction, and a third portion extending from the second portion to pass through the opening. The third portion has a contact portion located outside the accommodating space to be elastically contacted with the mating connector.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

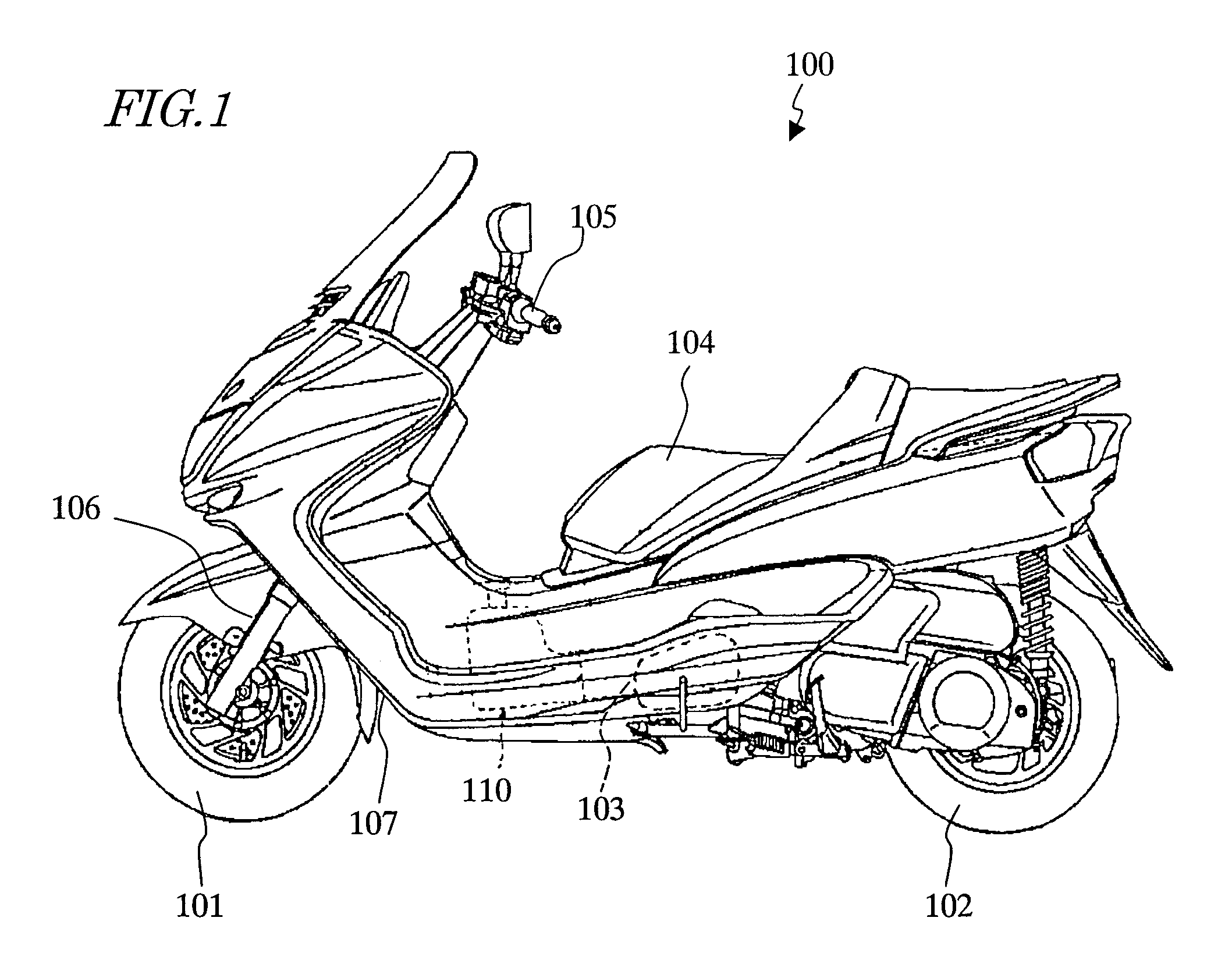

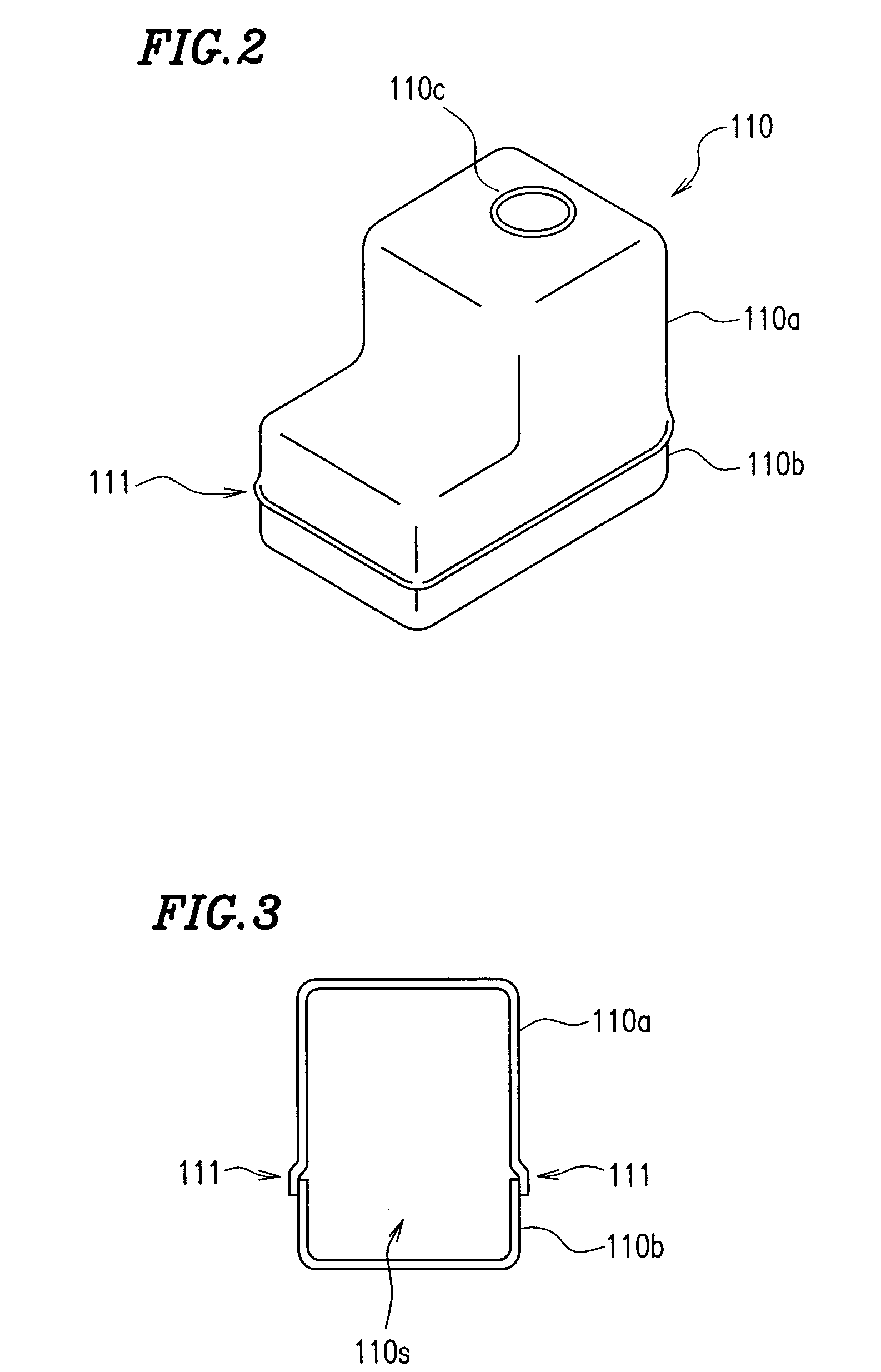

Cast part made of aluminum alloy, fuel tank, and production method for the same

ActiveUS20090250476A1Improve ductilityImprove toughnessLarge containersFurnace typesFuel tankHardness

Owner:YAMAHA MOTOR CO LTD

Concrete wall and prefabricated profiled steel sheet composite plate connecting structure and construction process thereof

PendingCN112211338ASimple structureEasy constructionFloorsArchitectural engineeringStructural engineering

The invention discloses a concrete wall and prefabricated profiled steel sheet composite plate connecting structure and a construction process thereof, and belongs to the technical field of building structures. The concrete wall and prefabricated profiled steel sheet composite plate connecting structure comprises a concrete wall body and a prefabricated profiled steel sheet concrete composite plate, a first connecting piece is embedded in the concrete wall body, the first connecting piece is fixedly connected with a plurality of connecting studs, and a post-pouring area is reserved in the prefabricated profiled steel sheet concrete composite plate. Stud holes are reserved in a profiled steel sheet located in the post-pouring area, the prefabricated profiled steel sheet concrete composite plate is arranged above the part, located outside the concrete wall body, of the first connecting piece, the connecting studs are inserted into the stud holes of the profiled steel sheet, and high-strength concrete or high-strength mortar is poured in the post-pouring area. According to the concrete wall and prefabricated profiled steel sheet composition plate connecting structure and the construction process thereof, the structure is simple, construction is convenient, the force transmission mode between components is clear, enough deformation capacity is achieved at the connecting position, and the integrity and safety of the structure are enhanced.

Owner:辽宁省城乡市政工程集团有限责任公司

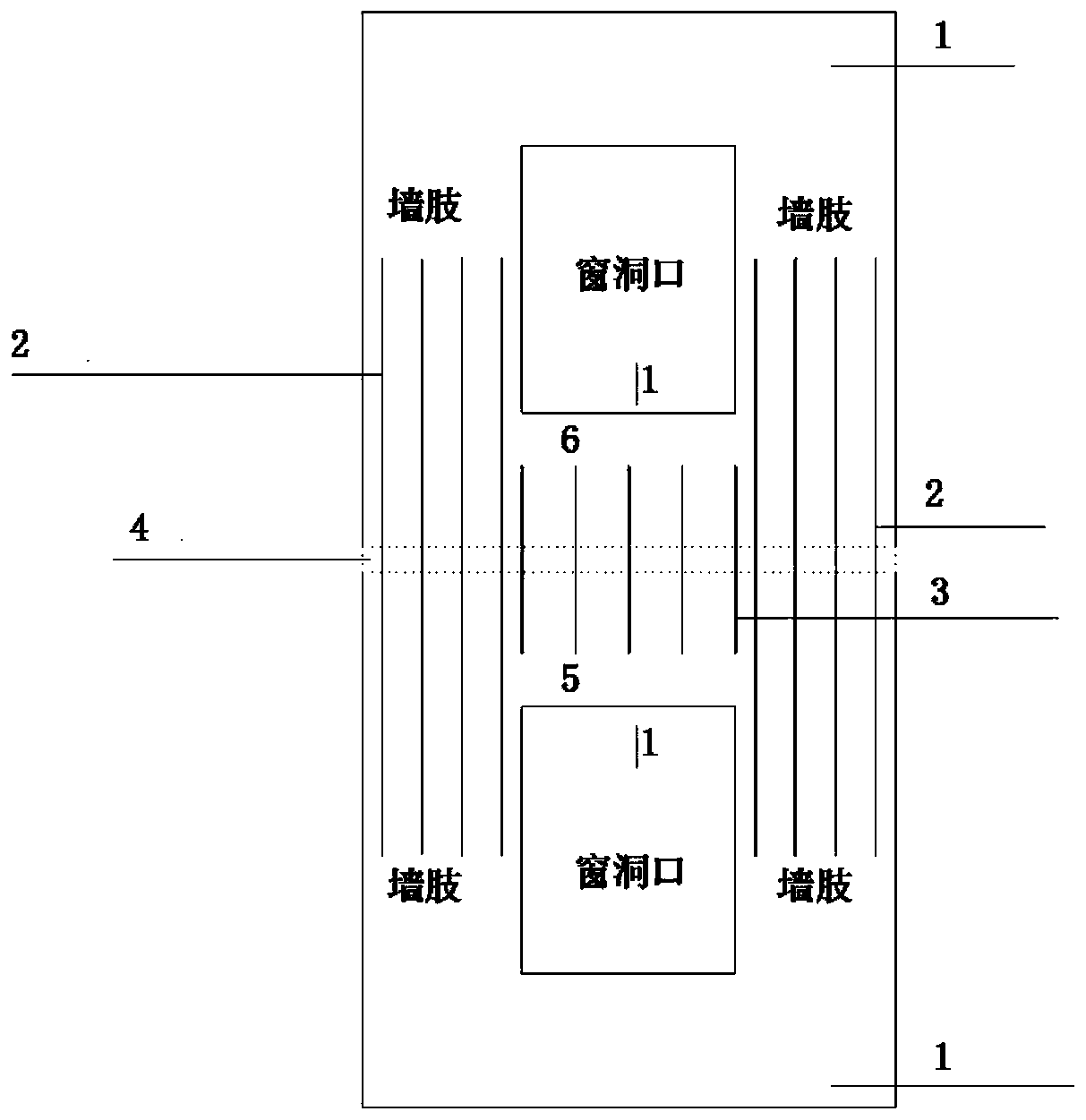

Window opening forming superimposed shear wall coupling beam assembling construction method

ActiveCN111576880ASufficient lateral stiffnessSufficient deformabilityConstruction materialWallsClassical mechanicsWindow opening

The invention relates to a window opening forming superimposed shear wall coupling beam assembling construction method which comprises the following steps: prefabricating a superimposed shear wall wallboard comprising a window upper wall coupling beam and a window lower wall coupling beam, and transporting the wallboard to a construction site for assembling; and adopting interlayer vertical connecting rebars and post-poured core concrete to effectively connect upper-layer and lower-layer superimposed wallboards. According to the construction method, through changing the quantity of vertical connecting rebars in window upper wall and window lower wall core post-poured concrete when window opening forming superimposed wallboards are assembled, all-pass seam and zero connection coupling beams, half-pass seam and weakly-connected coupling beams, half-pass beam and equi-connection coupling beams can be formed separately to meet different anti-seismic demands; the half-pass seam and weakly-connected upper-lower superimposed deep coupling beams can realize multi-stage working mechanism; this types of coupling beams have sufficient resistant-lateral rigidity and deformation capacity underthe action of frequent earthquakes and earthquakes with the design intensity and can be converted into double coupling beam stress mechanism under the action of the rare occurrence earthquake to meetthe performance objective at different stages.

Owner:WUHAN UNIV OF TECH +1

Method of manufacturing an anisotropic conductive film

InactiveUS7231706B2Increase intervalHigh strengthNon-insulated conductorsCoupling contact membersAnisotropic conductive filmEngineering

An anisotropic conductive film is prepared by winding an insulated wire around a core member to form one roll of a winding layer, placing an insulating resin film on the obtained winding layer, and repeating the step of winding the insulated wire and the step of placing the insulating resin film to give a laminate alternately having the winding layer comprising a single row of insulated wires and an insulating resin layer made from the insulating resin film. A coating layer and insulating resin layer are melted to integrate the winding layer and the insulating resin layer. The laminate then is sliced along a plane forming an angle with the insulated wire in a desired film thickness.

Owner:NITTO DENKO CORP

High-strength steel pipe and producing method thereof

InactiveUS20120118425A1Increase production capacitySufficient deformabilityFurnace typesRigid pipesCarbideCementite

This high-strength steel pipe includes, by mass%, C: 0.02% to 0.09%, Mn: 0.4% to 2.5%, Cr: 0.1% to 1.0%, Ti: 0.005% to 0.03%, Nb: 0.005% to 0.3%, and a balance consisting of Fe and inevitable impurities, in which Si, Al, P, S, and N are limited to 0.6% or less, 0.1% or less, 0.02% or less, 0.005% or less, 0.008% or less, respectively, the bainite transformation index BT is 650° C. or less, and the microstructure thereof is a single bainite microstructure including first bainite and second bainite, the first bainite being a gathered microstructure of bainitic ferrite including no carbide, and the second bainite being a mixed microstructure of bainitic ferrite including no carbide and cementite between the bainitic ferrites.

Owner:NIPPON STEEL CORP

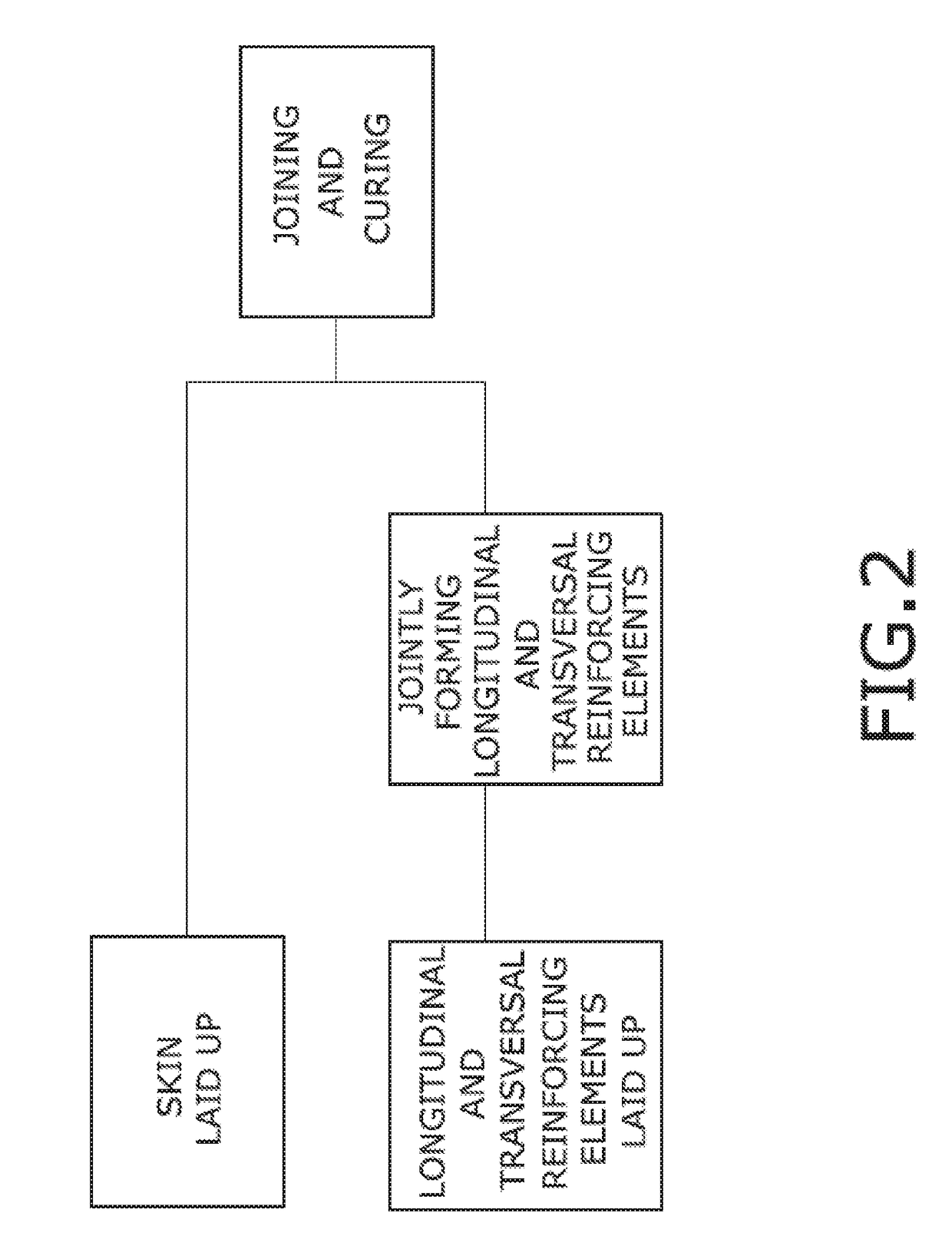

Method for manufacturing a stiffened panel made from composite material

ActiveUS20170225406A1Reduce recurring costReduce laborDomestic articlesBiomedical engineeringComposite material

A method for manufacturing a stiffened panel made from composite material comprising a skin and elongated reinforcing elements wherein some of the elongated reinforcing elements cross each other. The method comprises the steps of (a) laying up a flat laminate comprising stacked plies of composite layers for forming a structure comprising the elongated reinforcing elements of the panel, (b) cutting the flat laminate along intersection lines of planes defining the webs of two crossing reinforcing elements, (c) cutting in the flat laminate the outline of the elongated reinforcing elements, (d) forming the structure comprising the elongated reinforcing elements of the panel, (e) laying up plies of composite layers for forming the skin, and (f) curing the laid-up plies of the skin and the formed structure comprising the elongated reinforcing elements.

Owner:AIRBUS DEFENCE & SPACE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com