Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Stop coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for inhibiting hydrocarbons steam cracking furnace from coking and carburizing

ActiveCN101294099AShort injection timeLow costThermal non-catalytic crackingEconomic benefitsPre treatment

The invention relates to a method for suppressing coking and carburizing of hydrocarbon steam cracking furnaces, which comprises the following steps: arranging at least one segment of heat transfer enhancement furnace pipe in the furnace pipe of radiation section of the cracking furnace, and preprocessing the hydrocarbon steam cracking furnace by using a sol composition during heat reserve period of the cracking furnace, wherein the sol composition contains at least one selected from Si sol, Al sol and Zr sol, and the mass concentration of pure oxide in the sol composition is 0.1 to 10% the weight of the sol composition. The method provided by the invention has the advantages of low cost, simple operation, environment friendliness, and no influence on downstream system, and can significantly prolong the service life and the operation cycle of the cracking furnace on the basis of effectively suppressing coking and carburizing of the cracking furnace pipe, thus improving output of ethylene products, etc. and improving the economic benefit of an ethylene plant.

Owner:CHINA PETROLEUM & CHEM CORP +1

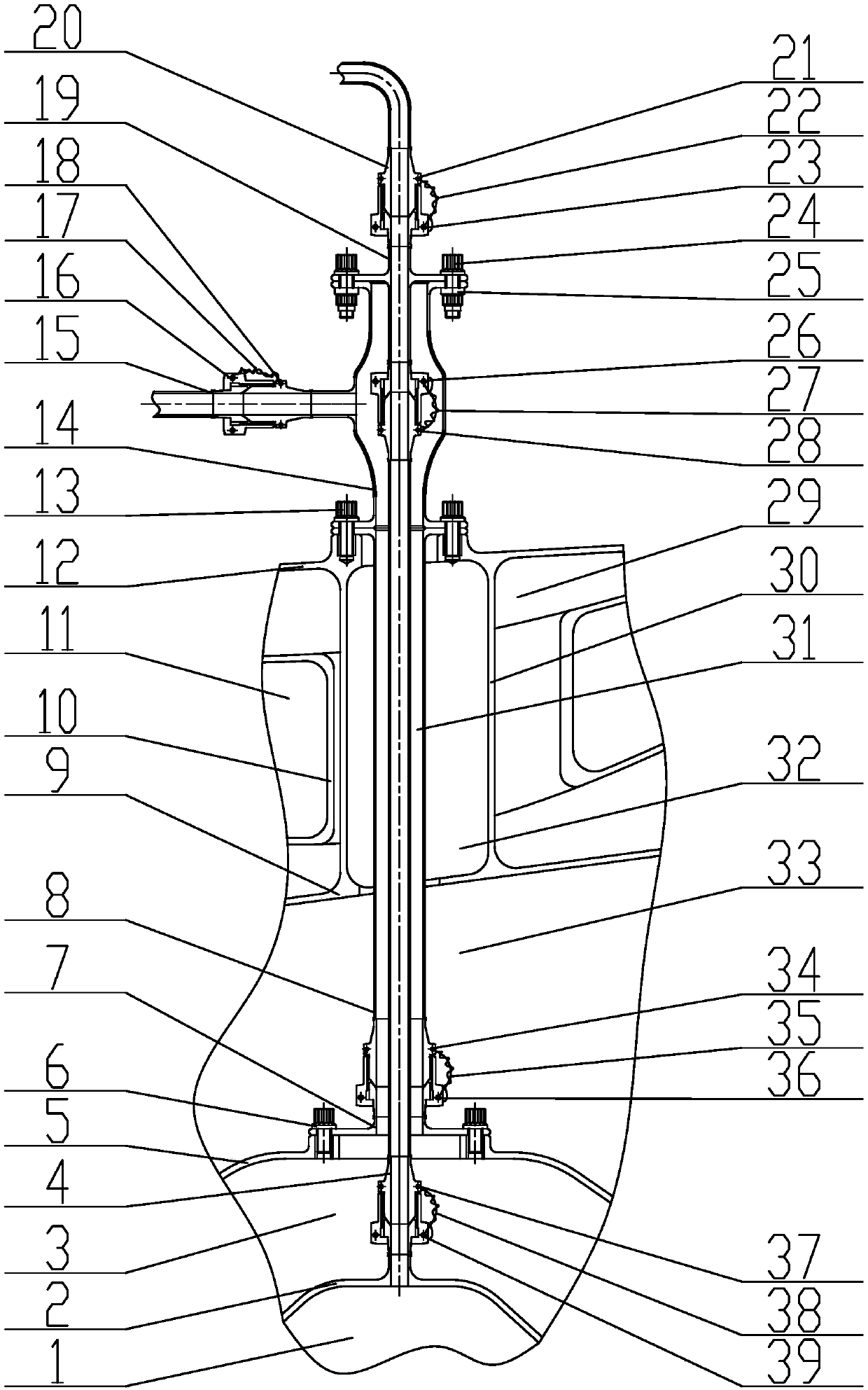

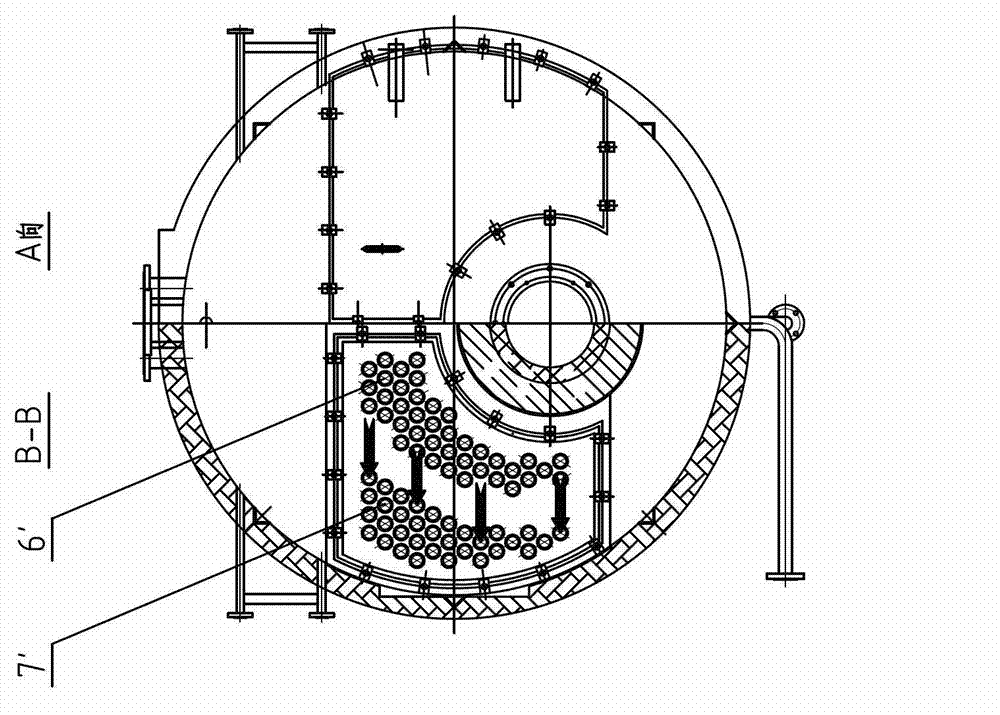

Vertical coal dust corner tube boiler

InactiveCN102644911ACompact structureStructure, compact arrangement of four cornersSteam boilersAir preheaterCoal dust

The invention discloses a vertical coal dust corner tube boiler, which comprises a burner, a boiler body, an air preheating device, a waste heat water tank, a convection bank, an upper collecting box, a top collecting box, a boiler barrel and a lower collecting box. The lower collecting box is arranged at the bottom of the boiler body, and the upper collecting box and the top collecting box are arranged on top of the boiler body and communicated through a steam communicating pipe. The vertical coal dust corner tube boiler is characterized in that the burner is arranged at the bottom of the boiler body which adopts a vertical film type water cooling wall structure, four lowering pipes are arranged at four corners, and two ends of the lowering pipe and the film type water cooling wall are communicated with the upper collecting box and the lower collecting box respectively. The convection tube bundle is arranged outside the film type water cooling wall, the top of the convection tube bundle is communicated with a boiler chamber smoke outlet, and the bottom of the convection tube bundle is communicated with the waste heat water tank. The vertical coal dust corner tube boiler has the advantages of being compact in integral structure, simple in appearance display, small in covered area, low in steel consumption, big in boiler water circulation pressure difference and safe and reliable in water circulation and the like.

Owner:HANGZHOU JUNENG BOILER

Process for synthesizing 2-chloro-5-chloromethylpyridine

InactiveCN1631881AAvoid evaporation lossPrevent polymerization and cokingOrganic chemistryOrganic chloride compoundPyridine

A method for synthesizing 2-chlorine-5-chloromethyl pyridine, uses 2-chlorine-5- as the raw material, organic chloride as solvent, in the conditions of temperature:80-180deg.C and normal pressure, initiate by chloride or light, through choosing chlorination reaction to synthesize 2-chlorine -5-chloromethyl pyridine directly. The invention has high conversion rate and utilization ratio of raw material little coking in chlorination reaction, and high seletivity and productivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

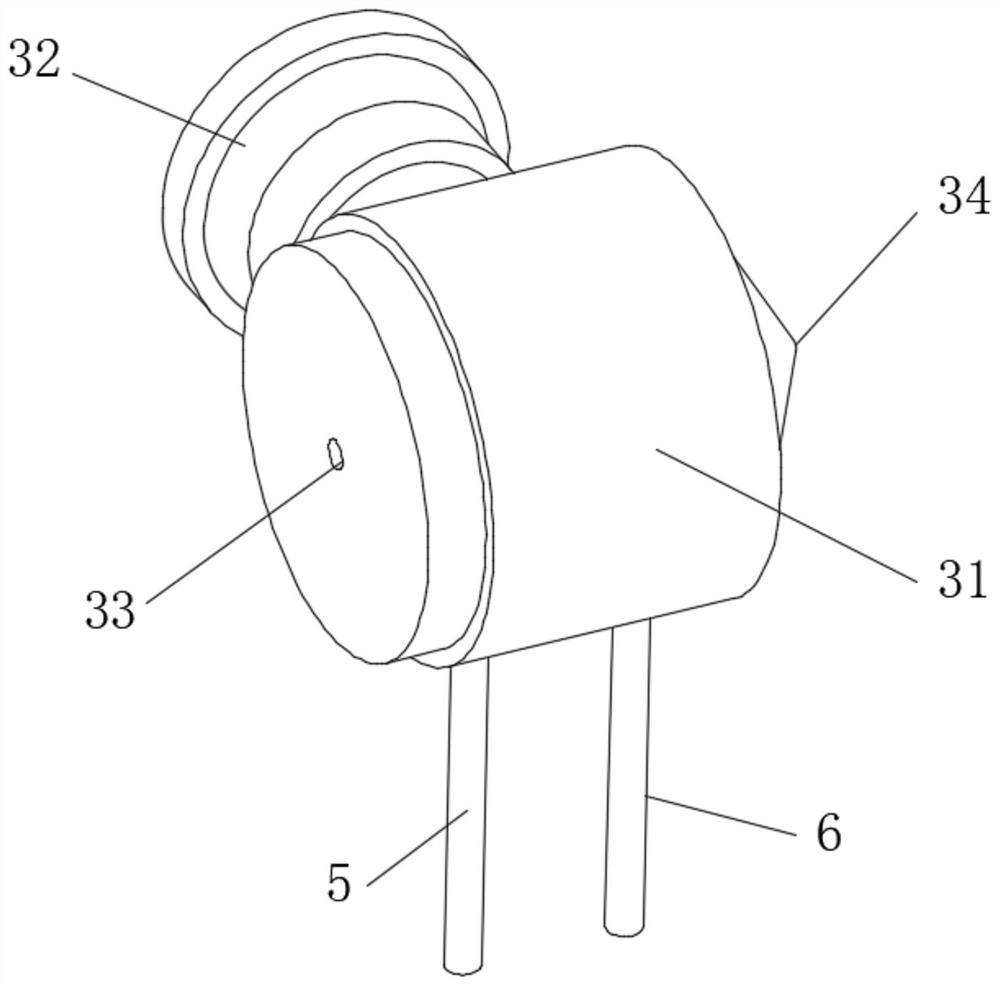

Heat compensated oil collection tank

The invention relates to a thermal compensation oil tank. It comprises holding cap, holding tank, holding ditch and drawing bucket; one end of holding ditch is fixed jointed, and the other end is freely jointed, the two sides of holding ditch are equipped with stop in cross direction; one end of holding tank ais fixed jointed and the other end is freely jointed, the two sides of holding tank are equipped with stop in cross direction; the holding cap is installed between holding tank. The thermal compensation oil tank possesses good gas distribution and liquid collection property, reduces liquid retention time, avoids coking, and expands freely under high temperature and gurantee normal operation of tower under high temperature.

Owner:TIANJIN UNIV +1

Three-return-stroke powder heat conduction oil boiler

The invention discloses a three-return-stroke powder heat conduction oil boiler. The three-return-stroke powder heat conduction oil boiler comprises a circulating oil pump, a hearth, a burnout chamber, a convection tube bundle, tail heat exchange equipment, a combustor, a slag falling device, a lower header and an upper header, wherein the lower header is arranged at the bottom of a boiler body; the upper header is arranged at the top of the boiler body; the combustor is arranged at the front part, the top, the bottom or the side part of the hearth of the boiler; the boiler body has a full-film type water-cooled wall structure, and four main downcomers are arranged at four corners; the convection tube bundle is arranged in a convection tube bundle flue, the convection tube bundle flue is longitudinally arranged, and the height of the convection tube bundle flue is equal to that of the hearth; the upper and lower ends of the convection tube bundle, the main downcomers and a film type water-cooled wall are communicated with the upper header and the lower header respectively; the burnout chamber and the hearth are longitudinally arranged abreast in a back-to-back way, and the height of the burnout chamber is equal to that of the hearth; the hearth, the burnout chamber, the convection tube bundle flue and the tail heat exchange equipment are sequentially conducted in series; two-stage combustion-supporting and denitration secondary air is distributed in the hearth. The three-return-stroke powder heat conduction oil boiler has the characteristics of long flue gas flow, complete fuel combustion and high heat exchange efficiency.

Owner:HANGZHOU JUNENG BOILER

Vertical coal powder corner tube boiler

The invention discloses a vertical coal powder corner tube boiler which comprises combustors, a boiler hearth, a high-temperature air pre-heater, an economizer, a low-temperature air pre-heater convection bank, an upper header, a top header, a boiler barrel and a lower header, wherein the lower header is arranged on the bottom of a boiler body, the upper header and the top header are arranged on the top of the boiler body and are communicated through a steam communicating pipe. The vertical coal powder corner tube boiler is characterized in that the combustors are arranged in a V shape, the boiler body is of a vertical corner type membrane type water-cooling wall structure, four descending pipes are arranged in four corners, the descending pipes and two ends of the membrane type water-cooling wall are respectively communicated with the upper header and the lower heater, the convection bank is arranged on the outer side of the membrane type water cooling wall, the top of the convection bank is communicated with a hearth smoke outlet, and the bottom of the convection bank is communicated with the high-temperature air pre-heater. The vertical coal powder corner tube boiler has the advantages of compact integrated structure, simple appearance arrangement, small occupation area, low steel consumption, large water circulation pressure difference, safety and reliability in water circulation, and the like.

Owner:HANGZHOU JUNENG BOILER

Horizontal pulverized coal fired boiler with two furnace pipes

InactiveCN103032865AFull reaction combustionImprove sealingBoiler flue tubes/fire tubesSteam boilersSmall footprintEngineering

The invention discloses a horizontal pulverized coal fired boiler with two furnace pipes. The horizontal pulverized coal fired boiler comprises a boiler shell cylindrical body and an externally-hung cylindrical body, wherein the boiler shell cylindrical body is provided with the two furnace pipes, a front pipe plate, a rear pipe plate, a front smoke box, a film-type wall reversal chamber, a skin plate and a second return smoke pipe, wherein the second return smoke plate is arranged below the two furnace pipes; the externally-hung cylindrical body is internally provided with a third return smoke pipe; the third return smoke pipe is communicated with the front smoke box by virtue of a smoke flue; the externally-hung cylindrical body is further provided with a smoke outlet; and the externally-hung cylindrical body is communicated with a water way of the boiler shell cylindrical body by virtue of an outlet pipe. The pulverized coal fired boiler is arranged as a horizontal double-furnace-pipe structure; the two furnace pipes are positioned above, and the smoke pipe is positioned below, so that smoke circulates smoothly; the overall structure is compact, the appearance arrangement is simple, the occupied area is small, and the steel consumption is low; integral transportation can be realized; and the pulverized coal fired boiler is within the protection range of the invention.

Owner:HANGZHOU JUNENG BOILER

Anti-coking burner for pulverized coal boiler and boiler installed with the burner

InactiveCN102287816AEnhance jet stiffnessReduce jet deflection driftCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLow loadEngineering

The invention discloses an anti-coking burner for a pulverized coal boiler and a pulverized coal boiler installed with the burner. Separated light powder channel and thick powder channel, as well as light powder nozzle and thick powder nozzle; peripheral air ducts are arranged on the outer edges of the thick and light powder channels and the nozzle. A regulator is provided on the flow channel wall in the pulverized coal separator. When the burner is running at a high evaporation rate, the separation block of the burner regulator is properly withdrawn, and at the same time, the peripheral air is opened to reduce the concentration of the separated coal powder. The temperature here is 900°C-950°C, thereby preventing the melting of ash Potential for coking nearby. When the load is low or the calorific value of the coal is low, the density ratio can be adjusted to the maximum value through the adjustment of the density adjustment handwheel, and the peripheral wind can be properly turned off to make it burn stably.

Owner:蒋振华

Thermal protection structure of oil-gas mixture for aero-engine

ActiveCN109630270AStop cokingEliminate riskGas turbine plantsTurbine/propulsion lubricationAviationEngineering

The invention provides a thermal protection structure of an oil-gas mixture for an aero-engine. The thermal protection structure of the oil-gas mixture for the aero-engine comprises an oil-gas ventilation pipeline assembly inside a support plate, a sealing cavity outer casing adaptor seat, a sealing air guiding pipe assembly inside the support plate, a two-way ventilation adaptor, an exterior oil-gas ventilation welded assembly, a split bi-functional assembly, and an exterior sealing air guiding pipe assembly.

Owner:AECC SHENYANG ENGINE RES INST

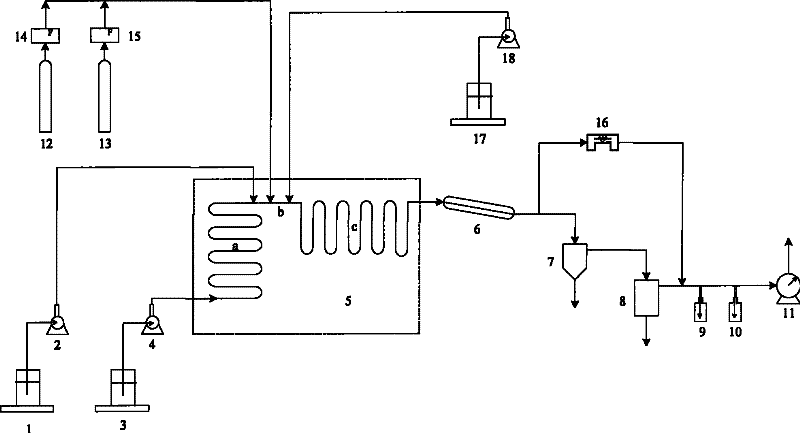

Method for preparing high-quality fuel oil and/or chemical raw materials from biomass pyrolysis liquid

ActiveCN110028985AAvoid aggregation and cokingAvoid inactivationHydrocarbon oils refiningBiofuelsBiomassChemistry

The invention discloses a method for preparing high-quality fuel oil and / or a chemical raw material from biomass pyrolysis liquid. The method comprises the following steps: carrying out hydrodeoxygenation reaction on biomass pyrolysis liquid in a catalyst full-mixed-flow circulating system in a fluidized bed reactor to obtain deoxidized oil, and carrying out hydrocracking reaction on the obtaineddeoxidized oil in a fixed bed reactor to obtain high-quality fuel oil and / or the chemical raw material. According to the method, condensation and coking of the biomass pyrolysis liquid can be prevented, the problem that a catalyst is fast to inactivate is solved, and the biomass pyrolysis liquid can be converted into high-quality fuel oil and chemical products which can be directly used by vehicles.

Owner:HENAN BUF BIOENERGY CO LTD +2

Horizontal type pulverized coal boiler with single furnace pipe

InactiveCN103062746AFull reaction combustionImprove sealingBoiler drums/headersWater-tube boilersEngineeringSmall footprint

The invention discloses a horizontal type pulverized coal boiler with a single furnace pipe. The horizontal type pulverized coal boiler comprises a shell barrel body and a plug-in barrel, wherein the single furnace pipe, a front tube plate, a rear tube plate, a front smoke box, a membrane wall backflash chamber, an outer wrapping plate and a second back stroke smoke tube are arranged in the shell barrel body, and the second back stroke smoke tube is arranged on the lower side of the single furnace pipe; a third back stroke smoke tube is arranged in the plug-in barrel and communicated with the front smoke box through a flue; a smoke outlet is further arranged on the plug-in barrel body; and the plug-in barrel body is communicated with a waterway of the shell barrel body through an outlet tube. The horizontal type pulverized coal boiler adopts the structural arrangement of the single furnace pipe, is smooth in smoke circulation by arranging the single furnace pipe on the upper portion and the smoke tube on the lower portion, and is compact in integral structure, simple in appearance distribution, small in occupation, low in steel consumption, and capable of achieving integral transportation.

Owner:HANGZHOU JUNENG BOILER

Heavy fuel oil additive containing benzopyran multi-hydroxy metal compound

InactiveCN1763158APromote combustionIncrease surface tensionLiquid carbonaceous fuelsBenzopyranOil additive

The heavy fuel oil additive containing benzopyran polyhydroxy metal compound is one kind of catalyst capable of promoting heavy petroleum part to burn completely and reducing the ablation and wear of heavy fuel oil on engine parts. It contains benzopyran polyhydroxy metal compound obtained with benzopyran polyhydroxy compounded from camellia plant and inorganic metal salt through reaction in 6-30 weight portions, macro molecular surfactant extracted from camellia plant 1-8 weight portions and solvent 62-95.2 weight portions. The additive of the present invention may be used for mixed oil with heavy oil components and mixed oil of petroleum oil and plant oil for burning in furnace, kiln and diesel enginge.

Owner:蔡可而

Horizontal type two-channel pulverized coal fired boiler

InactiveCN103047638AFull reaction combustionImprove sealingBoiler flue tubes/fire tubesWater-tube boilersBoiler furnaceThermal insulation

The invention discloses a horizontal type two-channel pulverized coal fired boiler. The horizontal type two-channel pulverized coal fired boiler comprises a boiler shell barrel body, a left outer-hung barrel body and a right outer-hung barrel body; and the boiler shell barrel body is provided with a left boiler furnace, a right boiler furnace, a front pipe plate, a rear pipe plate, a front smoke box, a left reversal chamber, a right reversal chamber, a skin plating, a left secondary return stroke smoke pipe and a right secondary return stroke smoke pipe. A left third return stroke smoke pipe and a right return stroke smoke pipe are respectively arranged in the left outer-hung barrel body and the right outer-hung barrel body, and the left third return stroke smoke pipe and the right return stroke smoke pipe are communicated with the front smoke box through a left smoke channel and a right smoke channel respectively. The horizontal type two-channel pulverized coal fired boiler has the advantages that: (1) a boiler body adopts the arrangement of the horizontal type independent double boiler furnace structure, overall structure is compact, appearance arrangement is simple, floor space is small, steel consumption is low, and overall transportation can be achieved; (2) the left and right reversal chambers adopt membrane wall structures, furnace walls only need thermal insulation materials, overall sealing and thermal insulation performance are good, and air leakage is little; and (3) product manufacture period is short, mounting is convenient, and operation is easy.

Owner:HANGZHOU JUNENG BOILER

Vertical type modular coal water slurry corner tube boiler

InactiveCN103134036ACompact structureOptimize layoutIndirect carbon-dioxide mitigationSteam boilersAir preheaterCoal water

The invention discloses a vertical type modular coal water slurry corner tube boiler. The vertical type modular coal water slurry corner tube boiler comprises a boiler body, a hearth, a combustor, a combustion stabilizing chamber, a dry bottom hopper, an air preheater, a coal economizer, a convection tube beam, an upper collecting tank, a top collecting tank, a boiler barrel and a lower collecting tank. The boiler body comprises 4 down pipes arranged at four corners and a membrane water wall. Two ends of each down pipe and two ends of the membrane water wall are respectively communicated with the upper collecting tank and the lower collecting tank. The convection tube beam is arranged on outer side of the membrane water wall, the top is communicated with a smoke outlet of the hearth, and the bottom is communicated with the bottom of the air preheater. The dry bottom hopper is arranged at the bottom of the boiler body. The boiler body is divided into the boiler barrel, the dry bottom hopper, the convection tube beam and the membrane water wall to be manufactured and installed. The vertical type modular coal water slurry corner tube boiler has the advantages of being compact in integral structure, simple in appearance arrangement, small in occupied area, low in steel consumption, large in boiler water circulating differential pressure, safe and reliable in water circulation, quick and simple in manufacture and installation, reliable in boiler operation, simple and convenient to maintain and the like.

Owner:HANGZHOU JUNENG BOILER

Preparation method of anti-coking composite ceramic coating for power station boiler

ActiveCN114525466AImprove thermal conductivityImprove heat transfer efficiencyMolten spray coatingComposite ceramicAluminium hydroxide

The invention relates to a preparation method of an anti-coking composite ceramic coating for a power station boiler, and belongs to the technical field of high-temperature protective coatings. The invention particularly relates to an anti-coking composite ceramic coating material and a preparation method thereof. The composite ceramic coating material is composed of a thermal chemical reaction ceramic bottom layer and a surface glaze layer. The thermal chemical reaction ceramic bottom layer comprises the following raw materials: aggregate, a binder, a dispersing agent and water; the aggregate is prepared by uniformly mixing chrome green, boron nitride and aluminum oxide; the binder is prepared by uniformly mixing phosphoric acid with the mass concentration of 85%, magnesium oxide, aluminum hydroxide, zinc oxide and deionized water; the dispersing agent is polyacrylic acid. The bonding strength of the anti-coking composite ceramic coating is 26.6-30.2 Mpa, the high temperature corrosion resistance index is 0.116-0.158 mg / mm < 2 >, and the thermal shock resistance index is 7-15. The boiler surface is effectively prevented from coking, and the heat efficiency of the boiler is improved to a small extent. And the actual service life of the coating can exceed 10000 hours, so that the use safety and the service life of the boiler are prolonged.

Owner:ZHONGDIAN HUACHUANG ELECTRIC POWER TECH RES +2

Anti-coking oil collecting tank for passing vaporized oil

ActiveCN104623923ASolve the problem of high temperature cokingIncrease collection speedVacuum distillationFractional distillationFuel tankPulp and paper industry

The invention relates to an anti-coking oil collecting tank for passing vaporized oil. Each liquid collecting tank is composed of one or more members with a square tank structure; one end of the liquid collecting tank close to the tower wall is overlapped on a support ring, the other end is overlapped on the edge of a liquid collecting channel, the end overlapped on the support ring is higher than the end overlapped on the liquid collecting channel, and thus the liquid collecting tank is inclined to the liquid collecting channel. The liquid collecting tank in the middle part uplifts, the two ends of the middle liquid collecting tank are respectively overlapped on two neighbored liquid collecting channels, and the middle liquid collecting tank is inclined to the second liquid colleting channel. A liquid baffle plate is in a square tank shape or a triangular tank shape and is fixed above a gap between the liquid collecting tanks through a rib plate or a support plate so as to form a gas channel. The liquid collecting channel has a square tank shape structure, the oil collecting tank comprises one or more liquid collecting channels, one end of the liquid collecting channel is overlapped on a withdrawal hopper, and the bottom plate is inclined to the withdrawal hopper. The number of withdrawal hopper is one or two, and the bottom plate of the withdrawal hopper is inclined to the withdrawal opening. The provided oil collecting tank can reduce the stay time of liquid in the oil collecting tank, reduces the flow resistance, prevents the happening of coking, and guarantees the normal operation of towers at a high temperature.

Owner:PETROCHINA CO LTD +1

Method for preparing fuel oil from biomass pyrolysis liquid

The invention discloses a method for preparing fuel oil from biomass pyrolysis liquid. Unpretreated biomass pyrolysis liquid is added into a reaction area of a fluidized bed reactor under the protection of a hydrogen donor for hydrotreating. The biomass pyrolysis liquid is hydrogenated and converted into fuel oil in a catalyst full-mixed-flow circulating system fluidized bed reactor formed throughthe combined action of circulating oil, a catalyst, hydrogen and an inner component, one part of the fuel oil serves as circulating oil and returns to the fluidized bed reactor, and the other part ofthe fuel oil is discharged outwards to serve as a product. The obtained fuel oil can be mutually dissolved with fossil fuel oil in any proportion, the sulfur and nitrogen content is very low, and meanwhile, a certain proportion of oxygen is contained, so that complete combustion is facilitated, and the fuel oil is especially suitable for high-altitude areas. Meanwhile, the biomass pyrolysis liquid is prevented from being condensed and coked under heating action, the problem that a catalyst is fast inactivated is solved, coke is prevented from being formed, and the requirement for industrial long-period operation can be met.

Owner:HENAN BUF BIOENERGY CO LTD +2

Cable extruder

The invention relates to the technical field of wires and cables, and discloses a cable extruder. The cable extruder comprises a machine body, wherein a feeding port is fixedly formed in the top of the machine body; a machine head is fixedly arranged on the front surface of the machine body; a motor is fixedly arranged on the back surface of the machine body; an extrusion sleeve positioned in themachine body is fixedly arranged at the bottom of the feeding port through a feeding port; a rotating shaft is movably sleeved with the extrusion sleeve; a honeycomb plate is fixedly arranged on the front surface of the extrusion sleeve; a cooling water outlet pipe and a cooling water inlet pipe are fixedly arranged on the two sides of the bottom of the machine head correspondingly; a spiral waterpipeline is arranged in the machine head; and a scraping head is movably arranged on the extrusion sleeve. According to the cable extruder, the scraping head with a spring is arranged in the extrusion sleeve, so that the situation of dead glue coke materials is effectively reduced, and the production efficiency is improved; and the spiral cooling water pipeline is arranged in an extrusion table of the machine head, so that the extrusion quality of the cable is guaranteed.

Owner:江西圣塔电缆科技有限公司

Vertical type coal dust corner tube boiler

InactiveCN103062748AFull reaction combustionImprove sealingSteam boilersSmall footprintTubular membrane

The invention discloses a vertical type coal dust corner tube boiler which comprises a burner, a boiler furnace, a high temperature air preheater, a coal economizer, a low temperature air preheater convection tube bundle, an upper collecting box, a top collecting box, a boiler barrel and a lower collecting box. The lower collecting box is arranged at the bottom of a boiler body, and the upper collecting box and the top collecting box are arranged at the top of the boiler body and are communicated through a vapor communicating pipe. The vertical type coal dust corner tube boiler is characterized in that the burner is arranged at the top of the boiler body, the boiler body is of a vertical type tubular membrane type water-cooled wall structure, four down pipes are arranged at four corners, and the down pipes and two ends of the membrane type water-cooled wall are communicated with the upper collecting box and the lower collecting box respectively. The convection tube bundle is arranged on the outer side of the membrane type water-cooled wall, the bottom of the convection tube bundle is communicated with a hearth smoke outlet, and the top of the convection tube bundle is communicated with the high temperature air preheater. The vertical type coal dust corner tube boiler has the advantages that an integral structure is compact, the appearance is arranged simply, an occupied area is small, steel consumption is small, water circulating differential pressure of the boiler is large, and water circulation is safe and reliable, and the like.

Owner:HANGZHOU JUNENG BOILER

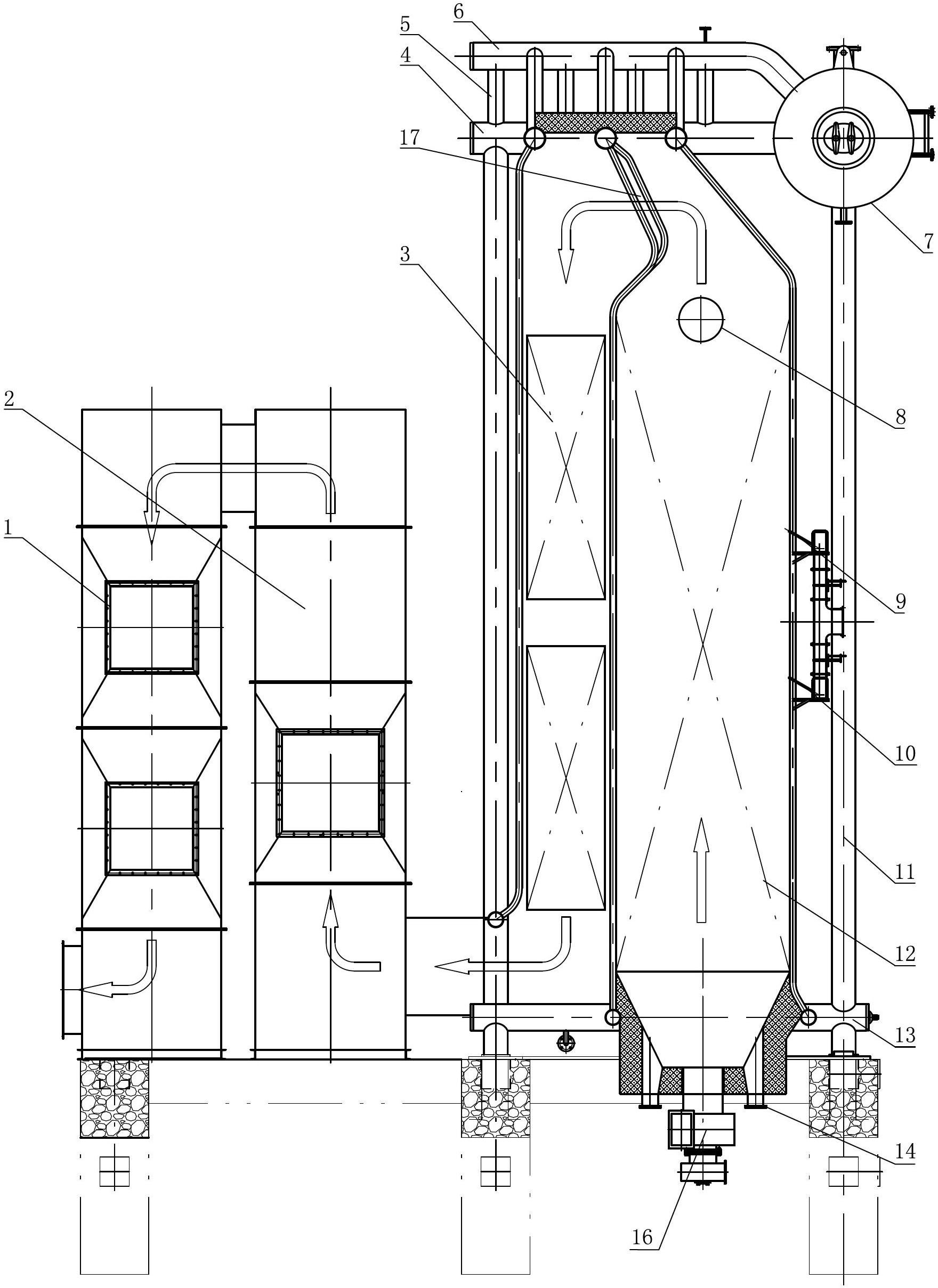

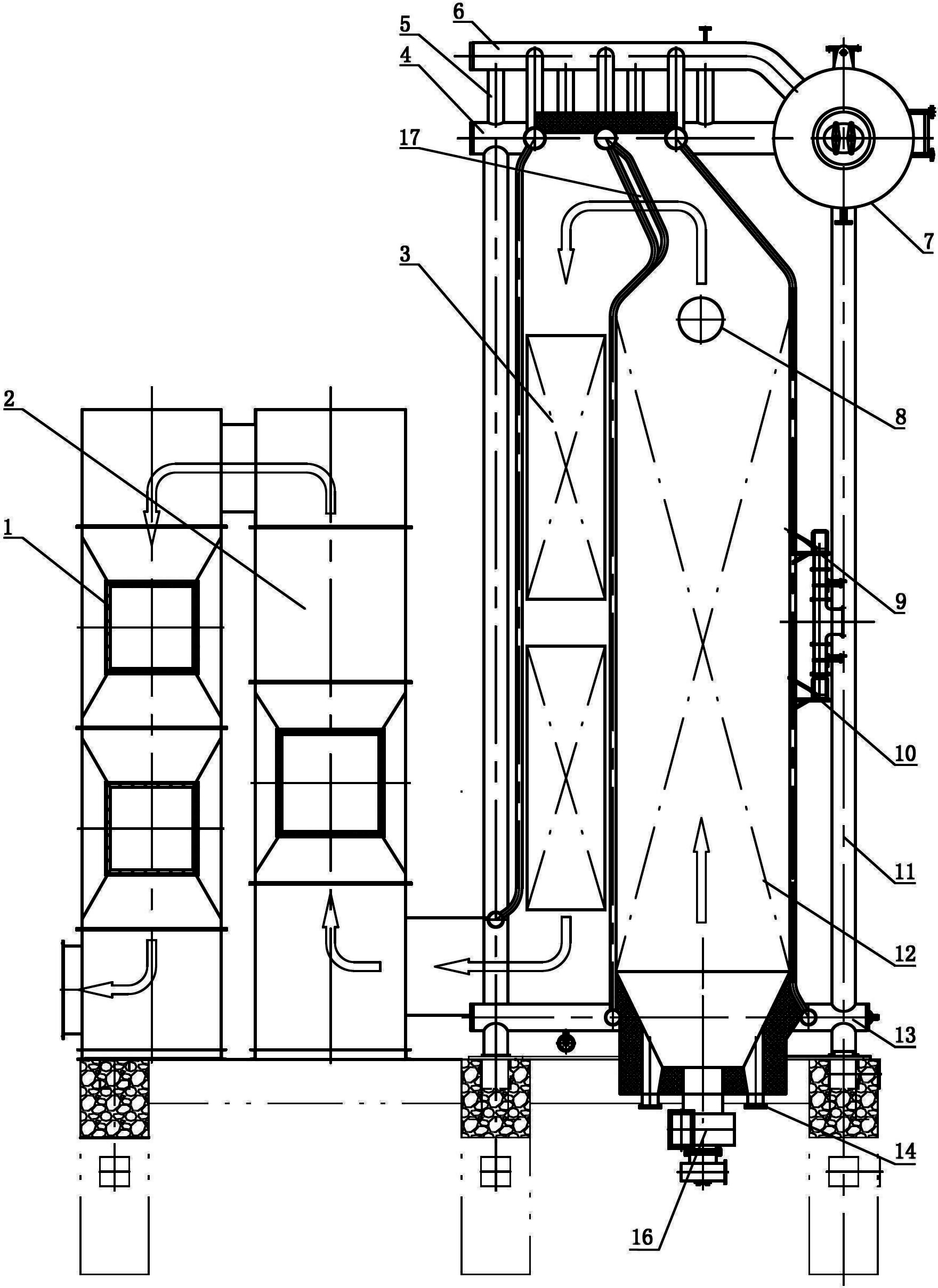

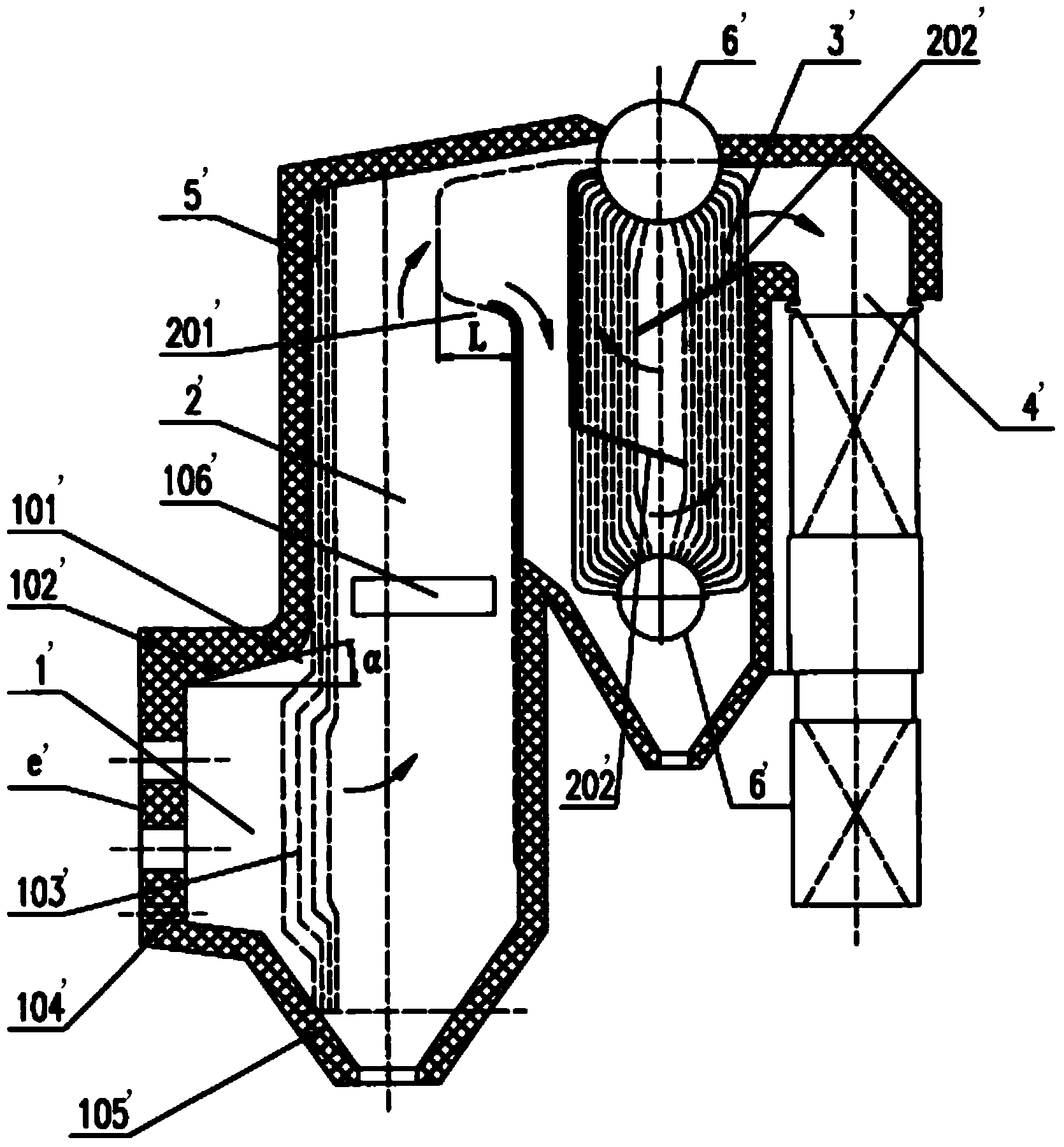

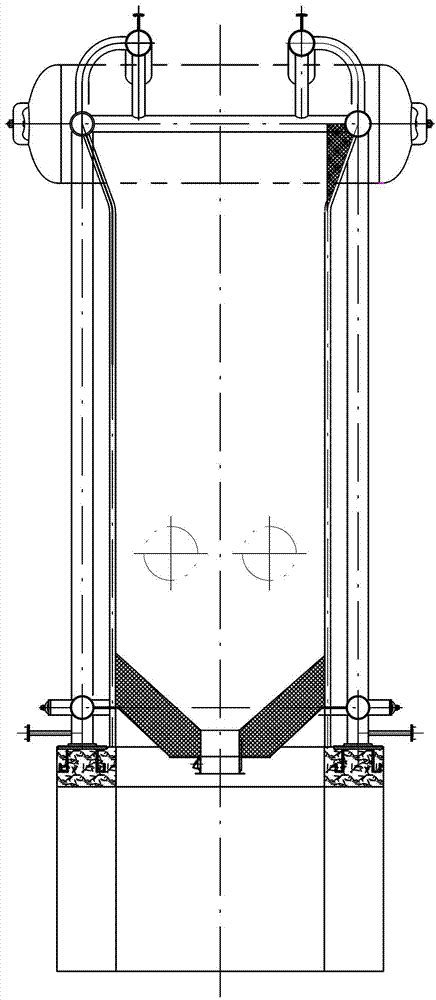

Device for preventing coal dust in gas-solid separator of boiler for circulating fluidized bed from coking

InactiveCN101701707BStop cokingConducive to safe and economical operationFluidized bed combustionApparatus for fluidised bed combustionFluidized bedEngineering

The invention relates to a method for preventing coal dust in a gas-solid separator of a boiler for a circulating fluidized bed from coking. According to the design provided by the invention, a low-temperature medium communicating pipe is arranged at the inlet of the gas-solid separator, and the low-temperature medium is derived from the intermediate extracted steam of a steam turbine or the outlet exhaust gas of a boiler induced draft; an electric butterfly valve is additionally arranged on the communicating valve; and temperature measuring devices are arranged at the inlet, outlet and discharge hole of the gas-solid separator. When the coal dust keeps burning and the exhaust gas rises in the gas-solid separator, the coal dust in the gas-solid separator is coked and the discharge hole isblocked, in order to prevent the coal dust in the gas-solid separator from coking, the electric butterfly valve can be switched on by an actuating mechanism according to the preset temperature of a controller and the low-temperature medium can be mixed into the high-temperature exhaust gas to reduce the temperature of the high-temperature exhaust gas. By using a low-temperature medium to reduce the temperature of the exhaust gas in the gas-solid separator, the invention has the advantages of high temperature regulating speed and high temperature regulating reliability.

Owner:WUXI HUAGUANG IND BOILER

Method for producing smoke-prevention, dust-control and energy saving combustion improver

A method for producing a smoke-eliminating, dust-removing, and energy-saving combustion-supporting agent, comprising the steps of: a) mixing 4.0-6.0 parts by weight of potassium chloride, 3.0-4.0 parts by weight of magnesium chloride, and 4.5-5.5 parts by weight of Fe 2 o 3 After crushing and fine grinding, mix, place in a reaction pot, add water, and stir for reaction; b) crush 6.0-8.0 parts by weight of ammonium nitrate, place in another reaction pot, add water, stir for reaction, and a ) the last reactant is added, then mixed, stirred and reacted; c) 25-30 parts by weight of heavy calcium carbonate is pulverized, placed in a reaction pot, added 0.5-1.0 parts by weight of nitric acid and water, stirred, mixed After dehydration, calcium nitrate is generated, and then mixed with the reactant obtained in step b), reacted, dried, added rare earth quartz barite carbonate, after the reaction, added kaolin ore and mixed, and the reaction is complete An industrially usable combustion accelerant is obtained. The combustion accelerant obtained by the invention can play the role of catalysis and heat release in the combustion of coal, and at the same time has a certain effect of fixing sulfur, which can reduce the pollution to the environment.

Owner:王林泉 +1

Method for suppressing coking and carbonizing for hydrocarbons steam cracking unit

ActiveCN101161785BShort injection timeStop cokingThermal non-catalytic crackingEthyleneMaterials science

The invention provides a method for restraining coking and carburizing of hydrocarbon steam cracking device, including the following steps: during hot standby of a cracking furnace, combination which prevents coking and carburizing is injected into the cracking furnace, wherein, the combination is sol combination containing at least one sort of silica sol, aluminum sol and zirconium sol. The method which is simple and feasible, environmental friendly and low in cost does not influence the downstream system of an ethylene plant; meanwhile, the method can effectively restrain coking and carburizing of cracking furnace tube so as to prolonging service life and operation cycle of the cracking furnace.

Owner:CHINA PETROLEUM & CHEM CORP +1

Boiler burner arrangement method, lignite boiler and combustion air control method of lignite boiler

PendingCN113669721AReduce the impactStop cokingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBrown coalCombustor

The invention relates to a boiler burner arrangement method, a lignite boiler and a combustion air control method of the lignite boiler, belongs to the technical field of boilers, and aims at solving the problems that in the combustion process of an existing lignite boiler, pulverized coal airflow wall painting, high-temperature corrosion, water cooling wall slagging, nitrogen oxide emission rising and the like are likely to occur. According to the boiler burner arrangement method, burners are arranged at the four corners of a hearth of a boiler on the same horizontal plane respectively, and the arrangement method comprises the steps that each burner is provided with a thick pulverized coal nozzle, a thin pulverized coal nozzle and a secondary air nozzle; the thick pulverized coal nozzle, the thin pulverized coal nozzle and the secondary air nozzle are in one-to-one correspondence to spray out thick-phase pulverized coal airflow, thin-phase pulverized coal airflow and secondary air. Concentrated-phase pulverized coal airflow is wrapped inside, so that the pulverized coal airflow is separated from the furnace wall through secondary air, pulverized coal cannot make contact with the furnace wall, and the problems of coking and high-temperature corrosion are fundamentally eradicated.

Owner:HARBIN BOILER

A cable extrusion machine

The invention relates to the technical field of wires and cables, and discloses a cable extruder, comprising a body, a feeding port is fixedly installed on the top of the body, an organic head is fixedly installed on the front of the body, a motor is fixedly installed on the back of the body, and the bottom of the feeding port passes through The feeding port is fixedly installed with an extrusion sleeve located inside the body, a rotating shaft is movably sleeved inside the extrusion sleeve, a honeycomb plate is fixedly installed on the front of the extrusion sleeve, and two sides of the bottom of the machine head are fixedly installed respectively. The cooling water outlet pipe and the cooling water inlet pipe are provided with a spiral water pipe in the machine head, and a scraper head is movably installed on the extrusion sleeve. In this cable extruder, the scraper head with spring is arranged in the extrusion sleeve, which effectively reduces the situation of dead glue and coke, and improves the production efficiency. The extrusion quality of the cable is improved.

Owner:江西圣塔电缆科技有限公司

Horizontal type pulverized coal boiler with single furnace pipe

InactiveCN103062746BSmooth circulationCompact structureBoiler drums/headersWater-tube boilersSmall footprintMechanical engineering

The invention discloses a horizontal type pulverized coal boiler with a single furnace pipe. The horizontal type pulverized coal boiler comprises a shell barrel body and a plug-in barrel, wherein the single furnace pipe, a front tube plate, a rear tube plate, a front smoke box, a membrane wall backflash chamber, an outer wrapping plate and a second back stroke smoke tube are arranged in the shell barrel body, and the second back stroke smoke tube is arranged on the lower side of the single furnace pipe; a third back stroke smoke tube is arranged in the plug-in barrel and communicated with the front smoke box through a flue; a smoke outlet is further arranged on the plug-in barrel body; and the plug-in barrel body is communicated with a waterway of the shell barrel body through an outlet tube. The horizontal type pulverized coal boiler adopts the structural arrangement of the single furnace pipe, is smooth in smoke circulation by arranging the single furnace pipe on the upper portion and the smoke tube on the lower portion, and is compact in integral structure, simple in appearance distribution, small in occupation, low in steel consumption, and capable of achieving integral transportation.

Owner:HANGZHOU JUNENG BOILER

Method for inhibiting hydrocarbons steam cracking furnace from coking and carburizing

ActiveCN101294099BShort injection timeLow costThermal non-catalytic crackingEconomic benefitsPre treatment

The invention relates to a method for suppressing coking and carburizing of hydrocarbon steam cracking furnaces, which comprises the following steps: arranging at least one segment of heat transfer enhancement furnace pipe in the furnace pipe of radiation section of the cracking furnace, and preprocessing the hydrocarbon steam cracking furnace by using a sol composition during heat reserve periodof the cracking furnace, wherein the sol composition contains at least one selected from Si sol, Al sol and Zr sol, and the mass concentration of pure oxide in the sol composition is 0.1 to 10% the weight of the sol composition. The method provided by the invention has the advantages of low cost, simple operation, environment friendliness, and no influence on downstream system, and can significantly prolong the service life and the operation cycle of the cracking furnace on the basis of effectively suppressing coking and carburizing of the cracking furnace pipe, thus improving output of ethylene products, etc. and improving the economic benefit of an ethylene plant.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy fuel oil additive containing benzopyran multi-hydroxy metal compound

InactiveCN100343371CPromote combustionIncrease surface tensionLiquid carbonaceous fuelsBenzopyranOil additive

The heavy fuel oil additive containing benzopyran polyhydroxy metal compound is one kind of catalyst capable of promoting heavy petroleum part to burn completely and reducing the ablation and wear of heavy fuel oil on engine parts. It contains benzopyran polyhydroxy metal compound obtained with benzopyran polyhydroxy compounded from camellia plant and inorganic metal salt through reaction in 6-30 weight portions, macro molecular surfactant extracted from camellia plant 1-8 weight portions and solvent 62-95.2 weight portions. The additive of the present invention may be used for mixed oil with heavy oil components and mixed oil of petroleum oil and plant oil for burning in furnace, kiln and diesel enginge.

Owner:蔡可而

Coal-saving combustion improver and production method thereof

InactiveCN105199810AImprove combustion efficiencyEmission reductionSolid fuelsFuel additivesSesquioxideSlag

The invention relates to a coal-saving combustion improver and a production method thereof. The coal-saving combustion improver comprises the following ingredients by weight: 40 to 60 parts of furnace slag, 10 to 15 parts of magnesium chloride, 15 parts of potassium chlorate, 35 parts of sodium nitrate, and 30 parts of aluminum sesquioxide. The coal-saving combustion improver and the production method have the advantages that not only is the production technology simple and convenient, but also the types and the contents of raw materials in the formula are reasonable; the raw materials are uniformly mixed, and the mixture functions gradually along with the combustion temperature rise during the combustion process of coal, so that the combustion-supporting duration is long, and coking can be prevented effectively; moreover, high-molecular compounds in coal are combusted sufficiently to release a great amount of heat, and reduce waste gas emission and environmental pollution.

Owner:阳开金

Oil collection tank having expansion ring, and application thereof

Owner:TIANJIN UNIV

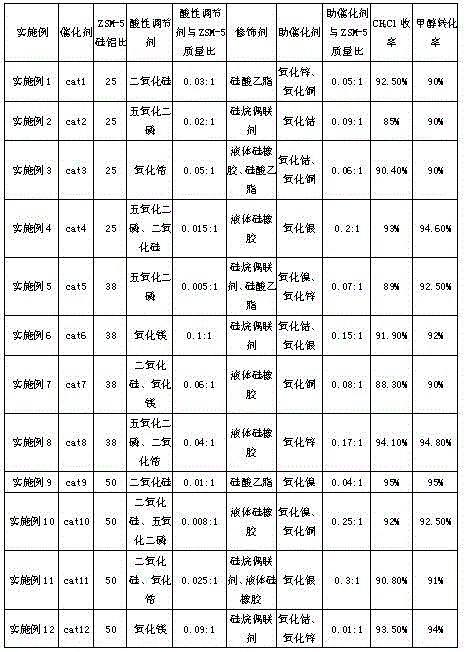

Catalyst used for synthesizing methyl chloride by gas-solid phase reaction and preparation method thereof

InactiveCN103331179BHigh yieldImprove conversion rateMolecular sieve catalystsCatalyst activation/preparationPhosphoric acidZinc nitrate

The invention discloses a catalyst used for synthesizing methyl chloride by gas-solid phase reaction and a preparation method thereof. The catalyst is prepared by loading an acidity regulator, a modification agent and a cocatalyst on to ZSM-5 carrier. The acidity regulator is an oxide, and the precursor of the acidity regulator is one or more selected from silica sol, phosphoric acid, zirconium nitrate, and magnesium nitrate; the modification agent is one or more selected from ethyl silicate, liquid silicone rubber, and a silane coupling agent; the cocatalyst is a metal oxide, and the precursor of the cocatalyst is one or more selected from nicdel nitrate, cupric nitrate, zinc nitrate, silver nitrate, and cobalt nitrate. The catalyst is used for synthesizing methyl chloride by gas-solid phase reaction of methanol and hydrogen chloride. The acidity regulator is used for changing the acidity of the catalyst; the modification agent is used for modifying the pore structure of the catalyst; and the cocatalyst is used for changing the electronic structure of the catalyst, and promoting catalytic activity and selectivity; so that catalytic activity of the catalyst is high, raw material conversion rate is high, methyl chloride yield is high, selectivity is high, and by-product is less.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com