Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Stable heat exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

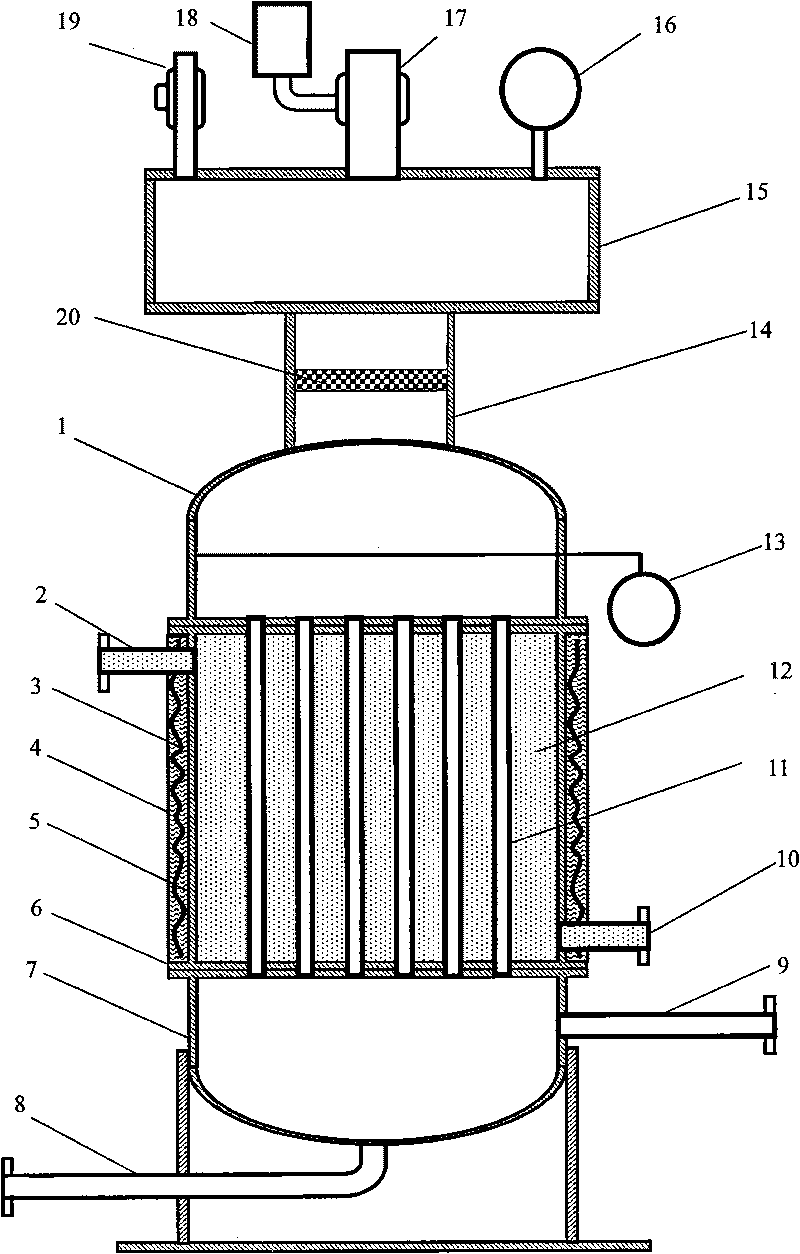

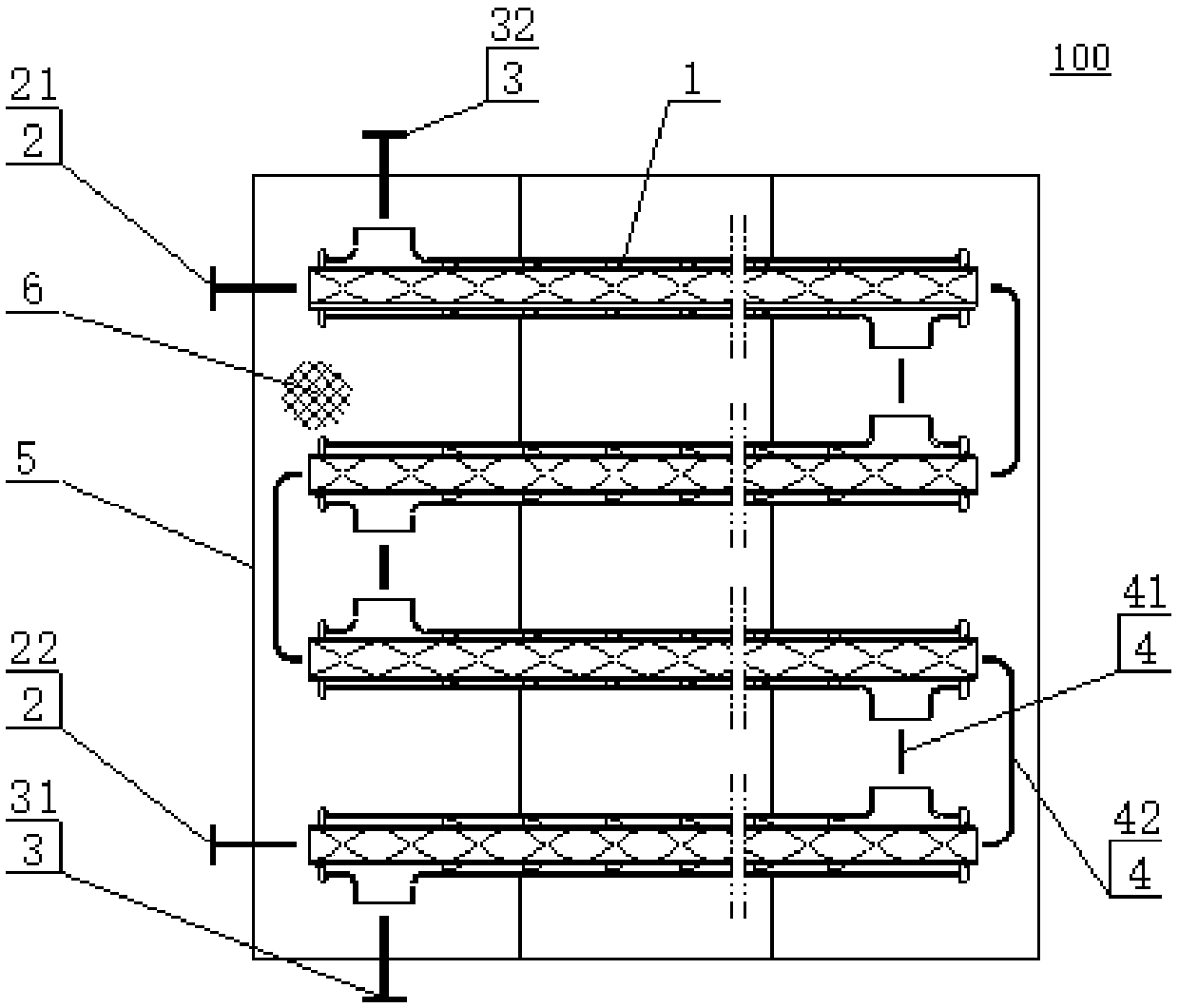

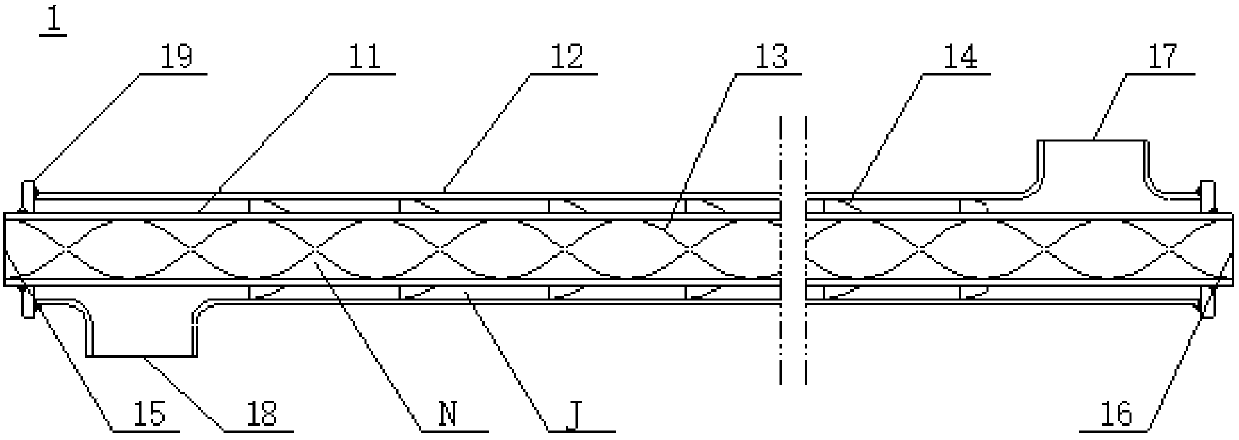

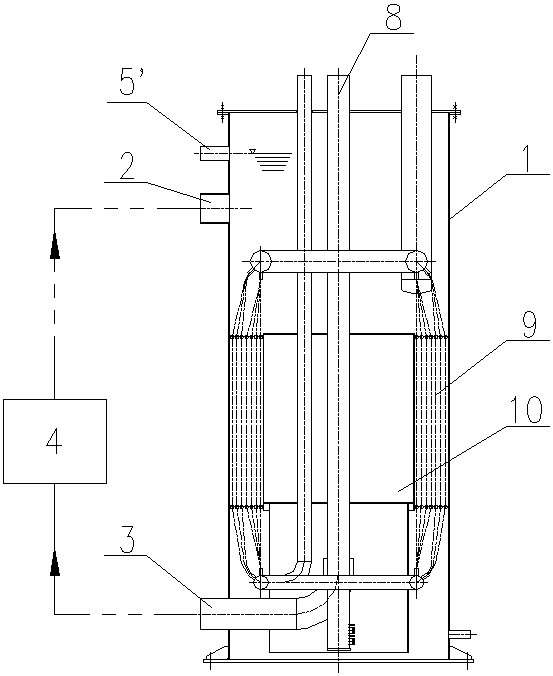

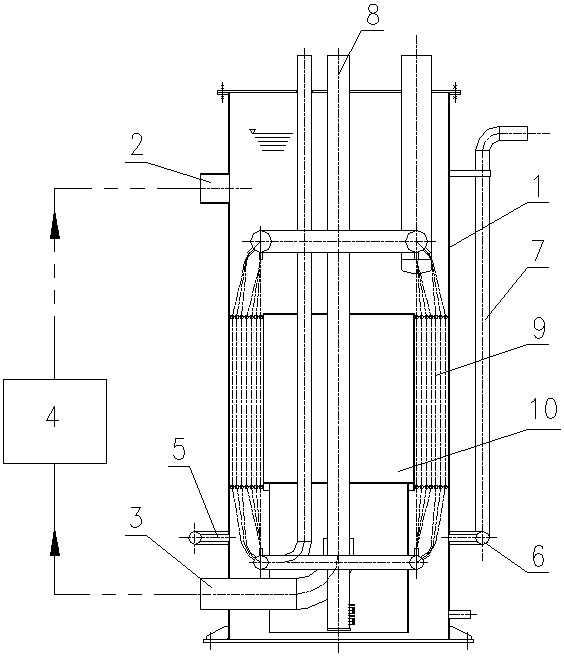

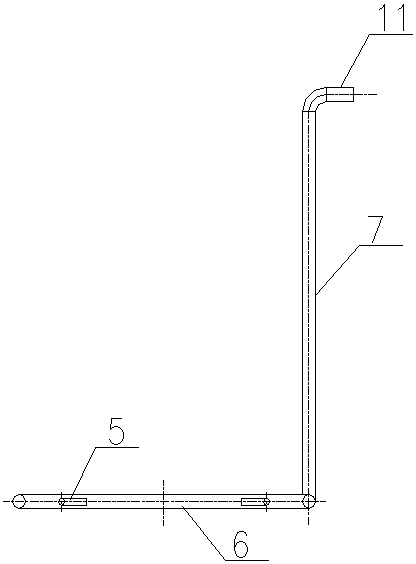

Molten salt tube-shell type steam generating device and method

InactiveCN101699163AStable steam parametersIncrease effective heat storage capacitySteam generation using hot heat carriersEngineeringMolten salt

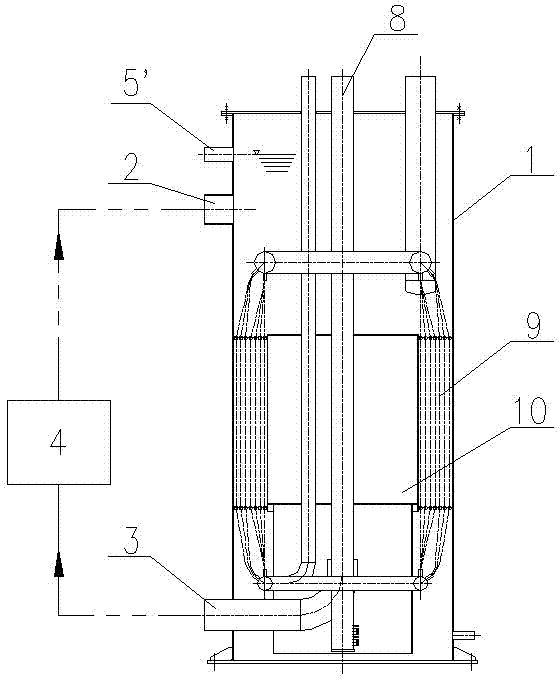

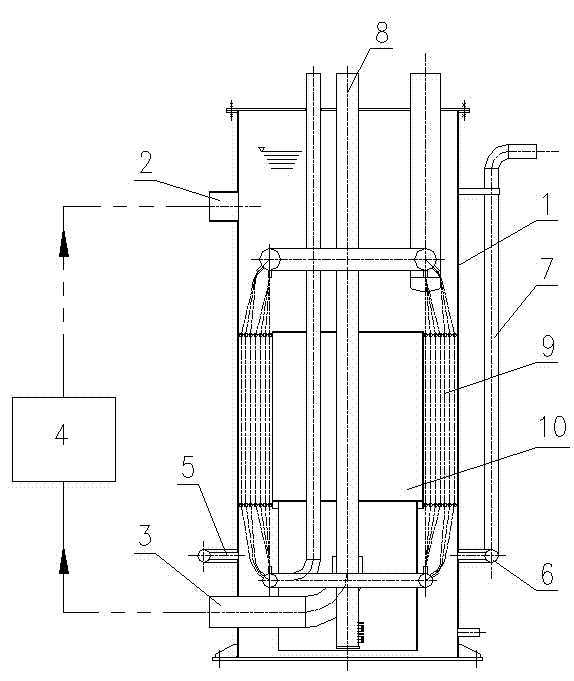

The invention provides a molten salt tube-shell type steam generating device and a molten salt tube-shell type steam generating method. The device comprises a tube-shell type heat exchanger, a steam separation output component and a heating and heat preservation component, wherein the steam separation output component is arranged on the top of the tube-shell type heat exchanger, and the heating and heat preservation component is arranged on the outer side of the container wall of the tube-shell type heat exchanger; the tube-shell type heat exchanger is provided with a top tube box, a tube body and a bottom tube box in sequence from top to bottom, wherein the inside of the tube body is provided with tube bundles of which both ends are fixedly connected with the tube body by tube plates, and the gaps between the tube bundles are filled with molten salt; and the outer side of the tube body is provided with a molten salt inlet tube and a molten salt outlet tube, and the bottom tube box is provided with a water inlet tube and a water outlet tube. The method comprises the following steps of: pre-heating the tube body; and orderly performing molten salt filling, hot water filling, and steam separating and outputting. The device has the advantages of big effective heat storage capacity, long-term stable operation, and relatively low manufacturing cost and maintenance cost, and can meet the requirements on large-scale solar mid- and high-temperature heat utilization in industry.

Owner:SOUTH CHINA UNIV OF TECH +1

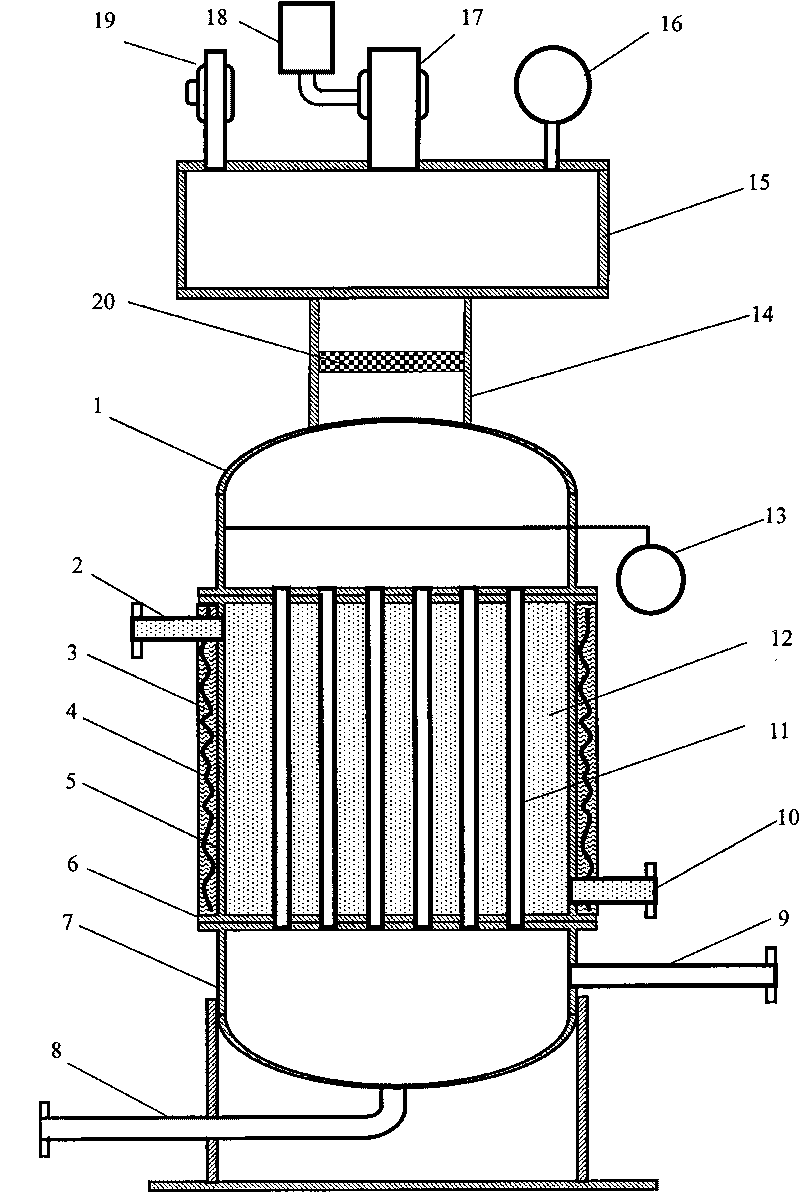

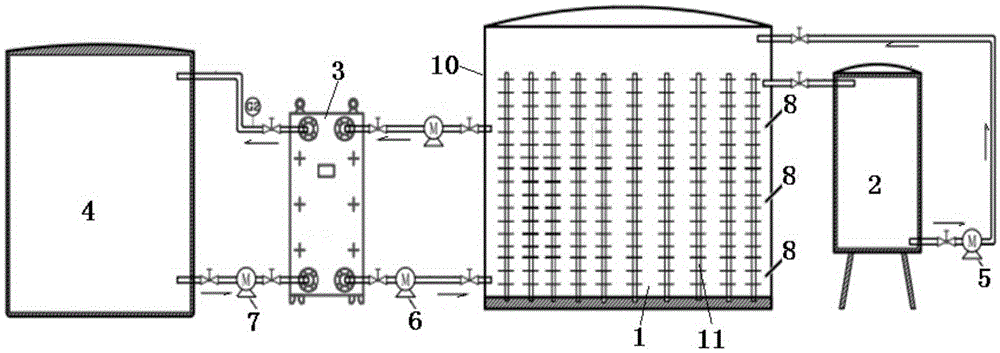

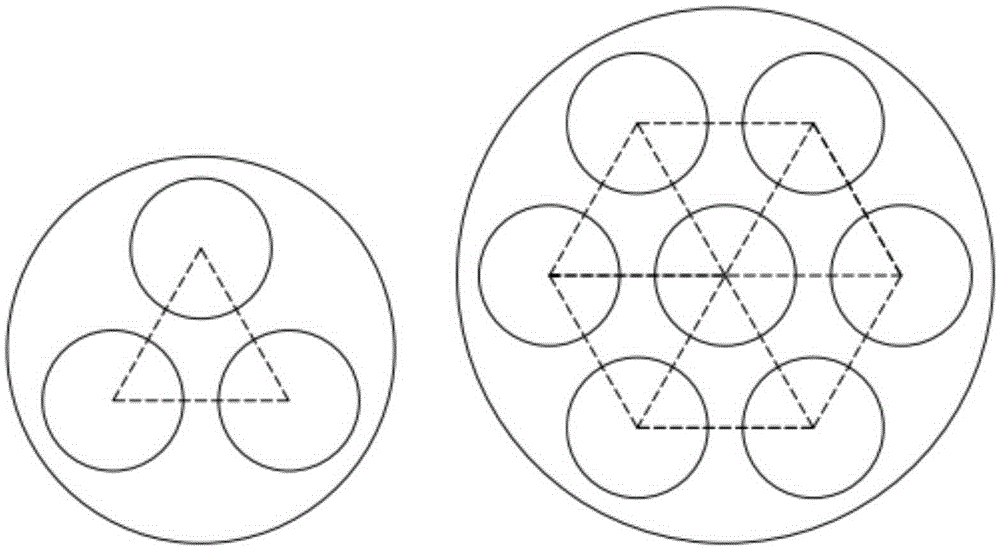

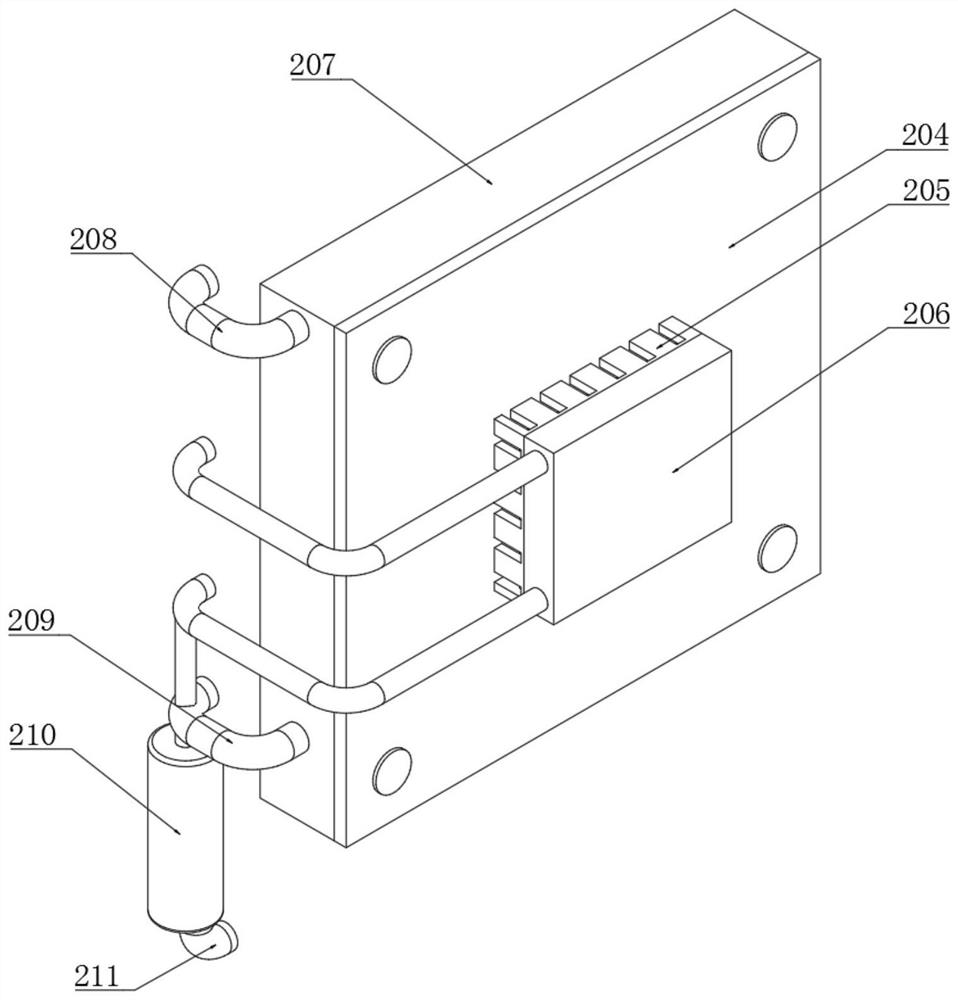

Molten salt heat storage device

InactiveCN105423795ASimple structureReasonable structureHeat storage plantsWater storage tankMolten salt

The invention discloses a molten salt heat storage device. The molten salt heat storage device comprises a molten salt heat storage furnace, an oil storage tank, a plate heat exchanger and a heat-insulation water storage tank. The molten salt heat storage furnace comprises a furnace body and vertical pipes which are evenly arranged in the furnace body in a regular triangle or regular hexagon mode and used for packaging molten salt. Electric heating belts are wound on the outer walls of the vertical pipes. The furnace body is filled with conduction oil serving as heat exchange fluid. The oil storage tank is communicated with the molten salt heat storage furnace and used for storing the conduction oil. The molten salt heat storage furnace is communicated with the plate heat exchanger, and the plate heat exchanger is communicated with the heat-insulation water storage tank. According to the molten salt heat storage device, the molten salt is used as heat storage media, flowing is not needed, a molten salt pump is omitted, the structure is simple, and corrosion is smaller; the traditional high-temperature conduction oil is used for heat exchange; the cost is lower, and operation is easier; the vertical pipes used for packaging the molten salt are arranged in a special mode, so that heating is uniform, the efficiency is higher, the structure is reasonable, the efficiency is high, energy is saved, environmental friendliness and stability are achieved, and safety and reliability are achieved.

Owner:江苏巨鼎新能源科技有限公司

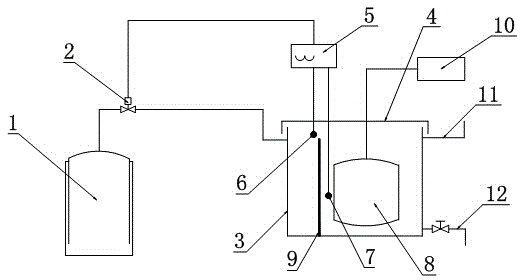

Liquid nitrogen cooling cryogenic device and implementation method for same

ActiveCN104677000AReduce equipment input costsLow running costLighting and heating apparatusCooling fluid circulationProcess engineeringTemperature measurement

The invention discloses a liquid nitrogen cooling cryogenic device and an implementation method for the same. The cryogenic device comprises a self-pressurization liquid nitrogen tank, a cryogenic container, a liquid nitrogen dedicated cryogenic electromagnetic valve, a temperature control alarm and a sample container, wherein the cryogenic container is connected with a liquid outlet of the self-pressurization liquid nitrogen tank through a liquid nitrogen pipeline; the liquid nitrogen dedicated cryogenic electromagnetic valve is arranged in the liquid nitrogen pipeline; the temperature control alarm is connected with the liquid nitrogen dedicated cryogenic electromagnetic valve, and is provided with a first temperature measurement probe and a second temperature measurement probe; the sample container is arranged in the cryogenic container; both the first and second temperature measurement probes are positioned in the cryogenic container; the second temperature measurement probe is lower than the first temperature measurement probe; an organic matter medium filling pipe and an organic matter medium discharging pipe are further arranged on the cryogenic container respectively. The cryogenic device is simple in structure, low in cost and convenient to control, and has good cryogenic cooling and cryogenic constant temperature control effects, so that the requirements of a miniature cryogenic device in a laboratory can be met, and the requirements of larger-sized engineering operation can further be met.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

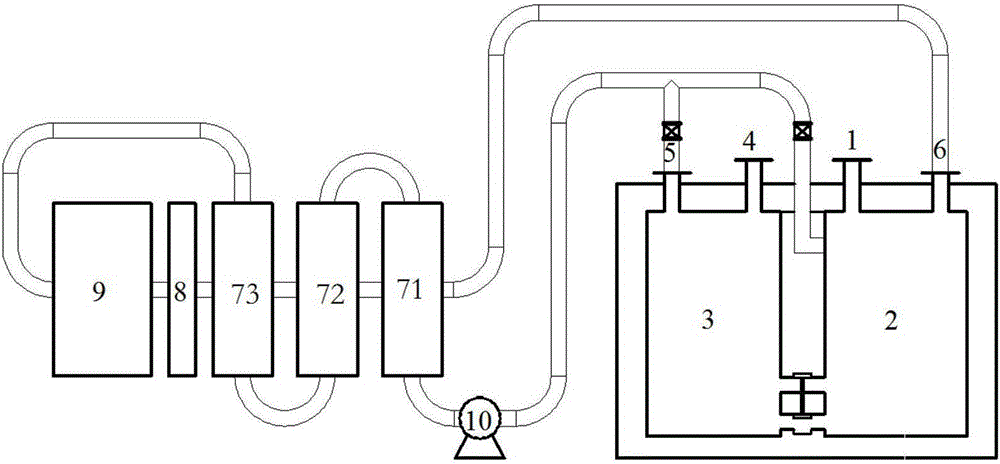

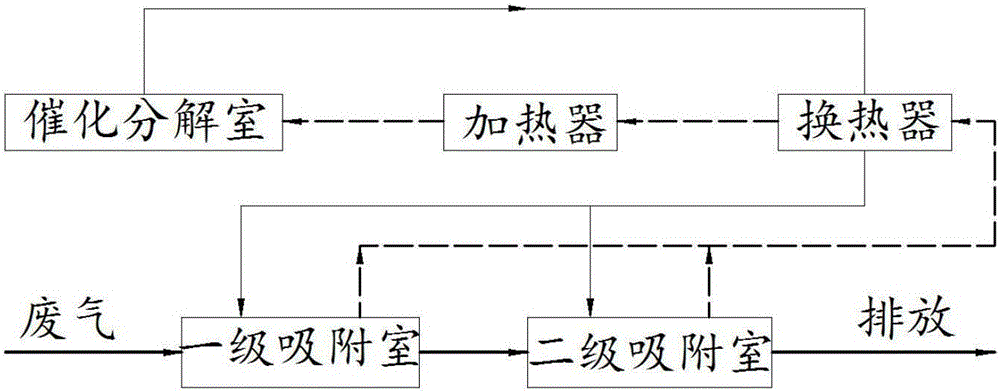

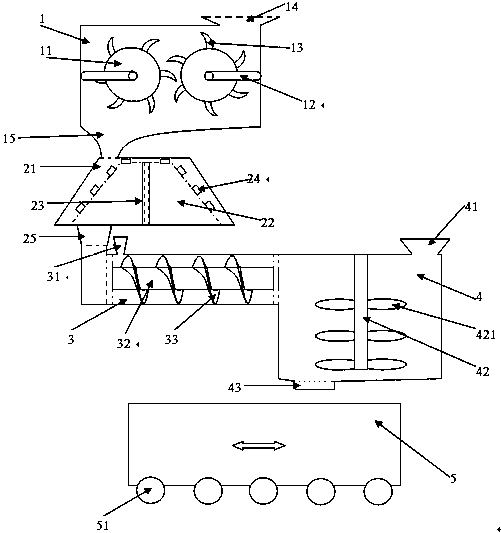

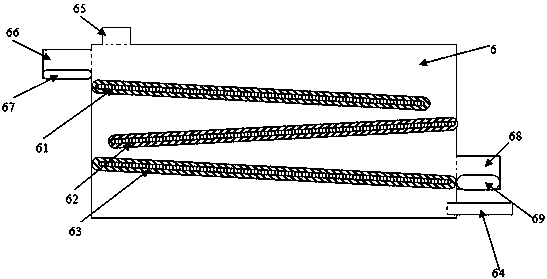

Low concentration, large wind volume and high odor waste gas concentration energization equipment and technology thereof

ActiveCN105749695AImprove purification efficiencyAvoid regional competitive adsorptionDispersed particle separationIncinerator apparatusAir volumeDesorption

The invention discloses a low concentration, large wind volume and high odor waste gas concentration energization equipment and a technology thereof and belong to the field of industrial waste gas purification.The equipment comprises a waste gas inlet, an adsorption and desorption chamber and a catalytic decomposition chamber, the equipment further comprises a heat exchanger, a heater and an internal circulation fan, wherein an adsorbing agent is arranged in the adsorption and desorption chamber, a waste gas inlet, a desorption gas outlet, an exhaust port and a desorption gas inlet are formed in the adsorption and desorption chamber, the desorption gas inlet is communicated with one end of the internal circulation fan by a pipeline, the other end of the internal circulation fan, the heat exchanger, the heater and one end of the catalytic decomposition chamber are connected sequentially, and the other end of the catalytic decomposition chamber is connected with the heat exchanger which is connected with the desorption gas outlet.Multiple stages of absorption systems are adopted, so that pollutant components with weak adsorption force can be removed more efficiently, the odor purification efficiency is improved, and multicomponent gas can reach the standard stably; the adsorption efficiency of organic waste gas is improved, and waste heat of catalytic waste gas is recycled so that the energy saving effect is remarkable.

Owner:南大恩洁优环境技术江苏股份公司

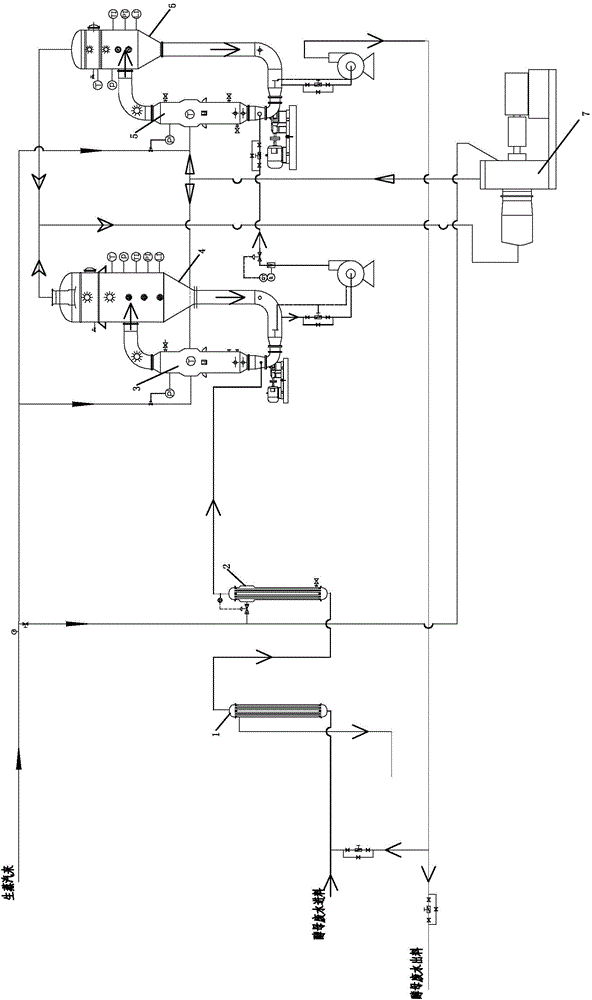

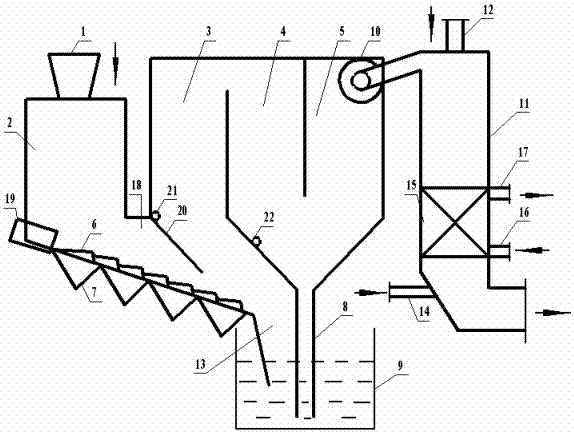

Yeast wastewater zero discharge treatment method

ActiveCN104787823AAvoid entrainmentSolve the phenomenon of reducing separation efficiencyWater/sewage treatment by heatingWater treatment multistage treatmentsYeastGas phase

The invention discloses a yeast wastewater zero discharge treatment method, and belongs to the field of yeast wastewater treatment. The method solves the technical problems of high operating cost and drywall phenomenon in the existing multi-stage film fall evaporator yeast wastewater concentration. The method comprises the following steps: firstly, preheating yeast wastewater for two times to 90 DEG C; secondly, performing circulation of heating and separation by evaporating till the concentration of solid content in the yeast wastewater is 30 percent; thirdly, performing circulation of heating and separation by evaporating till the concentration of solid content in the yeast wastewater is 50 percent, and ensuring that a discharged material part returns a material inlet part; then adopting conventional centrifugation and spray drying methods to obtain organic fertilizer and feed additives; discharging condensate water after the condensate water is subjected to biochemical treatment and meet wastewater standard. The method effectively controls the concentration of materials in all links, and avoids the drywall phenomenon of heating tubes. According to the method, evaporated and separated gas phase is reused, so that the production cost is reduced.

Owner:ZHEJIANG QIANCAOSU BIOTECH CO LTD

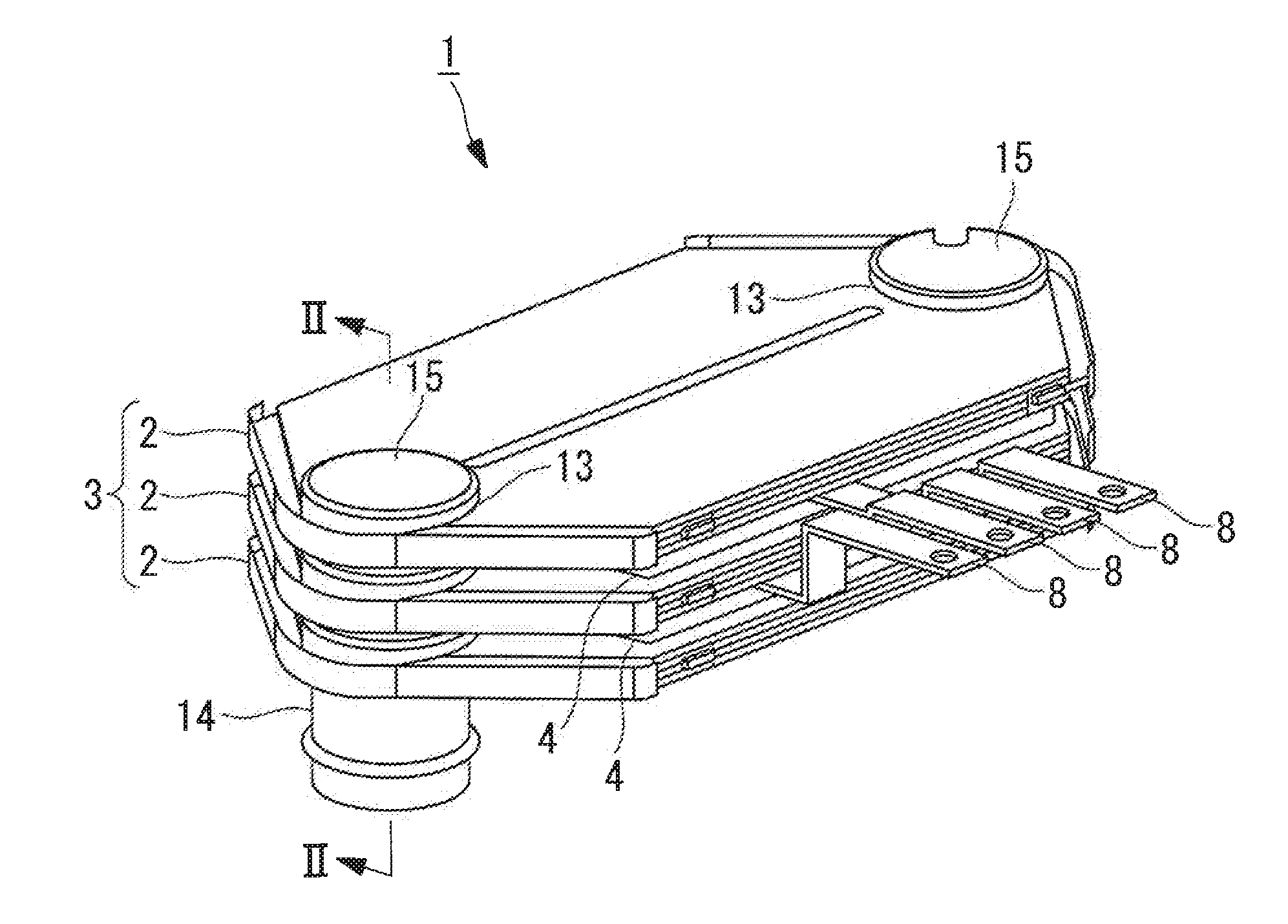

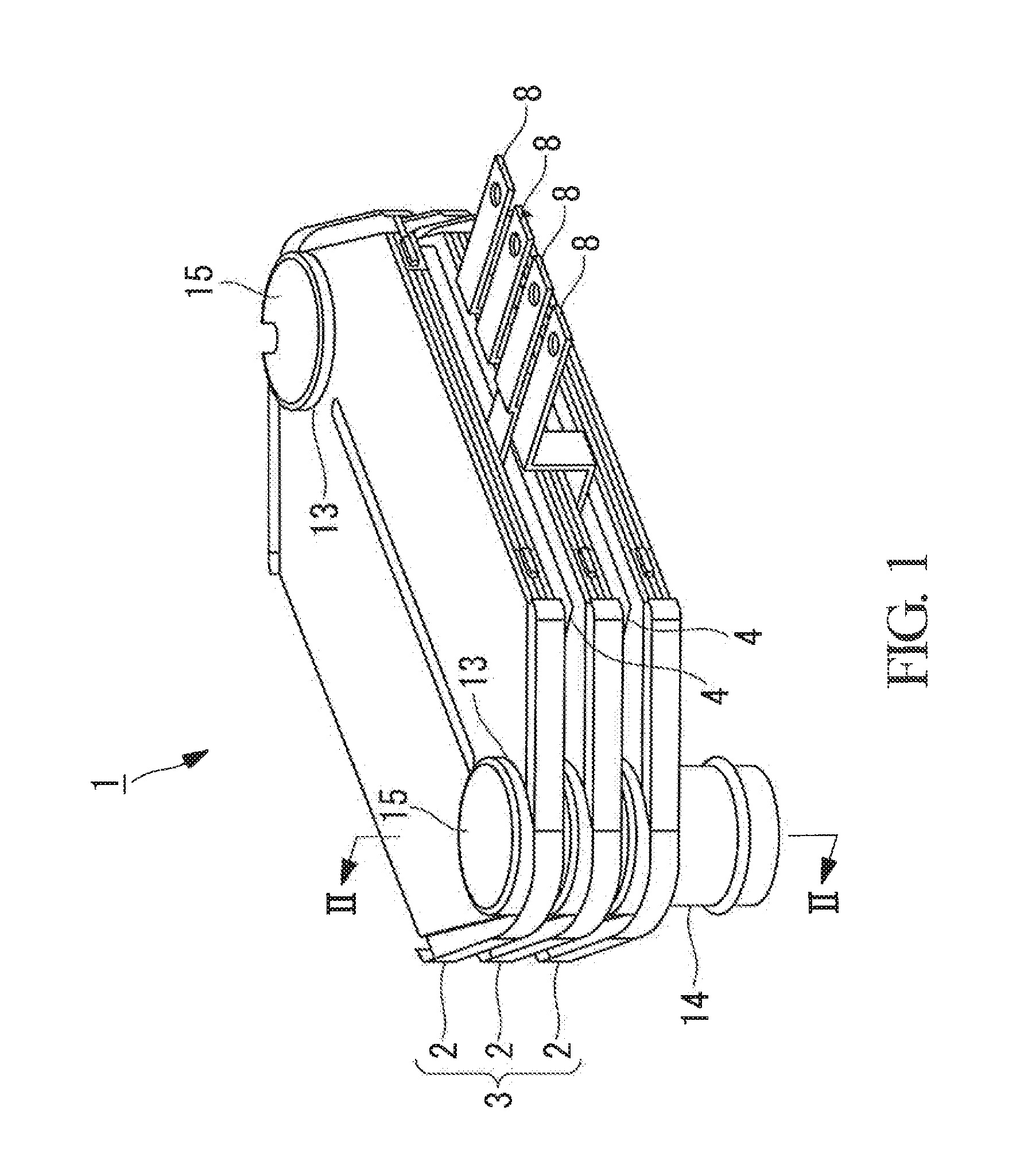

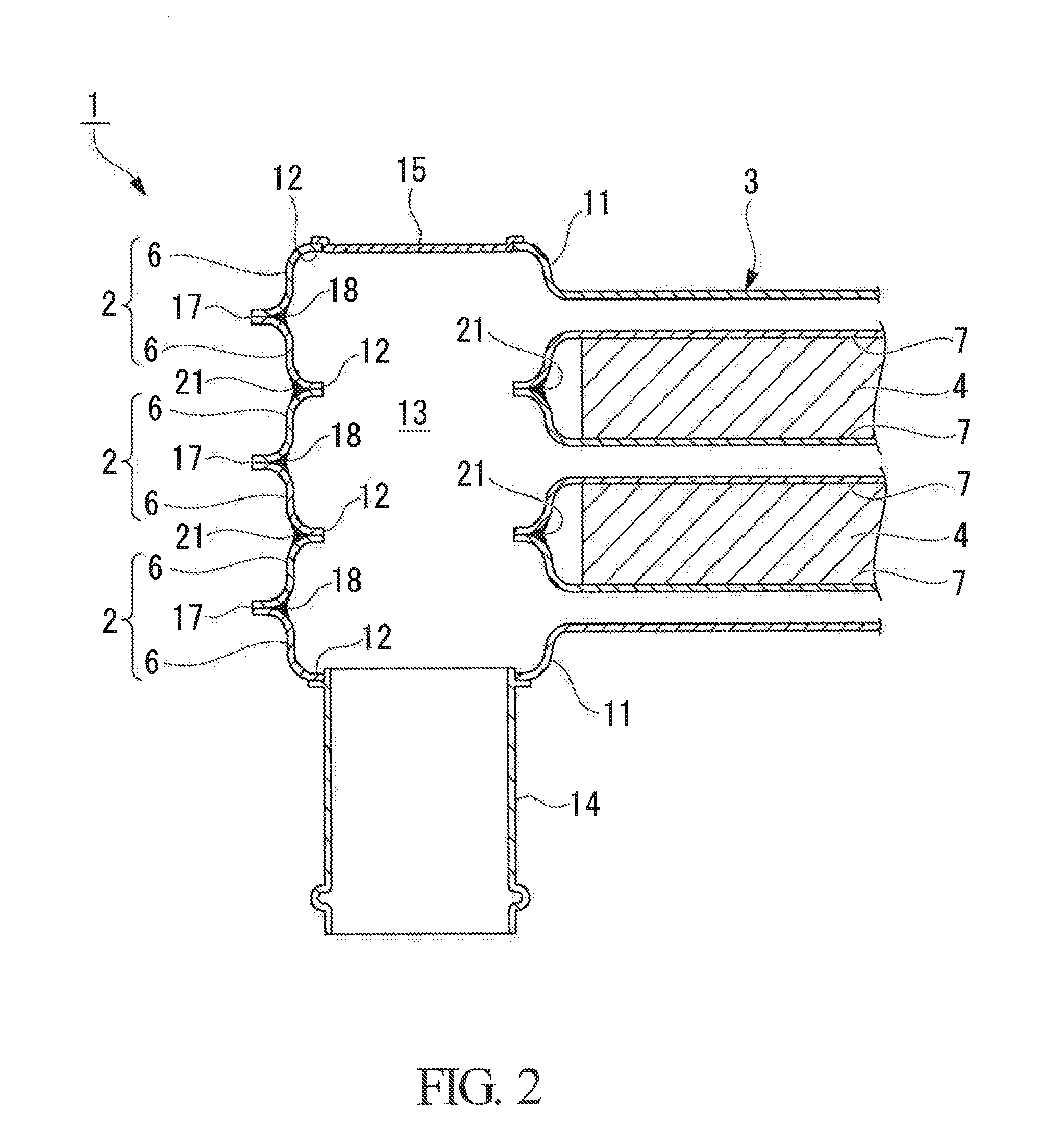

Hot-water heater manufacturing method and hot-water heater manufactured by the same

InactiveUS20130287379A1Stable heat exchangeImprove reliabilitySoldering apparatusImmersion heating arrangementsEngineeringThermal water

Provided is a hot-water heater manufacturing method capable of obtaining stable heat exchange characteristics by applying a moderate contact surface pressure between heating-medium circulating tubes and heater members that constitute a hot-water heater, and capable of improving the reliability by enhancing the joint strength between the heating-medium circulating tubes, with a simple and easy manufacturing process.

Owner:MITSUBISHI HEAVY INDUSTIRES AUTOMOTIVE THERMAL SYST CO LTD

Double-pipe heat transfer enhancement unit component and penetrating hybrid cyclone efficient double-pipe heat exchanger

ActiveCN107764099AReduced delivery power consumptionReduce heating energy consumptionHeat exchanger casingsStationary tubular conduit assembliesCycloneSocial benefits

The invention discloses a double-pipe heat transfer enhancement unit component and a penetrating hybrid cyclone efficient double-pipe heat exchanger. The double-pipe heat transfer enhancement unit component comprises an inner pipe, an outer pipe, an inner pipe twisting reinforcement part and an inter-pipe twisting reinforcement part, wherein an inner cavity allowing sludge to circulate therein isdefined in the inner pipe; the outer pipe sleeves the inner pipe; an outer cavity allowing sludge to circulate therein is defined between the outer pipe and the inner pipe; a first circulation openingis formed in the inner pipe twisting reinforcement part; and a second circulation opening is formed in the inter-pipe twisting reinforcement part. According to the double-pipe heat transfer enhancement unit component of the embodiment, two heat exchange fluids can conduct complicated flowing including spirally rotary flowing and porous penetrating hybrid flowing, so that the heat exchange fluidsare prevented from bias flowing, precipitation, cementation and blockage, mud-mud long-term stable and efficient heat exchange can be realized, the sludge conveying flow resistance and the pumping power dissipation are remarkably reduced, and accordingly, remarkable energy-saving economic benefits and environment-friendly social benefits can be achieved in sludge treatment.

Owner:TSINGHUA UNIV

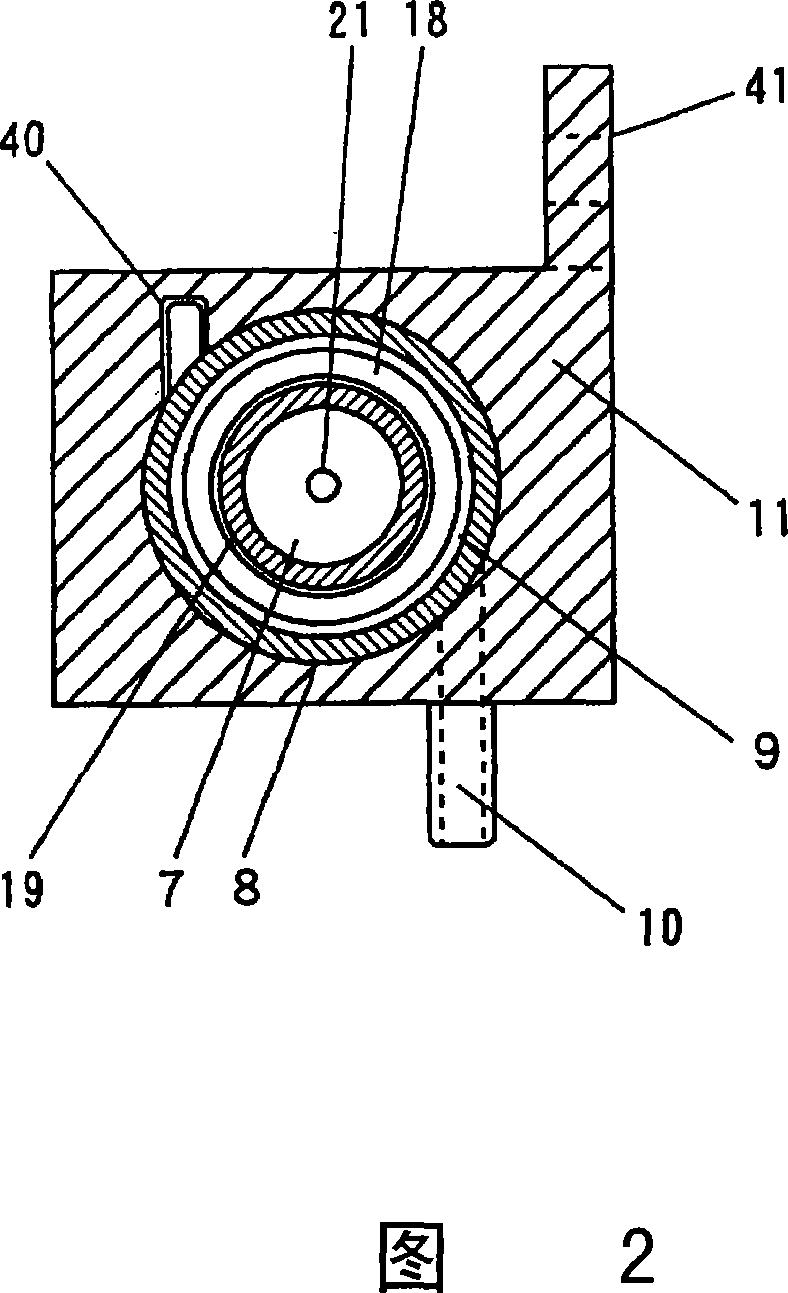

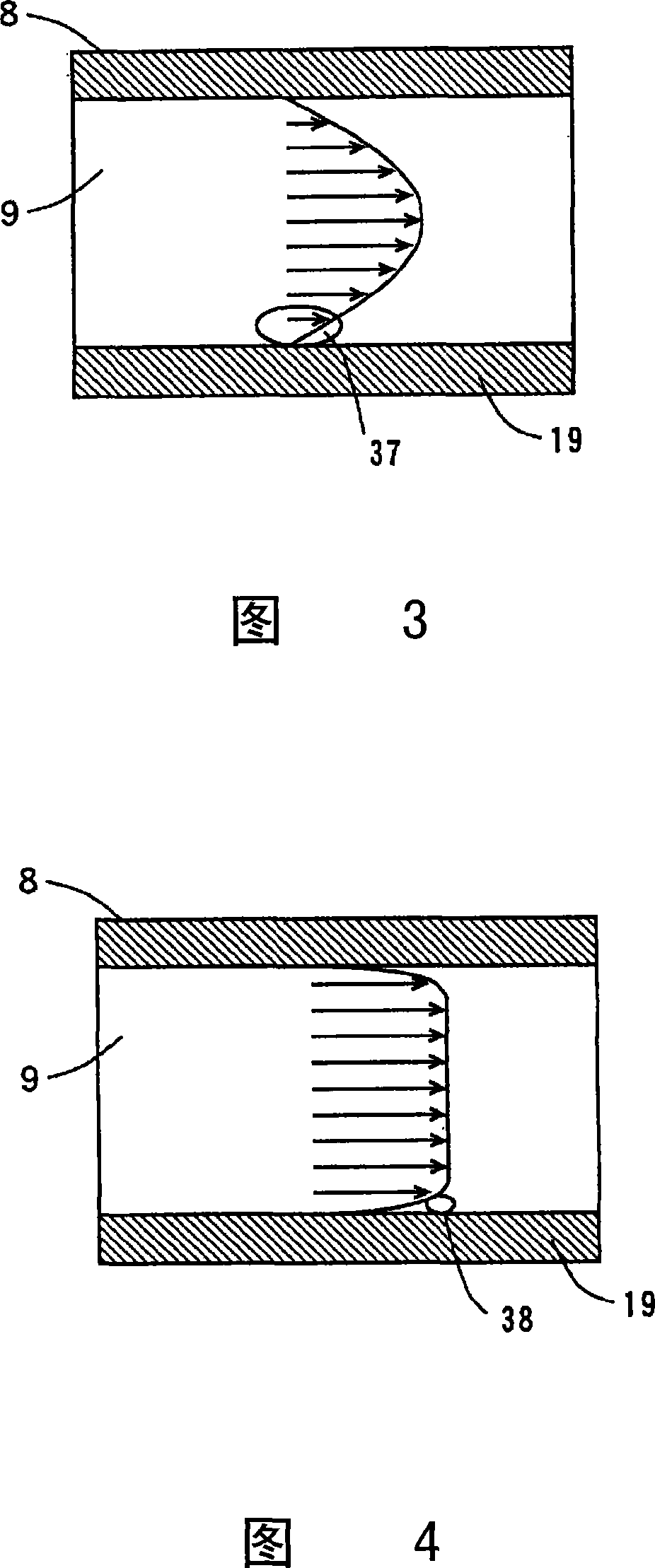

Fluid heating device, and hot water supply device using it

InactiveCN101213408APrevent flowImprove heat exchange efficiencyWater heatersHelical coilEngineering

A fluid heating device mainly includes: for example, an armored heater having a sheath made of copper and heating a heating element for heating a fluid (such as water); 1 casing member; a flow path for fluid flow formed by the space between the outer surface of the sheathed heater and the inner surface of the first casing member; having an inlet for introducing the fluid into the flow path, by A second case member made of, for example, resin; and a third case member made of, for example, resin, having an outflow port for taking out a heating fluid (for example, warm water) in the flow path. A helical coil made of, for example, copper is provided in the first case member, and the helical coil is wound helically around the outer periphery of the sheath heater within the flow path.

Owner:PANASONIC CORP

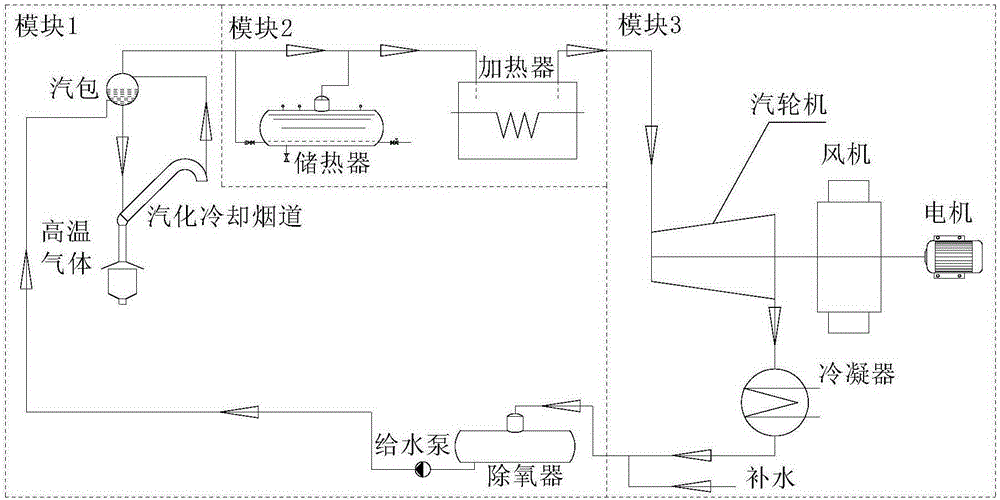

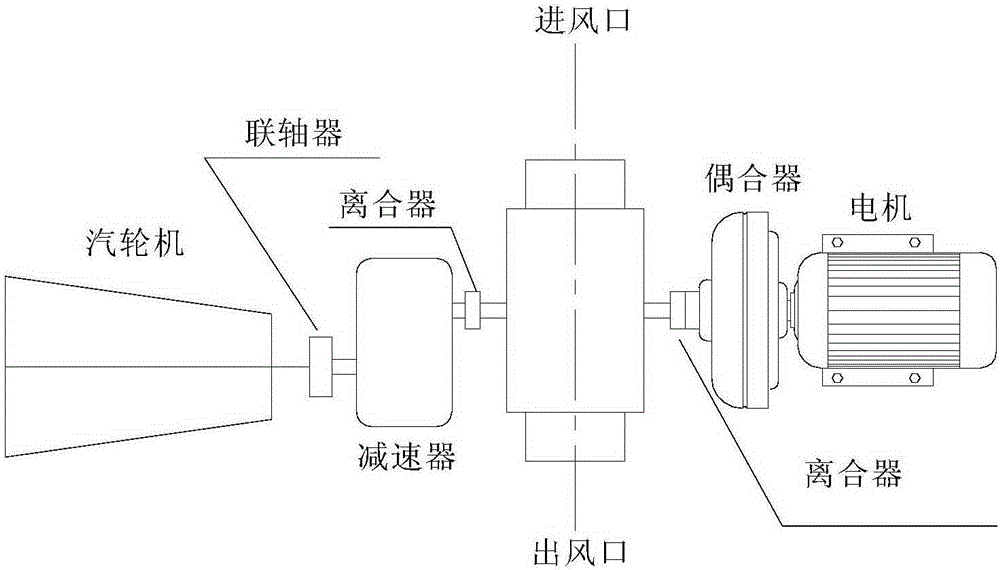

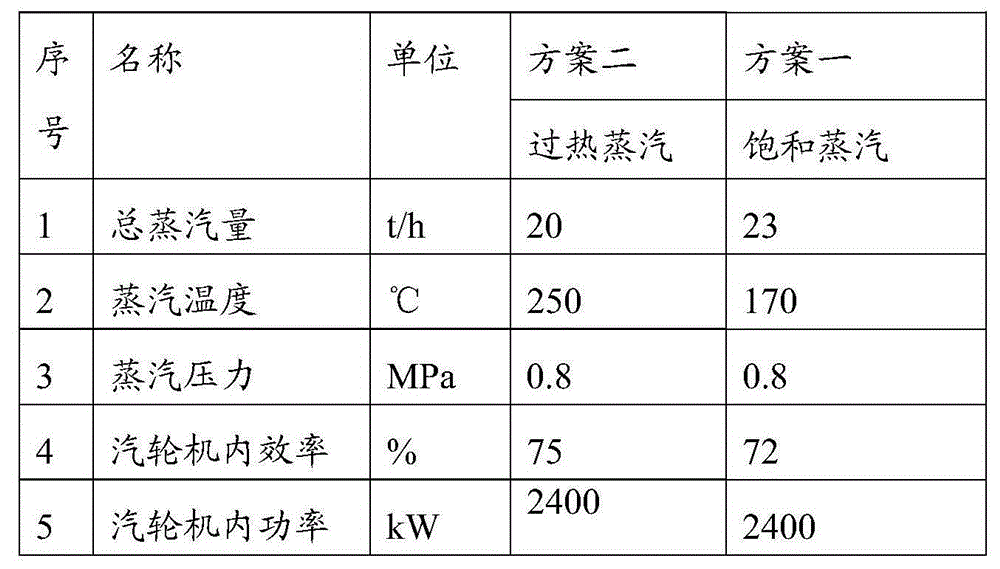

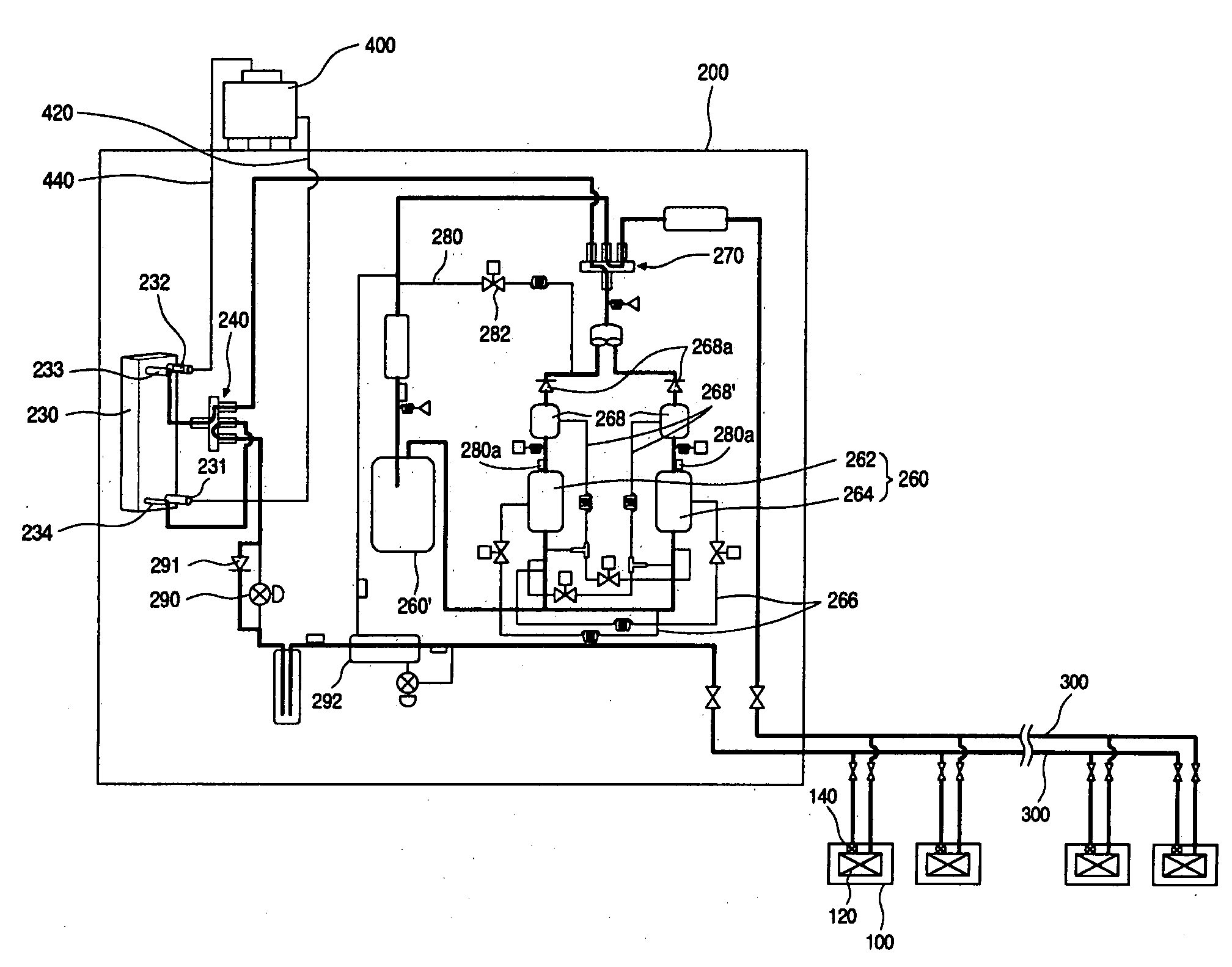

System for dragging converter flue gas induced draft fan by aid of converter steam

InactiveCN105200184AEfficient use ofAchieve steady flowIncreasing energy efficiencyManufacturing convertersExhaust valveDeaerator

The invention discloses a system for dragging a converter flue gas induced draft fan by the aid of converter steam. The system comprises a waste heat boiler unit, the converter flue gas induced draft fan, a steam heat storing and flow stabilizing unit and a steam turbine set unit. The waste heat boiler unit comprises a waste heat boiler, a steam drum and an oxygen remover, middle-low-pressure steam is generated after cooling water in a vaporization cooling flue of a converter is heated, and is gathered in the steam drum, and saturated steam is generated by a pressure-control exhaust valve; the steam heat storing and flow stabilizing unit comprises heat storage devices and a control valve, the saturated steam is stored in the heat storage devices, and steam with stable flow can be assuredly supplied; the steam turbine set unit comprises a steam turbine, a condenser, a condensate water pump, a steam seal heater and a low-temperature heater, the steam does expansion work in the steam turbine and then is exhausted into the condenser to be condensed to obtain water, the water is pressurized by the condensate water pump and flows through the steam seal heater and the low-temperature heater, then oxygen in the water is removed by the oxygen remover of the waste heat boiler unit, and water without the oxygen is pressurized by a feed water pump of the vaporization cooling flue of the converter and flows through a high-temperature flue of the converter; the converter flue gas induced draft fan can be dragged by the steam turbine to run.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

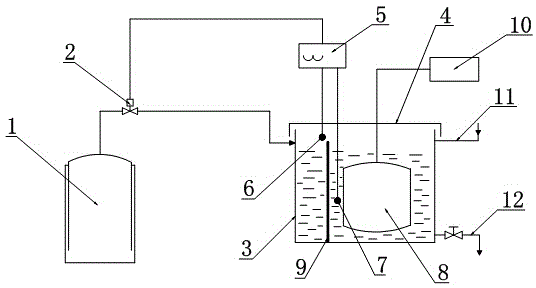

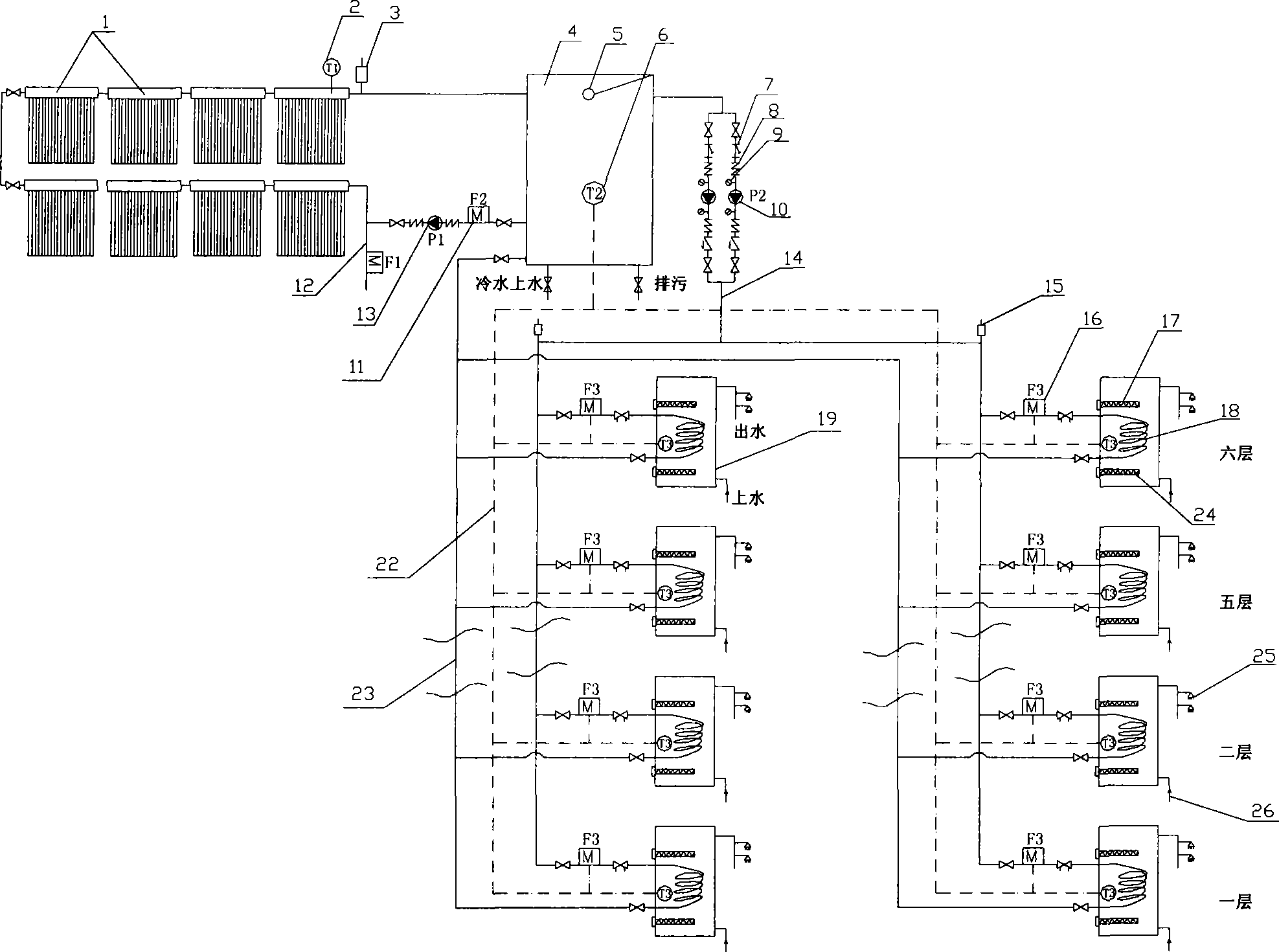

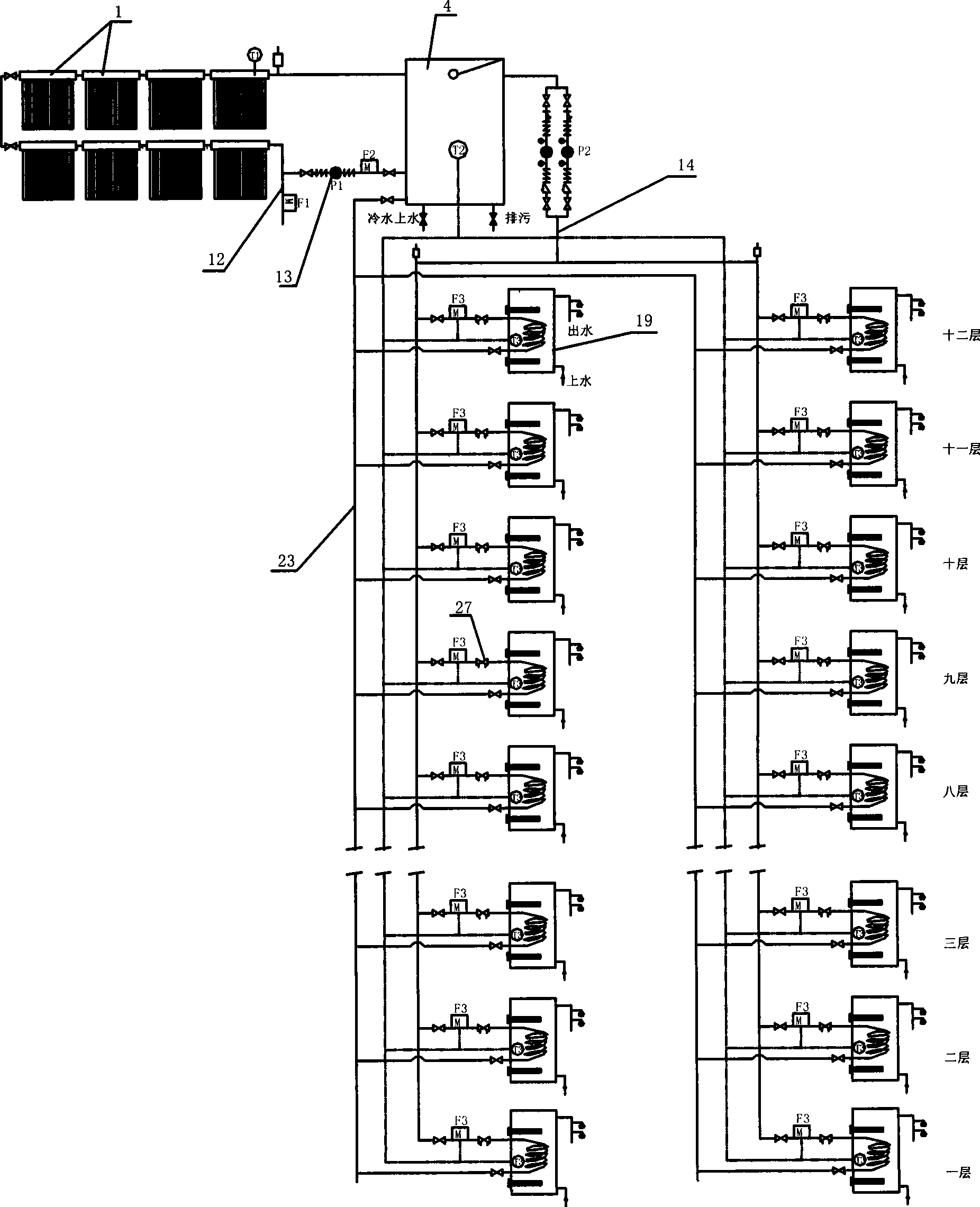

Solar centralized heat collection household water tank exchange heat supply system

InactiveCN101545654ADo not have to deal with measurement issuesSimple structureLighting and heating apparatusDomestic hot-water supply systemTemperature controlElectricity

The invention discloses a solar centralized heat collection household water tank exchange heat supply system, which comprises a solar heat collection device, wherein the solar heat collection device is communicated with a household heat exchange device through a heat supply pipeline. The solar heat collection device comprises a plurality of solar heat collectors, solar heat collection heat insulation water tanks, an anti-freezing closure electromagnetic valve and a solar circulating pump which are orderly connected in series through a pipeline. A pipeline of the solar heat collection device is provided with a branch pipeline, and the branch pipeline is provided with a normally closed heat temperature control electromagnetic valve. The system has the advantages of no (water, electricity and coal) metering problem, simple and reasonable structure, and steady heat exchange.

Owner:陈勇

Hot-blast stove

PendingCN107388578AImprove combustion efficiencyStable heat exchangeAir heatersSolid fuel combustionCold airCombustion chamber

A hot-blast stove comprises a gasification chamber, a combustion chamber, a burn-out chamber, an air mixing chamber, a fire grate, a tail flue and the like. The gasification chamber, the combustion chamber, the burn-out chamber and the air mixing chamber are sequentially horizontally parallelly arranged to form a reciprocating type material air flow channel. The fire grate is obliquely arranged at the bottoms of the gasification chamber and the combustion chamber. Primary air chambers are arranged at the bottom of the fire grate. The inclined bottom of the burn-out chamber is provided with a tertiary air pipe. A heat exchanger is arranged in the tail flue and used for heating cold air into hot air. The tail flue part in the front of the heat exchanger is provided with a primary cold air pipe, and the tail flue part at the rear of the heat exchanger is provided with a secondary cold air pipe. The hot-blast stove is long in material air flow channel travel, good in gasification and combustion effect, clean in flue gas and capable of acquiring hot air and hot flue gas.

Owner:北京禾适科技有限公司

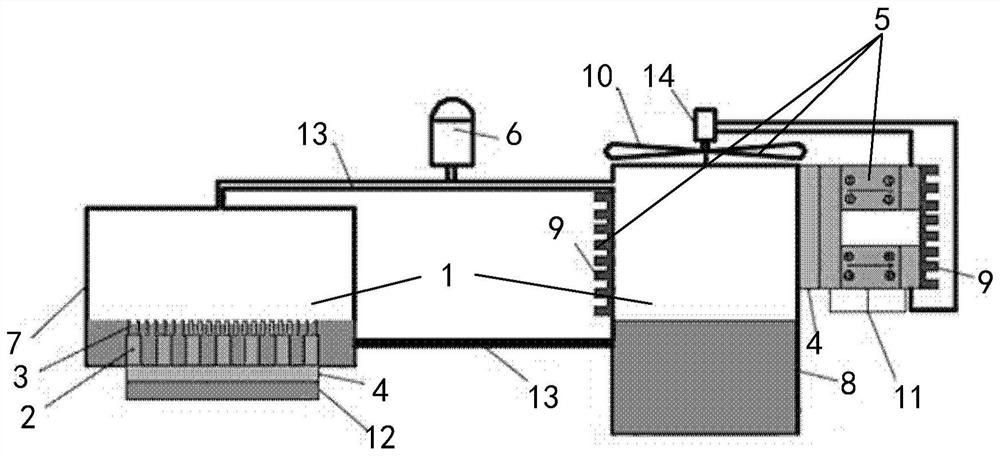

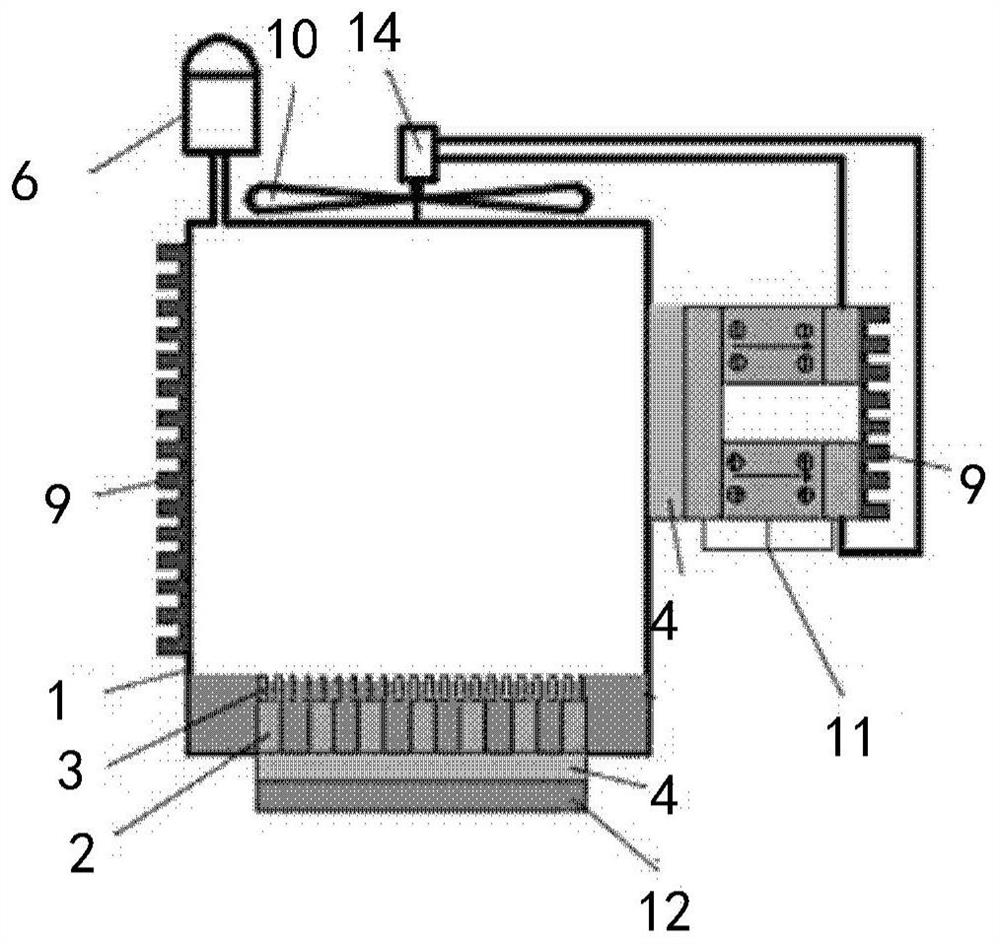

Battery heat dissipation device special for new energy vehicle

InactiveCN112652836AExtend your lifePractical Process SafetyCell temperature controlBattery isolationThermodynamicsNew energy

The invention relates to the technical field of new energy vehicles, in particular to a battery heat dissipation device special for a new energy vehicle. The battery heat dissipation device special for the new energy vehicle comprises a battery pack heat exchange mechanism, a radiator and a heat exchange liquid circulation assembly, wherein the battery pack heat exchange mechanism comprises a main heat exchange shell formed by assembling an upper shell and a lower shell, a first cavity used for heat exchange of a battery pack is formed in an inner cavity of the upper shell, and a second cavity used for letting in cooling liquid is formed in an inner cavity of the lower shell. A partition plate used for partitioning the upper shell and the lower shell and a supporting piece used for bearing the battery pack are sequentially arranged in an inner cavity of the main heat exchange shell from bottom to top. The device has the beneficial effects that an immersion type heat exchange mode is adopted, the heat exchange efficiency is better, heat generated during operation of the battery pack can be rapidly guided out so as to avoid long-time accumulation of the heat in the battery, the risk of causing a fire disaster is reduced, and the whole battery is safer in the practical process.

Owner:HANGZHOU POLYTECHNIC

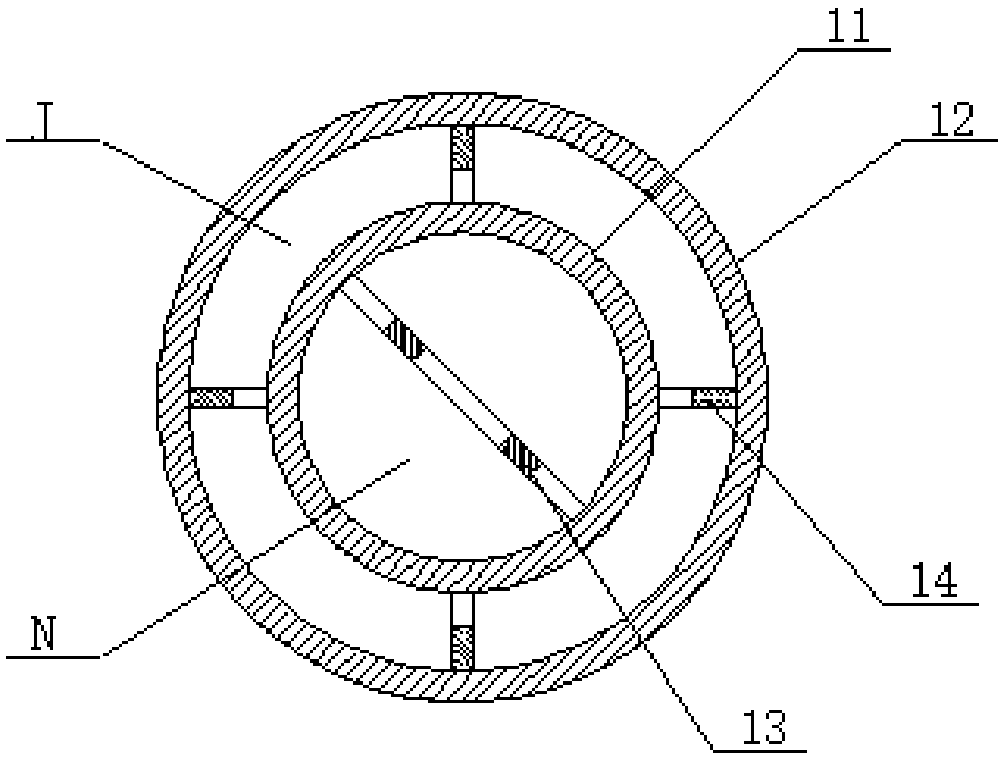

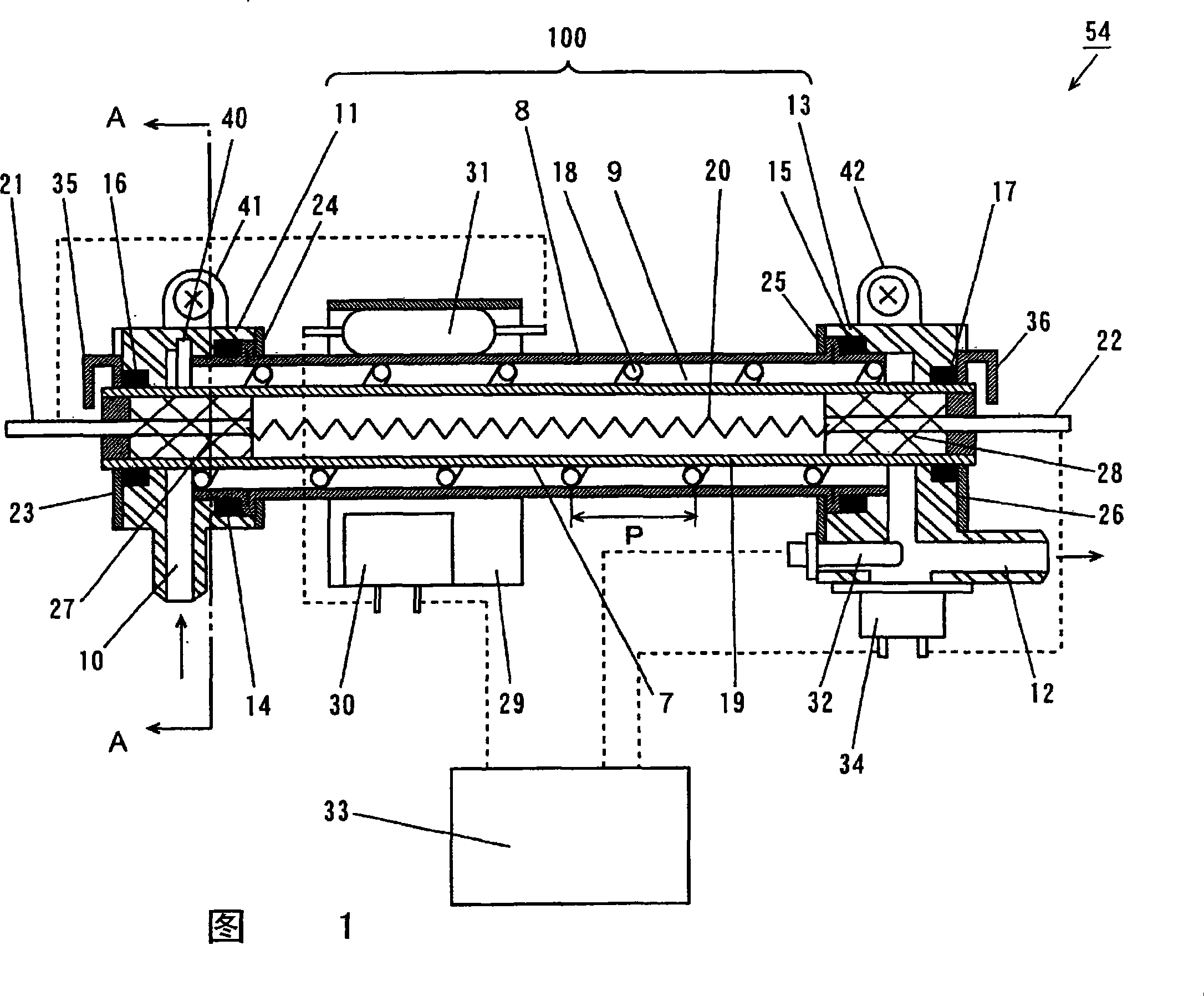

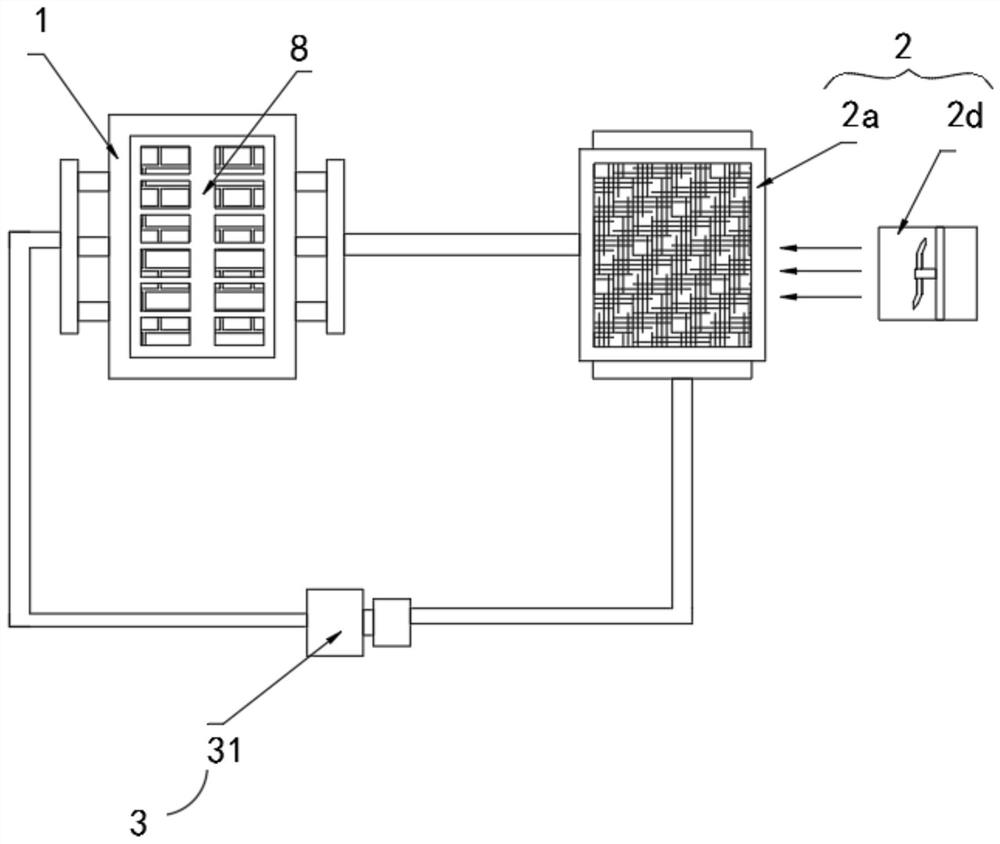

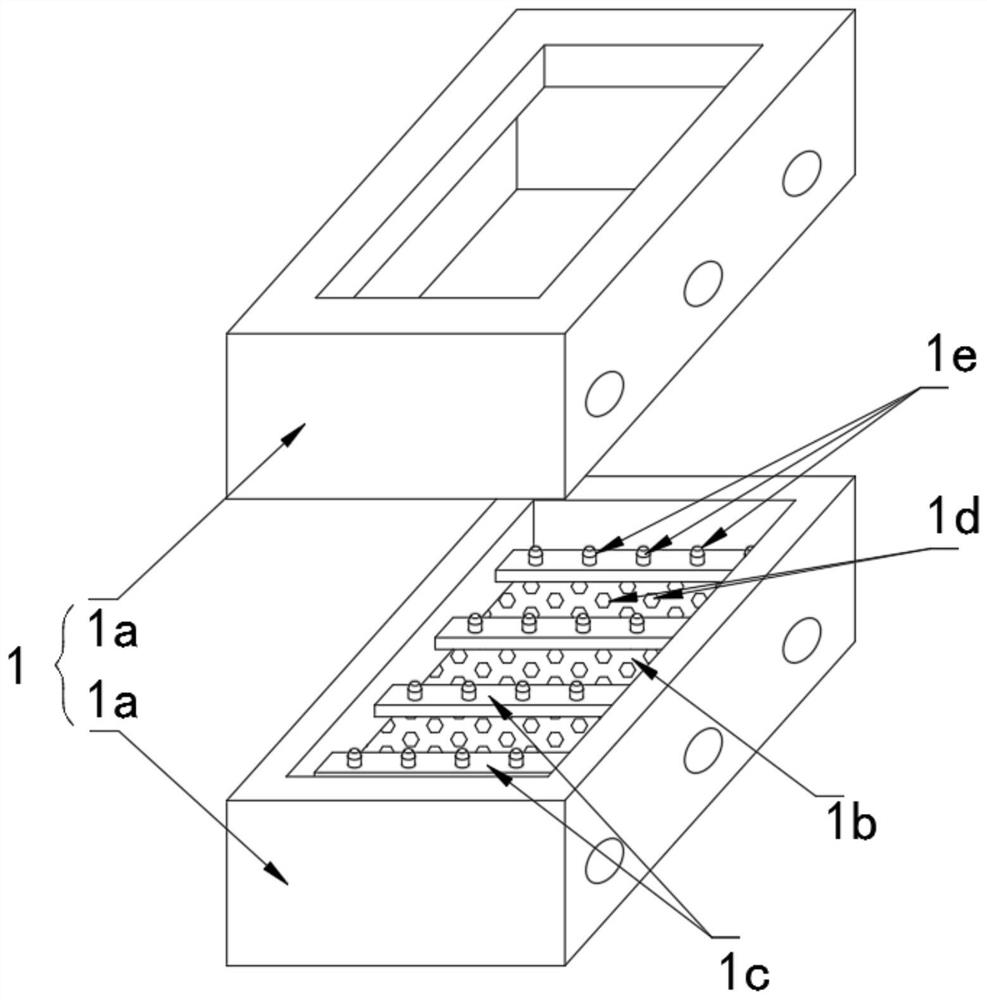

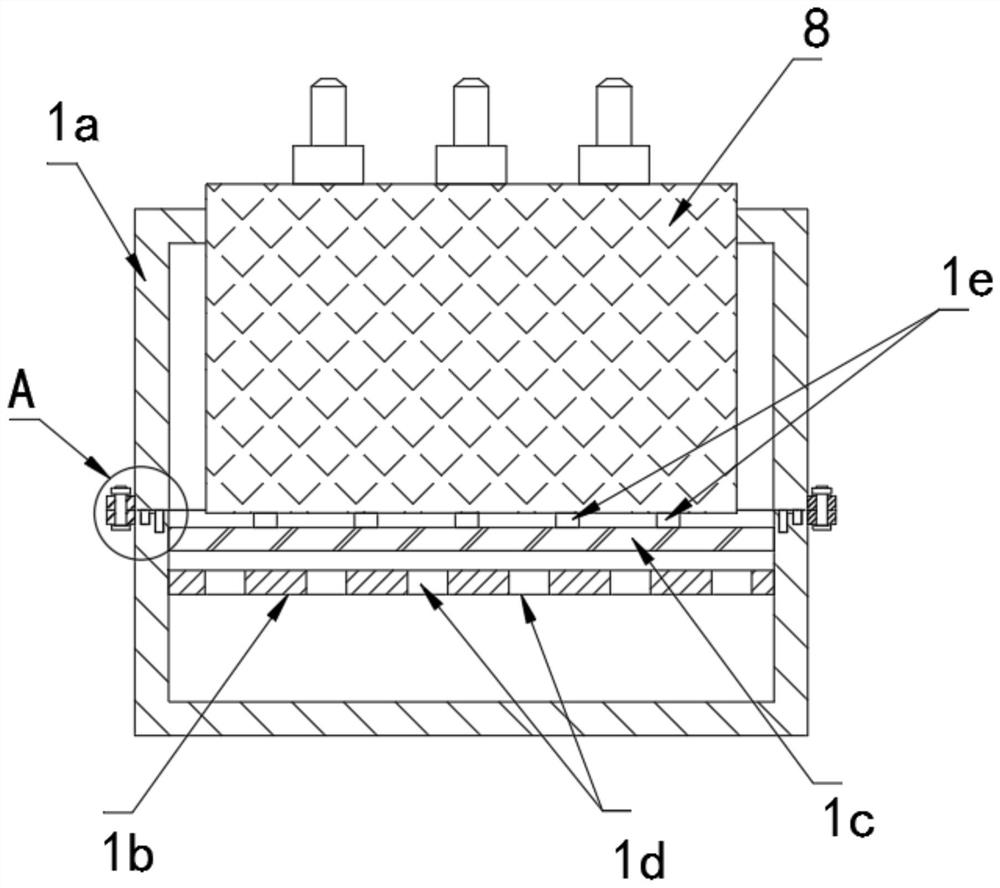

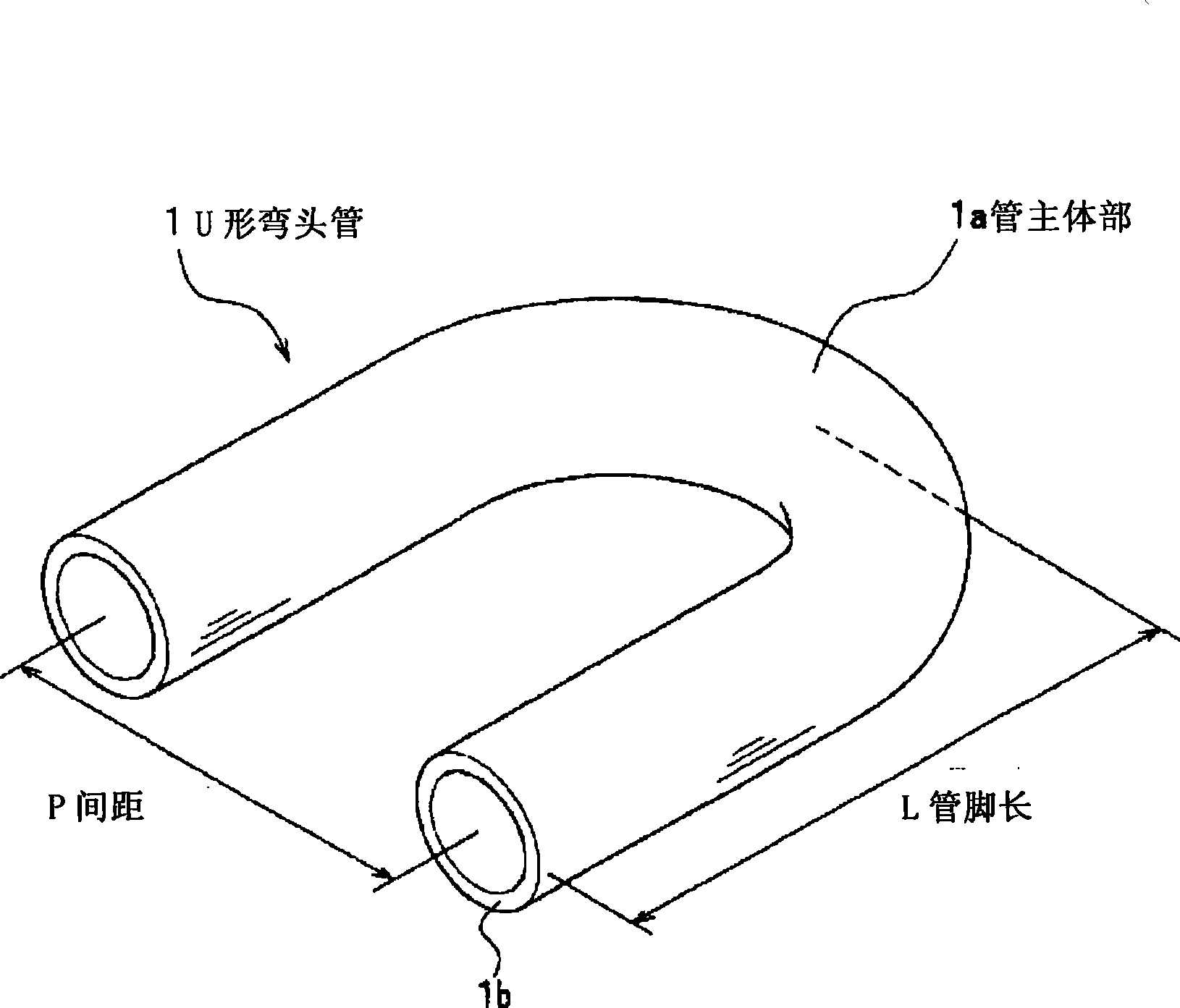

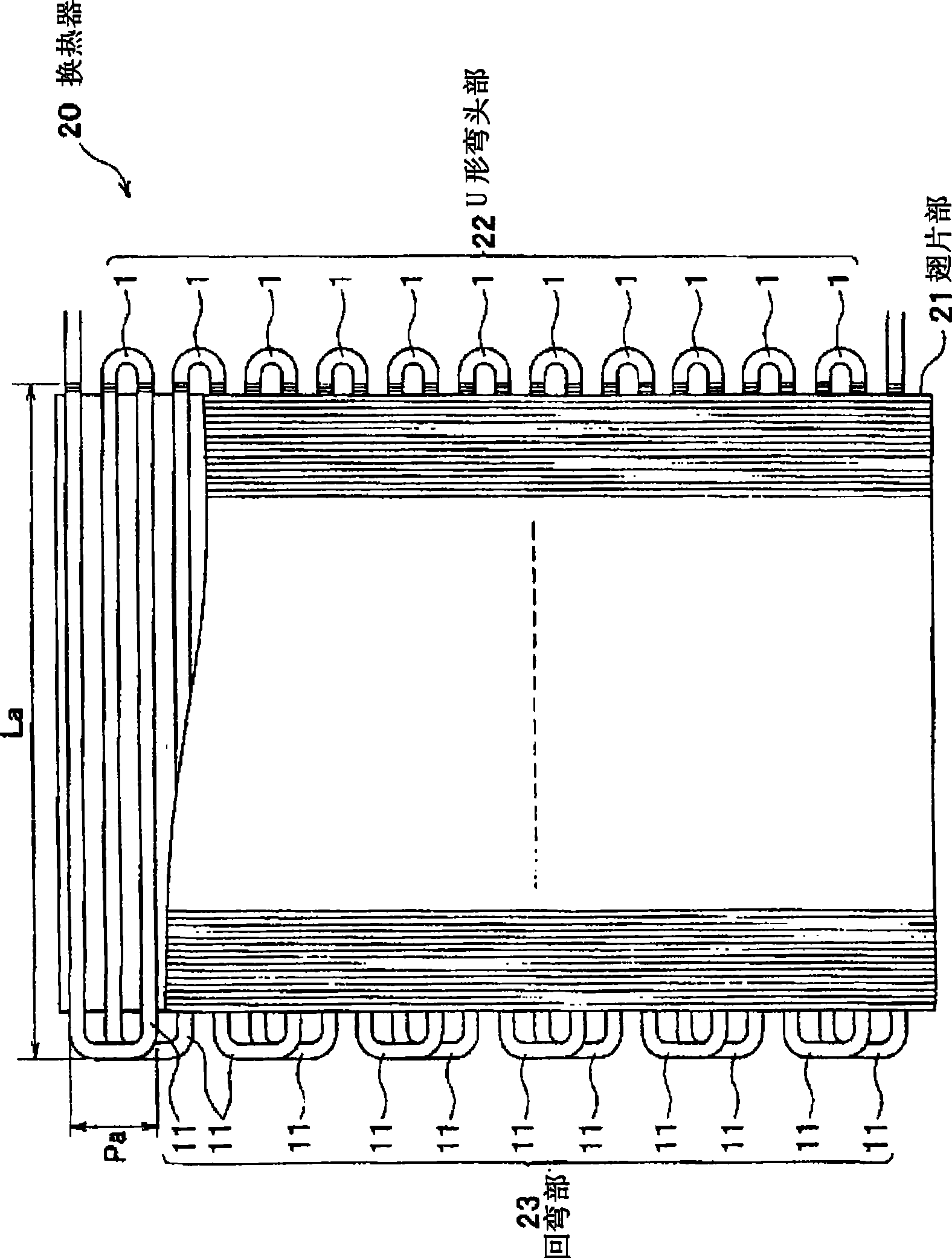

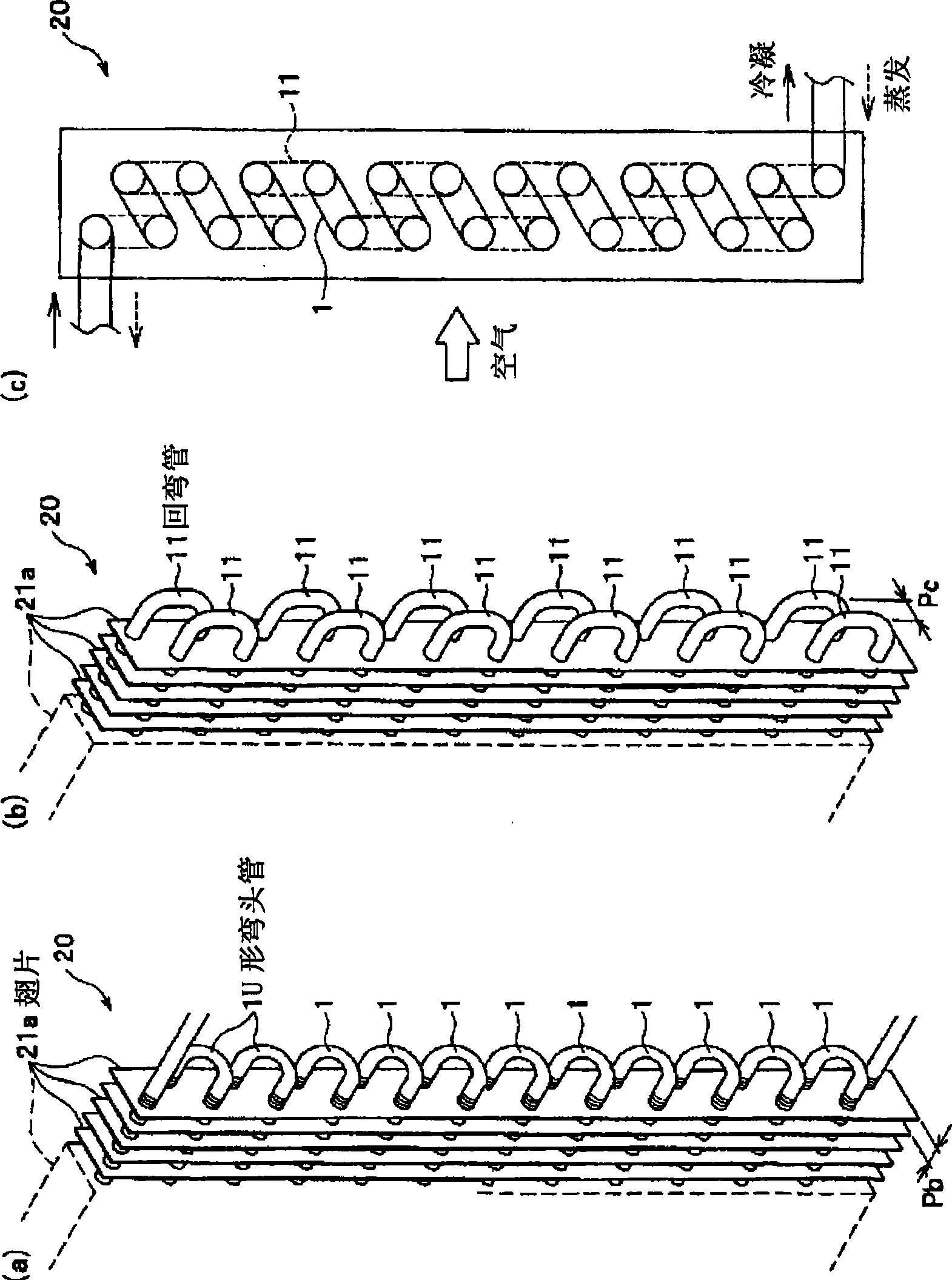

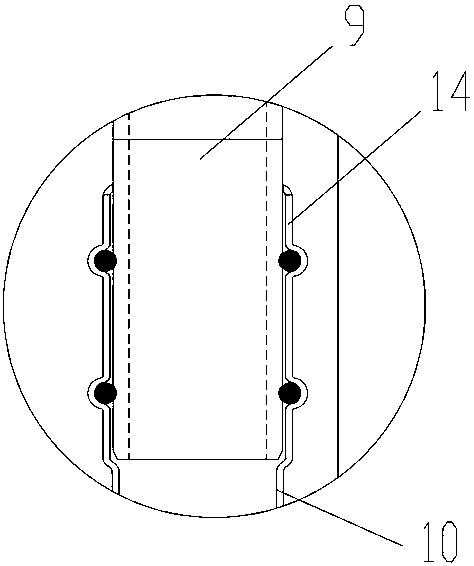

Fin-and-tube type heat exchanger, and its return bend pipe

ActiveCN101466992AStable heat exchangeImprove evaporation effectCompression machines with non-reversible cycleEvaporators/condensersEngineeringTubes types

Provided is a fin-and-tube type heat exchanger using a return bend pipe capable of improving the evaporation performance of the heat exchanger still better. This heat exchanger comprises a hair pin unit having a multiplicity of hair pin pipes arranged in parallel, a return bend unit having a multiplicity of such return bend pipes arranged in parallel as are jointed to the individual hair pin pipe end portions of the hair pin portions, and a fin portion having a multiplicity of fins arranged in parallel at a constant spacing on the outer surfaces of the hair pin pipes. The pipe insides are fed with a coolant. The heat exchanger has first grooves formed in the inner faces of the return bend pipes. The groove pitch ratio (P1 / P2) between a first groove pitch (P1), as taken in the section normal to the pipe axis, of the first grooves, and a second groove pitch (P2), as taken in the section normal to the pipe axis, of second grooves of a helical shape formed in the pipe inner faces of the hair pin pipes satisfies 0.65 to 2.2. At the same time, the groove sectional area ratio (S1 / S2) between a first groove sectional area (S1) per groove, as taken in the section normal to the pipe axis, of the first grooves and a second groove sectional area (S2) per groove, as taken in the section normal to the pipe axis, of the second grooves satisfies 0.3 to 3.6.

Owner:KOBELCO & MATERIALS COPPER TUBE LTD

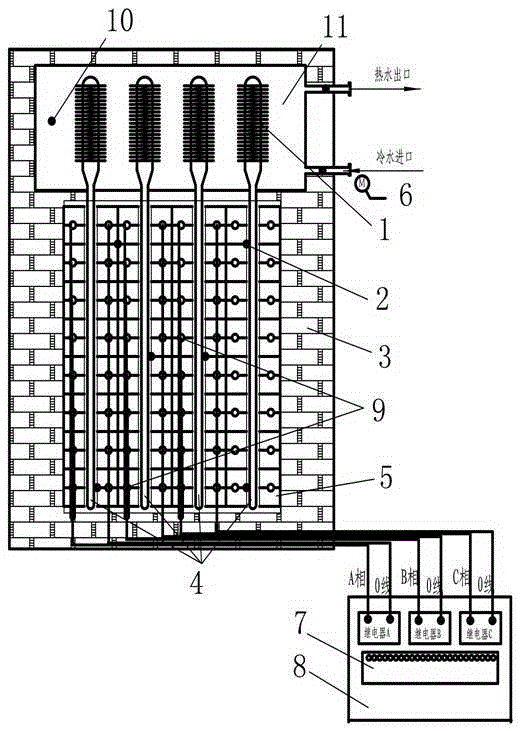

Solid heat storage directly-heated type heating device

InactiveCN105387514AReasonable structureInstant releaseHeating fuelLighting and heating apparatusComputer control systemElectricity

The invention provides a solid heat storage directly-heated type heating device. The heating device comprises a solid heat storage pile, a heat pipe exchanger and a computer control system. The solid heat storage pile is located on the lower portion of the directly-heated type heating device, the heat pipe exchanger is located on the upper portion of the directly-heated type heating device, and the outer wall forms an overall structure of the directly-heated type heating device through a heat insulation layer (3). A heat storage system is reasonable in structure, efficient, environmentally friendly, stable, safe, reliable, easy to operate, high in heat storage temperature and stable in heat exchange process, energy is saved, valley point electricity heat storage can be utilized, the heat storage capacity of the whole machine is high, hot water can be instantly released, output is continuous, duration can be guaranteed, zero pollution and zero emission are achieved, and the heating device is suitable for independent large-area central heating of living areas, office buildings, schools, restaurants and the like in the South and North of China.

Owner:北京谷能中科新能源科技有限公司

Straw recycling treatment method

ActiveCN107787691ARealize one-stop productionImprove efficiencyChemical industryCuttersCasting moldPre treatment

The invention relates to a straw recycling treatment method. A straw recycling treatment device is adopted for production and comprises a crushing cavity, a fine grinding cylinder, a conveying cavity,a mixing cavity, a casting mold pressing machine and a steam chamber. The method comprises the steps of crushing, grinding, modifying, mixing with cement, casting mold, pressing, and aerated curing.By arranging equipment of a specific structure, the efficiency of the whole method is improved, and integrated equipment manufacturing from primary raw materials to final products is achieved withoutpretreating the raw materials, so that the overall production cost is reduced, and the production stability is improved.

Owner:ZHEJIANG KUNLUN ENVIRONMENTAL PROTECTION EQUIP

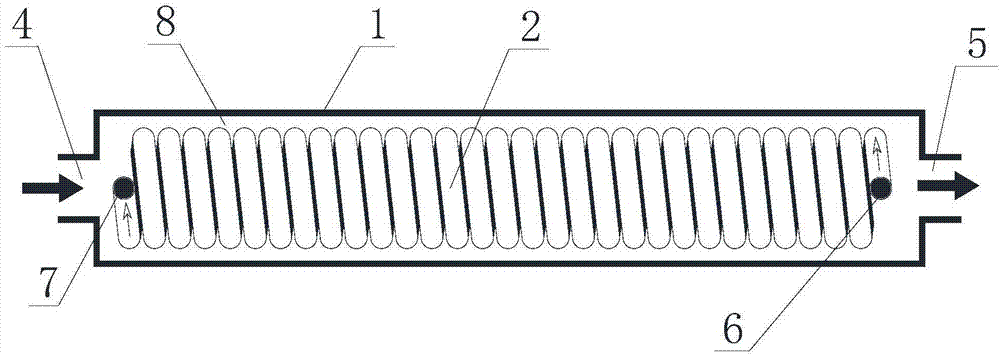

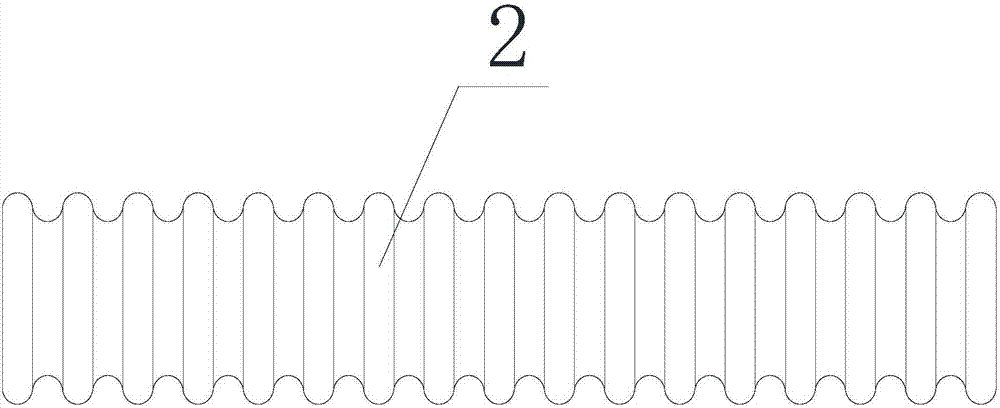

Waste hydrothermal recycler with anti-blocking function and using method thereof

PendingCN107166996AEffective heat transferLower discharge temperatureSafety devices for heat exchange apparatusCorrosion preventionWarm waterWastewater

The invention discloses a waste hydrothermal recycler with an anti-blocking function and a using method thereof. The waste hydrothermal recycler comprises a thermal recycling corrugated pipe installed in a sewage pipe. The direction of a water flow in the thermal recycling corrugated pipe is opposite to the direction of a water flow in the sewage pipe, and a cleaning device used for flushing the outer wall of the thermal recycling corrugated pipe is arranged in the sewage pipe. According to the waste hydrothermal recycler with the anti-blocking function and the using method thereof, the thin-wall stainless steel corrugated pipe is adopted, and the corrugated pipe is coiled to be in a spiral shape to enable waste hot water to flow from the middle and the periphery of the spiral coiled pipe so that all the positions of the whole spiral corrugated coiled pipe can effectively exchange heat; by adopting a pipe-arranging mode of cold water thermal-recycling and waste hot water reverse-flowing, the using effect of the thermal recycler is greatly improved, the warm-water outlet temperature of the thermal recycler is effectively improved, and the discharging temperature of the waste hot water is greatly reduced; and a compressed air pipe is designed below the corrugated spiral pipe and in the sewage pipe, long-term stable heat-exchanging of the thermal recycling corrugated pipe is greatly guaranteed, and the whole thermal recycler is prevented from being blocked by dirt.

Owner:成都恒新源暖通工程有限公司

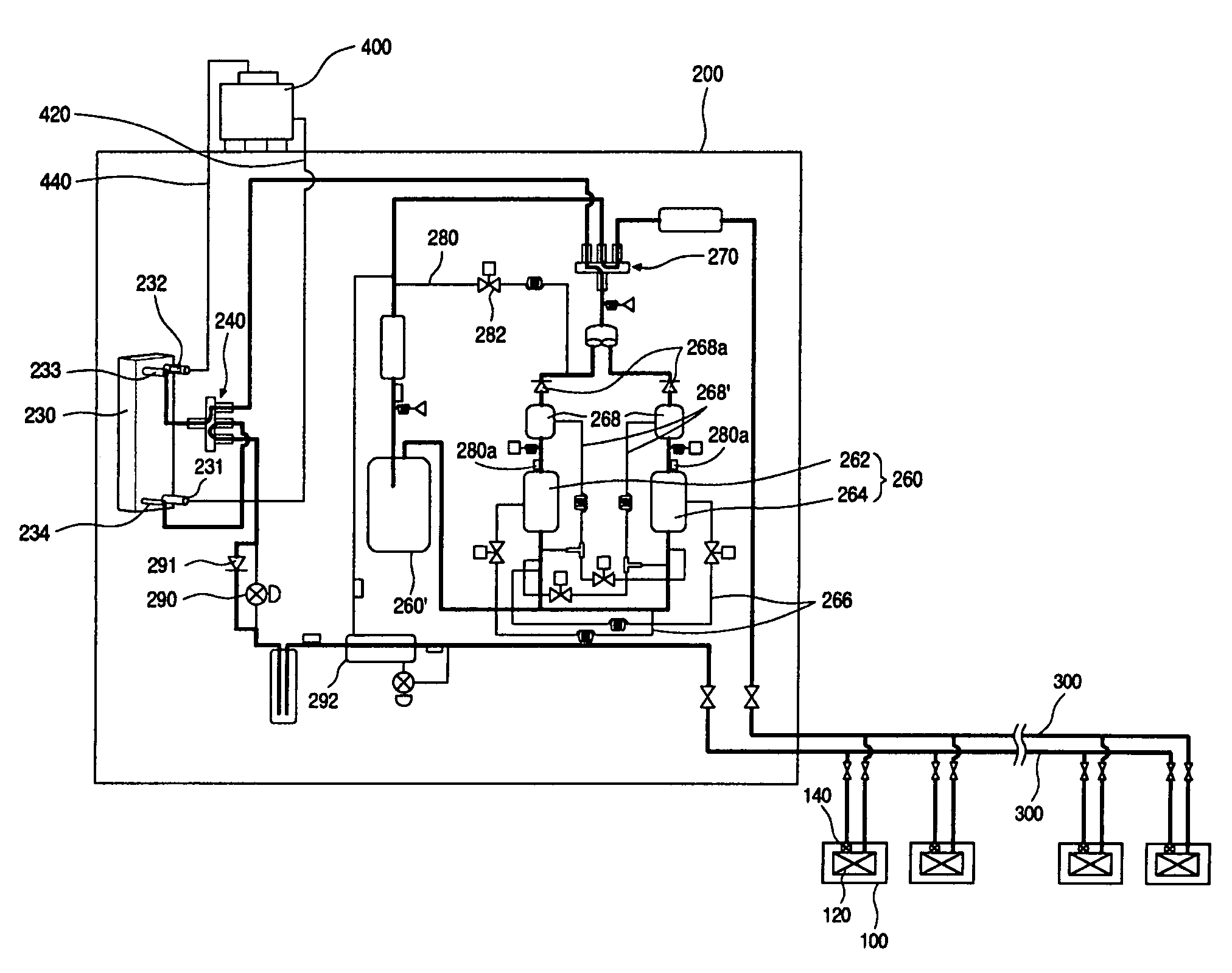

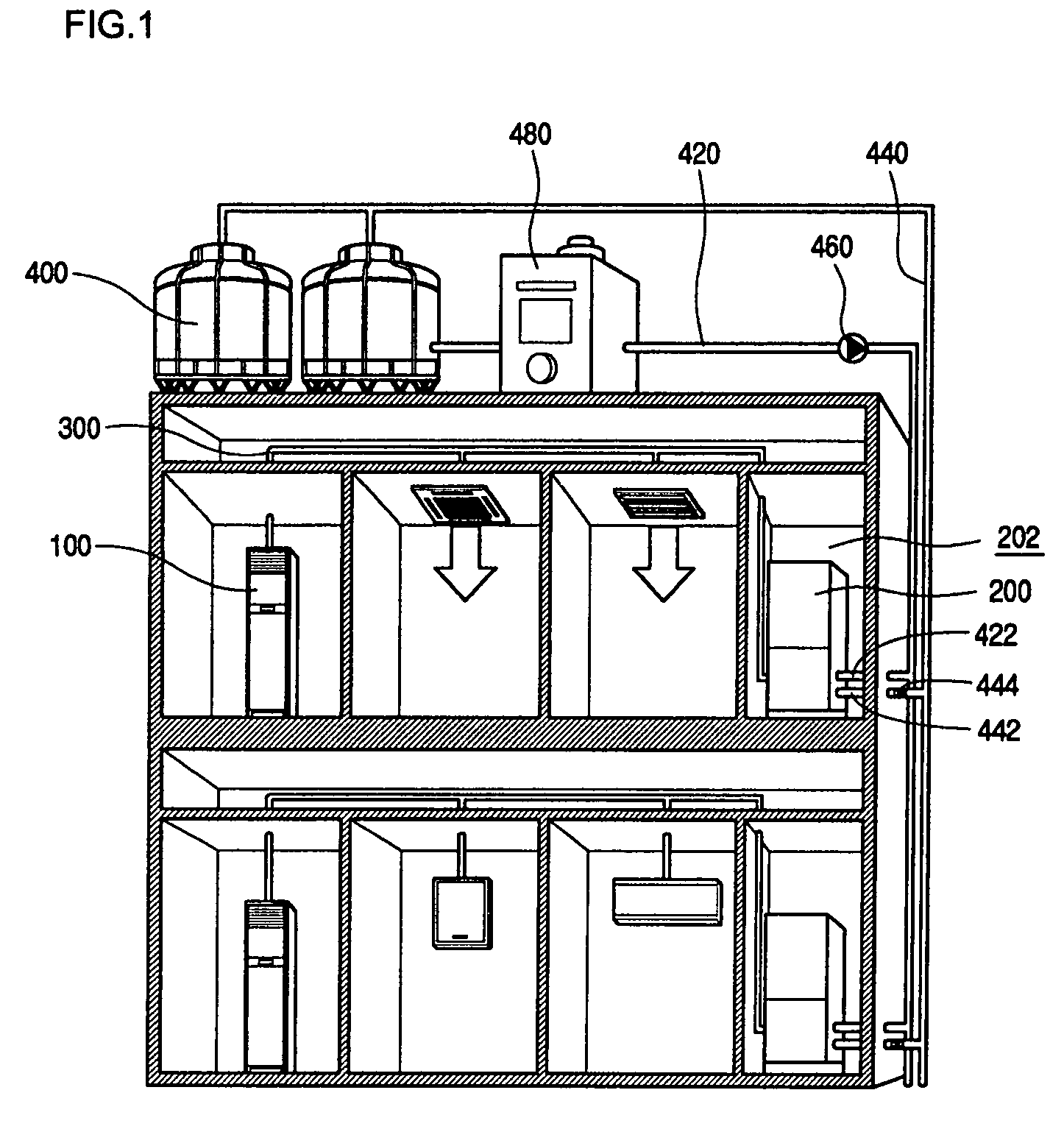

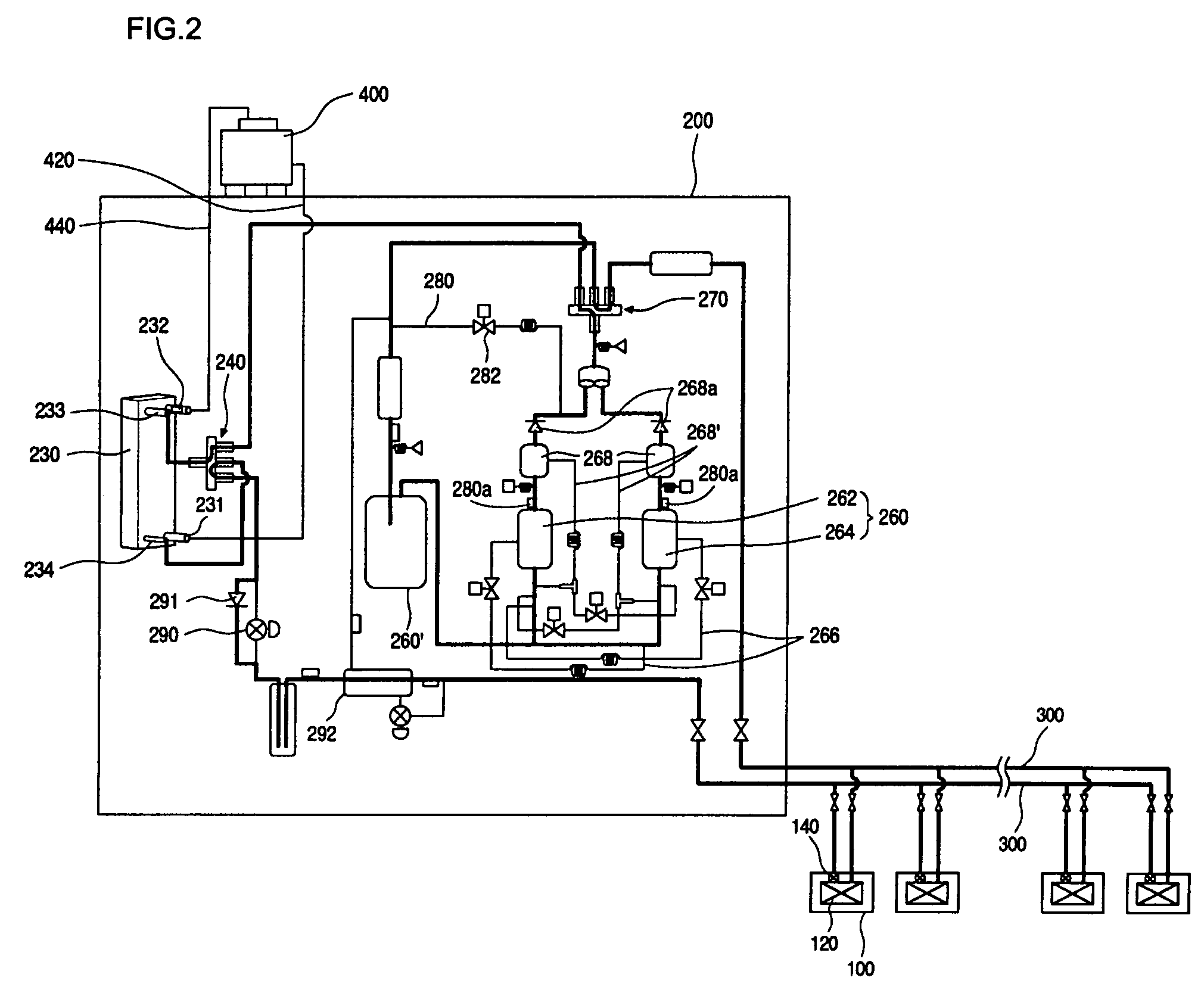

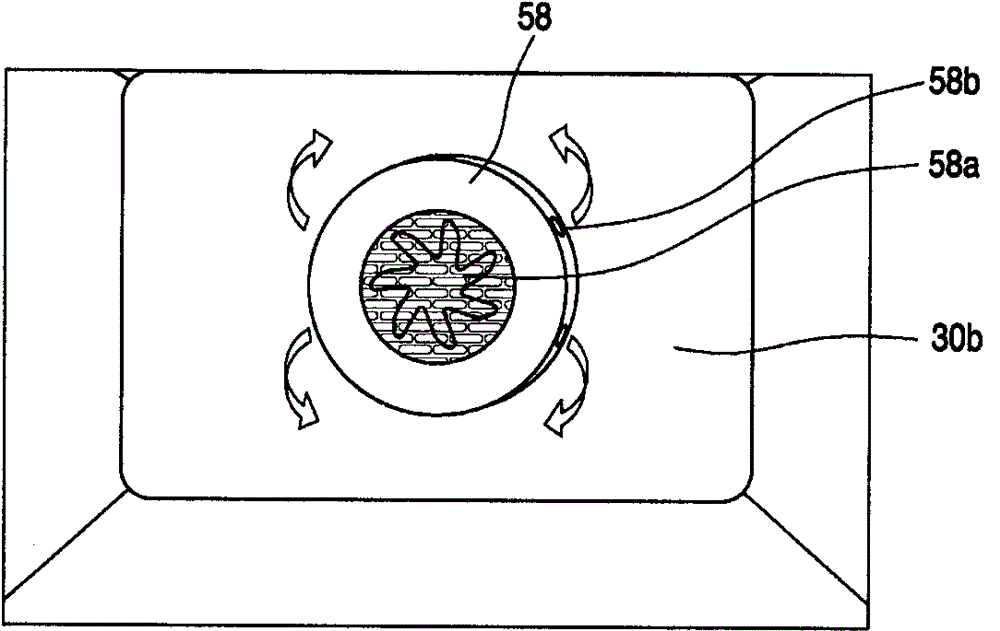

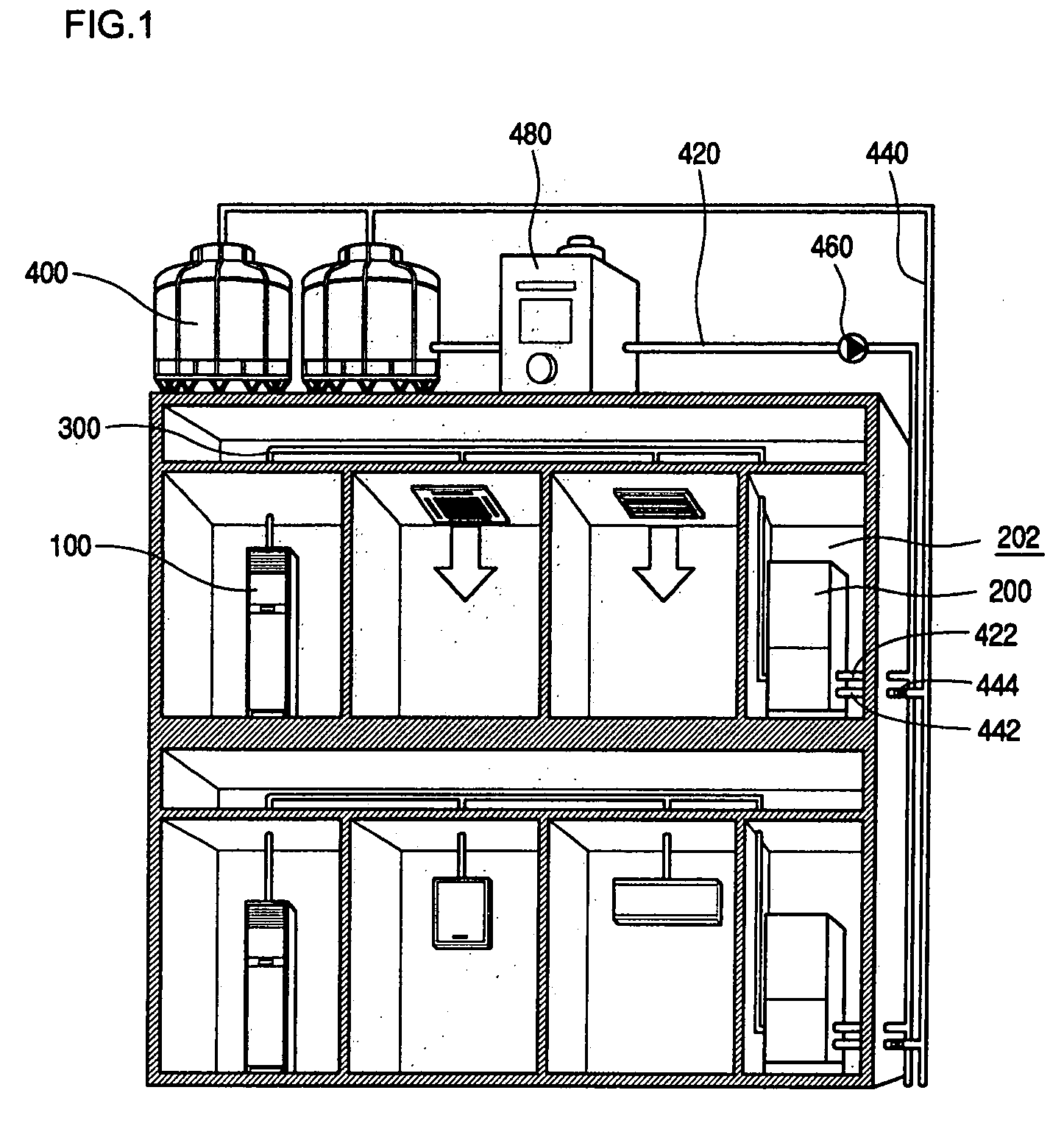

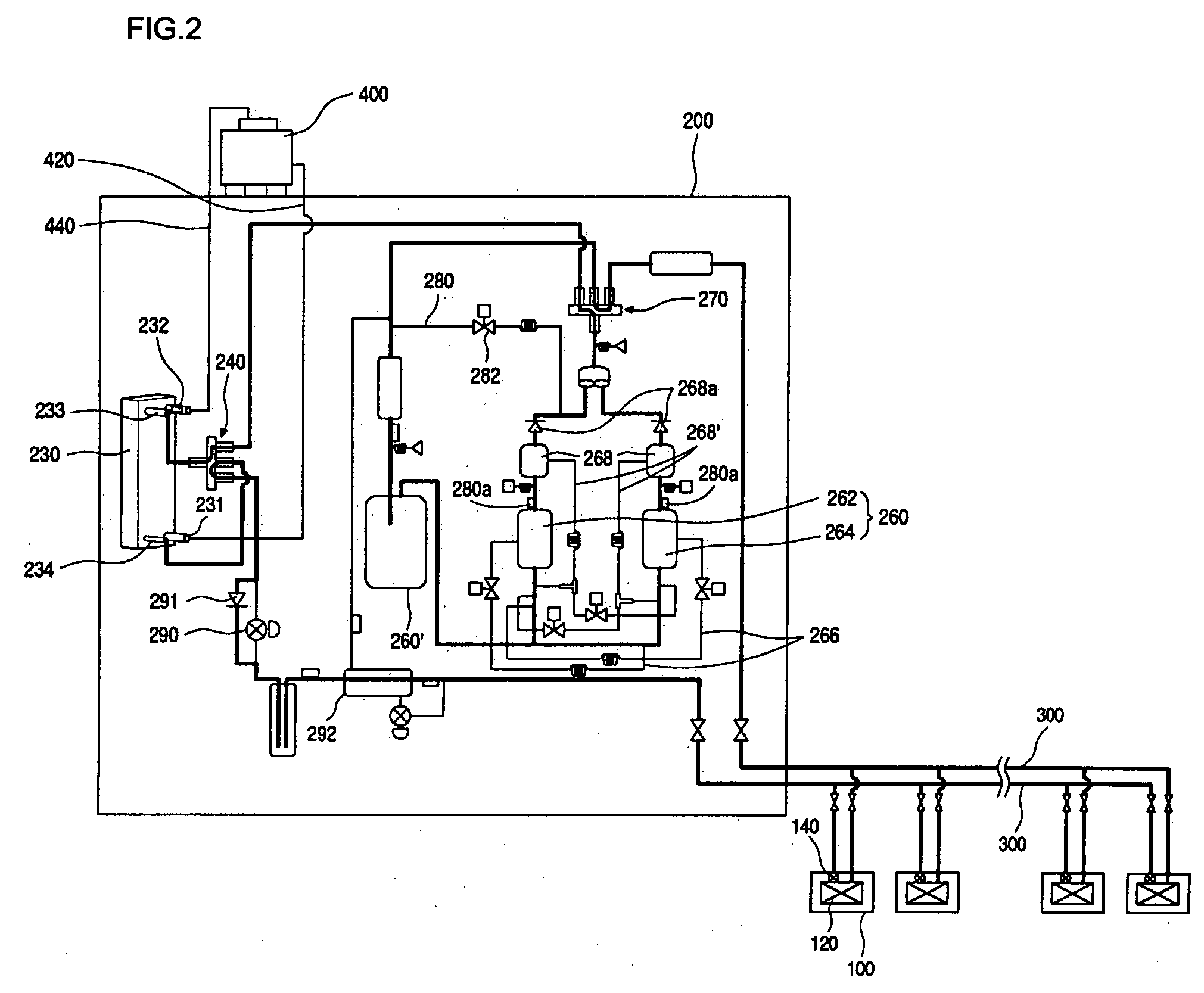

Water cooling type air conditioner

InactiveUS7918104B2Improving cooling and heating efficiencyMaximizing heat exchangeMechanical apparatusCompression machines with non-reversible cycleWater flowEngineering

A water cooling type air conditioner is provided. The water cooling type air conditioner includes first and second heat exchangers, a refrigerant pipe, and a direction controlling unit. The first heat exchanger performs heat exchange between air and refrigerant. The second heat exchanger performs heat exchange between the refrigerant and cooling water. The refrigerant pipe is connected between the first heat exchanger and the second heat exchanger to guide a flow of the refrigerant. The direction controlling unit is disposed on one side of the second heat exchanger and controls the refrigerant and the cooling water flowing inside the second heat exchanger to flow in respectively opposite directions.

Owner:LG ELECTRONICS INC

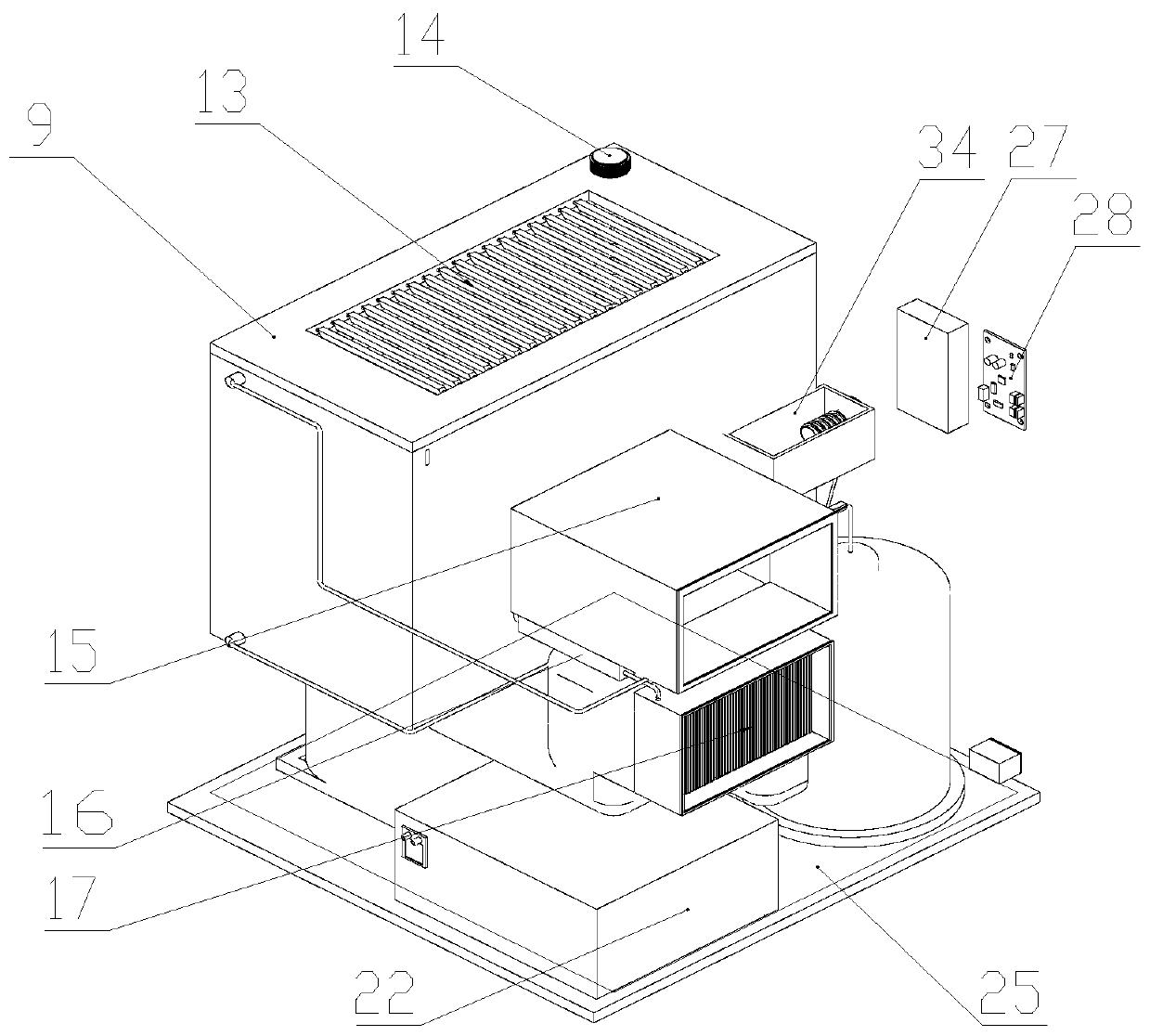

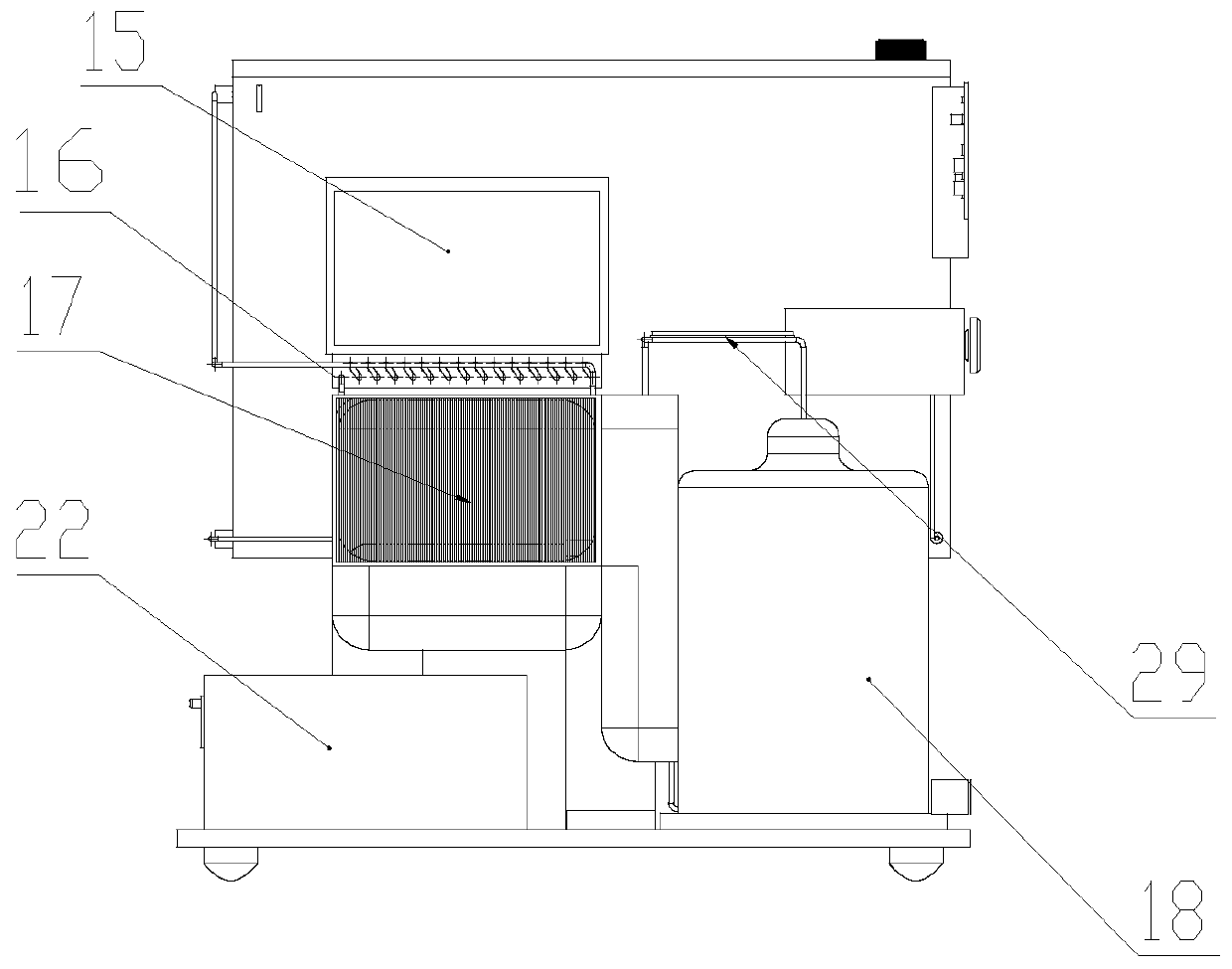

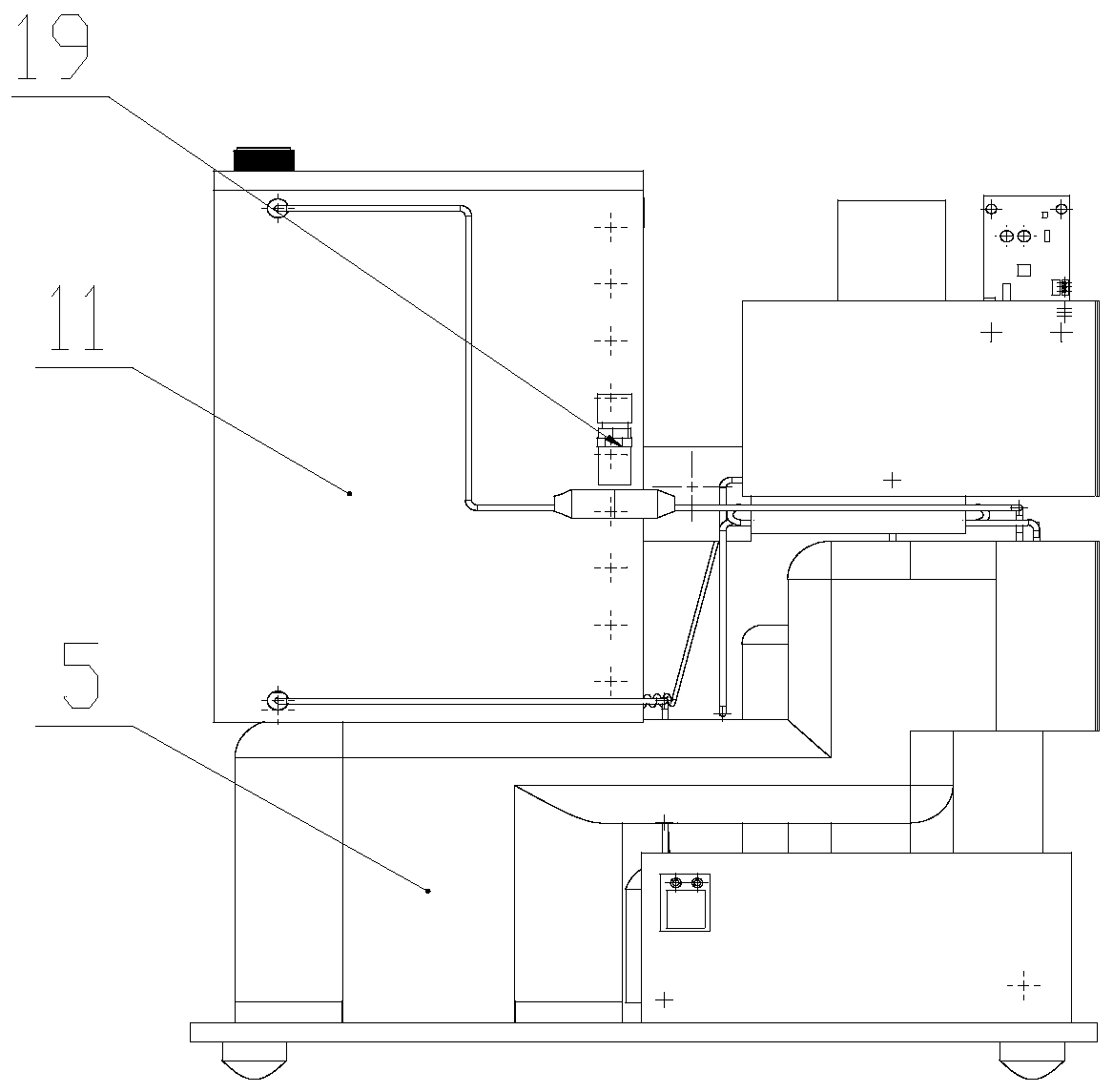

Portable outdoor air conditioner and refrigerator integrated machine

PendingCN109974170AMeet needsLarge cooling capacityLighting and heating apparatusDomestic refrigeratorsElectricityRefrigerated temperature

The invention relates to the technical field of household electrical appliances, in particular to a portable outdoor air conditioner and refrigerator integrated machine. The machine comprises a compressor, a condenser, a throttle valve and an inflation pipe evaporator, and the compressor, the condenser, the throttle valve and the inflation pipe evaporator are sequentially connected through pipelines to form a closed circuit; the condenser comprises a primary condensing assembly and a secondary condensing assembly; the inflation pipe evaporator is arranged on the inner wall of a cold cavity body, and the cold cavity body is a heat insulation box body; a draught fan, an integrated air duct and an electricity supplying assembly are also included, the electricity supplying assembly comprises astorage battery, a solar photovoltaic power generation assembly and a municipal electricity charging interface; a charging interface and municipal electricity charging interface of the solar photovoltaic power generation assembly are connected with an input interface of the storage battery, and electricity is supplied to the compressor and the draught fan. The machine has the advantages that theenergy consumption is lower, the power is higher, functions are diversified, the size is small and the weight is lighter.

Owner:XI AN JIAOTONG UNIV

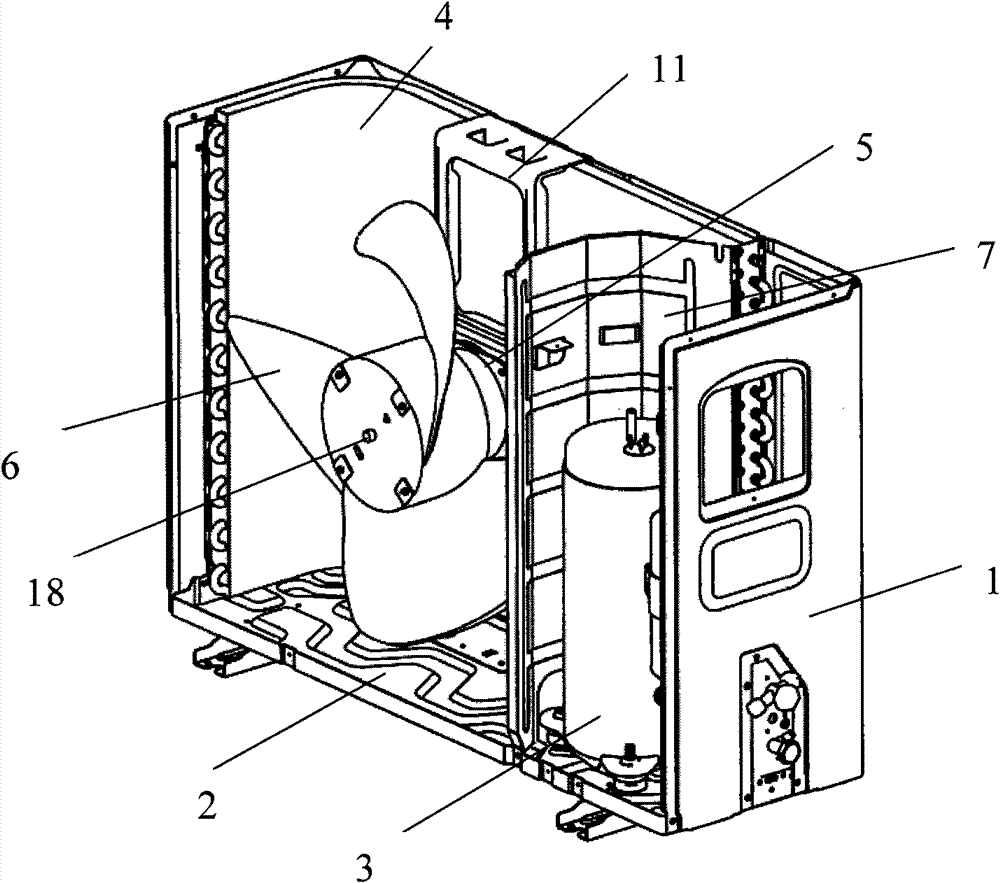

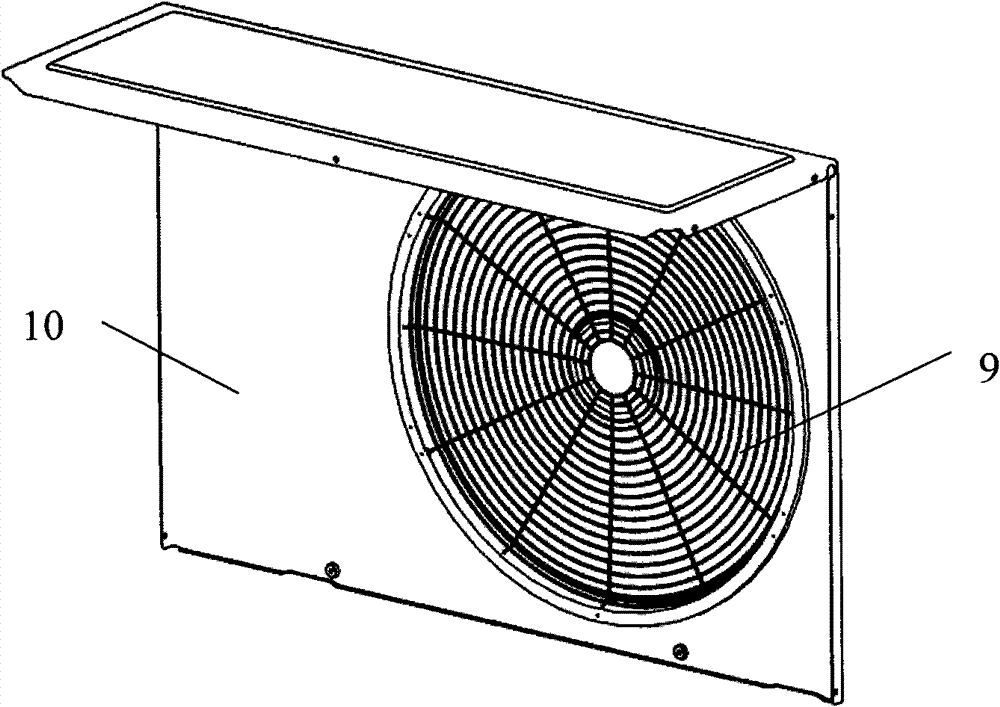

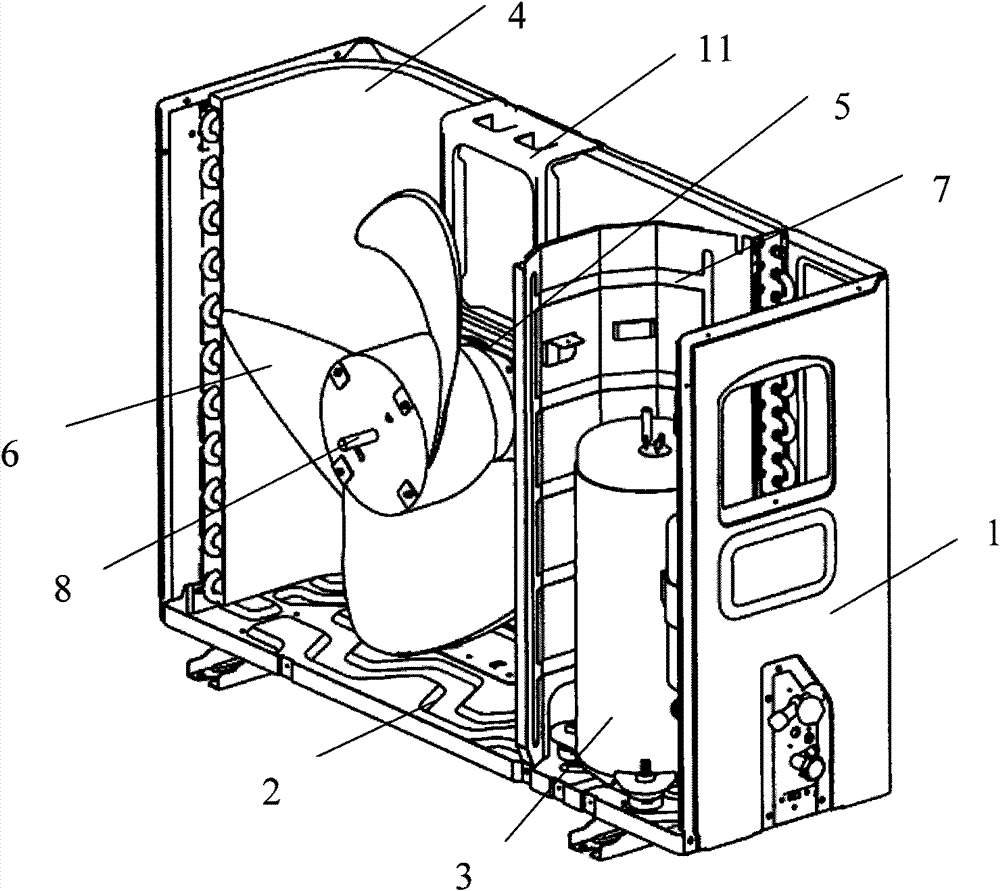

Split type air conditioner outdoor machine

InactiveCN101769568BSmooth rotationUniform and stable flowLighting and heating apparatusAir conditioning systemsBusiness efficiencyControl theory

The invention discloses a split type air conditioner outdoor machine which comprises a main casing, an auxiliary casing, a chassis, a compressor, a condenser, a fan motor, an outdoor fan and a baffle plate. A rolling bearing is arranged in the opposite position of the inside of a gas exhaust grid at the front end surface of the auxiliary casing and an output shaft of the fan motor. The output shaft of the fan motor is extended and inserted into the rolling bearing. When the fan motor rotates, the output shaft drives the rolling bearing to rotate, thereby preventing the outdoor fan from swinging left and right. As the gas exhaust grid at the front end surface of the air conditioner outdoor machine is additionally provided with a motor fixing structure, and the output shaft of the motor is extended to match with the motor fixing structure, the fan is stable in rotation, and the air can uniformly and stably flow. The heat exchange is uniform, the condenser is well utilized, the energy efficiency ratio is enhanced, and the noise is decreased.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

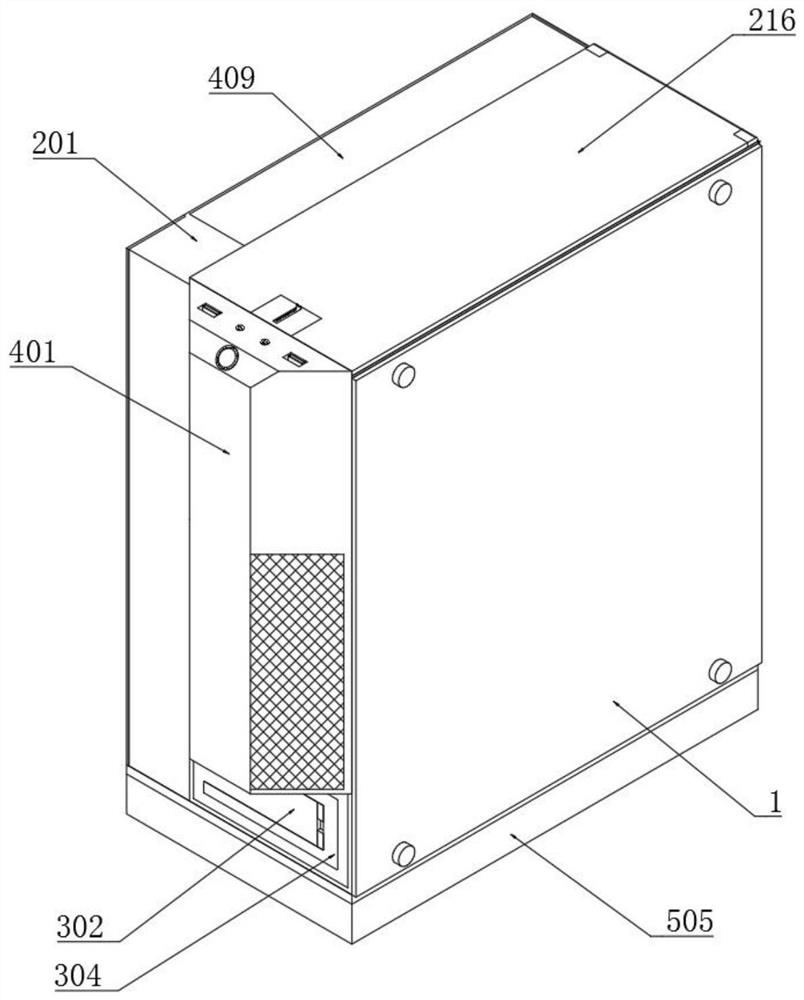

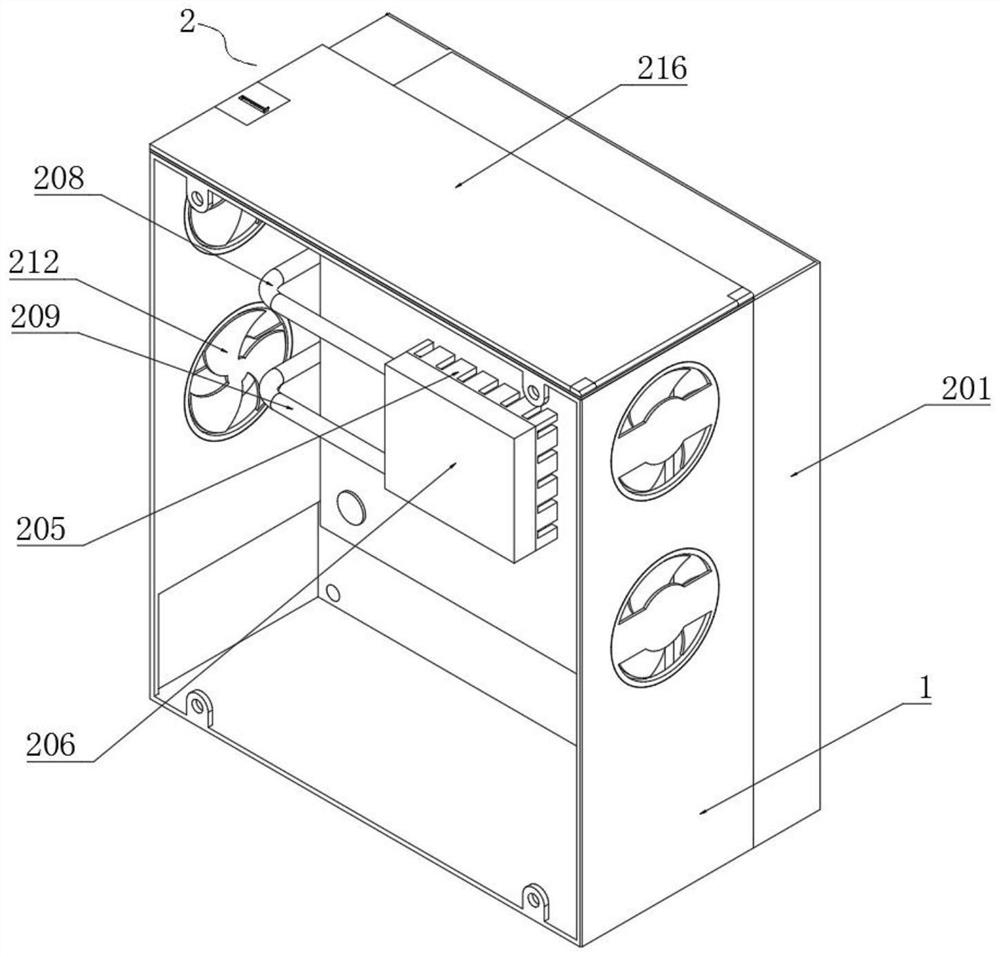

Computer hardware temperature detection and control device

InactiveCN113985992AAffect normal useRapid coolingDigital data processing detailsHollow article cleaningPhysicsComputer case

The invention discloses a computer hardware temperature detection and temperature control device. The device is characterized in that temperature detectors are mounted at the side end of a fixed mounting block, a fixed heat conduction box sleeves the side end of a porous heat conduction plate, a heat absorption box is fixedly mounted at the position, close to a mainboard, of a shell, backflow pipes penetrate through the tops of one ends of the fixed heat conduction box and the heat absorption box, the water inlet end of an input pipe is fixedly connected with a water outlet end of a booster pump, acceleration fans symmetrically penetrate through the two ends of the shell, an auxiliary fan is installed at the top end of the shell, and a blocking protection plate is welded to one end of a force spring. According to the invention, temperature detection is carried out on different positions in a computer case through the multiple temperature detectors, and heat dissipation is carried out on the interior of computer case through multiple heat exchange and dissipation methods, so rapid cooling can be performed when internal temperature is higher than external temperature and rapid isolation can be carried out when external air temperature is higher than the temperature of the internal case; and thus, the situation that the internal temperature is too high continuously due to interchange of the internal temperature and the external temperature and normal use of a computer is affected is avoided.

Owner:JILIN AGRI SCI & TECH COLLEGE

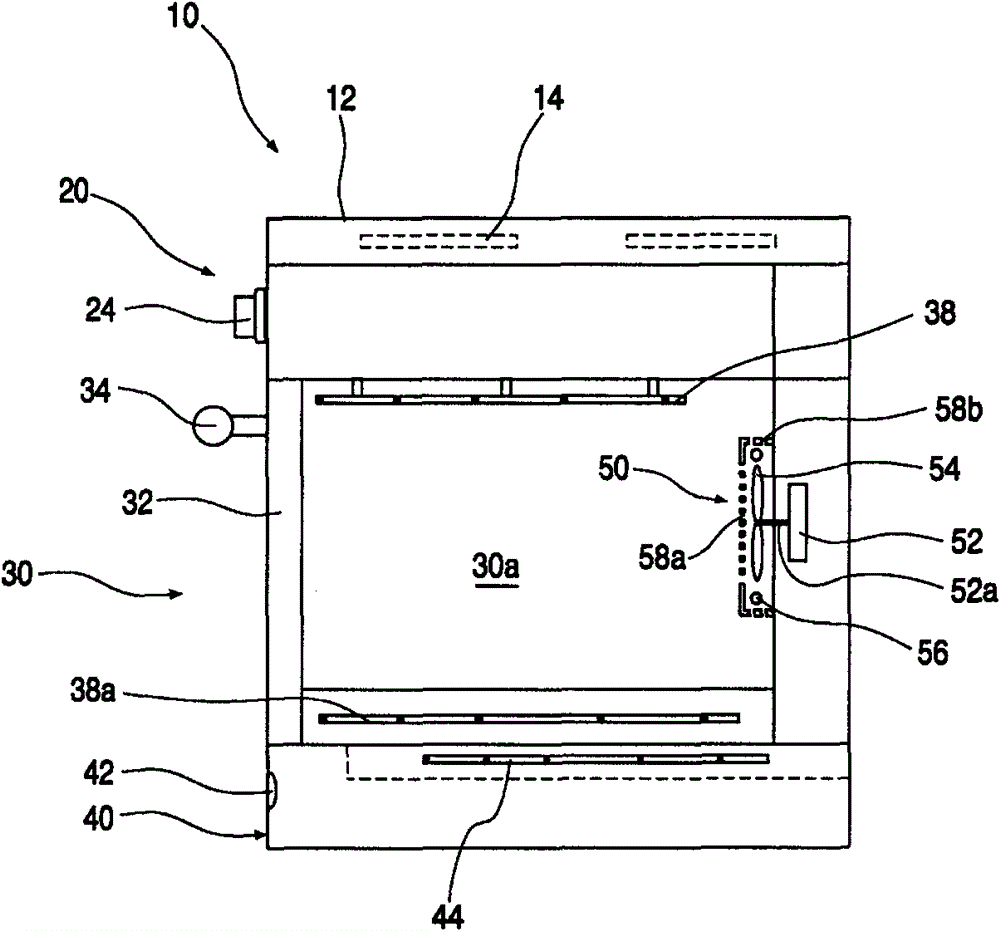

electric oven

InactiveCN102232801BThe temperature rise remains stableSpeed up cookingRoasters/grillsEngineeringElectric stove

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Water cooling type air conditioner

InactiveUS20080053142A1Improving cooling and heating efficiencyMaximizing heat exchangeMechanical apparatusCompression machines with non-reversible cycleWater flowEngineering

A water cooling type air conditioner is provided. The water cooling type air conditioner includes first and second heat exchangers, a refrigerant pipe, and a direction controlling unit. The first heat exchanger performs heat exchange between air and refrigerant. The second heat exchanger performs heat exchange between the refrigerant and cooling water. The refrigerant pipe is connected between the first heat exchanger and the second heat exchanger to guide a flow of the refrigerant. The direction controlling unit is disposed on one side of the second heat exchanger and controls the refrigerant and the cooling water flowing inside the second heat exchanger to flow in respectively opposite directions.

Owner:LG ELECTRONICS INC

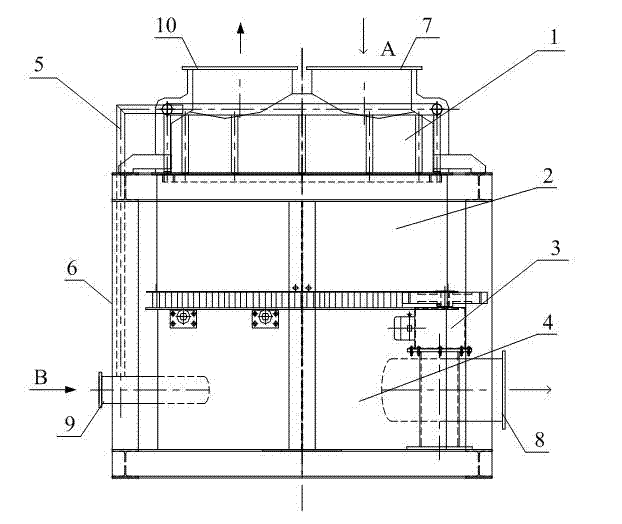

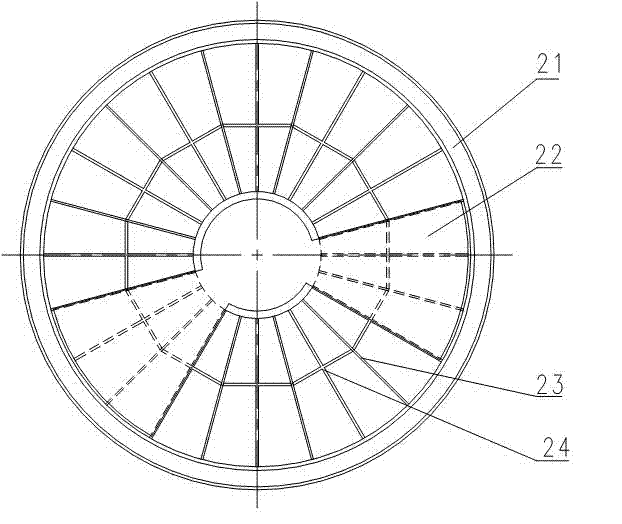

Commutatorless high-temperature heat exchanger

InactiveCN102954701AEffective isolationStable temperatureCombustion processIncreasing energy efficiencyThermal stateFree rotation

The invention relates to a commutatorless high-temperature heat exchanger. A heat storage device comprises a lower cylinder, a rotor heat storage body and an upper cylinder which are arranged in sequence, wherein the lower cylinder is fixedly arranged on a framework; the lower cylinder is partitioned into a low-temperature air chamber and a low-temperature gas chamber; a side face of the lower cylinder is provided with a low-temperature air inlet and a low-temperature gas outlet; the rotor heat storage body is supported against the lower cylinder in a free rotation manner and is filled with a heat storage medium; the upper cylinder is positioned on the rotor heat storage body and is fixedly arranged on the framework; the upper cylinder is partitioned into a high-temperature gas chamber and a high-temperature air chamber; the top of the upper cylinder is provided with a high-temperature gas inlet and a high-temperature air outlet; the high-temperature gas inlet in the upper cylinder is communicated with the low-temperature gas outlet in the lower cylinder; the low-temperature air inlet in the lower cylinder is communicated with the high-temperature air outlet in the upper cylinder; and a driving mechanism on the framework is in drive connection with the rotor heat storage body to drive the rotor heat storage body to rotate. The high-temperature gas heat is continuously transferred to combustion-supporting air by the rotation of the rotor heat storage body, so that thermal-state continuous operation and heat exchange are realized, and the heat exchange efficiency is high.

Owner:苏州有色金属研究院有限公司 +2

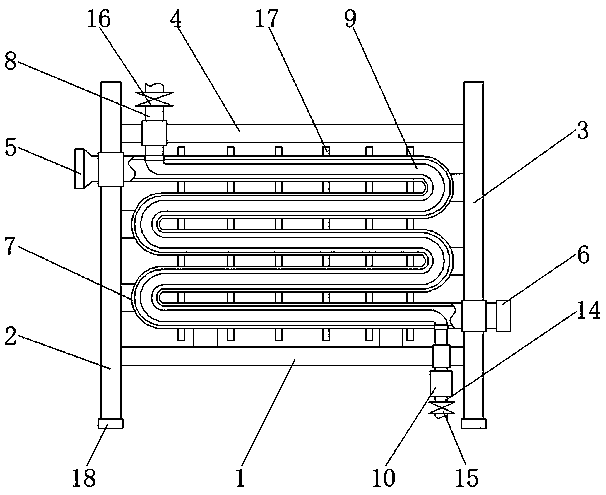

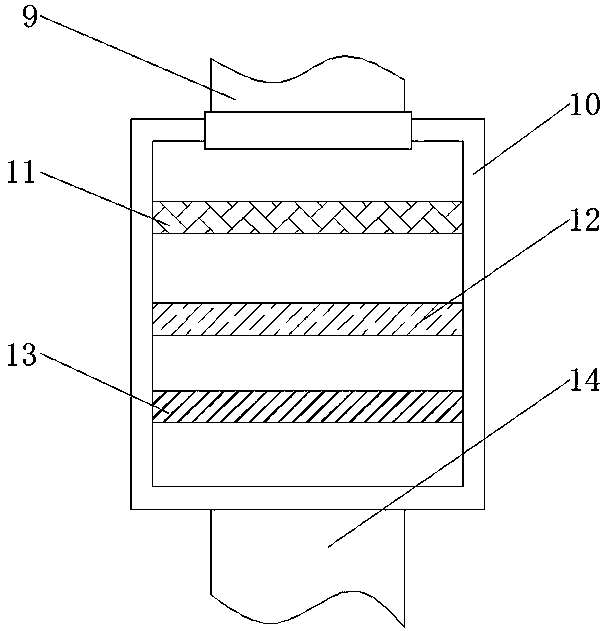

Combined type efficient heat exchanger

PendingCN108645250AAvoid erosionExtended service lifeChemical industryCorrosion preventionTemperature differenceEngineering

The invention discloses a combined type efficient heat exchanger, and relates to the technical field of heat exchangers. The combined type efficient heat exchanger comprises a first supporting rod, the two ends of the first supporting rod are fixedly connected with a first vertical rod and a second vertical rod correspondingly, and the portion located between the opposite sides of the first vertical rod and the second vertical rod and located at the top of the first supporting rod is fixedly connected with a second supporting rod. The combined type efficient heat exchanger exchanges heat though the temperature difference between a first S-shaped spiral tube type heat exchange tube and a second S-shaped spiral tube type heat exchange tube, and exchanges heat though the temperature difference between the air temperature and the first S-shaped spiral tube heat exchange type tube by using fin plates, the heat exchange efficiency is improved, the energy consumption is reduced, the heat exchange process tends to be stable, dust particles, peculiar smell and harmful gas in hot fluid are removed through a triple filter structure, erosion of harmful substances in the hot fluid to the secondS-shaped spiral tubular heat exchange tube is avoided, and the service life of the second S-shaped spiral tube type heat exchange tube is prolonged.

Owner:盐城中自科技有限公司

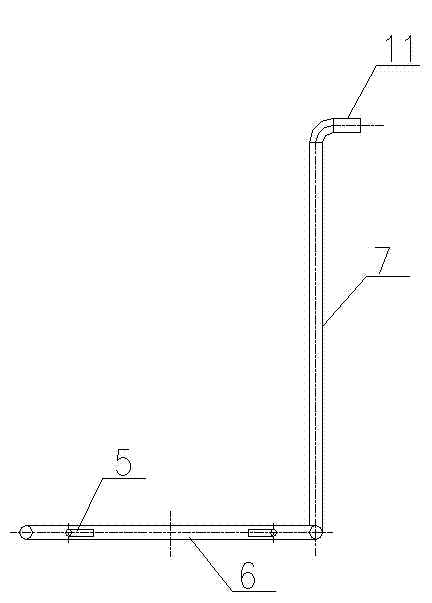

Overflow structure of water bath vaporizer

ActiveCN104747907AReduce the temperatureReduce consumptionPressure vesselsContainer discharging from pressure vesselsWater bathsWater storage

The invention relates to an overflow structure of a water bath vaporizer and overcomes the heat loss caused by direct discharge of a large amount of hot water which is not subjected to heat exchange, so that the consumption of water vapor is further reduced and the heat transfer efficiency is improved. A water storage barrel is internally provided with a water storage chamber for storing liquid water; overflow openings are formed in the water storage barrel; a water inlet is formed in the upper part of the water storage barrel while a water suction opening is formed in the lower part of the water storage barrel; the overflow openings are formed in the lower part of the water storage barrel and positioned above the water suction opening and are communicated with the lower part of the water storage chamber; the plurality of overflow openings are horizontally and uniformly distributed in the peripheral direction of the water storage barrel; a liquid collecting pipe is circular, is horizontally positioned at the periphery of the water storage barrel and is fixed together and communicated with the overflow openings; an ascension pipe is vertically arranged, the bottom end of the ascension pipe is fixed together and communicated with the liquid collecting pipe, the top end of the ascension pipe is communicated with atmosphere, and when the top end is higher than the liquid level of liquid water in the water storage barrel, the ascension pipe is bended in the horizontal direction; the bended pipe body is horizontally arranged, and a small hole is formed in the top of the pipe body.

Owner:CHINA NAT AIR SEPARATION ENG CO LTD

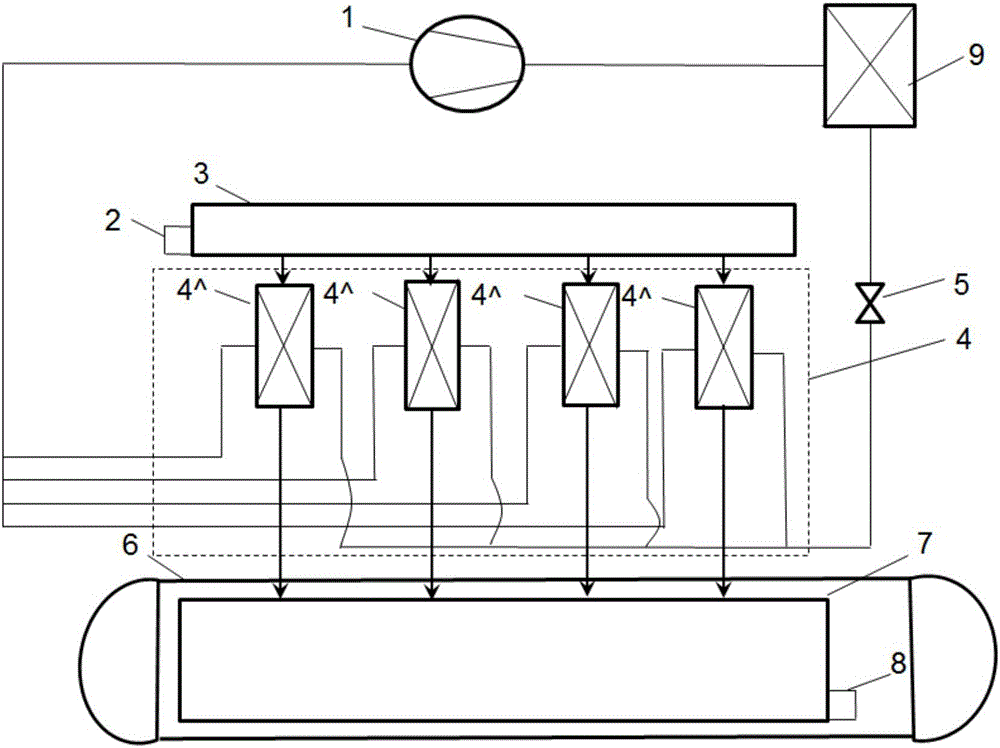

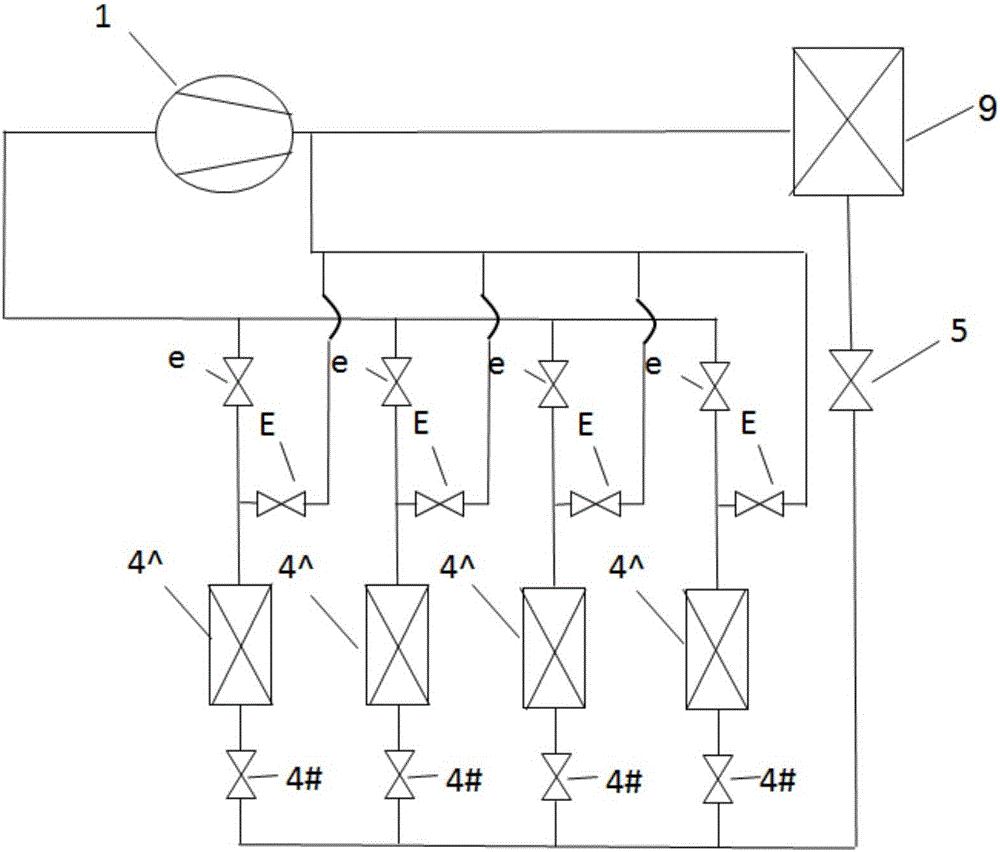

Protein concentration system and application method thereof

ActiveCN106317165AReduce the temperaturePlay the role of evaporationChemical industryPeptide preparation methodsProtein solutionHigh energy

The invention discloses a protein concentration system which comprises a compressor, a liquid inlet tank, a heat exchange system, a throttling valve, a liquid storage tank and a condenser, wherein the heat exchange system at least comprises two honeycomb heat exchangers; the liquid inlet tank is provided with a liquid inlet port, the bottom is provided with a circular hole, and the liquid inlet tank communicates with the upper part of each honeycomb heat exchanger through the circular hole; the lower part of each honeycomb heat exchanger communicates with the liquid storage tank; the heat exchange system also communicates with the compressor and the condenser; the throttling valve is arranged between the heat exchange system and the condenser; and the condenser communicates with the compressor. The invention also discloses an application method of the protein concentration system. The water in the protein solution is separated out in the form of ice slurry, so the system disclosed by the invention has the advantages of stable and reliable heat exchange and favorable concentration effect. Compared with the existing protein freeze concentration system, the system disclosed by the invention has the advantages of simple structure, stable heat exchange, high stability, high energy efficiency and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

An overflow structure of a water bath vaporizer

ActiveCN104747907BReduce the temperatureReduce consumptionPressure vesselsContainer discharging from pressure vesselsWater bathsWater storage

The invention relates to an overflow structure of a water bath vaporizer and overcomes the heat loss caused by direct discharge of a large amount of hot water which is not subjected to heat exchange, so that the consumption of water vapor is further reduced and the heat transfer efficiency is improved. A water storage barrel is internally provided with a water storage chamber for storing liquid water; overflow openings are formed in the water storage barrel; a water inlet is formed in the upper part of the water storage barrel while a water suction opening is formed in the lower part of the water storage barrel; the overflow openings are formed in the lower part of the water storage barrel and positioned above the water suction opening and are communicated with the lower part of the water storage chamber; the plurality of overflow openings are horizontally and uniformly distributed in the peripheral direction of the water storage barrel; a liquid collecting pipe is circular, is horizontally positioned at the periphery of the water storage barrel and is fixed together and communicated with the overflow openings; an ascension pipe is vertically arranged, the bottom end of the ascension pipe is fixed together and communicated with the liquid collecting pipe, the top end of the ascension pipe is communicated with atmosphere, and when the top end is higher than the liquid level of liquid water in the water storage barrel, the ascension pipe is bended in the horizontal direction; the bended pipe body is horizontally arranged, and a small hole is formed in the top of the pipe body.

Owner:CHINA NAT AIR SEPARATION ENG CO LTD

Electronic device cooling device

ActiveCN111613592AImprove cooling effectStable deliverySemiconductor/solid-state device detailsSolid-state devicesThin membraneEngineering

The invention provides an electronic device cooling device. The device comprises a working body (1), wherein the working body (1) is a sealed cavity, a cooling medium is arranged in the sealed cavity,a plurality of micro-channels (2) are arranged on the inner bottom surface of the sealed cavity, nano porous films (3) with capillary force are arranged at the upper parts of the micro-channels (2),a heat conduction structure (4) is arranged outside the bottom surface of the sealed cavity, and an electronic device (12) exchanges heat with the cooling medium through the heat conduction structure(4); the heat dissipation device (5) is arranged on the outer surface of the working body (1) so as to dissipate heat in the working body (1); and the energy storage device (6) is arranged at the upper part of the working body (1) and is used for stabilizing the pressure in the working body.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

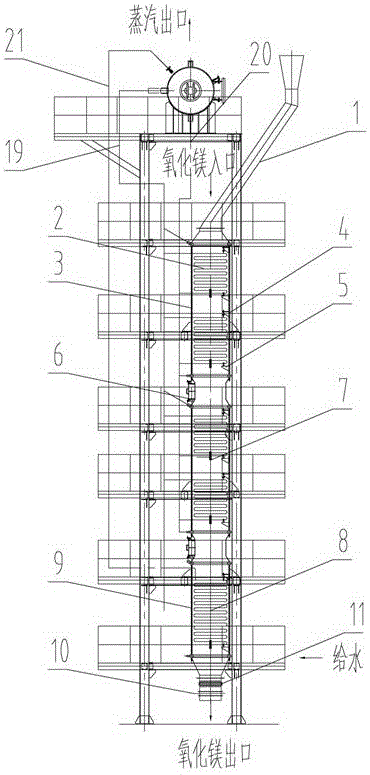

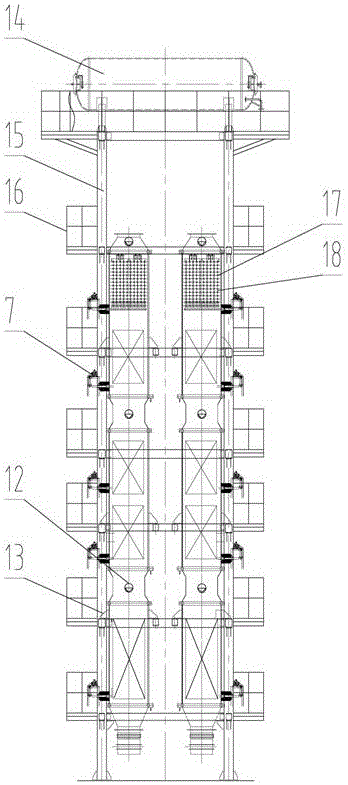

High-temperature solid micro-powder residual heat boiler

PendingCN106482083AUniform heat exchangeStable heat exchangeSteam generation using hot heat carriersSocial benefitsEconomic benefits

The invention relates to a high-temperature solid micro-powder residual heat boiler. The boiler comprises an evaporator, a water-cooling wall, a coal economizer, a wall-type water heater, a vapor-moisture separator, a vapor-moisture connecting pipeline, a mechanical vibration feeder, a material inlet, a material outlet, an expansion device, a steel rack and a platform, wherein feed water enters the wall-type water heater, enters the coal economizer, enters the vapor-moisture separator through a water feed pipe, enters an inlet header of the evaporator and the water-cooling wall from a downcomer of the vapor-moisture separator, reaches an outlet header after heat exchange in a snake-shaped pipe heat-exchange surface, and enters the vapor-moisture separator through an ascending pipe; and the separated saturated vapor is exhausted from a vapor outlet for power generation or utilization by the vapor-moisture separator, the separated water is subjected to the circulation repeatedly, and vapor is generated in the repeated circulation. The high-temperature solid micro-powder residual heat boiler has the technical effects of uniform and stable heat exchange, can be used for reclaiming a great number of vapor, and has good economic benefit and social benefit.

Owner:天津健威泽节能环保科技股份有限公司

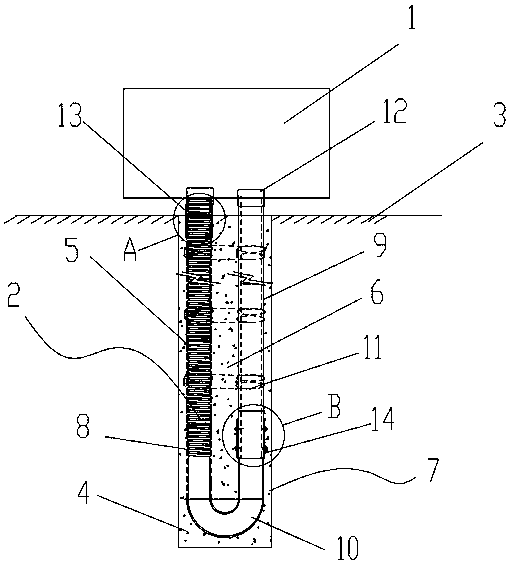

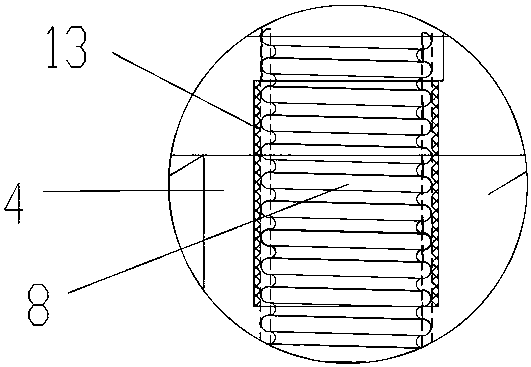

Stainless steel corrugated pipe ground heat source heat exchange system and setting method thereof

InactiveCN108088102AEasy to operateEasy to installHeat pumpsGeothermal energy generationPolyolefinButt joint

The invention discloses a stainless steel corrugated pipe ground heat source heat exchange system and a setting method thereof. The system comprises an overground heat exchange device and an underground heat exchange device, wherein the underground heat exchange device comprises a ground source hole arranged under a ground foundation and a heat exchange piece arranged in the ground source hole; the heat exchange part comprises a stable filling part and at least one heat exchange system unit, each heat exchange system unit comprises a stainless steel corrugated pipe section, a polyolefin material pipe section and a stainless steel bent pipe section; the stainless steel corrugated pipe section and the polyolefin material pipe section are arranged in parallel in the vertical direction of theground source hole; one end of the stainless steel bent pipe section is connected to the lower end of the stainless steel corrugated pipe section in a butt joint mode, and the other end is connected to the lower end of the polyolefin material tube section in a butt joint mode, and communicates with the stainless steel bent pipe section and the polyolefin material pipe section; and the stable filling piece is filled in the ground source hole, so that the sealing stability of the heat exchange system unit is achieved. According to the stainless steel corrugated pipe ground heat source heat exchange system, the heat exchange area is greatly increased, and heat exchange amount is greatly improved.

Owner:GREENTOWN DECORATION ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com