Yeast wastewater zero discharge treatment method

A technology of yeast wastewater and treatment method, which is applied in the field of yeast wastewater treatment, can solve the problems of high operating cost and dry wall, and achieve the effects of reducing energy consumption, reducing production cost, and avoiding dry wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

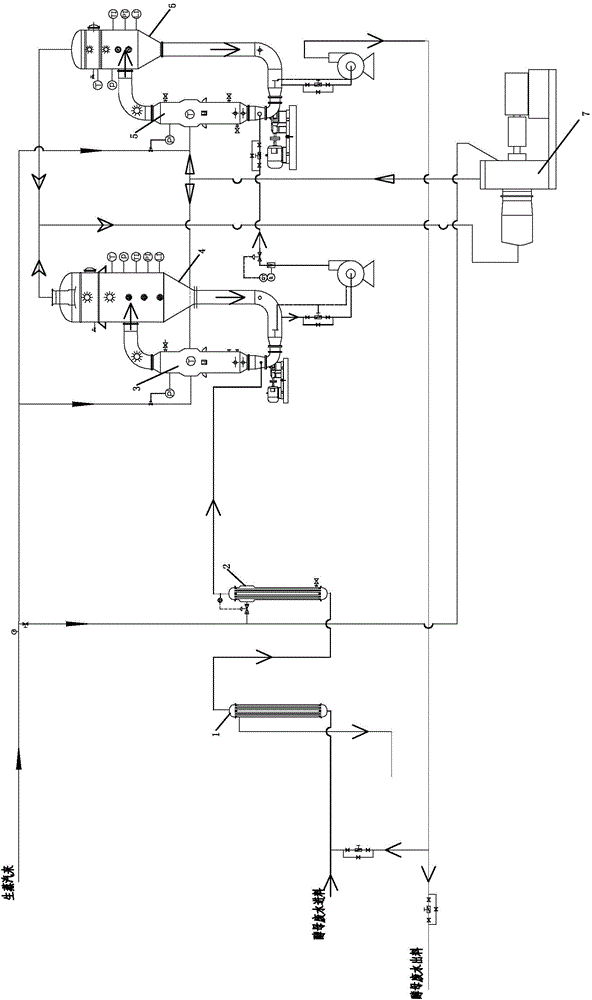

[0022] combine figure 1 To describe in detail, the zero-discharge treatment method of yeast wastewater in the present invention is accomplished through the following steps:

[0023] Step 1. The yeast wastewater is passed into the first-stage tubular preheater 1 and preheated to 70°C with condensed water, and then passed into the second-stage tubular preheater 2 with raw steam for heat exchange and preheated to 90°C. ℃;

[0024] Step 2, then flow into the first-effect heater 3 to heat up to a temperature rise of 2°C, and then pass into the first-effect evaporation separator 4 for evaporation to obtain a double-material flow including gas phase and liquid phase, and the gas phase is passed into the steam compressor 7 for treatment and recycling Back in the heater, the liquid phase is circulated back to the first-effect heater 3 and mixed with the continuously fed yeast waste water to perform heating and evaporative separation cycles until the solid content in the yeast waste wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com