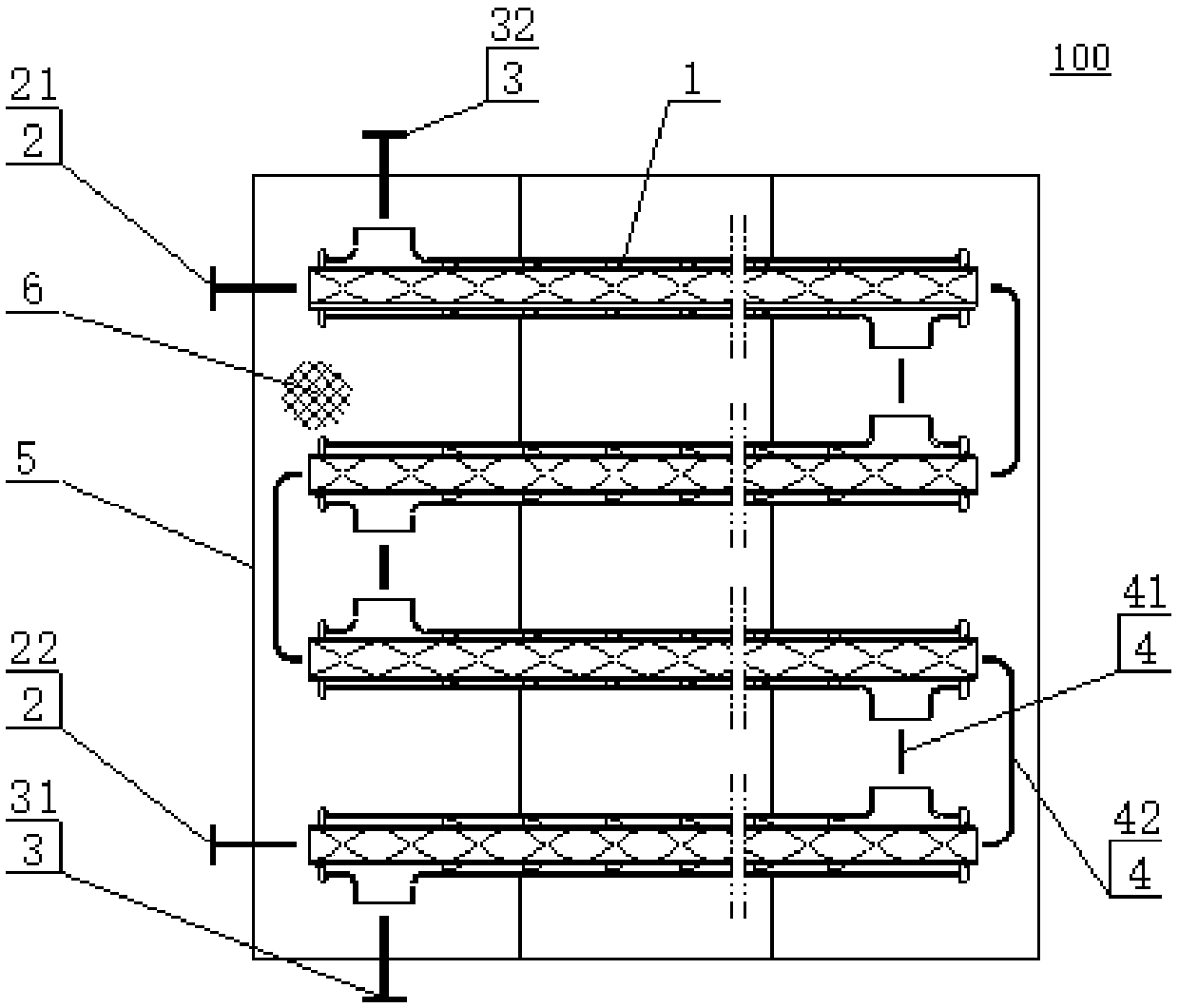

Double-pipe heat transfer enhancement unit component and penetrating hybrid cyclone efficient double-pipe heat exchanger

A technology of enhanced heat exchange and unit components, applied in the field of penetrating mixing swirl heat exchangers and penetrating mixing swirl high-efficiency sleeve heat exchangers, can solve the problem of sludge sleeve heat exchangers Large land, difficult to achieve stable heat exchange between sludge and sludge, high power consumption of sludge transportation, etc., to achieve significant energy saving, economic benefits and environmental protection benefits, reduce sludge transportation power consumption, and reduce sludge heating energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

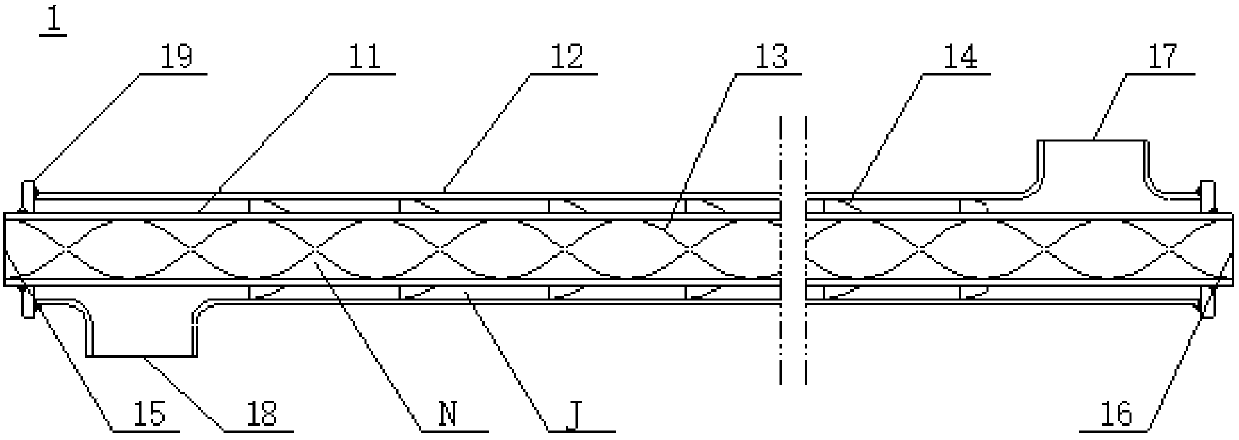

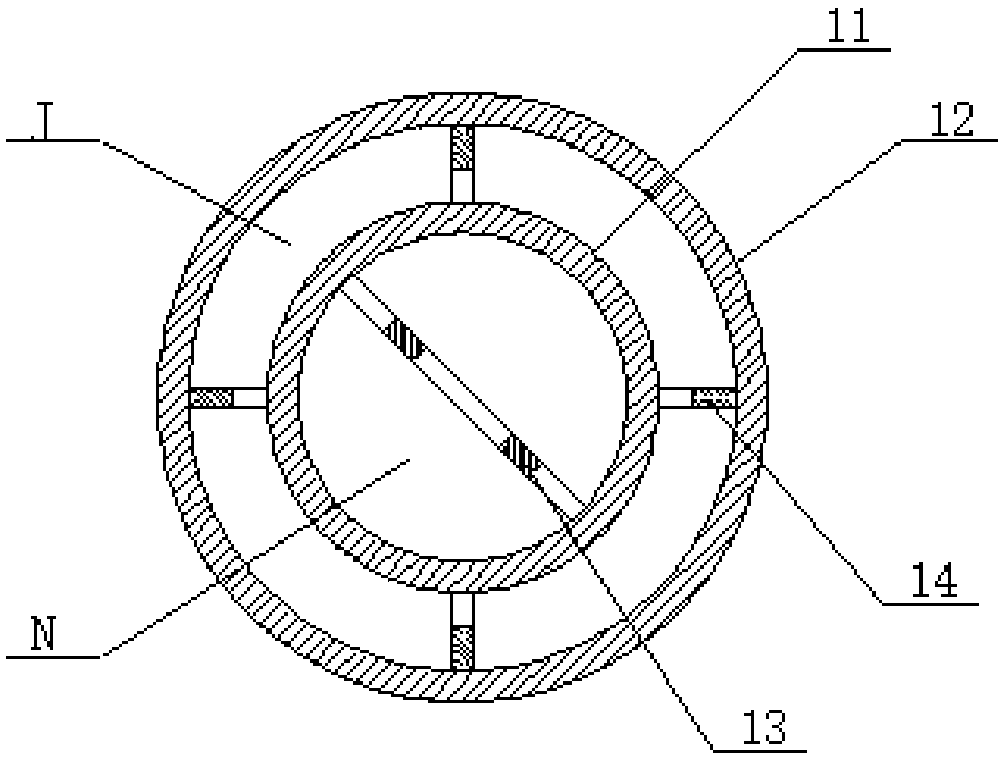

[0063] Example 1: If Figure 4-Figure 7 As shown, the inner tube twist reinforcement 13 and the inter-sleeve twist reinforcement 14 of this example are formed as a single-ended helical twisted belt, and the inter-sleeve twist reinforcement 14 is welded on the outer wall of the inner tube 11, and the inner tube The twisted reinforcement 13 is welded on the outer wall of the sleeve inner tube 11 . The inner tube twist reinforcement 13 is provided with a first flow port 133, and the first flow port 133 includes a circular first flow hole 1331 formed in the middle of the inner tube twist reinforcement 13 and a circular first flow hole 1331 arranged at the inner tube twist The edge of the reinforcement member 13 is formed as a semicircular first circulation gap 1332 .

example 2

[0064] Example 2: If Figure 8 As shown, the inner tube twisted reinforcing member 13 of this example includes a plurality of twisted strips 131 and a plurality of connecting pieces 132 , and every adjacent two twisted strips 131 are connected by a connecting piece 132 .

example 3

[0065] Example 3: If Figure 9 As shown, the inner tube twisted reinforcing member 13 of this example includes a plurality of twisted strips 131 and a connecting piece 132 , and the twisted strips 131 are axially spaced apart from the connecting piece 132 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com