Vortex type extracted gas dilution mixer for coal mine

A gas extraction and swirling technology, which is applied in the fields of ultra-low concentration methane thermal countercurrent oxidation and low-density energy recovery, can solve the problems of large flow resistance, increased energy consumption of transporting gas, complex structure, etc., and avoid friction explosion , reduce transmission power consumption, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

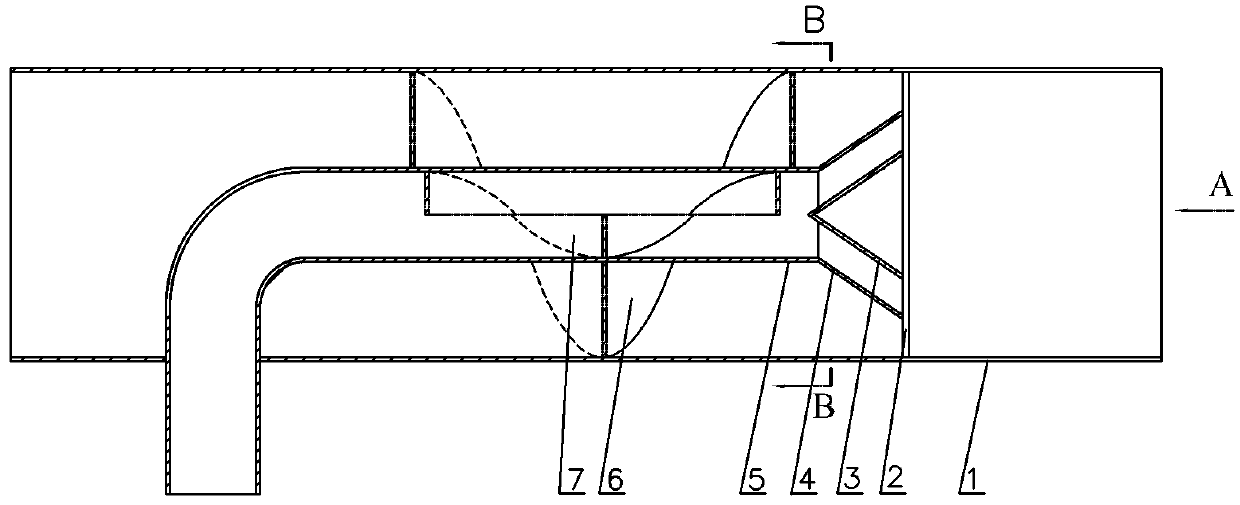

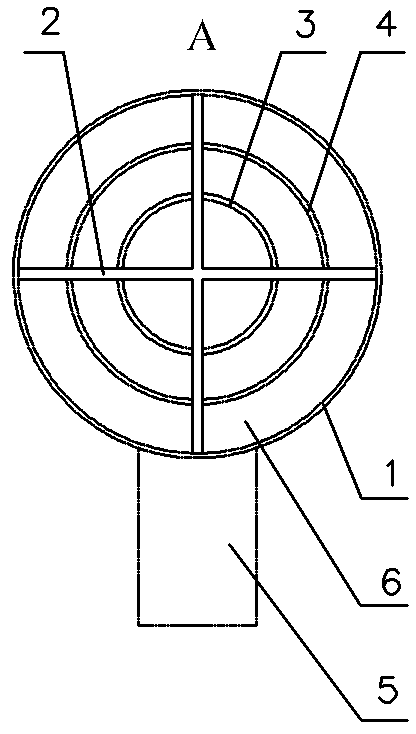

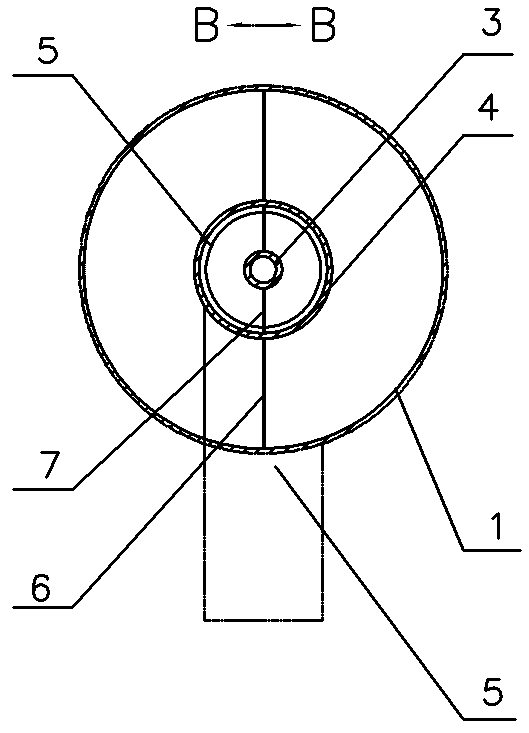

[0019] exist Figure 1-3 In the shown embodiment: it includes a tubular casing 1, a gas injection pipe, an inner helical blade 7, an outer helical blade 6, a reinforcing rib 2 and a diversion cone 3, and the gas injection pipe includes an inlet pipe 5 and is installed at the inlet The expansion tube 4 at the outlet end of the tube 5, wherein the diameters of the housing 1 and the inlet tube 5 are constant, the expansion tube 4 adopts a variable-diameter tube with a gradually larger inner diameter, and the expansion angle is 60°, and the cross-sectional area of the outlet end of the expansion tube 4 is the shell 65% of the cross-sectional area of the body 1, the axial distance between the outlet end and the outlet end of the housing 1 is three times the diameter of the housing 1, the inlet pipe 5 is a 90° elbow, and the distance between the elbow and the outlet end of the expansion pipe 4 The axial distance between them is not less than 6 times the diameter of the inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com