A method for preparing carbon-based composite materials for supercapacitors

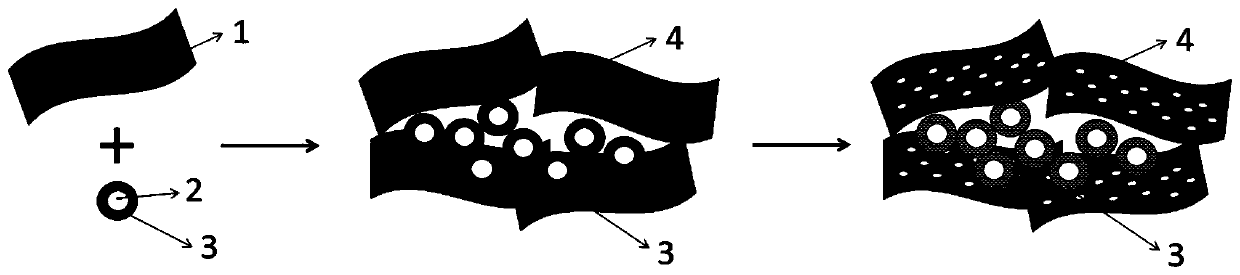

A carbon-based composite material, supercapacitor technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc. The effect of increasing effective specific surface area and electrical conductivity, increasing surface wettability, and avoiding interlayer stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Add 10 mg of PMMA monomer and 8 mg of potassium persulfate (KPS) to 300 ml of deionized water, and stir with a magnetic stirrer for 4 hours at 70 ° C under a nitrogen atmosphere;

[0037] (2) Take 150ml of the solution of step (1), add 8ml of acrylonitrile (AN) and 8mg of potassium persulfate (KPS) into 100ml of deionized water, and stir with a magnetic stirrer for 2 hours under a nitrogen atmosphere at 70°C;

[0038] (3) the PMMA / PAN solution of step (2) is centrifuged, washed several times with deionized water and dried;

[0039] (4) Weigh 60 mg of GO powder, add 30 ml of deionized water, and sonicate for 1 hour;

[0040] (5) Weigh 1 g of the PMMA / PAN powder in step (3) and add deionized water, and ultrasonicate for 1 hour;

[0041] (6) Mix and sonicate the solutions in step (4) and step (5) for 1 hour;

[0042] (7) The mixed solution in the vacuum filtration step (6) is dried to obtain GO / PMMA / PAN;

[0043] (8) heating the GO / PMMA / PAN powder in step (7) at 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com