A high-performance nanocrystalline thermally deformed NdFeB permanent magnet and its preparation method

A thermal deformation and permanent magnet technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problem of unsatisfactory plastic deformation ability of high melting point materials, reduction of magnet remanence and magnetic energy product, NdFeB microscopic Microstructure deterioration and other problems, to achieve the effect of inhibiting grain growth, increasing strength and hardness, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

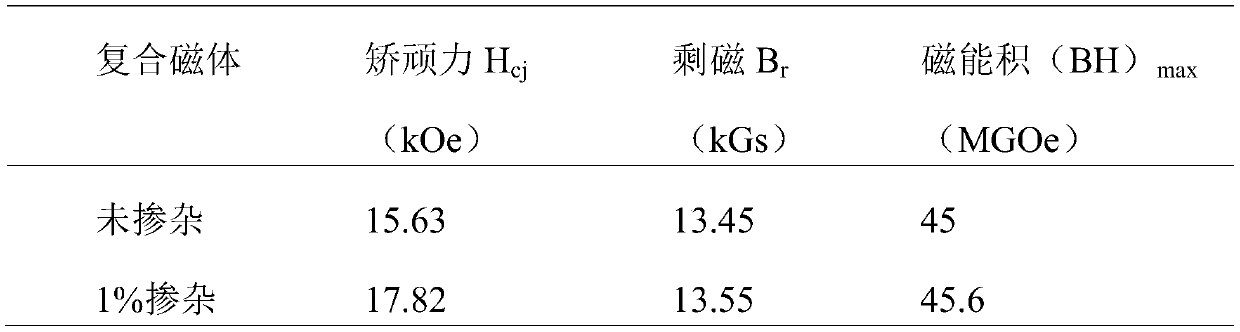

Embodiment 1

[0045] ① Select the nominal composition of the main alloy and the auxiliary alloy as Nd 13.5 Fe 76 co 4.5 Ga 0.5 B 5.5 (at%) and FeCoNi 1.25 Cu 1.25 Al 0.5 According to the nominal composition ratio, the material ratio of the two alloys is carried out respectively.

[0046] ②The prepared alloy raw material Nd 13.5 Fe 76 co 4.5 Ga 0.5 B 5.5 and FeCoNi 1.25 Cu 1.25 Al 0.5 Put them into vacuum arc melting furnace or induction melting furnace respectively, and melt them repeatedly 5 times under the protection of inert gas, so that the ingots are fully alloyed, and alloy ingots are respectively obtained after cooling.

[0047] ③ Put the obtained main alloy ingot into the quartz tube of the vacuum rapid quenching furnace after coarse crushing, and perform rapid quenching of the melt under the protection of the argon atmosphere to obtain the required rapid quenching strips. Wherein, the diameter of the nozzle of the quartz tube is 0.8mm, the distance from the roller su...

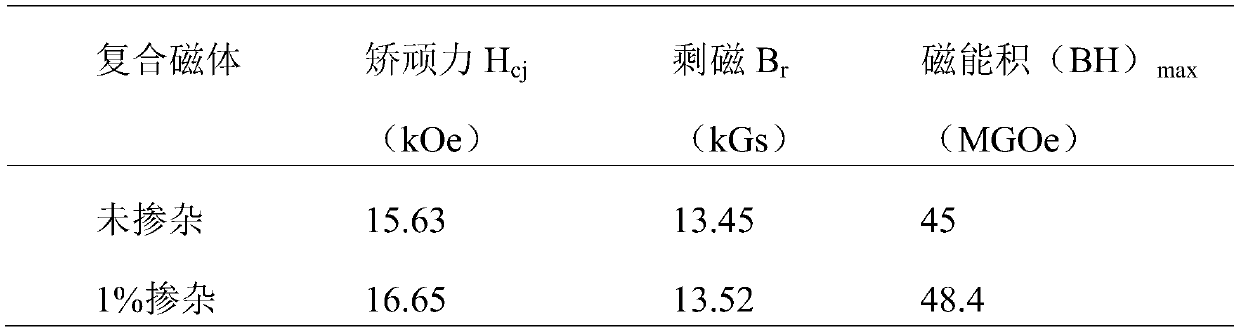

Embodiment 2

[0053] ① Select the nominal composition of the main alloy and the auxiliary alloy as Nd 13.5 Fe 76 co 4.5 Ga 0.5 B 5.5 (at%) and FeCoNi(AlSi) 0.2 According to the nominal composition ratio, the material ratio of the two alloys is carried out respectively.

[0054] ②The prepared alloy raw material Nd 13.5 Fe 76 co 4.5 Ga 0.5 B 5.5 and FeCoNi(AlSi) 0.2 Put them into vacuum arc melting furnace or induction melting furnace respectively, and melt them repeatedly 5 times under the protection of inert gas, so that the ingots are fully alloyed, and alloy ingots are respectively obtained after cooling.

[0055] ③ Put the obtained main alloy ingot into the quartz tube of the vacuum rapid quenching furnace after coarse crushing, and perform rapid quenching of the melt under the protection of the argon atmosphere to obtain the required rapid quenching strips. Wherein, the diameter of the nozzle of the quartz tube is 0.6mm, the distance from the roller surface is 2mm, and the ro...

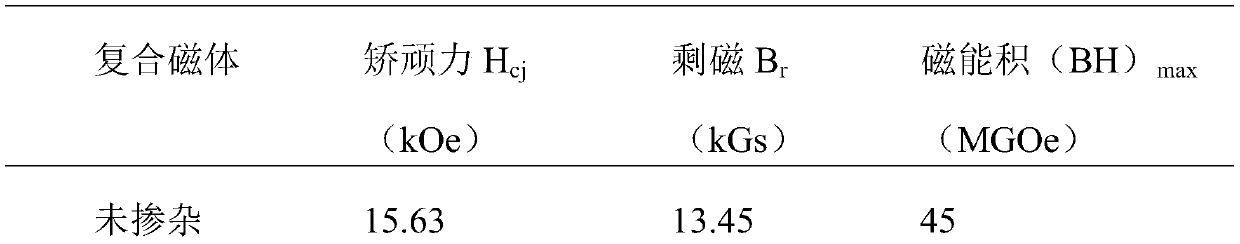

Embodiment 3

[0061] ① Select the nominal composition of the main alloy and the auxiliary alloy as Nd 13.5 Fe 76 co 4.5 Ga 0.5 B 5.5 (at%) and Al 0.25 CoFeNiCu 0.75 According to the nominal composition ratio, the material ratio of the two alloys is carried out respectively.

[0062] ②The prepared alloy raw material Nd 13.5 Fe 76 co 4.5 Ga 0.5 B 5.5 and Al 0.25 CoFeNiCu 0.75 Put them into vacuum arc melting furnace or induction melting furnace respectively, and melt them repeatedly 5 times under the protection of inert gas, so that the ingots are fully alloyed, and alloy ingots are respectively obtained after cooling.

[0063] ③ Put the obtained main alloy ingot into the quartz tube of the vacuum rapid quenching furnace after coarse crushing, and perform rapid quenching of the melt under the protection of the argon atmosphere to obtain the required rapid quenching strips. Wherein, the diameter of the nozzle of the quartz tube is 1mm, the distance from the roller surface is 1mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com