Gas drainage, dilution and mixing demister

A technology for gas extraction and mist eliminators, applied in mixers, gas discharge, mixers with rotary stirring devices, etc. Dryness, reduction in conveying power consumption, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

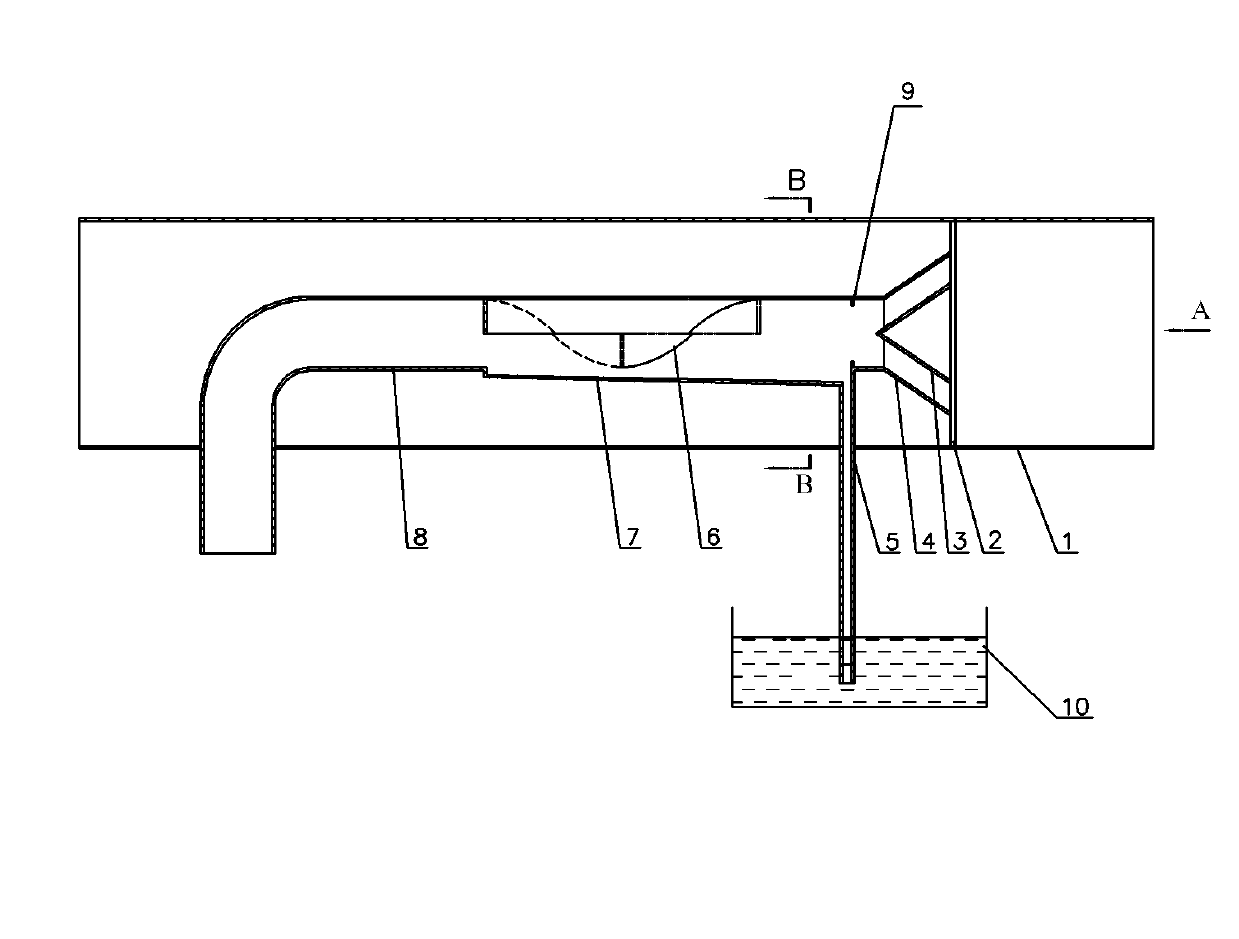

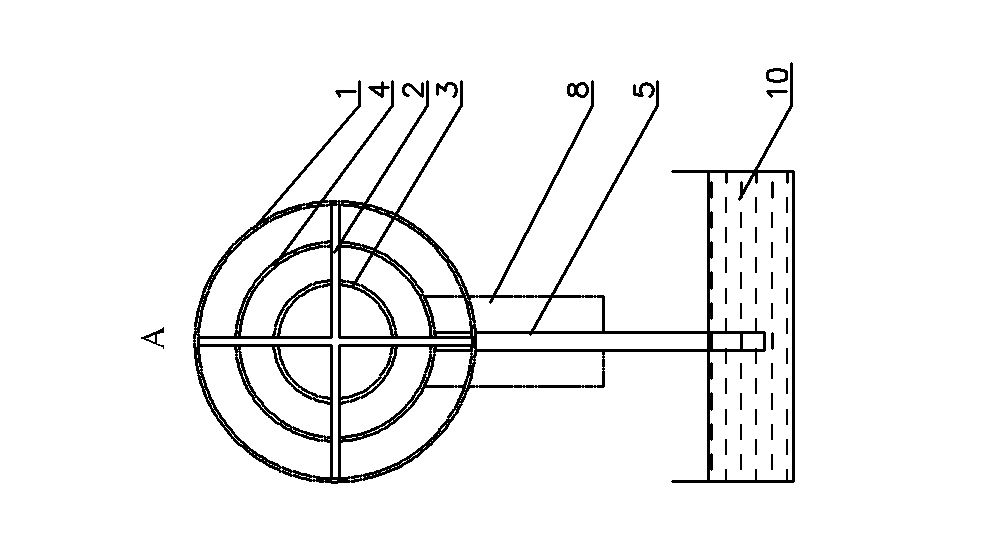

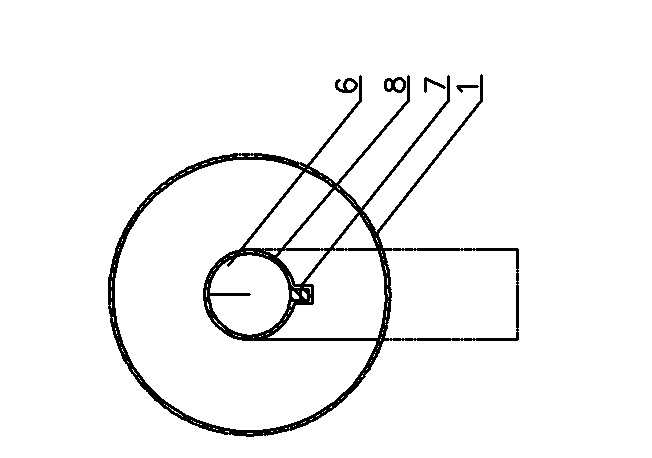

[0024] exist Figure 1-3 In the shown embodiment: it includes a tubular casing 1, a gas injection pipe, an inner helical blade 6, a baffle ring 9, a reinforcing rib 2, a diversion groove 7, a diversion pipe 5, a water seal groove 10 and a diversion Cone 3, the gas injection pipe includes an inlet pipe 8 and an expansion pipe 4 installed at the outlet end of the inlet pipe 8, wherein the inlet pipe 8 is a 90° elbow, the inlet end is set outside the shell 1, and the inlet pipe 8 is a straight pipe section close to the inlet end The straight pipe section vertically penetrating into the housing 1 and close to the outlet end is horizontally arranged in the housing 1, connected with the expansion tube 4 and facing the outlet end of the housing 1; the diversion cone 3 is a cone structure, located in the expansion tube 4, The pointed head faces away from the outlet end of the expansion tube 4, the expansion tube 4, the housing 1 and the diversion cone 3 are fixedly connected through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com