Hot-blast stove

A hot blast stove and grate technology, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of single heat medium, etc., and achieve the effects of clean flue gas, high fuel combustion efficiency, and good energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention and working process will be further described below in conjunction with accompanying drawing.

[0022] The orientation terms such as up, down, left, right, front and rear in this application document are established based on the positional relationship shown in the drawings. If the drawings are different, the corresponding positional relationship may also change accordingly, so this should not be understood as limiting the scope of protection.

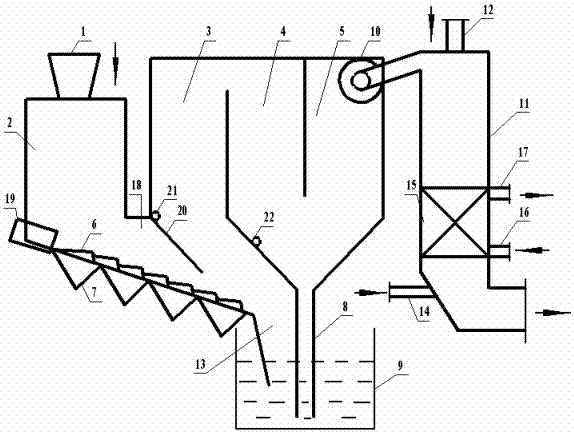

[0023] Such as figure 1 As shown, a hot blast stove includes a feed bin 1, a gasification chamber 2, a combustion chamber 3, a burnout chamber 4, an air mixing chamber 5, a fire grate 6, a separator 10, a tail flue 11 and a water seal tank 9 Wait.

[0024] The feed bin 1 is set above the gasification chamber 2, fuels such as biomass are fed into the gasification chamber 2 from the feed bin 1, gasification occurs in the gasification chamber 2, and the generated gasification gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com