Commutatorless high-temperature heat exchanger

A high-temperature heat exchanger without reversing technology, which is applied in the field of industrial furnaces, can solve problems such as furnace pressure fluctuations, increased operating risks for operators, and failure of the combustion system to achieve continuous operation in a hot state and heat exchange. Heat exchange efficiency and the effect of preventing hot gas from leaking out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

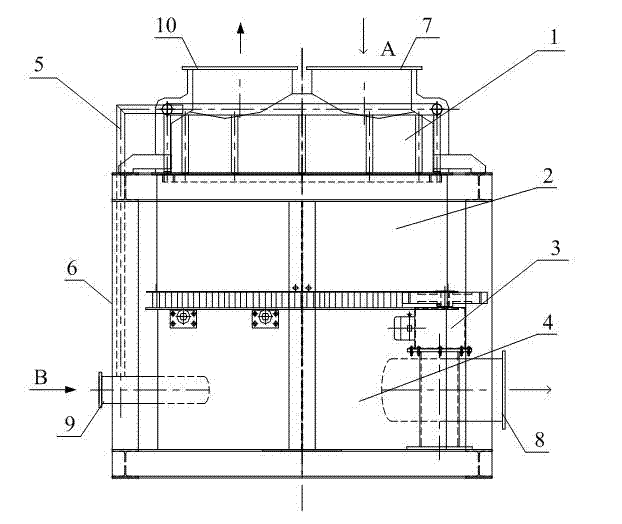

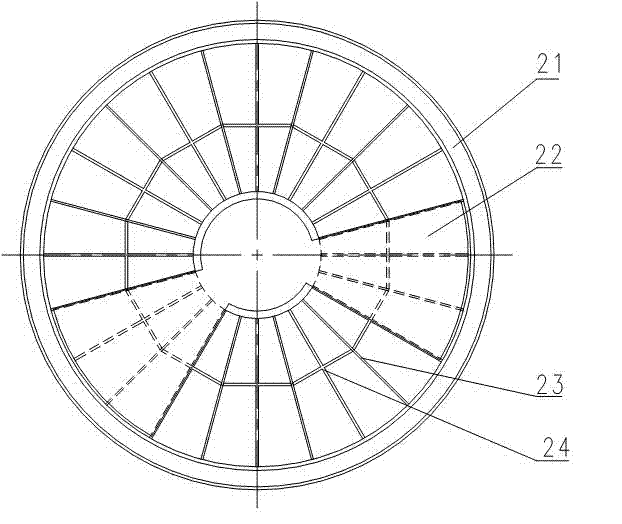

[0016] Such as figure 1 As shown, a non-reversing high-temperature heat exchanger includes a frame 6, a heat storage device and a driving mechanism 3. The heat storage device is in a cylindrical structure and includes a lower cylinder 4, a rotor heat storage body 2 and an upper cylinder arranged in sequence. body 1, the lower cylinder body 4 is fixed on the frame 6, the interior of the lower cylinder body is divided into a low-temperature air chamber and a low-temperature flue gas chamber, and the side of the lower cylinder body is provided with a low-temperature air inlet 9 and a low-temperature flue gas outlet 8; the rotor heat storage body 2 Rotatably supported on the lower cylinder body 4, the rotor heat storage body 2 is filled with heat storage medium; the upper cylinder body 1 is located on the rotor heat storage body and fixed on the frame, and the upper cylinder body is divided into a high-temperature flue gas chamber and a high-temperature Air cavity, the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com