Protein concentration system and application method thereof

An application method, protein technology, applied in the field of protein concentration, can solve the problems of high cost, poor reliability, high energy consumption, etc., and achieve the effect of stable and reliable heat exchange, stable heat exchange, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

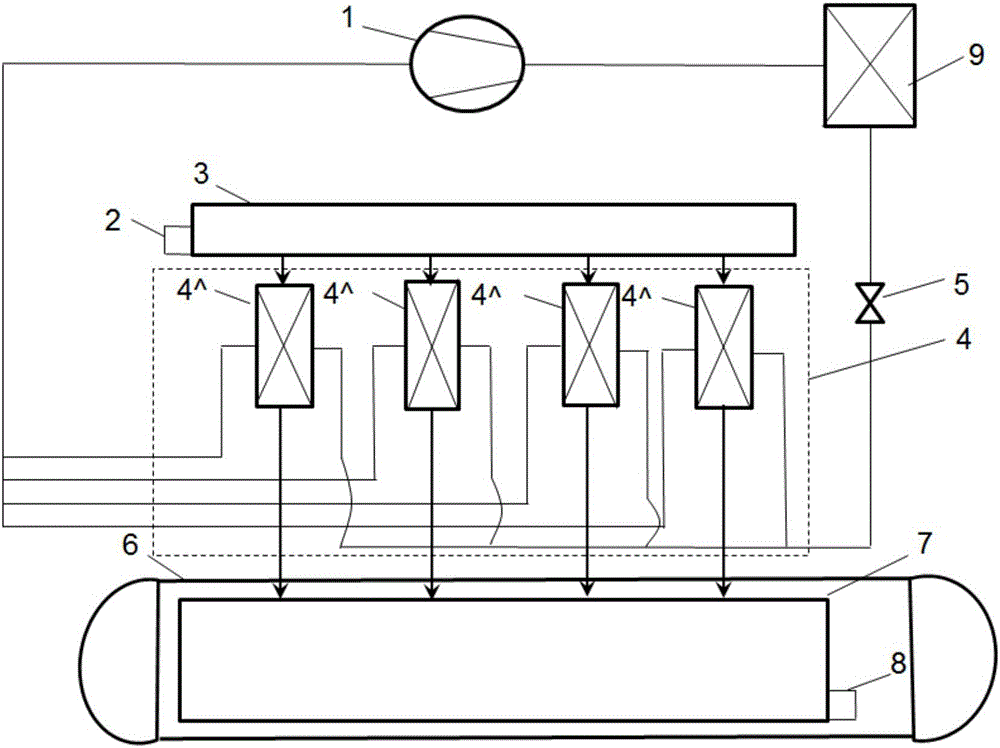

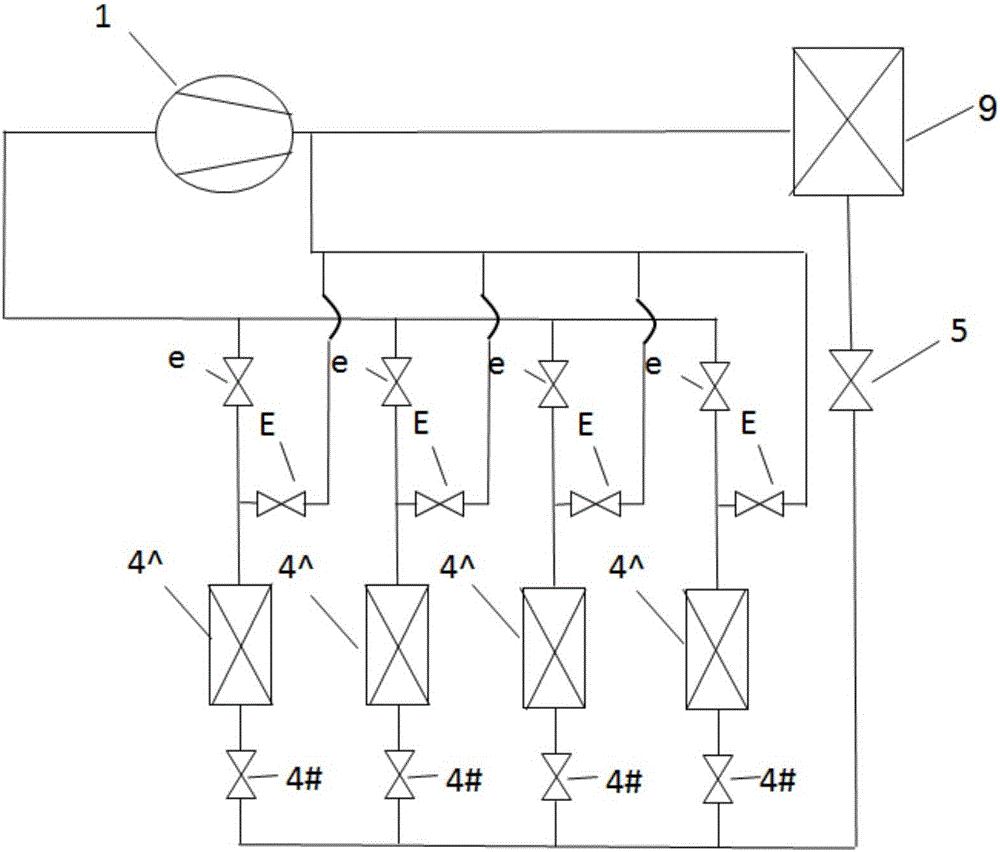

[0033] Embodiment 1 Protein Solution Freeze Concentration System

[0034] A protein solution freeze concentration system, such as figure 1 and figure 2 As shown, the system includes a compressor 1 , a liquid inlet tank 3 , a heat exchange system 4 , a throttle valve 5 , a liquid storage tank 7 , and a condenser 9 . The heat exchange system 4 contains at least two honeycomb heat exchangers 4^, each honeycomb heat exchanger 4^ is arranged in parallel at intervals, at the same height, and contains refrigerant; one side of the liquid inlet tank 3 is provided with a liquid inlet 2, The bottom is provided with a round hole, which communicates with the upper part of each honeycomb heat exchanger 4^ through the round hole; the lower part of each honeycomb heat exchanger 4^ communicates with the liquid storage tank 7; the heat exchange system 4 also It communicates with the compressor 1 and the condenser 9 , and a throttling valve 5 is set between the heat exchange system 4 and the ...

Embodiment 2

[0036] Embodiment 2 Application method of a protein solution freeze concentration system

[0037] An application method of a protein solution freeze concentration system, such as figure 1 and figure 2 shown, including the following steps:

[0038] S1. The protein solution to be concentrated enters the liquid inlet tank 3 from the liquid inlet 2;

[0039] The protein solution obtained by S2 and S1 flows through the round hole at the bottom of the liquid inlet tank 3 from top to bottom under the action of gravity on one side of the honeycomb heat exchanger 4^, and passes through the other side of the honeycomb heat exchanger 4^. Compressor 1, throttling valve 5 and condenser 9 are processed to obtain low-temperature and low-pressure wet steam refrigerant for heat exchange, so that the moisture in the protein solution freezes and becomes liquid ice that remains on the wall of the honeycomb heat exchanger 4^ superior;

[0040] The concentrated protein solution obtained in S3 ...

Embodiment 3

[0045] Embodiment 3 Application method of a protein solution freeze concentration system

[0046] An application method of a protein solution freeze concentration system, such as figure 1 and figure 2 shown, including the following steps:

[0047] S1. The protein solution to be concentrated enters the liquid inlet tank 3 from the liquid inlet 2;

[0048] The protein solution obtained by S2 and S1 flows through the round hole at the bottom of the liquid inlet tank 3 from top to bottom under the action of gravity on one side of the honeycomb heat exchanger 4^, and passes through the other side of the honeycomb heat exchanger 4^. Compressor 1, throttling valve 5 and condenser 9 are processed to obtain low-temperature and low-pressure wet steam refrigerant for heat exchange, so that the moisture in the protein solution freezes and becomes liquid ice that remains on the wall of the honeycomb heat exchanger 4^ superior;

[0049] The concentrated protein solution obtained in S3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com